Rotary drying and recycling device for desulfurized gypsum

A recovery device, desulfurization gypsum technology, applied in drying, dryer, heating device and other directions, can solve problems such as unfavorable storage of desulfurization gypsum, difficulty in meeting the demand for desulfurization gypsum, incomplete dehydration of desulfurization gypsum, etc., and achieve complete water loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

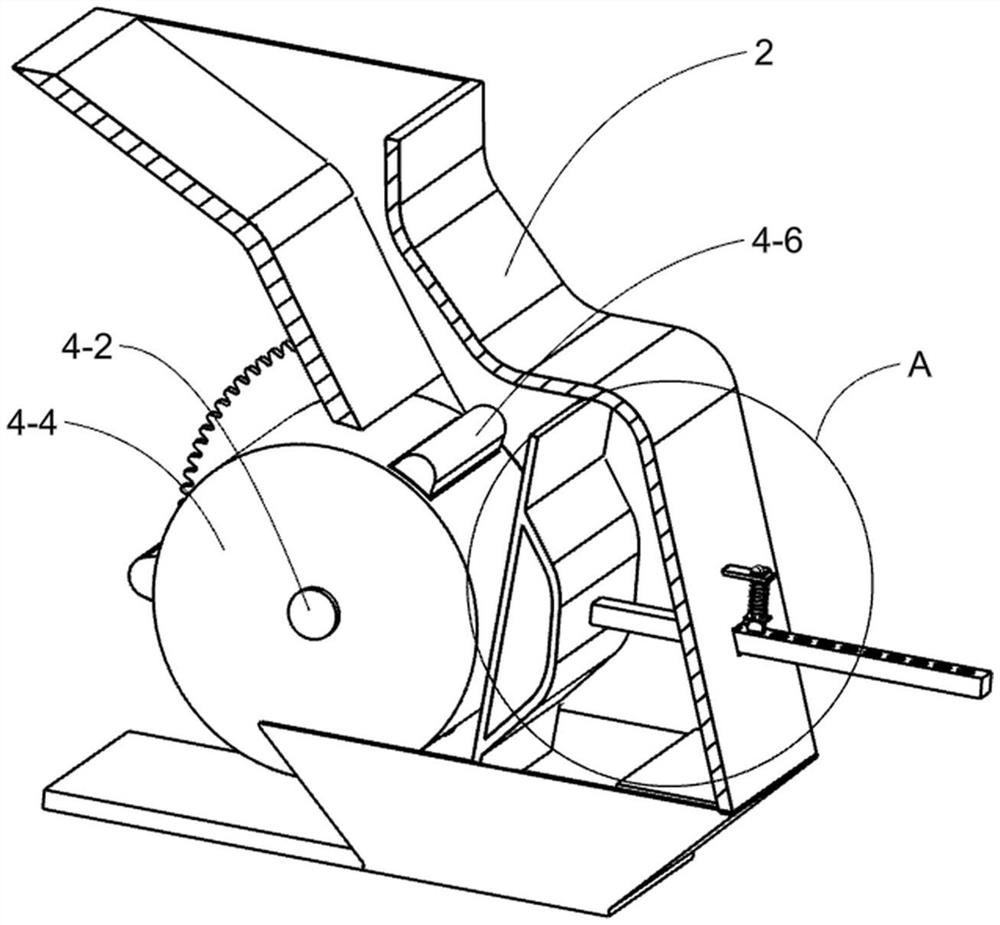

[0024] Embodiment: a kind of desulfurization gypsum rotary drying recovery device, such as Figure 1-8 As shown, it includes a base 1, a bulk material frame 2, a supporting plate 3, a preliminary bulk material mechanism 4, an adjustment mechanism 5, a rotating heating mechanism 6, a shaking mechanism 7 and a material blowing mechanism 8. The bulk material used for placing desulfurized gypsum The material frame 2 is fixed on the upper side of one end of the base 1, the support plate 3 is fixed on one side of the base 1 and is close to the bulk material frame 2, and the preliminary bulk material mechanism for primary crushing and processing of desulfurized gypsum 4 is set on the bulk material frame 2 and the supporting plate 3, the adjustment mechanism 5 is set on the bulk material frame 2, and the rotary heating mechanism 6 for preliminary drying and processing of desulfurized gypsum is set on the bulk material frame 2 At the lower end, the shaking mechanism 7 is arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com