Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

92results about How to "Scrape off in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extrusion filter

ActiveCN103072251AOutstanding and Beneficial Technical EffectsIncrease productivityEngineeringHeating temperature

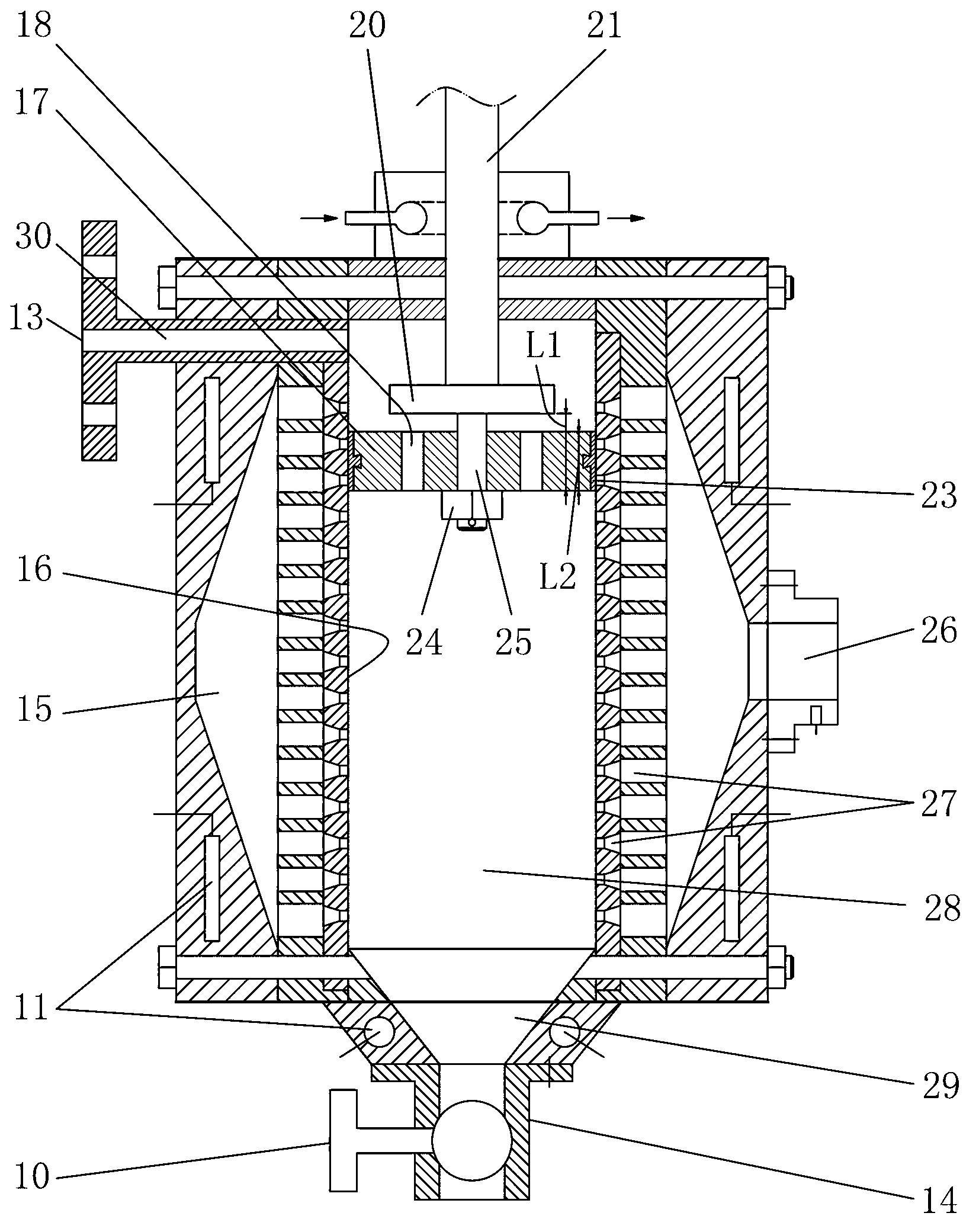

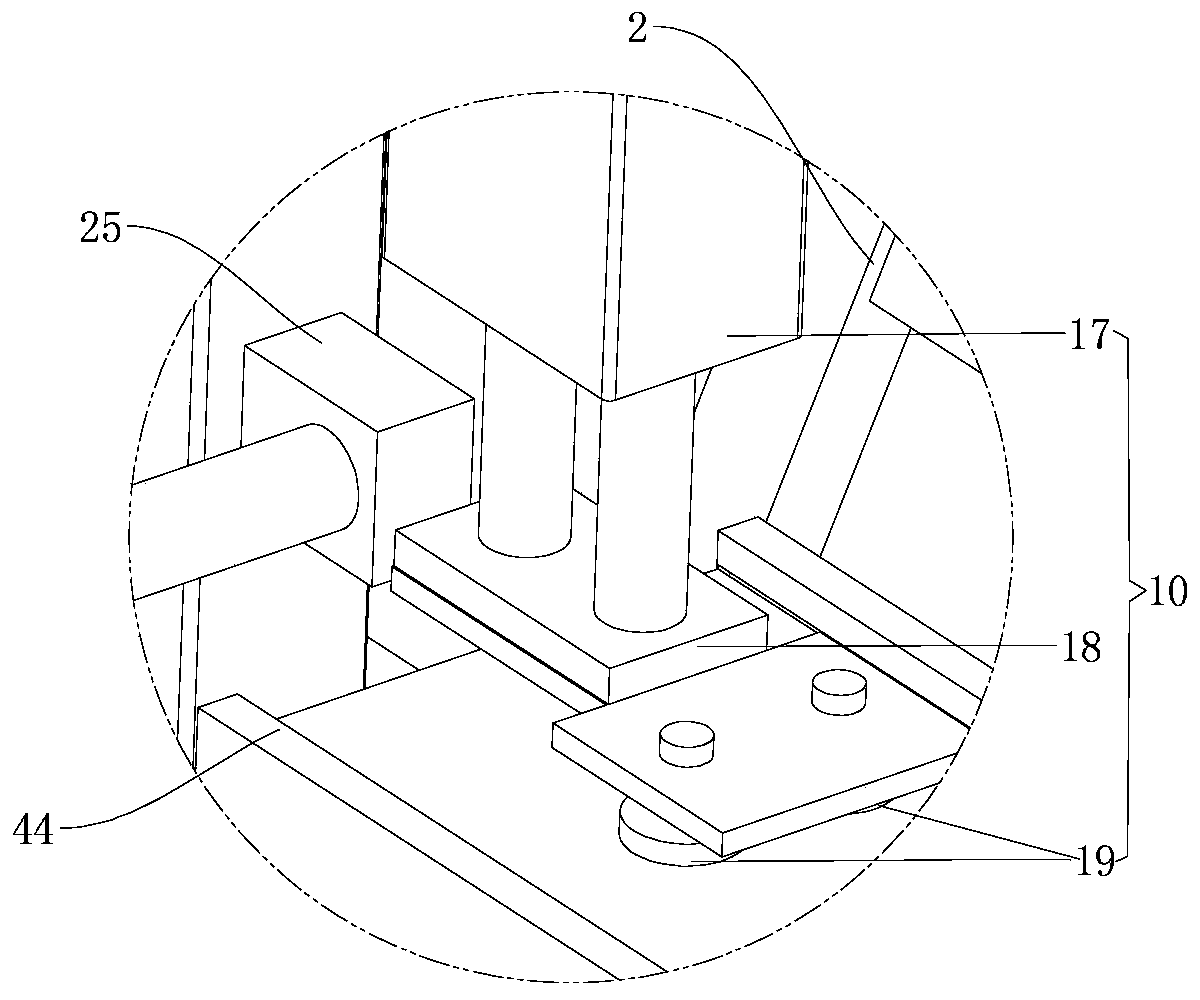

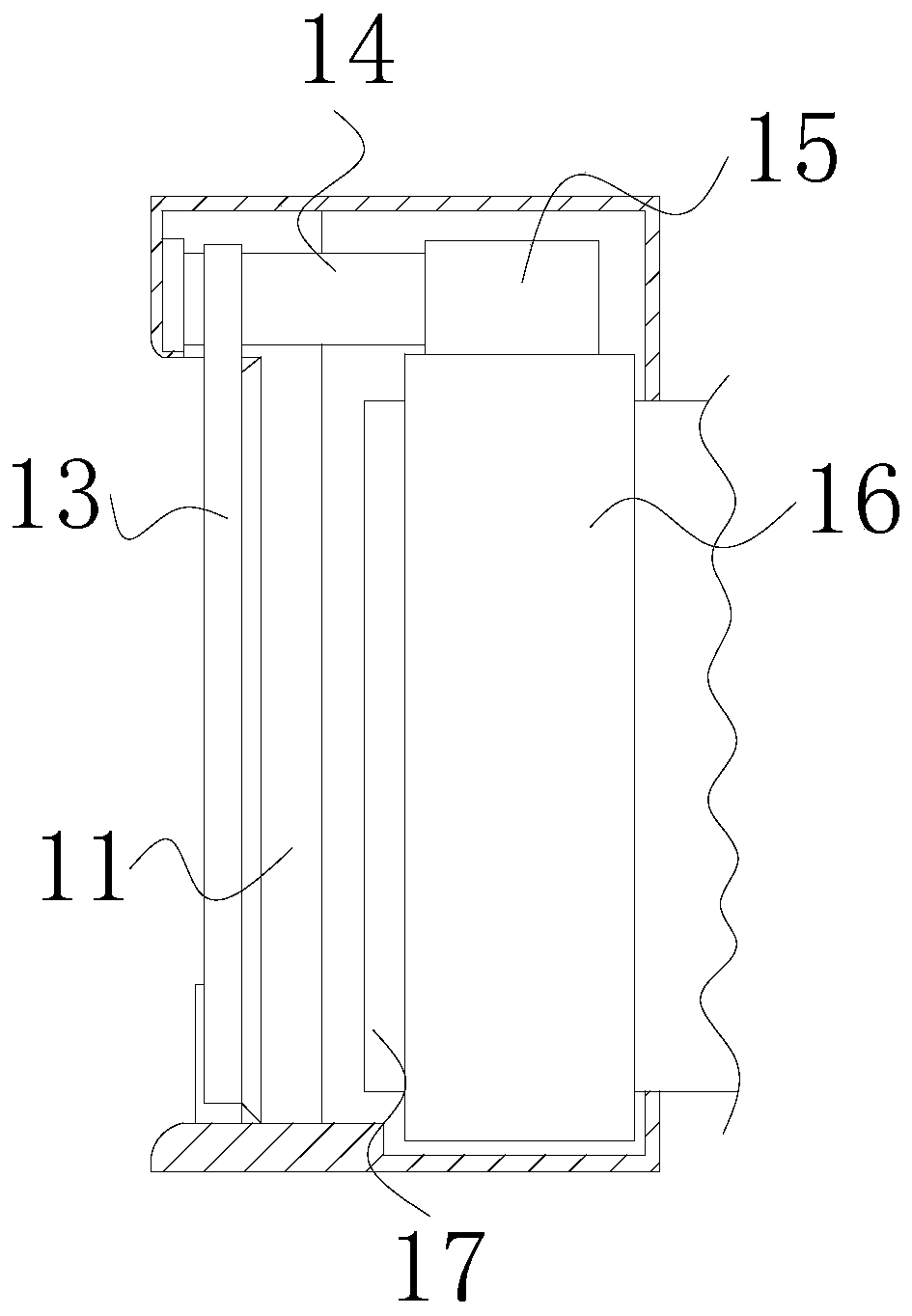

The invention belongs to the technical field of plastic granulation and relates to an extrusion filter. The extrusion filter comprises a casing, a feeding connector arranged on the casing, a heating temperature control device and a material extrusion device; a discharging port of the material extrusion device is connected with an impurity filter with a filter screen; an impurity scraping and discharging device for scraping impurities on the filter screen into an impurity storage cavity and discharging the impurities to the outside of the impurity filter is arranged in an inner cavity of the impurity filter; the filter screen formed by a plurality of radially-arranged filtering holes is arranged on the side wall of the inner cavity of the impurity filter; and a discharging connector communicated with a discharging cavity at the outer side of the filter screen is arranged on the outer wall of the impurity filter. The extrusion filter has the benefits that the impurities generated in the granulation and the production of the extrusion filter can be cleared without machine halt; and the extrusion filter has the advantages of easiness in structure manufacture, high strength, uneasiness in blockage, long service life, high production efficiency and low production cost and is suitable for the granulation of waste plastics.

Owner:陈艳

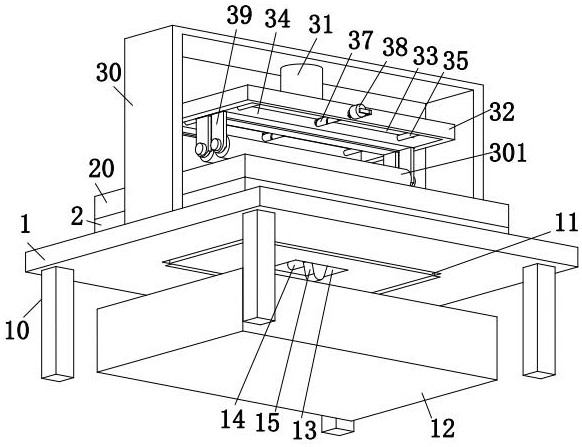

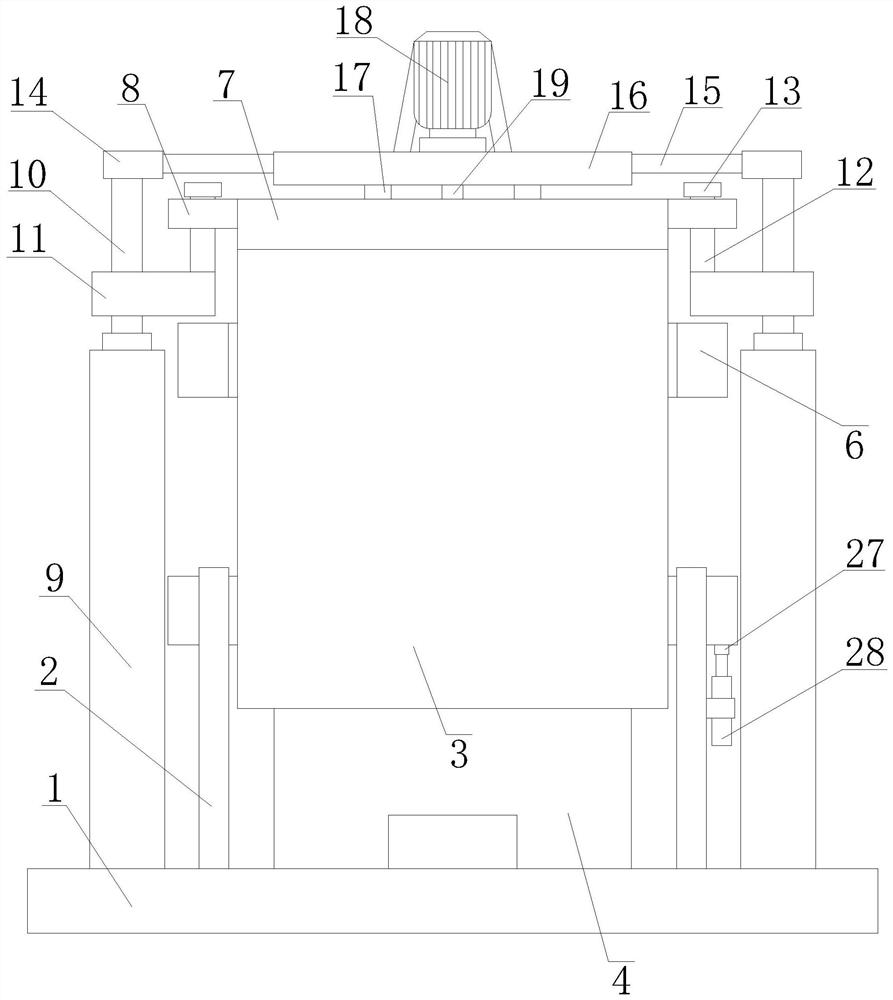

Tile stacking and laying device for building construction

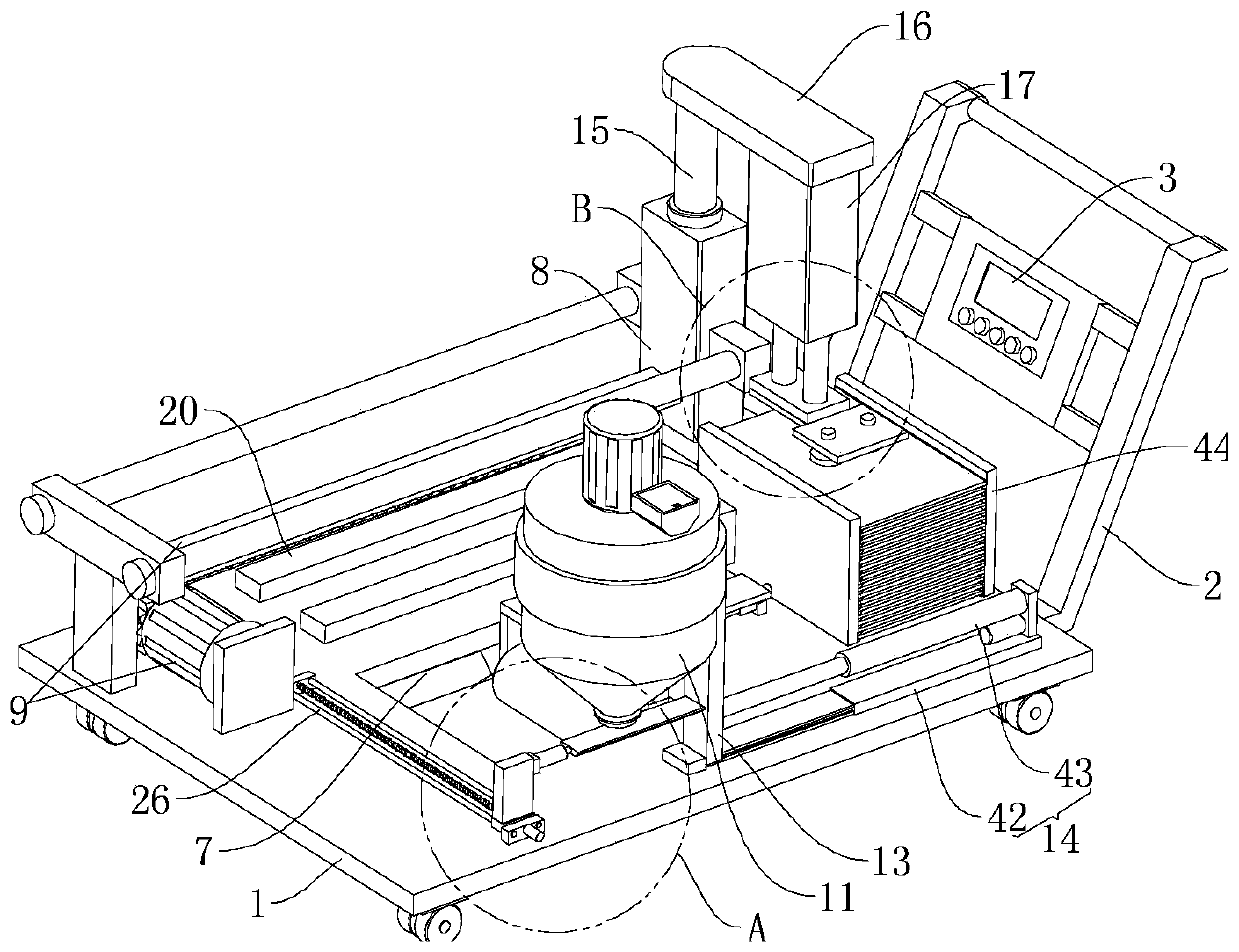

The invention relates to the technical field of engineering construction, in particular to a tile stacking and laying device for building construction. The tile stacking and laying device for the building construction comprises a flat plate trolley and a laying mechanism, the laying mechanism comprises a material receiving assembly, a flattening assembly and a leveling assembly, and a transfer mechanism and a paste feeding mechanism are further included. The transfer mechanism comprises a sliding rod, a driving assembly and an adsorption assembly, the paste feeding mechanism comprises a stirring kettle and a stirring assembly, and a push assembly is arranged at the top of the flat plate trolley. The push assembly, the material receiving assembly, the flattening assembly, the leveling assembly, the driving assembly, the adsorption assembly and the stirring assembly are all electrically connected with a control panel. According to the tile stacking and laying device for the building construction, the manual tile fixing is replaced with an automatic mode, the speed of fixing tiles is sped up, the working efficiency is improved, the labor intensity is reduced, and the fixing work of the tiles can be completed only by pushing the flat plate trolley by one person; and getting cement slurry many times in a short period of time is not required, the time of tile fixing is shortened, thelabor force is reduced, and the cost of tile fixing is reduced.

Owner:云和县凯毅德电子设备厂

Lining band type filter press with press rolls for fixing mud

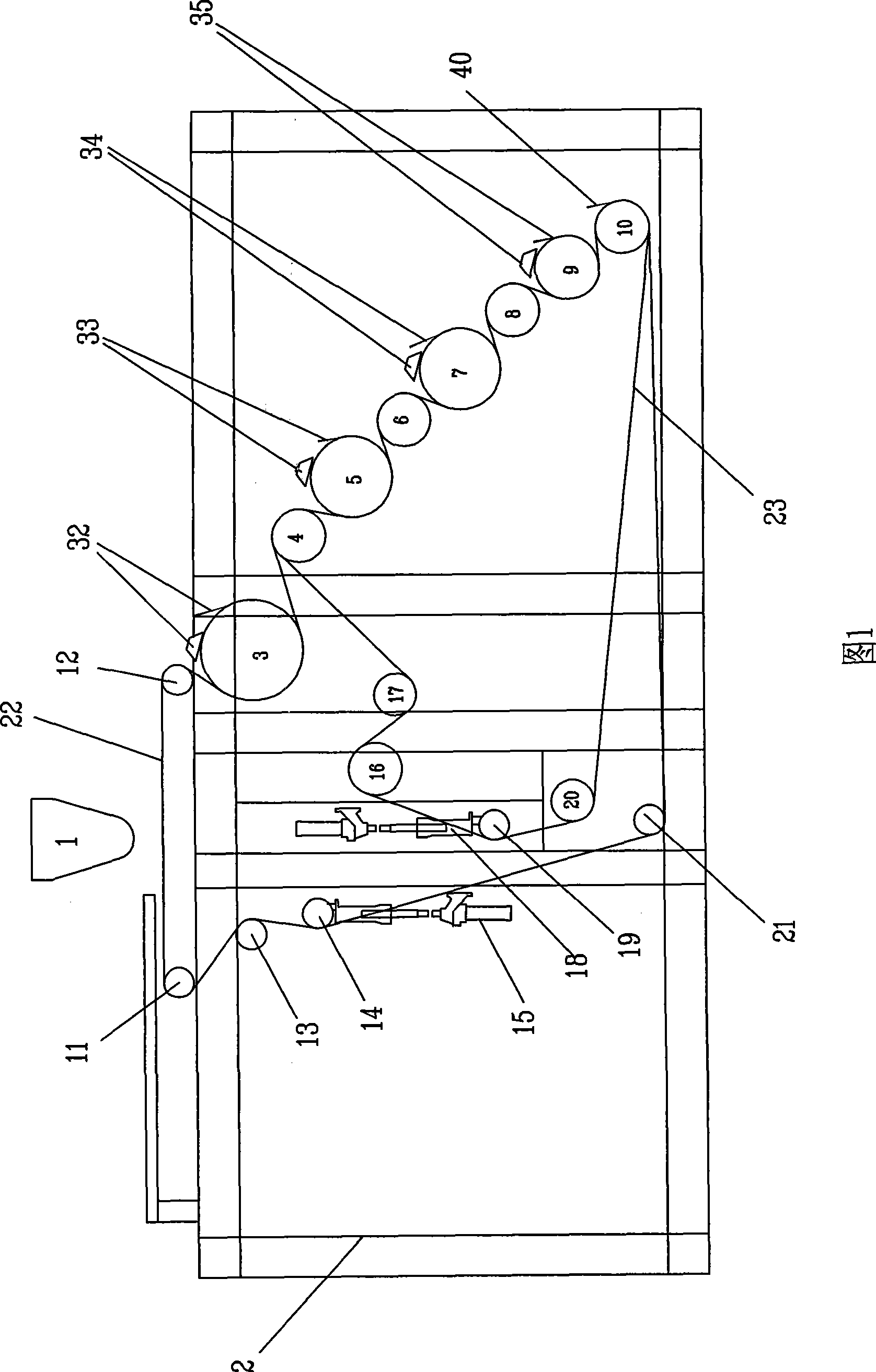

InactiveCN101376073ARestore elasticityImprove working conditionsPressesMoving filtering element filtersPulp and paper industryFilter press

The invention discloses a lining belt type pressure filter with a solid mud press roller. The press filter comprises a stander, a driving device, a feeding device, a press area and an auxiliary device, and has the structure that the press area comprises the solid mud press roll, a carrier roller, a guide roller, a filtering stripe and a compression lining belt; the solid mud press roller is a press roller with a solid mud layer covering the surface of the roller, and the solid mud layer adopts the material which has high elasticity, high recoverability, and high fraction coefficient, and is easy to separate from dehydrate material; the solid mud press roller is provided with a maintenance device, which is arranged behind the press position of the solid mud press roller, and the elasticity and the fraction coefficient of the solid mud layer can be recovered in time through the maintenance to the solid mud press roller by the maintenance device; the filtering stripe wraps the solid mud press roller, the carrier roller and the guide roller in sequence; the compression lining belt and the filtering stripe are stacked in parallel in the press segment of the press area; the driving device drives filtering stripe and the compression lining belt; and the feeding device and the auxiliary device are arranged in the corresponding positions of the filtering stripe. The pressure filter of the invention has solid mud structure, thereby effectively solving the problem of mud leaking and achieving better press filter effect.

Owner:ZHEJIANG HUAZHANG TECH

Squeezing type dewatering machine

The invention discloses a squeezing type dewatering machine, which comprises a frame. A filter cylinder with filtering holes is fixed onto the frame, a conical screw rod with a helical blade is mounted in the filter cylinder, the filter cylinder comprises a primary filter cylinder body and a secondary filter cylinder body which are connected with each other, the primary filter cylinder body is provided with a feeding port, the secondary filter cylinder body is conically contracted along the pushing direction, and a squeezing cylinder is connected to the tail end of the secondary filter body. The conical screw rod penetrates through the primary filter cylinder, the secondary filter cylinder and the squeezing cylinder, a discharging device is arranged at the tail end of the squeezing cylinder, and the conical screw rod is driven by a power device. Materials can be dewatered for three times by means of the squeezing type dewatering machine, and since the conical screw rod is conical and the secondary filter cylinder body is conically contracted along the pushing direction, the space between the conical screw rod and the secondary filter cylinder body is small, and materials can be better dewatered. The squeezing type dewatering machine is low in required centrifugal rotation speed, high in dewatering capacity, low in noise pollution and environment-friendly.

Owner:JIANGSU FANGSHENG MACHINERY

Gradation roller coating device of aluminum plate

PendingCN107321568ARoller evenlyIncrease productivityLiquid surface applicatorsCoatingsSurface coverBellows

The invention provides a gradation roller coating device of an aluminum plate. The gradation roller coating device comprises a material conveying conveyer belt device, a primary roller coating device, a first drying air box, a secondary roller coating device, a second drying air box and a material discharging conveyer belt device, wherein the output end of the material conveying conveyer belt device is provided with the primary roller coating device; a material charging coating roller mechanism, a transition coating roller mechanism, a roller coating roller mechanism and a scraper device are arranged in the primary roller coating device; the first drying air box is arranged between the primary roller coating device and the second roller coating device; an air blower is arranged below the first drying air box; a plurality of heating pipes are arranged above the first drying air box; a second drying air box is arranged between the secondary roller coating device and the material discharging conveying device; material feeding is realized for the roller coating roller mechanism through the transition coating roller mechanism, so that paint with uniform thickness can be smeared on the surface of the roller coating roller; roller coating is performed in a grading manner using the two roller coating devices; besides, drying is separately performed after roller coating; uniform roller coating of the aluminum plate is ensured; and production efficiency is improved.

Owner:嘉兴亿豪新材料股份有限公司

Composite fireproof glass processing device

ActiveCN111300955ACreamySpray evenlyLamination ancillary operationsControlling laminationGlass slideSupport plane

The invention relates to a fireproof material, in particular to a composite fireproof glass processing device. To technical problems in the prior art, the invention provides the composite fireproof glass processing device. The composite fireproof glass processing device comprises a supporting frame, a control screen, a motor, a fireproof glue spraying mechanism, a double-layer pressing mechanism,an edge glue spreading mechanism and a storage cabin, wherein a control screen is arranged at the top of the right end of the supporting frame; and a motor is arranged on the left of the top of the supporting frame. According to the invention, double-layer glass is pushed and pressed from the middle to two sides, so the phenomenon that different thicknesses of fireproof glue in different areas caused by pressing of a part of areas affect fireproof quality and glass flatness is avoided; meanwhile, overflowing fireproof glue at edges is removed in time, so the situation that the overflowing fireproof glue is adhered to the surface of fireproof glass and is difficult to remove after being solidified is avoided; the situation that the glass slides down during carrying due to the fact that theglass is more smooth is prevented; and the edges of the double layers of the glass are aligned, so the two-layer glass is prevented from deviating during pressing.

Owner:浙江四季乐新能源股份有限公司

Film pasting machine for rock wool boards

InactiveCN106003994AImprove efficiency and qualityScrape off in timeLaminationLamination apparatusWoolEngineering

A film laminating machine for rock wool boards according to the present invention comprises a frame, the front end of the frame is provided with an active conveying roller, the rear of the active conveying roller is driven and connected with a parallel driven laminating roller, and the upper part of the driven laminating roller is provided with a feeding roller. Film roller, there is a rubber coating cylinder between the driven film roller and the film supply roller; behind the driven film roller, there are two transmission rollers located above the rock wool board transmission channel, and there are metal rollers between the two transmission rollers. The crawler track, the inner side of the metal crawler track is provided with a heating device and a cooling device, and the heating device is located in front of the cooling device. The beneficial effects of the present invention are: the present invention can not only evenly apply glue to the aluminum foil, but also carry out the hot pressing and cooling process, and can also scrape off the overflowing glue in time, thereby greatly improving the efficiency and quality of the film sticking.

Owner:SHANDONG SUNLIGHT ROCK WOOL TECH CO LTD

Spraying device for sofa wooden plates

ActiveCN108080191AExtended service lifeScrape off in timeLiquid spraying apparatusAdhesiveEngineering

A spraying device for sofa wooden plates comprises a tank body, the upper end of a screw is fixedly connected to the top of the inner wall of the tank body, the screw and a center line of the top of the inner wall of the tank body are collinear, two sides of the screw are provided with slide channels, a sliding sleeve is movably mounted on the screw, the top and bottom of the sliding sleeve are both opened, sliding strips are fixedly mounted on the two sides of the inner wall of the sliding sleeve, the sliding strips are positioned in the corresponding slide channel and can slide along the same, a motor is fixedly mounted on one side of the sliding sleeve, a gear is fixedly mounted on an output shaft of the motor, a screw sleeve is threadedly mounted on the screw, and the screw sleeve is in threaded fit with the screw. After the motor stops operating, a scraper plate never contacts the inner wall of the tank body under the action of a torsion spring, so that adhesion of the scraper plate to the inner wall of the tank body due to long-term idling is avoided; the screw sleeve rotates to drive a rotary shaft to synchronously rotate with the screw sleeve, the rotary shaft can stir adhesive in the tank body through a support rod and a corresponding floater, clotting of the adhesive can be avoided, the adhesive can be sprayed out evenly, and the adhesive can be stored for longer time.

Owner:新乡市大班家具实业有限公司

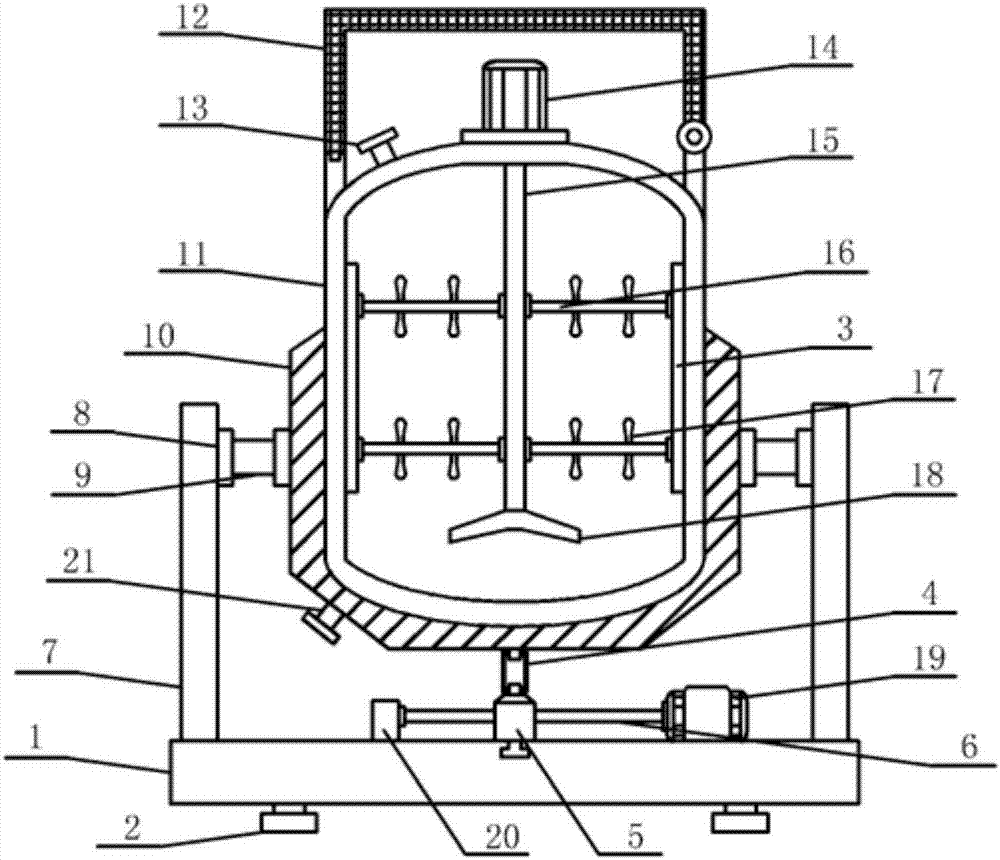

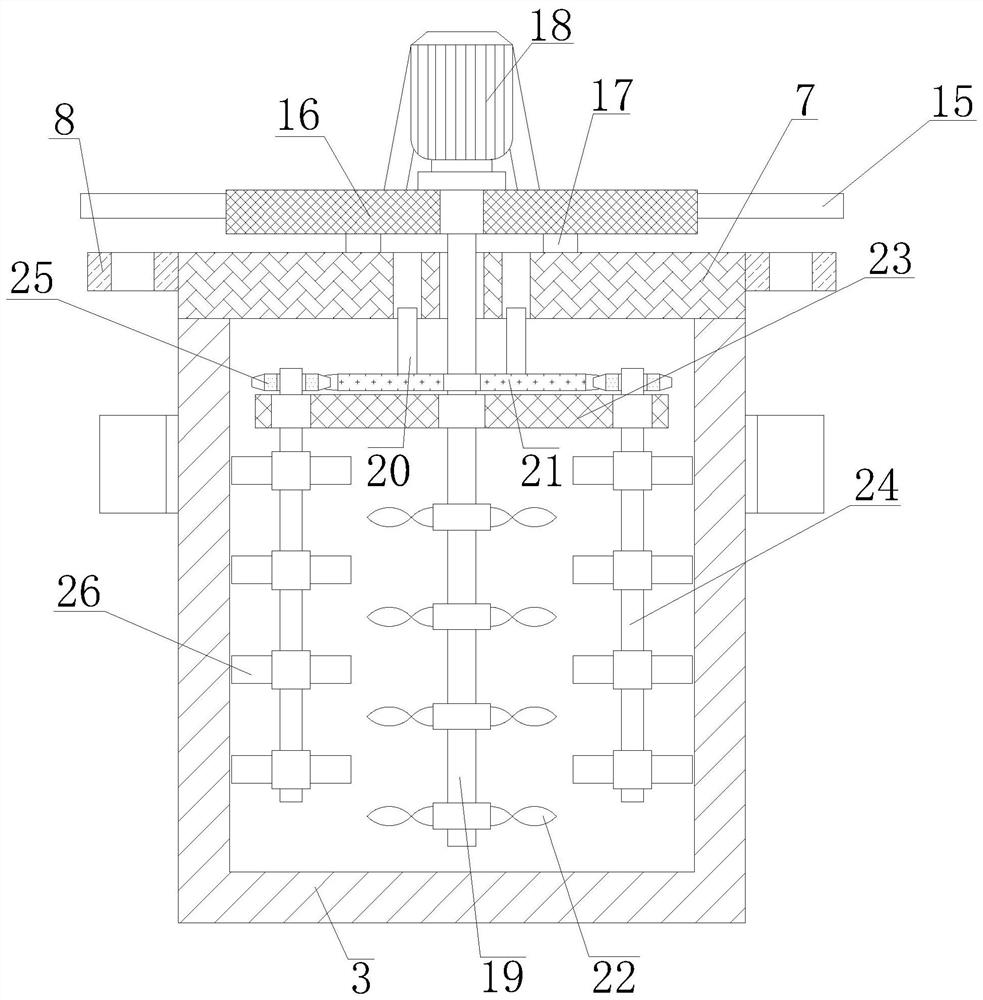

Tin paste agitator for production of LED (light-emitting diode) circuit boards and agitation method

InactiveCN107970841AAffect the quality of useImprove sealingShaking/oscillating/vibrating mixersTransportation and packagingCouplingEngineering

The invention discloses a tin paste agitator for the production of LED (light-emitting diode) circuit boards in the technical field of LEDs. Pillars are mounted on the left side and the right side ofthe top of a base plate, wherein supporting bearings sleeve the outer ends of supporting shafts, moreover, the two sets of supporting shafts are symmetrically arranged on the outer wall of a base, anagitating tank is arranged in an inner cavity of the base, a top sealing cover is arranged on the top of the agitating tank through hinges, a feed pipe and an agitating motor are respectively arrangedon the left side and the center of the top of the agitating tank, furthermore, both the feed pipe and the agitating motor are arranged in an inner cavity of the top sealing cover, and an agitating shaft is connected to the bottom power end of the agitating motor through a coupling. The sealing performance of the tin paste agitator is good; by arranging the top sealing cover, the feeding pipe andthe agitating motor having the possibility of air leakage are wrapped in a sealed space in the process of agitation, consequently, a good sealed environment is provided for the agitating tank, and tinpaste is prevented from being in contact with the air to cause the phenomenon of tin paste oxidation and affecting the quality of the tin paste in use.

Owner:董桂芳

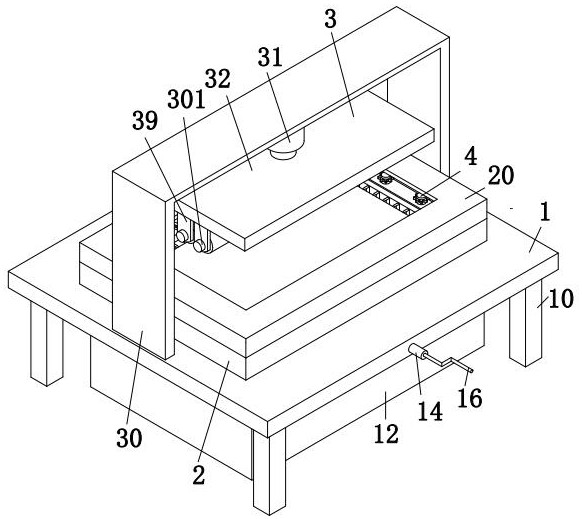

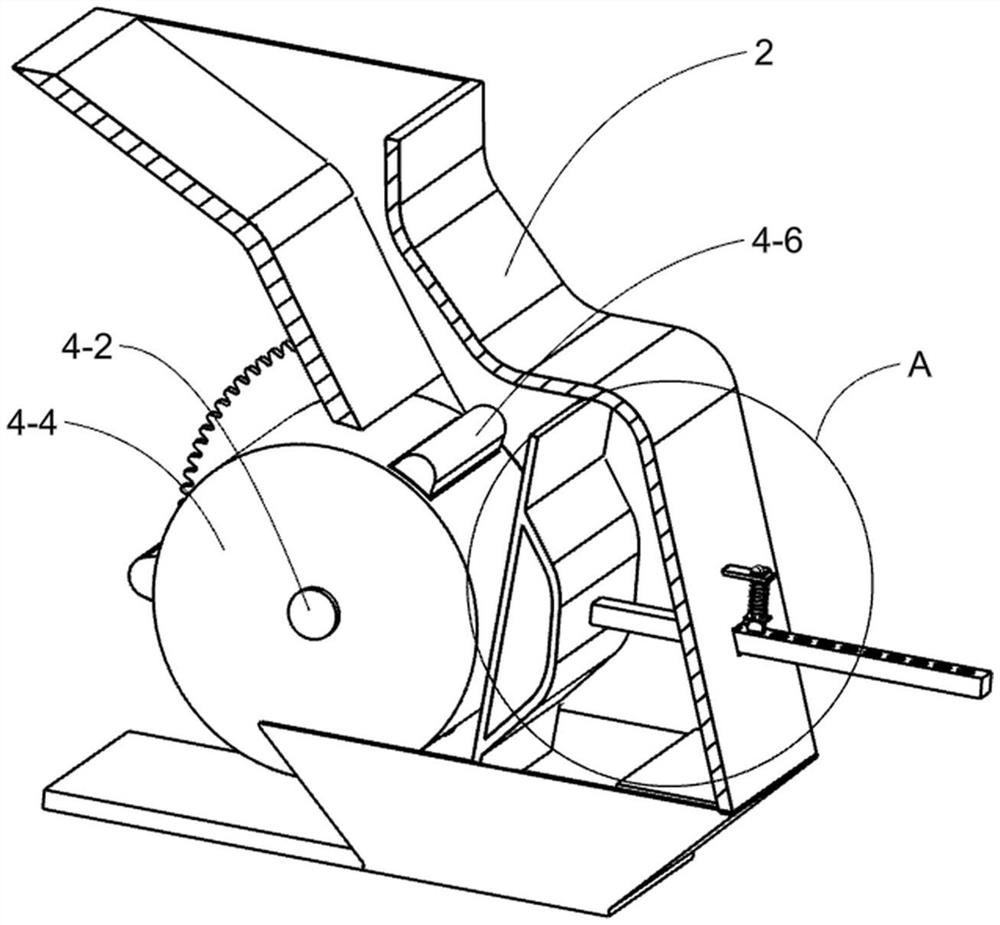

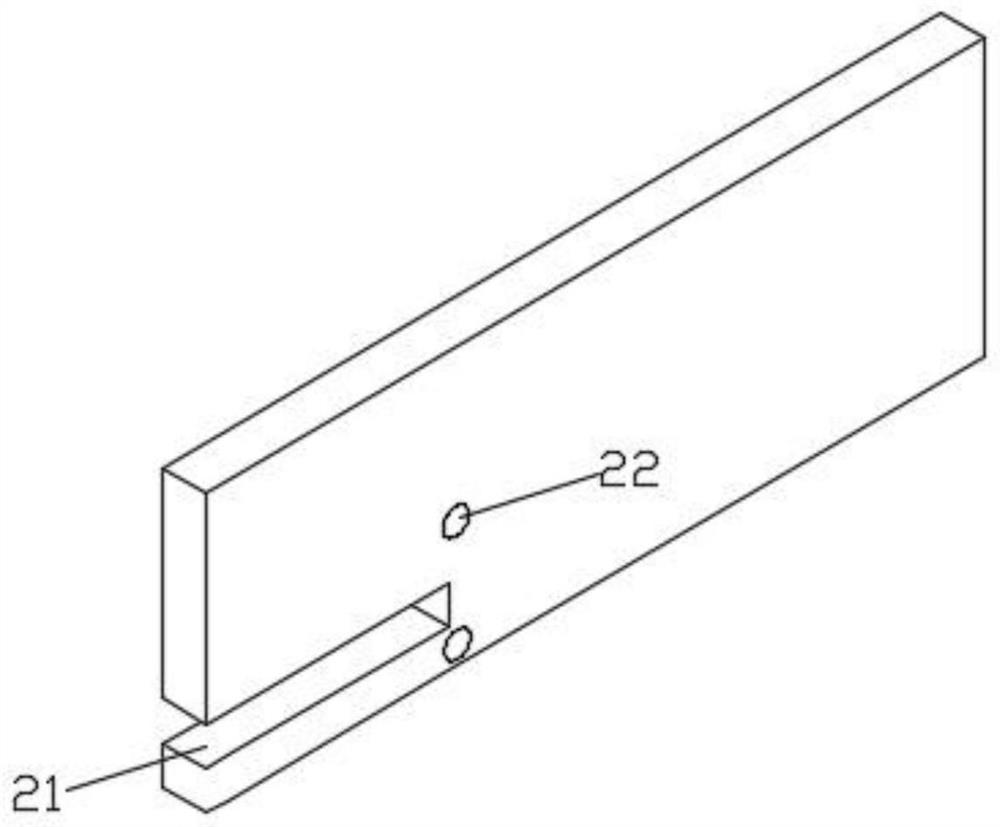

Composite processing equipment for manufacturing multi-layer composite board

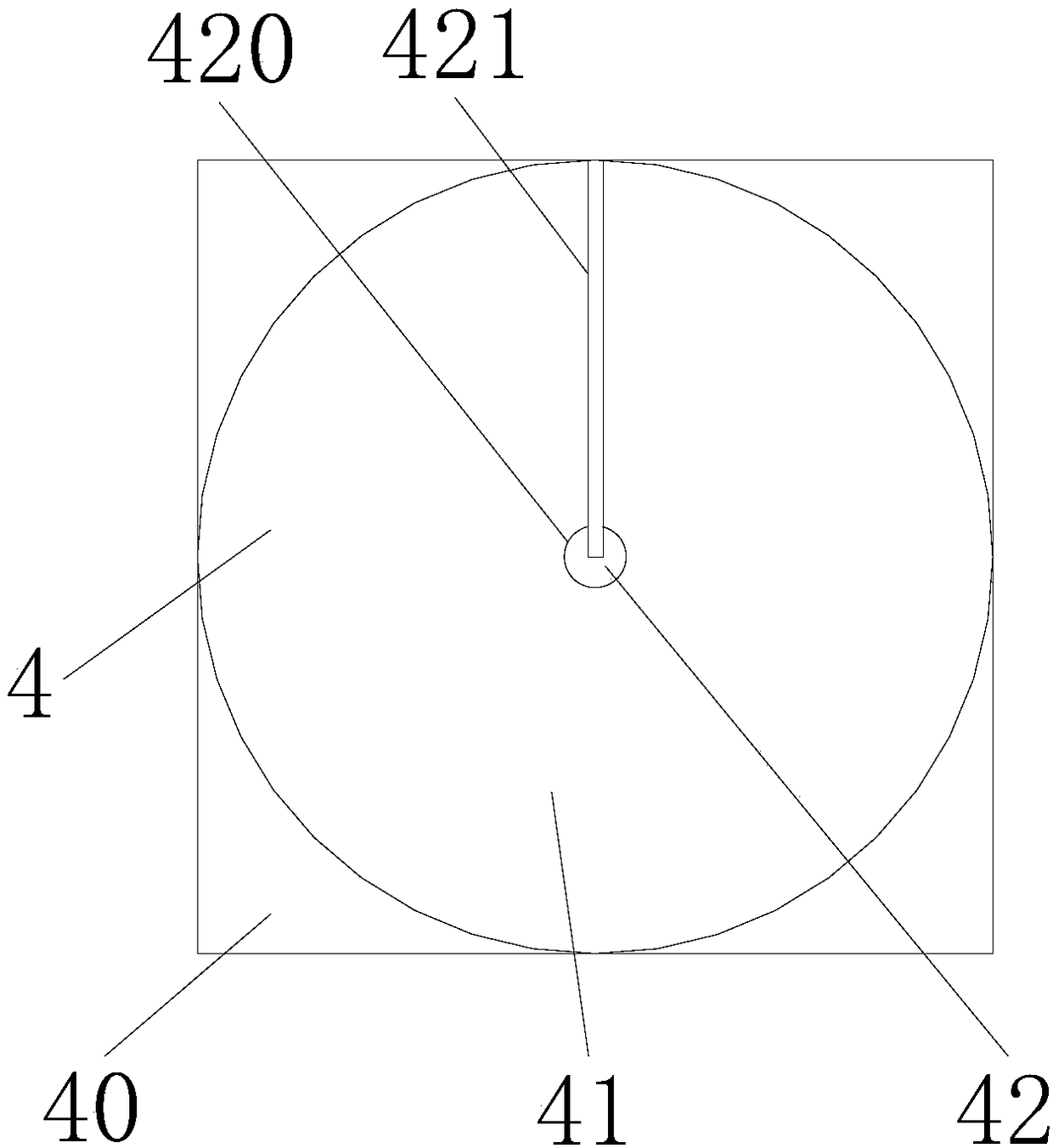

ActiveCN113276234AConditions that affect the effect of useScrape off in timePlywood pressesVeneer pressesComposite plateWorkbench

The invention relates to composite processing equipment for manufacturing a multi-layer composite board. The composite processing equipment comprises a workbench, a placing frame, a pressing mechanism and a scraping mechanism, wherein the placing frame and the pressing mechanism are mounted on the upper end face of the workbench; and the placing frame is of a concentric-square-shaped structure, and the scraping mechanism is mounted in the placing frame. The pressing mechanism adopted by the composite processing equipment is used for pressing the multi-layer composite board in a rolling mode, excess glue can be extruded towards the outer side of the multi-layer composite board, and the situation that the the excess glue accumulates and consequently the use effect of the multi-layer composite board is affected is avoided; and meanwhile, the excess glue extruded by the multi-layer composite board is scraped in time through the scraping mechanism, and therefore the situation that the glue stays on the side wall of the multi-layer board for a long time to adhere to the side wall of the multi-layer board and is difficult to clean is avoided.

Owner:徐州杨氏木业有限公司

Light source type anti-burn self-dewatering greenhouse

PendingCN112075261AScrape off in timeStrong targetingClimate change adaptationCleaning using toolsThermodynamicsExternal energy

The invention discloses a light source type anti-burn self-dewatering greenhouse which comprises a greenhouse body. A containing groove is horizontally formed in the middle of the upper end face of the greenhouse body, a light-transmitting plate is fixedly connected to a groove opening of the containing groove in a sealed manner, a driving agent is placed in the containing groove, and arc-shaped grooves communicating with the containing groove are symmetrically formed in the greenhouse body; and a first permanent magnet block is slidably connected into each arc-shaped groove in a sealed manner, and a sealed space formed by the side face, away from the containing groove, of each first permanent magnet block and the corresponding arc-shaped groove is a driving area. According to the light source type anti-burn self-dewatering greenhouse, by arranging the driving agent, the first permanent magnet blocks and second permanent magnet blocks, the mechanism that the driving agent is decomposedunder strong light and synthesized under weak light is used, so that a scraper can be driven to slide on the inner wall of the greenhouse body in a reciprocating manner, and therefore dust removal and cleaning can be conducted on the inner wall of the greenhouse body; and condensate water on the inner wall of the greenhouse body can be scraped off in time when sunlight irradiates the greenhouse,pertinence is high, input of external energy is not needed, and energy conservation and environmental protection are achieved.

Owner:周朝煜

Horizontal well self-centering moving piston type cone valve pump

ActiveCN109162908AScrape off in timeSmooth dischargePositive displacement pump componentsFlexible member pumpsReciprocating motionEngineering

The invention provides a horizontal well self-centering moving piston type cone valve pump. The horizontal well self-centering moving piston type cone valve pump is used in horizontal well and inclined well pumping conditions. The horizontal well self-centering moving piston type cone valve pump is composed of a pump cylinder body, a sand scraping type plunger piston, a stirring centralizer, a walking cone valve and a fixed cone valve. The problems of sand abrasion and eccentric wear between a long pump cylinder and a moving plunger piston, horizontal well valve leakage as well as valve ball difficult opening and loose closing can be effectively solved. The sand scraping type plunger piston adopts a moving piston type spiral sand scraping plunger piston and combine with a compensation ringto prevent sand falling into an annular gap between the long pump cylinder and the moving plunger piston, a spiral sand scraping column timely scraping and discharging out of sand adsorbed to the cylinder wall of the long pump cylinder, and the stirring centralizer adopts a double centralizing spiral tooth stirring rod body to realize self-centering of the sand scraping type plunger piston and the walking cone valve. The walking cone valve adopts a structure of a fixed cone valve and a moving cone valve seat and automatically opens and closes with the reciprocating movement of the stirring centralizer, the fixed cone valve adopts a structure of a moving cone valve and a fixed cone valve seat, and a fixed cone valve body is opened and closed smoothly through assisting of double springs anda guide rod.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Roller type fruit shell separating machine

The invention relates to the field of fruit shell separation equipment, and discloses a roller type fruit shell separating machine. The roller type fruit shell separating machine comprises a machine frame and a material conveying belt, and further comprises at least one roller which is arranged above the material conveying belt and stretches across the width direction of the material conveying belt, needle thorns are arranged on the peripheries of the rollers so as to pierce fruit shells on the material conveying belt and perform subsequent separation when the rollers rotate, the rotating direction of the rollers is the same as the running direction of the material conveying belt, and a distance is formed between the free end of each needle thorn on the rollers and the surface of the material conveying belt; and the roller type fruit shell separating machine further comprises slag discharging mechanisms which are arranged corresponding to the rollers, and the slag discharging mechanisms can strip the fruit shells on the needle thorns of the rollers. According to the fruit shell separating machine, the concept that a traditional fruit shell separating machine needle thorn plate is used for sorting shells through up-and-down periodic movement is subverted, then the mode by which the needle thorns are fully distributed on the surfaces of the rollers which do rotating motion, so that sorting of the fruit shells is always carried out through the needle thorns on the mixed fruit shell materials on the material conveying belt in the rotating process of the rollers, the material conveying belt can be used for continuous conveying, the needle thorns are orderly and densely arranged on the rollers, so that the separation efficiency and the separation rate of the fruit shells areensured.

Owner:HUNAN DASANXIANG TEA OIL CO LTD

Rotary drying and recycling device for desulfurized gypsum

ActiveCN112047653AScrape off in timePiled upDrying machine combinationsDrying gas arrangementsThermodynamicsEngineering

The invention relates to a processing device for desulfurized gypsum, in particular to a rotary drying and recycling device for desulfurized gypsum, and aims to solve the problems that desulfurized gypsum of an existing drying device for desulfurized gypsum is not dehydrated thoroughly, and crushing degree of desulfurized gypsum cannot be adjusted according to use requirements. The rotary drying and recycling device for desulfurized gypsum comprises a base, a material scattering frame, a supporting plate, a primary material scattering mechanism, an adjusting mechanism, a rotary heating mechanism and the like. The material scattering frame is fixedly arranged at one end of the base, the supporting plate is fixedly arranged on one side face of the base, the preliminary material scattering mechanism is arranged on the material scattering frame and the supporting plate, the adjusting mechanism is arranged on the material scattering frame, and the rotary heating mechanism is arranged at oneend of the material scattering. Crushing degree of the desulfurized gypsum can be adjusted according to use requirements, and the desulfurized gypsum can be heated, dried and air-dried in sequence, so that water in the desulfurized gypsum is lost more thoroughly.

Owner:山西鑫途化工股份有限公司

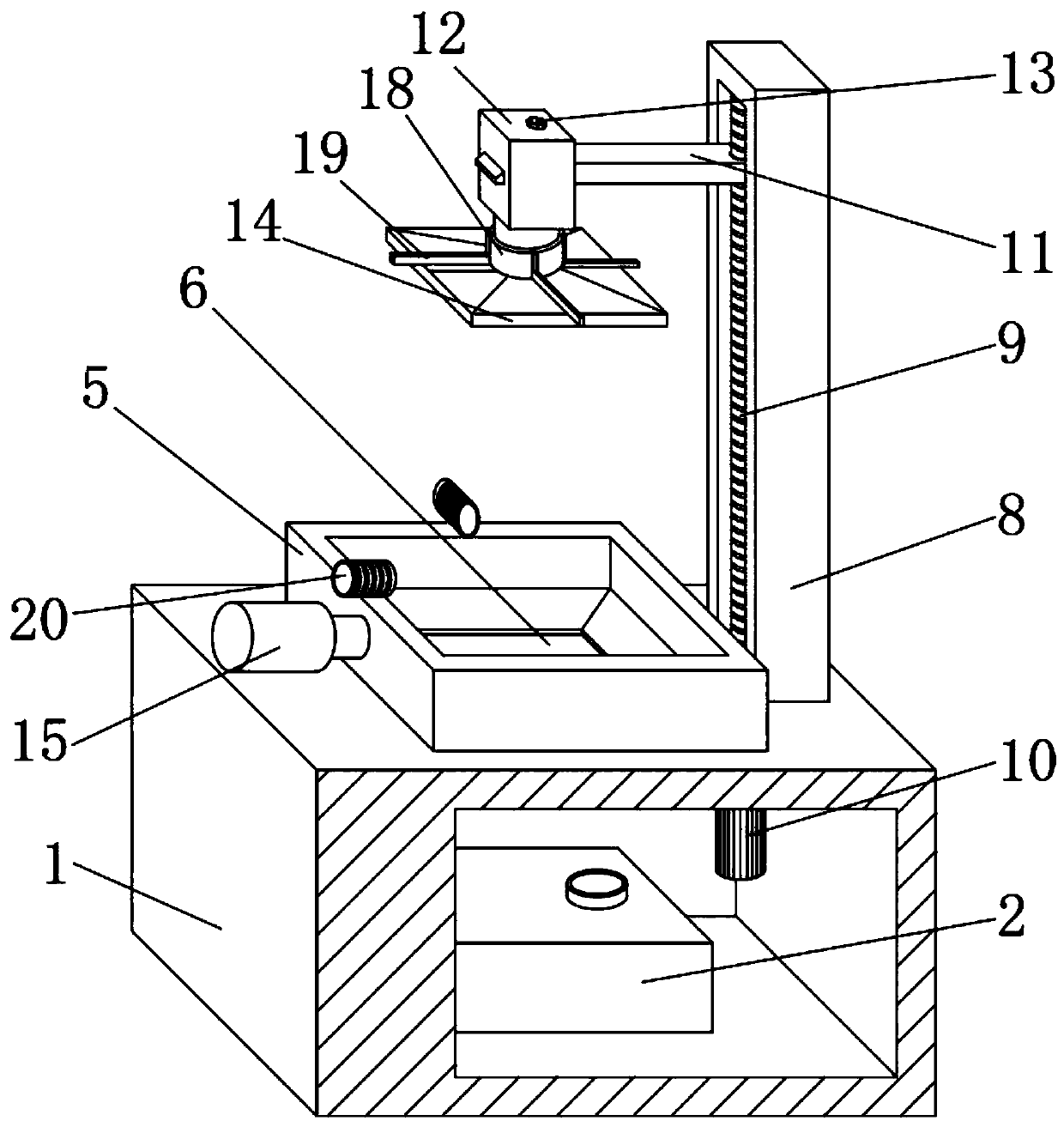

Photocuring 3D printer

ActiveCN111546631AImprove cleanlinessDifficult to remove completelyManufacturing enclosures3D object support structuresComputer printing3d printer

The invention relates to the technical field of 3D printing equipment, and discloses a photocuring 3D printer. The photocuring 3D printer comprises a box body, wherein a DLP projector is fixedly installed in an inner cavity of the box body, a light transmitting groove is formed in the top of the box body, tempered glass is fixedly installed on the upper surface of the box body, and liquid groovesare fixedly formed in the periphery of the upper surface of the tempered glass. According to the photocuring 3D printer, when a hydraulic device pushes the liquid grooves to move left and right, staggered power-on and power-off of two electromagnets are controlled, so that scraper blades with magnet components are attracted to rotate in a reciprocating mode under staggered power-off of the electromagnets, a rotating sleeve is controlled to rotate to drive the four scraper blades to completely cover and slide the upper surface of a forming platform plate, after the forming platform plate ascends, liquid resin adhering to the upper surface of the forming platform plate can be scraped away in time, the situation that after a curing part is formed, the forming platform plate moves upwards to be removed, then much time needs to be consumed for resin dripping is avoided, and the using efficiency of the equipment is improved.

Owner:深圳市深华科科技有限公司

Prefabricated concrete building block forming manufacturing machine and manufacturing method

ActiveCN113414864AScrape off in timeAvoid the problem of sticking to the inner wall of the tankSolid waste managementHollow article cleaningCircular discConstruction engineering

The invention relates to a prefabricated concrete building block forming manufacturing machine and a manufacturing method. The prefabricated concrete building block forming manufacturing machine comprises a workbench, a fixing device and a moving device, the top of the workbench is provided with the fixing device, the fixing device is provided with the moving device, and the moving device comprises a supporting plate, a stirring tank, a circular plate, a stirring frame, a conical material leakage pipe, a disc block, a moving frame and a vibrating frame. Concrete raw materials left on the inner wall of a tank body can be scraped in time, so that the problem that traditionally, other materials in concrete are adhered to the inner wall of the tank to cause certain errors of raw material mixing ratio is avoided, and vibration exhaust can be conducted on the concrete in a mold, so that a formed concrete building block is harder and more durable, and then the service life of the concrete building block is prolonged.

Owner:邵阳大汉宝科混凝土有限公司

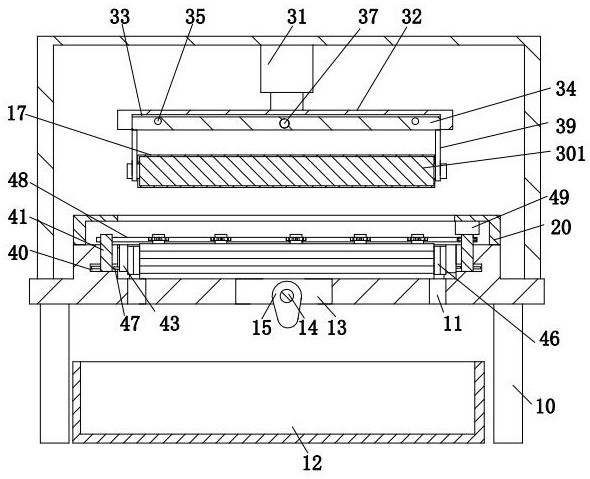

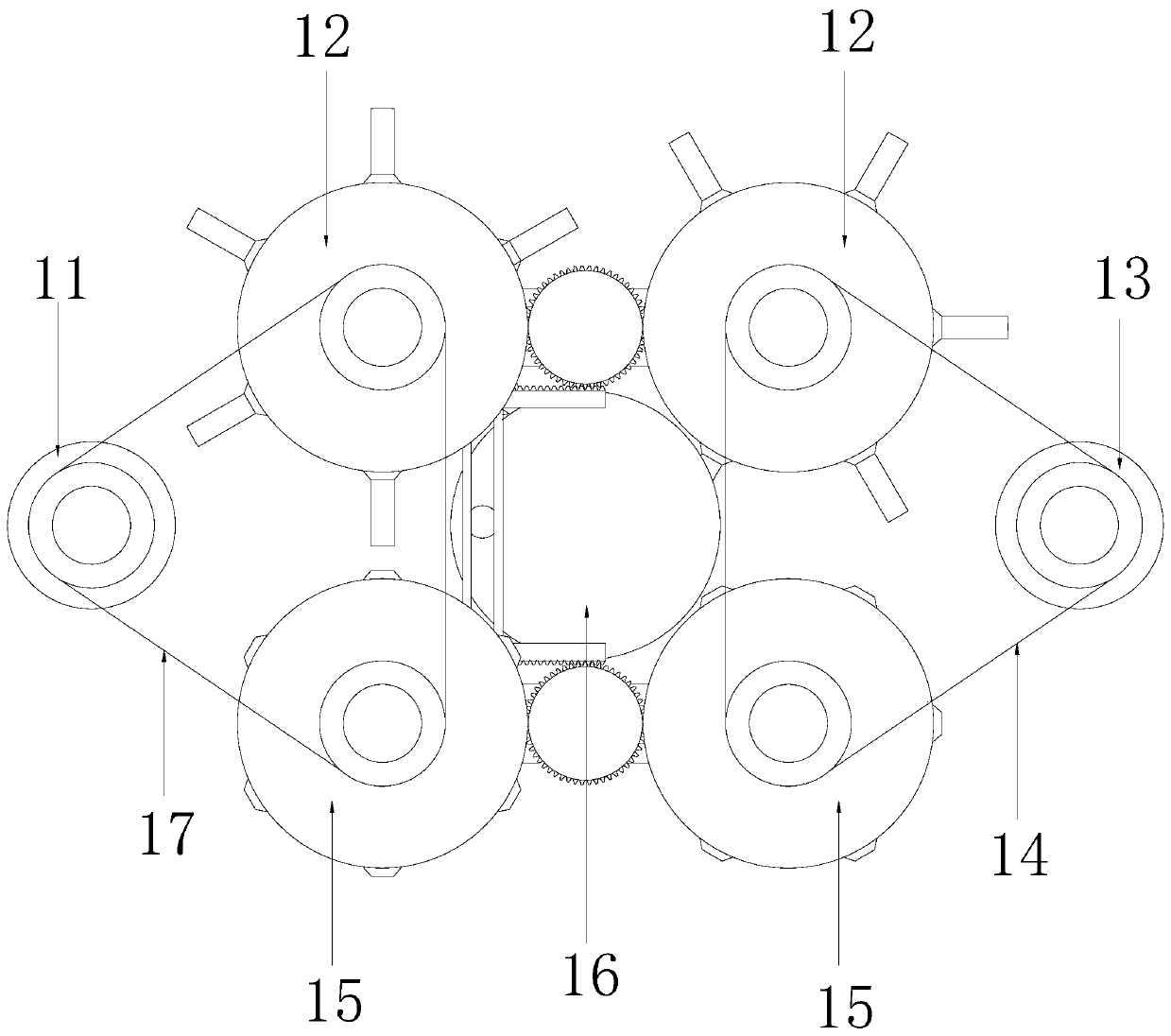

Secondary adjustable sugarcane juice crusher

ActiveCN112450450APrevent slidingGuaranteed squeezing effectJuice extractionAgricultural engineeringMechanical engineering

The invention relates to a secondary adjustable sugarcane juice crusher. Sugarcane is sent into a guide-in roller set; the guide-in roller set cuts and squishes the sugarcane through ring teeth on theside surfaces of two guide-in rollers; anti-skid grooves between the ring teeth horizontally clamped on the surfaces of the sugarcane, so that the relative sliding between the sugarcane and the guide-in rollers can be avoided; the cut and squished sugarcane enters a pressing roller set to press sugarcane juice out to fall in a material receiving box below; the dried long sugarcane bagasse entersbetween a crushing roller and a protective cover; the sugarcane bagasse is cut up by crushing knives on the crushing roller to fall in a waste residue below; a material scraping knife hinged on the protective cover can timely scrape the sugarcane bagasse which coheres on the pressing rollers and is not easy to fall, so that the pressing effects of the pressing rollers can be guaranteed; a power supplying device includes a storage battery and a matching battery charger and inverter; and the power supplying device is installed on a base plate so as to provide power for outdoor use. The crusher is various in function, high in efficiency, good in effect, clean, sanitary and suitable for promotion and application in small and medium businesses.

Owner:毛红生

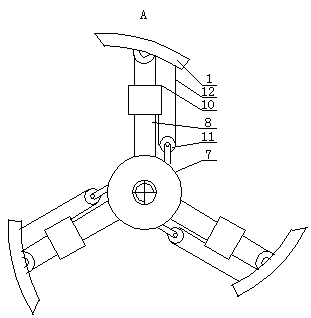

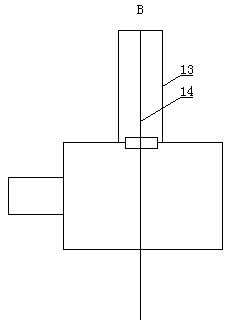

Elastic scraper type crystallizer

PendingCN107537175AIncrease the areaImprove work efficiencySolution crystallizationElectric machineryPhysics

The invention provides an elastic scraper type crystallizer which comprises a cylinder, wherein the upper and lower ends of the cylinder form a closed cylindrical structure through the sealing of an upper flat cover and a lower sealing head; a rack is arranged outside the upper end of a main shaft; the upper end surface of the rack is connected with a motor component; the motor component drives the main shaft to rotate; a rotor main body rotates through rotation of the main shaft; the rotor main body comprises a rotor main body inner wall and a rotor main body outer wall; a cavity formed by the rotor main body inner wall is an inner cooling cavity; a cavity formed by the rotor main body outer wall and the cylinder inner wall is an outer cooling cavity; an inner circle scraping film component is arranged on the rotor main body inner wall; an outer circle scraping film component is arranged on the rotor main body outer wall; a feed port is formed in the upper flat cover; a discharge portis formed in the bottom end of the lower sealing head. The elastic scraper type crystallizer provided by the invention has a simple structure and effectively reduces the friction and scratch of a product caused by rotation, bounce and vibration.

Owner:无锡力马化工机械有限公司

Mixing device used for precision casting wax production and capable of cleaning box wall

InactiveCN111974273AImprove uniformityQuality improvementShaking/oscillating/vibrating mixersRotary stirring mixersHydraulic cylinderMechanical engineering

The invention relates to the technical field of mixing devices for precision casting wax production, and discloses a mixing device used for precision casting wax production and capable of cleaning a box wall. The mixing device comprises a base; two support plates are symmetrically and fixedly connected to the top of the base; a mixing box is rotatably connected between the side surfaces, close toeach other, of the two support plates; a cushion block is fixedly connected to the top of the base; two first hydraulic cylinders are symmetrically and fixedly connected to the top of the cushion block through fixing sleeves; and a push plate is fixedly connected between the output ends of the two first hydraulic cylinders. The mixing device solves the problems that after an existing wax mixing device is used for mixing processing, a large amount of residual wax is often adhered to the inner wall of the existing wax mixing device, and the residual wax is difficult to clean, so that the subsequent wax mixing processing quality is influenced, and the labor intensity of workers is greatly increased.

Owner:安徽宜安精密机械零部件有限公司

Dry anaerobic fermentation treatment equipment for high-content organic solid waste

InactiveCN110961427APromotes anaerobic fermentationExclude influenceSolid waste disposalCleaning using toolsEnvironmental engineeringFermentation

The invention discloses dry anaerobic fermentation treatment equipment for high-content organic solid waste. The equipment comprises a feed hopper, a crushing chamber, a crushing device, a dry anaerobic fermentation machine body and socles, wherein the socles are vertically connected to the bottom of the dry anaerobic fermentation machine body, the feed hopper is connected to the top of the dry anaerobic fermentation machine body, the feed hopper is communicated with the crushing chamber, and the crushing chamber is provided with the crushing device connected with the dry anaerobic fermentation machine body. Compared with the prior art, the equipment is advantaged in that alternate pulverization is performed, a scraping sleeve is taken as a static tool, a pulverizing knife is taken as a moving tool, so the organic solid waste attached to the crushing knife can be scraped in time; the situation that more organic solid waste is attached to surfaces of pulverizing cutters, and pulverizingof the organic solid waste is consequently affected is avoided, the pulverizing quality of the organic solid waste of the pulverizing cutters is improved, the organic solid waste is pulverized more thoroughly, follow-up anaerobic fermentation of the organic solid waste is facilitated, moreover, equipment does not stop, and pulverizing efficiency is greatly improved.

Owner:张杰

Automatic classified collection device for nanopowder

ActiveCN102672192ASolve the problem of cooling effect dropScrape off in timeNanotechnologyCooling effectEngineering

The invention discloses an automatic classified collection device for a nanopowder. The automatic classified collection device comprises a support frame and a plurality of collection units, wherein the support frame comprises an upper support plate and a lower support plate; the collection unit comprises a collection barrel, a powder scraping brush and collection grooves; the both ends of the collection barrel are clamped on the support frame via limit holes in the upper support plate and the lower support plate of the support frame respectively; a gear is arranged at the top end of the collection barrel and connected with a motor via a chain; the powder scraping brush and the plurality of collection grooves are clung to the outer wall of the collection barrel; the both ends of the powder scraping brush are fixed on the upper support plate and the lower support plate of the support frame respectively; and the collection grooves are fixed on the powder scraping brush. According to the invention, the problem of cooling effect reduction of the collection barrel due to deposition thickness increment of nanoparticles of the conventional device is solved; the collection grooves are arranged at different heights, thus realizing separate collection for the nanoparticles deposited at different heights; and the device can realize continuous production for the nanopowder.

Owner:北京丰都清源高新技术有限公司

Lens moisture-proof accurate monitoring device

ActiveCN112073697AImprove efficiencyGuaranteed clarityTelevision system detailsColor television detailsSound sourcesEngineering

The invention discloses a lens moisture-proof accurate monitoring device which comprises a base, a lens rotating mechanism with an accurate monitoring function is arranged in the base, a rainwater detection mechanism for detecting lens moisture is arranged at the left end in the base, and a lens water scraping mechanism for wiping the lens moisture is arranged at the upper end in the base. The monitoring device has the advantages that the monitoring device can automatically detect the rain potential and can scrape rainwater on the outdoor monitoring lens in time so as to guarantee the definition of the surface of the lens and guarantee that a cleaned picture can be monitored and recorded, water scraping can be conducted on the lens through the scraping plate, water on the scraping plate can also be removed regularly to ensure the efficiency of the water scraping of the lens. When a sound source is generated in a monitoring area, the monitoring device can rotate the lens to the positionfor timely monitoring.

Owner:绍兴市日杰建筑科技有限公司

Rapid singeing apparatus for linen textile processing

InactiveCN108642783AReduce the temperatureGuarantee product qualitySingeingBiochemical engineeringElectric machinery

The invention discloses a rapid singeing apparatus for linen textile processing, which relates to the technical field of a linen textile singeing apparatus. The rapid singeing apparatus comprises a box body, wherein one end inside the box body is provided with a brushing apparatus, one end inside the box body is provided with a flame spraying gun, the other end inside the box body is provided withtwo scraper plates, the other end inside the box body is provided with two cooling rollers, the middle part of the inner side wall of the brushing apparatus is fixedly connected with a motor, the middle part of the front surface of the motor is fixedly connected with a motor gear, two eccentric gears are arranged inside the brushing apparatus, the edge of each eccentric gear is movably connectedwith one end of a linkage rod by virtue of a pin shaft, the other end of the linkage rod is movably connected with one end of a translation rod by virtue of a pin shaft, and the other end of the translation rod is fixedly connected with a hairbrush. By adopting the rapid singeing apparatus for the linen textile processing, fluff adhered on the surface of a linen fabric can be brushed away in advance, the quantity of the fluff to be singed can be reduced, the flame spraying gun can rapidly and efficiently burn the fluff, and the scraper plates can scrape the fluff residues, so that the rapid singeing apparatus is simple and practical.

Owner:浙江载信亚麻科技有限公司

PVC sheet flooring gluing device

InactiveCN111760698AImprove gluing efficiencyStir wellSpraying apparatusElectric machineTransmission belt

The invention discloses a PVC sheet flooring gluing device. The device comprises a bottom plate, two side plates are arranged on the bottom plate, transmission shells are mounted on the side plates, four conveying rollers are rotatably mounted between the two transmission shells, two glue spraying shells are arranged between the two side plates, multiple spraying heads are arranged on the glue spraying shells, two conveying cylinders are arranged on one side plate, glue is added into a glue hopper, the glue enters the two conveying cylinders from two flow dividing pipes through a conveying pipe, a second motor is started, an output shaft of the second motor drives one end shaft to rotate, the two end shafts drive two conveying screw rods to rotate through a belt wheel and a transmission belt of a belt, the conveying screw rods convey glue into the glue spraying shells, the spraying heads on the two glue spraying shells spray glue to the two faces of the PVC sheet flooring, after glue spraying, the PVC sheet flooring enters a conveying box from a conveying inlet and outlet, and the technical problem that in the prior art, in the PVC sheet flooring gluing process, glue is easily mixed unevenly, and meanwhile, gluing efficiency is poor can be solved.

Owner:安徽华帆新材料科技有限公司

A farmland self-cleaning stain monitoring device based on big data

InactiveCN109922240AIt will not affect the effect of monitoringScrape off in timeTelevision system detailsColor television detailsEngineeringFuselage

The invention discloses a farmland self-cleaning stain monitoring device based on big data. The device structurally comprises a decontamination dust-blocking mirror, a baffle, a protective cover, anda machine body, the decontamination dust-blocking mirror is in clearance fit with the machine body; the decontamination dust-blocking mirror comprises an outer mirror surface; a protective shell, a shaking rod, an auxiliary shaft, a sensing end, a sensing receiving end and a camera end, after the monitor positioned in the farmland is placed for a long time; the main rod drives the extension cartridge case to rotate together; when rotating to a position where the original length cannot reach, the rotating shaft rotates; the extension cartridge case supported by the one-way convex rod can loseresistance; the one-way arc push rod is used for assisting in boosting; the extending sliding body is unfolded together; after being wiped for a certain distance, the air returns to the same distanceand is extruded into the expansion soft skin to be buffered and released, and after being properly mounted, the air flows back into the to-be-pressed bag and waits for the next operation, so that thefly excrement can be scraped off in time when being placed for a long time and is difficult to treat, and even the monitoring effect is not affected.

Owner:泉州台商投资区淇凯工业设计有限公司

Bathroom rack preventing water spot retention

The invention discloses a bathroom rack preventing water spot retention. The structure comprises strong pastes, a mounting clamping block, an integrated fixing placing plate, and an independent separating placing plate. The strong pastes are fixedly connected with the mounting clamping block, and the strong pastes and the mounting clamping block are vertical to each other. The mounting clamping block is provided with clamping holes. The integrated fixing placing plate is in a U-shaped structure. Two ends of the integrated fixing placing plate are fastened with the clamping holes of the mounting clamping block. The integrated fixing placing plate is provided with a slot position. The slot position of the integrated fixing placing plate is provided with the independent separating placing plate. Through gravity of objects which are placed on the independent separating placing plate, transmission of a rotating device is driven. When the objects are taken down and no gravity applies pressure, the rotating device drives under an elastic action of a spring. Through the transmission, a wiper is driven to rotate, to realize to scrap water spots on the upper surface of a round plate to a plate scraping slot and then fall into a water tank. Water spots can be scraped in time, bacterial breeding and incrustation caused by retention of water spots are prevented, and the bathroom rack is sanitary in use and aesthetics of the bathroom rack is maintained.

Owner:福州市思华年科技信息咨询有限公司

Automatic forming system for steel reinforced concrete prefabricated column

InactiveCN113246289ARapid positioningEasy to operateStrutsFeeding arrangmentsReinforced concreteArchitectural engineering

The invention relates to an automatic forming system for a steel reinforced concrete prefabricated column. The automatic forming system comprises a moving device, a lifting device, a lifting plate, a cleaning device and a compaction device. The automatic forming system can solve the following problems possibly encountered in the pouring forming process of an existing steel reinforced concrete prefabricated column, wherein a, after each time of concrete pouring is completed, poured concrete slurry can only be manually compacted by using a concrete vibrating rod, the manner is relatively high in labor intensity and low in compaction efficiency, and certain potential safety hazards exist in manual high-altitude operation; and b, after the compaction is finished, the concrete slurry attached to the surface of the concrete vibrating rod cannot be cleaned in time, so that the effect of compaction next time is poor, and the forming quality of the steel reinforced concrete prefabricated column is reduced.

Owner:张登登

Essence with whitening and moisturizing functions and preparation method thereof

InactiveCN114533641AScrape off in timeGuaranteed Filtration EfficiencyCosmetic preparationsToilet preparationsEngineeringNiacin

The invention discloses a preparation method of essence with whitening and moisturizing functions, which comprises the following steps: adding deionized water, pearl powder, a humectant, essence, xylitol, caprolactam-based silicone oil, trehalose, citric acid and niacin amine into a first reaction kettle, stirring to obtain a clear and transparent mixed solution, then adding a thickening agent, and sprinkling into the mixed solution; dissolved mixed liquid is guided into the filtering tank through the feeding pipe, the mixed liquid entering the filtering tank falls onto the filtering plate and enters the filtering cylinder through the flow guide holes, undissolved impurities in the mixed liquid can be filtered and separated through the filtering holes in the filtering cylinder, meanwhile, the adjusting motor drives the multiple filtering shafts to rotate, scraping plates on the filtering shafts rotate, and therefore the impurities in the mixed liquid can be filtered and separated. Impurities on the inner wall of the filter cartridge are scraped in time; guiding the separated mixed solution to a second reaction kettle through a liquid discharge pipe for continuous reaction to obtain a solution; and S2, adding the nymphaea hybrid extract and the preservative into the solution in the step S2, and stirring.

Owner:邓光浩

Preparation process of printing ink

ActiveCN113893942AAvoid cloggingGuaranteed unobstructedPlastic recyclingHollow article cleaningElectric machineryEngineering

The invention belongs to the technical field of printing ink preparation, and particularly relates to a preparation process of printing ink. The preparation process comprises a supporting assembly, a motor, a feeding assembly and a cleaning assembly, the motor is fixedly installed at the top of the supporting assembly, the feeding assembly is installed above the supporting assembly, and a dredging assembly is connected to the lower portion of the feeding assembly. A fixing block is installed in the middle of the feeding assembly, a transmission assembly is installed on the outer side of the lower portion of the dredging assembly, a grinding assembly is installed below the transmission assembly, a crushing assembly is installed in the middle of the left side of the grinding assembly, and a cleaning assembly is arranged at the front end of the left side of the grinding assembly. When the device is used for cleaning the inner wall, sticking substances on the inner wall can be crushed and dried at first, and then the sticking substances are cleaned through a scraping plate on the device, so that the sticking substances cannot cake after being scraped off, and the defect that the sticking substances on the inner wall are easy to cake when an existing printing ink preparation device is used is overcome.

Owner:临沂市都兴工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com