Large inclination belt conveyor

A belt conveyor, large inclination technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high cost and high energy consumption, and achieve the effect of solving material sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

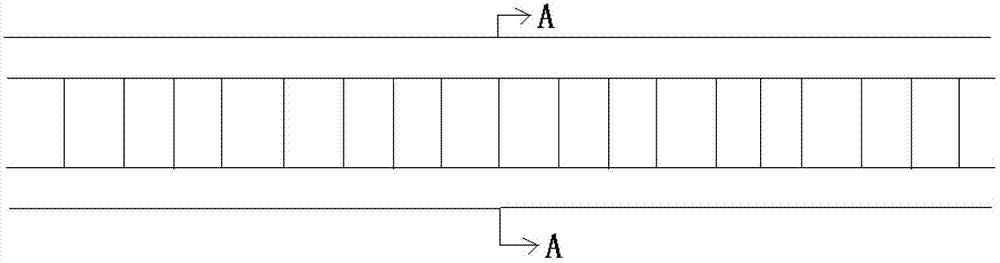

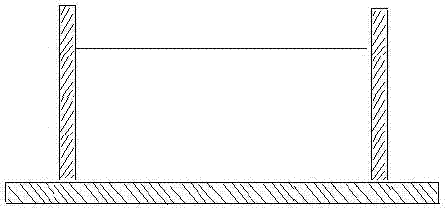

[0016] A belt conveyor with a large inclination angle, including a bracket, a motor roller 1, a discharge funnel, a tail wheel 3, idler rollers, a conveyor belt, and a redirection device; the bracket is divided into five parts, and the head frame from top to bottom 2. Intermediate support 6, concave arc section support 12, tail intermediate support 5 and tail frame 11; the discharge funnel and electric drum are fixed on the head frame 2; the conveyor belt is a sidewall belt and is also provided with a transverse partition Vertically connect the rib and the bottom surface of the conveyor belt; the redirection device includes a pinch pulley 13 and a redirection roller 14, which are all fixed on the concave arc section bracket 12, and the pinch pulley 13 is placed above the redirection roller 14.

[0017] The beating cleaner 9 is fixed on the head frame 2, and the conveyor belt bypasses the beating cleaner 9; 9, the protrusions vibrate the conveyor belt.

[0018] The empty secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com