Electro-hydraulic proportion control system of pressure delivery device

A technology of delivery device and electro-hydraulic ratio, applied in fluid pressure actuation device, fluid pressure actuation system components, servo meter circuit, etc., can solve the problems of low control precision, high labor intensity, low reliability, etc. Improve control performance, reduce labor intensity, and facilitate the effect of mechatronics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

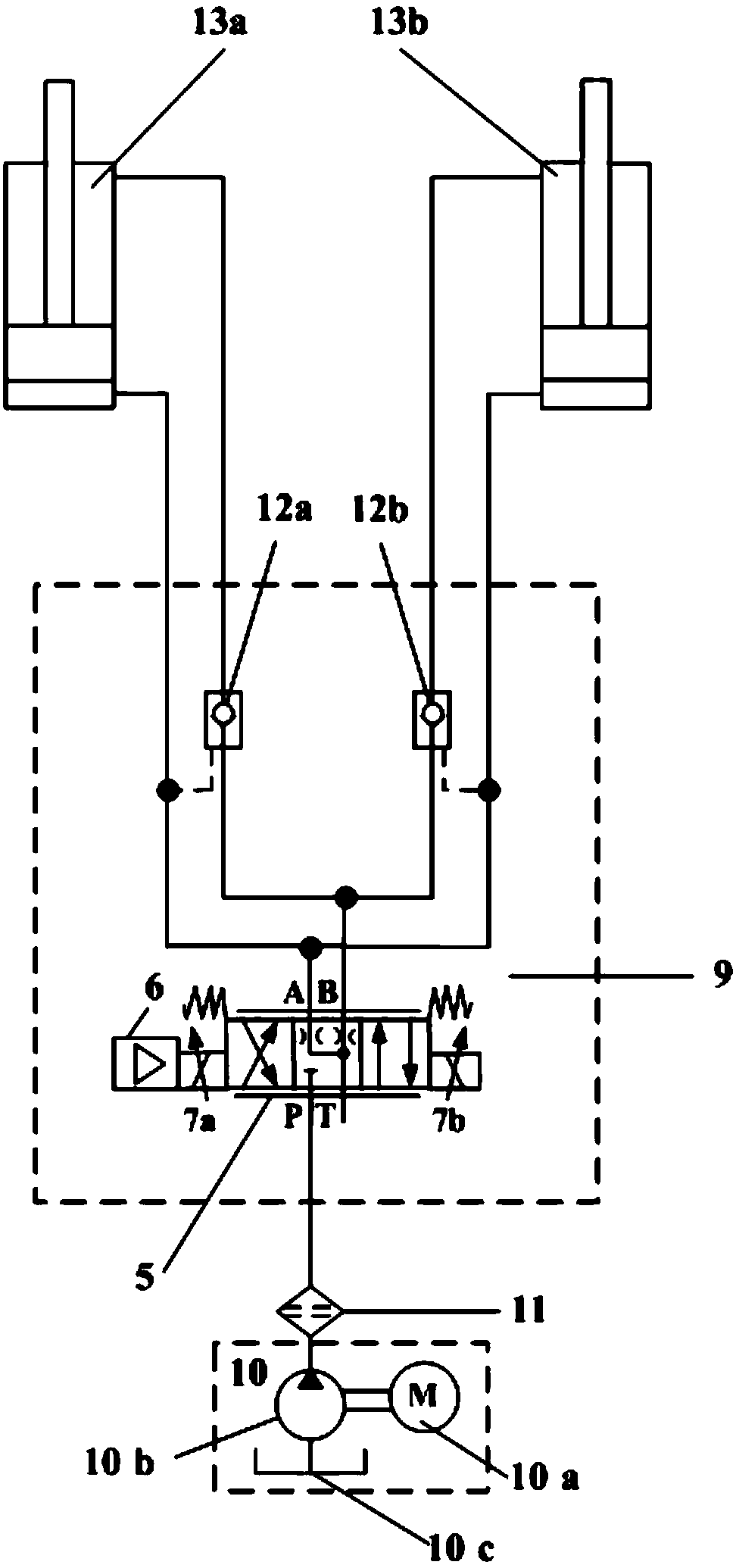

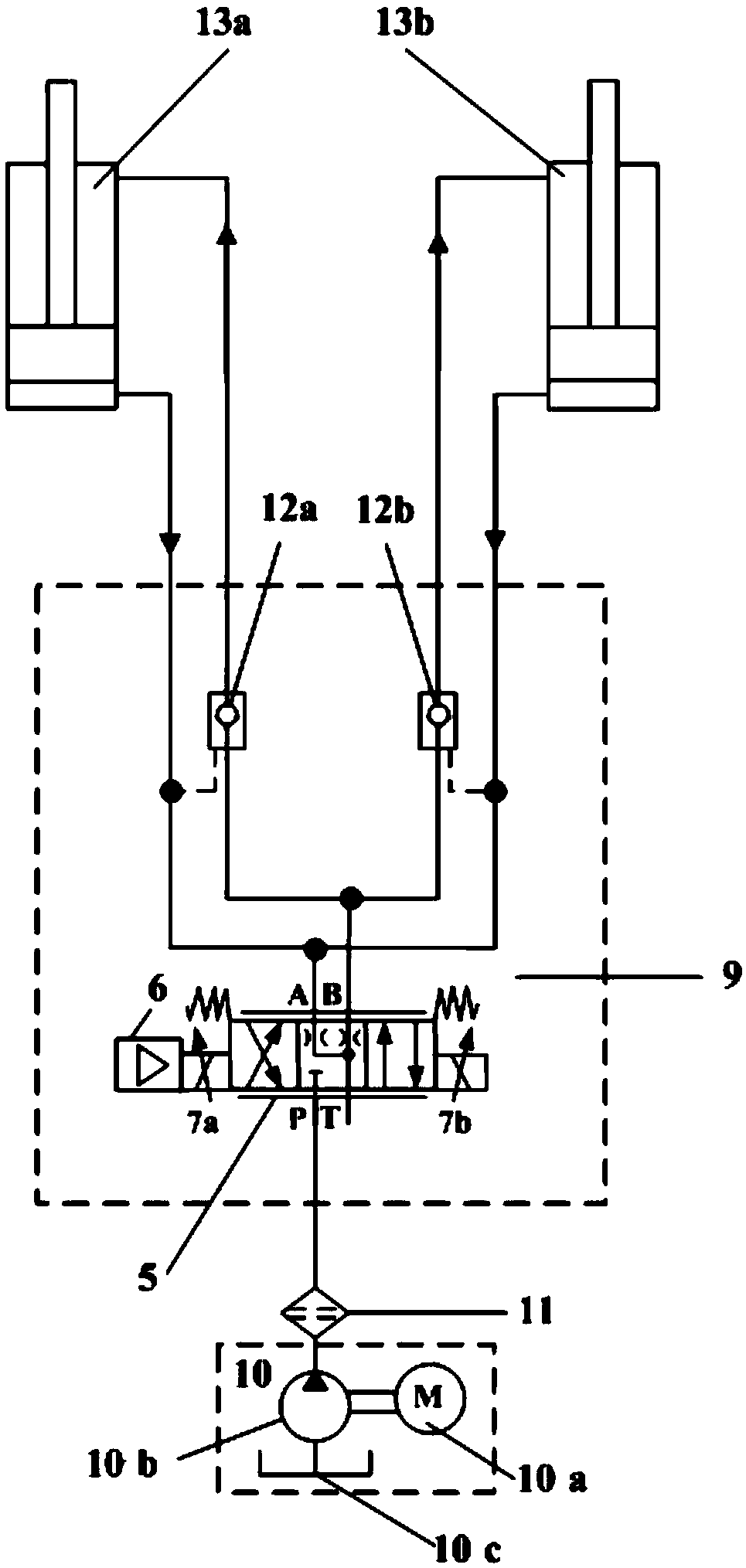

[0035] see Figure 1 to Figure 10 , an electro-hydraulic proportional control system of a pressurized delivery device of the present invention mainly includes a power distribution cabinet 1, an electric control box 2, a receiver 3, a transmitter 4, an electromagnetic proportional valve 5, a proportional amplifier 6, and a proportional electromagnet 7. Main valve spool 8, valve block 9, surface hydraulic pump station 10, oil filter 11, two sets of hydraulic control check valves 12, two-stage hydraulic cylinder 13 and tubing packer 14. Use the power distribution cabinet 1 to supply power, input it to the matching electric control box 2, and input the ramp signal to the electro-hydraulic proportional control system, and the amplified electrical signal acts on the proportional electromagnet 7 through the proportional amplifier 6 to drive the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com