Double-drive type hoisting permanent magnet

A permanent magnet and magnetic pole technology, applied in the field of hoisting equipment, can solve the problems of sliding of the hoisting permanent magnet, no anti-reverse device, and high damage rate, and achieve the effects of cost saving, convenient maintenance and reduction of manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

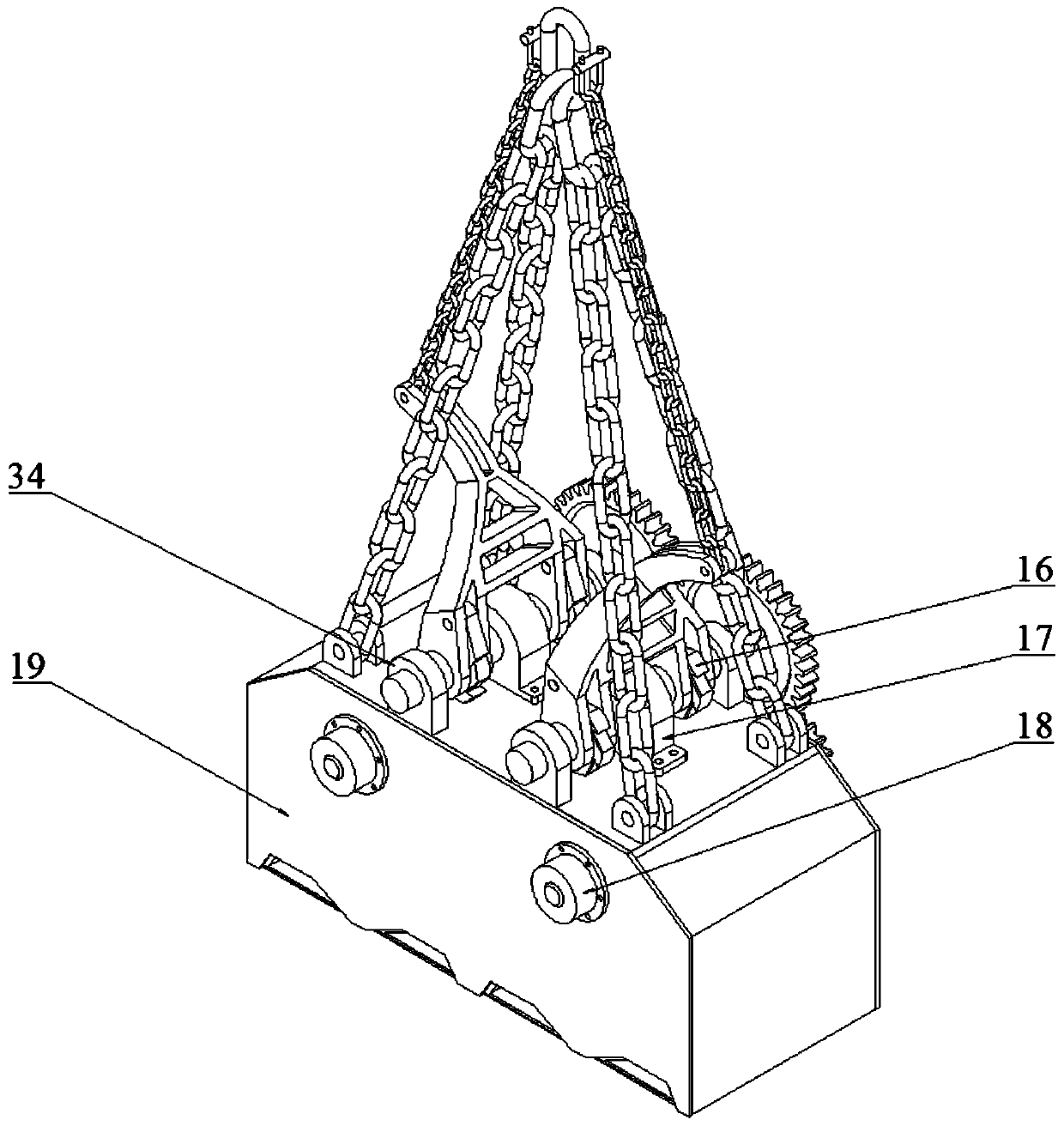

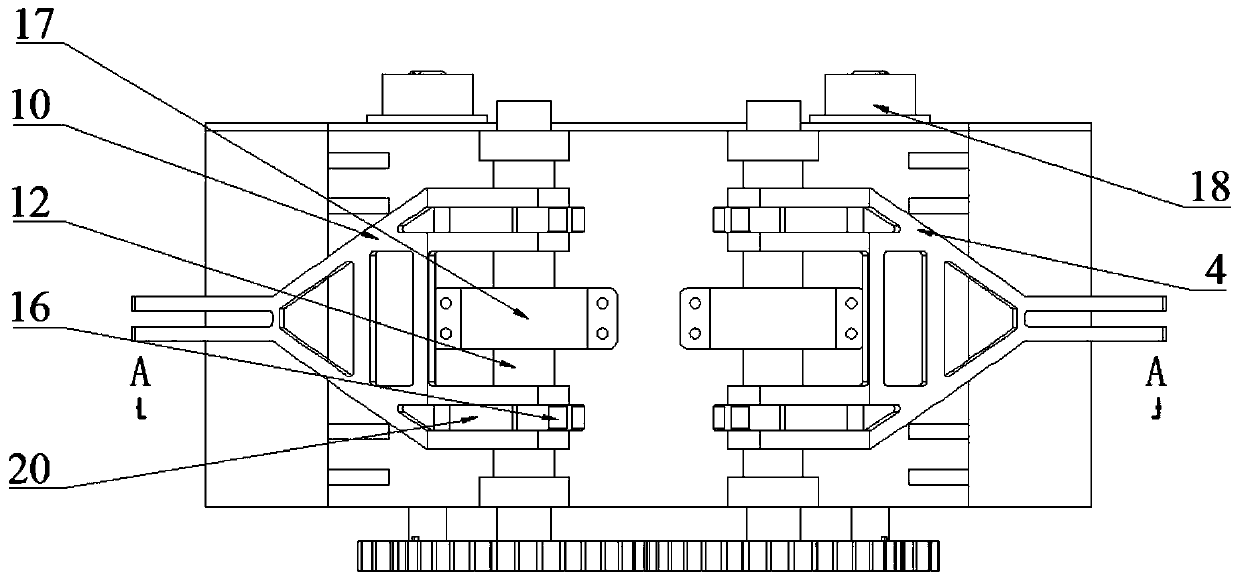

[0028] see figure 1 , 2 , 3, 4, the lifting ring 1 is used to connect with the hook of the crane or the crane; there are four lifting chains 2, one end of which is connected with the lifting ring 1, and the other end is respectively connected with the lifting lug 6 through a pin shaft, The lifting lugs 6 are fixedly connected with the upper casing 35 respectively, one end of the left small lifting chain 9 is connected with the lifting ring 1, and the other end is connected with the left swing bar 10 through a pin shaft; one end of the right small lifting chain 3 is connected with the lifting ring 1 connection, the other end is connected with the right swing rod 4 through a pin shaft, the left swing rod 10 and the right swing rod 4 have the same structure, and are respectively composed of two identical fork-shaped arms, which are respectively sleeved on two driving shafts 12 , the drive shaft 12 is installed on the bearing seat 34 of the upper housing 35; the drive pawl 20 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com