Translational control system and method of feeding arm of heating furnace

A technology of control system and feeding arm, applied in control/adjustment system, non-electric variable control, position/direction control, etc., can solve problems such as jamming, billet slipping, sliding edge falling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

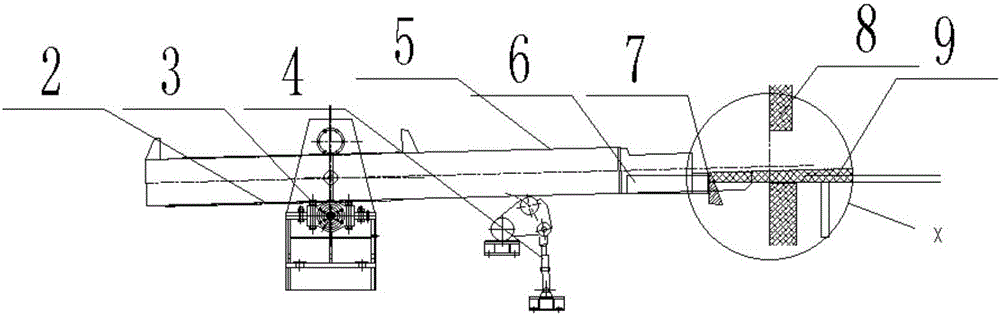

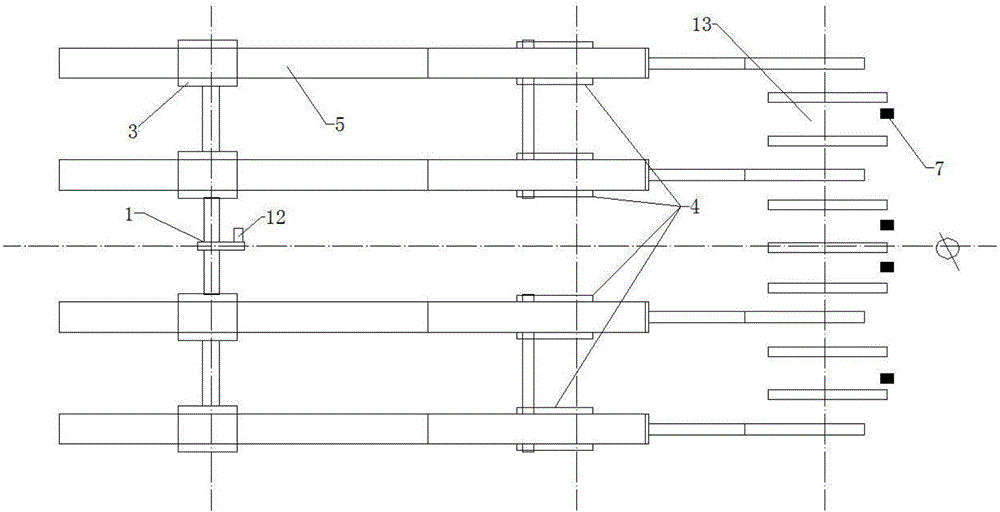

[0019] Below, referring to the accompanying drawings, through the description of the embodiments, the specific implementation of the present invention, such as the control system involved, the mutual connection relationship, and the implementation method, are further described in detail, so as to help those skilled in the art understand the present invention Have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions.

[0020]For the translation control of the existing hydraulic motor-driven heating furnace feed arm, when the feed arm moves in automatic or manual mode, once for some reason (such as the loss of high and low signals in the automatic mode of the feed arm or manual mode) The lower operation interruption, etc.) will interrupt the movement of the feed arm, and the existing hydraulic motor-driven heating furnace feed arm translation control system will make the hydraulic motor proportional control valve in the neutral se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com