Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Solve the problem of slippage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Winding forming method for double-layer composite material of rotator

InactiveCN102941676ASolve the problem of slippageImprove winding qualityConductor CoilMaterials science

The invention relates to a winding forming method for a double-layer composite material of a rotator, belongs to the forming field of composite materials, solves the problems that an inner layer material is easy to shift in a conventional winding method of the double-layer composite material, aims to increase winding quality, and is suitable for the formation of rotators with the inner molded surface in a truncated cone shape or a revolution surface. The method comprises a preparation step, a winding forming step, a curing step, a processing step and a product protection step. The winding forming method changes a winding forming sequence of a conventional double-layer composite material, and immediately winds a part of external layer external layer prepreg cloth after a part of internal layer prepreg cloth is winded, so that a trend of slipping outward of the internal prepreg cloth can be prevented in time, and internal and external quality of the double-layer composite material can be effectively improved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

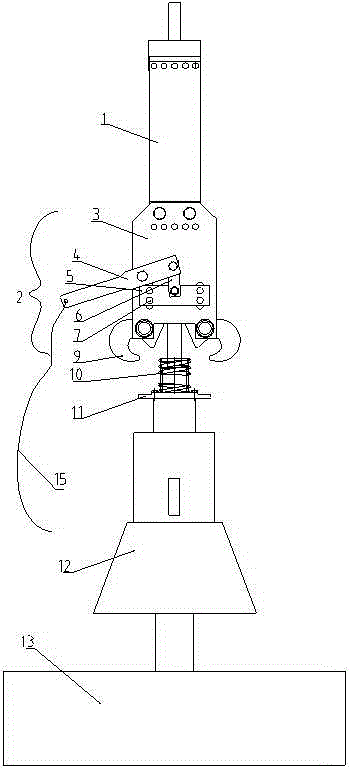

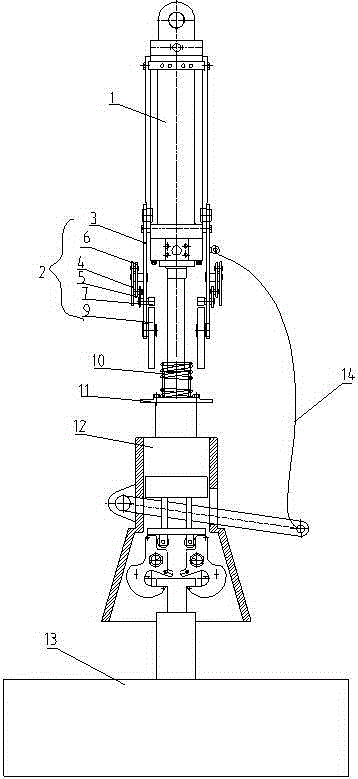

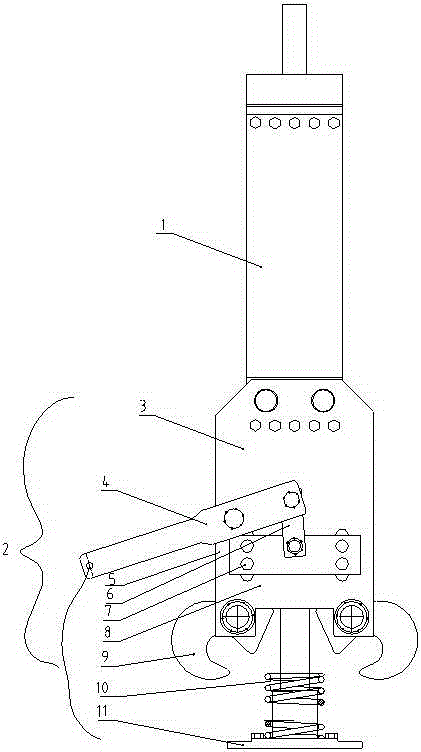

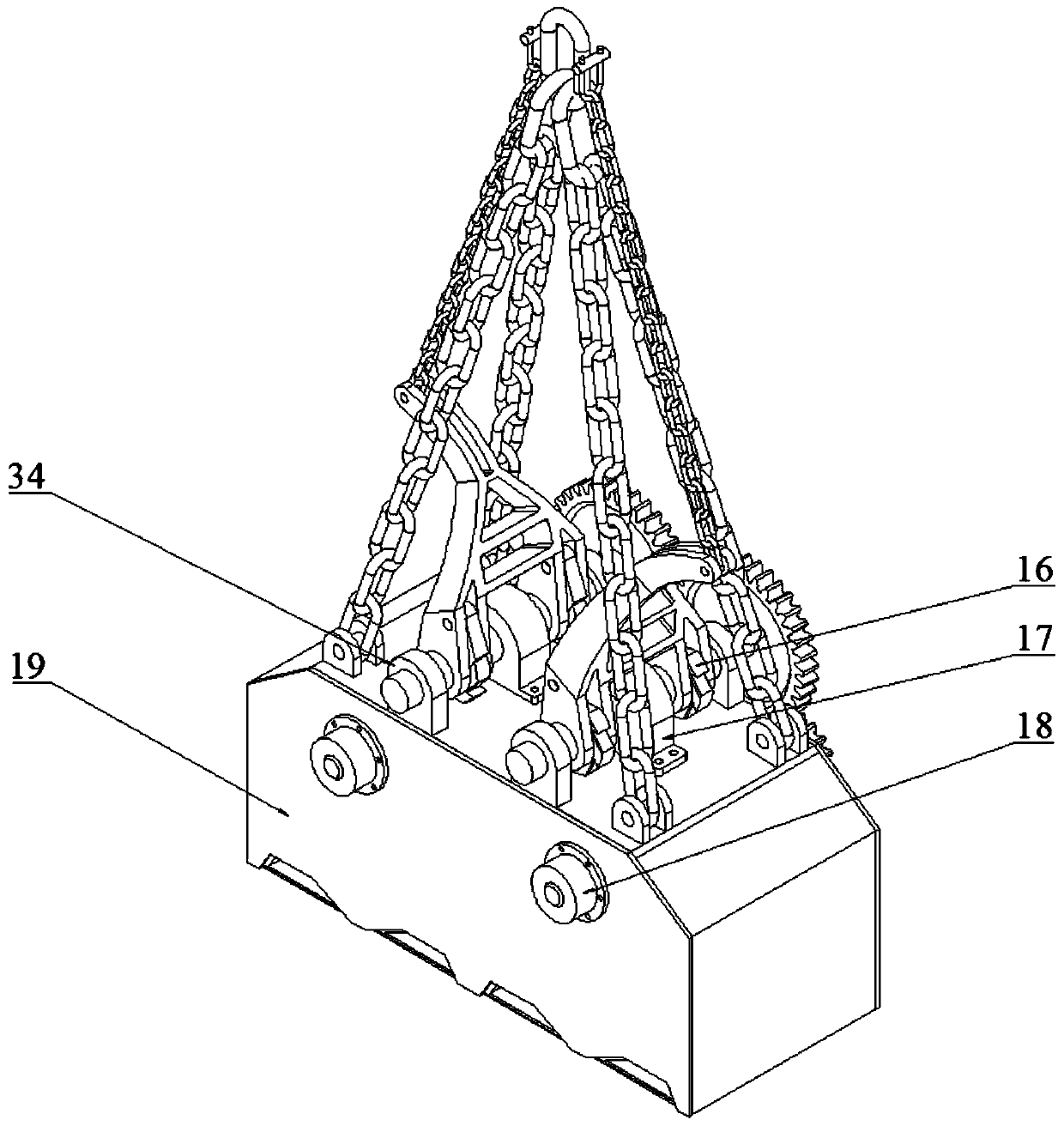

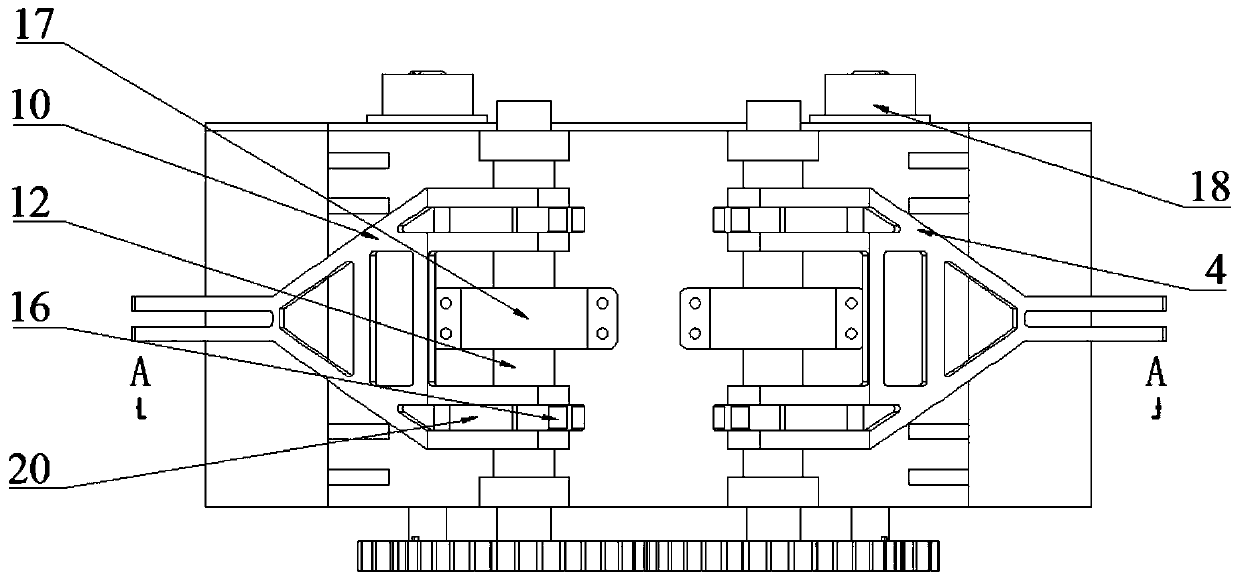

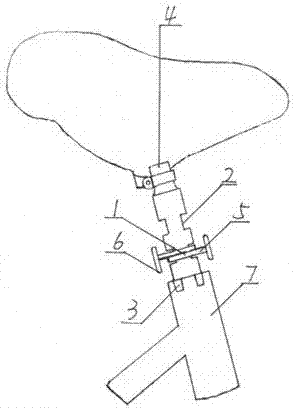

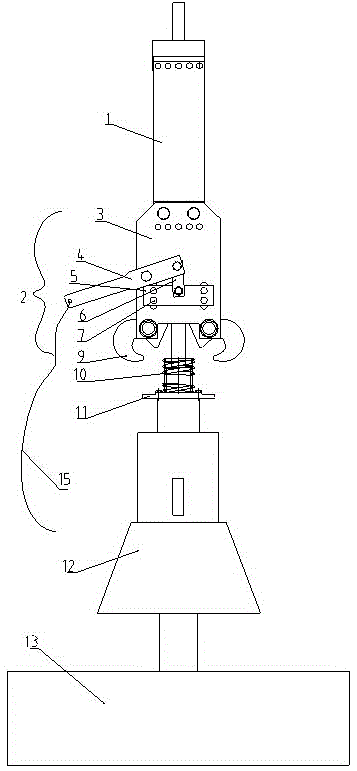

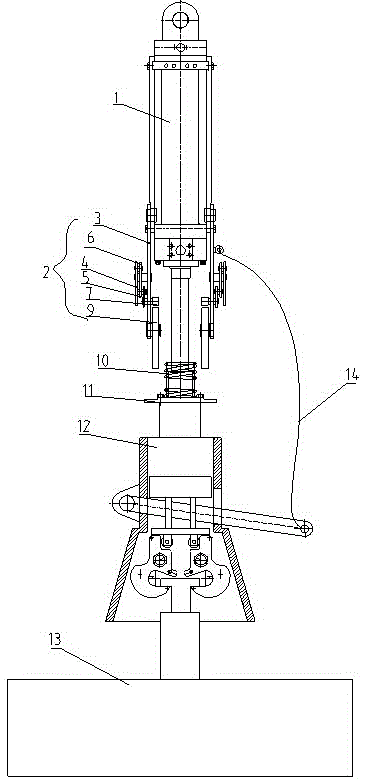

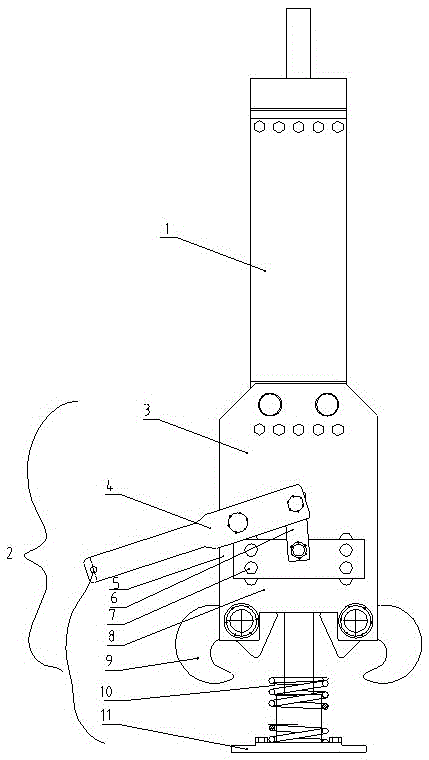

Automatic hydraulic unhooking device

InactiveCN105174022AAvoid internal leakageLow maintenanceLoad-engaging elementsSoil preservationEngineeringHeavy load

The invention discloses an automatic hydraulic unhooking device. The automatic hydraulic unhooking device comprises an oil cylinder, an automatic hooking device and a hydraulic system for controlling the pressure of a rod cavity of the oil cylinder, wherein the automatic hooking device is fixed at the end part of a piston rod of the oil cylinder; the automatic hydraulic unhooking device is also provided with mechanical locks, and the mechanical locks are mounted on an outer cylinder wall of the oil cylinder in pairs; an unlocking rope is arranged on the mechanical locks; an unhooking rope is mounted between the automatic hooking device and the mechanical locks; one end of the unhooking rope is connected with the automatic hooking device, and the other end of the unhooking rope is connected with the mechanical locks. According to the automatic hydraulic unhooking device disclosed by the invention, a hammer is lifted by the mechanical locks, and the hydraulic bearing of a high-speed oil cylinder is replaced by the rigid bearing of a mechanical-lock structure, so that the problem that when the heavy load of the high-speed oil cylinder is lifted, a piston rod slides off is solved; the working pressure in the high-speed oil cylinder is low, and the sealing, manufacturing and maintenance cost is low; the piston rod of the high-speed oil cylinder is unlocked by the mechanical locks through the traction of the unlocking rope, so that the automatic hydraulic unhooking device is simple and convenient to operate, high in reliability, and suitable for impact machinery to perform unhooking operation.

Owner:CHANGSHA JIABAI PRECISION MACHINERY CO LTD

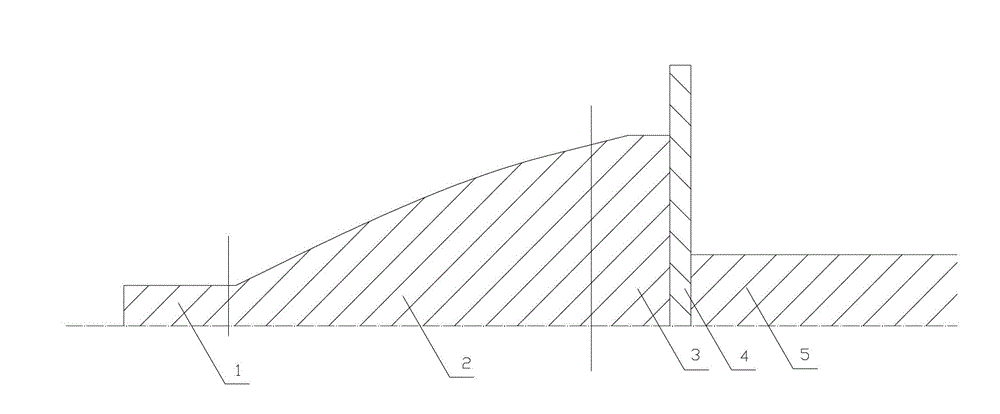

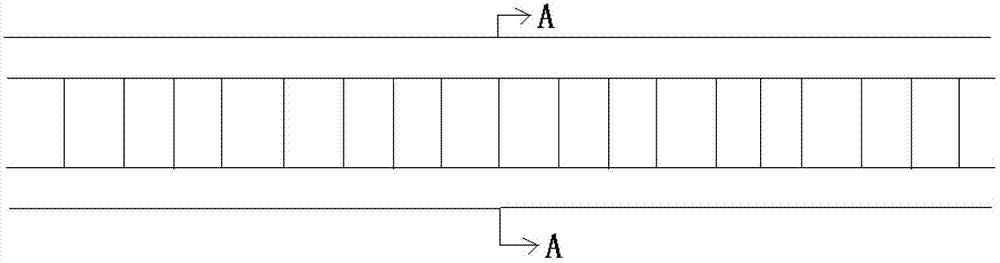

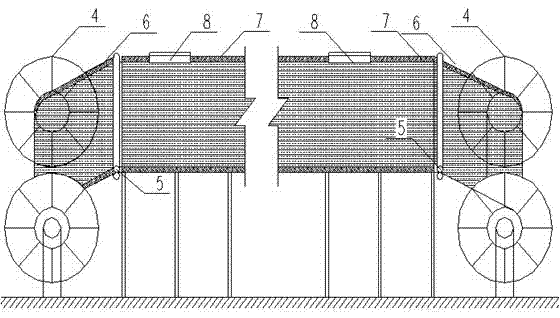

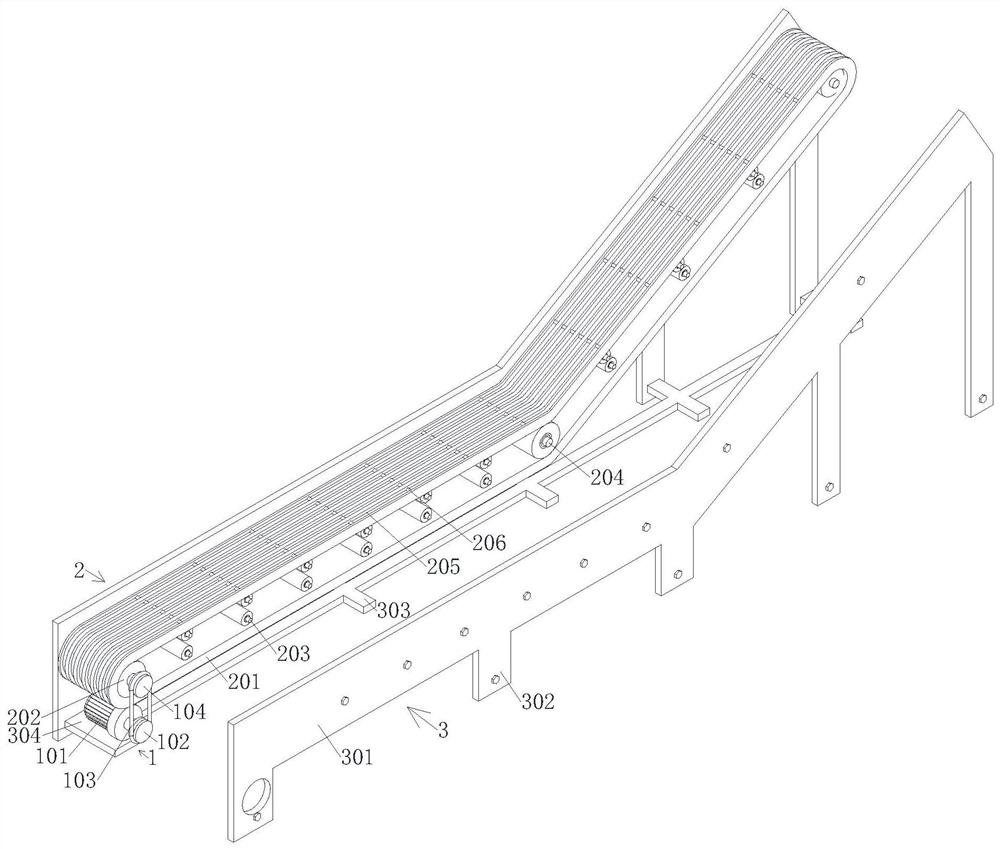

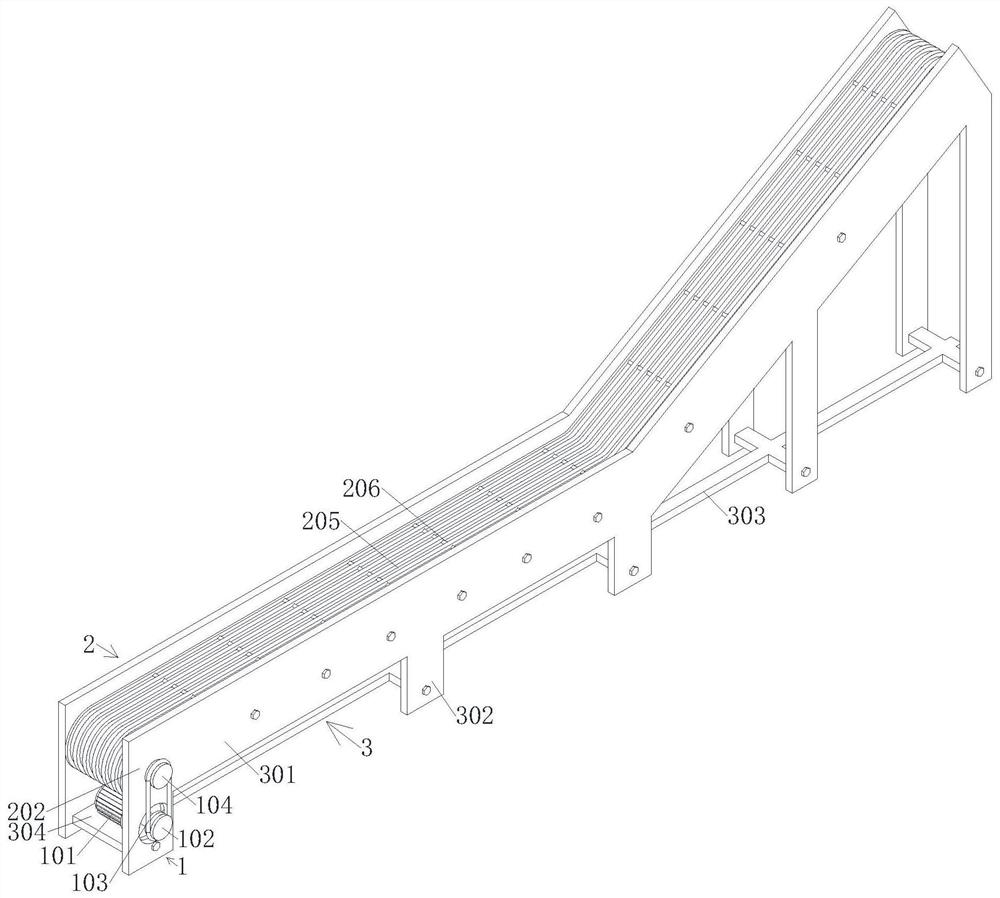

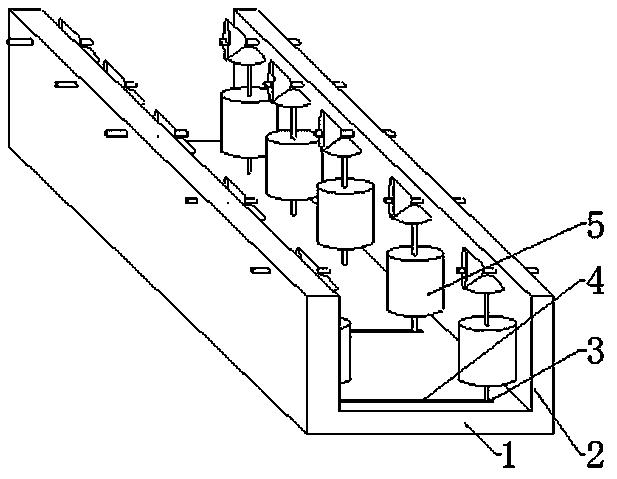

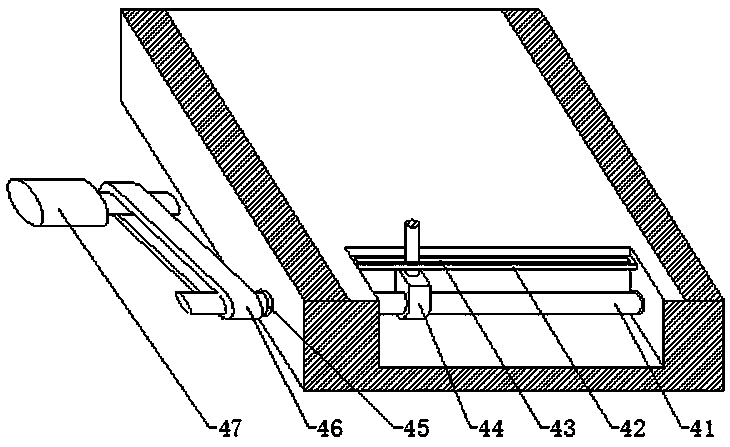

Large inclination belt conveyor

InactiveCN102874542ASolve material declineSolve the problem of slippageConveyorsCleaningEngineeringFlange

The invention provides a large inclination belt conveyor. The belt conveyor comprises a support, an electric roller, a discharging hopper, a supporting roller, a conveying belt and a redirection device, wherein the support consists of a head support, a middle support, a concave support, a tail middle support and a tail support sequentially from top to bottom; the discharging hopper and the electric roller are fixed on the head support; the discharging hopper is positioned on the right side of the electric roller; the conveying belt is a flange belt and provided with a transverse partition part vertically connected with flanges and the bottom surface of a conveying belt; the redirection device comprises a belt pressing wheel and a redirection roller, which are respectively fixed on the concave support, and the belt pressing wheel is positioned above the redirection roller; and the running direction of the conveying belt is changed through interaction of the belt pressing wheel and the redirection roller. By the steeply inclined belt conveyor, bulk materials can be lifted to reach a certain height, a self-cleaning function is realized, and the problem that the bulk materials can slide when conveyed at large inclination is solved.

Owner:JIANGSU TONGDA MACHINERY & EQUIP MFG

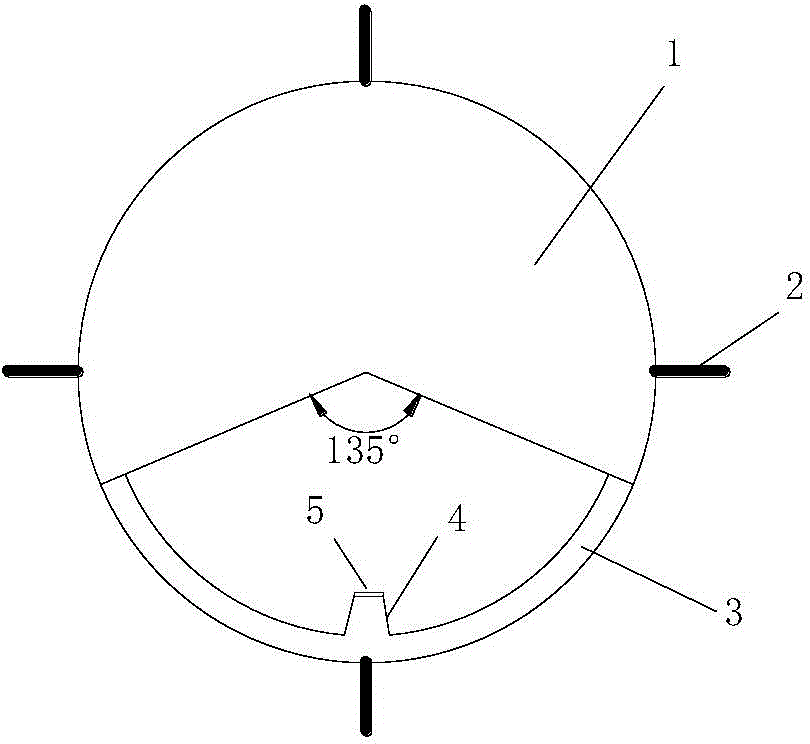

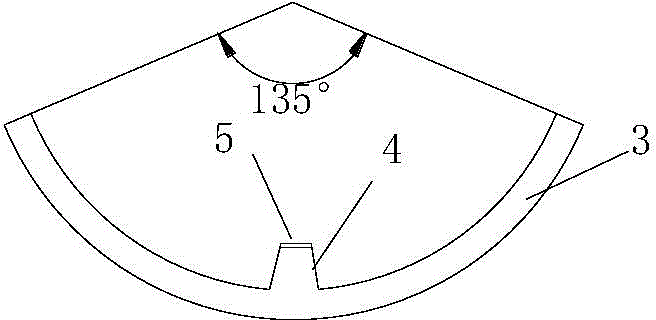

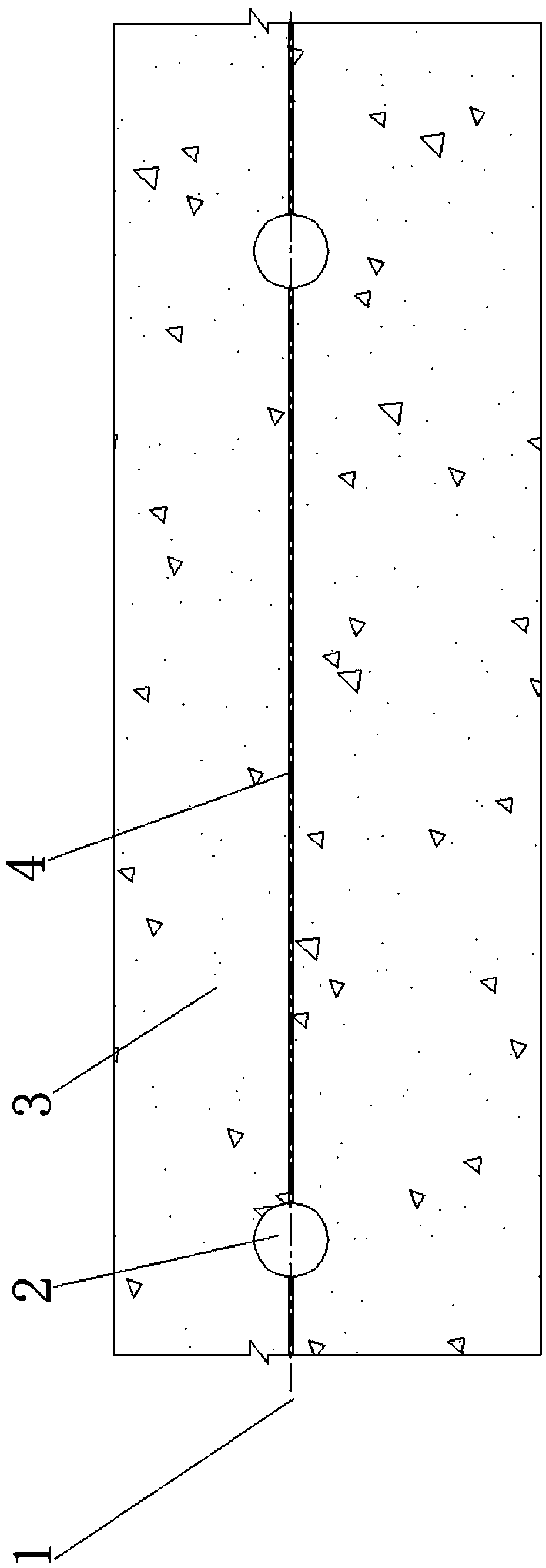

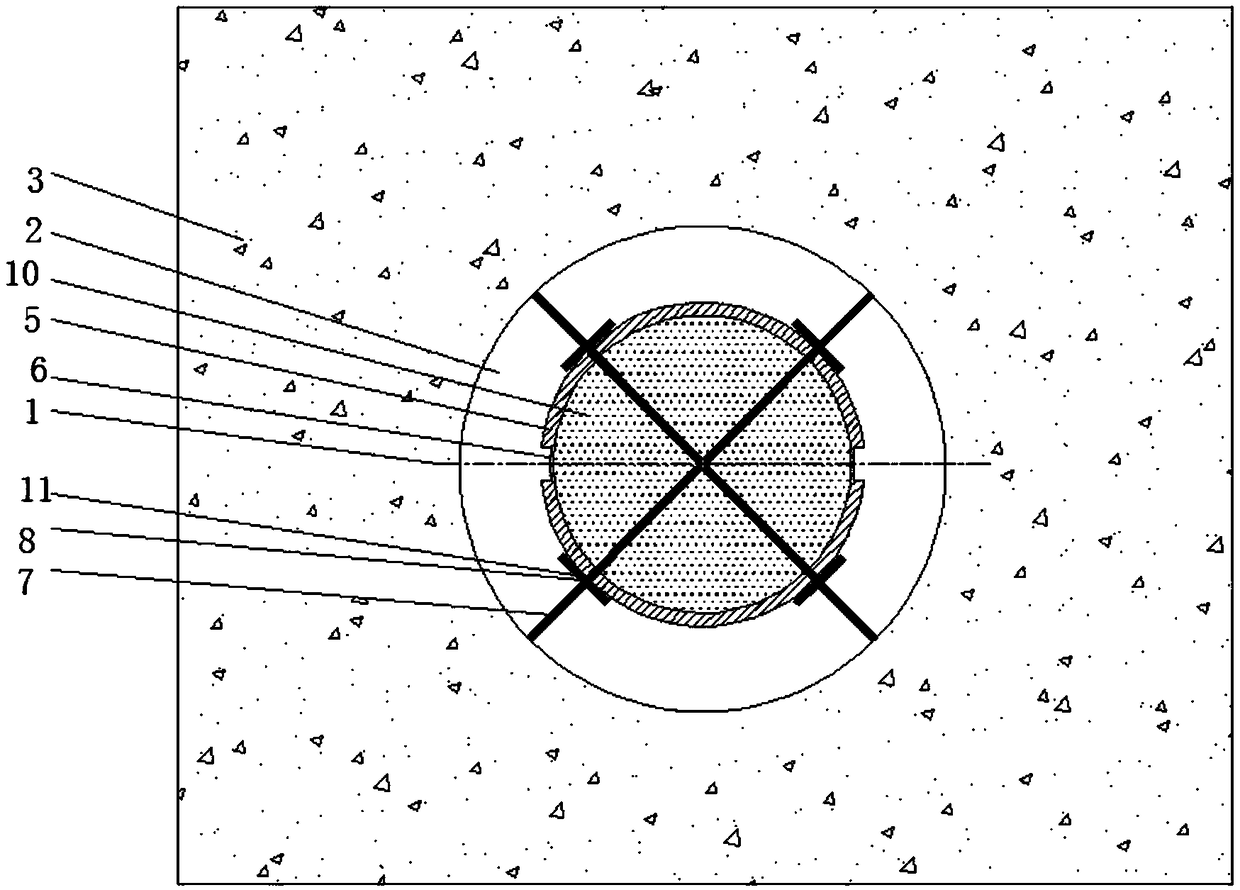

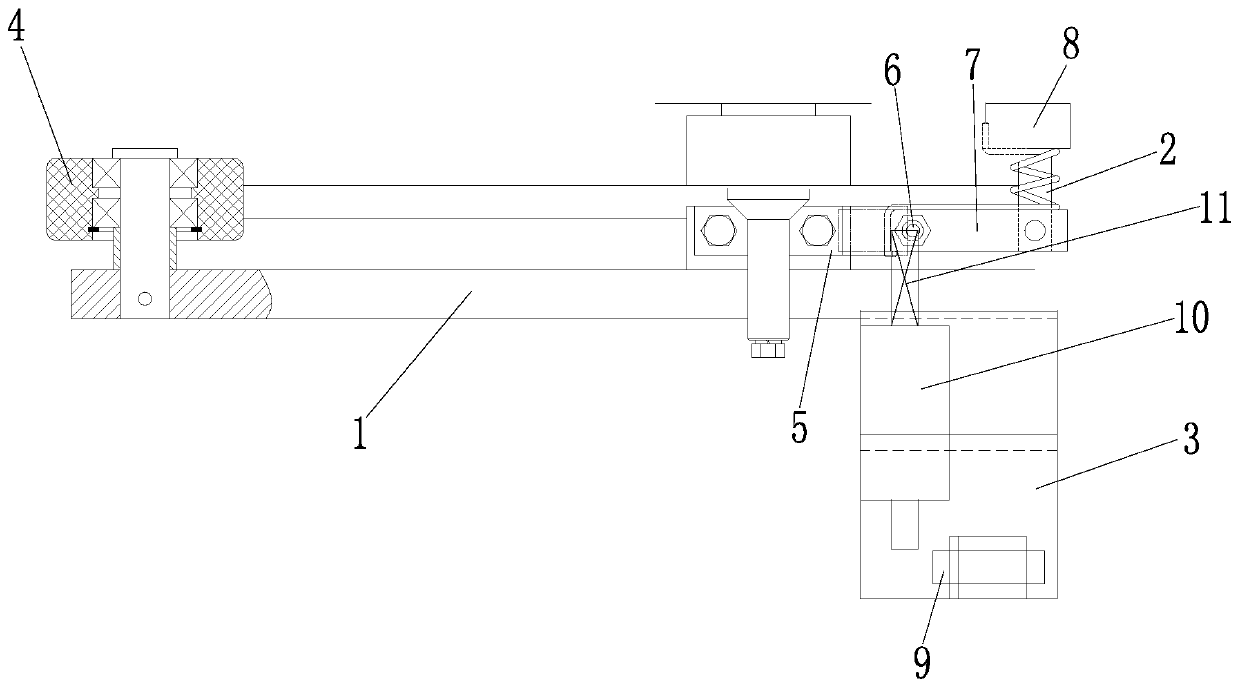

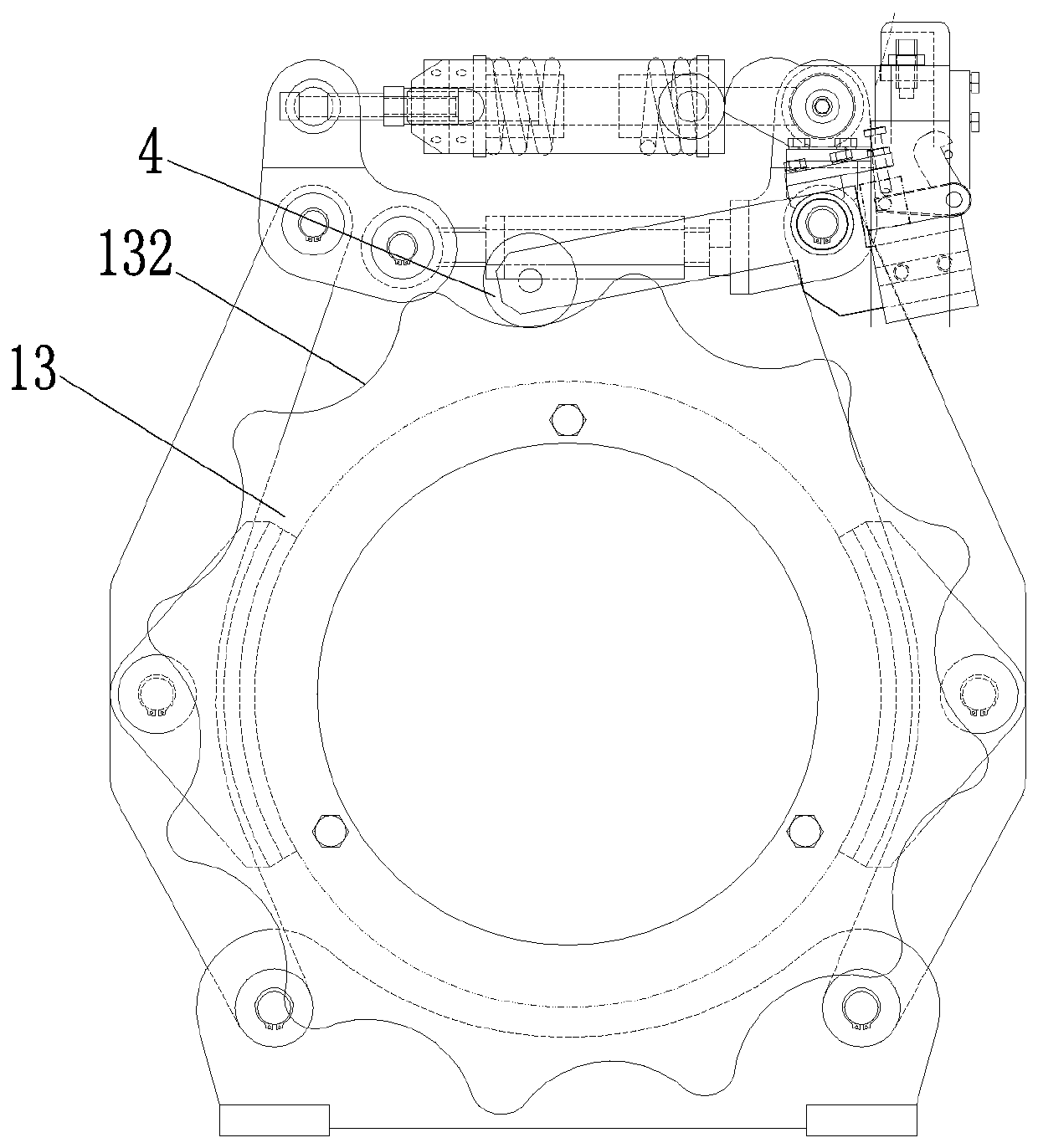

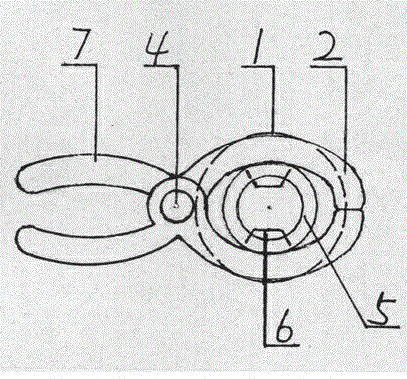

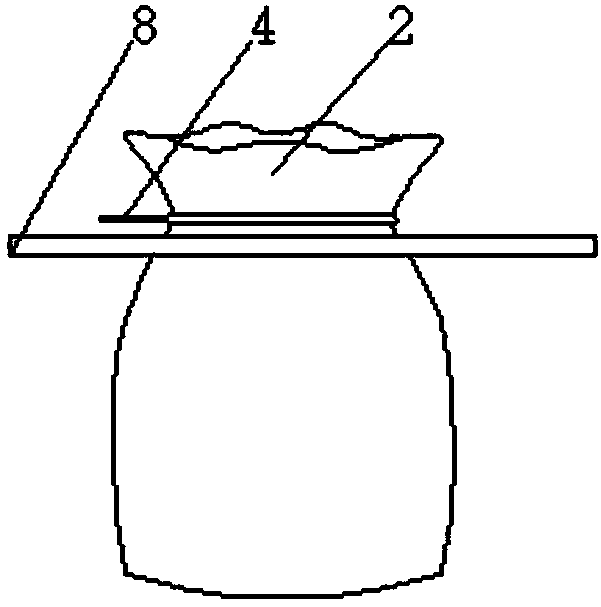

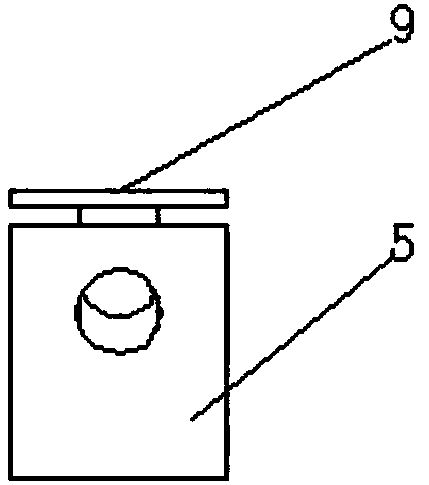

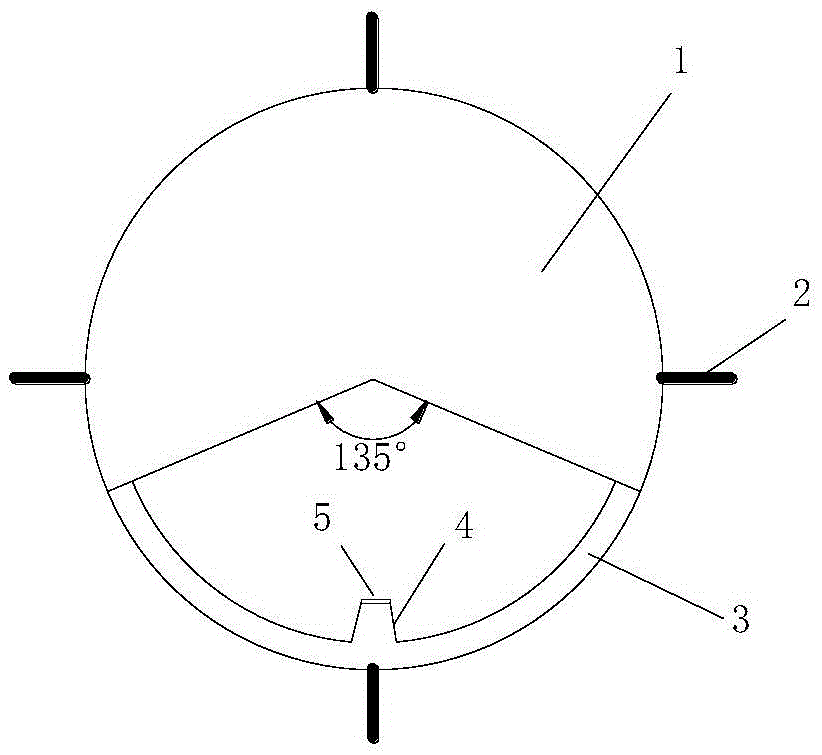

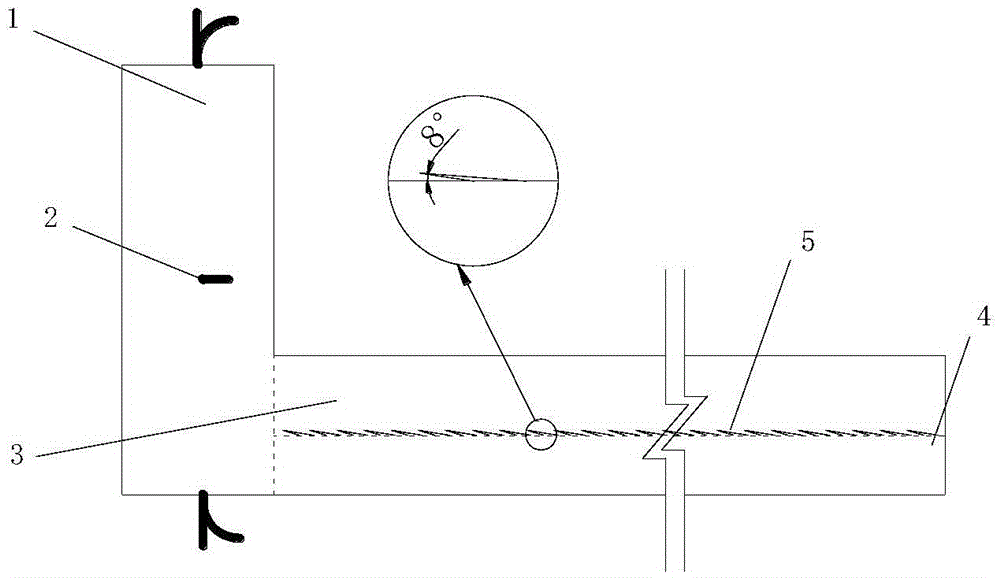

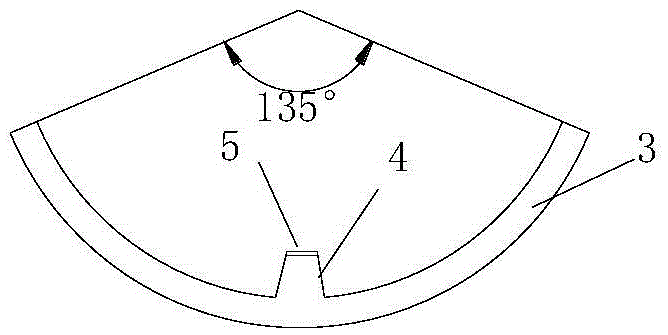

All-dimensional oriented blasting charge guide rail device and method thereof

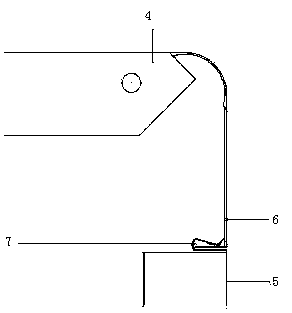

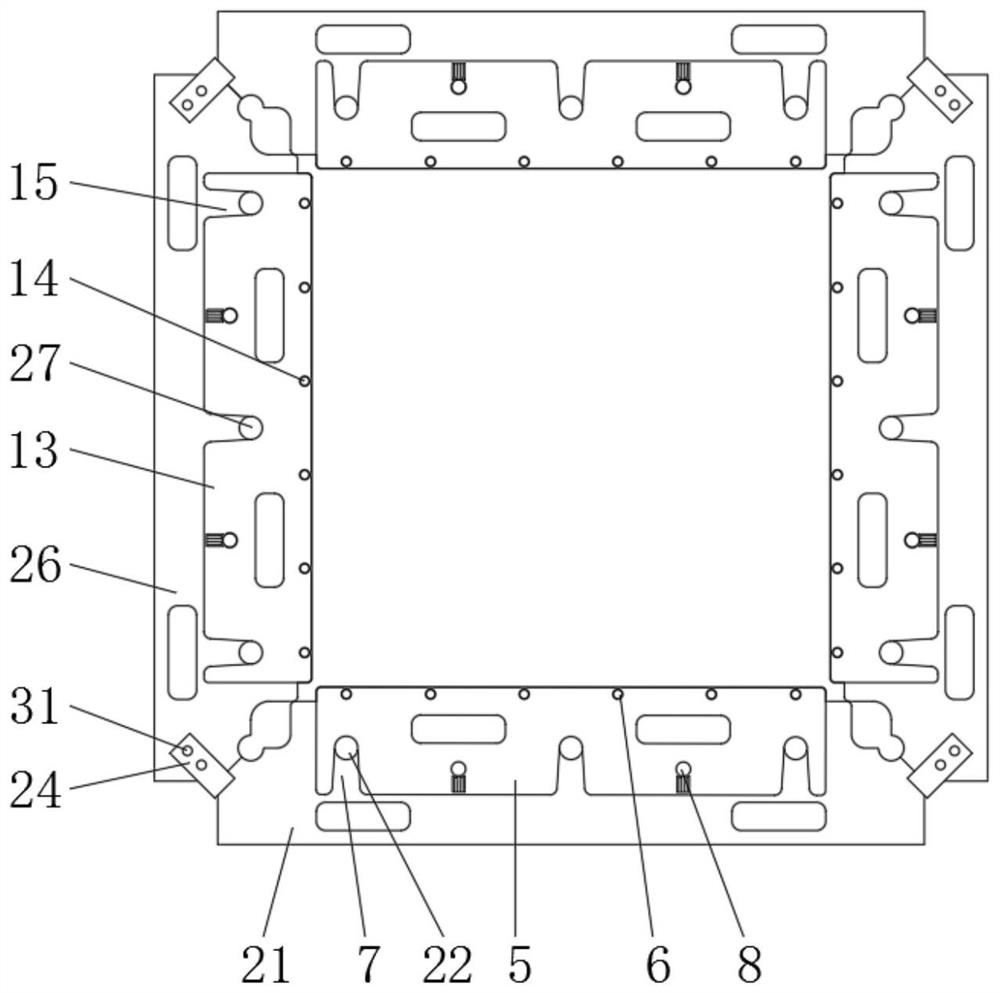

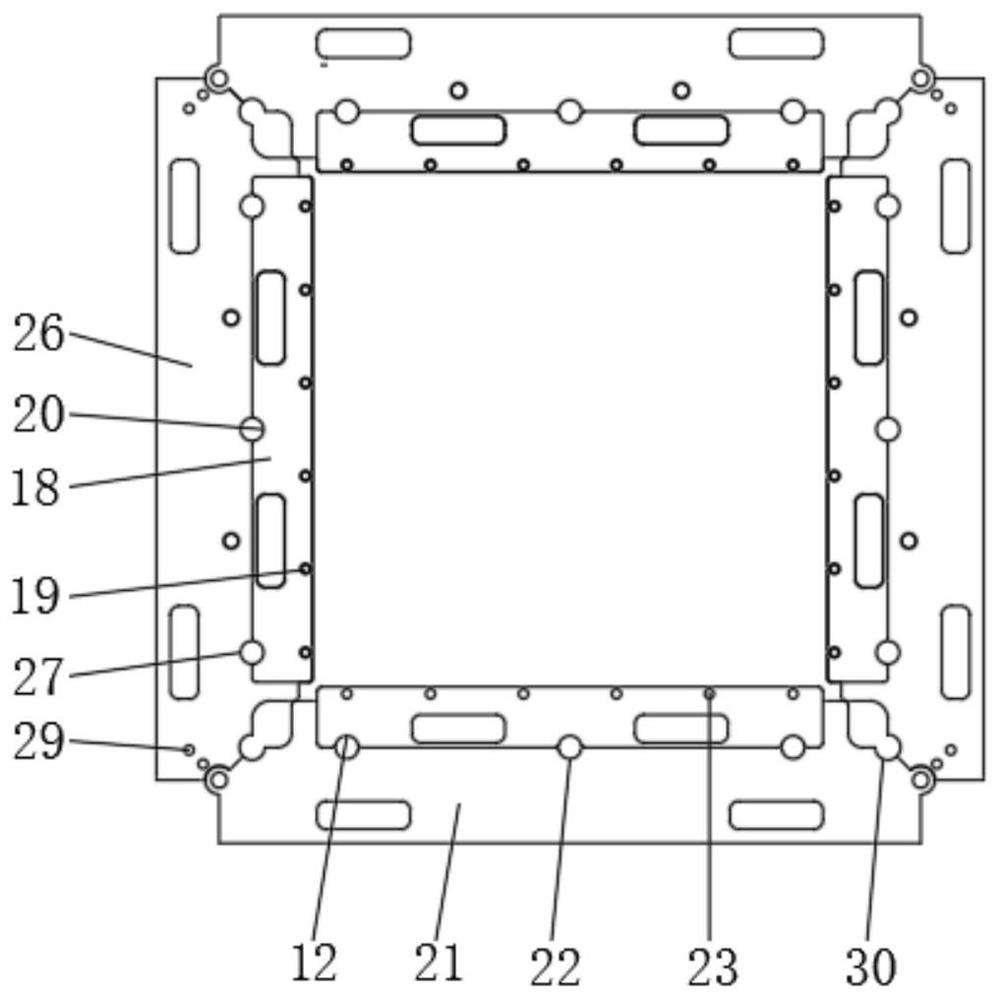

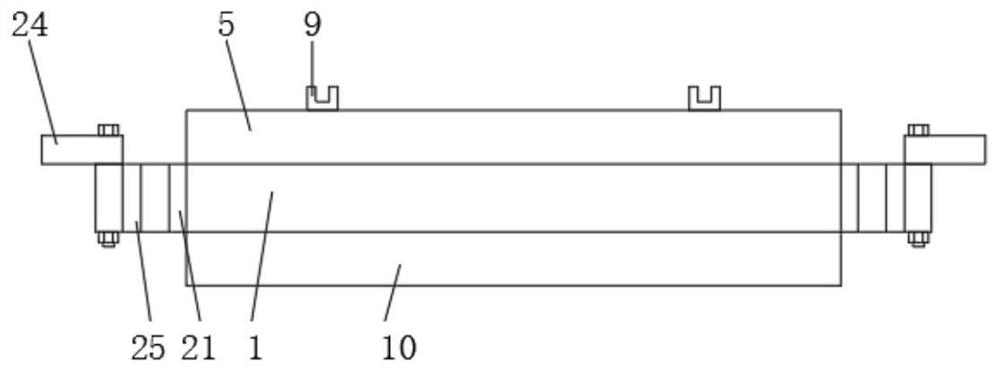

The invention discloses an all-dimensional oriented blasting charge guide rail device and a method thereof, and belongs to oriented blasting charge devices and methods. A first guide rail is connected with a plurality of common guide rails to form the device, antiskid wires (2) are mounted at the end (1) of the first guide rail, a longitudinal ridge (4) is arranged in the middle of a cartridge push rail (3) of the guide rail, cartridge antiskid saw teeth (5) are distributed on the longitudinal ridge (4), a hook hole (8) is formed in a front guide rail tail end (6), a metal hook (9) is arranged at a rear guide rail head end (7), the guide rails are connected through the metal hook (9) and the hook hole (8), the oriented blasting charge method is used for oriented blasting charge of middle and deep holes of forced grooving top-caving in the coal mining process, and the device is simple in integral structure and convenient to operate by the aid of traditional charge technology. The mounting directions of a cartridge energy-concentrated cover and the like is as same as the breaking direction of rocks, and accurate oriented control fracture blasting is realized.

Owner:CHINA UNIV OF MINING & TECH

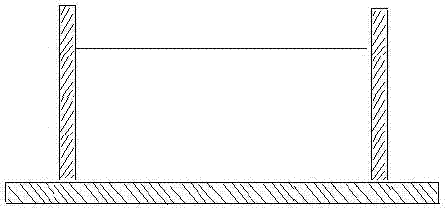

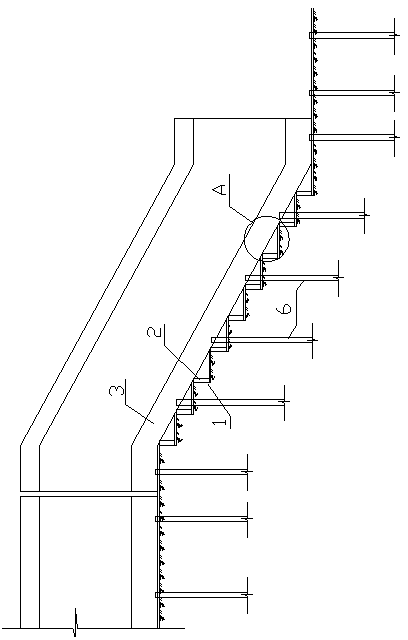

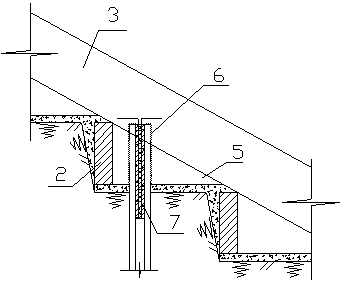

Construction method for controlling sliding of slope section of underground pipeline

ActiveCN104213567ASolve the problem of slippageReduce construction costsExcavationsSupporting systemUnderground pipeline

The invention relates to the field of engineering construction pipeline laying, in particular to a construction method for controlling sliding of a slope section of an underground pipeline. The method includes the steps of foundation pit enclosure construction and foundation pit side wall and top plate construction, and is characterized by further comprising foundation pit inside construction, wherein foundation pit inside construction includes the steps of foundation pit earth excavation, supporting structure building and foundation pit supporting system erection. In the step of foundation pit earth excavation, a foundation pit earth base is excavated into a step shape and is provided with structural piles; the foundation pit earth base is cleaned and leveled; a concrete cushion layer is poured for the first time on the bottom face of a foundation pit bottom plate; end face blocking walls of the foundation pit bottom plate are built; secondary concrete pouring is carried out on the bottom face of the foundation pit bottom plate; concrete pouring is carried out on the foundation pit bottom plate. According to the method, the angle of the base friction surface of the slope section is changed, so that the problem that upper slope section pipelines slide during deep foundation construction is solved, construction cost is lowered, construction process is accelerated, and construction quality is guaranteed.

Owner:CHINA MCC20 GRP CORP

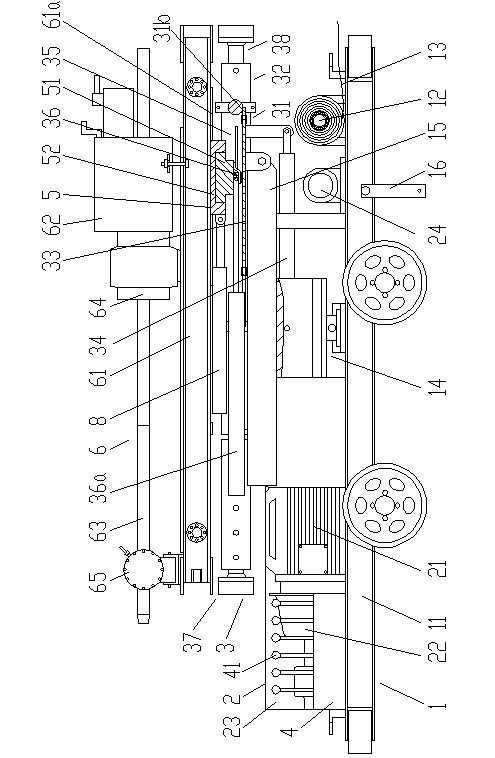

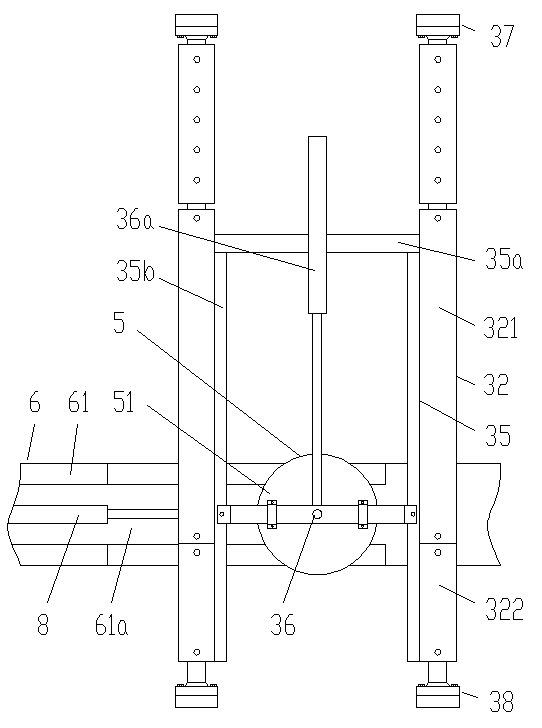

Wheel type truck-mounted drilling rig

The invention discloses a wheel type truck-mounted drilling rig which is characterized in that a movable frame with a drilling device is disposed on a body, the body comprises a mining flatbed truck and a hydraulic winch, a support seat is disposed on the mining flatbed truck, a support beam which is used for allowing the movable frame to be horizontal is disposed on the support seat, a guide rail clamp is further disposed on the mining flatbed truck, the movable frame comprises a #-shaped frame, two ends of the two crossbeams of the #-shaped frame are fixedly connected with main support oil cylinders, two longitudinal beams of the #-shaped frame forms two parallel guide rails which are in slide fit with a movable support, the movable support is hinged to the outer end of the support beam, a vertical oil cylinder which is used for allowing the movable frame to be vertical is connected between the movable support and the support seat, an n-shaped frame is fixedly connected between cylinder bodies the two main support oil cylinders, and a drilling rig turn plate is disposed between the n-shaped frame and the drilling device. The wheel type truck-mounted drilling rig has the advantages that the wheel type truck-mounted drilling rig can be moved in a tunnel without damaging sleepers, the drilling rig is good in rigidity, and drilling hole positions can be adjusted conveniently.

Owner:重庆市能源投资集团科技有限责任公司 +1

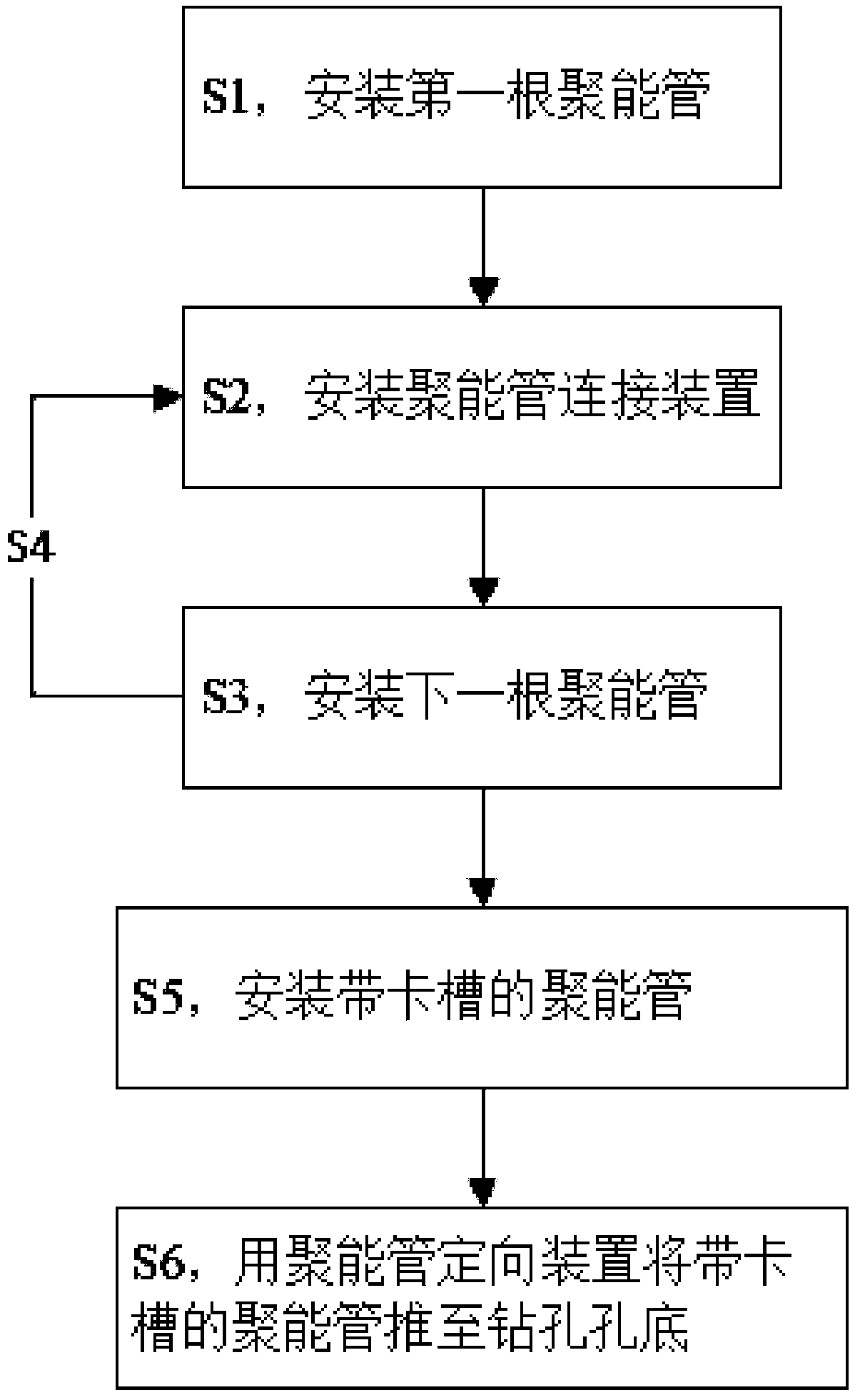

Coal mine roof panel deep hole pre-splitting blasting method

InactiveCN109470100ASolve the problem of missing medicineTroubleshooting Groove Alignment IssuesBlastingDetonatorEngineering

The invention discloses a coal mine roof panel deep hole pre-splitting blasting method. The coal mine roof panel deep hole pre-splitting blasting method comprises a step of installing a plurality of energy-gathered tubes which are full of explosives inside a deep drill hole of a roof panel; and the step comprises the following steps of: (S1) installing a first energy-gathered tube; (S2) installingan energy-gathered tube connecting device; (S3) installing a next energy-gathered tube; (S4) repeating the step (S2) and the step (S3), and installing the other middle energy-gathered tubes; (S5) installing the last energy-gathered tube provided with a clamping slot, repeating the step (S2) and the step (S3), installing detonators and connecting detonating cords; and (S6) pushing the energy-gathered tube provided with the clamping slot to the bottom of the drill hole by using an energy-gathered tube orienting device. The invention provides a coal mine roof panel cutting method which can effectively solve the problem about suspension of a roof panel; the suspended roof panel becomes broke waste rocks; and the problem about roof panel rotation pressure caused by suspension of the roof panelis effectively solved.

Owner:中矿科创(北京)煤炭技术有限公司

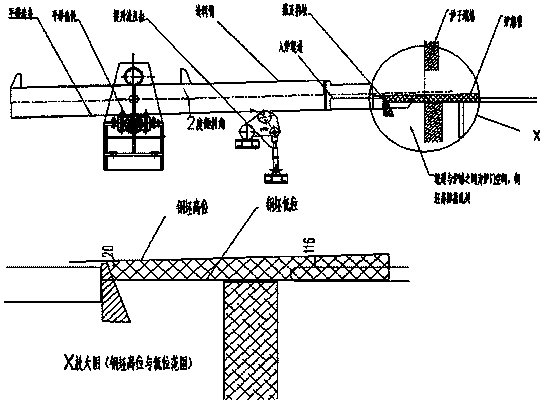

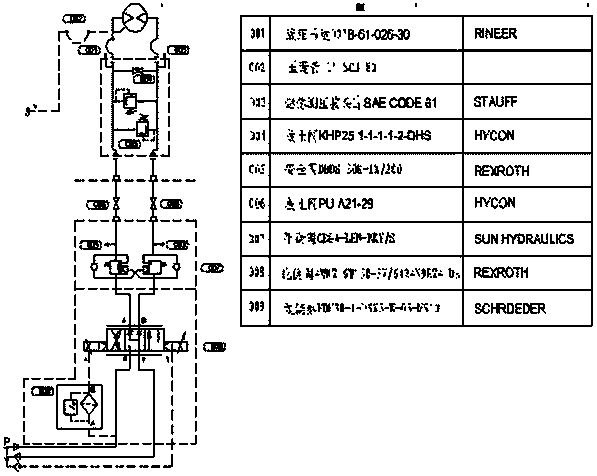

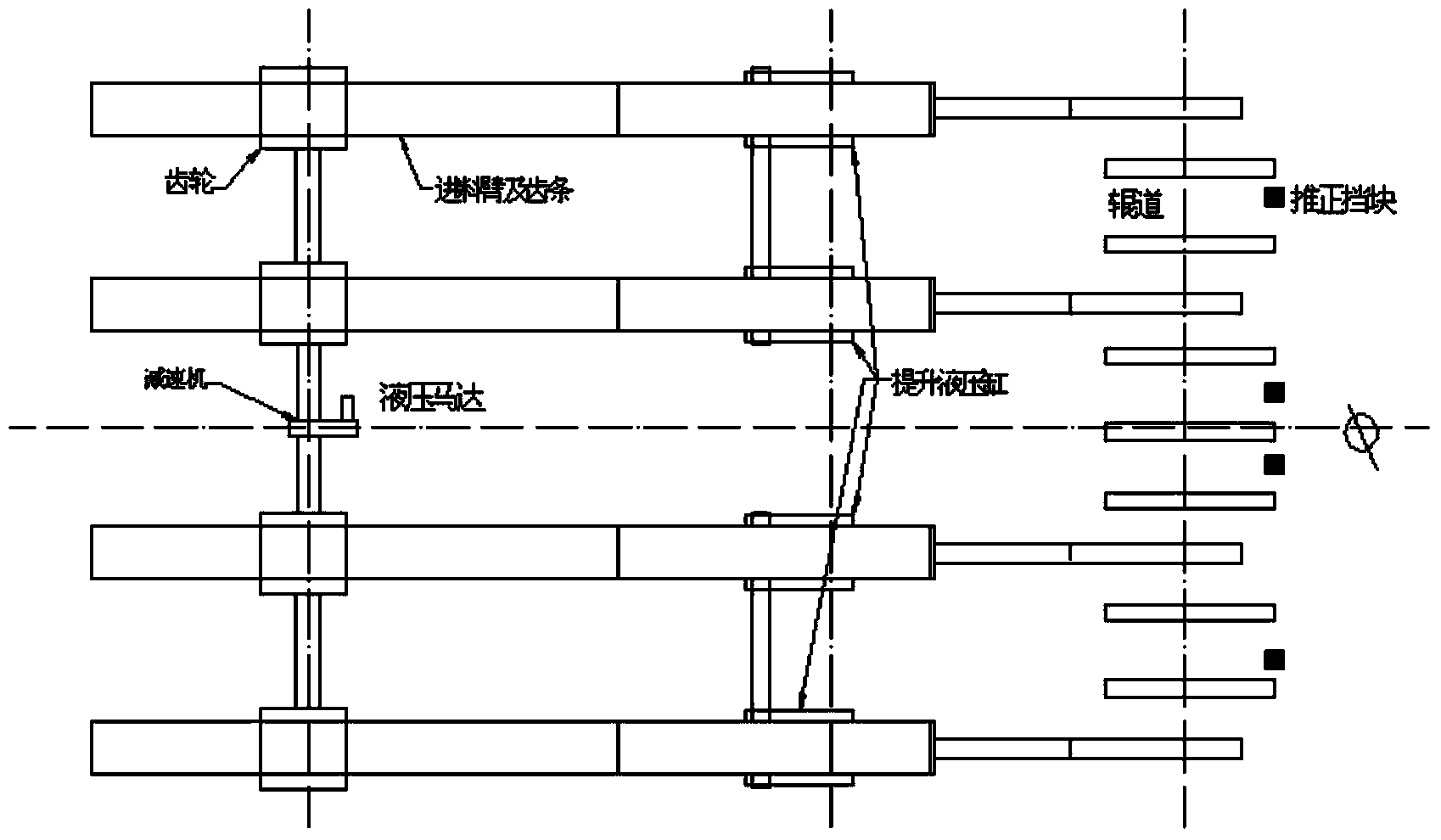

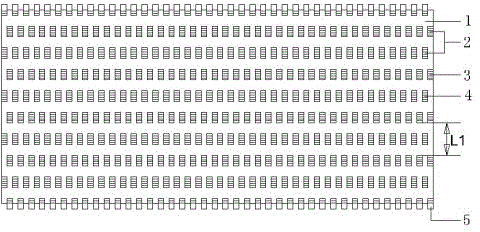

Translation control system and method for feeding arm of heating furnace

ActiveCN104090580ASolve the problem of slippageSolve the problem of billet slippingPosition/direction controlHydraulic motorAutomatic control

The invention relates to a translation control system and method for a feeding arm of a heating furnace. The system includes a feeding arm automatic control unit, a feeding arm manual control unit, and a feeding arm interrupt position maintaining unit. Output ends of the feeding arm automatic control unit, the feeding arm manual control unit and the feeding arm interrupt position maintaining unit are connected to an input end of a feeding arm speed and position controlling and switching function block respectively. An output end of the feeding arm speed and position controlling and switching function block is connected to an acceleration and deceleration rate control function block. Signals output by the acceleration and deceleration rate controlling function block are output to a proportional control valve power amplification plate of a feeding arm translation hydraulic motor after being processed by a digital-to-analog conversion function block. The translation control system and method for the feeding arm of the heating furnace are capable of effectively solving a problem of feeding arm glide and billet slide of a large H-type-steel heating furnace feeder and preventing glide of a variable-frequency-motor-driven heating furnace feeding arm.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Anti-skidding pedal for escalator

Owner:SUZHOU BENYI MECHANICAL & ELECTRICAL EQUIP

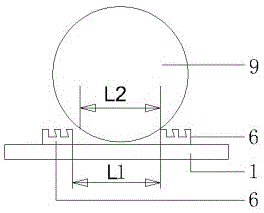

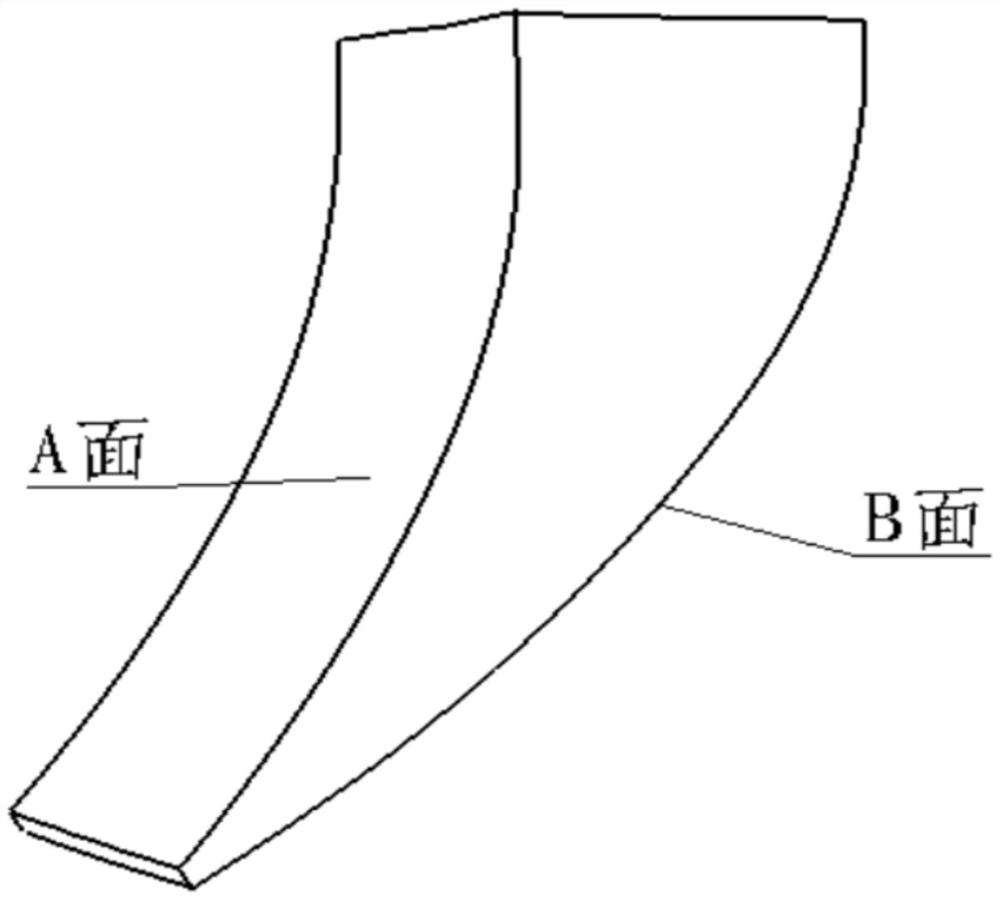

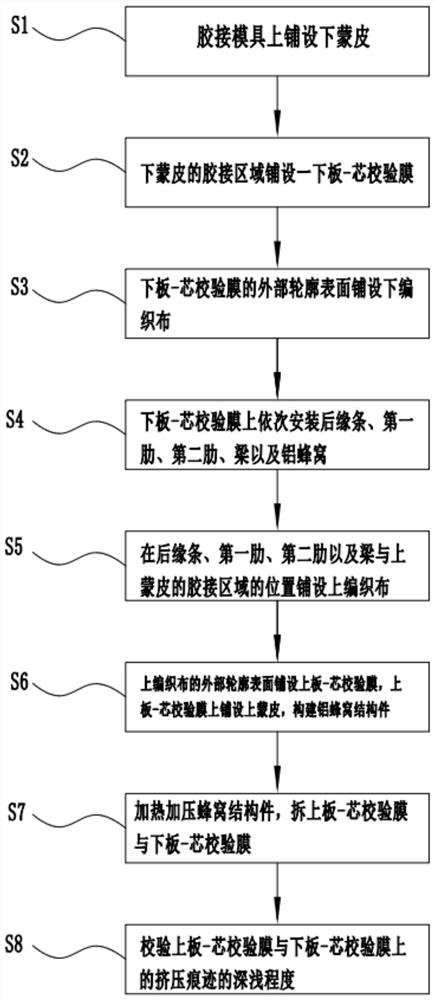

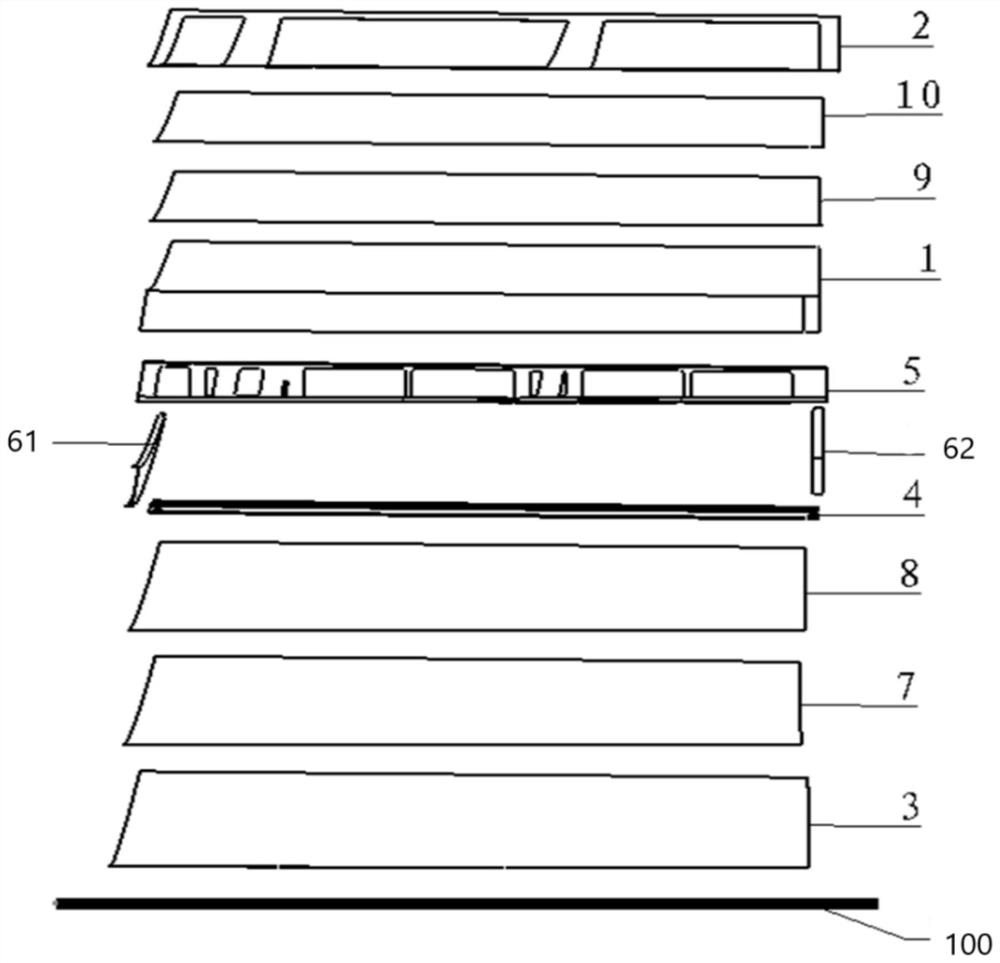

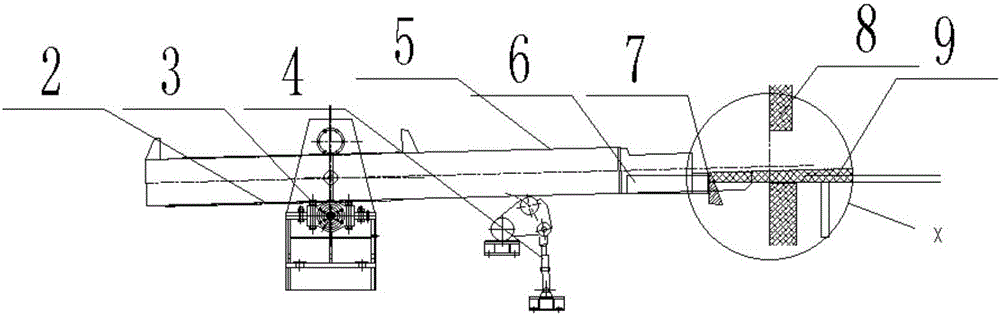

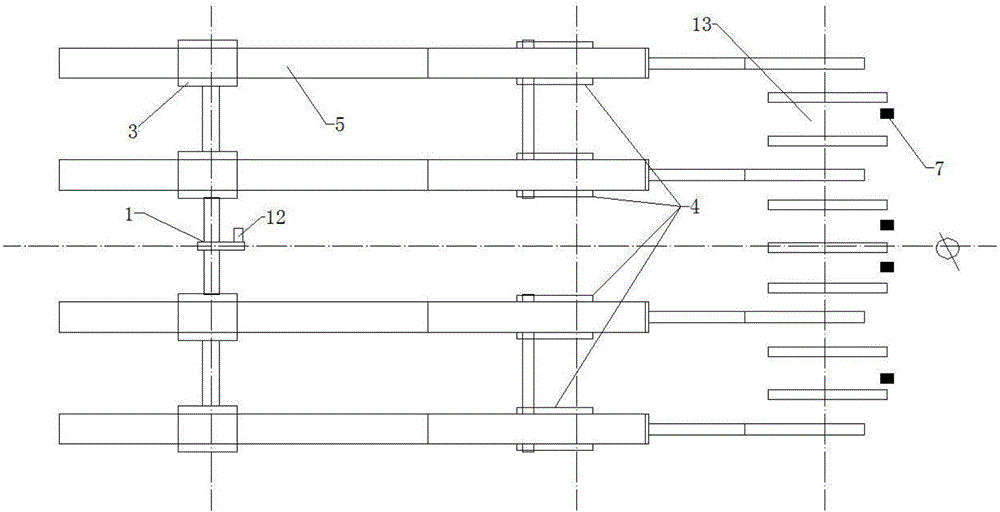

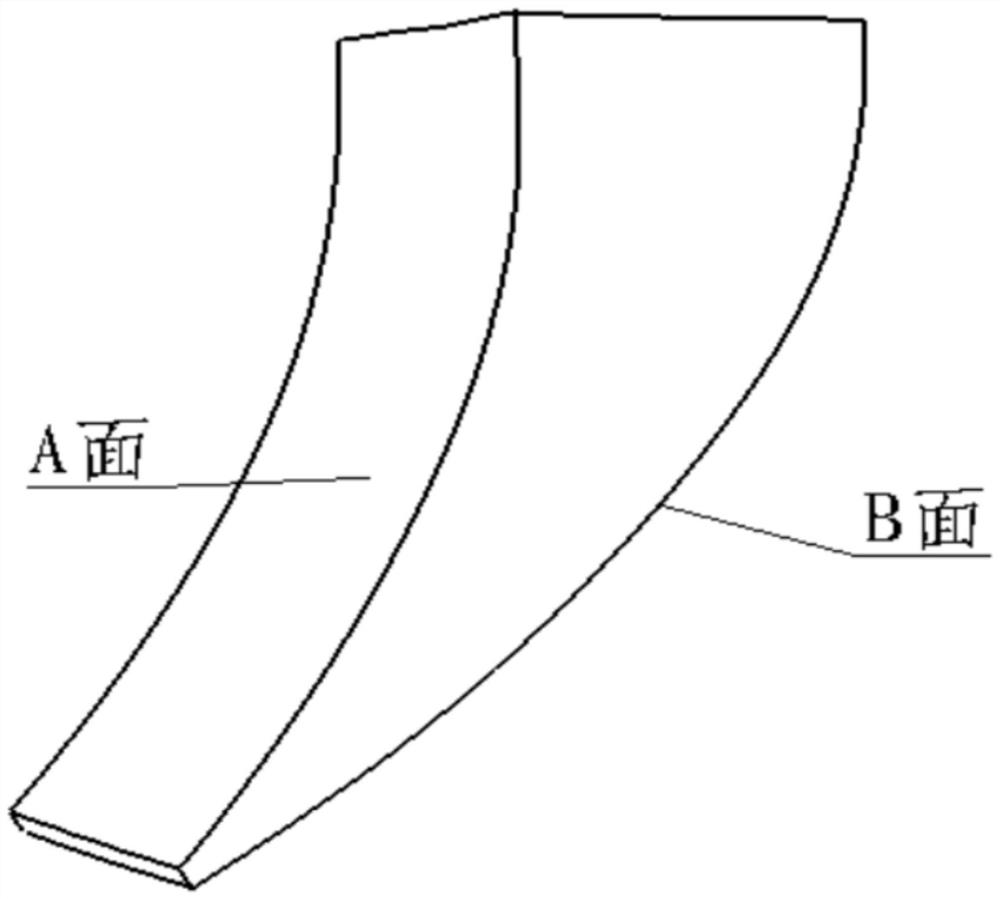

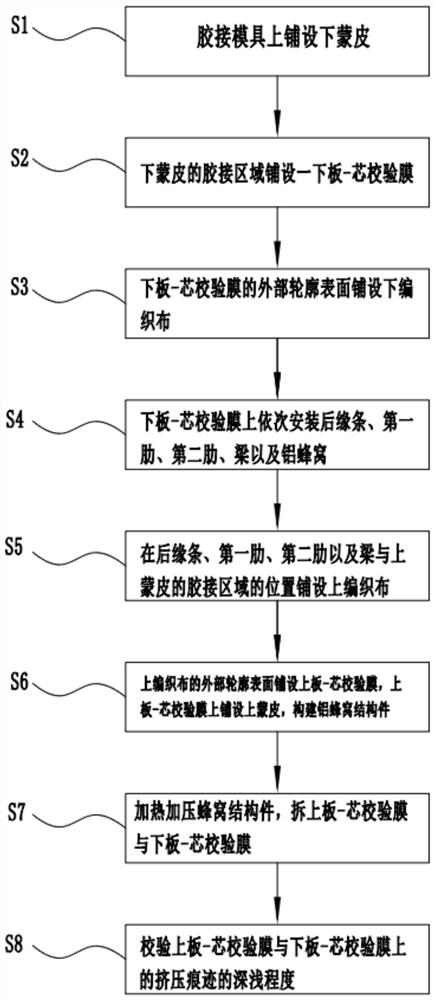

Method and tool for checking forming quality of cementing surface of double-curved-surface variable-thickness aluminum honeycomb

ActiveCN112793193AImprove the ability to resist instabilitySolve the problem of slippageDomestic articlesAluminum honeycombMechanical engineering

The invention relates to a method and a tool for checking the forming quality of a cementing surface of a hyperboloid variable-thickness aluminum honeycomb. The method comprises the following steps: laying a lower skin on a cementing mold; laying a lower plate-core verification film on the lower skin; laying lower woven cloth along the surface of the outer contour of the lower plate-core verification film, laying upper woven cloth on the cementing area of a rear edge strip, a first rib, a second rib, a beam and an upper skin, laying an upper plate-core verification film along the surface of the outer contour of the upper woven cloth, laying the upper skin on the upper plate-core verification film, carrying out vacuum packaging on the whole aluminum honeycomb structural part, putting the aluminum honeycomb structural part into an autoclave, after high-temperature pressurization for a period of time, opening the autoclave, taking out the honeycomb structural part, and separating out the upper plate-core verification film and the lower plate-core verification film; observing the depth degree of extrusion traces on the upper plate-core verification film and the lower plate-core verification film to verify the forming quality of the cementing surface of the aluminum honeycomb, the situation that the skin is damaged due to instability and slippage of the aluminum honeycomb is prevented, and the matching precision and verification comprehensiveness are improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Double-drive type hoisting permanent magnet

PendingCN109704183AEasy to manufactureEasy to installLoad-engaging elementsManufacturing cost reductionDrive shaft

The invention relates to a double-drive type hoisting permanent magnet, and belongs to hoisting equipment. The double-drive type hoisting permanent magnet comprises a lifting ring and a hoisting lifting chain, small lifting chains and swinging rods are connected, the swinging rods sleeve two driving shafts with clearances correspondingly, each set of driving ratchet wheel and pawl are symmetrically arranged in fork-shaped arms of the corresponding swing rod correspondingly, a driving cylindrical gear on the right side is meshed with a driven cylindrical gear on the right side, a driving cylindrical gear on the left side is meshed with a driven cylindrical gear on the left side, the driving cylindrical gear on the right side is meshed with the driving cylindrical gear on the left side, semicircular magnet yokes and iron-boron magnets form movable magnetic systems, a ferrite magnetic block is fixed between an outer magnetic yoke and an inner magnetic yoke to form a fixed magnetic system,each group of movable magnetic system is fixedly connected with two magnetic pole shafts correspondingly, the two groups of magnetic systems are arranged side by side and are separated by a middle separation plate in the middle. The double-drive type hoisting permanent magnet has the advantages that manufacturing, installation and maintenance are more convenient, the manufacturing cost is reduced, an anti-reversing device enables the work to be safer and more reliable, so that large-inclination-angle inclination resistance of the hoisting permanent magnet is realized, and the application range of the hoisting permanent magnet is widened.

Owner:CHANGCHUN UNIV

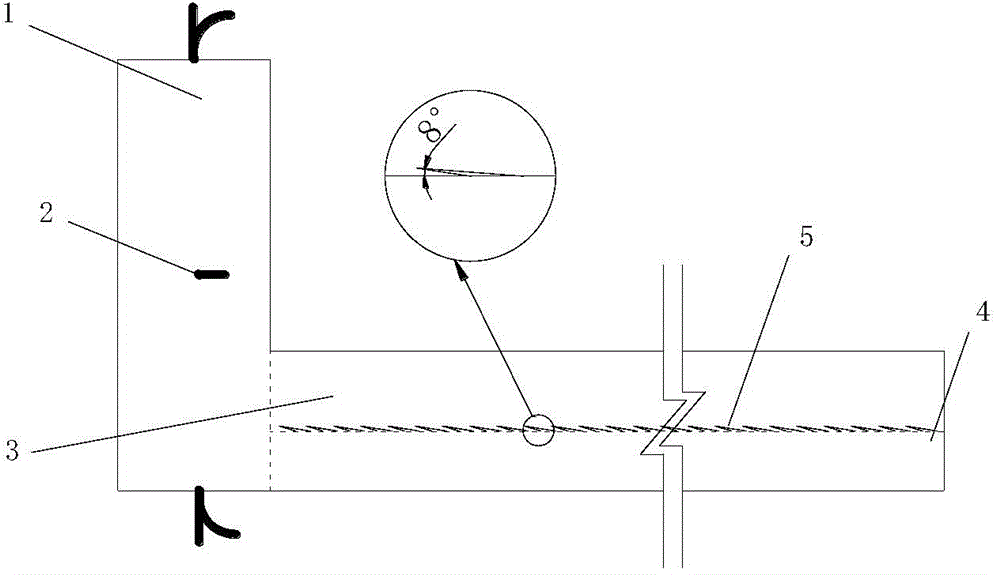

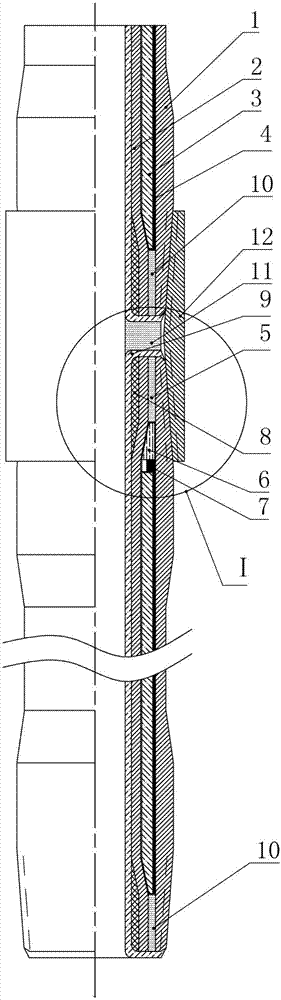

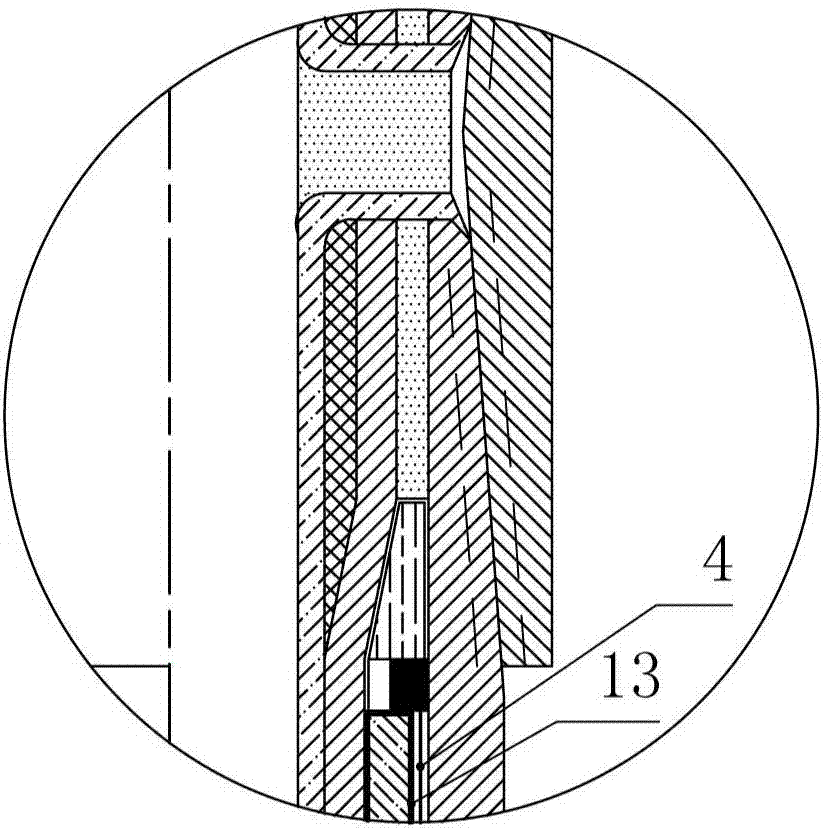

Wear-resistant and heat-insulating lined composite oil pipe

ActiveCN107165585AHigh viscosityImprove fluidityDrilling rodsThermal insulationThermodynamicsChemical control

The invention discloses a wear-resisting and heat-insulating lined composite oil pipe. The multifunctional composite oil pipe is composed of an anti-eccentric wear lining pipe, a pressure-bearing inner pipe, a heat-insulating layer, a steel oil pipe, an anti-slide forced sealing device and a forced sealing device from inside to outside, wherein the anti-slide forced sealing device and the forced sealing device are arranged at two ends of the oil pipe correspondingly; and a plurality of machined oil pipes are connected through oil pipe couplings so as to be used underground. According to the wear-resisting and heat-insulating lined composite oil pipe, the eccentric wear of rods and pipes in oil wells is solved, the temperature loss of crude oil in the process of lifting the crude oil from the bottom to the opening of a well is reduced, the crude oil temperature at the wellbore and the well opening is increased, the flow state of crude oil in the wellbore is improved after wax deposition and scaling in the oil pipe, the load of pumping units is reduced, heat washing of the oil wells and adding of chemical control agents are not needed, the ground gathering and transportation process is simplified, and conveying without heating single pipes is achieved. Finally, the purposes of saving energy, reducing emission, increasing income, improving efficiency and greatly reducing the oil exploitation cost are achieved.

Owner:刘兴仁 +1

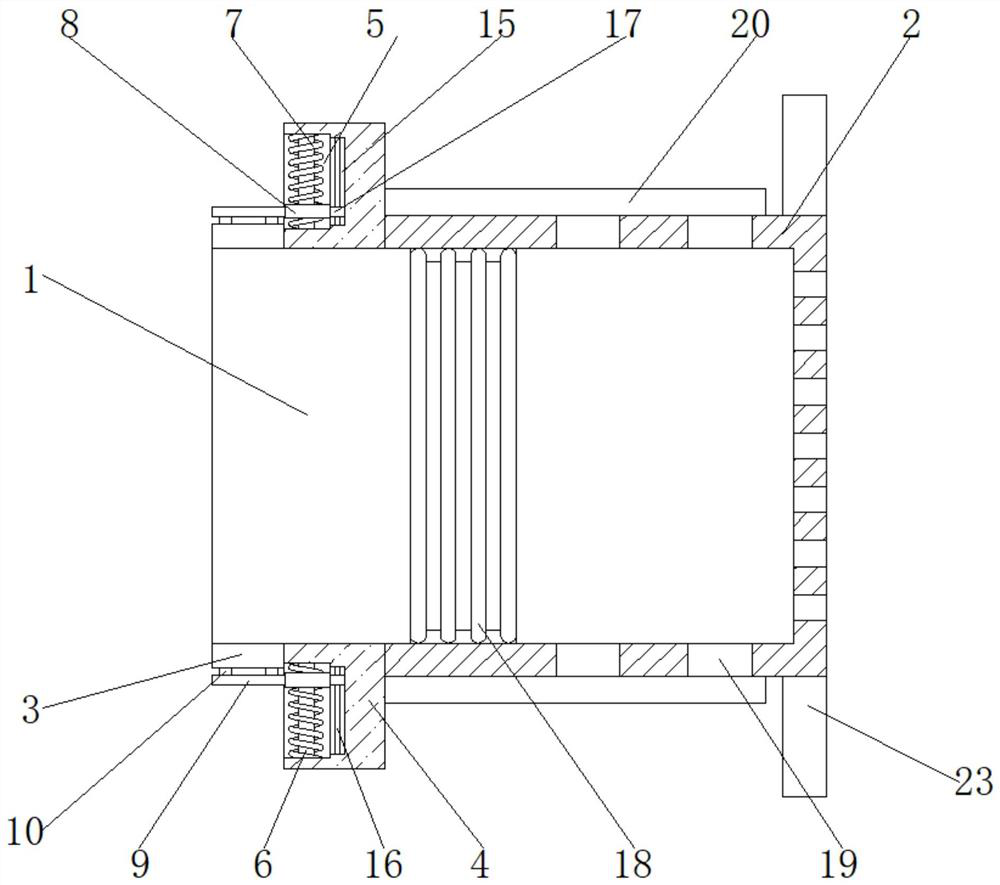

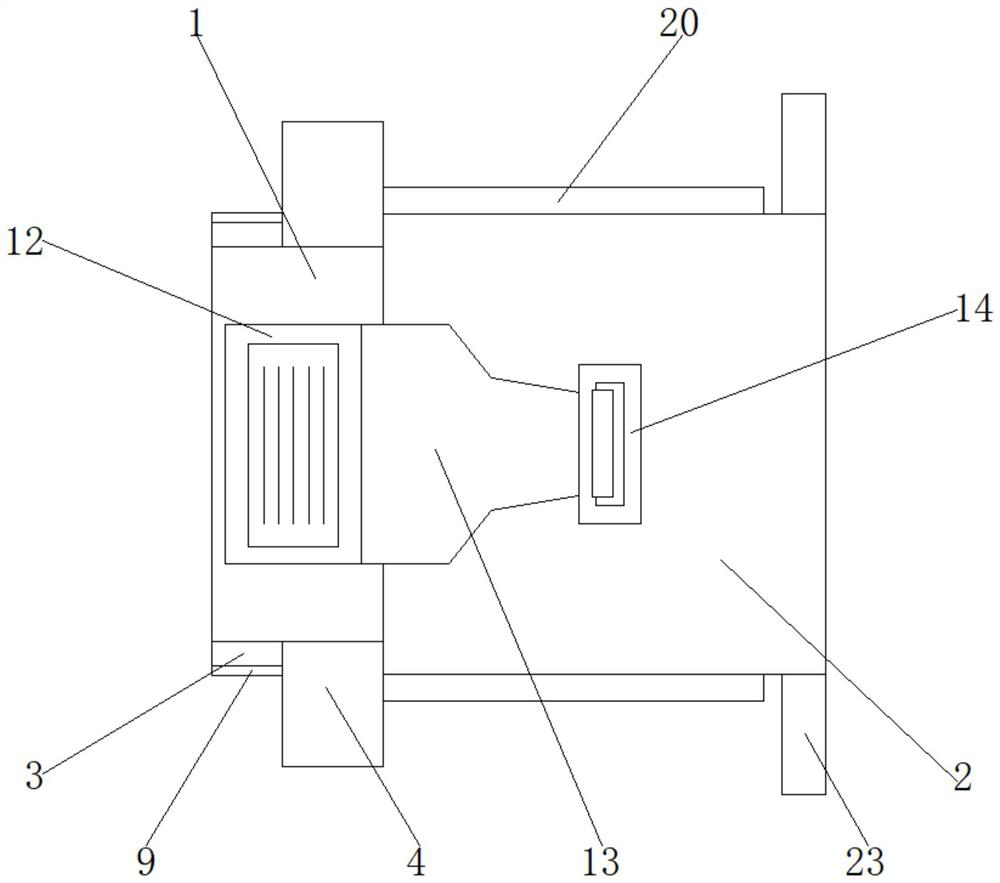

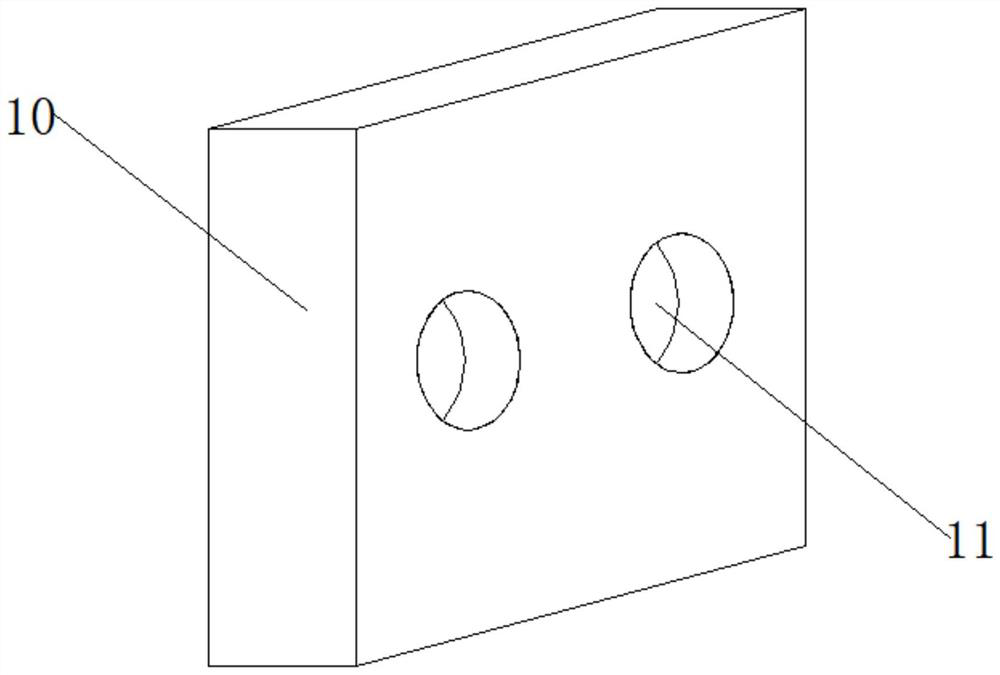

Wire harness wiring port fixing device with clamp

ActiveCN113285304AExtended service lifePrevent looseningEngagement/disengagement of coupling partsCouplings bases/casesStructural engineeringMechanical engineering

Owner:东莞市久宽精密五金电子有限公司

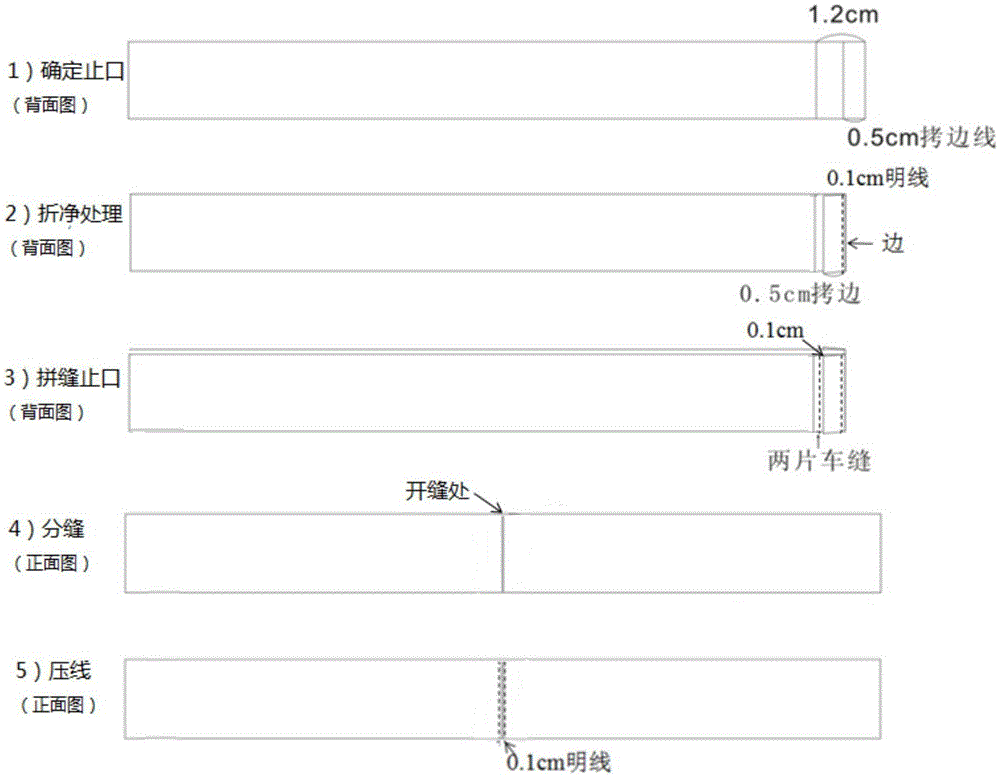

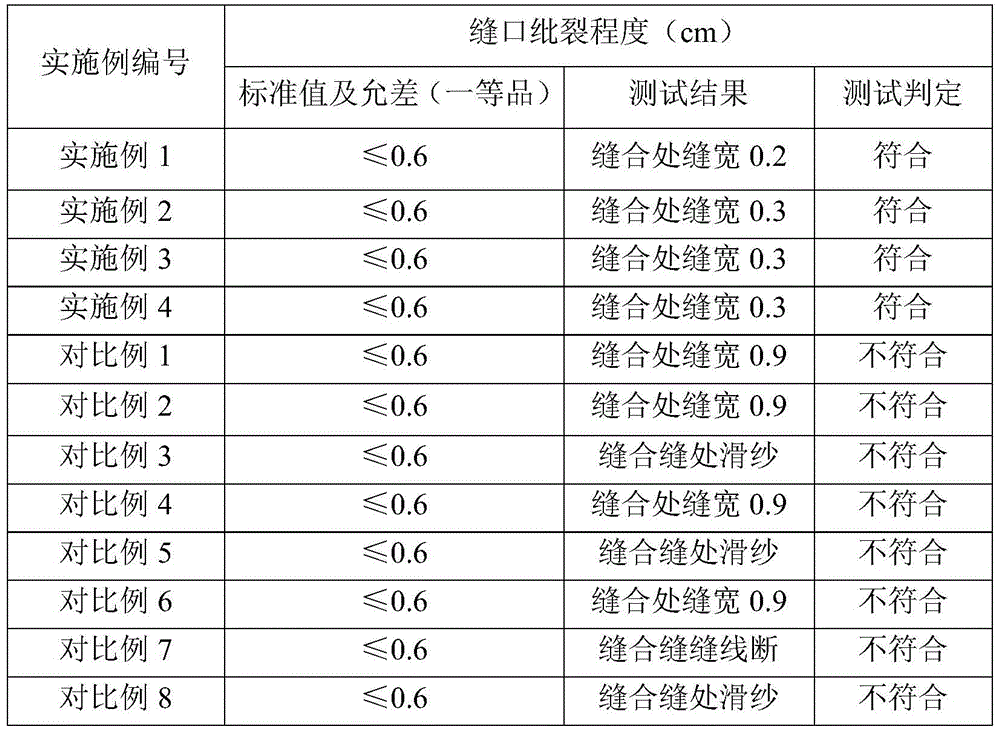

Novel anti-slippage process

The invention discloses a novel anti-slippage process. The novel anti-slippage process specifically comprises the following steps: firstly, determination of seam allowance; secondly, folding and baring treatment of overlock stitches; thirdly, piecing of the seam allowance; fourthly, parting; fifthly, line pressing. Then, in combination with specific limiting of parameters of each step in the process, the problem of slippage caused by stitch slipping of thin and easy-to-slip fabric materials is effectively solved, and the yarn fabrication cost and the fabric feeling of the materials are also guaranteed at the same time.

Owner:ZHUHAI JIAN XUAN CLOTHING LTD

Conveying system for solar treatment of kitchen waste and sludge

The invention discloses a conveying system for solar treatment of kitchen waste and sludge. The conveying system comprises a conveyor belt, an anti-glide device and conveyor belt winding devices; traction belts are mounted on the upper and lower surfaces of the conveyor belt and the conveyor belt is laid on a solar evaporation plate; the anti-glide device is clamped on the upper part of the conveyor belt, the lower opening of the anti-glide device is used for clamping the traction belts and the upper side of the anti-glide device is fixed on the solar evaporation plate; the conveyor belt winding devices are located at the two ends of the conveyor belt, and each conveyor belt winding device comprises a rotating disc, a speed reducer, a clutch and a fixed pressing plate. The conveying system for solar treatment of kitchen waste and sludge is used for solving the waste conveying problem in case that an angle of 30-45 degrees is formed between a solar evaporation device and the horizontal plane; the conveying system is convenient to use, high in practicability, and resistant to puncture and tear; besides, the service life of the conveyor belt can be increased and the use cost can be saved; besides, the glide and deviation problems of the conveyor belt are solved, and in the use process, waste and sludge are not prone to drop.

Owner:南方中金环境股份有限公司

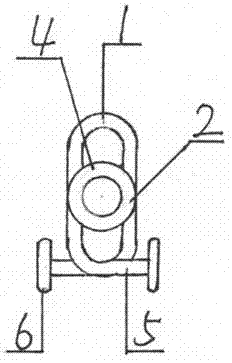

Transmission mechanism used for high-speed belt

InactiveCN107676437ATransmission high speedSolve the problem of slippageGearingDrive wheelCentrifugation

The invention belongs to the technical field of belt transmission, and in particular relates to a transmission mechanism for a high-speed belt, which includes a driving shaft, a driving wheel, a first output shaft, a driven wheel, a belt, a stretching mechanism, a lower pulley, an upper pulley, a differential device, first bevel tooth combination, centrifugal wheel, driving hollow wheel, centrifugal block, centrifugal block spring, etc., when the belt is in high-speed transmission, the upper pulley and the lower pulley make the differential work at different speeds, then the differential The device drives the stretching mechanism to lift the belt through the combination of bevel teeth, centrifugal wheel and driving hollow wheel, so that the belt is in a tensioned state and realizes the high-speed transmission of the belt. The invention solves the problem of the belt slipping phenomenon in the high-speed transmission of the traditional belt mechanism, and finally enables the belt transmission mechanism to realize high-speed transmission. The structure is simple and compact, and has good practical effect.

Owner:刘庆玲

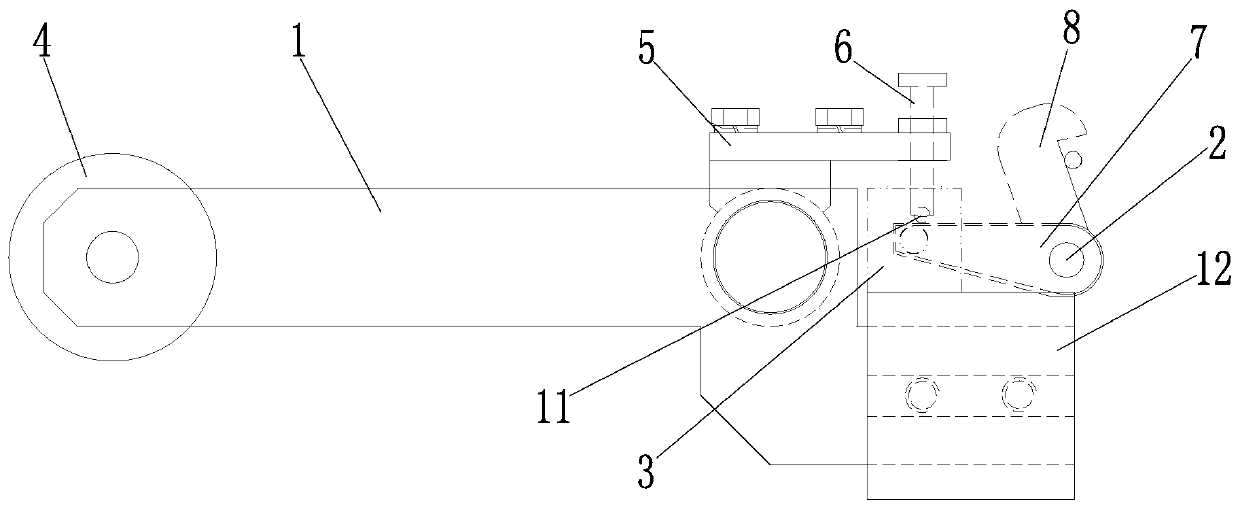

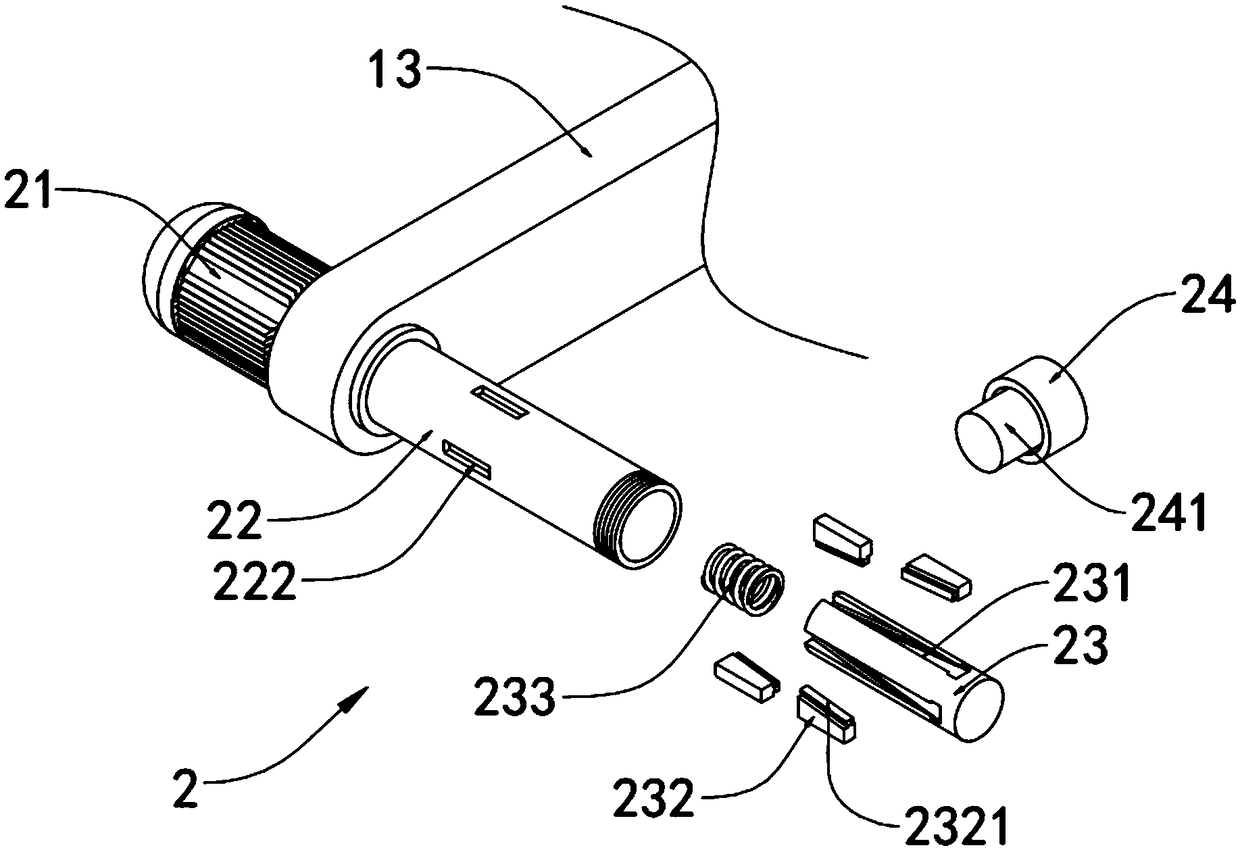

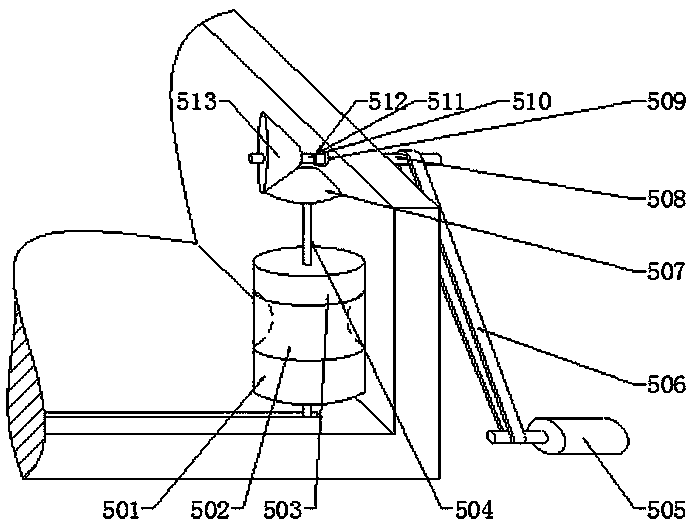

Anti-slip trigger mechanism

InactiveCN111252691AReduce the possibility of misuseSolve the problem of slippageWinding mechanismsElectric machineryControl theory

The invention discloses an anti-slip trigger mechanism. The anti-slip trigger mechanism comprises a swing arm, a brake arm and an angle aluminum bracket. The left end of the swing arm is connected with an elastic wheel, the swing arm is also connected with a pressing plate, the pressing plate is provided with a trigger bolt, the brake arm is provided with a small yoke plate and a trigger hook, thetrigger bolt is located above the small yoke plate, and the small yoke plate can drive the trigger hook to act through the brake arm. The angle aluminum bracket is provided with a photoelectric inductive switch and an electromagnet, the photoelectric inductive switch is used for detecting whether the electromagnet is normally attracted back or not, the electromagnet is connected with a plug pin,and the plug pin corresponds to the position between the trigger bolt and the small yoke plate. The anti-slip trigger mechanism can be used in a backup brake of a drum of a hoisting mechanism and solves the problem that a working platform continues to slide when a drum motor is off, and the possibility of drum motor misoperation is reduced when the backup brake locks the drum by arranging the photoelectric inductive switch.

Owner:PINGHU POINT HIGH RISE EQUIP +1

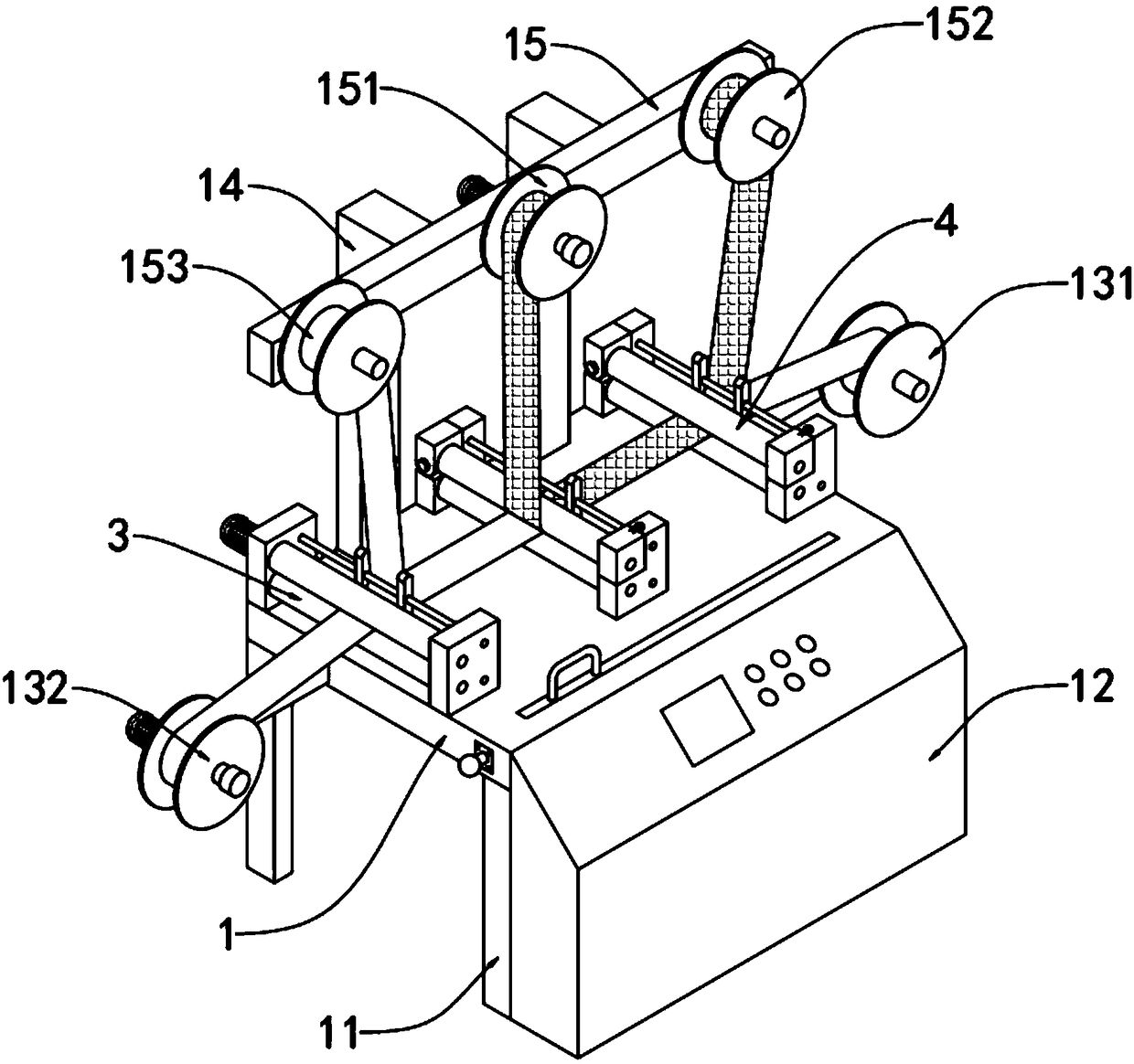

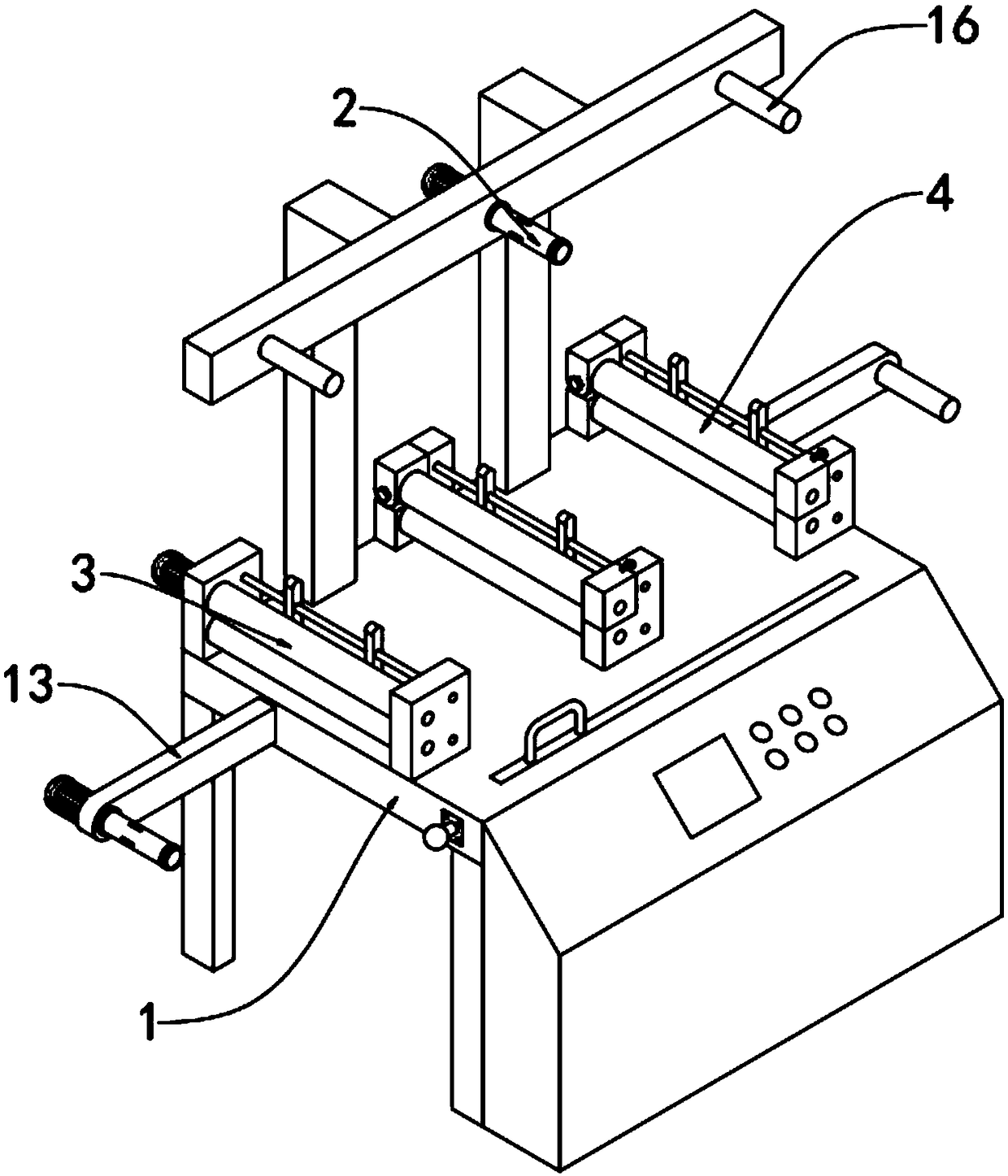

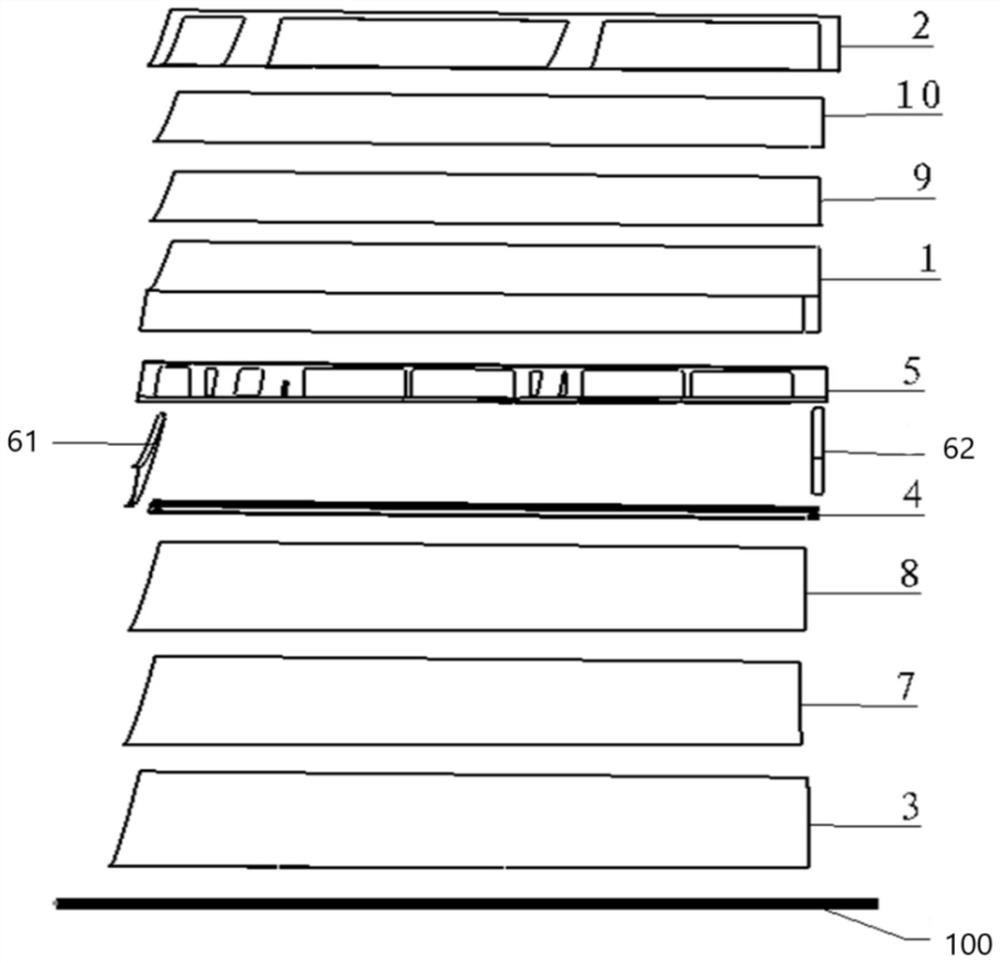

Die-cutting laminating machine

PendingCN109397837ASolve the problem of slippageConvenient connection workLamination ancillary operationsLaminationMechanical engineering

The invention relates to the technical field of die-cutting equipment, and particularly relates to a die-cutting laminating machine. The die-cutting laminating machine comprises a laminating machine body, wherein a sleeving device, a rolling device, a pressing device, an adjusting device, a protective device and a positioning device are arranged on the laminating machine body; according to the die-cutting laminating machine, by arranging the sleeving device, collection wheels are firmly fixed to the sleeving device to prevent the collection wheels from skidding during rotation; by arranging the openable pressing device, a top pressure wheel on the pressing device can be lifted up to facilitate the working personnel to perform material connection work; by arranging the adjusting device forlimiting materials, the materials are prevented from dislocating during laminating; and by arranging the protective device for protecting the working personnel, the working personnel are prevented from being injured.

Owner:江苏壹度科技股份有限公司

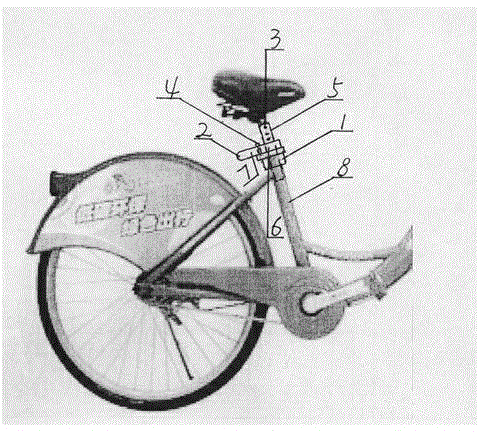

Locking device of bicycle seat tube

ActiveCN104787160ANovel structureSolve sliding and swinging left and rightCycle saddlesVehicle frameEngineering

The invention discloses a locking device of a bicycle seat tube. The locking device is composed of a base, calipers and tooth grooves; the base and a frame beam are connected into a whole; the calipers are arranged on the base, and a calipers shaft of the calipers is fixed on the base; a tooth protruding inward is arranged on each jaw of the calipers, the tooth grooves are formed in the two sides of the seat tube of a bicycle, and each tooth groove is matched with the corresponding tooth; when the calipers are in a closed state, each tooth of the calipers is capable of being connected with the corresponding tooth groove into a whole in a meshed mode, thereby the seat tube is locked and cannot slide downward or swing leftward or rightward; when the bicycle seat height needs to be adjusted, a calipers handle is pinched by a hand so that the teeth can leave the tooth grooves of the seat tube, the seat tube is drawn and inserted in the vertical direction, when the required height is reached, the calipers handle is loosened, the teeth are made to be meshed with the tooth grooves once again, and a bicycle seat can be located.

Owner:淄博优新新材料科技有限公司

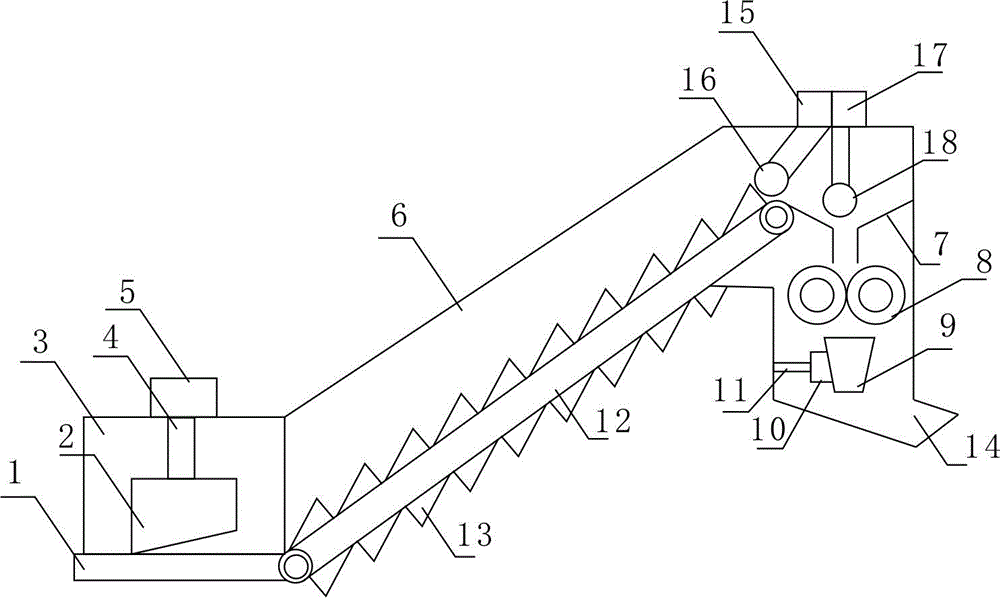

Automatic feeding device of preprocessing mixer

InactiveCN104353538APlay the role of transportationSolve the problem of slippageMixer accessoriesGrain treatmentsElectric machineryEngineering

The invention provides an automatic feeding device of a preprocessing mixer. The automatic feeding device comprises a primary processing device and a material conveying device communicated with the primary processing device, wherein the primary processing device is internally provided with an inclined plane press block; the inclined plane press block is connected with a press motor by a press rod; the material conveying device is internally provided with a material conveying track; the material conveying track is provided with a triangular material conveying block; the material conveying device is also internally provided with a guide plate; a grinding device used for grinding the material is arranged just under the guide plate; the upper end surface of the material conveying device is provided with a material brushing motor and a material pressing motor; the material brushing motor is connected with a guide brush circuit; the material pressing motor is connected with a guide press block circuit. According to the automatic feeding device of the preprocessing mixer, the problem that when the automatic feeding device of the existing mixer is used for feeding, the material is often stuck into pieces and is not easily mixed can be well solved.

Owner:SICHUAN XUHUA PHARMA

Translational control system and method of feeding arm of heating furnace

ActiveCN104090580BSolve the problem of slippagePosition/direction controlProportional controlAutomatic control

The invention relates to a translational control system and method of a feeding arm of a heating furnace. The system comprises an automatic control unit of the feeding arm, a manual control unit of the feeding arm, a maintenance unit for interrupting the position of the feeding arm; an automatic control unit of the feeding arm, a The output terminals of the manual control unit of the material arm and the interruption position holding unit of the material arm are connected to the input terminals of the speed and position control switching function block of the material arm respectively; the output terminals of the speed and position control switching function block of the material arm are connected to the addition and subtraction The speed control function block, the signal output by the acceleration and deceleration rate control function block is processed by the digital-to-analog conversion function block and then output to the power amplifier board of the proportional control valve of the feed arm translation hydraulic motor. The invention can effectively solve the problem that the feeding arm of the feeding machine of the large H-shaped steel heating furnace slides down and the billet slides down, and can also avoid the sliding down of the feeding arm of the heating furnace driven by the frequency conversion motor.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Method for calibrating the quality of the bonding surface of the hyperboloid variable thickness aluminum honeycomb and its calibrating tool

ActiveCN112793193BImprove the ability to resist instabilitySolve the problem of slippageDomestic articlesVariable thicknessAluminum honeycomb

The invention relates to a method and a tool for verifying the forming quality of the glued surface of a hyperboloid variable-thickness aluminum honeycomb. Lay a lower woven cloth on the outer contour surface of the board-core verification membrane, and lay an upper woven cloth on the trailing edge strip, the first rib, the second rib and the gluing area between the beam and the upper skin, along the outer contour of the upper woven cloth Lay the upper plate-core verification film on the surface, lay a skin on the upper plate-core verification film, vacuum-package the aluminum honeycomb structure as a whole and put it into an autoclave. After a period of high temperature and pressure, open the autoclave. Take out the honeycomb structure, disassemble the upper plate-core verification film and the lower plate-core verification film; observe the compression marks on the upper plate-core verification film and the lower plate-core verification film The degree of depth is used to verify the forming quality of the bonding surface of the aluminum honeycomb, to prevent the aluminum honeycomb from slipping and damaging the skin, and to improve the matching accuracy and the comprehensiveness of the calibration.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Locking device for snap ring bicycle seatpost

ActiveCN104760637BSolve the problem of slippageNovel structureCycle saddlesEngineeringMechanical engineering

The invention relates to a clamp ring type locking device of a bicycle seat tube. The clamp ring type locking device of the bicycle seat tube is composed of clamp rings, clamp grooves and bottom grooves. The clamp rings, the clamp grooves and the bottom grooves are matched with one another. Sections of the clamp grooves are formed at the sides of the bicycle seat tube symmetrically, and the clamp grooves are in a sunken inward shape. The elastic clamp rings are clamped to the clamp grooves. Handles and buttons are arranged on the clamp rings, pinching the buttons by a hand can enable the clamp rings to open outward and leave the clamp grooves, the bottom grooves are formed in the upper ends, corresponding to a bicycle tube, of the clamp rings, the clamp grooves entering the clamp grooves can exactly fall into the bottom grooves, and thereby the purpose of fixing the seat tube is achieved.

Owner:山东誉滕医疗器械有限公司

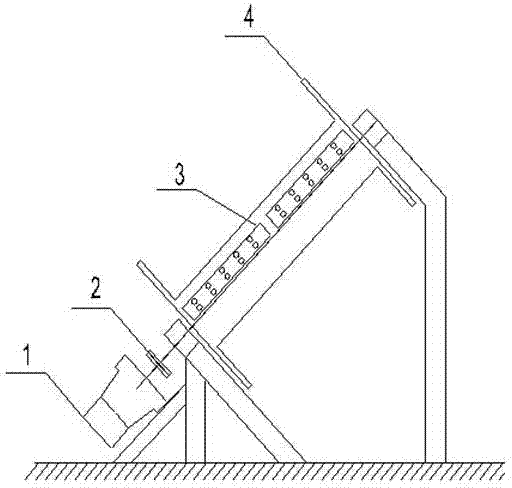

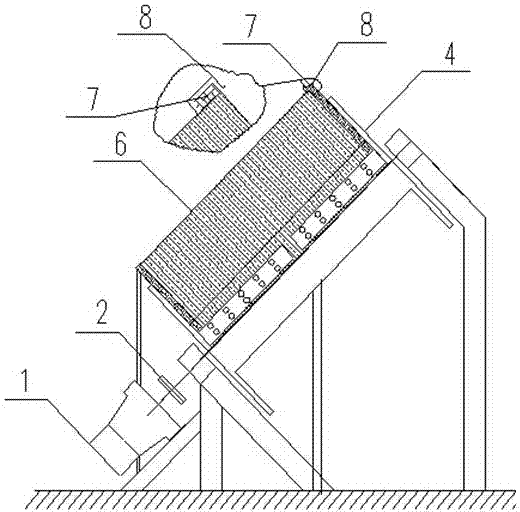

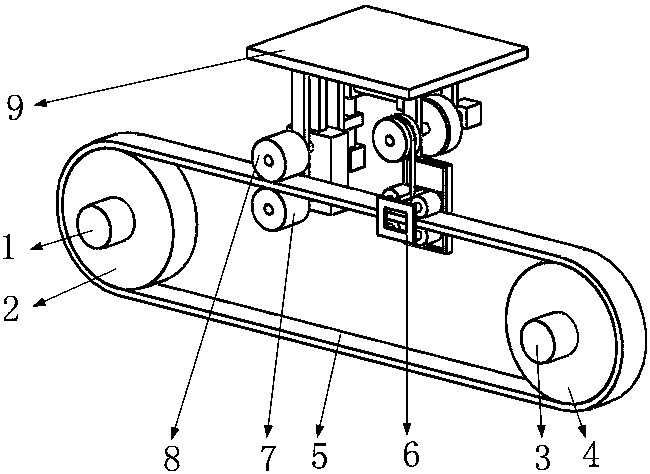

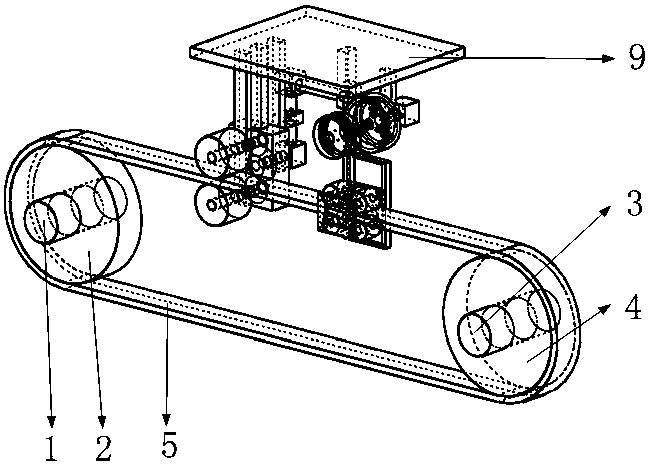

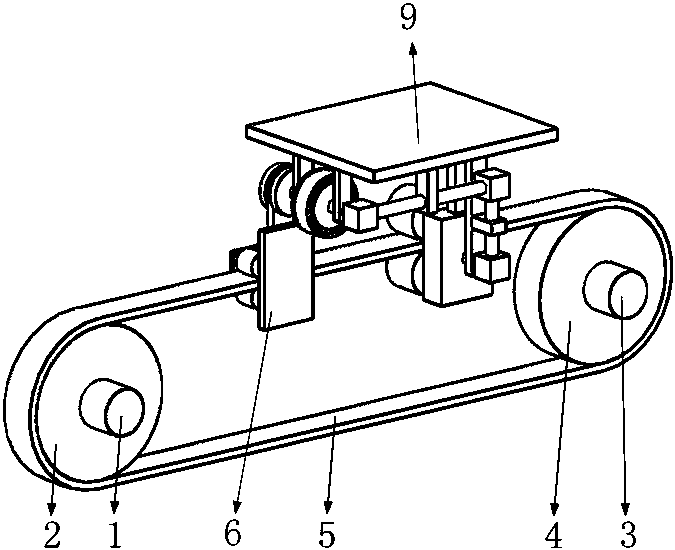

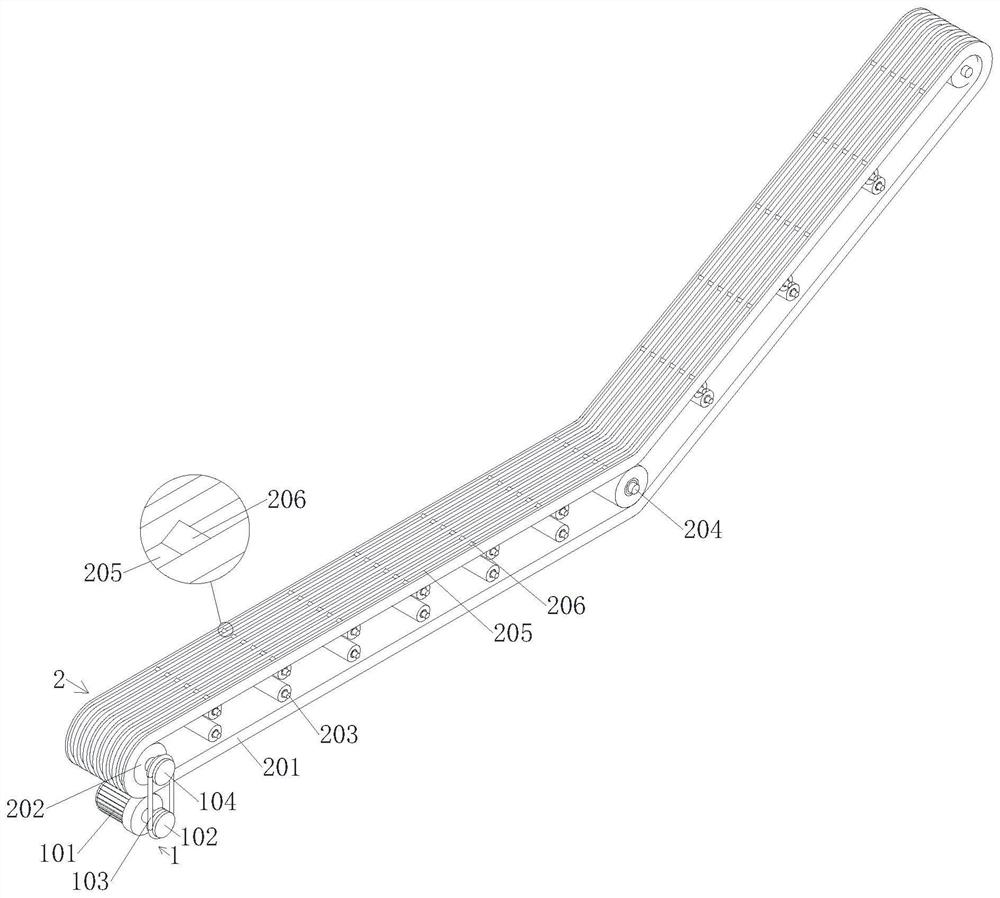

Automatic upward feeding and conveying device for aluminum profile machining

InactiveCN113682728ASolve the problem of slippagePrevent slippingConveyorsEngineeringStructural engineering

The invention discloses an automatic upward feeding and conveying device for aluminum profile machining, and relates to the technical field of aluminum profile machining. The automatic upward feeding and conveying device comprises a power mechanism, a conveying belt and a fixing frame, wherein the power mechanism is fixedly connected to the lower portion of the inner side of the fixing frame, the upper portion of the inner side of the fixing frame is movably connected with the conveying belt, the conveying belt comprises a crawler belt, a pipe groove and a clamping edge, the pipe groove is formed in the upper portion of the crawler belt, and the clamping edge is fixedly connected into the pipe groove. According to the automatic upward feeding and conveying device, through the power mechanism, the conveying belt and the fixing frame, the problems that an existing upward feeding and conveying device slides downwards and upward feeding separation is caused are solved.

Owner:佛山市迈德维尔智能科技有限公司

Wear-resisting type health care pillow cover

InactiveCN108577408AEasy to placeSolve the problem of not being convenient enough to useBlanketBed linenEngineering

Owner:广西福婵丝织科技有限公司

Guide rail device and method for omnidirectional directional blasting charge

The invention discloses an all-dimensional oriented blasting charge guide rail device and a method thereof, and belongs to oriented blasting charge devices and methods. A first guide rail is connected with a plurality of common guide rails to form the device, antiskid wires (2) are mounted at the end (1) of the first guide rail, a longitudinal ridge (4) is arranged in the middle of a cartridge push rail (3) of the guide rail, cartridge antiskid saw teeth (5) are distributed on the longitudinal ridge (4), a hook hole (8) is formed in a front guide rail tail end (6), a metal hook (9) is arranged at a rear guide rail head end (7), the guide rails are connected through the metal hook (9) and the hook hole (8), the oriented blasting charge method is used for oriented blasting charge of middle and deep holes of forced grooving top-caving in the coal mining process, and the device is simple in integral structure and convenient to operate by the aid of traditional charge technology. The mounting directions of a cartridge energy-concentrated cover and the like is as same as the breaking direction of rocks, and accurate oriented control fracture blasting is realized.

Owner:CHINA UNIV OF MINING & TECH

A metal material straightening machine

ActiveCN106694627BEasy spacing adjustmentSolve the problem of inconvenient distance adjustmentDrive shaftGear wheel

The invention provides a metal material straightening machine, comprising a screw rod, a threaded hole connection block, a belt I, a motor I, a connecting shaft, a bevel gear I, a bevel gear II, a rotating shaft, a gear shaft, a locating hole and a locating pin, wherein the screw rod is connected to the motor I through the belt I, and the threaded hole connection block is connected to the screw rod. The distance between left and right rollers in the invention is adjusted easily through this design, and the problem of uneasy adjustment of the distance between the left and right rollers is solved. The lower end of the connecting shaft is connected to the threaded hole connection block through a bearing II, and the upper end of the connecting shaft is connected to the bevel gear I fit to the bevel gear II installed on the gear shaft; the gear shaft is installed on the left end of a drive shaft through the locating hole and the locating pin. Straightening metal materials in different sizes is achieved through this design, and the disadvantage of narrow application scope of the straightening machine is overcome. The metal material straightening machine provided by the invention has the advantages of simple structure, wide application scope, easy operation and high reliability.

Owner:苏州科弗曼机械有限公司

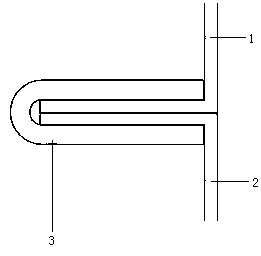

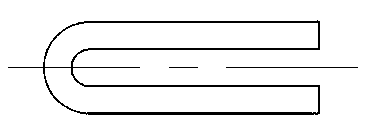

Novel refrigerator side panel splicing structure

InactiveCN103776227AReduce the numberLow costDomestic cooling apparatusLighting and heating apparatusEngineeringFace sheet

The invention provides a novel refrigerator side panel splicing structure, which is characterized in that the side panel splicing structure comprises a side panel and a rolled edge on one end, which is spliced with a front panel, of the side panel, the rolled edge is pocket-shaped and is provided with a pocket mouth and a U-shaped pocket bottom, and the pocket mouth is outwards turned cover to facilitate the insertion of the folded edge of the front panel. By using the splicing structure and abandoning a connecting insertion strip between the front panel and the side panel, the cost is reduced; when the front panel and the side panel are fixedly connected, the operation is facilitated and is simple and easy to learn, and the problem that the side panel slides downwards is solved.

Owner:JIANGSU STAR COLD CHAIN TECH CO LTD

Special tool for frame column positioning

PendingCN112031409ASolve the problem of prone to steel bar slippageSolve the problem of slippageForms/shuttering/falseworksIndustrial engineeringSmall hole

The invention discloses a special tool for frame column positioning, and relates to the technical field of building construction. The special tool comprises a first base plate and a second base plate,a first small hole and a second small hole are formed in one side of the first base plate and one side of the second base plate respectively, a first fixing plate is arranged at the top end of the first base plate, a third small hole is formed in one side of the first fixing plate, a first clamping groove and a first fixing hole are formed in the other side of the first fixing plate, a first buckle is fixedly connected with one side of the first fixing hole, a first top plate is arranged at the bottom end of the first base plate, a fourth small hole is formed in one side of the first top plate, and a first top groove is formed in the other side of the first top plate. According to the special tool for frame column positioning, the small holes can be connected and assembled before use, andthe position can be moved by opening the first fixing hole, the second fixing hole, the third fixing hole and the buckles when the position is changed, so that the problem of complex operation when the position is changed is solved.

Owner:CHINA CONSTR SCI & TECH CO LTD

A hydraulic automatic decoupling device

InactiveCN105174022BSolve the problem of slippageReduce work stressLoad-engaging elementsSoil preservationWorking pressureEngineering

The invention discloses an automatic hydraulic unhooking device. The automatic hydraulic unhooking device comprises an oil cylinder, an automatic hooking device and a hydraulic system for controlling the pressure of a rod cavity of the oil cylinder, wherein the automatic hooking device is fixed at the end part of a piston rod of the oil cylinder; the automatic hydraulic unhooking device is also provided with mechanical locks, and the mechanical locks are mounted on an outer cylinder wall of the oil cylinder in pairs; an unlocking rope is arranged on the mechanical locks; an unhooking rope is mounted between the automatic hooking device and the mechanical locks; one end of the unhooking rope is connected with the automatic hooking device, and the other end of the unhooking rope is connected with the mechanical locks. According to the automatic hydraulic unhooking device disclosed by the invention, a hammer is lifted by the mechanical locks, and the hydraulic bearing of a high-speed oil cylinder is replaced by the rigid bearing of a mechanical-lock structure, so that the problem that when the heavy load of the high-speed oil cylinder is lifted, a piston rod slides off is solved; the working pressure in the high-speed oil cylinder is low, and the sealing, manufacturing and maintenance cost is low; the piston rod of the high-speed oil cylinder is unlocked by the mechanical locks through the traction of the unlocking rope, so that the automatic hydraulic unhooking device is simple and convenient to operate, high in reliability, and suitable for impact machinery to perform unhooking operation.

Owner:CHANGSHA JIABAI PRECISION MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com