Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Stable flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

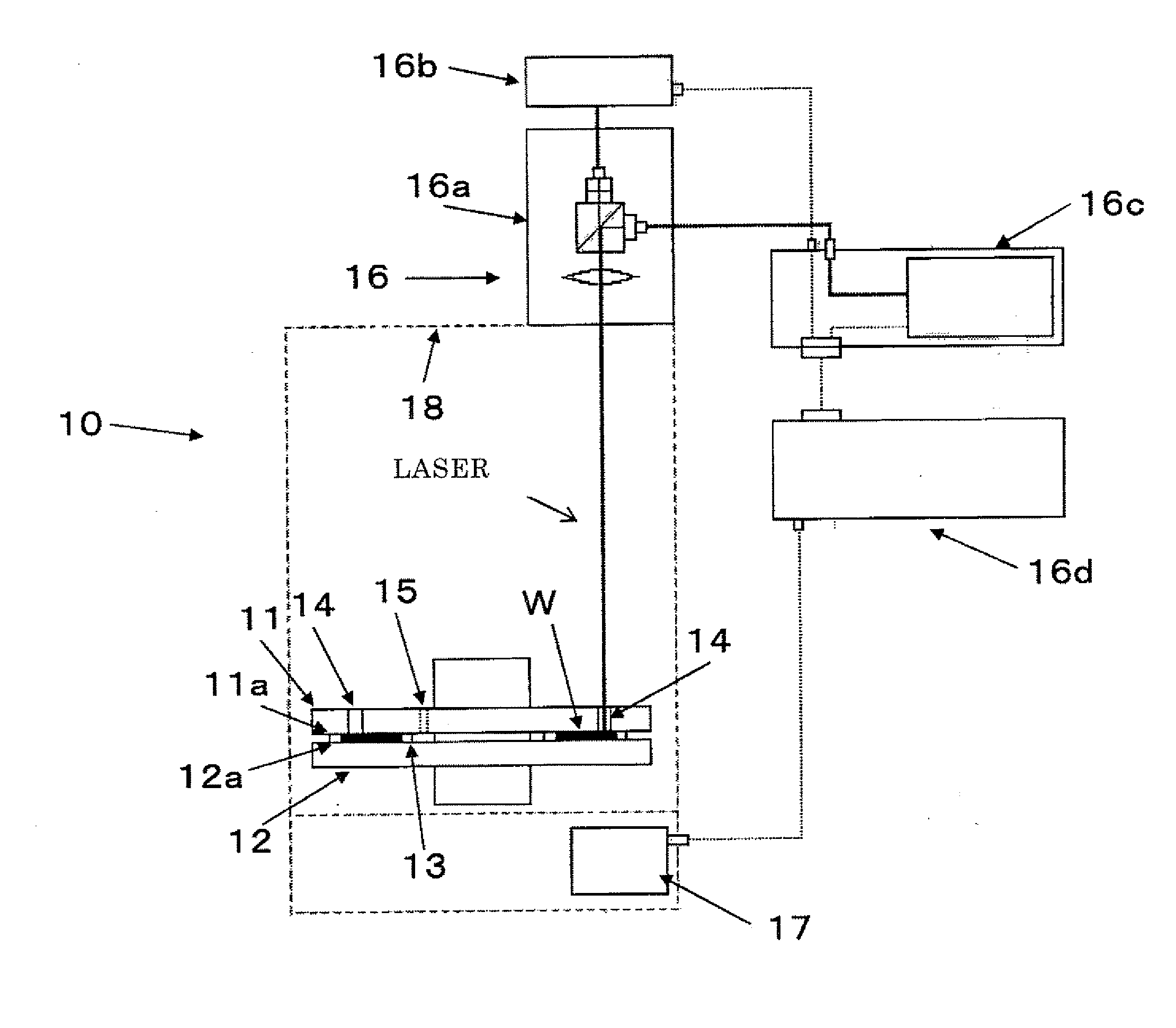

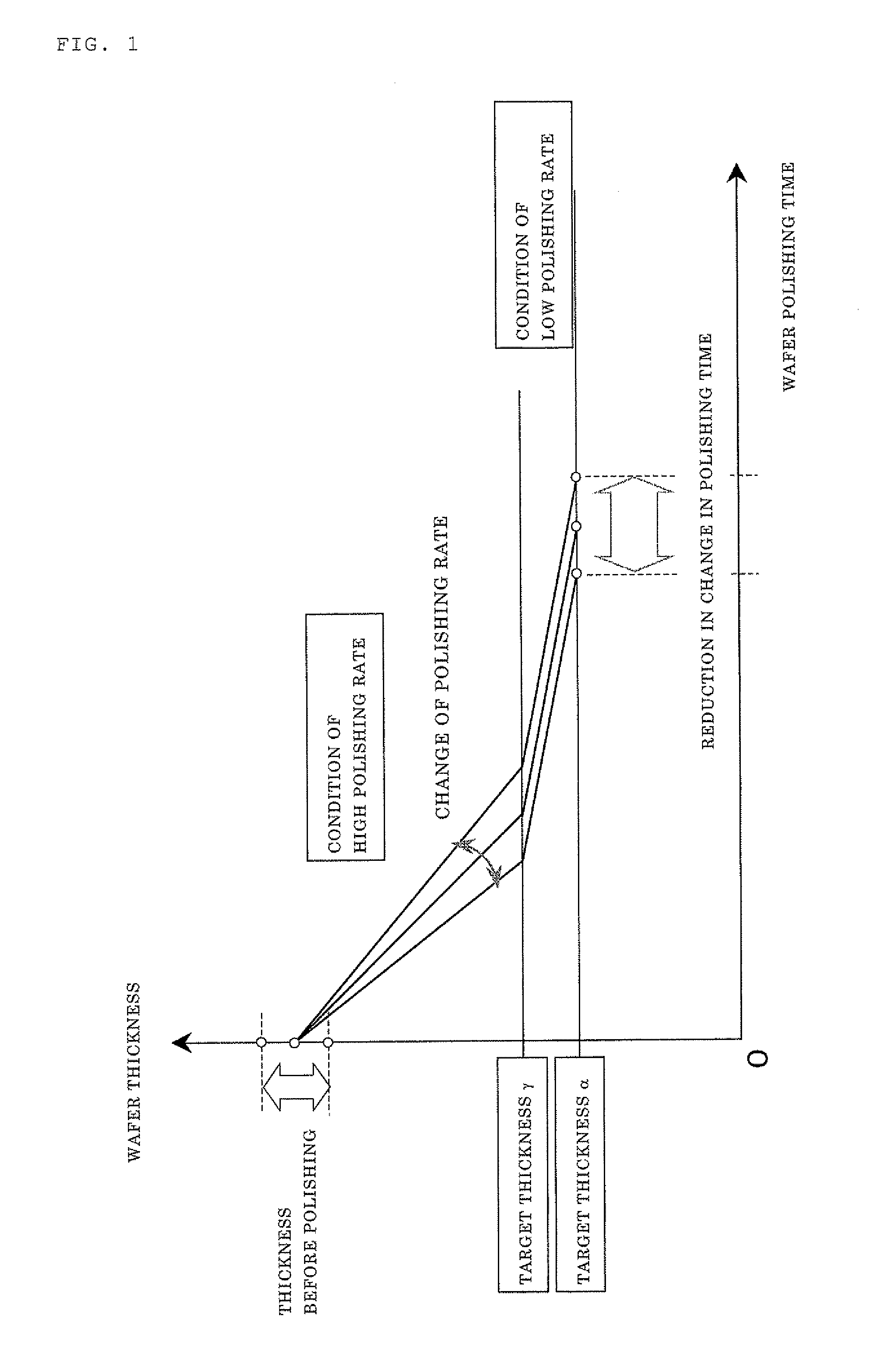

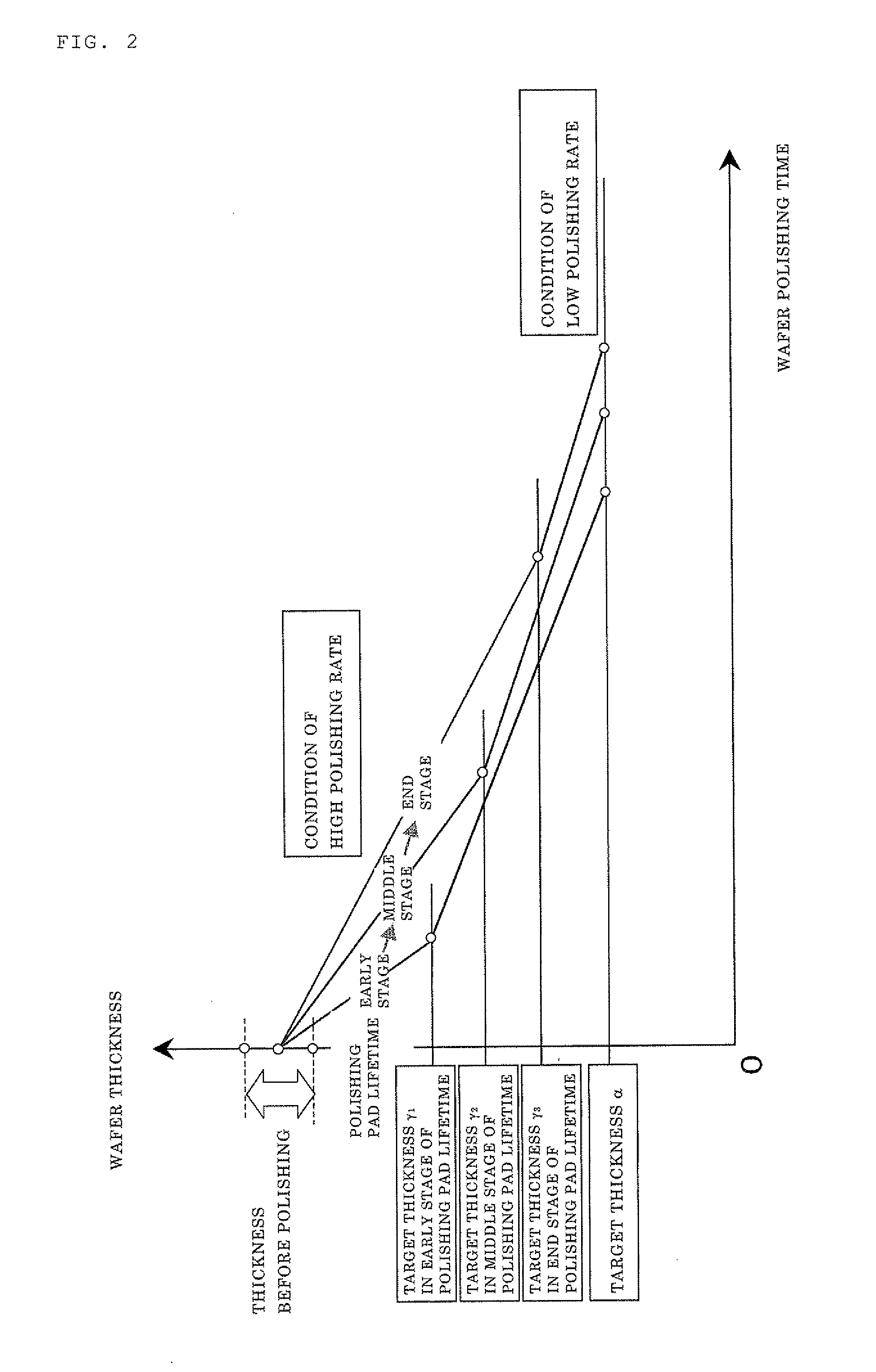

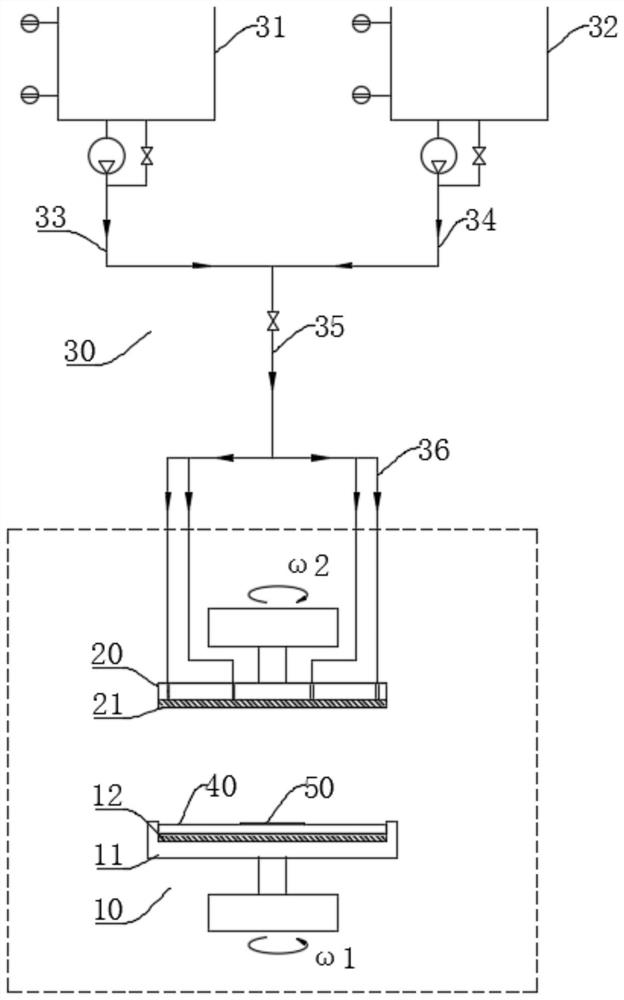

Wafer polishing method and double-side polishing apparatus

ActiveUS20110130073A1Easy to getImprove flatnessEdge grinding machinesSemiconductor/solid-state device testing/measurementWaferingPolishing

The present invention is a wafer polishing method including simultaneously polishing both surfaces of a wafer by pressing and rubbing the wafer, while holding the wafer with: a lower turn table having a flat polishing-upper-surface rotationally driven; an upper turn table having a flat polishing-lower-surface rotationally driven, the upper turn table being arranged with facing to the lower turn table; and a carrier having a wafer-holding hole for holding the wafer, wherein the polishing is performed while measuring a thickness of the wafer through a plurality of openings provided between a rotation center and an edge of the upper turn table or the lower turn table, and switching a polishing slurry with a polishing slurry having a different polishing rate during the polishing of the wafer. As a result, there is provided a wafer polishing method that can manufacture a wafer having a high flatness and a high smoothness at high productivity and high yield.

Owner:SHIN-ETSU HANDOTAI CO LTD

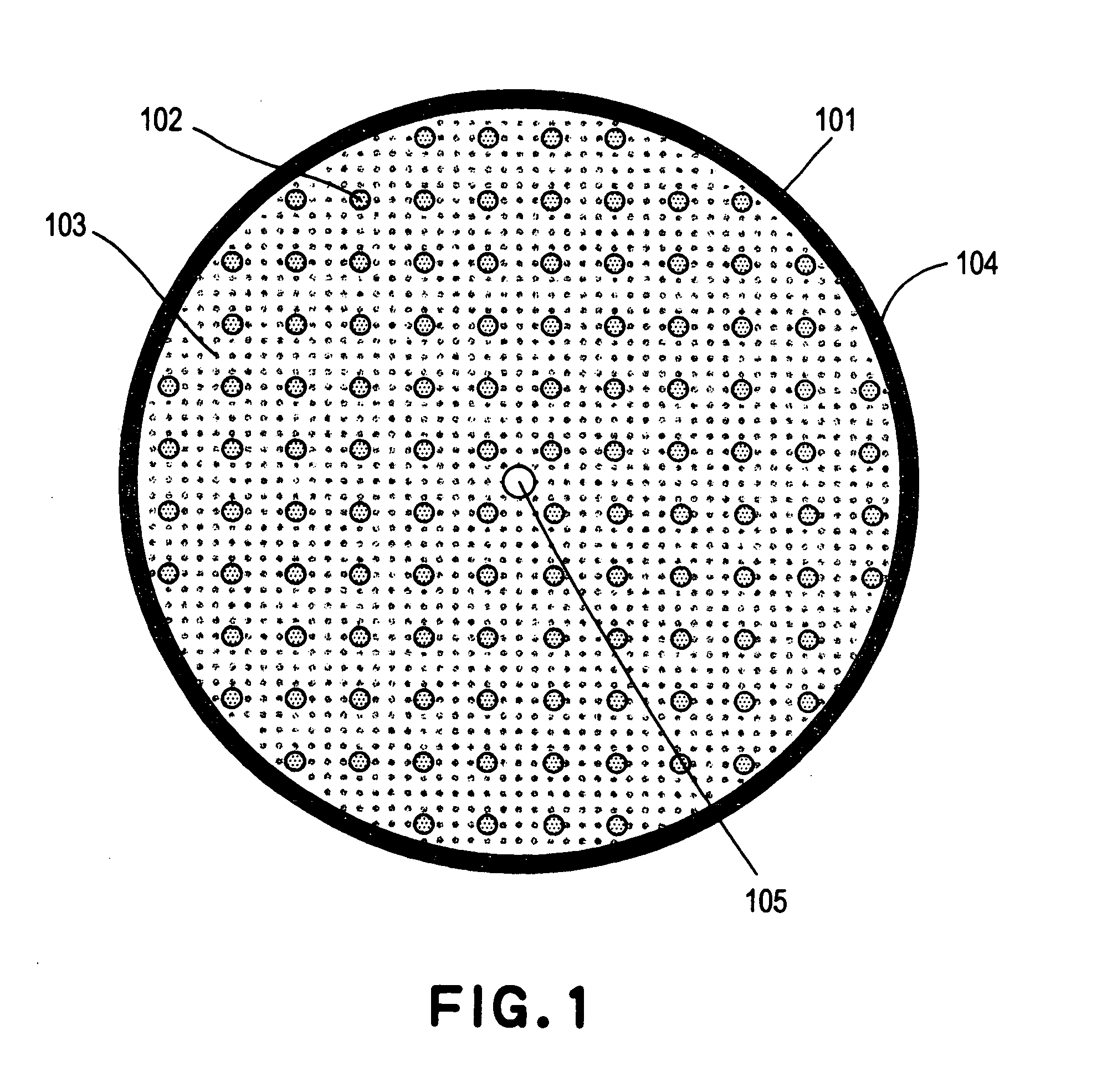

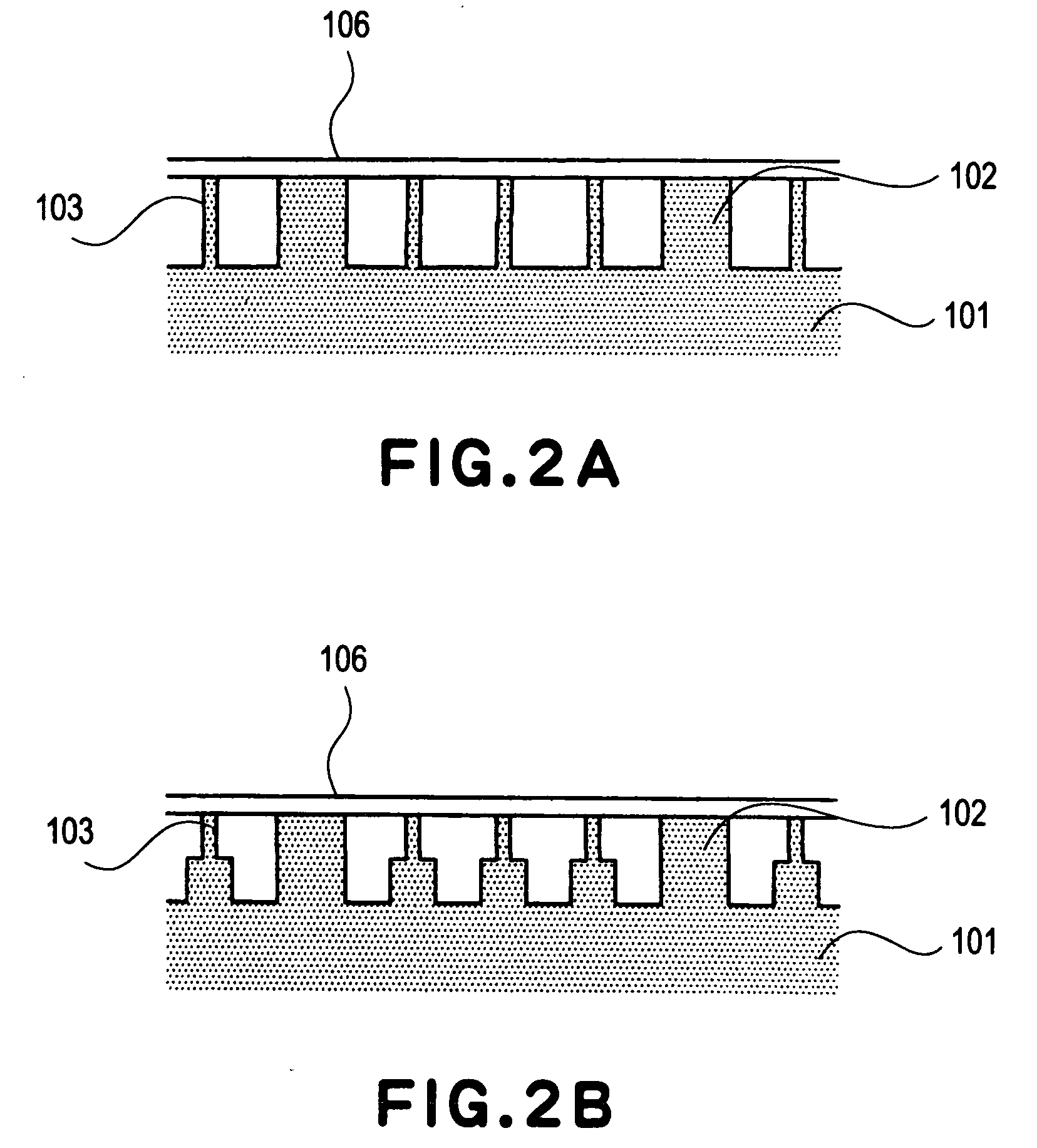

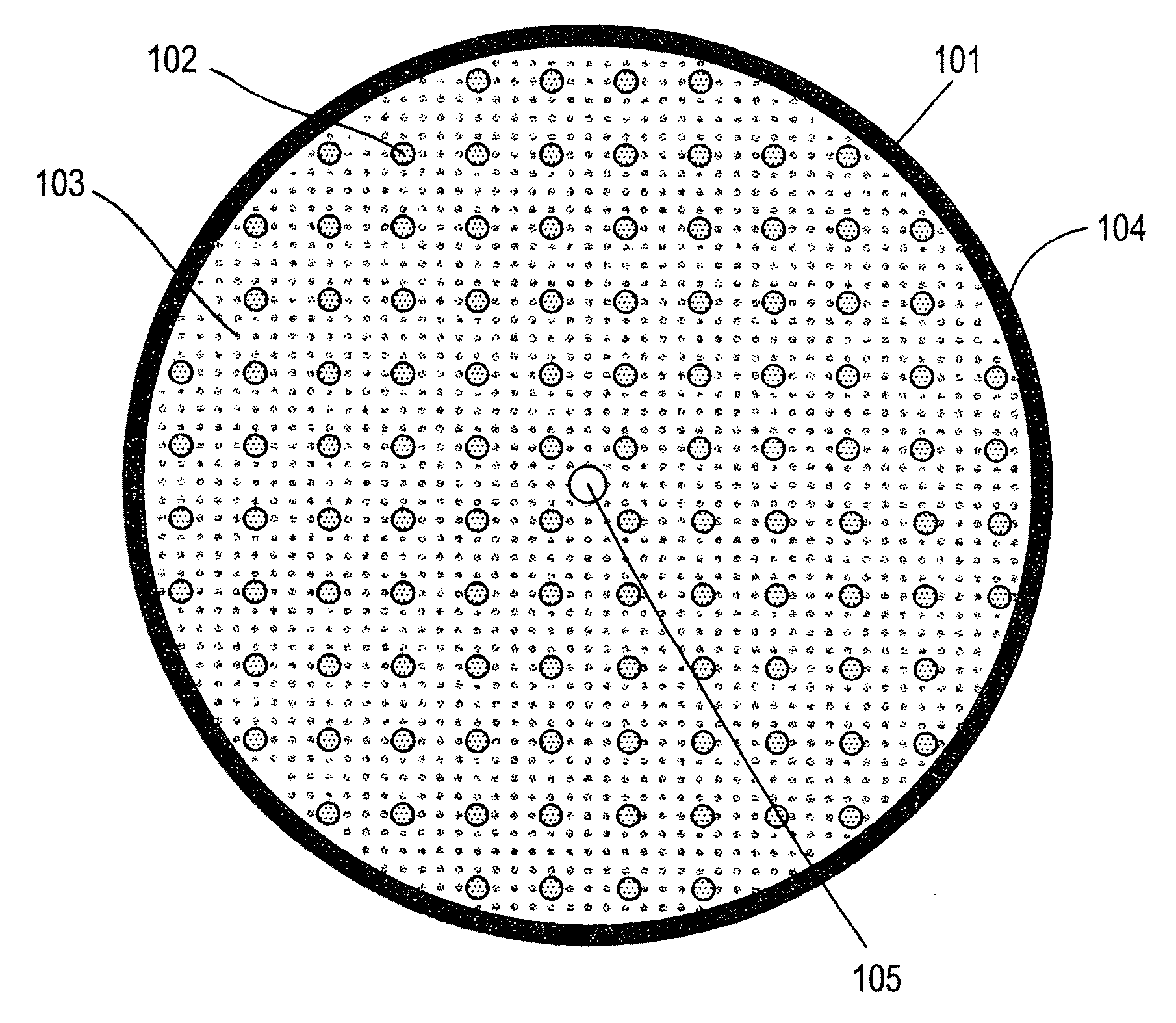

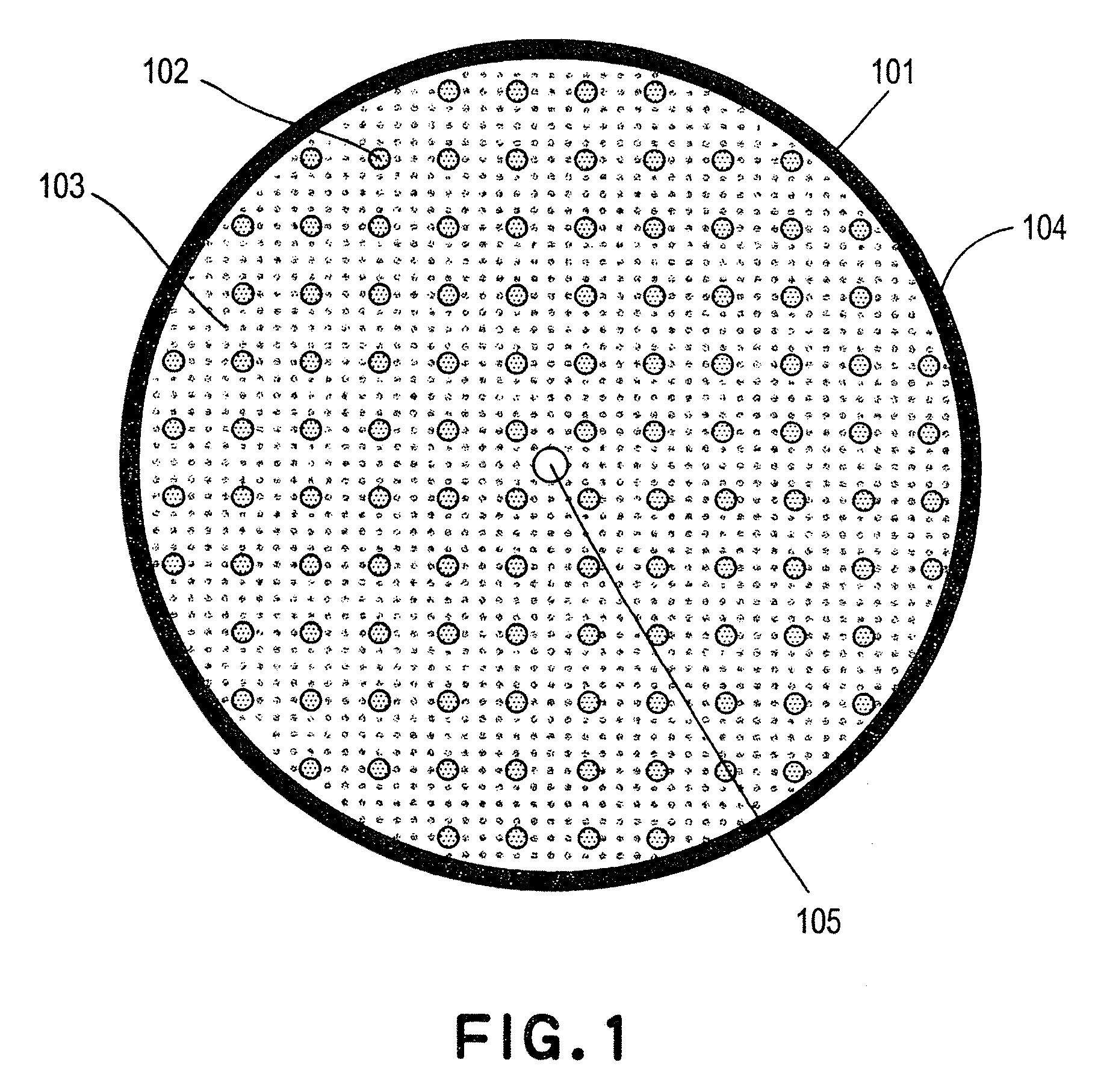

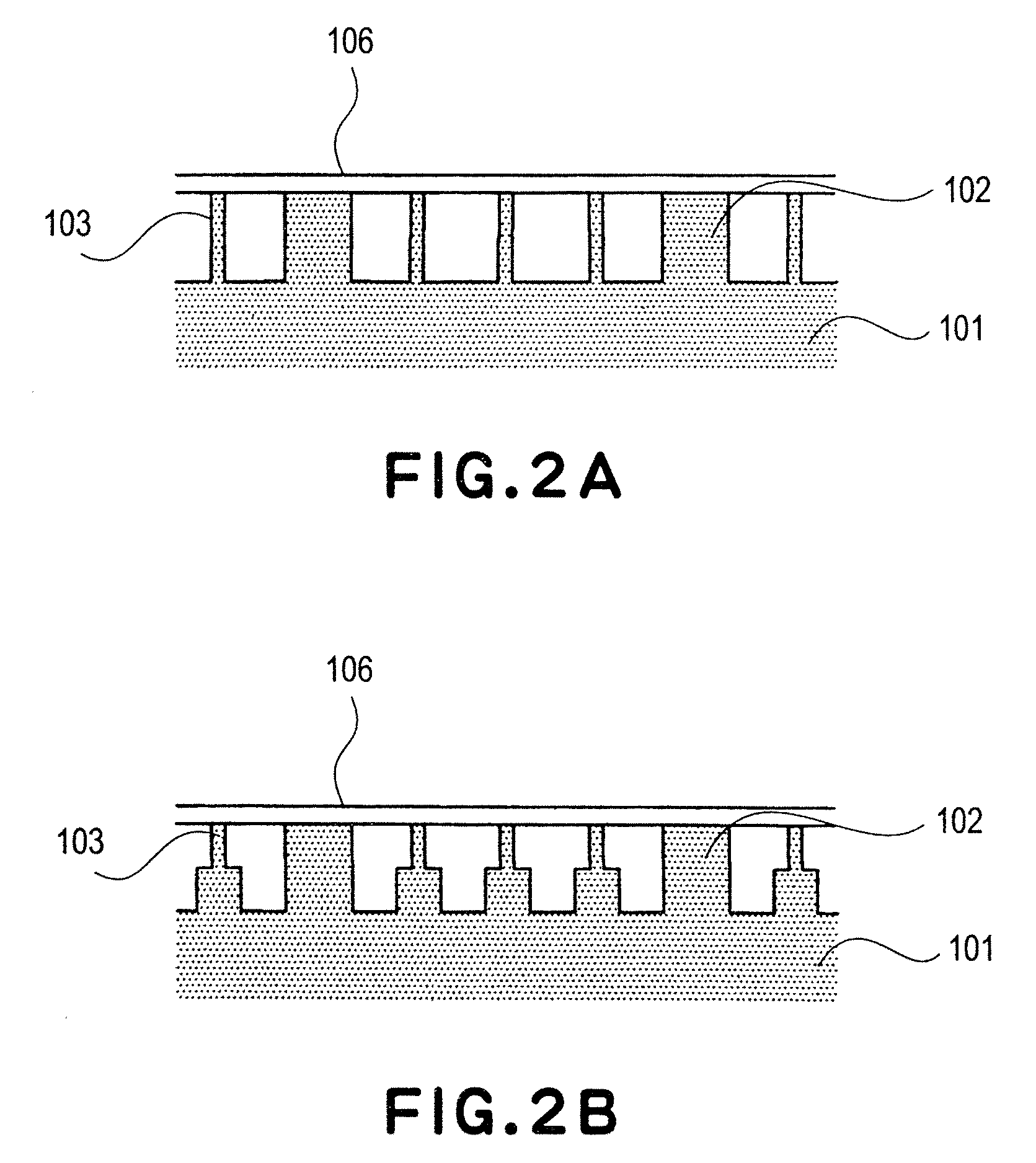

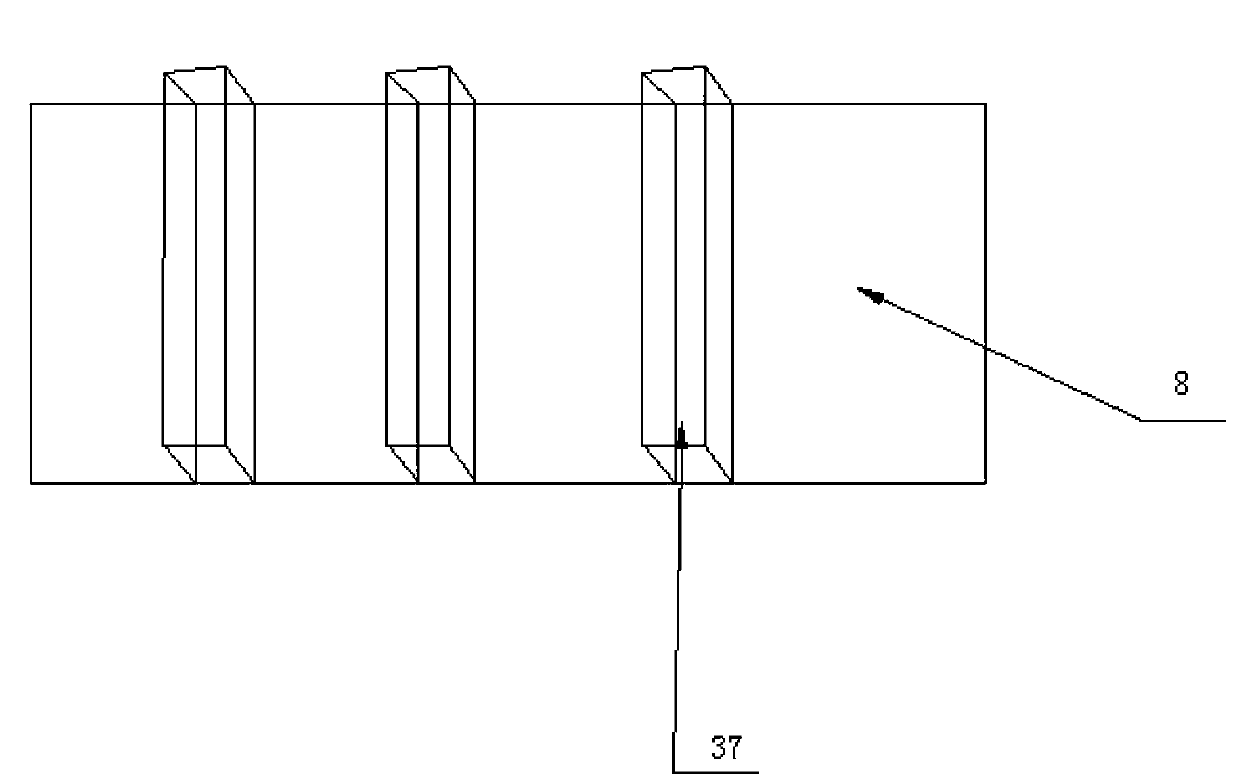

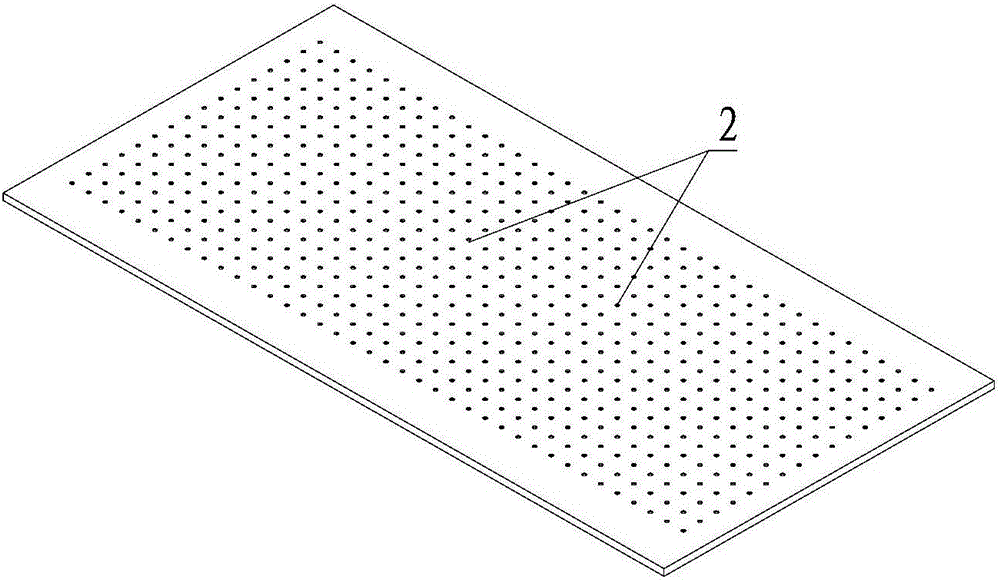

Substrate holding system and exposure apparatus using the same

InactiveUS20050152088A1Correction of flatnessStable flatnessSemiconductor/solid-state device manufacturingElectretsEngineeringFree space

Disclosed is a unique and improved substrate holding technique in accordance with an aspect of which there is provided a substrate holding system having a chuck for vacuum attraction and electrostatic attraction of a substrate, and including a ring-like rim for carrying a substrate thereon, a plurality of first protrusions disposed inside the rim, for carrying the substrate thereon, and a plurality of second protrusions disposed inside the rim, for carrying the substrate thereon, wherein a substrate carrying surface area of at least one first protrusion is smaller than a substrate carrying surface area of at least one second protrusion and wherein a smallest interval of the first protrusions is smaller than a smallest interval of the second protrusions.

Owner:CANON KK

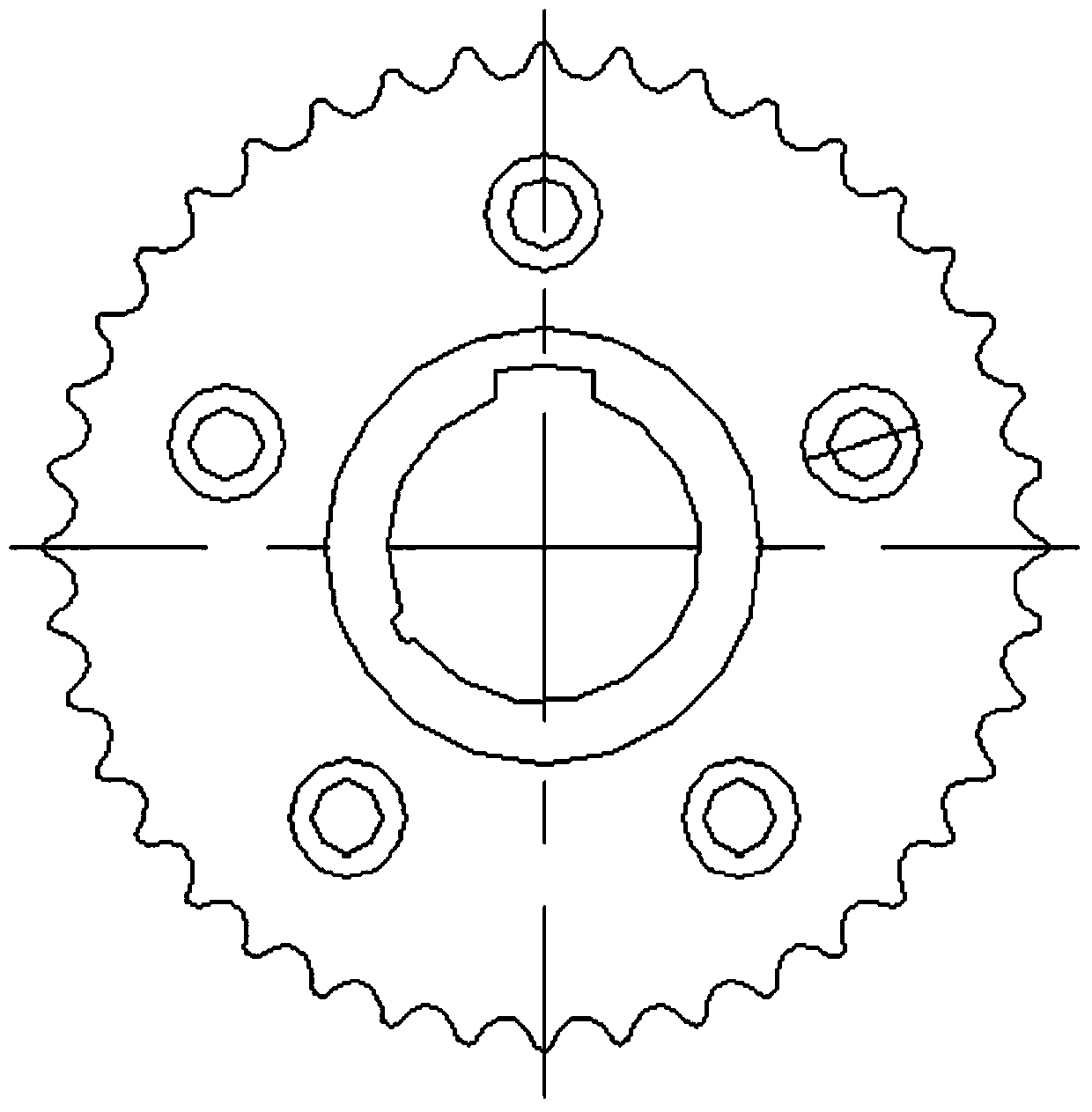

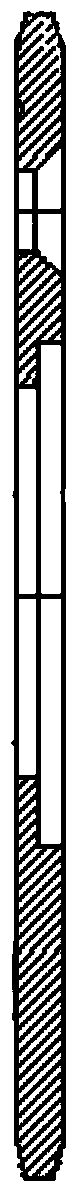

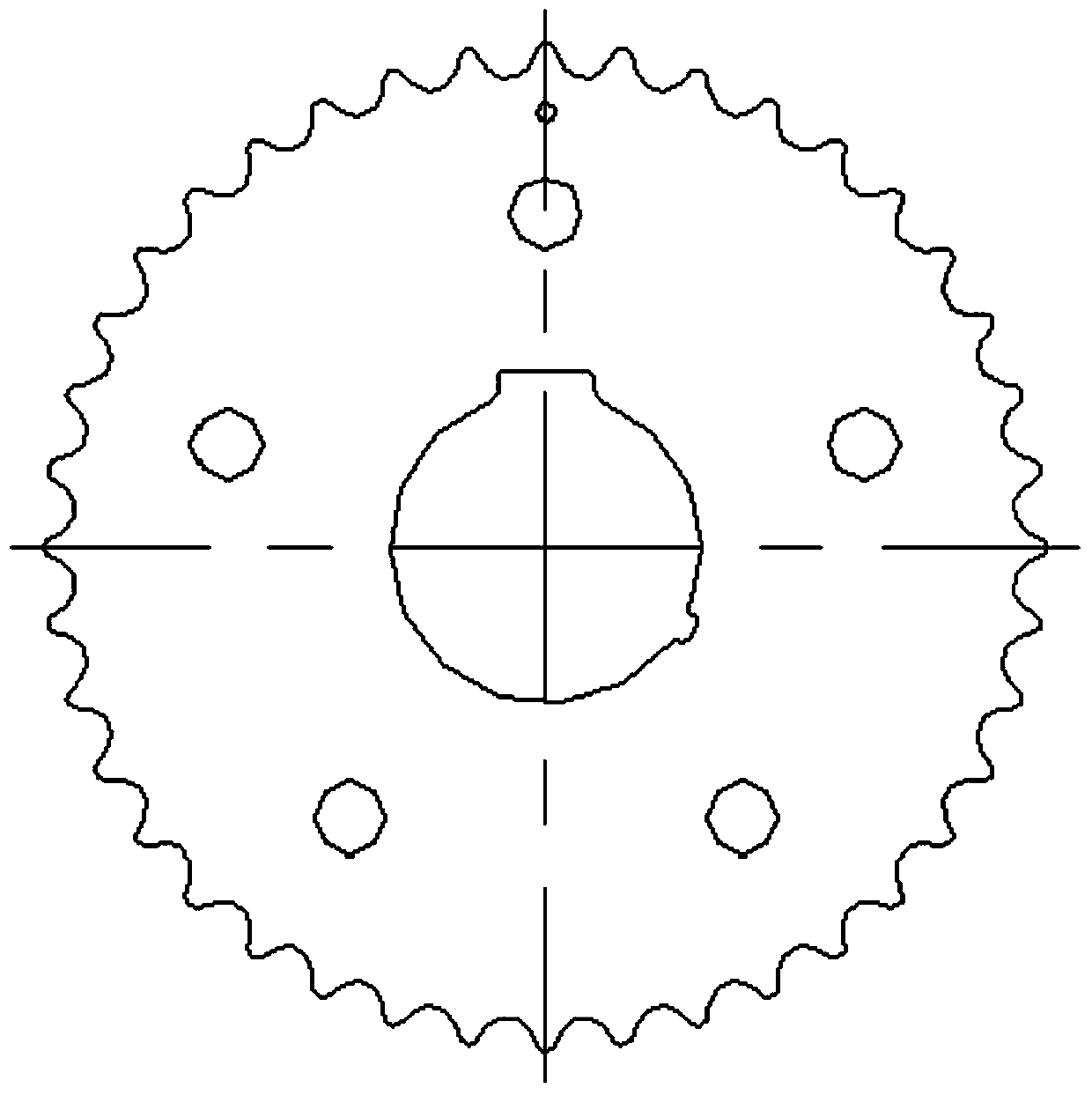

Method for machining automobile engine large chain wheels

The invention relates to a method for machining automobile engine large chain wheels. The method is characterized by including the following steps that uncoiling, straightening, and fine blanking are performed to form parts, wherein multiple taper holes are formed in the circumferential direction of each part, a shaft hole is formed in the center of each part, and the shape of each part is in a tooth shape; whether hard scratches exist on the surfaces of the parts or not is checked, then the products without the scratches are selected for cleaning, and it is guaranteed that residual water drops, corrosion and fine blanking oil do not exist; the parts are installed in a double-end-face grinding machine for surface coarse grinding; chamfering machining is performed on the two faces of tooth parts of the parts; burrs generated by the chamfering machining are removed; high-frequency quenching heat treatment is performed; shot blasting machining is performed; single-face accurate grinding is performed on the surfaces of the parts; the parts are placed into the double-end-face grinding machine again for surface accurate grinding; countersink milling machining is performed on the shaft holes formed in the centers of the parts; burr removal is performed; demagnetization is performed; cleaning, packaging and warehousing are performed. The method not only can meet the requirements for size precision and position precision of the products, but also enables the machining technology of the parts to be in the simplest and optimal state, and machining cost is reduced.

Owner:HUBEI AVIATION PRECISION MASCH TECH CO LTD

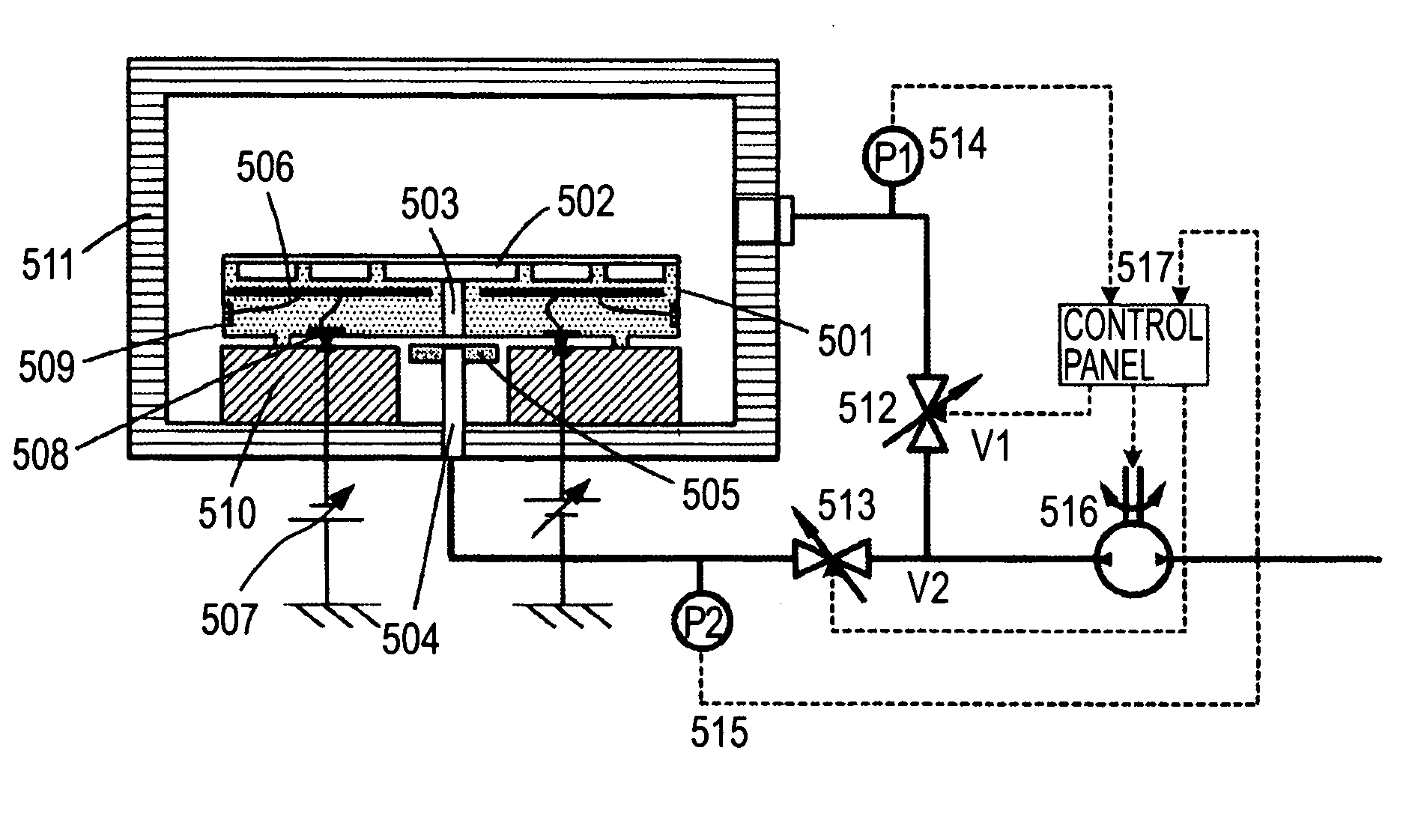

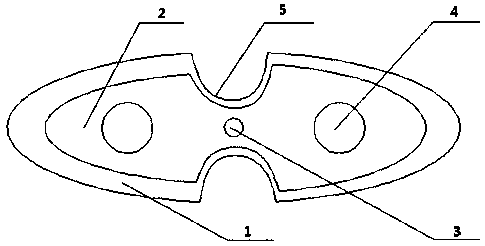

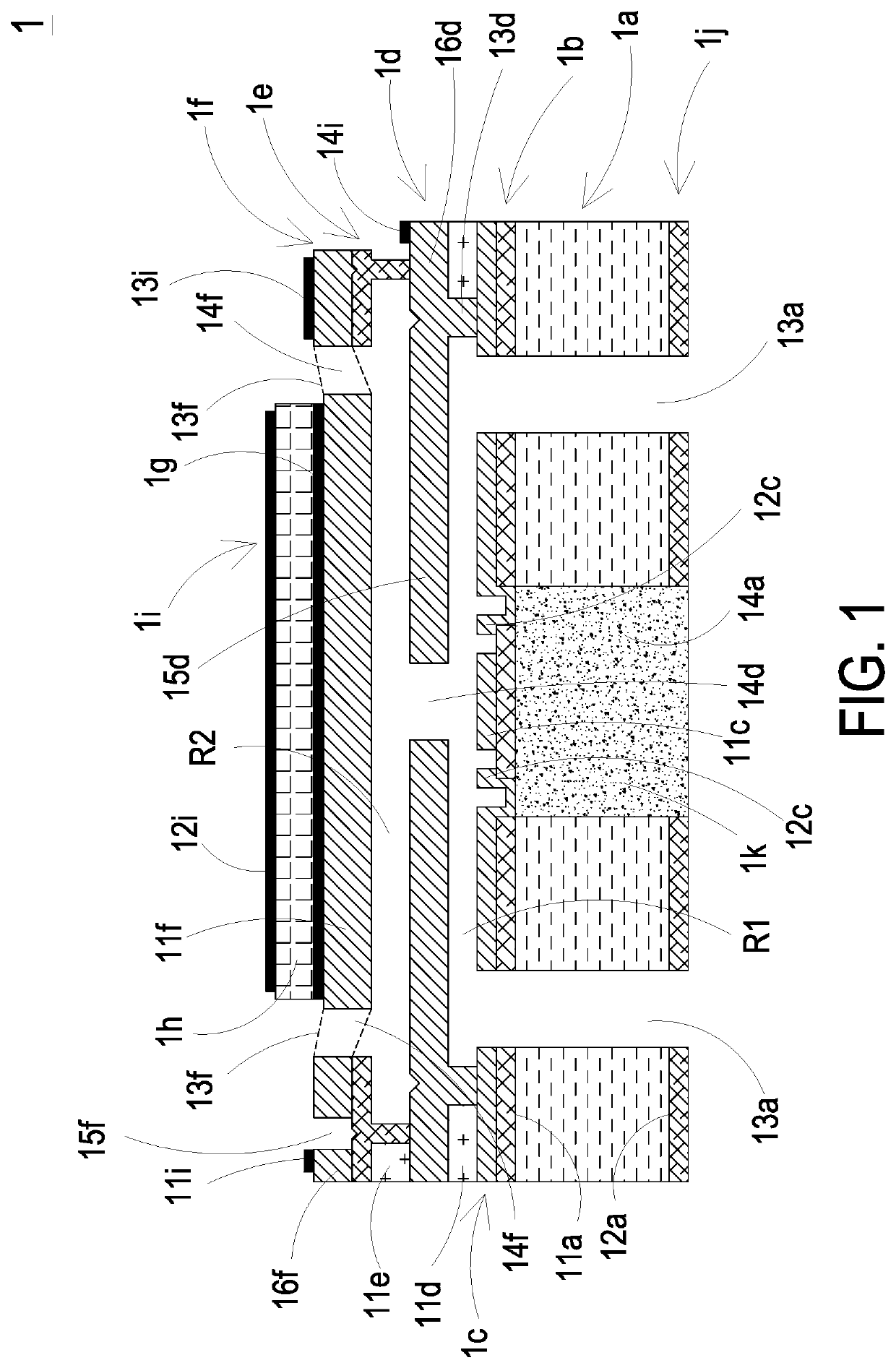

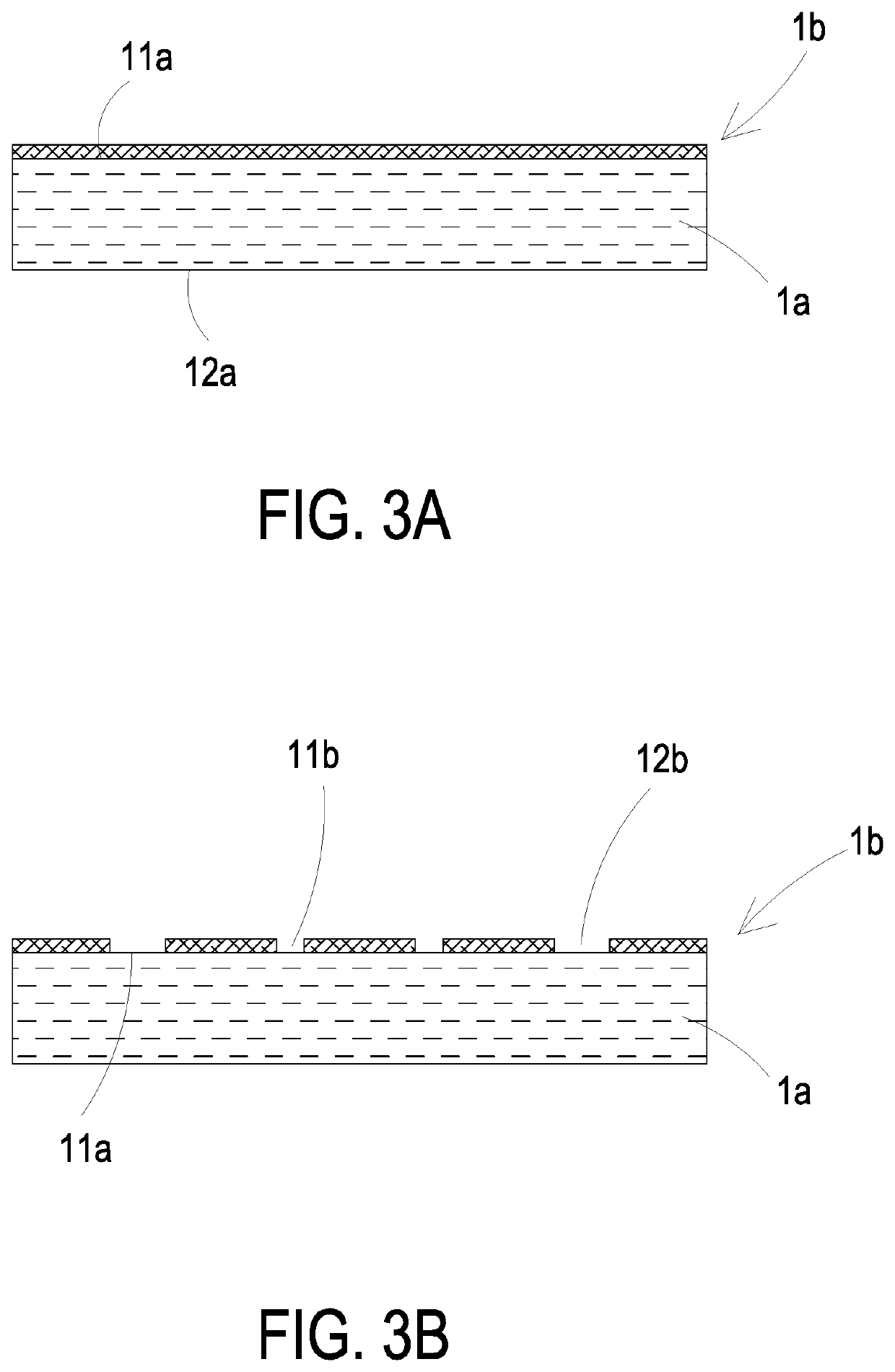

Micro channel structure

ActiveUS20200139368A1Reduce development costsLow mass production costValve arrangementsPositive displacement pump componentsInsulation layerMechanical engineering

A micro channel structure includes a substrate, a supporting layer, a valve layer, a second insulation layer, a vibration layer and a bonding-pad layer. A flow channel is formed on the substrate. A conductive part and a movable part are formed on the supporting layer and the valve layer, respectively. A first chamber is formed at the interior of a base part and communicates to the hollow aperture. A supporting part is formed on the second insulation layer. A second chamber is formed at the interior of the supporting layer and communicates to the first chamber through the hollow aperture. A suspension part is formed on the vibration layer. By providing driving power sources having different phases to the bonding-pad layer, the suspension part moves upwardly and downwardly, and a relative displacement is generated between the movable part and the conductive part, to achieve fluid transportation.

Owner:MICROJET TECH

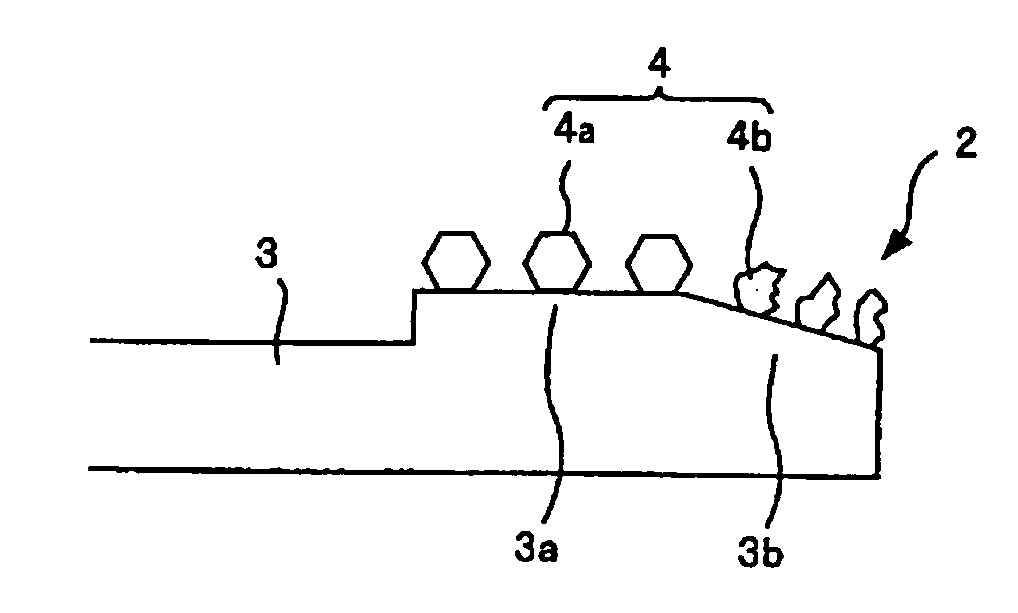

Substrate holding system and exposure apparatus using the same

InactiveUS20070247780A1Stable flatnessCorrection of flatnessSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringSupport surface

A substrate holding system for holding a substrate based on vacuum attraction and electrostatic attraction including a rim configured to support the substrate, a protrusion for the electrostatic attraction, configured to support the substrate inside the rim, and a protrusion for the vacuum attraction, configured to support the substrate inside the rim. A substrate supporting surface area of the protrusion of the electrostatic attraction is larger than a substrate supporting surface area of the protrusion for the vacuum attraction.

Owner:CANON KK

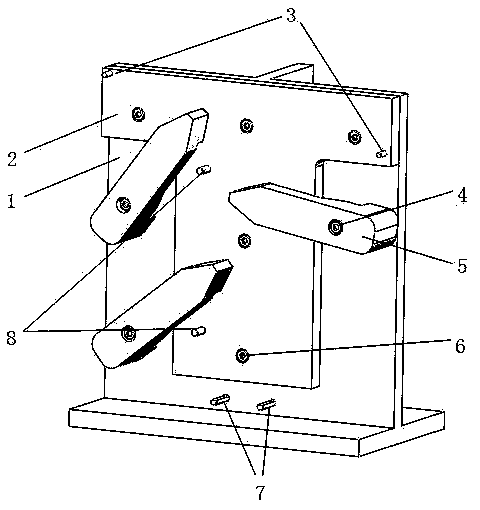

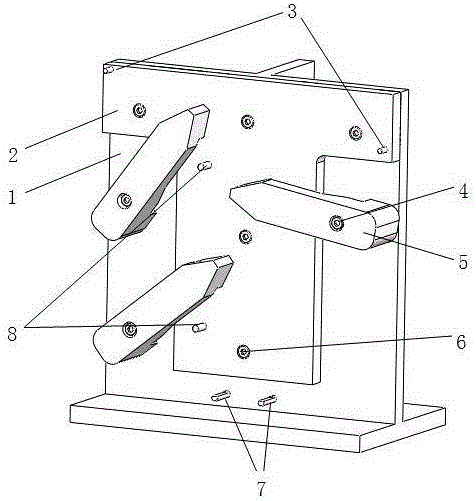

Special clamp for CNC (computer numerical control) machined groove and clamping method

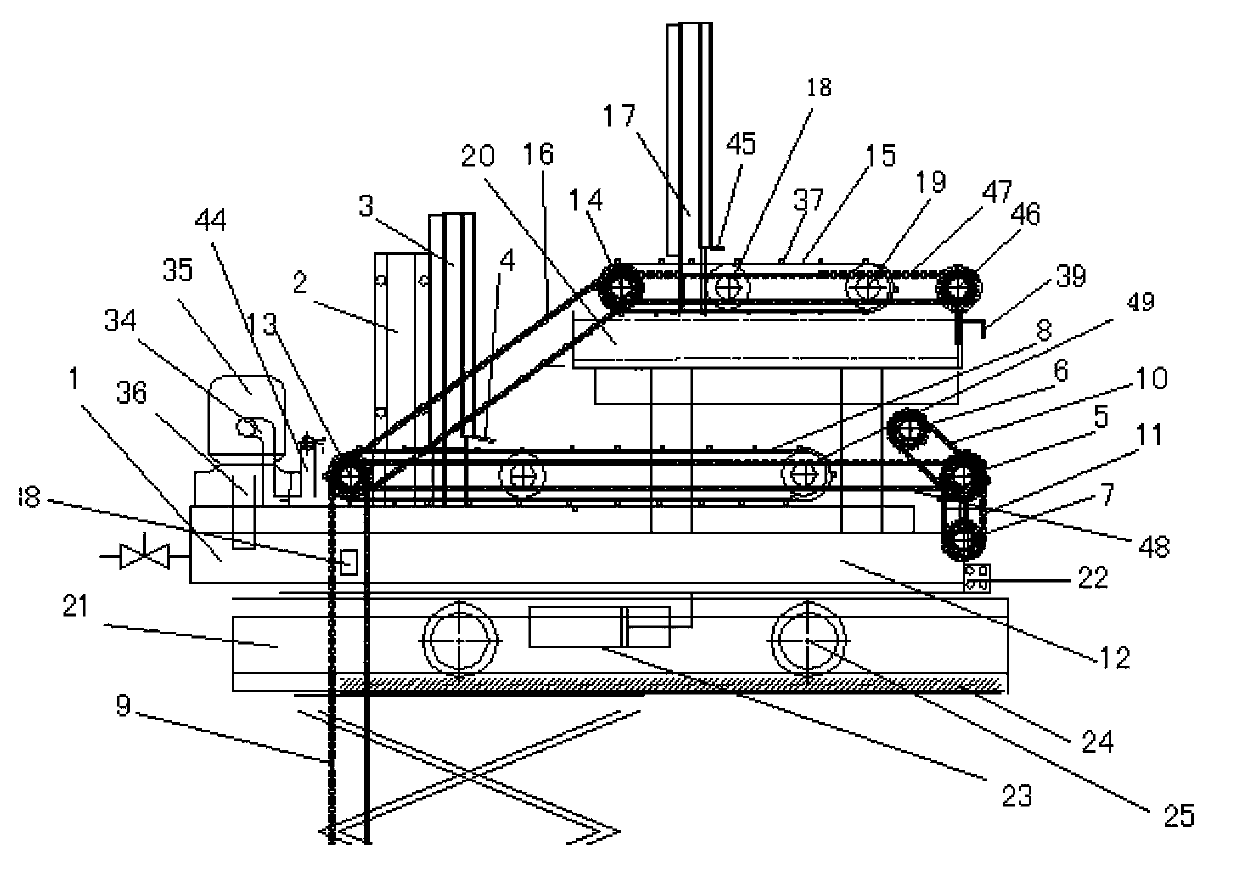

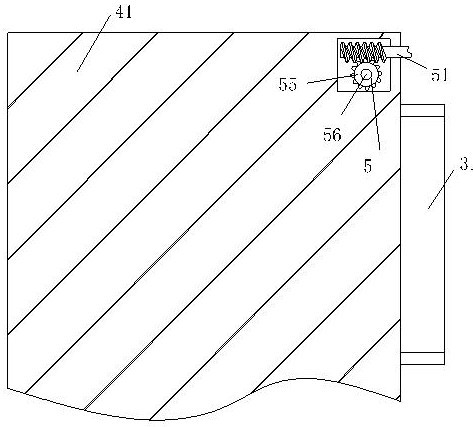

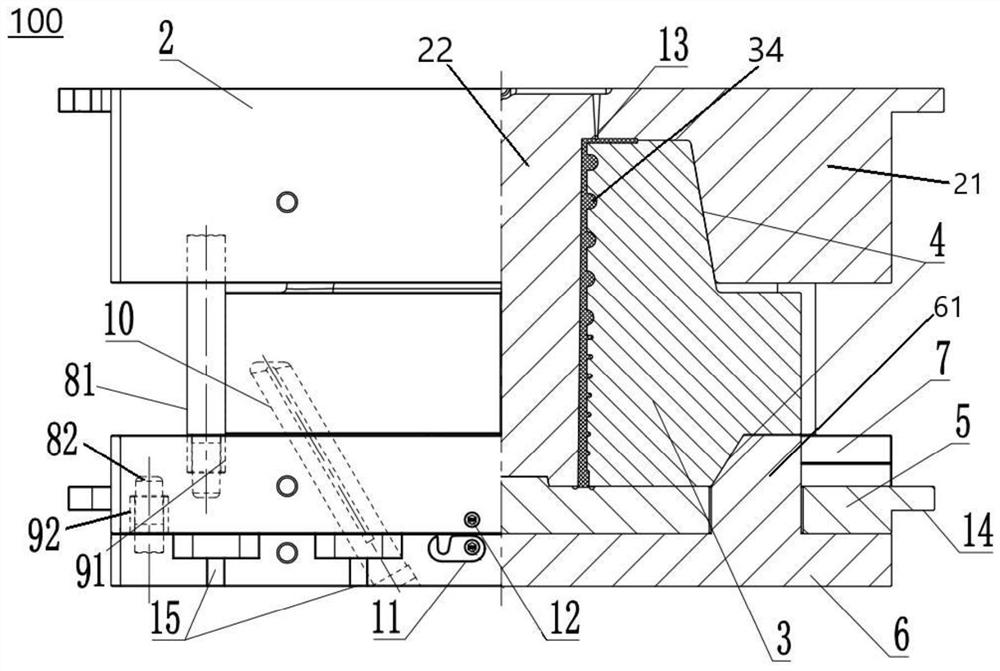

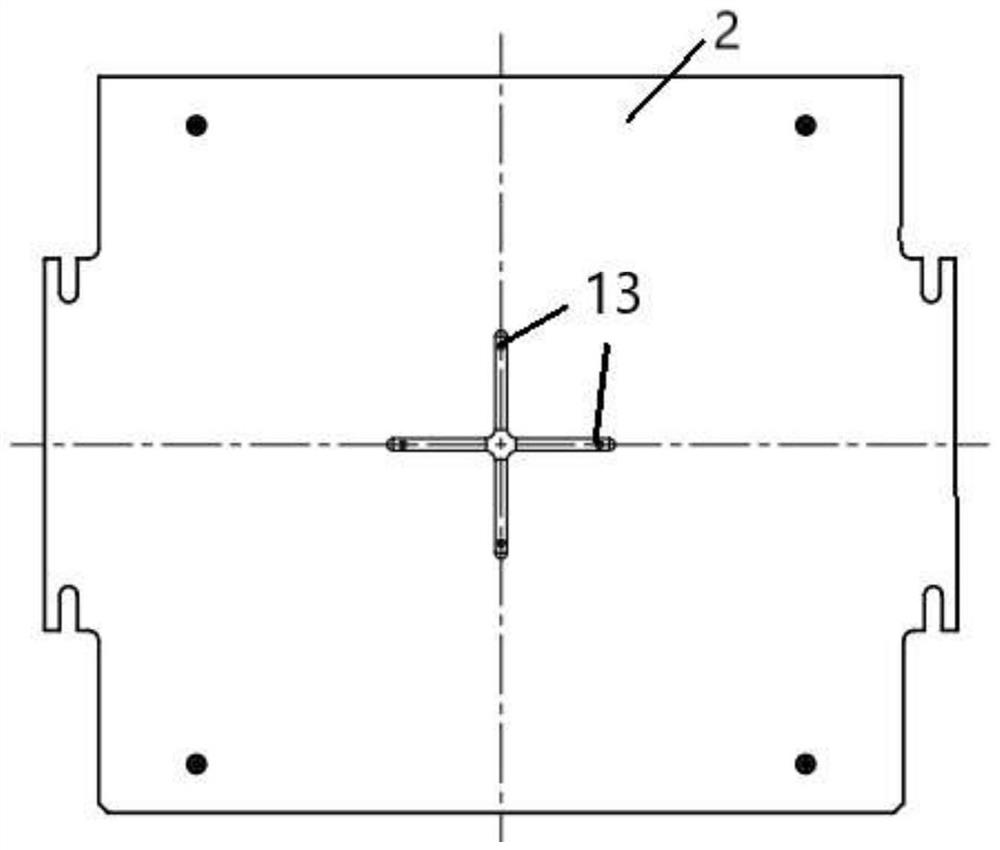

ActiveCN103949910AStable flatnessControl flatnessWork clamping meansPositioning apparatusMachining processEngineering

The invention discloses a special clamp for CNC machined groove. The clamp comprises a bottom frame and a clamp main board, wherein the bottom frame is delta-shaped; one side of the raised part in the middle of the bottom frame extends outward to form a supporting plate; the clamp main board is arranged on the side surface of the other side of the raised part; the clamp main board is T-shaped; the clamp also comprises three fixing units and three positioning units; the fixing units specifically comprise press blocks and M10 fixing screws; the press blocks are fixed on the bottom frame through the M10 fixing screws; each positioning unit specifically comprises two positioning pins. The clamp has the advantages that the integrated design and the positioning mode of the clamp are adjusted, positioning of holes and shapes are integrated in the clamp, three machining processes are accomplished on one clamp, the positioning mode of the holes is accomplished through the two positioning pins at opposite angles, the planeness stability of workpieces is properly controlled, the difficulty in machining of the groove is solved, and the machining precision and the production efficiency are improved.

Owner:强龙科技(苏州)有限公司

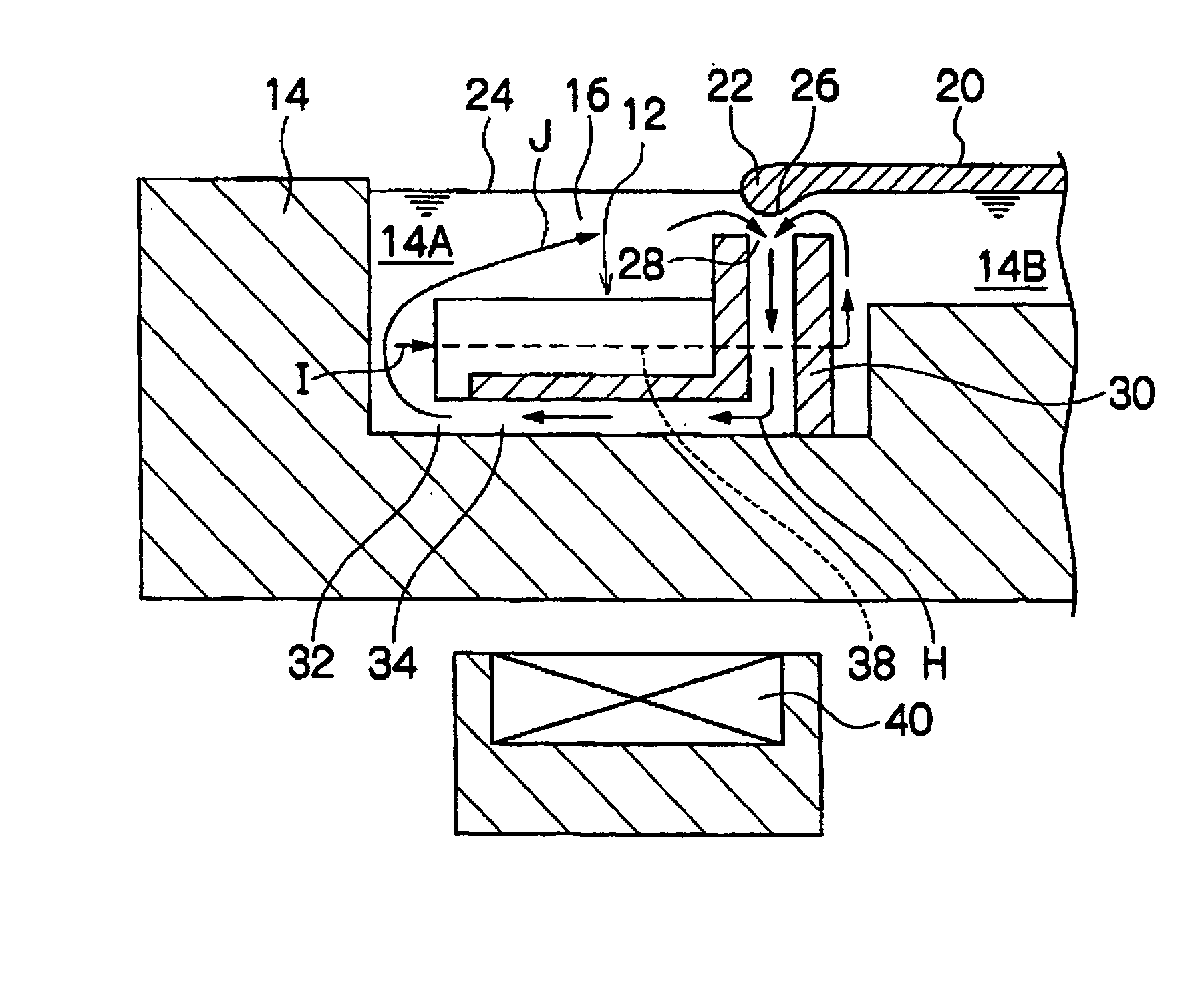

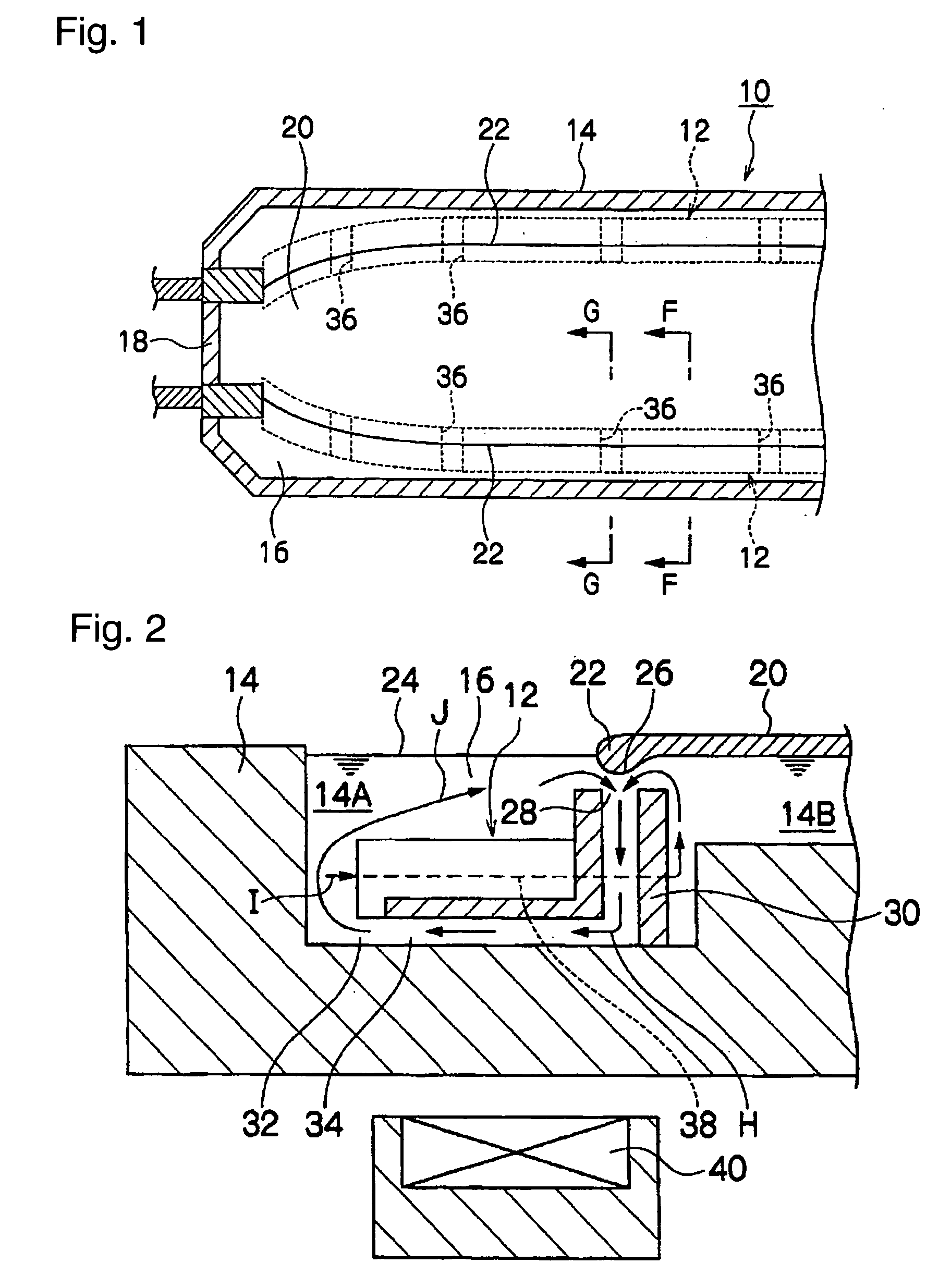

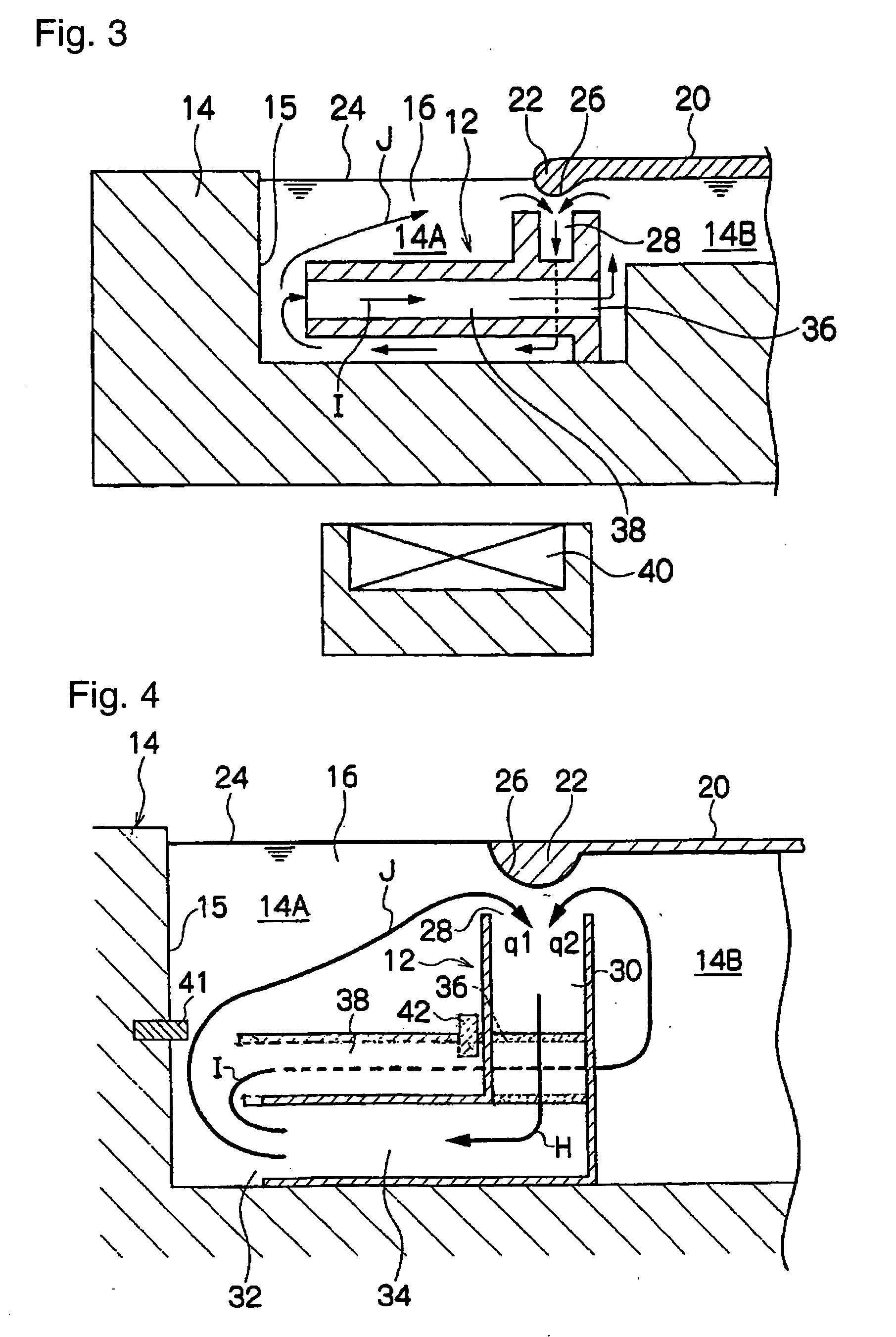

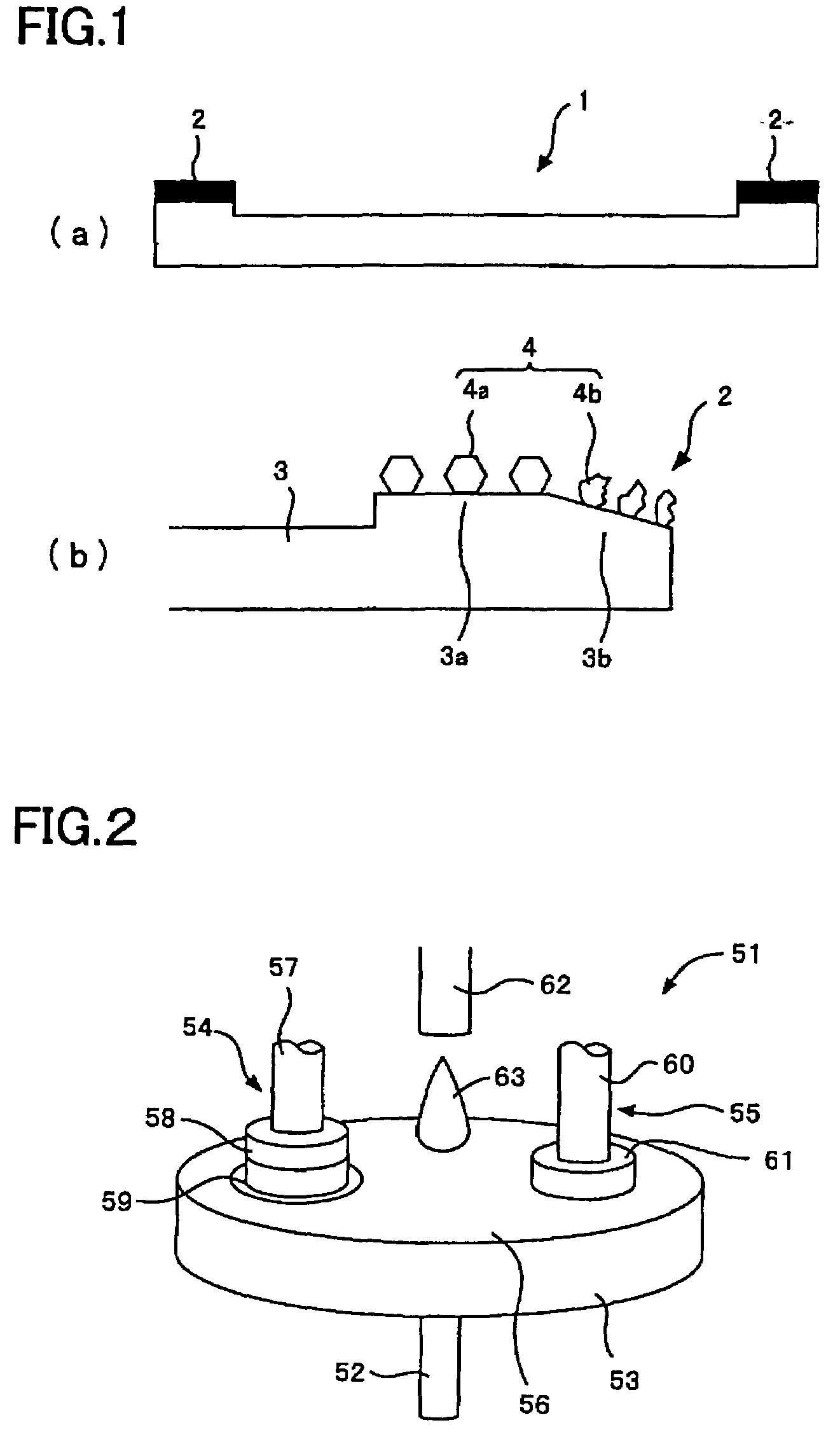

Method for manufacturing float glass and device therefor

It is an object of the present invention to provide a method for manufacturing float glass and a device therefor, which are capable of stably holding both edges of a molten glass ribbon. In accordance with gutter-like bodies 12 of a device for manufacturing float glass 10, a portion of molten tin 16 that flows out of outlets 32 of lateral ducts 34 of the gutter-like bodies 12 into vessel edge areas 14A can be directed to a vessel central area 14B through vertical ducts 30 and through holes 36. Since the flow rate q1 of the molten tin 16 that flows from each of the vessel edge areas 14A into each of the inlets 28, and the flow rate q2 of the molten tin 16 that flows from the vessel central area 14B into each of the inlets 28 are substantially equalized along the forward direction of the molten glass ribbon 20. Accordingly, recessed portions 26 are substantially uniformly formed on a bath surface 24 in such an appropriate shape to hold the edges along the forward direction of the molten glass ribbon 20, with the result that the edges 22 can be stably held in the recessed portions 26, making it possible to obtain a stable glass quality.

Owner:ASAHI GLASS CO LTD

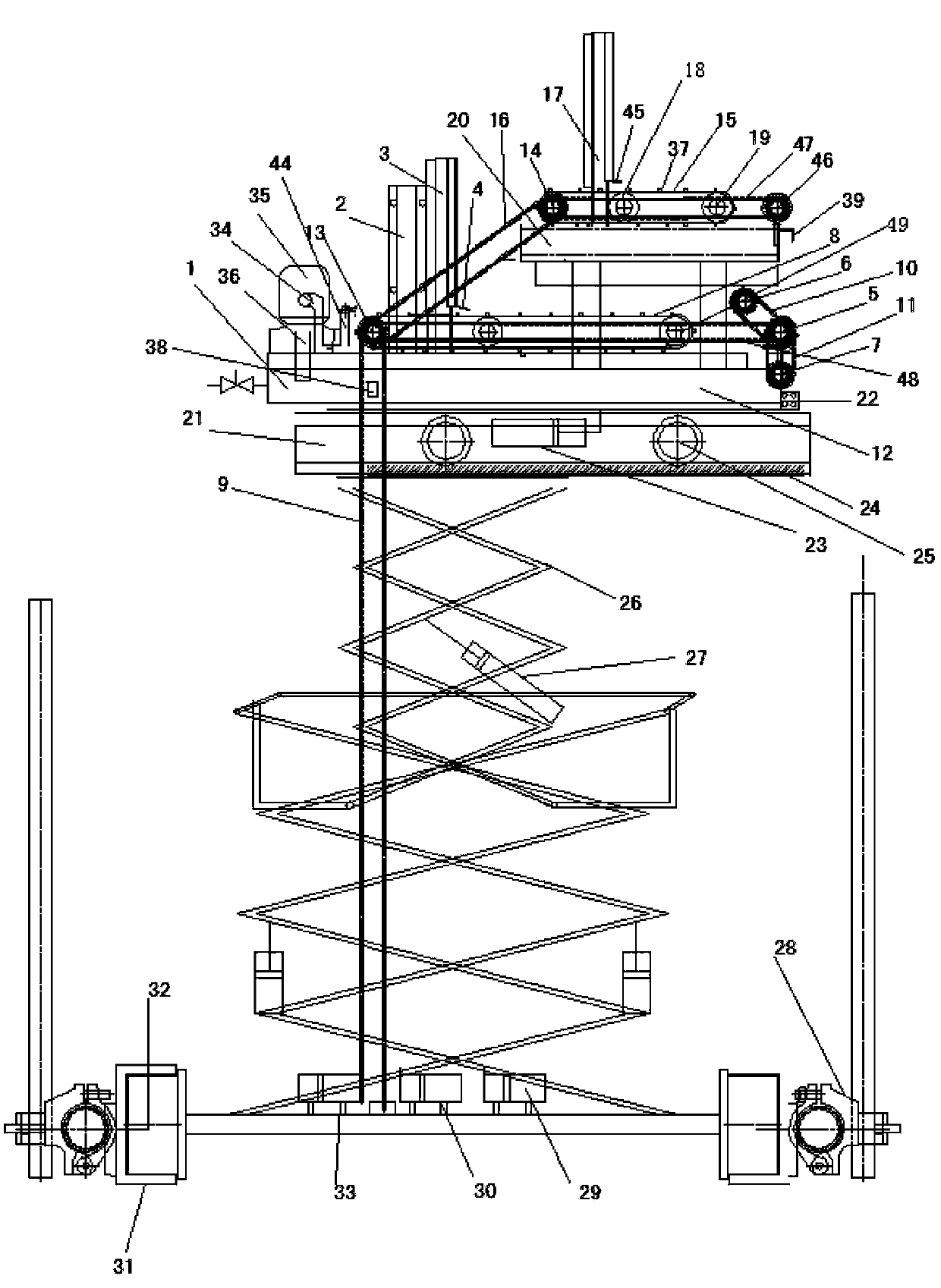

Synchronous all-in-one machine for automatically pasting ceramic tile and whitewashing wall

The invention discloses a synchronous all-in-one machine for automatically pasting ceramic tile and whitewashing wall. The synchronous all-in-one machine comprises a ceramic tile pasting main machine, a wall whitewashing main machine and a lifting machine arranged under the ceramic tile pasting main machine and wall whitewashing main machine; and the ceramic tile pasting main machine comprises a first stander, a first transporting mechanism arranged on the first stander and used for transporting ceramic tiles, a first lime box arranged above the first transporting mechanism and used for plastering the surfaces of the ceramic tiles, a channel steel type ceramic tile box filled with ceramic tiles, a first lime cutting plate arranged on the first stander, a ceramic tile rolling pasting shaft and a ceramic tile flat treading shaft. The synchronous all-in-one machine is simple to operate, the planeness of the wall whitewashing appearance of a building wall surface, and the planeness and the firmness of the ceramic tile pasting appearance can be realized, the ceramic tile pasting speed and the wall whitewashing speed can be greatly accelerated, the labor cost and the material cost can be reduced, and the time can be saved.

Owner:余选兵

Shielding cover frame and manufacturing process thereof

InactiveCN105964782AHigh strengthReduce residual stressMagnetic/electric field screeningRaw materialManufacturing engineering

The invention discloses a manufacturing process of a shielding cover frame, which comprises the following steps: S1, printing marks on a raw material tape entering a mold, where the marks are recesses or protrusions arranged at intervals, to prepare a blank; S2, Holes are made at the edges of the blank that need to be stretched and bent. Also disclosed is a shielding cover frame, which includes a body, the surface of the body is provided with a number of imprinted points, and the imprinted points are depressions or protrusions, and the stretched and bent edges of the surface are provided with punching holes. The shielding cover frame and the manufacturing process thereof of the present invention make the flatness of the product more stable, and can effectively reduce the maintenance cost of the mould.

Owner:SHENZHEN SUNWAY COMM

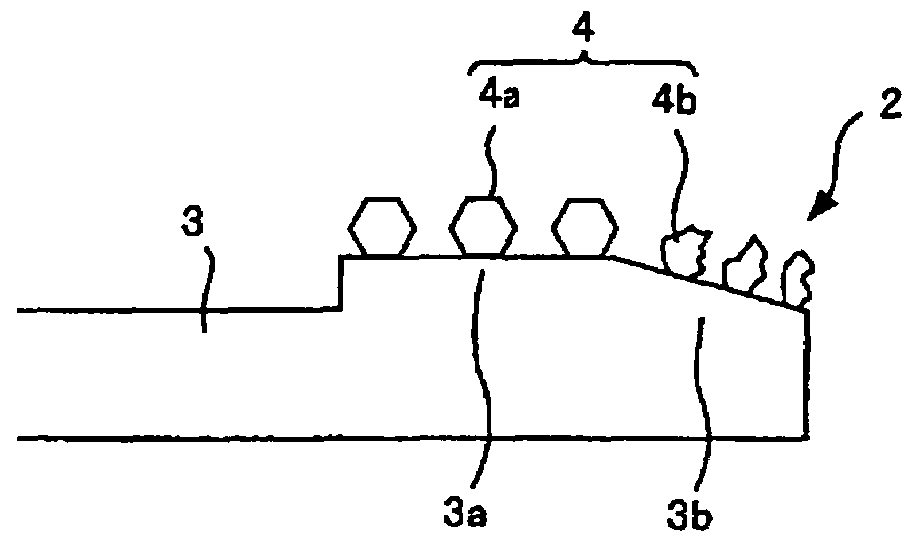

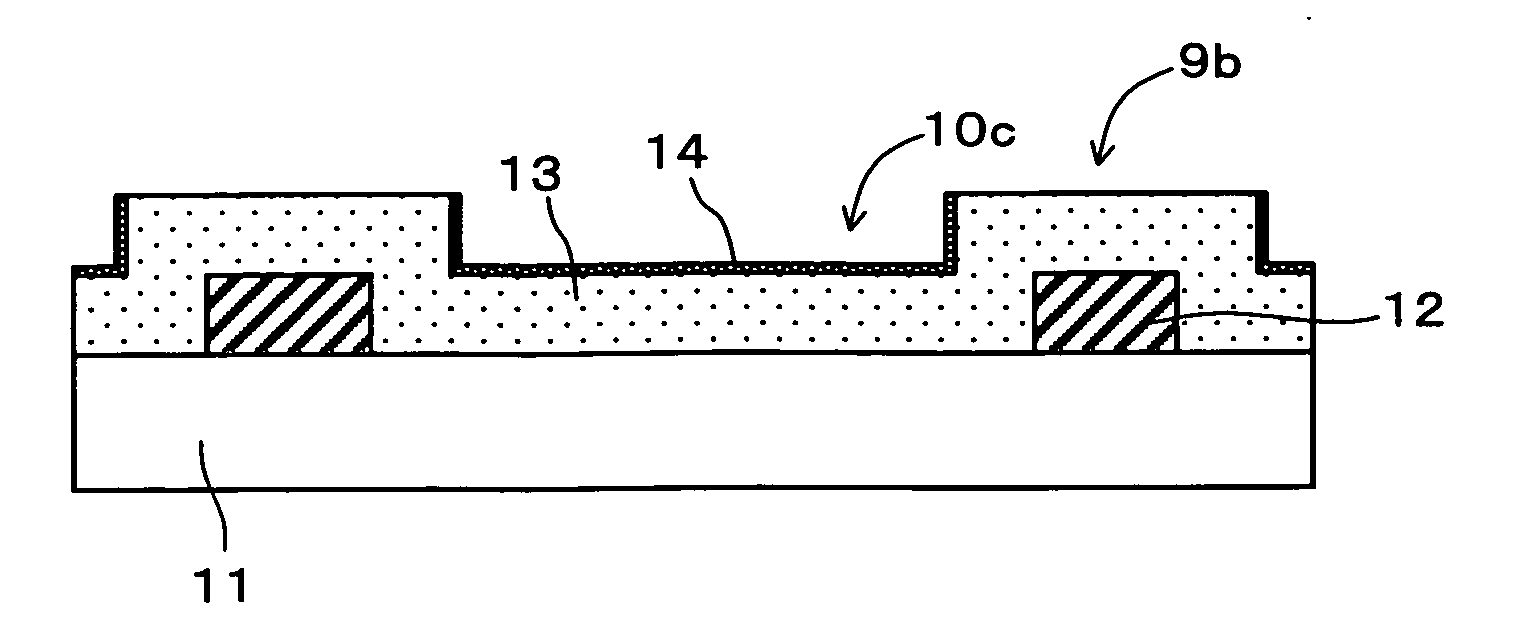

CMP pad conditioner

InactiveUS7540802B2Stable on the groundStable flatnessGrinding drivesBelt grinding machinesEngineeringSoldering

A CMP pad conditioner is provided with a grinding part formed by fixing abrasive grains on a metal base by soldering, wherein the grinding part has a flat part near an inner periphery and an inclined part near an outer periphery, wherein abrasive grains having regular shapes are fixed to the flat part, and wherein abrasive grains having acute shapes are fixed to the inclined part.

Owner:NORITAKE CO LTD +1

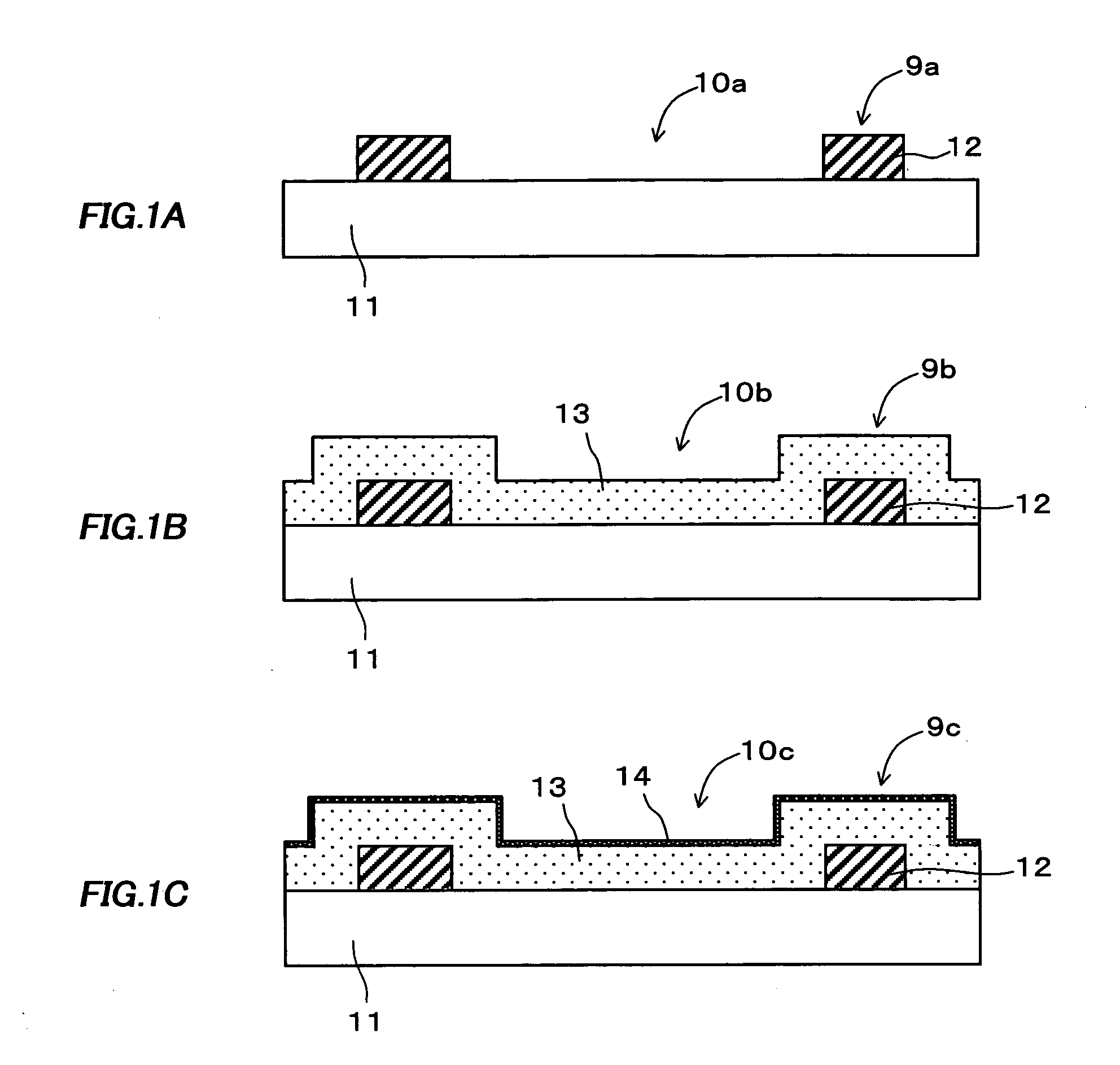

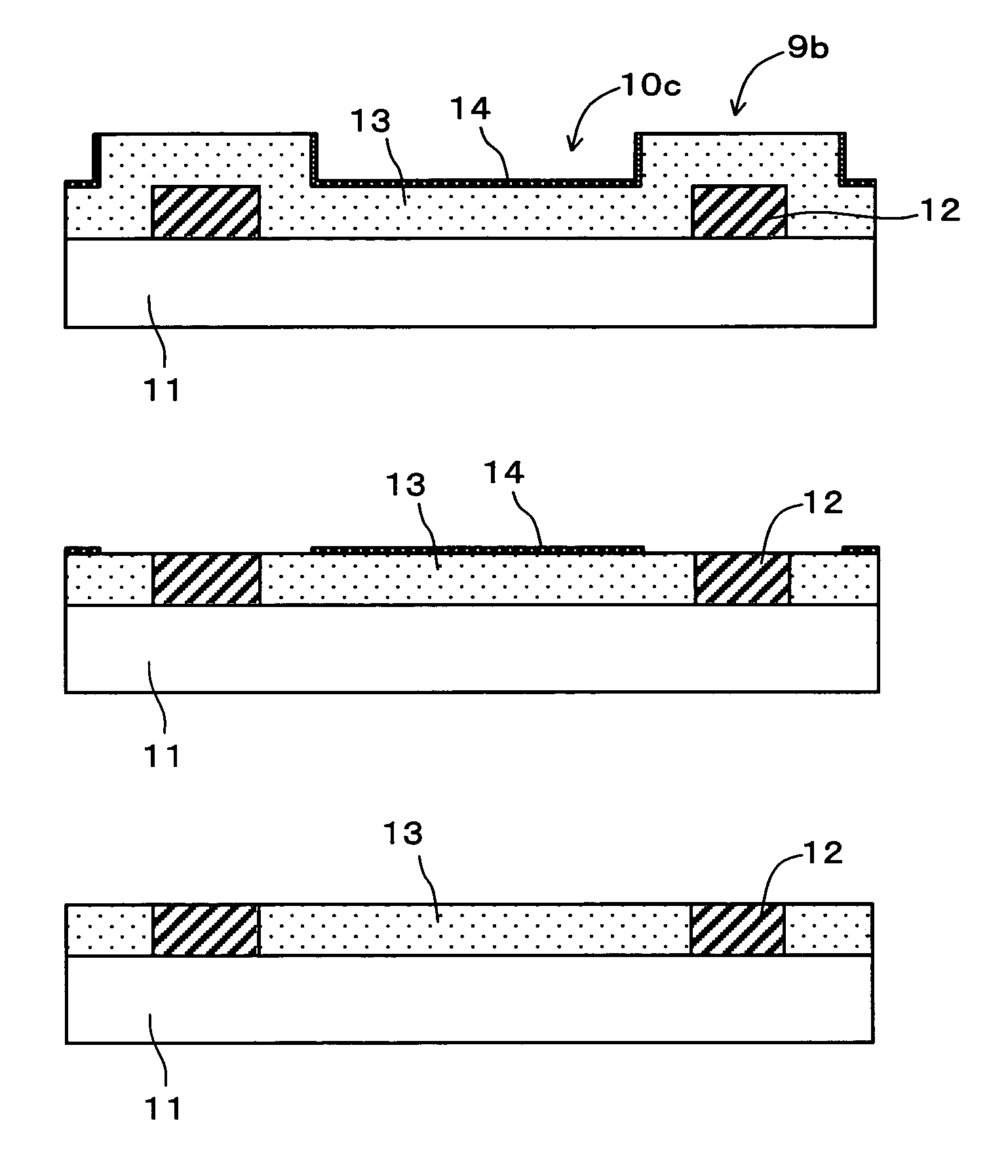

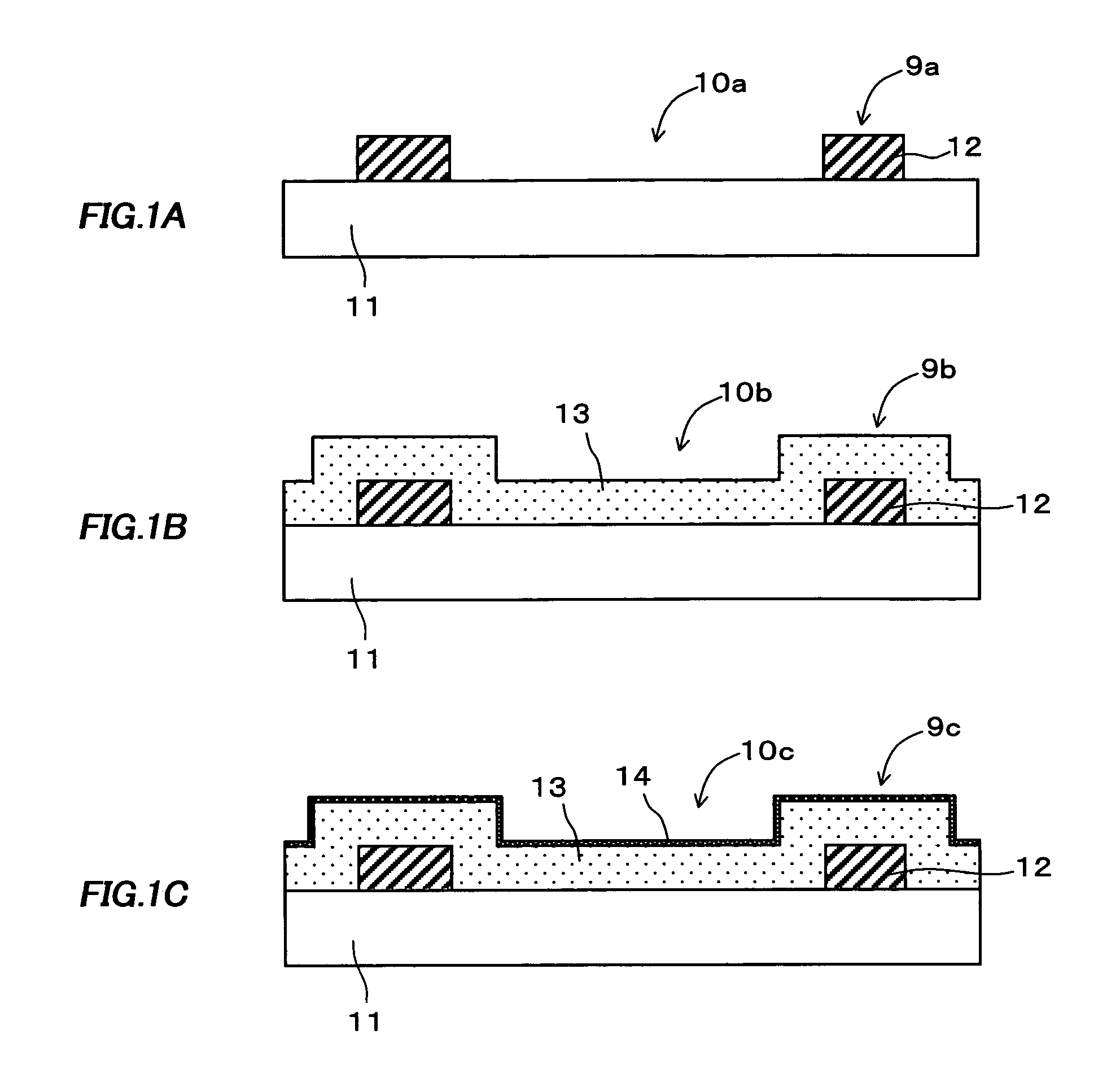

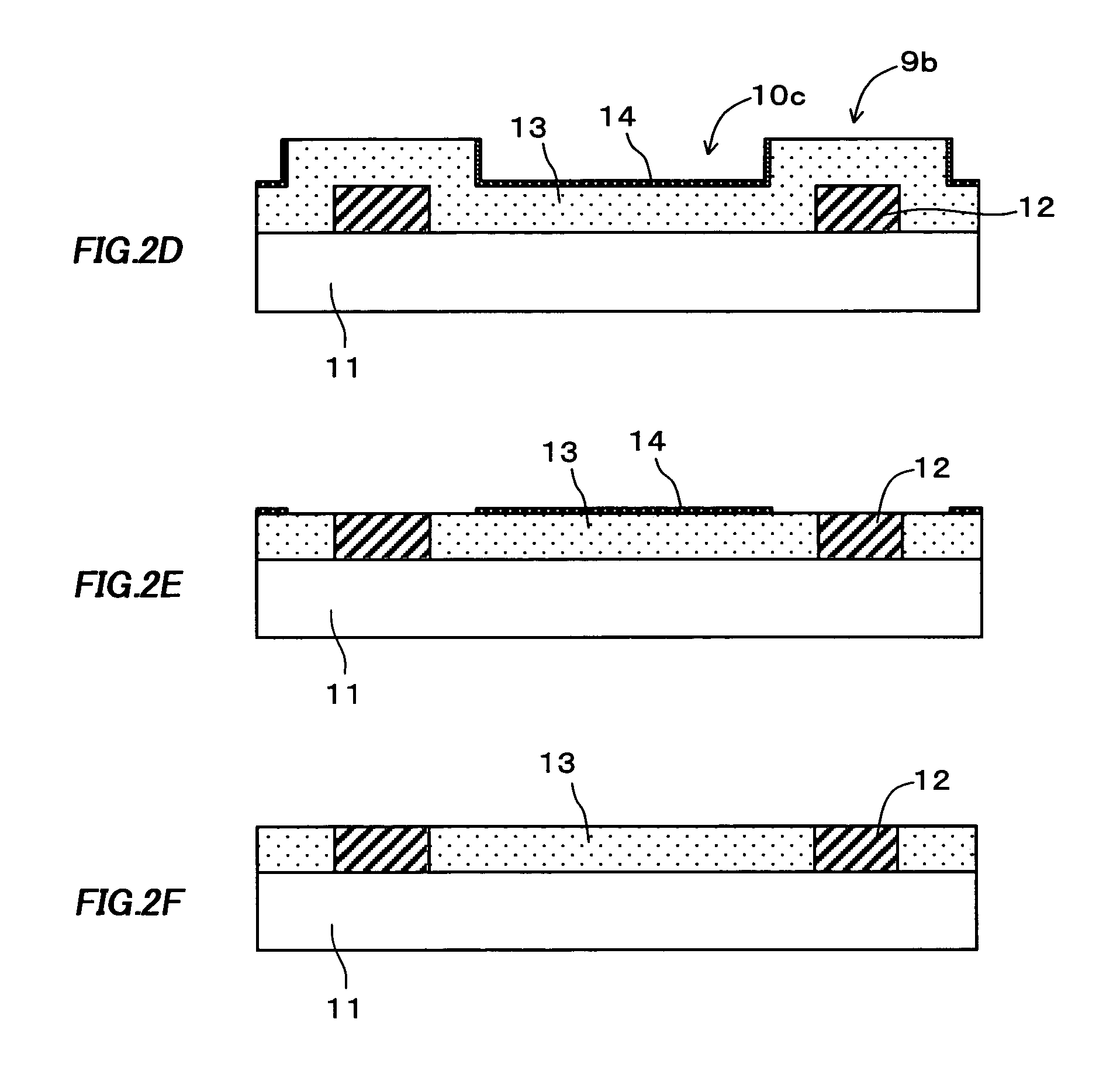

Semiconductor device fabrication method

ActiveUS20050282389A1Avoid it happening againAvoid dentsSemiconductor/solid-state device manufacturingSlurrySilicon

A semiconductor device fabrication method according to the invention comprises the steps of: (1) exposing a silicon layer by removing a portion of an insulating layer above a projected part of the silicon layer, the insulating layer covering the silicon layer; and (2) chemically and mechanically polishing the exposed silicon layer with a polishing slurry for the silicon layer while protecting the silicon layer with the remaining of the insulating layer.

Owner:SHARP KK

Ratproof butterfly optical cable and preparation method thereof

InactiveCN107422437AReduce weightImprove bending strengthFibre mechanical structuresEngineeringOptical fiber cable

The invention relates to a ratproof butterfly optical cable and a preparation method thereof. The ratproof butterfly optical cable comprises a sheath I, a sheath II, an optical fiber, and reinforcing members. Each of the sheath I and the sheath II is provided with two symmetrical flanks and a groove formed between the flanks. The optical fiber is disposed in the center of the ratproof butterfly optical cable, and a number of optical fiber cores is 2n, and n is a positive integer. The reinforcing members are disposed in the sheath II, and are symmetrically disposed on the two sides of the optical fiber. The preparation method comprises steps of S1, material drying and mixing, S2, sheath forming, S3, cable cooling, and S4 finished product take-up. The ratproof butterfly optical cable and the preparation method have advantages of good ratproof effect, low costs, and small stimulation.

Owner:FUJIAN SOUTHERN NEW CABLE

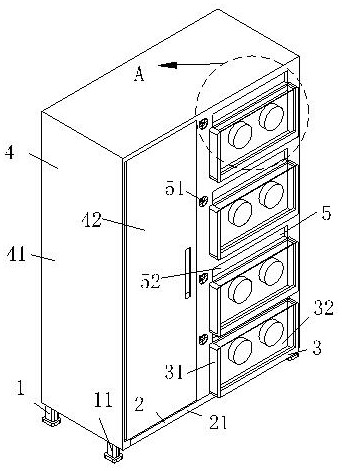

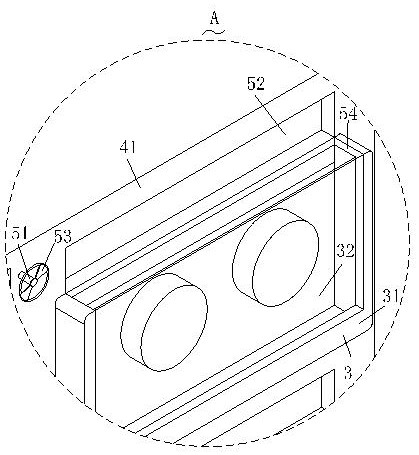

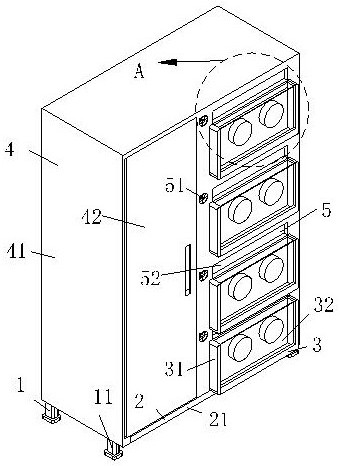

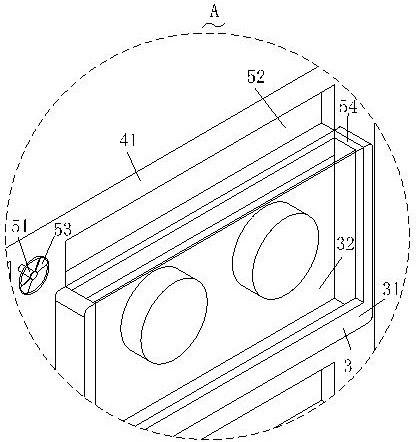

GCS low-voltage draw-out type switch cabinet with moisture-proof performance

ActiveCN113315020AEasy to adjustImprove efficiency and quality of installationSwitchgear detailsSubstation/switching arrangement casingsDamp proofingStructural engineering

The invention relates to the technical field of switch cabinets, in particular to a GCS low-voltage draw-out type switch cabinet with moisture-proof performance, which comprises a supporting structure, a sealing structure, a storage structure, an accommodating structure, a protection structure and a transmission structure, the arrangement of the sealing structure facilitates the sealing of the supporting structure, and the arrangement of the supporting structure facilitates the adjustment of the flatness of the accommodating structure in the same direction, thereby greatly improving the installation efficiency and quality of the accommodating structure. The protection structure can abut against the storage structure, the storage structure can be protected conveniently through the protection structure, misoperation of a rotary knob in the storage structure is effectively prevented, meanwhile, the storage structure is conveniently limited, and the stability of the storage structure is improved; and the transmission structure is conveniently driven through the protection structure, so that the transmission structure drives the storage structure to abut against the accommodating structure, the sealing performance between the storage structure and the accommodating structure is better, and the moisture-proof performance is greatly improved.

Owner:南通苏泰电气有限公司

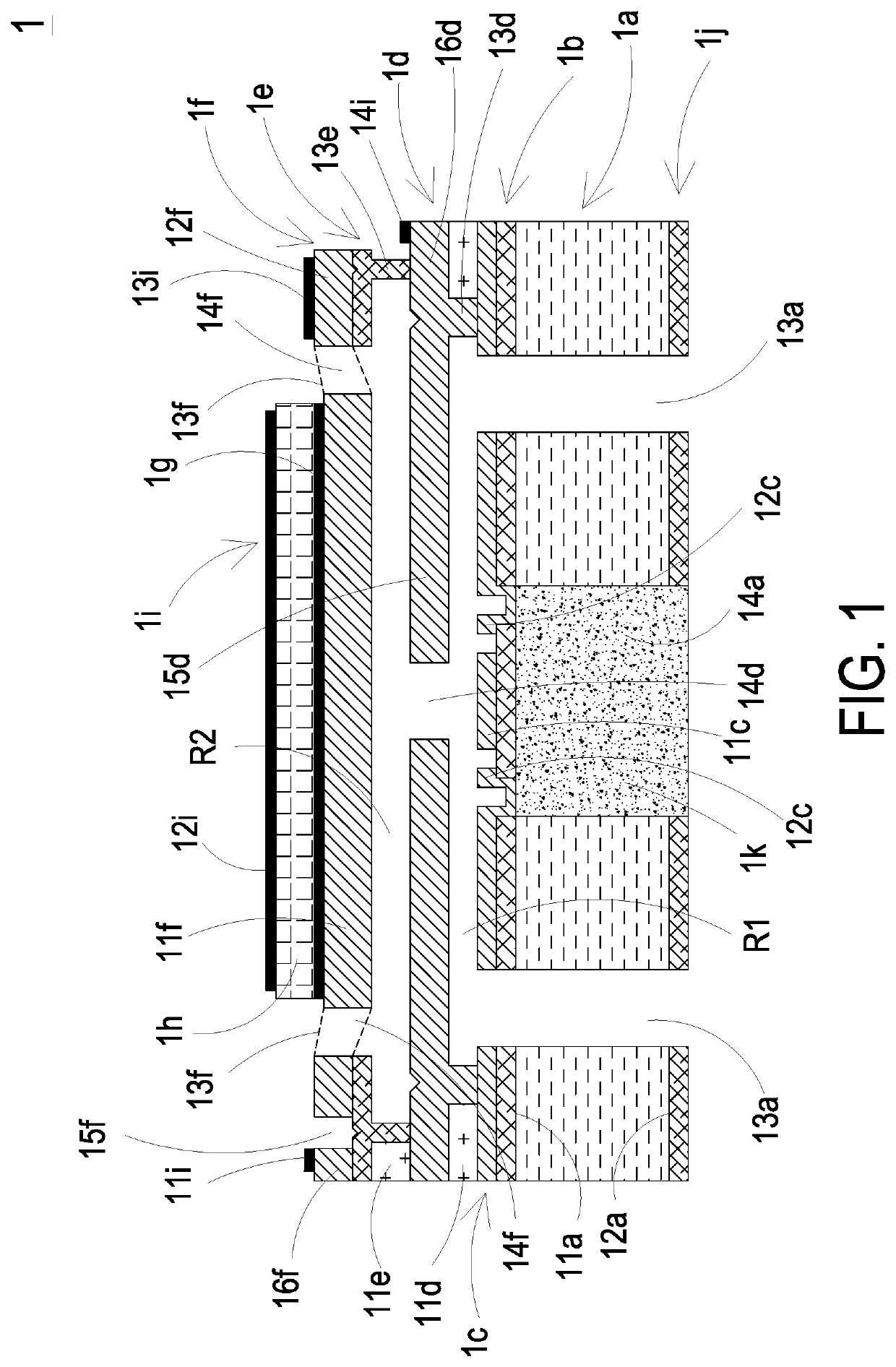

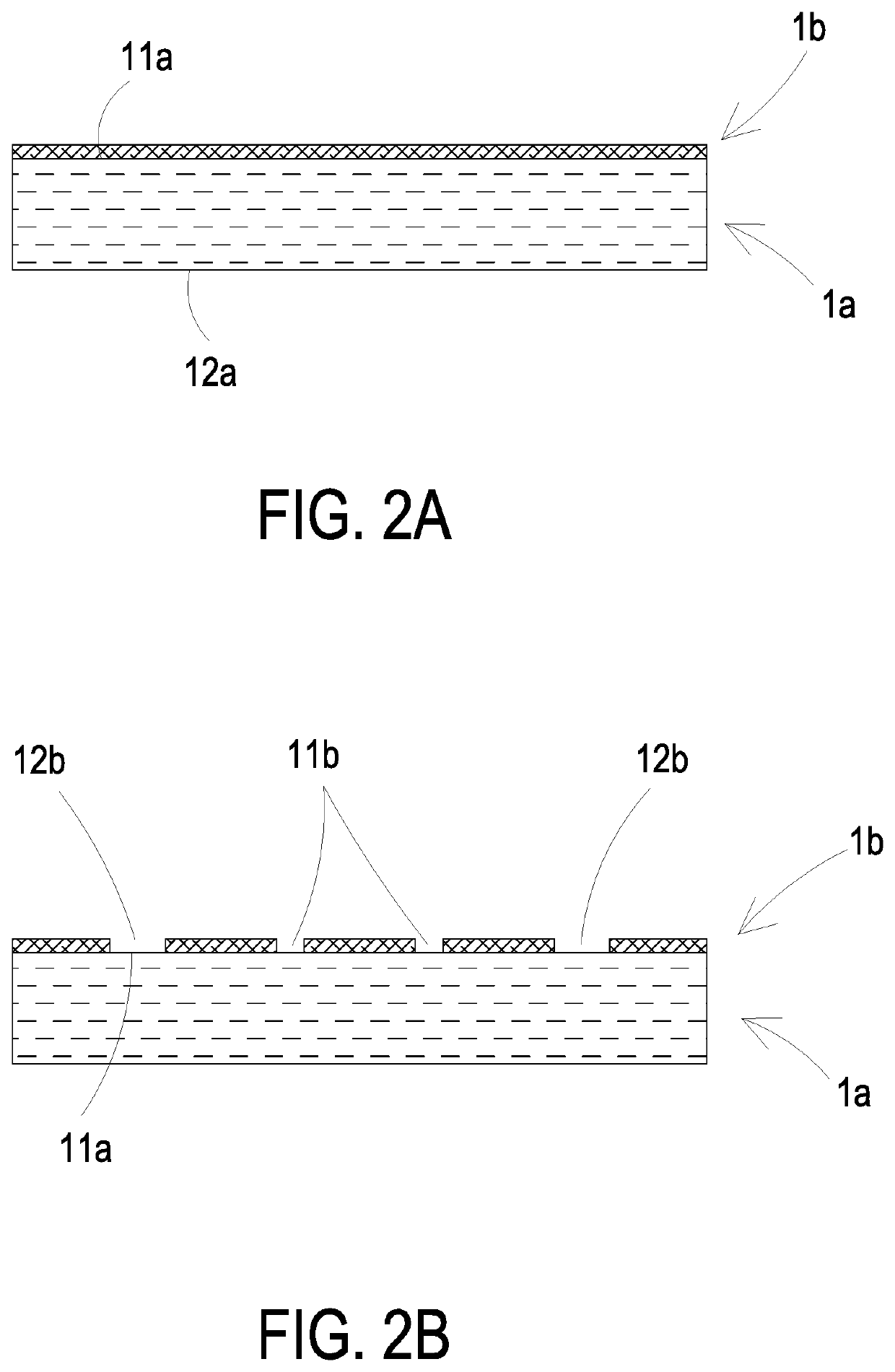

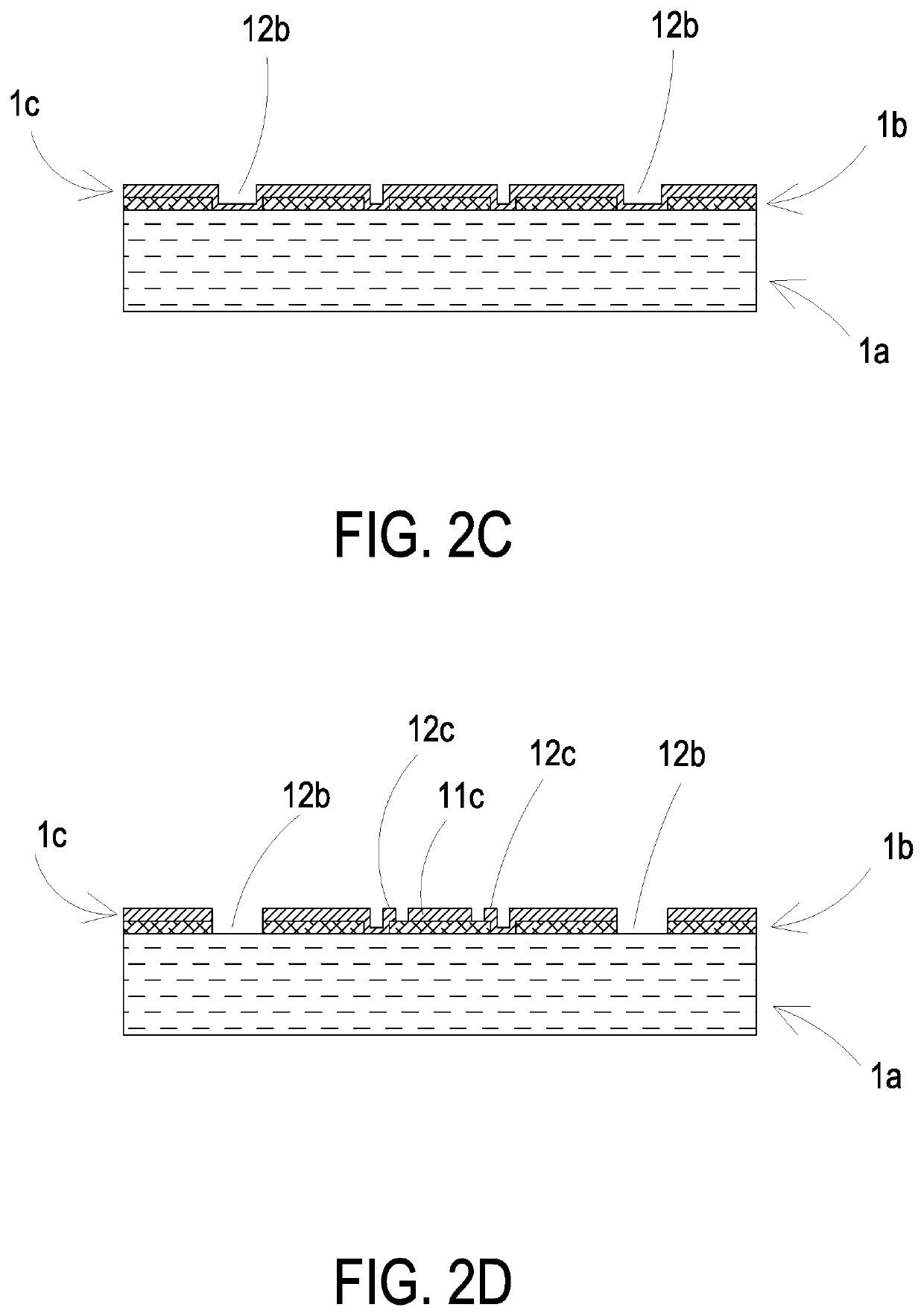

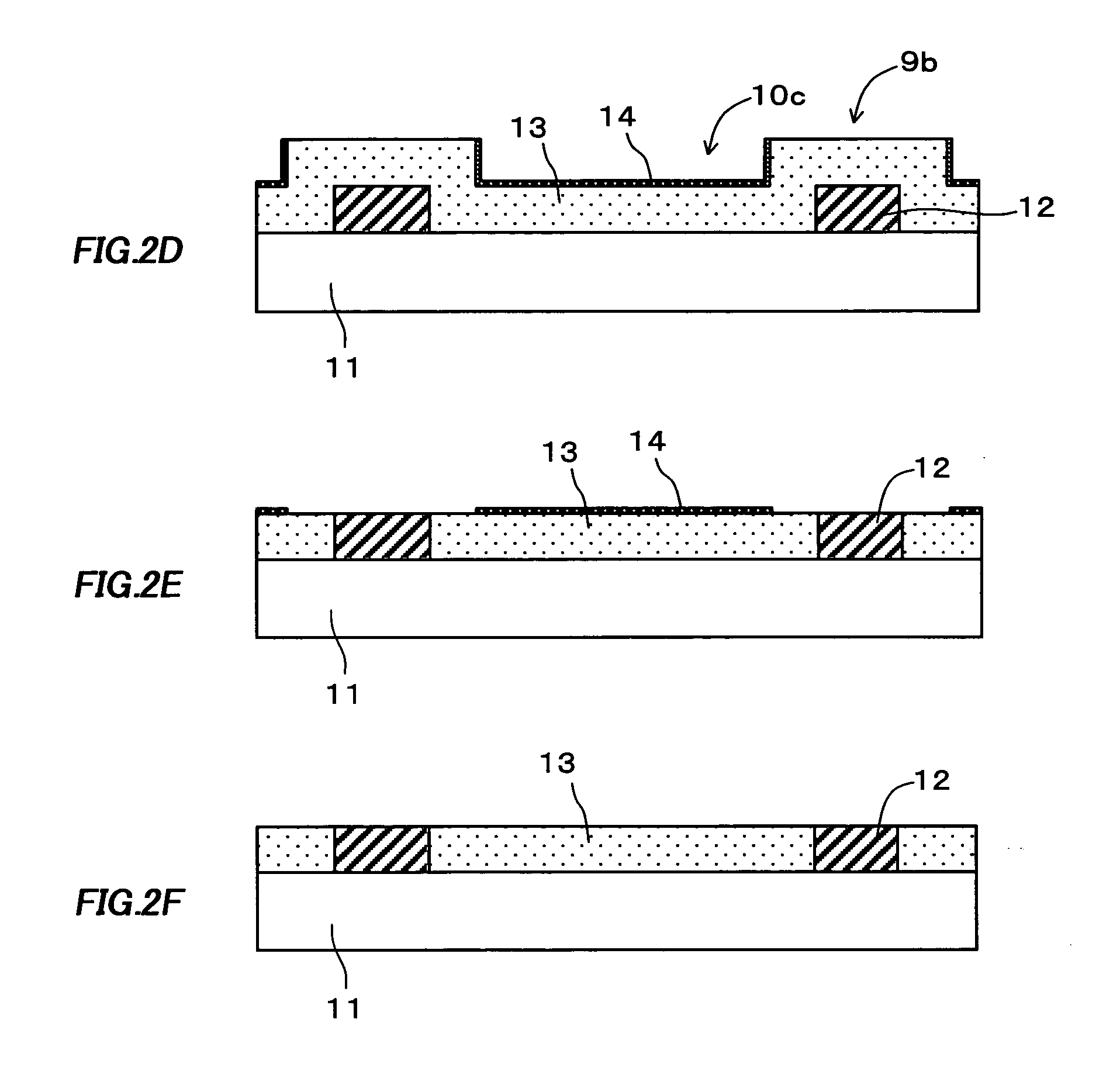

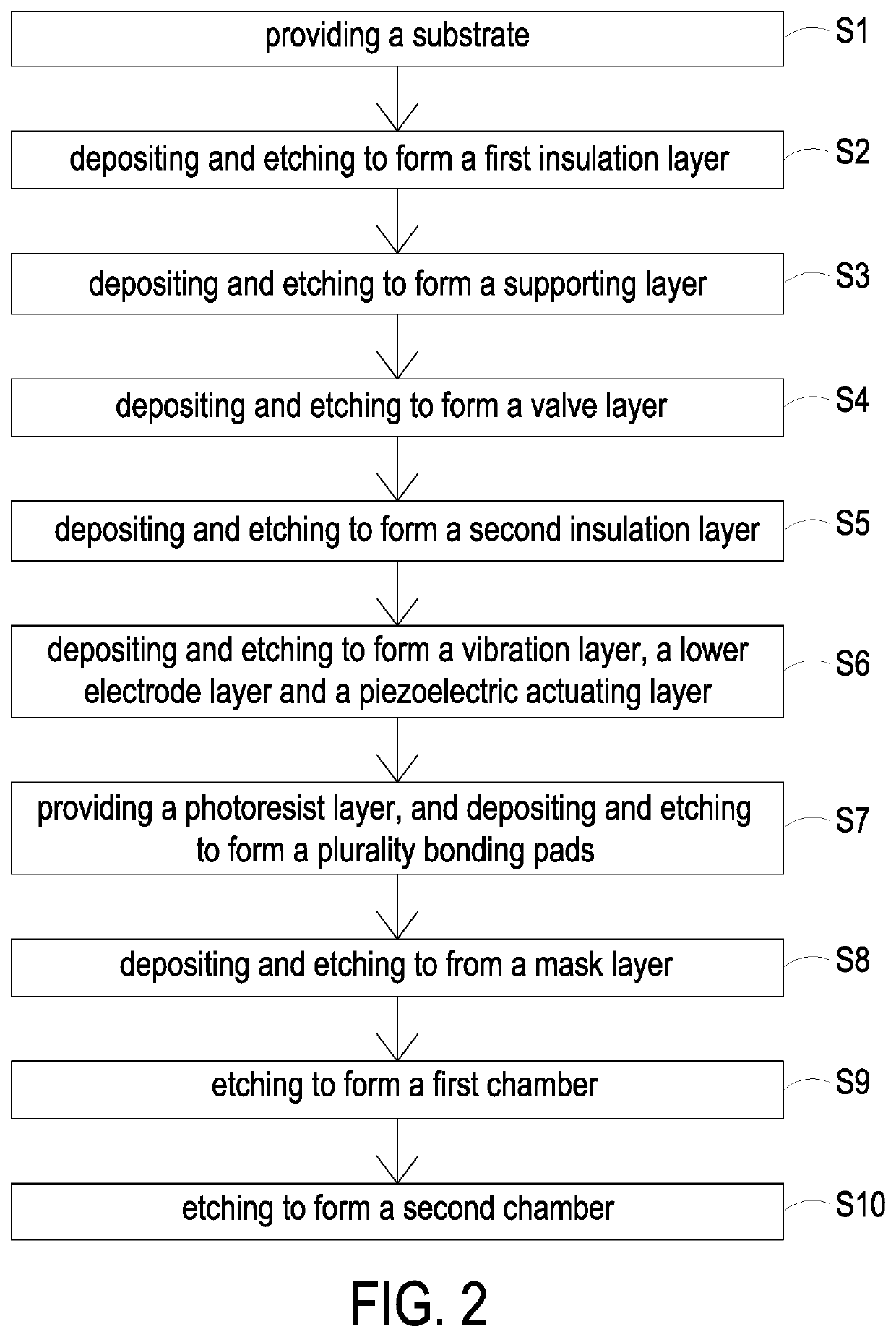

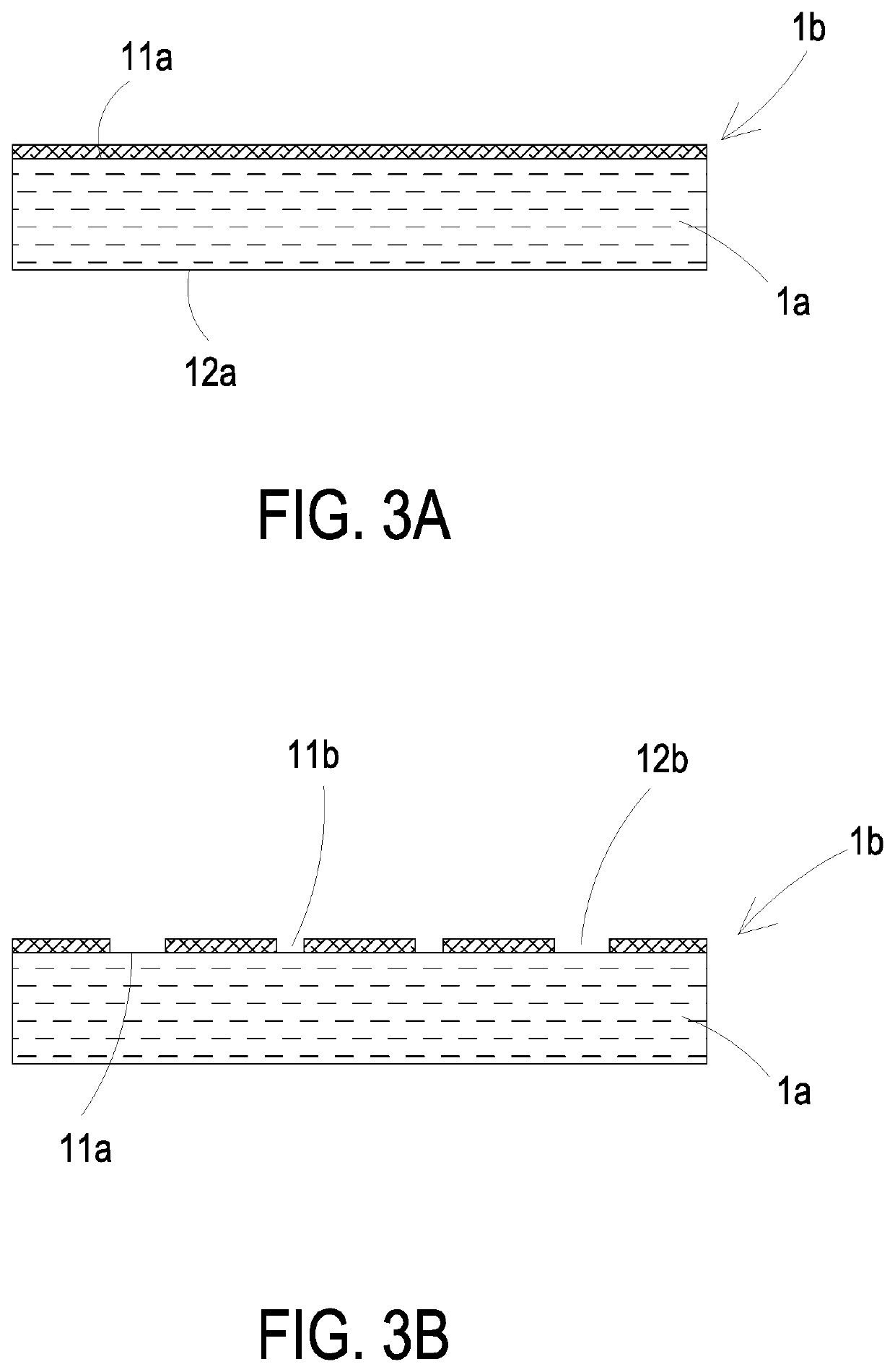

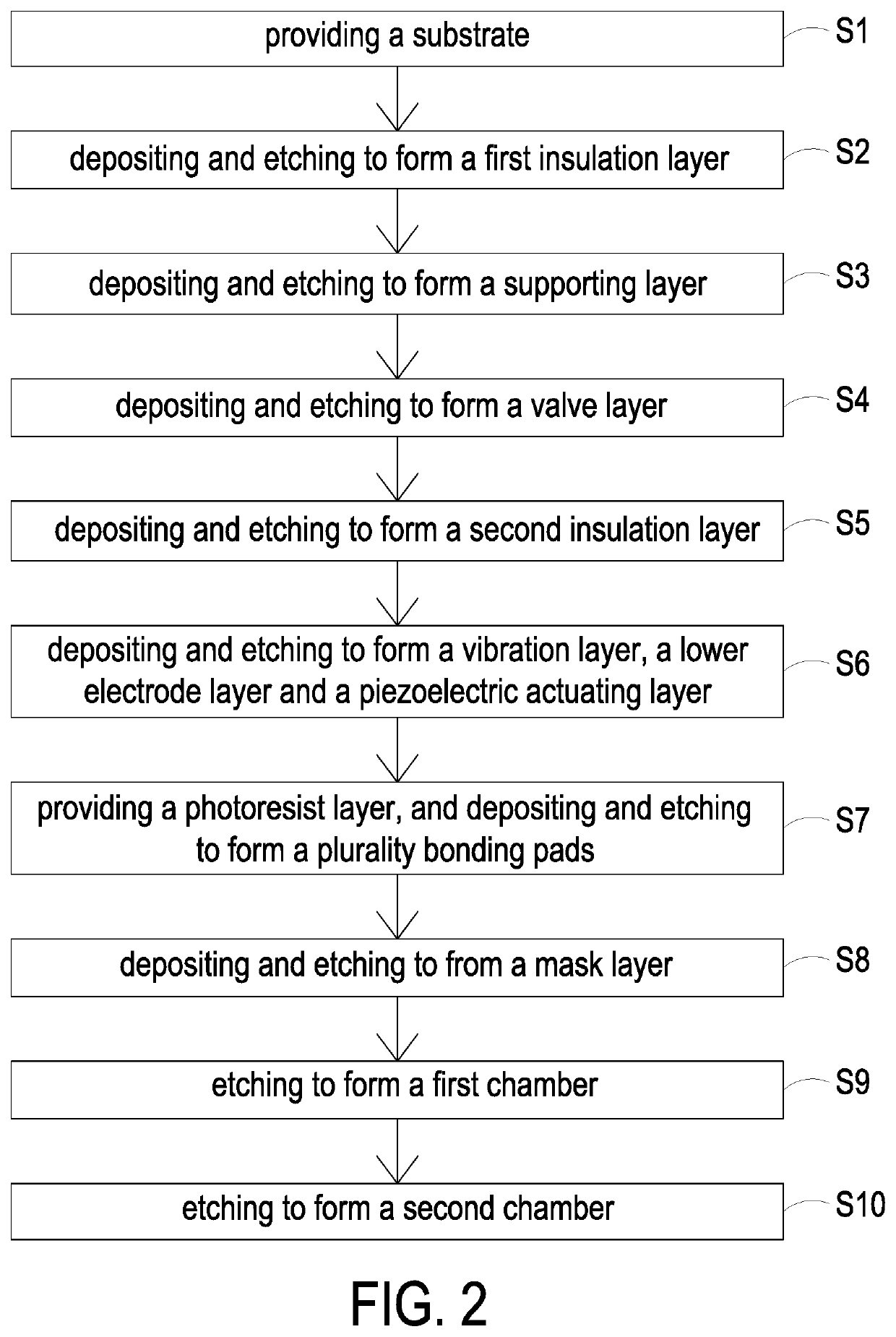

Manufacturing method of micro channel structure

ActiveUS20200140264A1Reduce development costsLow mass production costValve arrangementsDecorative surface effectsInsulation layerMechanical engineering

A manufacturing method of micro channel structure is disclosed and includes steps of: providing a substrate; depositing and etching to form a first insulation layer; depositing and etching to form a supporting layer; depositing and etching to form a valve layer; depositing and etching to form a second insulation layer; depositing and etching to form a vibration layer, a lower electrode layer and a piezoelectric actuating layer; providing a photoresist layer and depositing and etching to form a plurality of bonding pads; depositing and etching to from a mask layer; etching to form a first chamber; and etching to form a second chamber.

Owner:MICROJET TECH

Semiconductor device fabrication method

ActiveUS7030019B2Depression depressionStable flatnessSemiconductor/solid-state device manufacturingSlurrySilicon

A semiconductor device fabrication method according to the invention comprises the steps of: (1) exposing a silicon layer by removing a portion of an insulating layer above a projected part of the silicon layer, the insulating layer covering the silicon layer; and (2) chemically and mechanically polishing the exposed silicon layer with a polishing slurry for the silicon layer while protecting the silicon layer with the remaining of the insulating layer.

Owner:SHARP KK

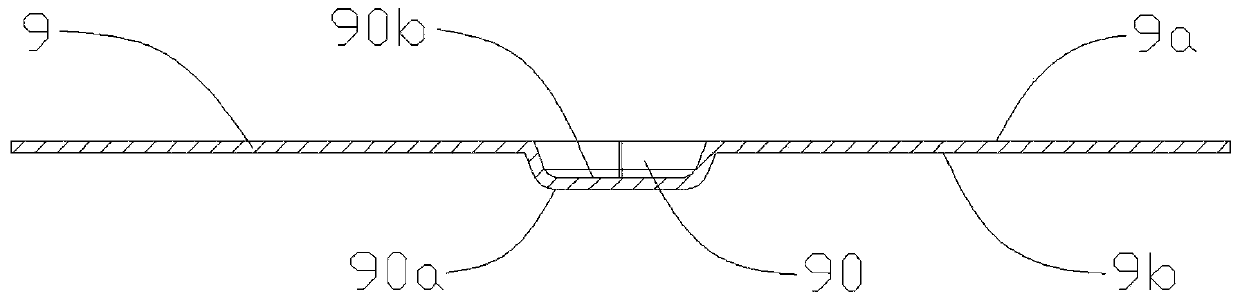

Stress relief stamping die, stress relief stamping method and metal plate stamping part

InactiveCN111266465ANot easy to warpControl deformationShaping toolsStructural engineeringStress relief

The invention discloses a stress relief stamping die, a stress relief stamping method and a metal plate stamping part. The stress relief stamping die is used for stamping a convex hull on a plate bodyof a metal plate and comprises a male die and a female die, the male die comprises a pressing head protruding towards the female die, the female die comprises a forming cavity corresponding to the pressing head, the forming cavity and the pressing head are matched to form the convex hull, the male die comprises a step surrounding the periphery of the pressing head, and the female die comprises astep groove surrounding the periphery of the forming cavity. The step surrounding the periphery of the pressing head is arranged on the male die, and the step groove surrounding the periphery of the forming cavity is arranged on the female die, so that during stamping, a circle of externally convex step part can be formed on the periphery of the convex hull of the metal plate stamping part, so that the internal stress between the convex hull and the plate body is sheared, the deformation of the plate body caused by relief of the internal stress is effectively limited, the stability of the flatness is guaranteed, and the stable operation of equipment is facilitated.

Owner:沪华五金电子(吴江)有限公司

CMP pad conditioner

InactiveUS20070218821A1Stable on the groundStable flatnessGrinding drivesBelt grinding machinesEngineeringSoldering

A CMP pad conditioner is provided with a grinding part formed by fixing abrasive grains on a metal base by soldering, wherein the grinding part has a flat part near an inner periphery and an inclined part near an outer periphery, wherein abrasive grains having regular shapes are fixed to the flat part, and wherein abrasive grains having acute shapes are fixed to the inclined part.

Owner:NORITAKE CO LTD +1

Modelling control method of decorative surface

InactiveCN102864917AFirmness and stabilityStable flatnessBuilding constructionsComputer Aided DesignQuality control

The invention provides a modelling quality control method of a decorative surface. The method comprises the following steps of A) examining and verifying construction drawings, finding out a circle centre of a surface model, decomposing an irregular surface into a plurality of circles, and determining the circle centre, a radius, an arc length and a positioning coordinate; B) decomposing and optimizing the surface model by using computer aided design (CAD), wherein field sizes and paying-off is required to be in accordance with the designed drawings strictly; using a computer to assist the paying-off, so that precision can be ensured; and C) inspecting and checking quality for nodes constructed on a cambered surface, and reducing unnecessary dimensional deviations. The flatness of the cambered surface is ensured, and firmness and construction quality are ensured. By the method disclosed by the invention, the stability and firmness of the steel structure foundation of the surface model, and the flatness and radian of the cambered surface meet the specified requirements. Impression effects meet a predetermined aim, the percent of pass is above 95%, and secondary rework is avoided.

Owner:苏州苏明装饰股份有限公司

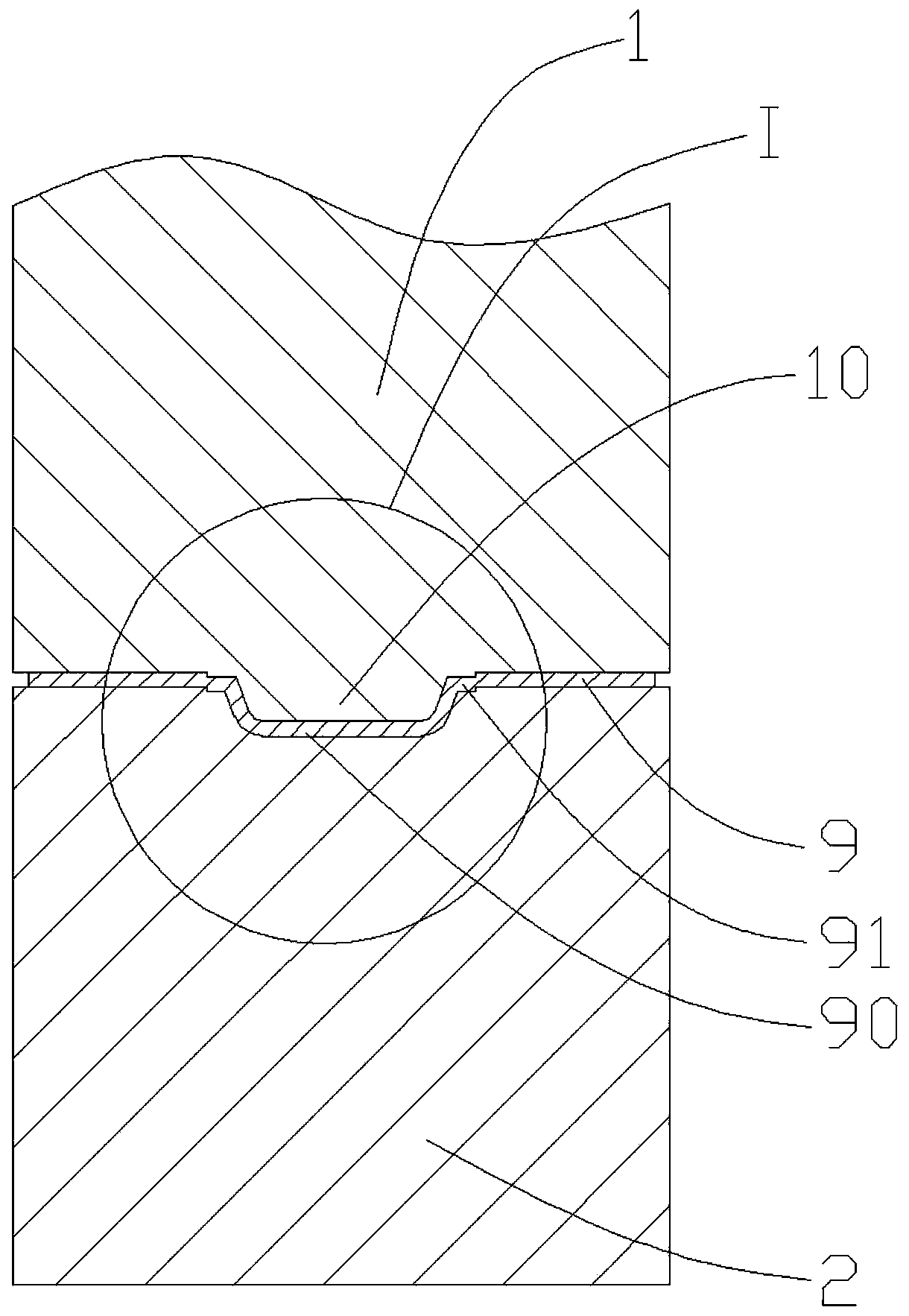

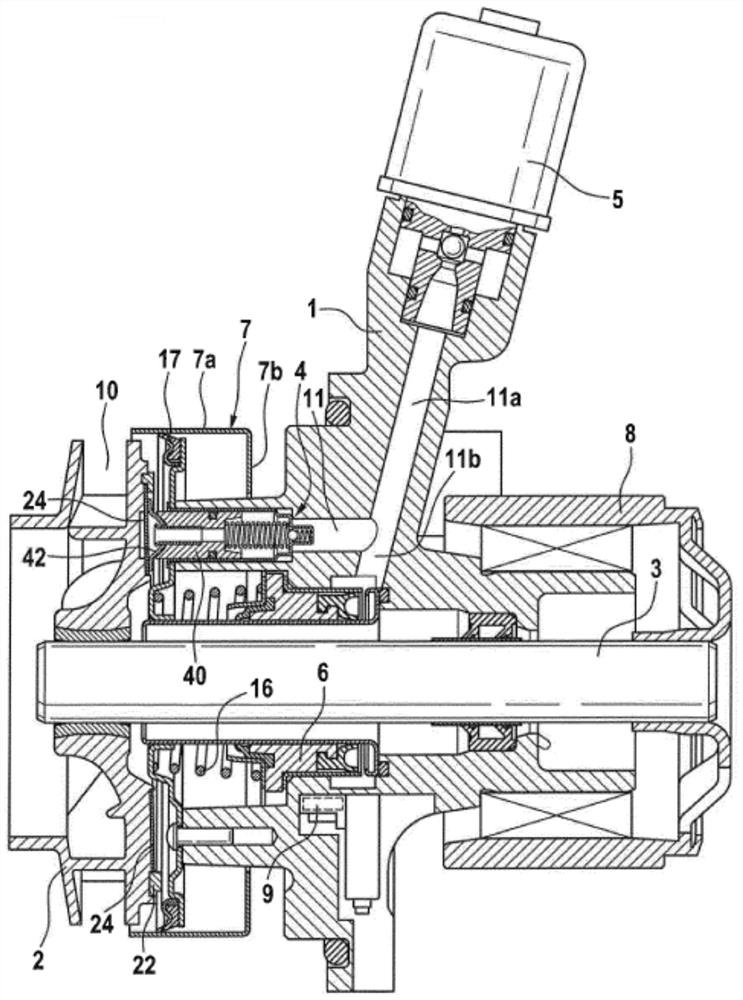

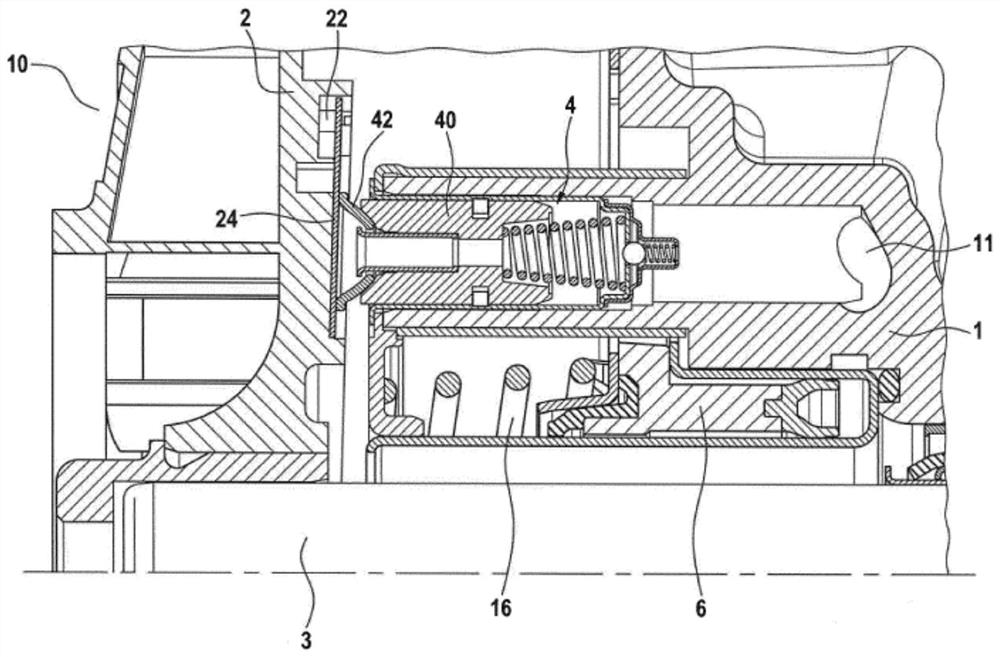

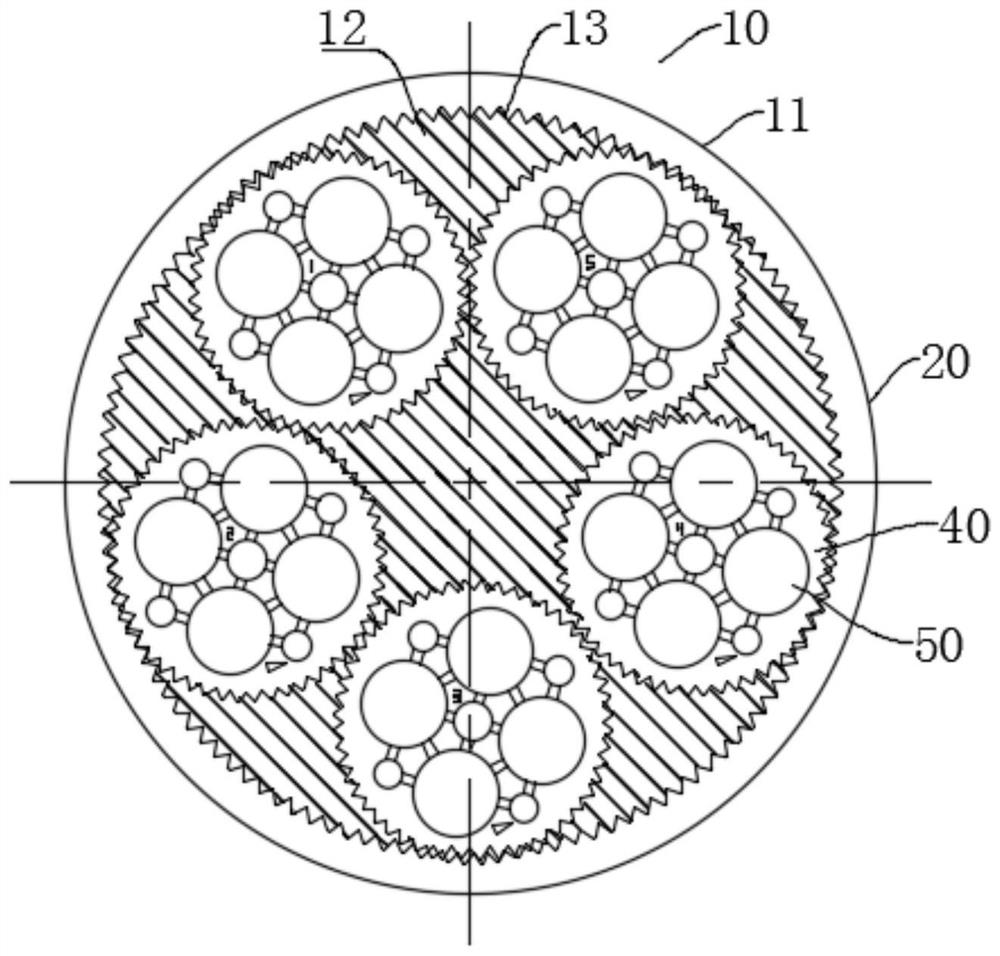

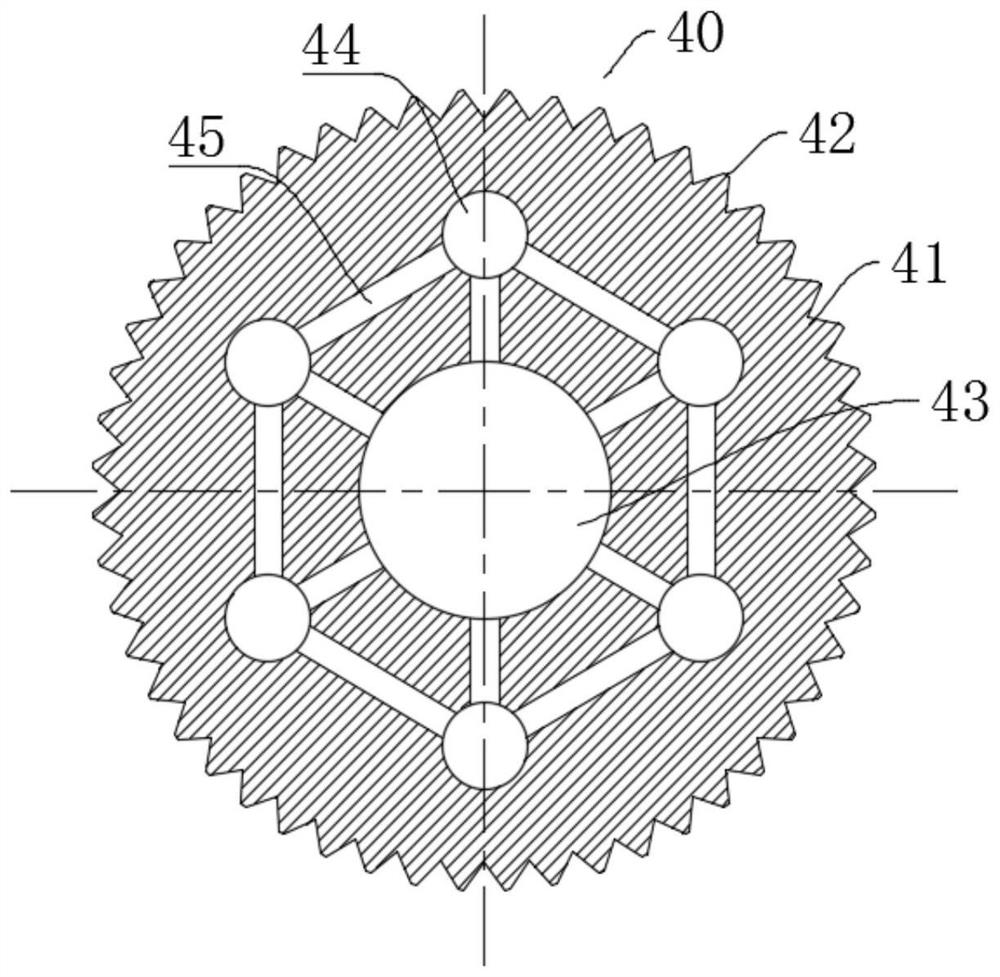

Controllable coolant pump with a filter disc, filter disc, and the production thereof

InactiveCN112119223AIncrease stiffnessAvoid local deformationPump componentsEngine controlPump chamberInternal combustion engine

The present invention provides a controllable coolant pump with a filter disc, a filter disc, and the production thereof. In a controllable coolant pump for conveying a coolant for an internal combustion engine, a conveying stream of the coolant can be limited by way of a control slide (7) which is actuated by way of a hydraulic actuator (6) in a hydraulic control circuit (11), wherein the hydraulic control circuit (11) is fed with the coolant from the conveying stream, and comprises an axial piston pump (4) and a proportional valve (5) for generating and controlling a pressure to the hydraulic actuator (6). A sliding pad (42) which is arranged towards a suction side of the axial piston pump (4) surrounds an inlet of the axial piston pump (4), and a filter disc (24) for filtering the coolant before an inlet into the hydraulic control circuit (11) is in sliding contact with the sliding pad (42), with the result that coolant is sucked from the pump chamber (10) through the filter disc (24) and the sliding pad (42) into the axial piston pump (4) while a rotational movement of the filter disc (24) is transferred into a lifting movement of the axial piston pump (4). The filter disc (24)consists of a ceramic material.

Owner:尼得科GPM有限公司

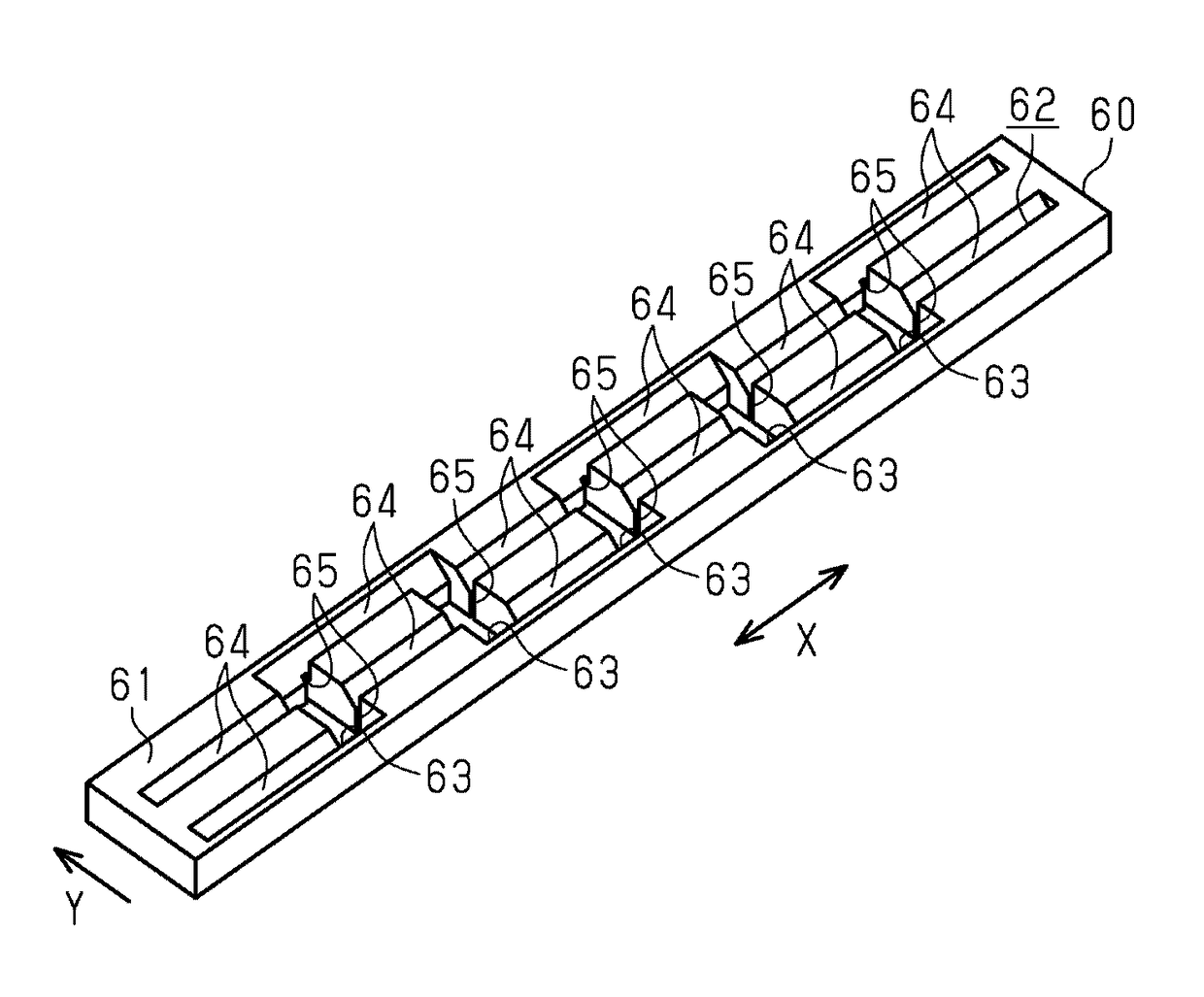

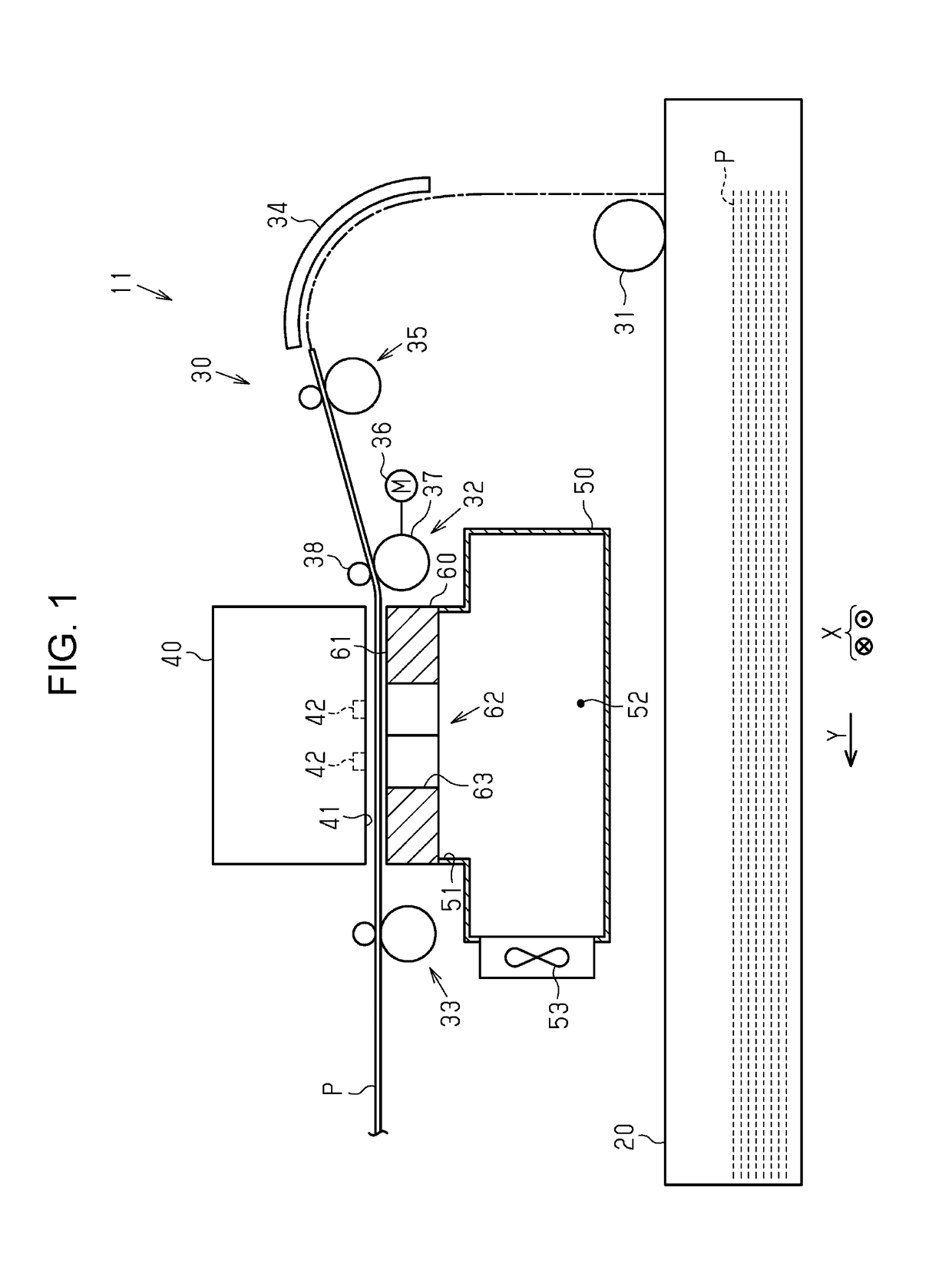

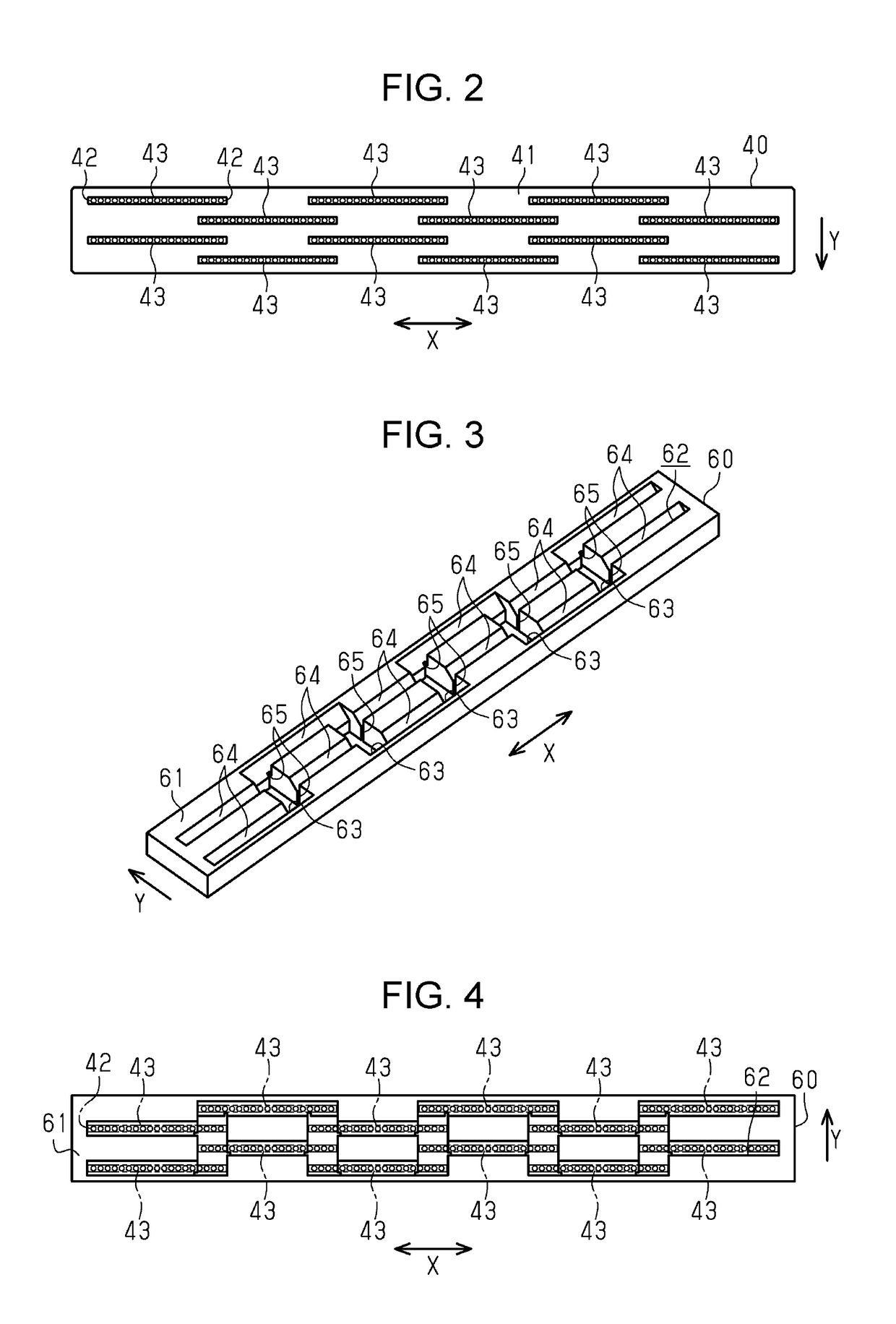

Recording apparatus with an enhanced medium support structure

ActiveUS10029469B2Stable flatnessReduce the possibilityOther printing apparatusEngineeringBoundary region

A recording apparatus includes a supporting portion that supports a sheet of paper transported and a recording head fixedly disposed at a position opposing the supporting portion, for recording. The recording head has nozzle rows for ejecting ink, and the nozzle rows are arranged side by side in the recording head in a direction intersecting a transport direction of the sheet. The supporting portion has a dumping portion including a position opposite the nozzle rows of the recording head, and the dumping portion is capable of receiving the ink ejected from the nozzle rows when the recording head performs flushing. The supporting portion has a supporting surface capable of supporting the sheet at a position not opposite the nozzle rows of the recording head. A slope inclining relative to the supporting surface is disposed in at least part of the boundary region between the dumping portion and the supporting surface.

Owner:SEIKO EPSON CORP

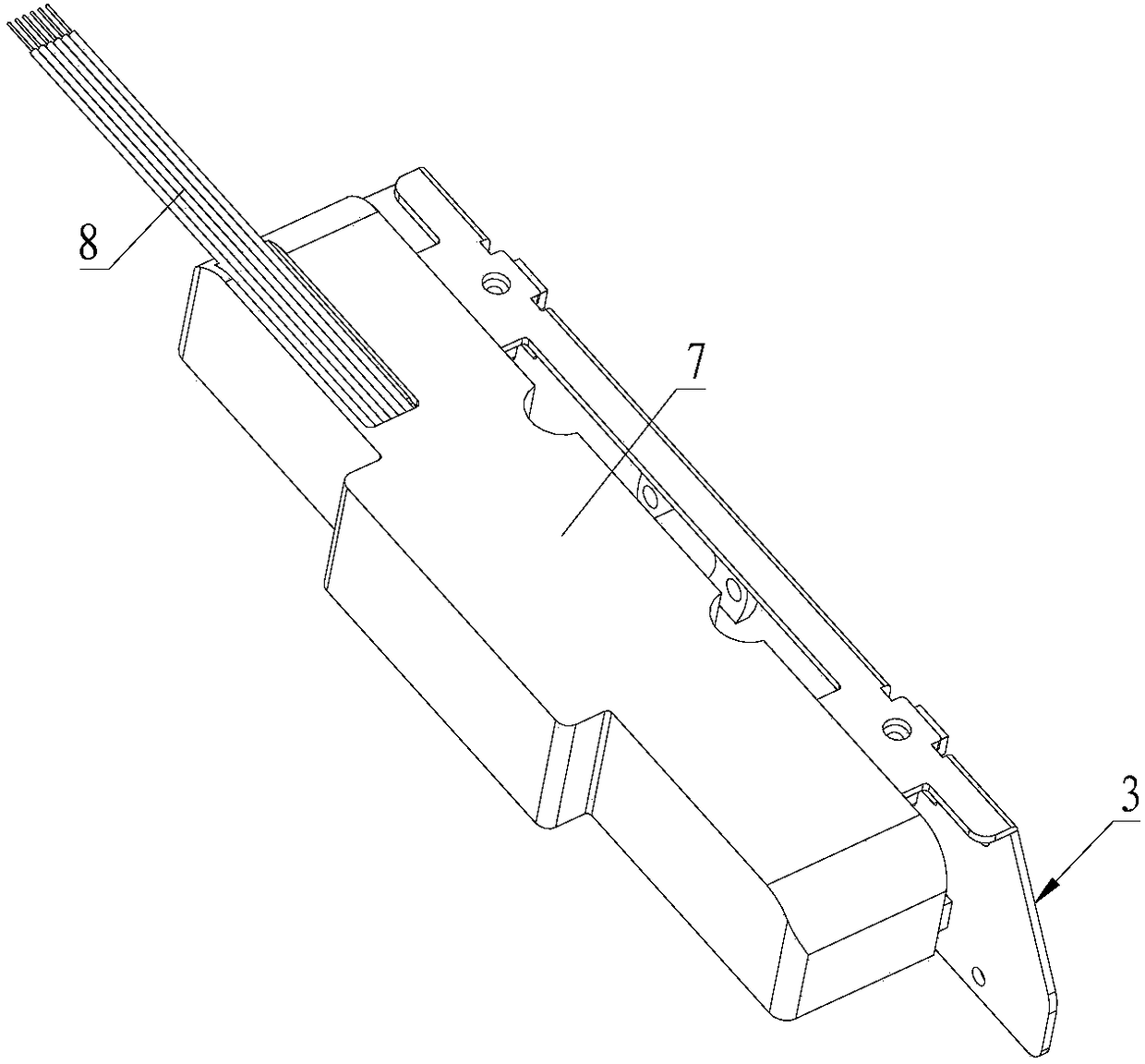

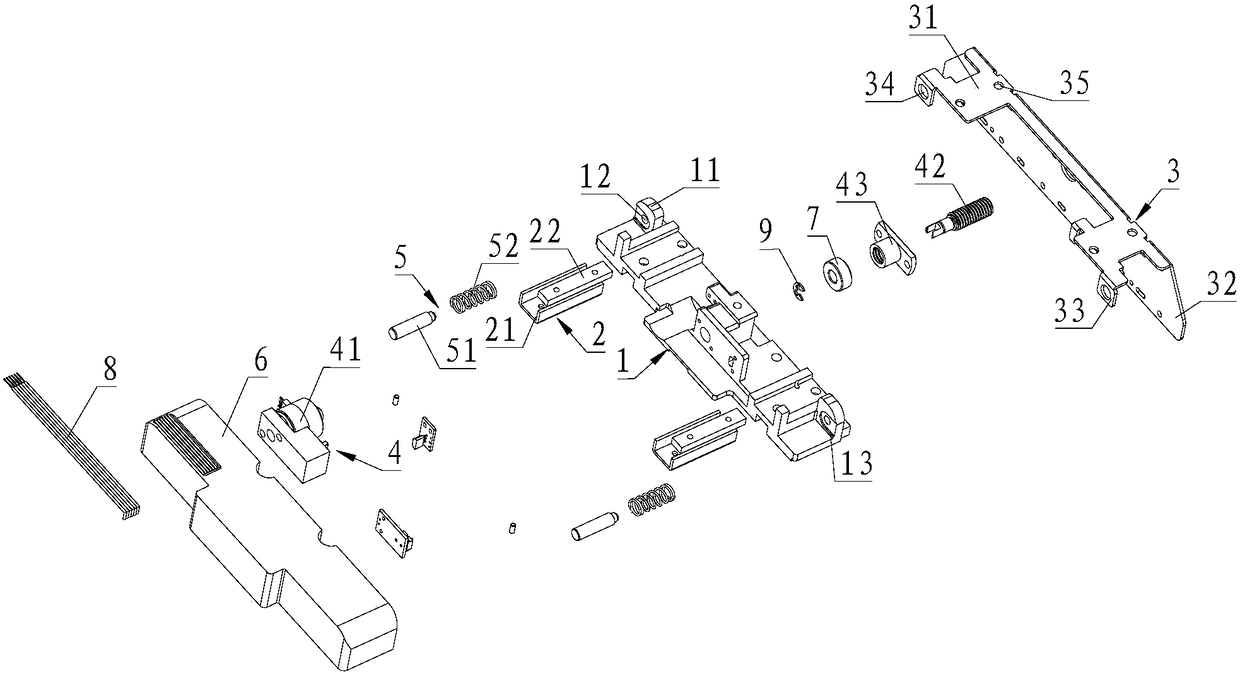

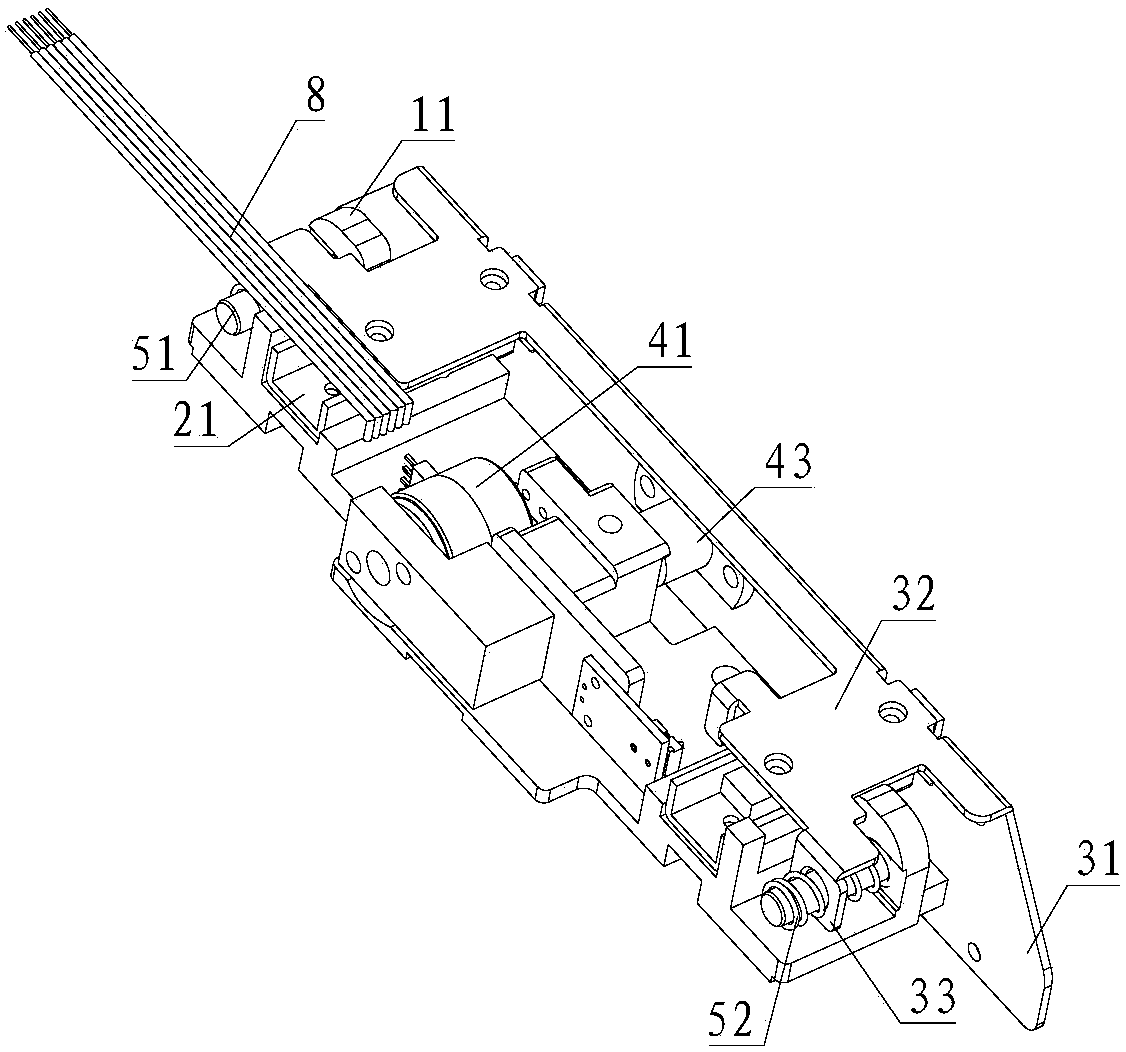

Electric Actuator

The invention discloses an electric actuator, which comprises a fixed base, a sliding mechanism arranged on the fixed base, a displacement plate arranged on the sliding mechanism, an electric drive mechanism and a spring assembly, wherein the electric drive mechanism is connected with the displacement plate and drives the displacement plate; the spring assembly comprises a guide post and a spring sleeving the guide post; one end of the guide post is connected with a fixed base and the direction of the guide post is the same as the displacement direction of the displacement plate; the displacement plate comprises a top plate and a side plate; the side plate is provided with a bending part opposite to the top plate; the bending part is provided with a through hole; the diameter of the through hole is greater than that of the guide post; the bending part sleeves the guide post through the through hole; and one end of the spring extends outside along the through hole and the other end abuts on the fixed base. By the electric actuator, automatic, accurate and fast control on the movement state of the displacement plate can be achieved; the human cost is relatively low; and the reliability is greatly improved.

Owner:SHENZHEN SMART MICROMOTOR CO LTD

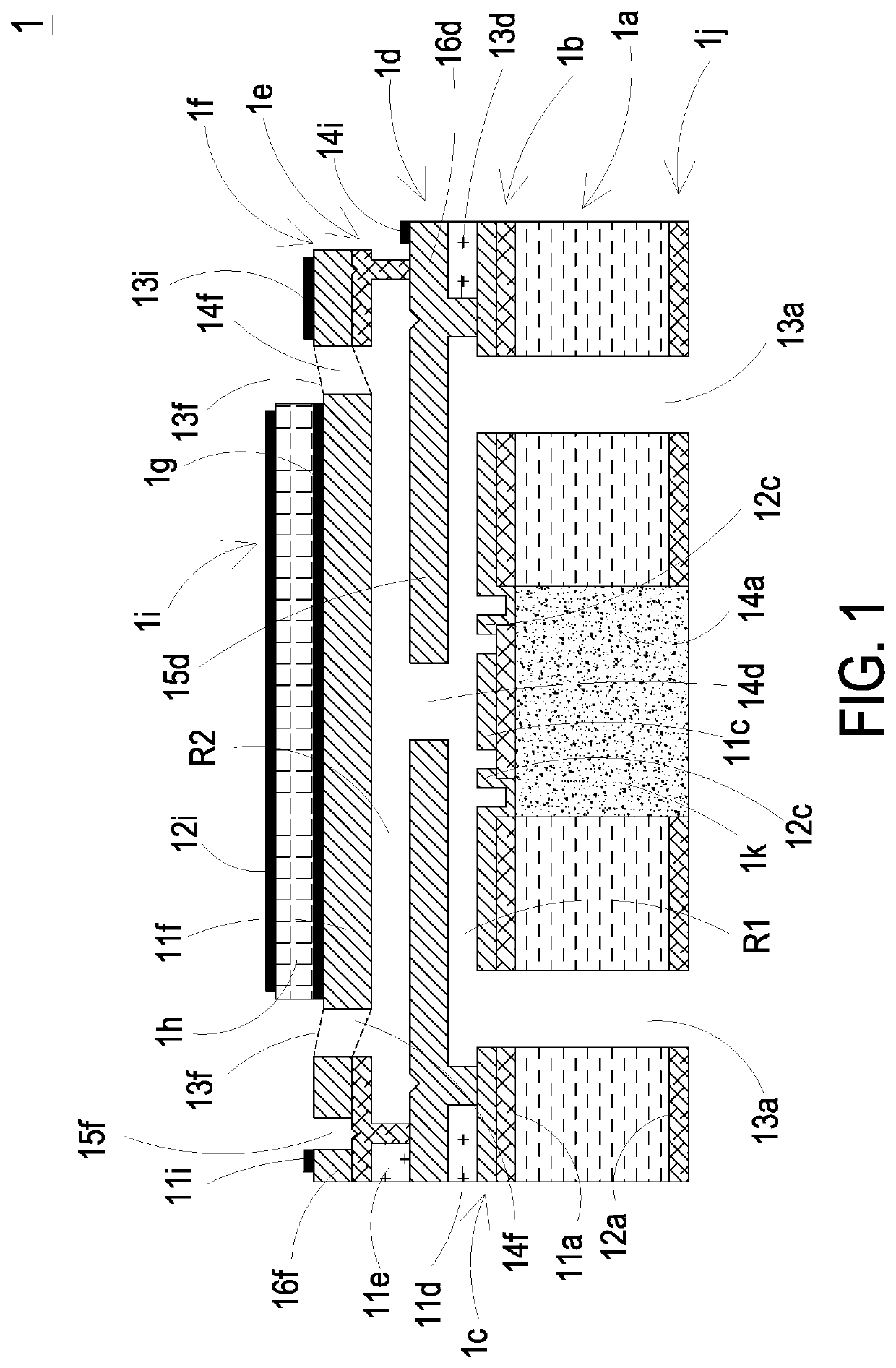

Manufacturing method of micro channel structure

ActiveUS10800653B2Low costStable flatnessValve arrangementsDecorative surface effectsInsulation layerEngineering

A manufacturing method of micro channel structure is disclosed and includes steps of: providing a substrate; depositing and etching to form a first insulation layer; depositing and etching to form a supporting layer; depositing and etching to form a valve layer; depositing and etching to form a second insulation layer; depositing and etching to form a vibration layer, a lower electrode layer and a piezoelectric actuating layer; providing a photoresist layer and depositing and etching to form a plurality of bonding pads; depositing and etching to from a mask layer; etching to form a first chamber; and etching to form a second chamber.

Owner:MICROJET TECH

A gcs low-voltage withdrawable switchgear with moisture-proof performance

ActiveCN113315020BImprove installation efficiencyImprove installation qualitySwitchgear detailsSubstation/switching arrangement casingsStructural engineeringMoisture resistance

The invention relates to the technical field of switch cabinets, in particular to a GCS low-voltage withdrawable switch cabinet with moisture-proof performance, including a support structure, a sealing structure, a storage structure, a storage structure, a protection structure and a transmission structure; the setting of the sealing structure is convenient for The support structure is sealed, and the setting of the support structure is convenient to adjust the flatness of the storage structure in the same direction, thereby greatly improving the efficiency and quality of the installation of the storage structure; the protection structure can conflict with the storage structure, and the setting of the protection structure is convenient. The storage structure is protected, thereby effectively preventing misoperation of the internal knobs of the storage structure, and at the same time, it is convenient to limit the storage structure and improve the stability of the storage structure; it is convenient to drive the transmission structure through the protection structure, so that the transmission structure drives the storage structure and the storage structure conflicts between them, thereby making the sealing performance between the storage structure and the storage structure better, thereby greatly improving the moisture-proof performance.

Owner:南通苏泰电气有限公司

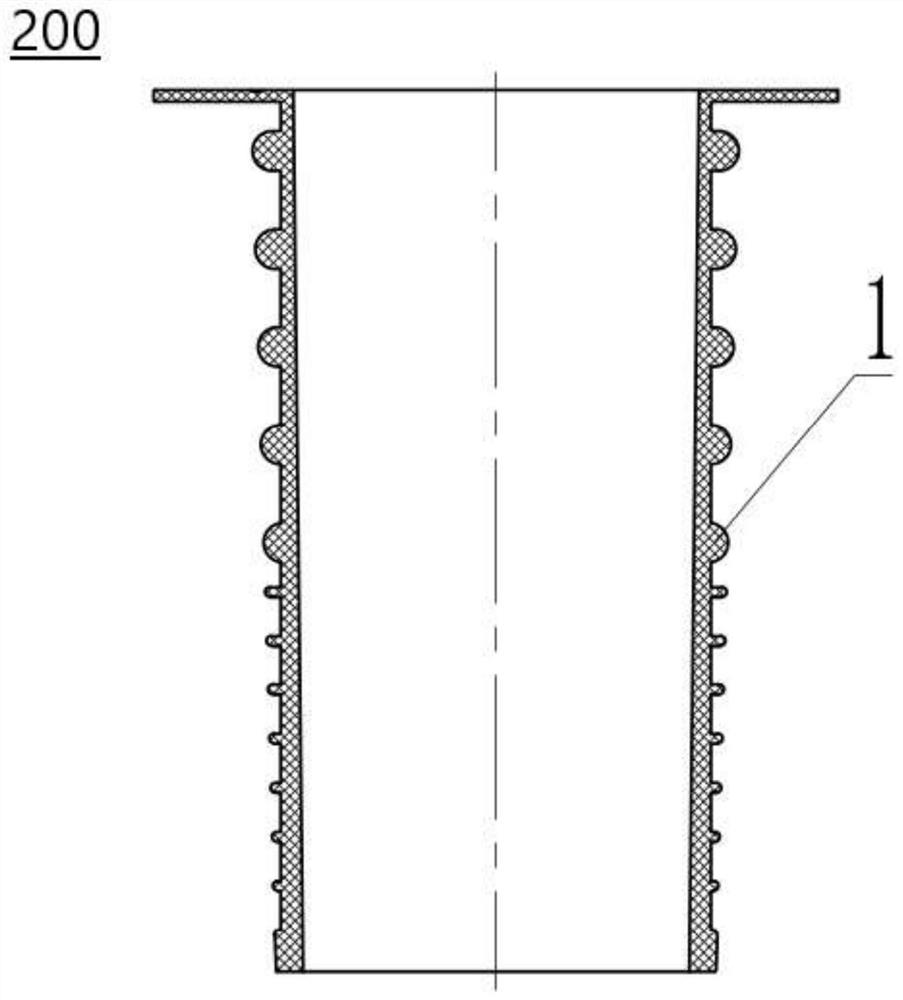

Forming mold, vulcanizing machine and rubber part forming method

The invention relates to a forming mold, a vulcanizing machine and a rubber part forming method. The forming mold is used for forming a rubber part with a framework and comprises a first mold plate, a second mold plate and a forming body; the second mold plate is arranged below the first mold plate; the forming body is provided with a through hole which is communicated up and down, and the inner wall of the through hole is provided with a plurality of grooves; in the mold closing state of the forming mold, the forming body integrated, and the through hole, the grooves, the first mold plate and the second mold plate form a cavity which is used for containing injection raw materials; and in the demolding state of the forming mold, the forming body is split so as to be separated from a finished product. The rubber part with convex ribs can be formed, the structure is simple, the forming cost is reduced, operation is convenient, and the production efficiency is improved.

Owner:ZHEJIANG TIANTIE IND

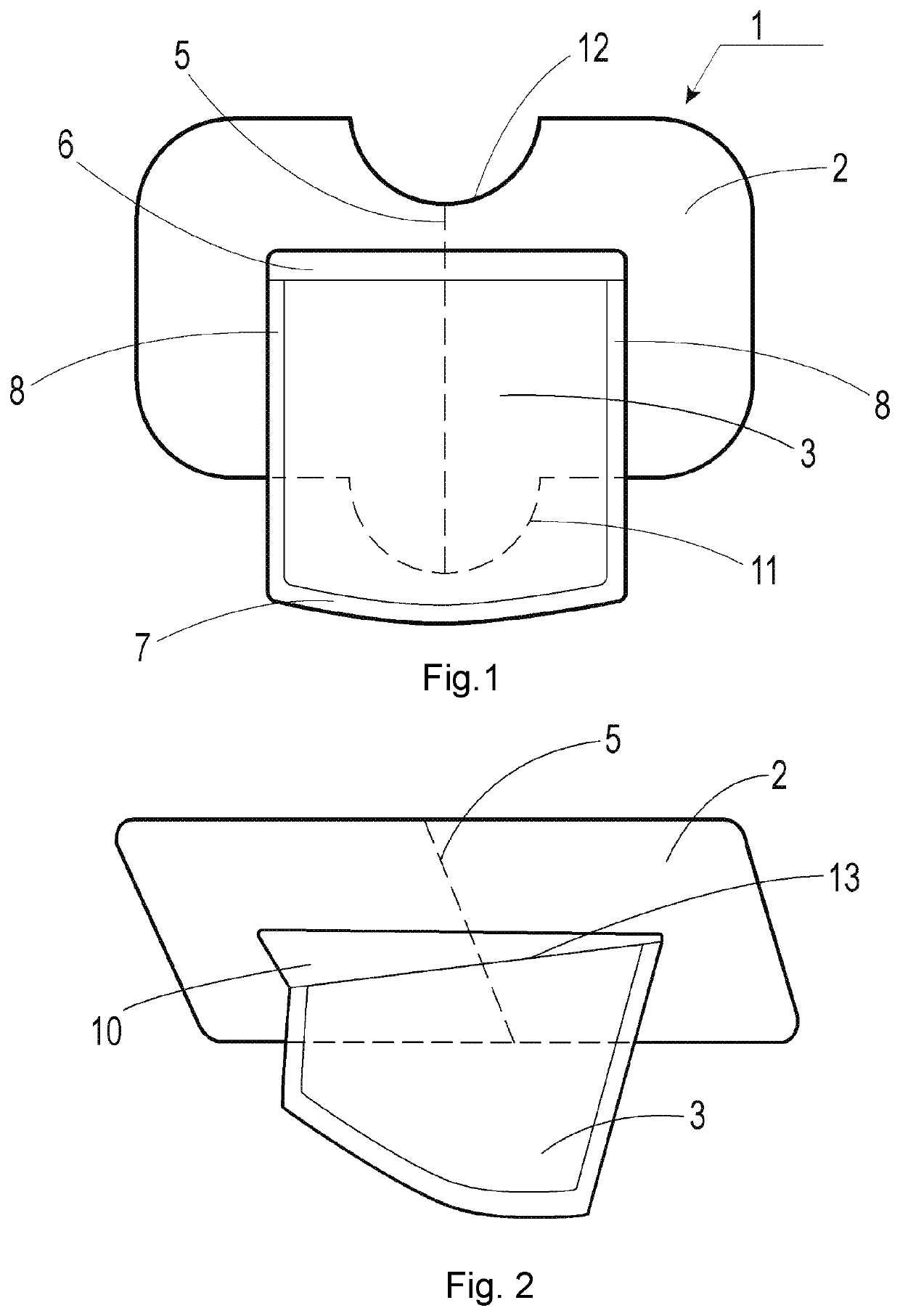

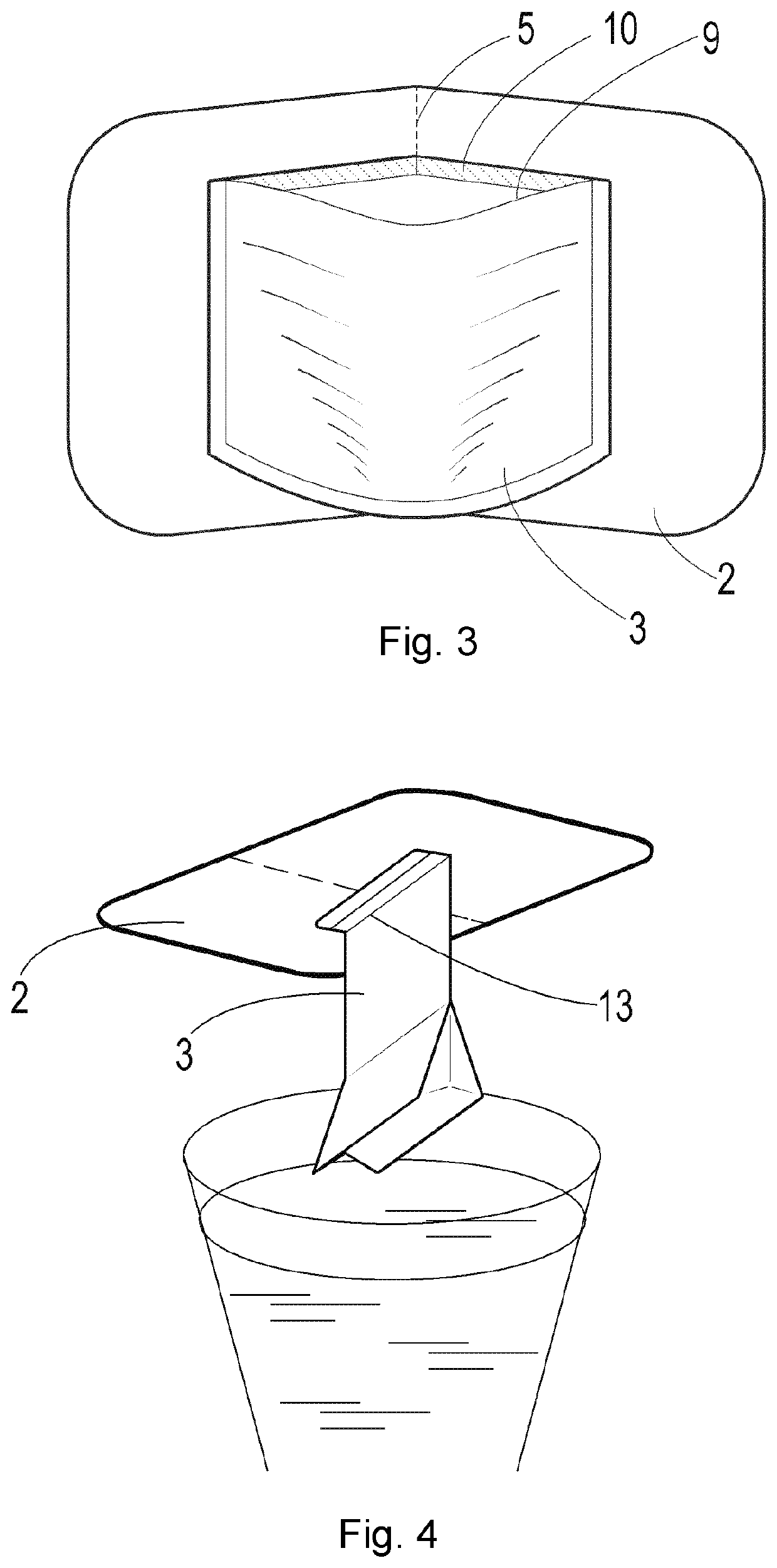

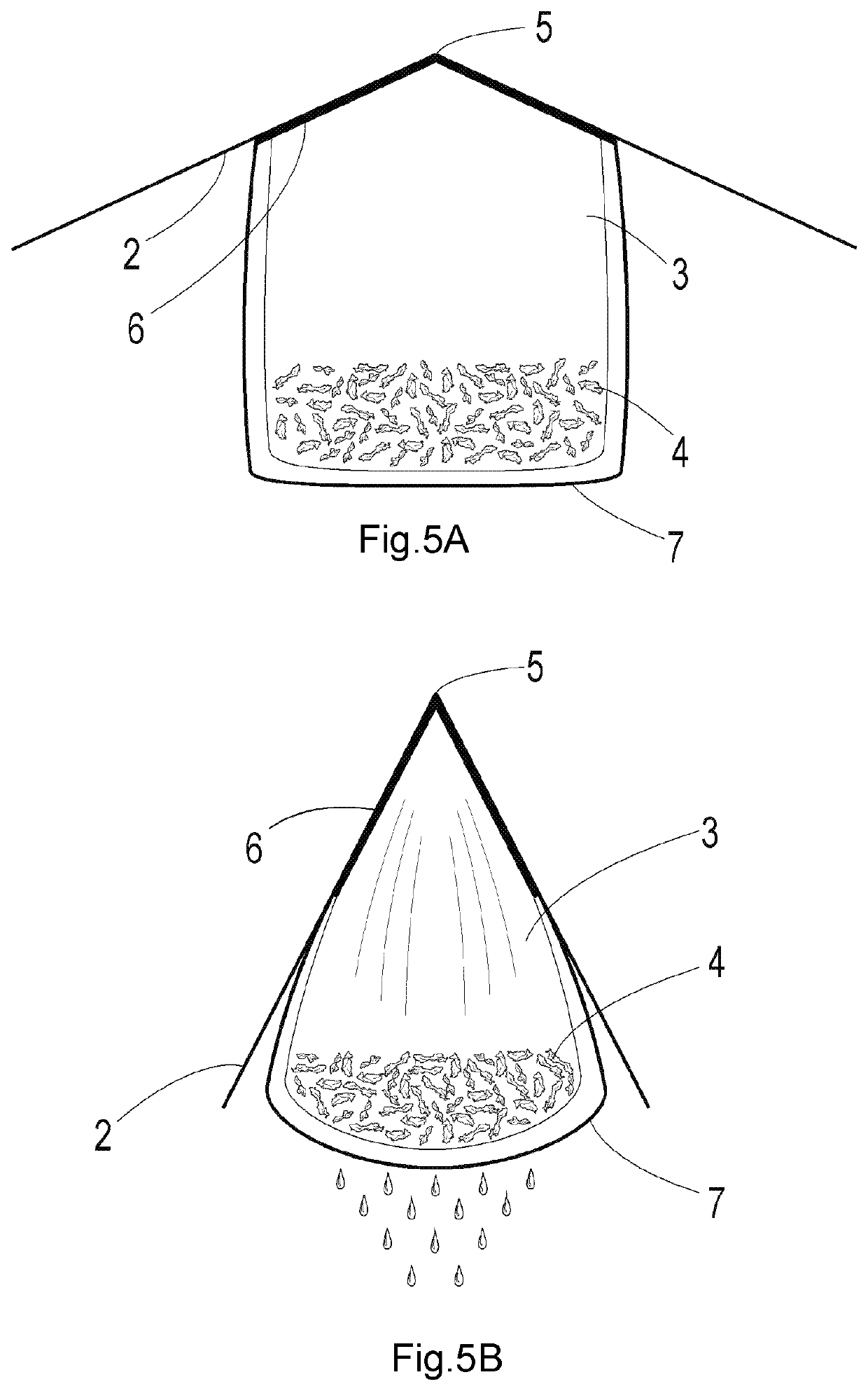

Single-use means for preparing a beverage

ActiveUS20190367262A1Stable flatnessImprove flatnessTransportation and packagingBeverage vesselsEngineeringMoisture

A single-use means for preparing a beverage from an infusible product, containing a bendable sheet-like base with a designated bend line, and a moisture-permeable bag for brewing a product, wherein the bag has an upper portion attached by one side to the sheet-like base, and an unattached lower portion, wherein the sheet-like base and the bag are designed and mutually arranged such that the sheet-like base can cover a vessel containing a liquid, in which the bag is immersed during the brewing of a product, and such that the product can be squeezed after brewing by bending the sheet-like base and pressing the bag from two opposing sides using the bent sheet-like base, wherein to allow more careful squeezing of an infusion from the product in the bag after brewing, the region in which the attached side of the upper portion of the bag is attached to the sheet-like base is situated along a line that intersects the bend line of the sheet-like base, wherein the line along which the attachment region of the bag is situated substantially coincides with the bend of the bag in its suspended state on the base during use.

Owner:NONIASHVILI ALEKSEY ILJICH

Large-size silicon wafer double-sided polishing method

InactiveCN113001379AImprove polishing effectEasy to cleanPolishing machinesGrinding drivesPolyolAdhesive

The invention provides a large-size silicon wafer double-sided polishing method. The method comprises the following steps of: controlling the pressure of a pressure plate arranged above a silicon wafer, and selecting a rough polishing solution with a corresponding particle size to roughly polish the double sides of the silicon wafer; and adjusting the pressure of the pressure plate, and selecting a fine polishing solution with a corresponding particle size to carry out fine polishing on the double sides of the silicon wafer, wherein the rough polishing solution or the fine polishing solution flows to an upper polishing pad and a lower polishing pad which are arranged on the two sides of the silicon wafer through the same main pipeline and the pressure plate; the fine polishing solution at least comprises a polyhydric alcohol compound; and the rough polishing solution and the fine polishing solution both comprise a mixed solution of SiO2 and NH4OH. After rough polishing and fine polishing are sequentially conducted on the silicon wafer, water film treatment is conducted on the double sides of the silicon wafer, an adhesive on the surface of the silicon wafer can be completely removed, and the cleaning effect is good; and the flatness within 0.5 [mu]m can also be obtained.

Owner:TIANJIN ZHONGHUAN ADVANCED MATERIAL TECH +1

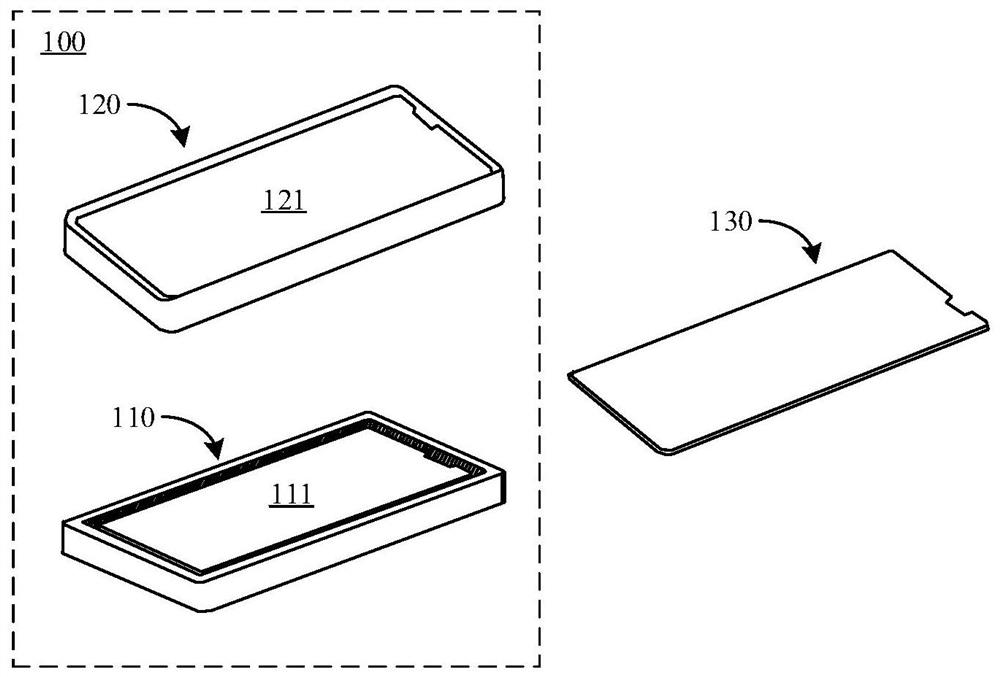

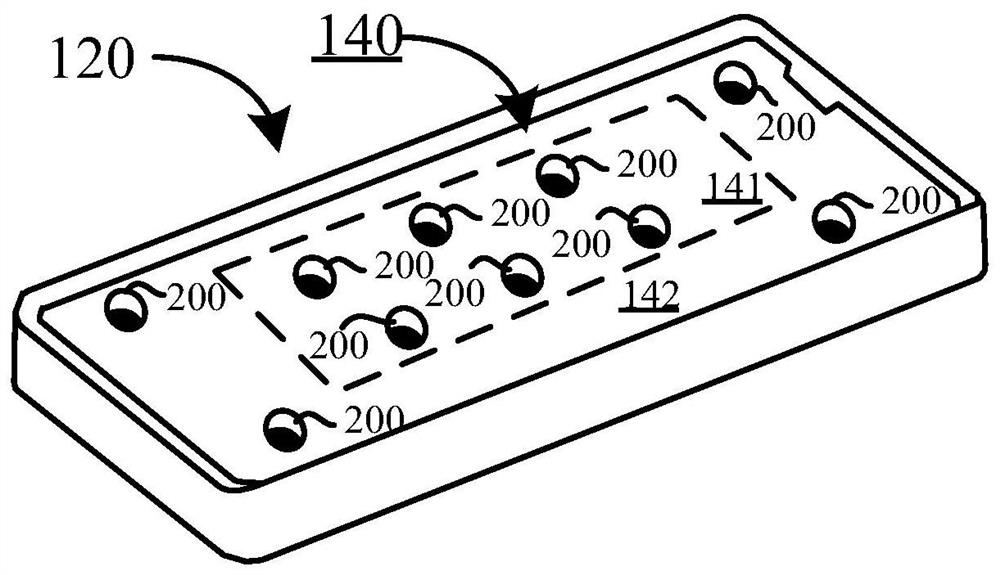

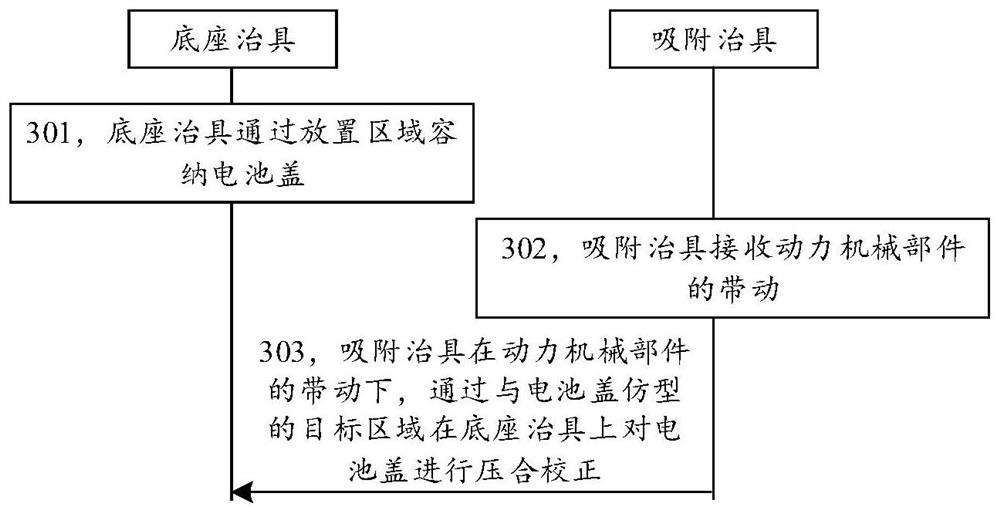

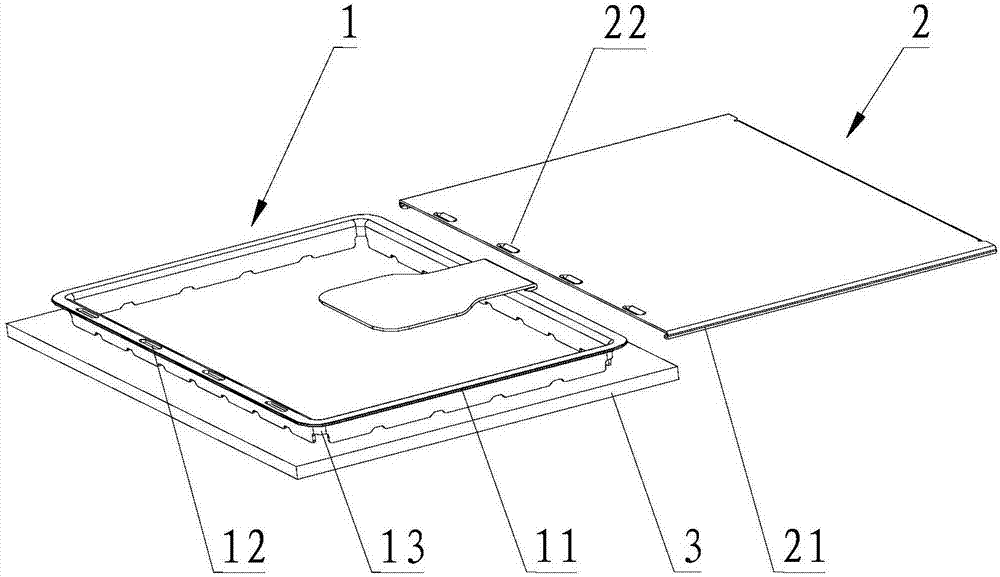

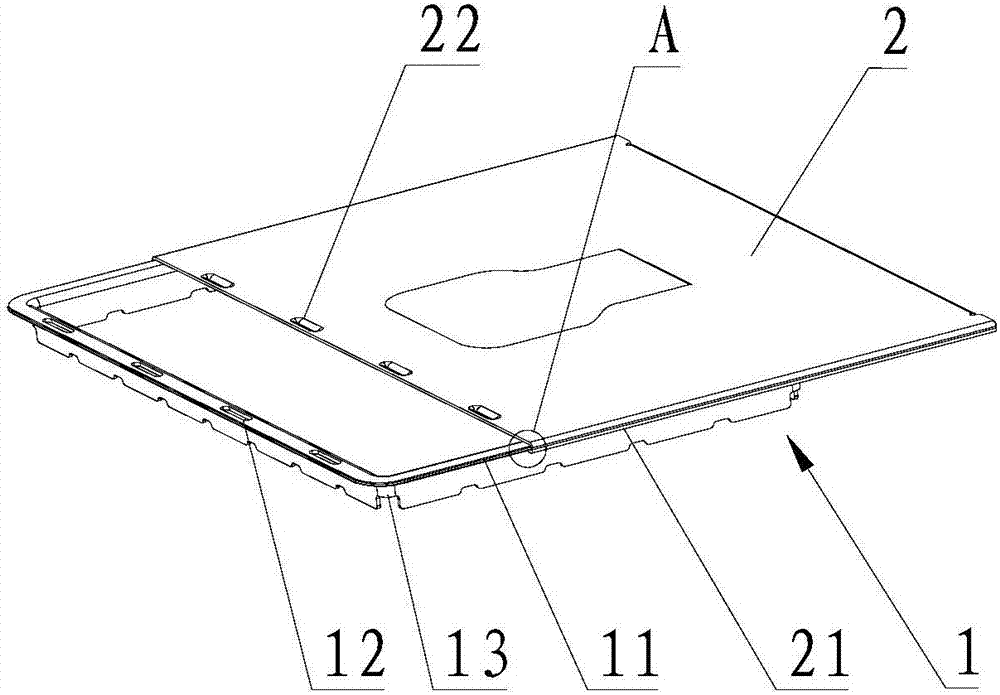

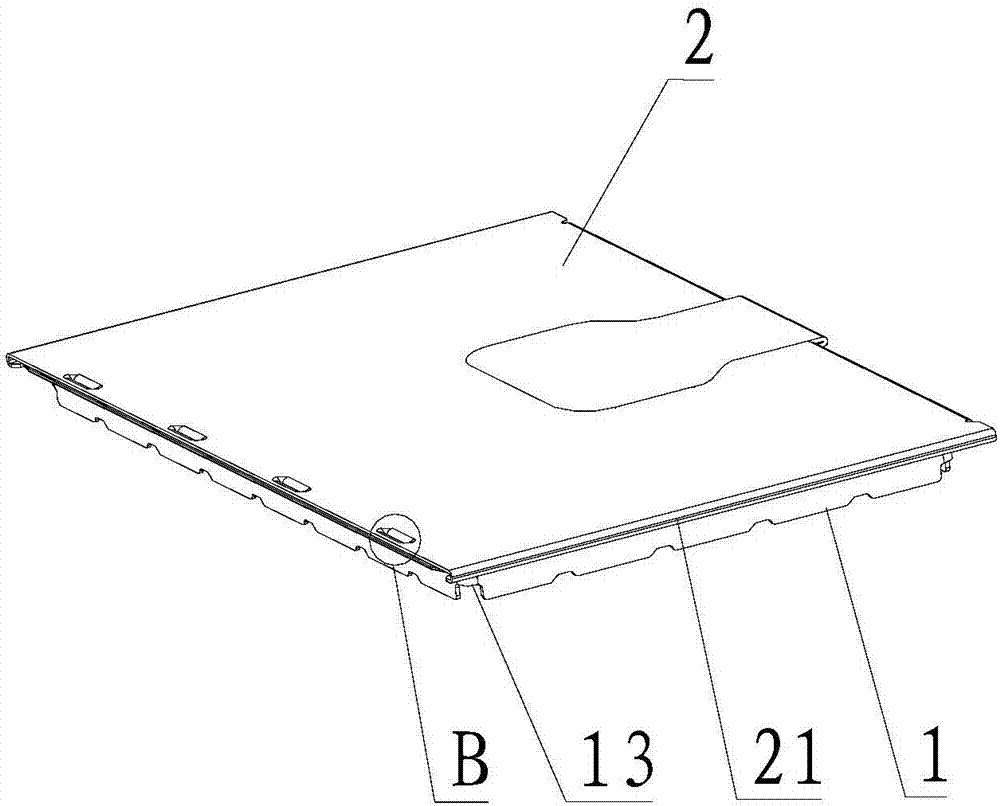

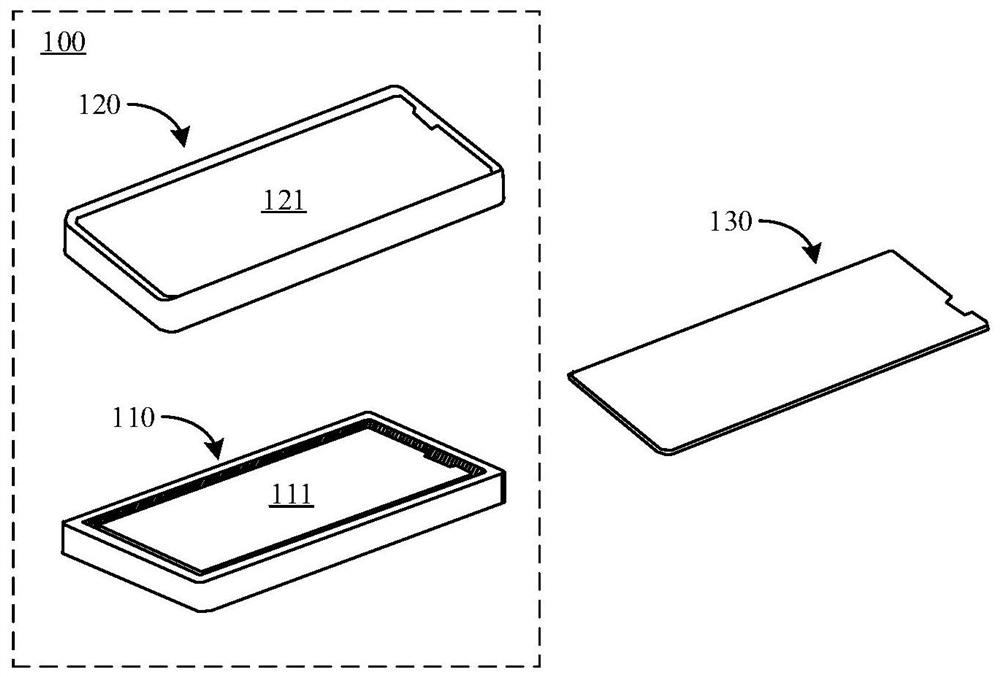

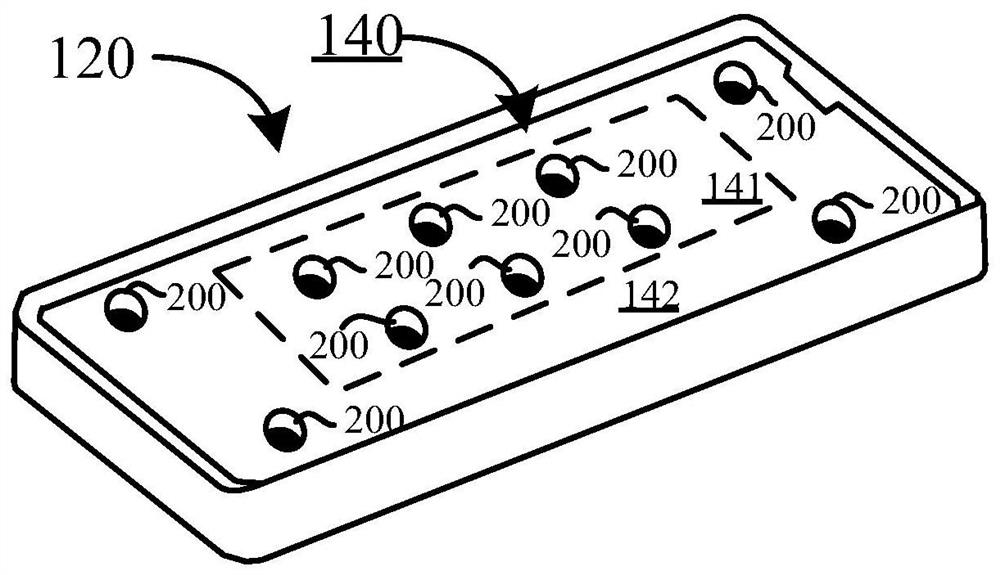

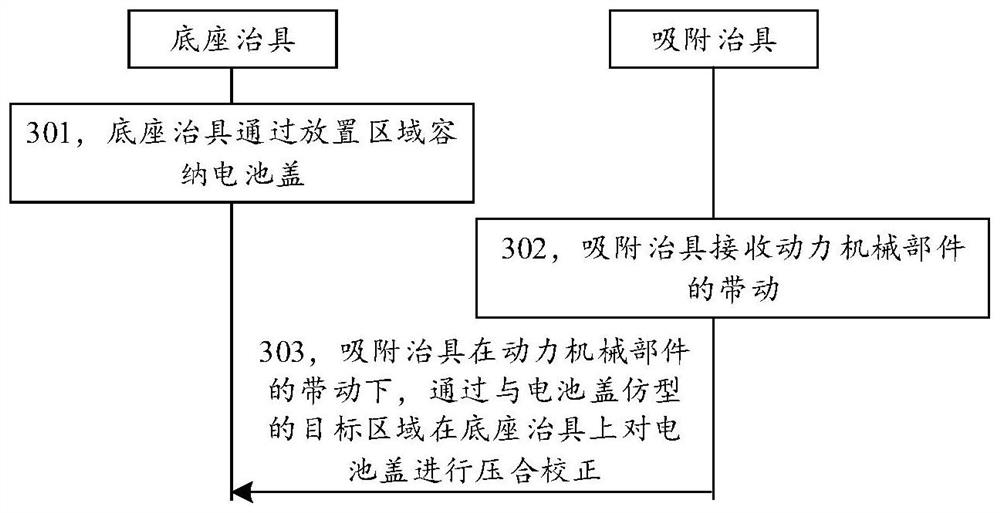

Assembling system, adsorption jig and assembling method for battery cover

ActiveCN112140034AStable flatnessAvoid Kickback SituationsFinal product manufactureMaterial gluingElectrical batteryMechanical engineering

The embodiment of the invention provides an assembly system, an adsorption jig and an assembly method for a battery cover, and relates to the field of part assemblies. The assembly system comprises the structure that a base jig comprises a placing area used for placing the battery cover; the adsorption jig comprises a target area and a power mechanical part, wherein the target area imitates the battery cover; and the adsorption jig is driven by the power mechanical part to press and correct the battery cover on the base jig. The battery cover is pressed and corrected in the base jig through the adsorption jig, the condition that the flatness of the battery cover can be kept stable after hot press molding is ensured, the problem that the flatness of the battery cover rebounds and deviates from edge finding positioning of a middle frame, so that a gap exists in the whole machine is solved, and the edge finding positioning accuracy of the battery cover is improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

A special fixture and clamping method for cnc machining grooves

ActiveCN103949910BStable flatnessControl flatnessWork clamping meansPositioning apparatusEngineeringMachining

The invention discloses a special clamp for CNC machined groove. The clamp comprises a bottom frame and a clamp main board, wherein the bottom frame is delta-shaped; one side of the raised part in the middle of the bottom frame extends outward to form a supporting plate; the clamp main board is arranged on the side surface of the other side of the raised part; the clamp main board is T-shaped; the clamp also comprises three fixing units and three positioning units; the fixing units specifically comprise press blocks and M10 fixing screws; the press blocks are fixed on the bottom frame through the M10 fixing screws; each positioning unit specifically comprises two positioning pins. The clamp has the advantages that the integrated design and the positioning mode of the clamp are adjusted, positioning of holes and shapes are integrated in the clamp, three machining processes are accomplished on one clamp, the positioning mode of the holes is accomplished through the two positioning pins at opposite angles, the planeness stability of workpieces is properly controlled, the difficulty in machining of the groove is solved, and the machining precision and the production efficiency are improved.

Owner:强龙科技(苏州)有限公司

Shielding cover

PendingCN107249293AReduce molding processEasy to adjustScreening casingsConvex structureStructural engineering

The invention relates to a shielding cover. The shielding cover comprises a shielding rack and a shielding cover, wherein an edge part is arranged at an edge position of the shielding rack and outwards extends along a length direction, an edge position of the shielding cover is inwards bent along a length direction to form a bending groove, at least one concave structure is arranged on an upper surface of the shielding rack, at least one convex structure is arranged on a lower surface of the shielding cover and is adaptive to the concave structure, and the edge part is inserted into the bending groove from a groove opening of the bending groove until the convex structure is clamped into the concave structure. The shielding cover has the advantages that the die development cost and the die repair cost are reduced, the production efficiency is improved, and the production cost is reduced.

Owner:SHENZHEN SUNWAY COMM

Battery cover assembly system, adsorption jig and assembly method

ActiveCN112140034BStable flatnessAvoid Kickback SituationsFinal product manufactureMaterial gluingElectrical batteryEngineering

Embodiments of the present disclosure provide a battery cover assembly system, an adsorption jig, and an assembly method, which relate to the field of component assembly. The assembly system includes: the base jig includes a placement area for placing the battery cover; the adsorption jig includes a target area and power mechanical parts that are modeled with the battery cover; the adsorption jig is driven by the power mechanical parts on the base Press and correct the battery cover on the jig. The battery cover is pressed and corrected in the base jig by the adsorption jig to ensure that the flatness of the battery cover can be kept stable after hot pressing, so as to avoid the rebound of the flatness of the battery cover and the edge-finding positioning of the middle frame. Offset, resulting in a gap problem in the whole machine, improving the accuracy of the edge-finding positioning of the battery cover.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com