Electro-hydraulic proportional control system and method of working device of loader

An electro-hydraulic proportional and working device technology, applied in mechanically driven excavators/dredgers, earthmovers/shovels, construction, etc., can solve the problems of low degree of automation, low operation efficiency, high labor intensity, etc. To achieve the effect of simple layout, small footprint, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the present invention more comprehensible, a preferred embodiment is described below in detail with the accompanying drawings.

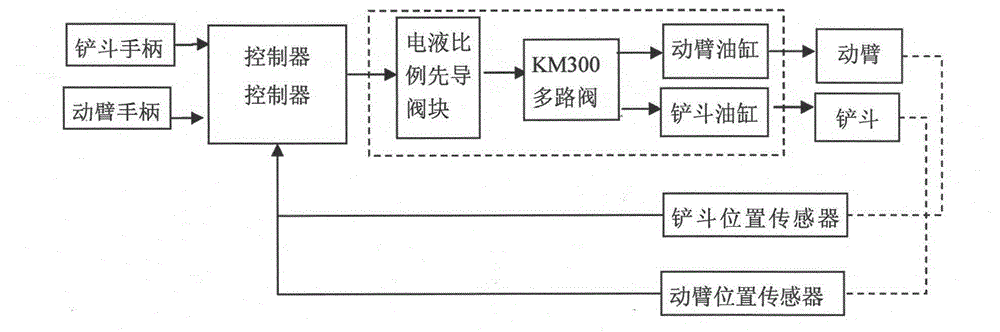

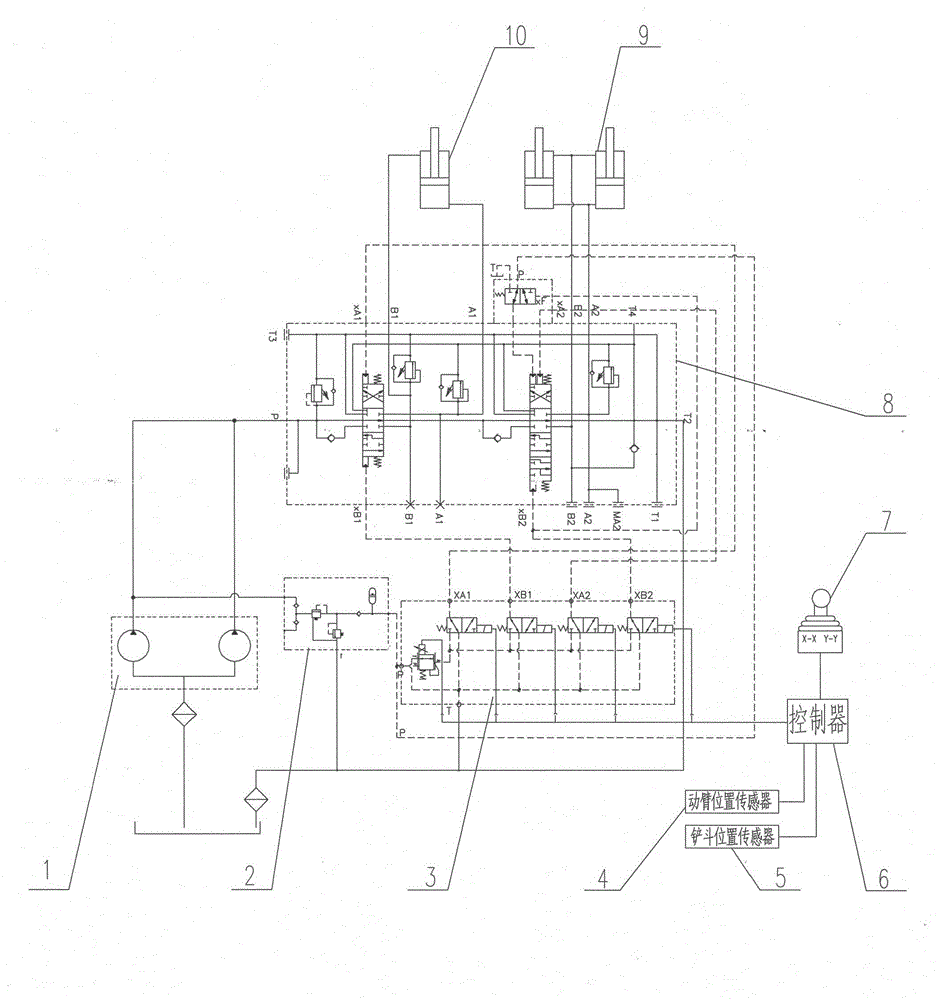

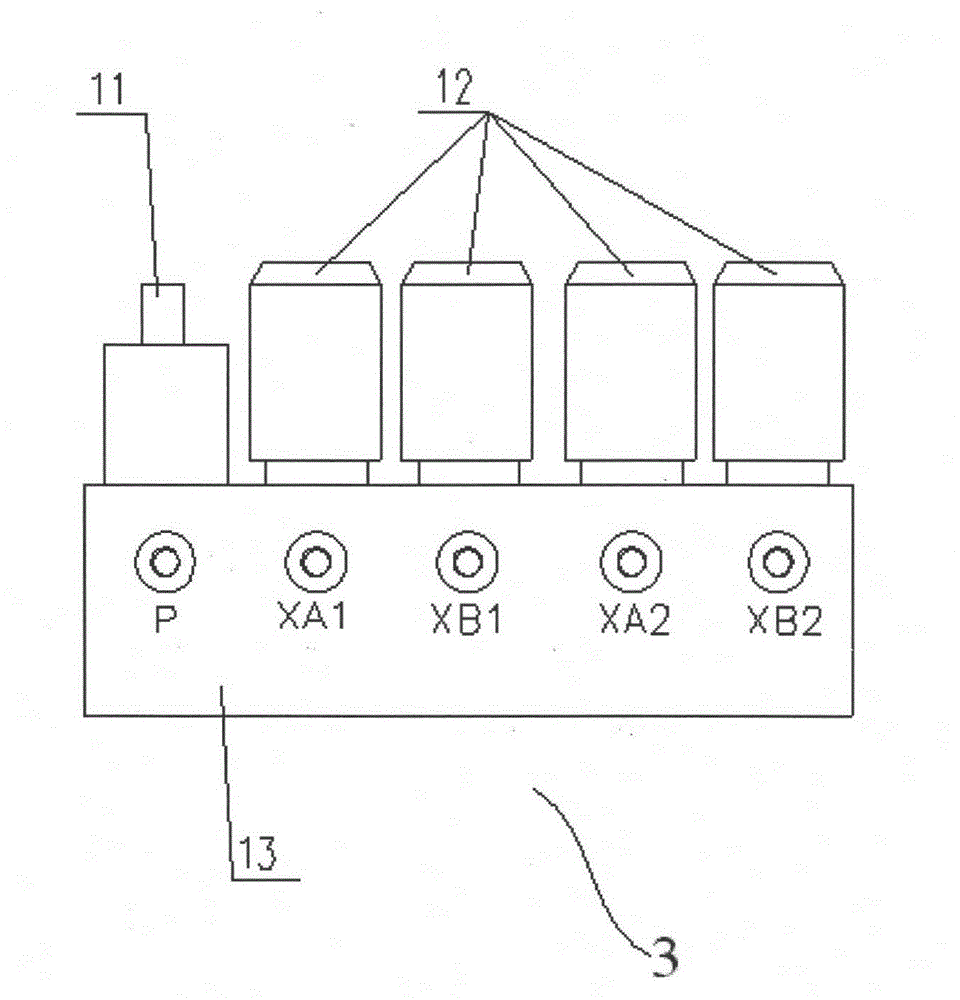

[0023] figure 1 with figure 2 Respectively are the structural block diagram and principle diagram of an electro-hydraulic proportional control system of a loader working device provided by the present invention. The electro-hydraulic proportional control system of a loader working device includes a controller 6, an input terminal of the controller 6 and The electric control handle 7, the boom position sensor 4, and the bucket position sensor 5 are connected, and the output of the controller 6 is connected to the proportional pressure reducing solenoid valve 11 and the directional solenoid valve 12 on the electro-hydraulic proportional pilot valve block 3; double pump The oil outlet of an oil pump in 1 is connected to the input oil port of the electro-hydraulic proportional pilot valve block 3 through the pilot oil source block 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com