Transmission mechanism used for high-speed belt

A technology of transmission mechanism and belt, applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., can solve the problems of reduced friction between belt and driving wheel, inability of belt transmission mechanism to achieve high-speed transmission, belt slippage, etc. The structure is simple and compact, the belt slip phenomenon is solved, and the practical effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

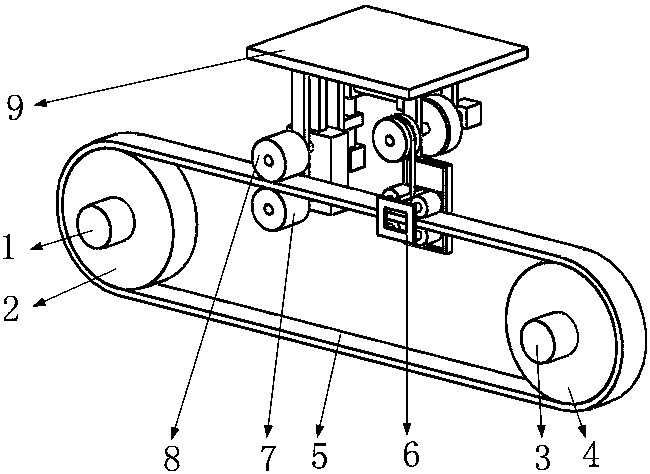

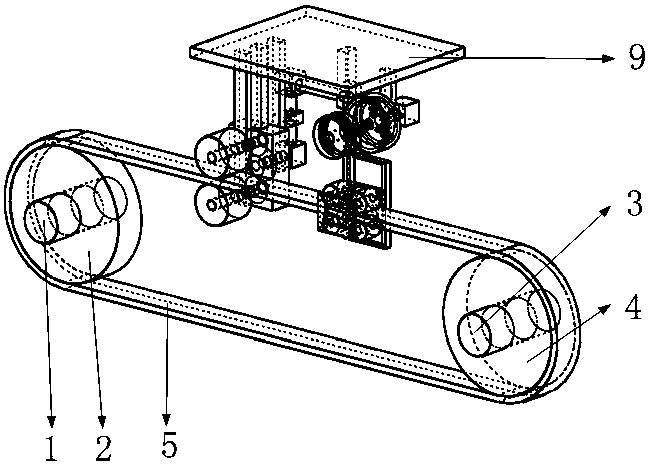

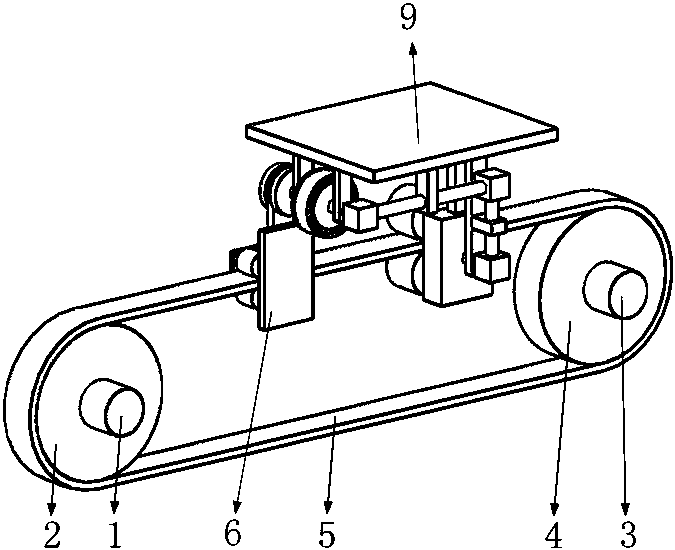

[0040] Specific implementation methods: such as figure 1 Shown, the effect that upper pulley 8 and lower pulley 7 cooperate with belt 5 among the present invention is: on the one hand, when belt 5 low-speed transmission, the rotating speed of upper pulley 8 and lower pulley 7 is identical; Belt 5 is stretched during transmission, and the rotating speed of upper pulley 8 is less than the rotating speed of lower pulley 7. Such as Figure 4 As shown, the function of the differential 13 is to adjust the output of the second output shaft 16 according to the rotation speeds of the upper pulley 8 and the lower pulley 7 . Such as Figure 5 As shown, the function of the first bevel tooth combination 21 , the second bevel tooth combination 22 and the third bevel tooth combination 23 is to transmit the output of the second output shaft 16 to the centrifugal wheel 28 . Such as Figure 7 As shown, three centrifugal blocks 29 are installed on the centrifugal wheel 28 and the effect that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com