Construction method for controlling sliding of slope section of underground pipeline

A technology of underground pipe gallery and construction method, which is applied in excavation, infrastructure engineering, construction, etc., can solve the problems of pipe gallery sliding, achieve the effects of accelerating construction progress, ensuring construction quality, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further illustrated below by specific examples.

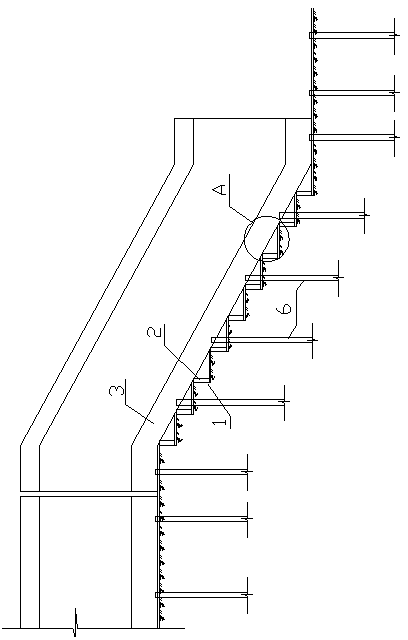

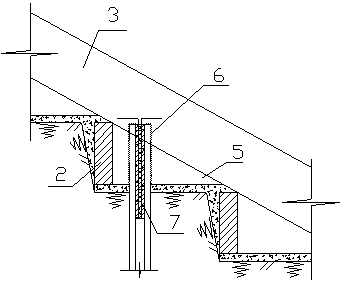

[0020] Such as figure 1 , figure 2 As shown, a construction method for underground pipe gallery to control slope section slippage, which includes the construction stage of the pipe gallery foundation pit enclosure structure at the beginning of the project, and the construction stage of the pipe gallery foundation pit side wall and roof structure at the end of the project; After the construction stage of the enclosure structure of the pipe gallery foundation pit, the internal construction stage of the pipe gallery foundation pit before the construction stage of the side wall and roof structure of the pipe gallery foundation pit, the internal construction stage of the pipe gallery foundation pit includes:

[0021] Step 1. Excavation of foundation pit earthwork and construction of supporting structures,

[0022] Step 2, foundation pit support system erection;

[0023] Step 3, excavating the eart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com