Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Sanding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

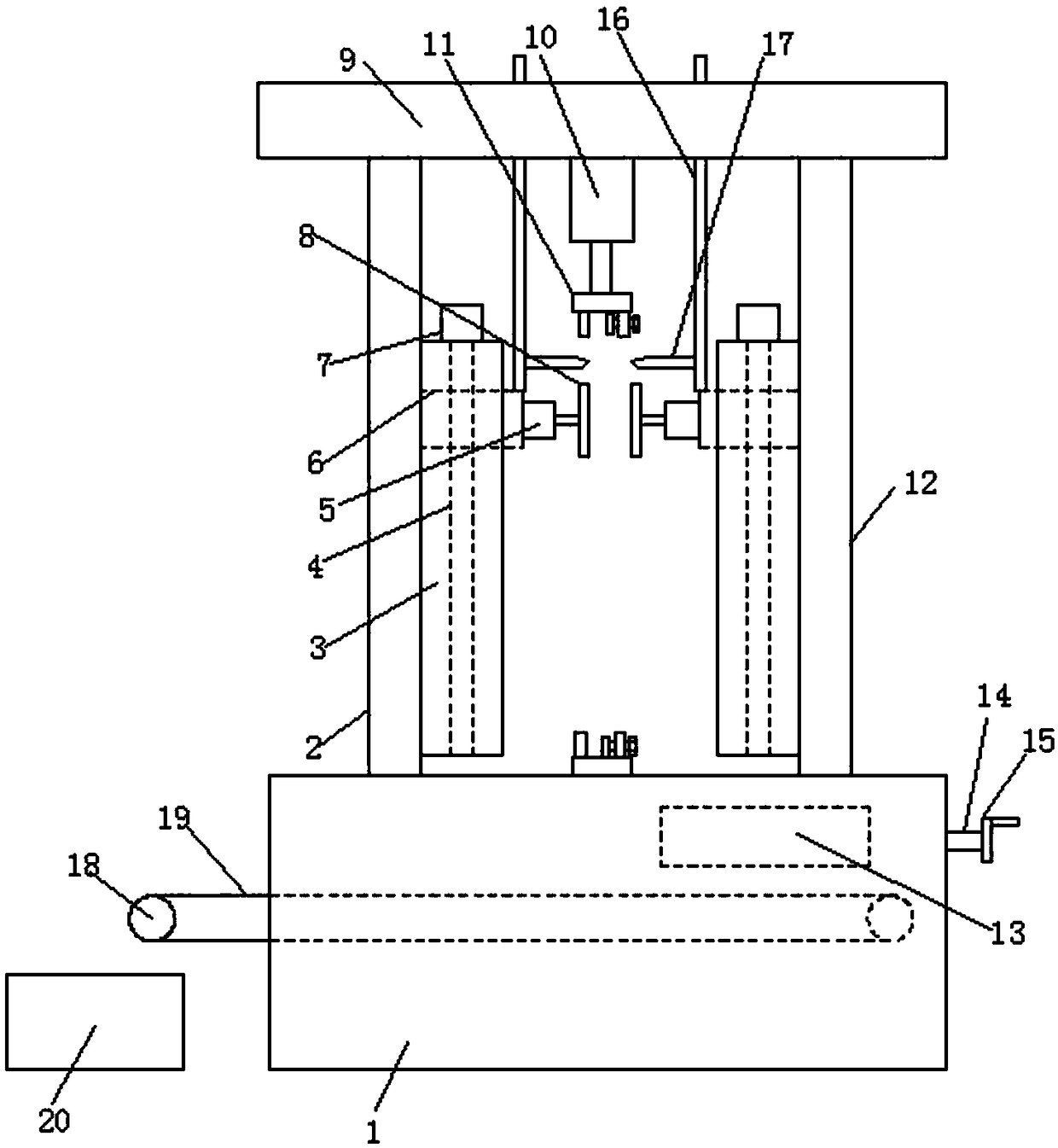

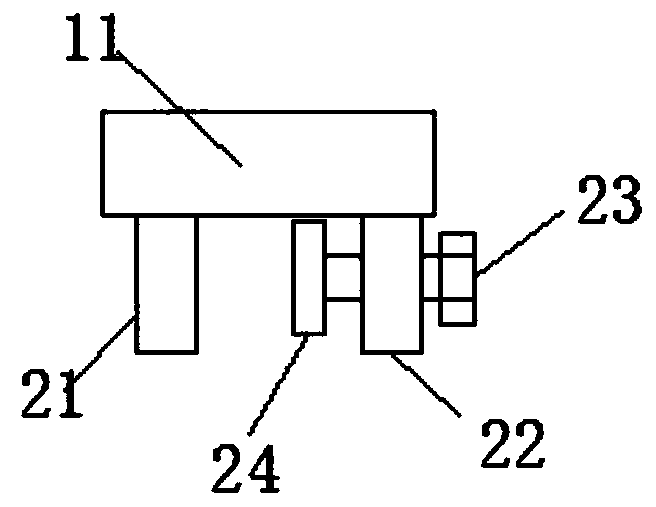

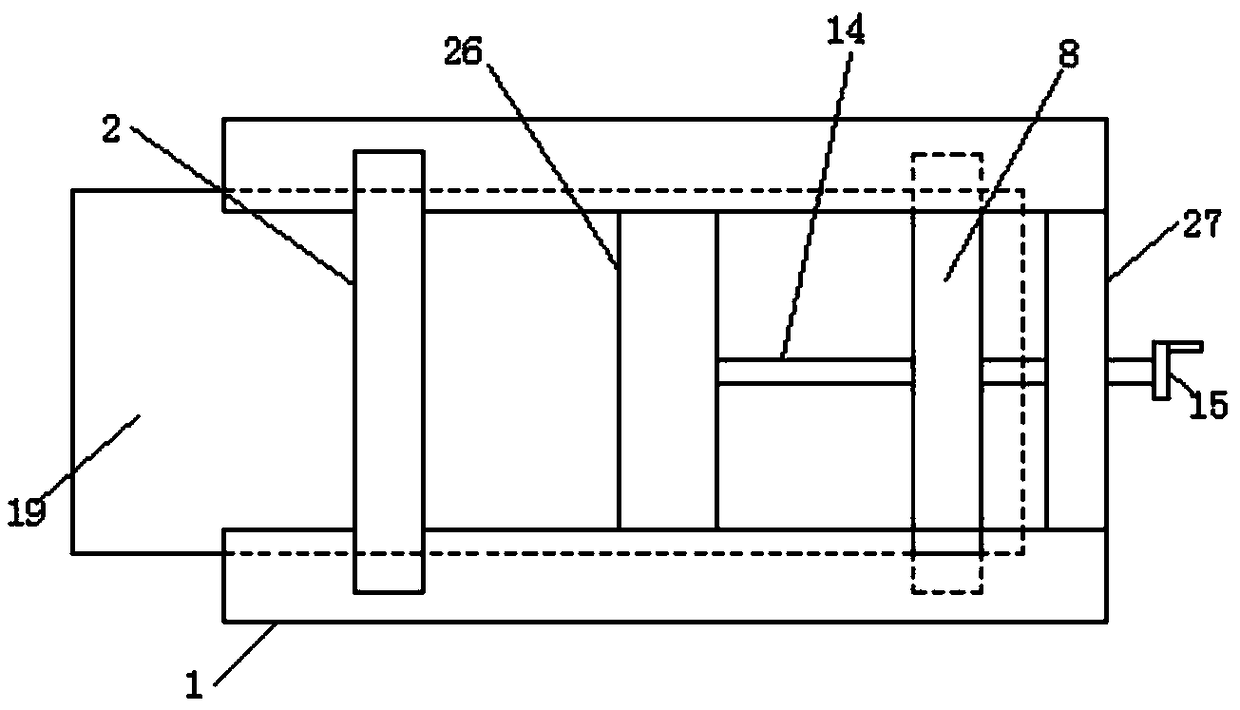

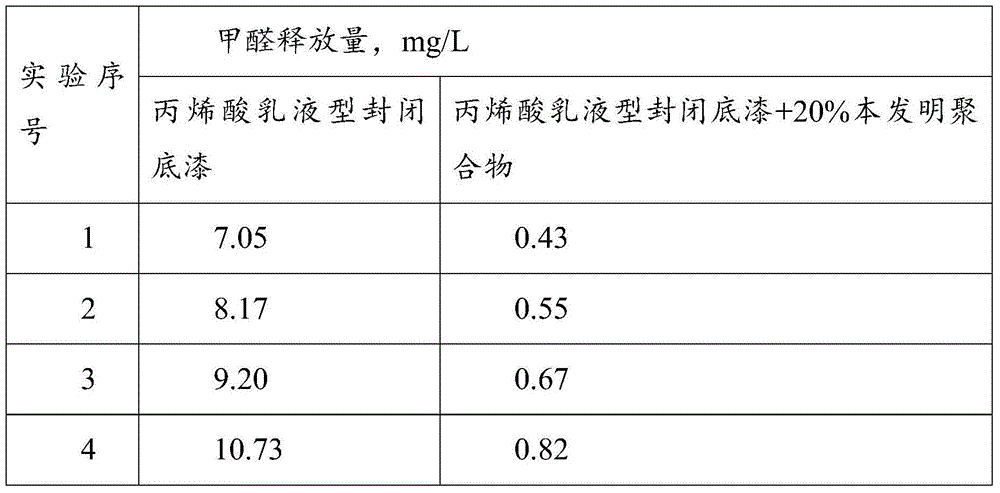

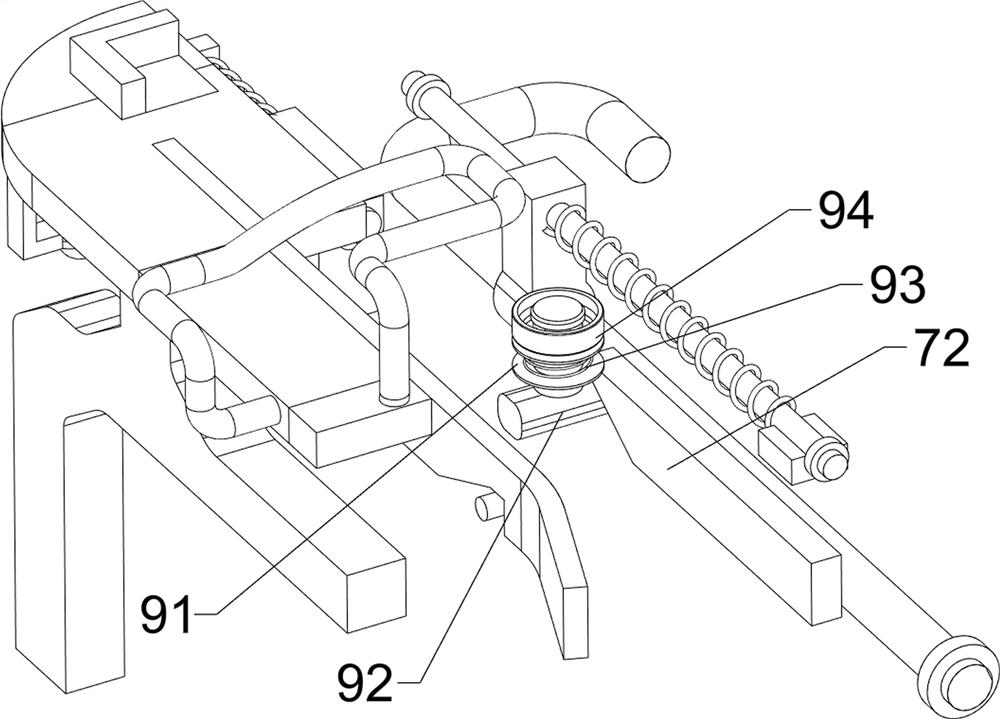

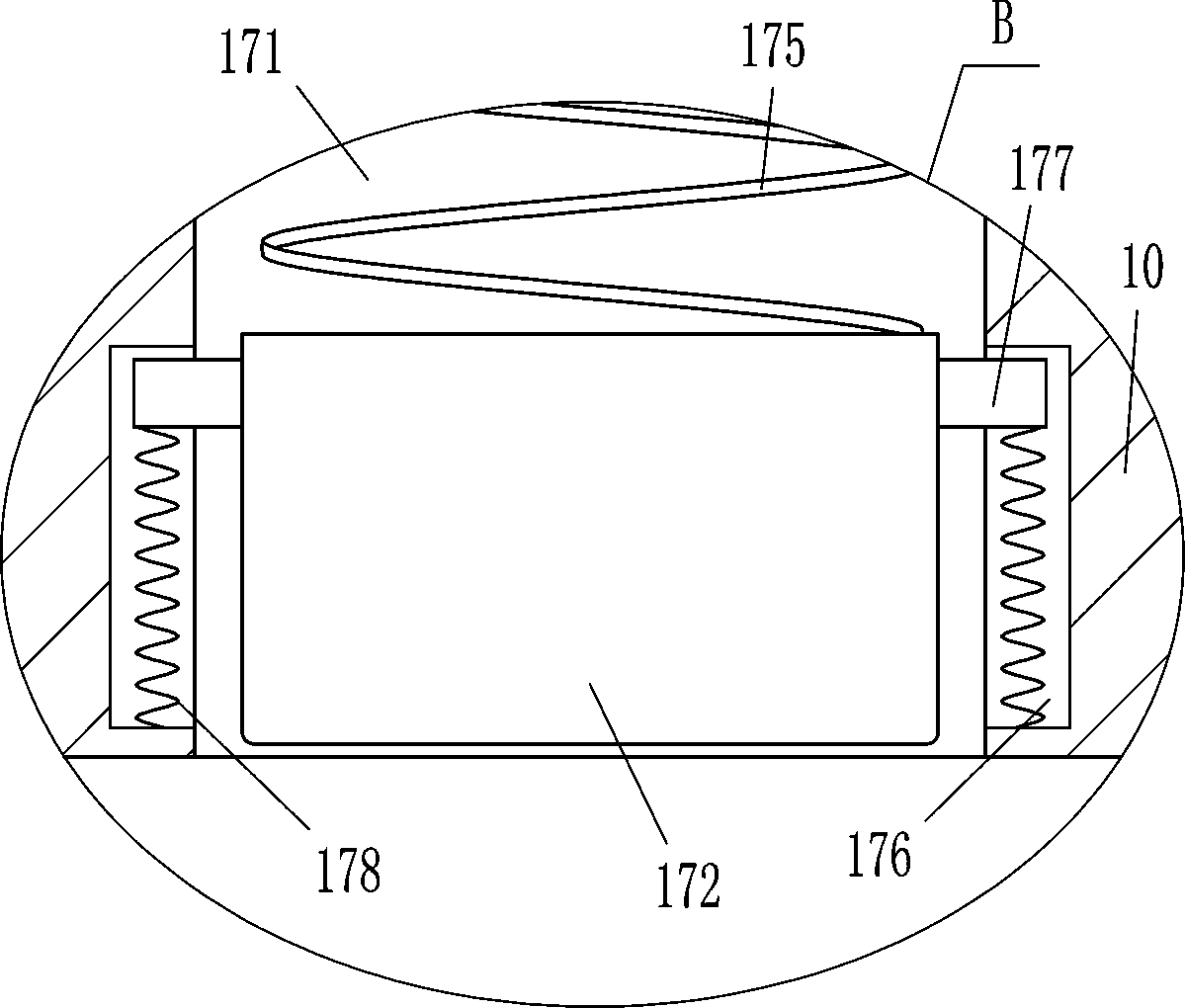

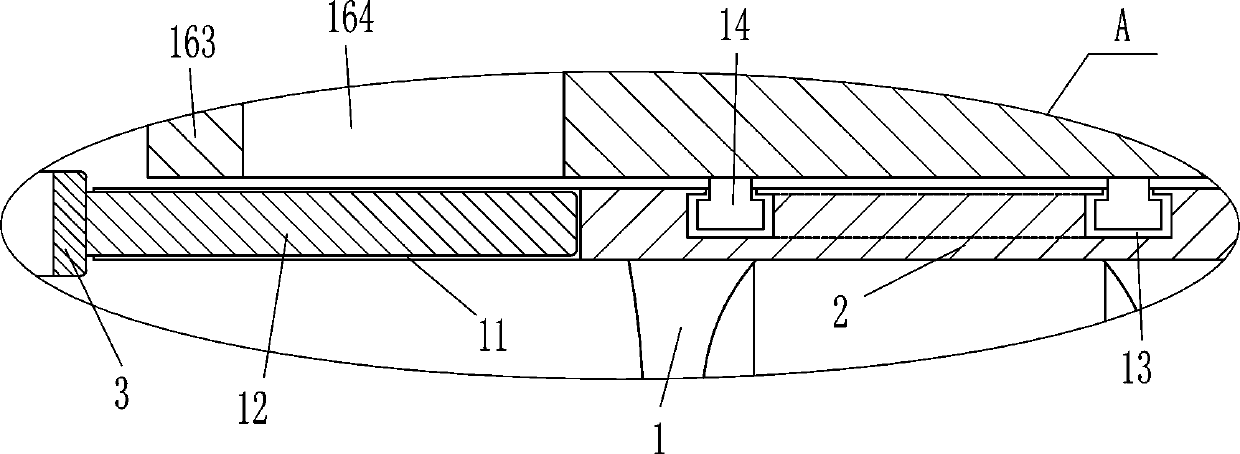

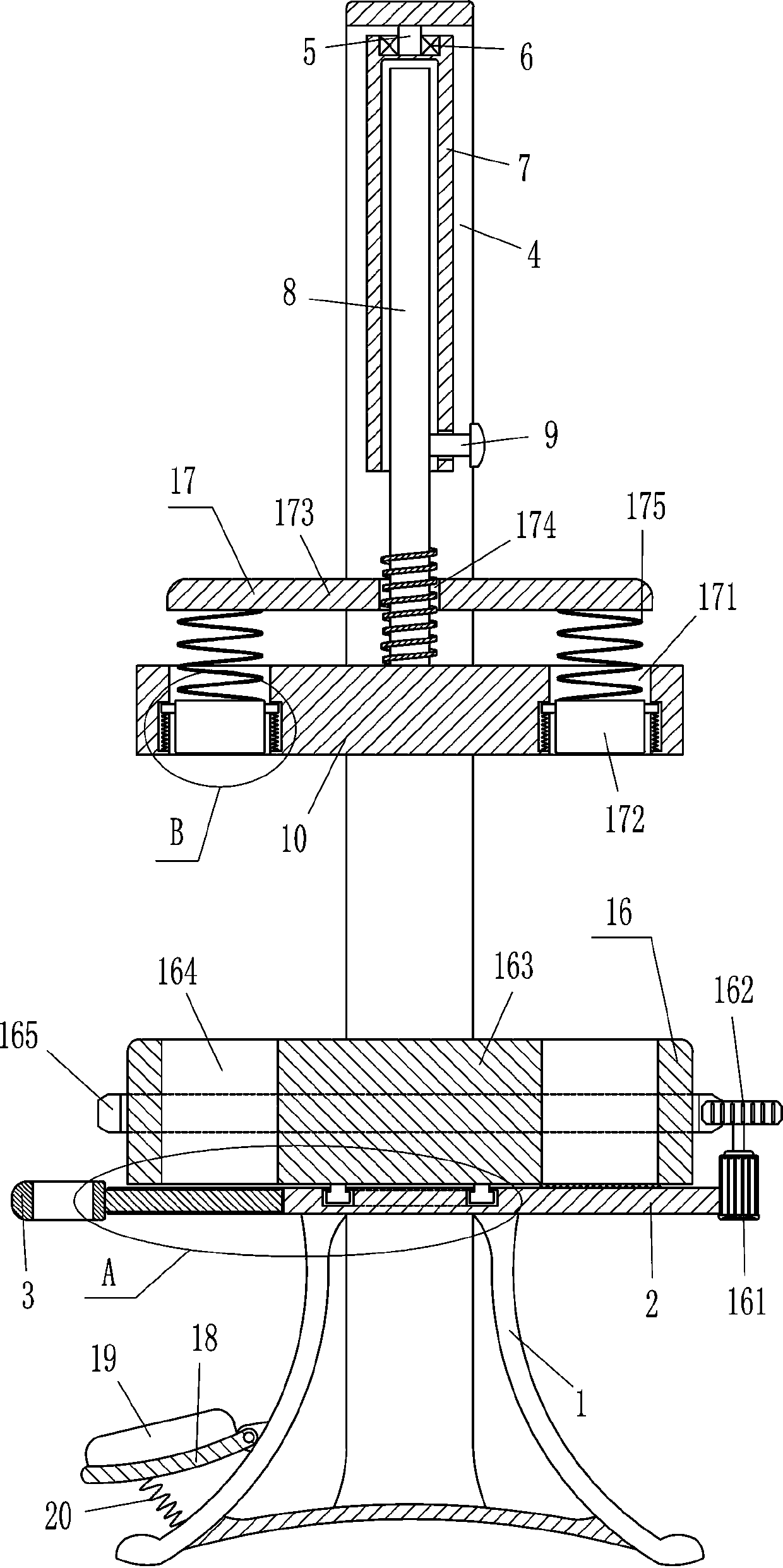

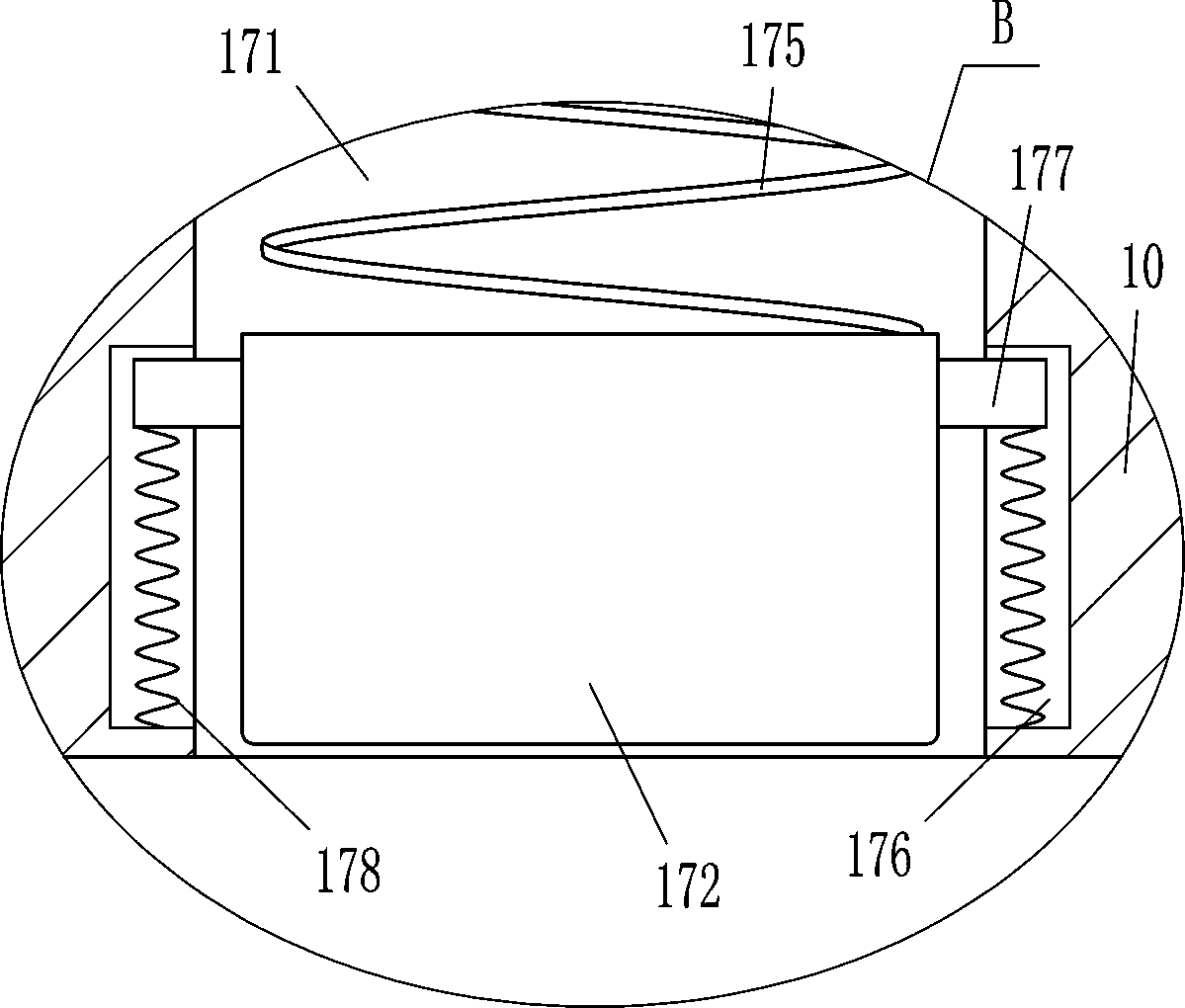

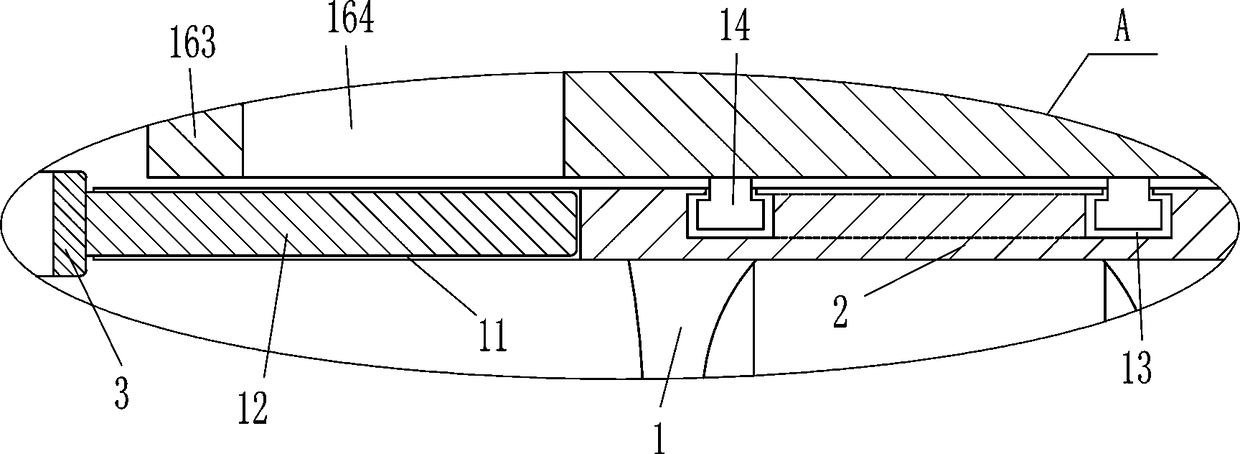

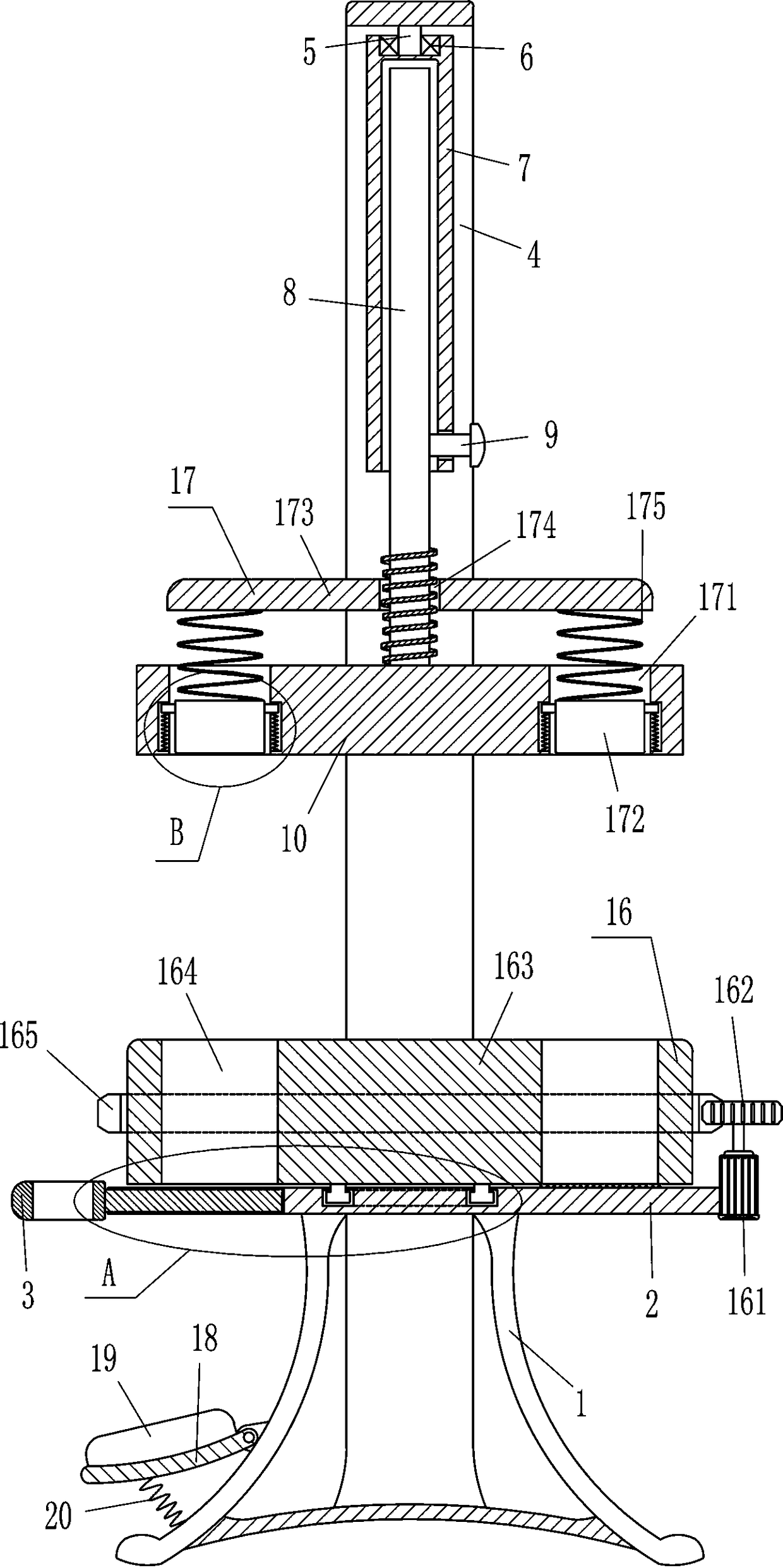

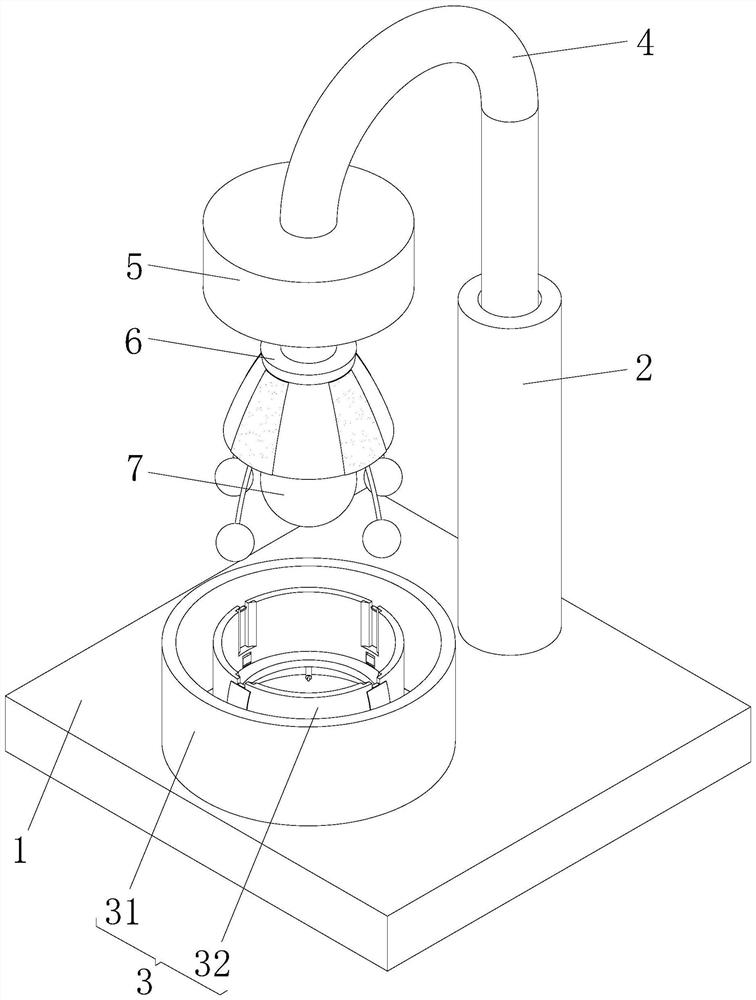

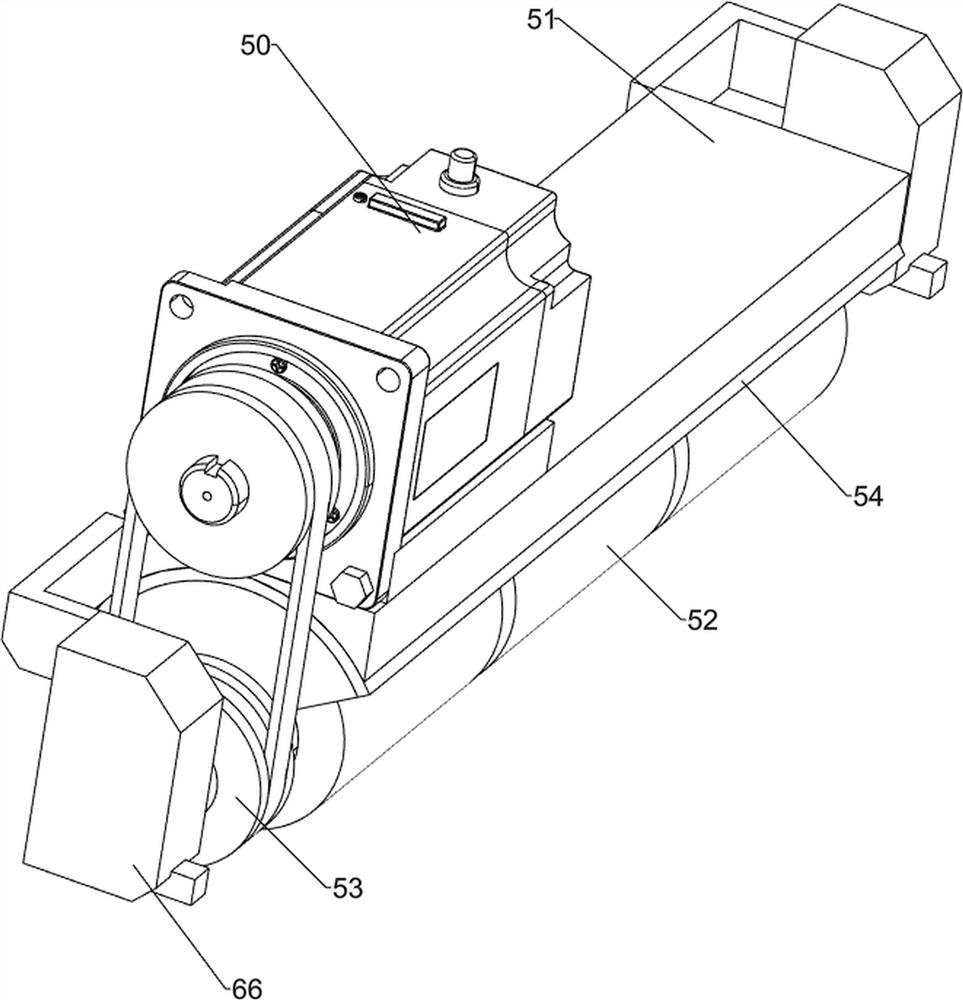

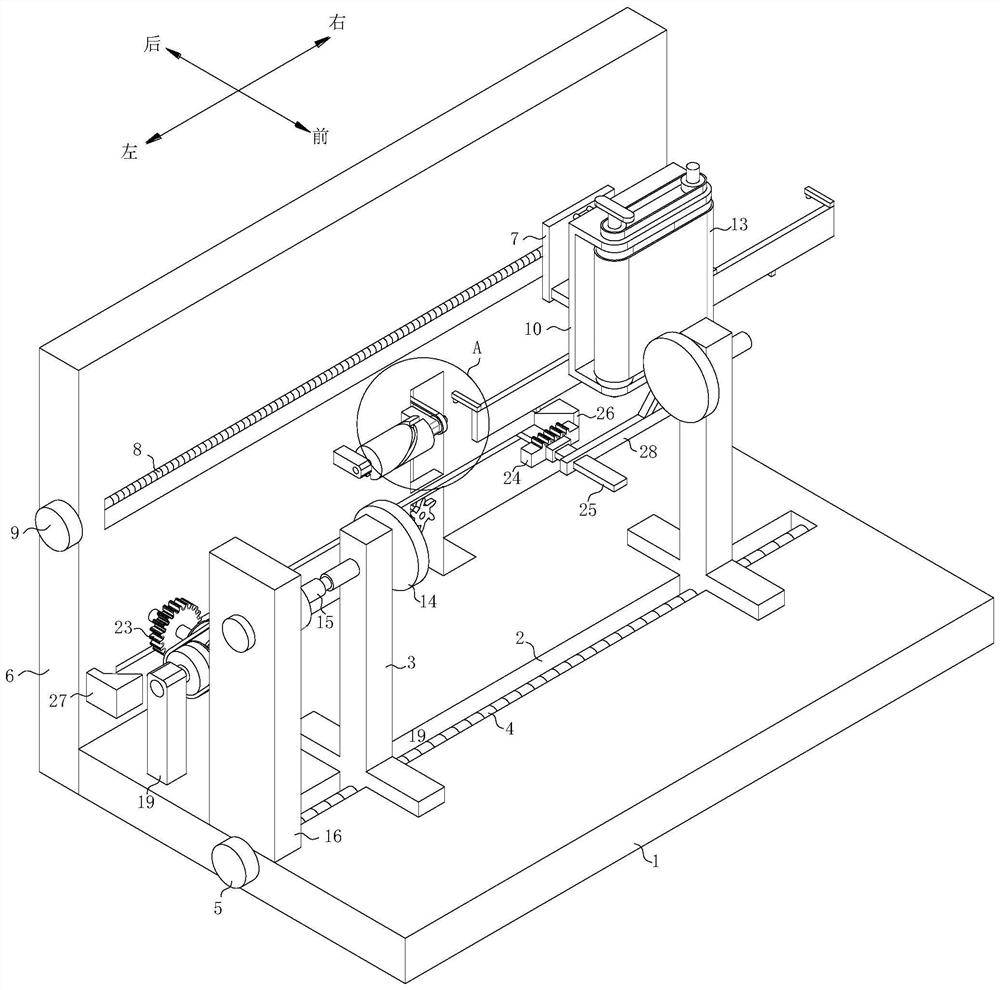

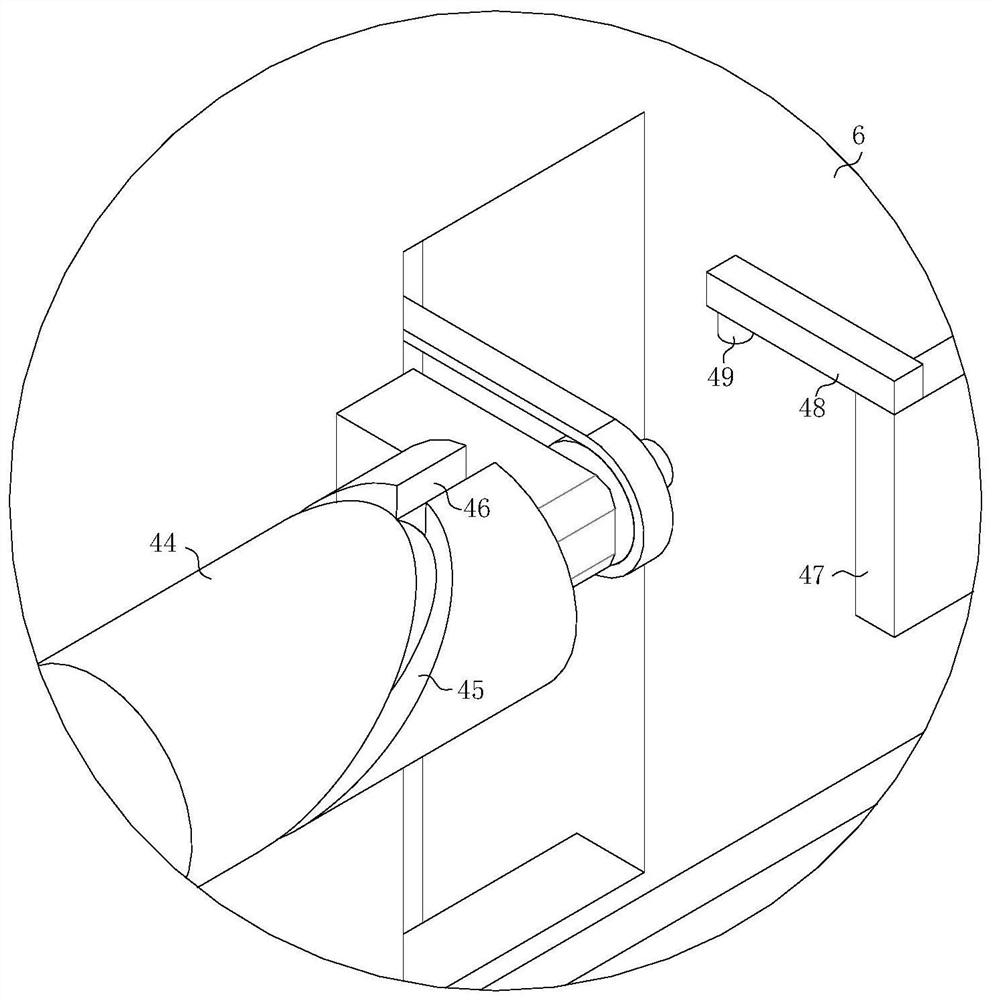

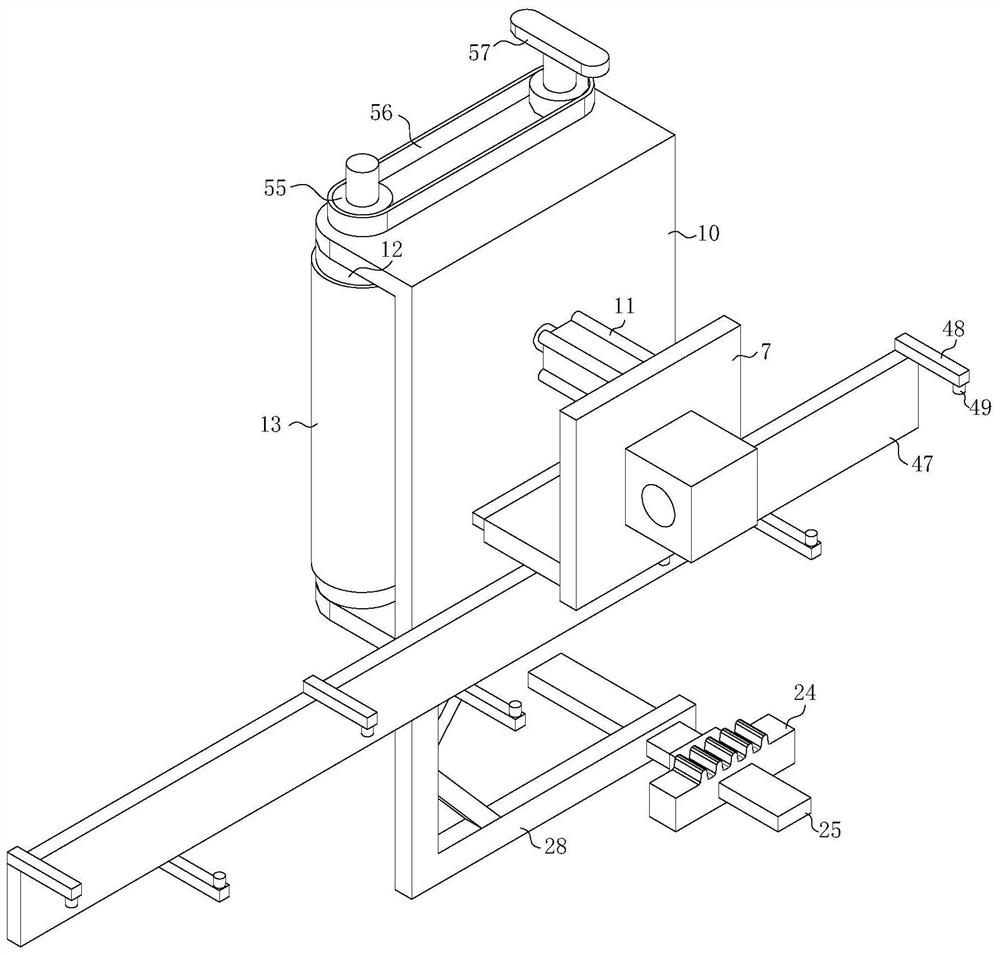

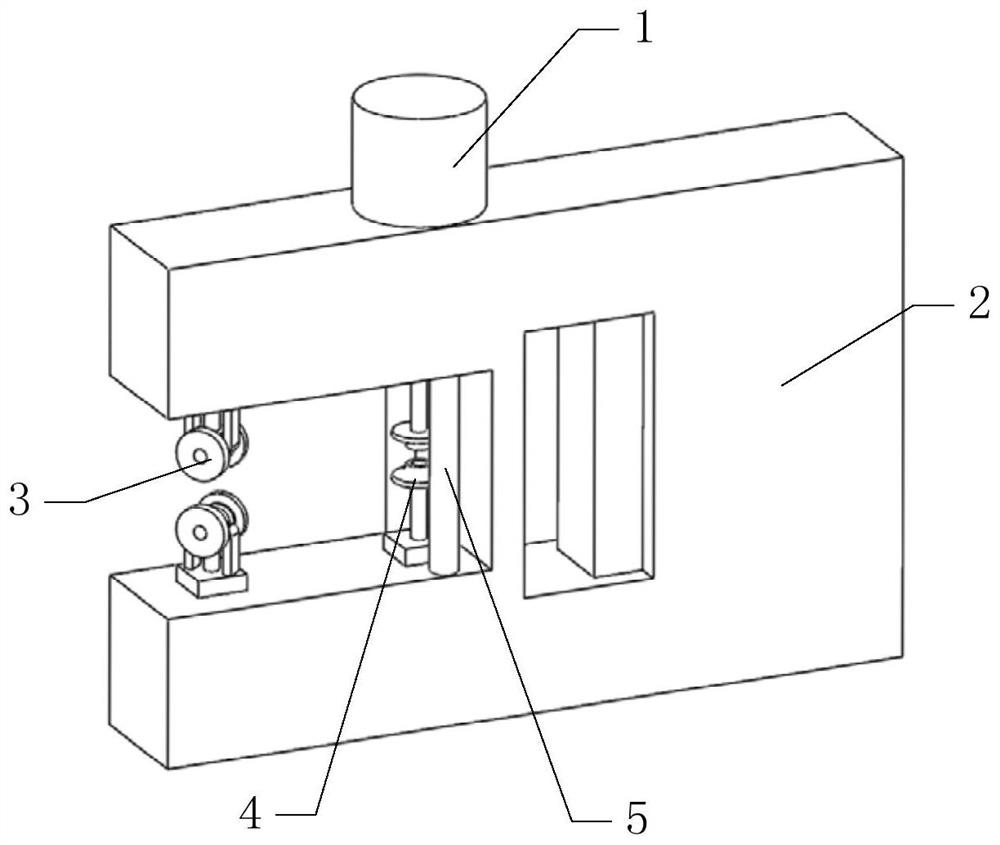

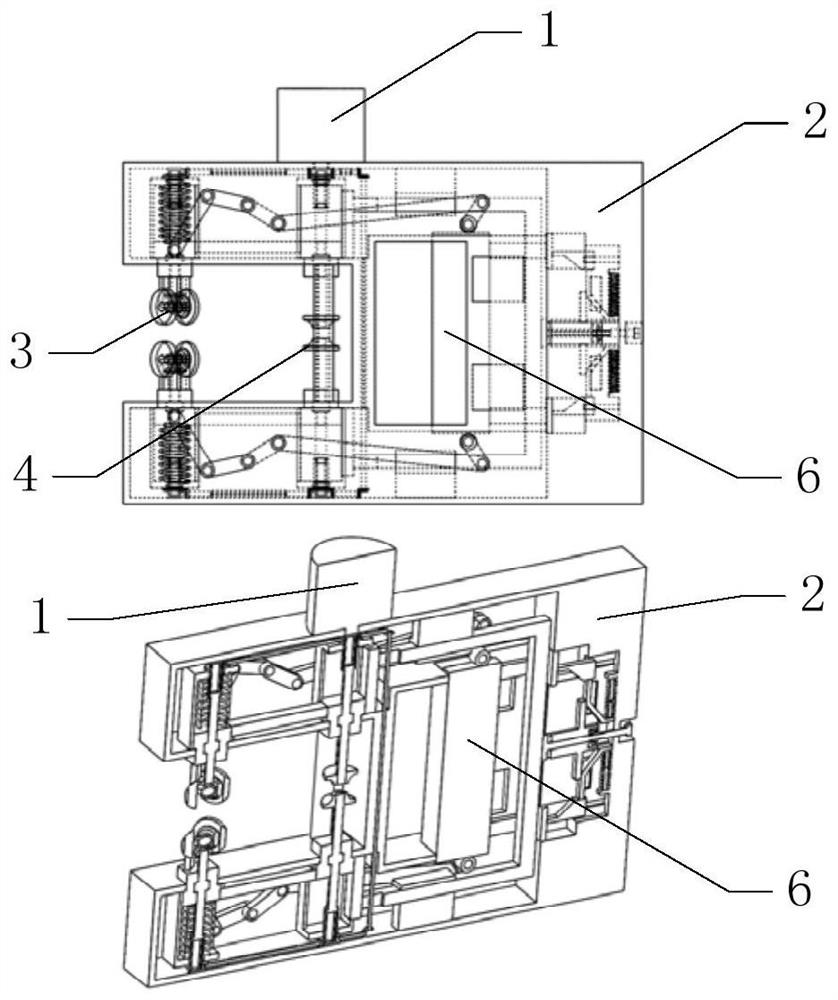

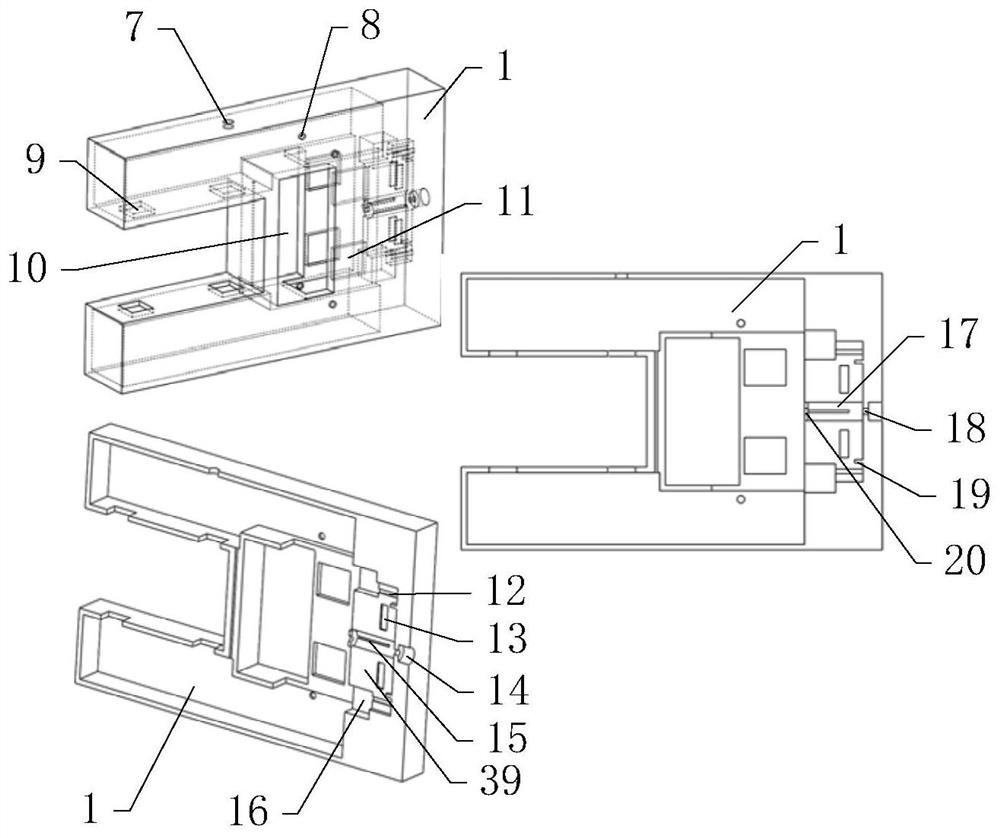

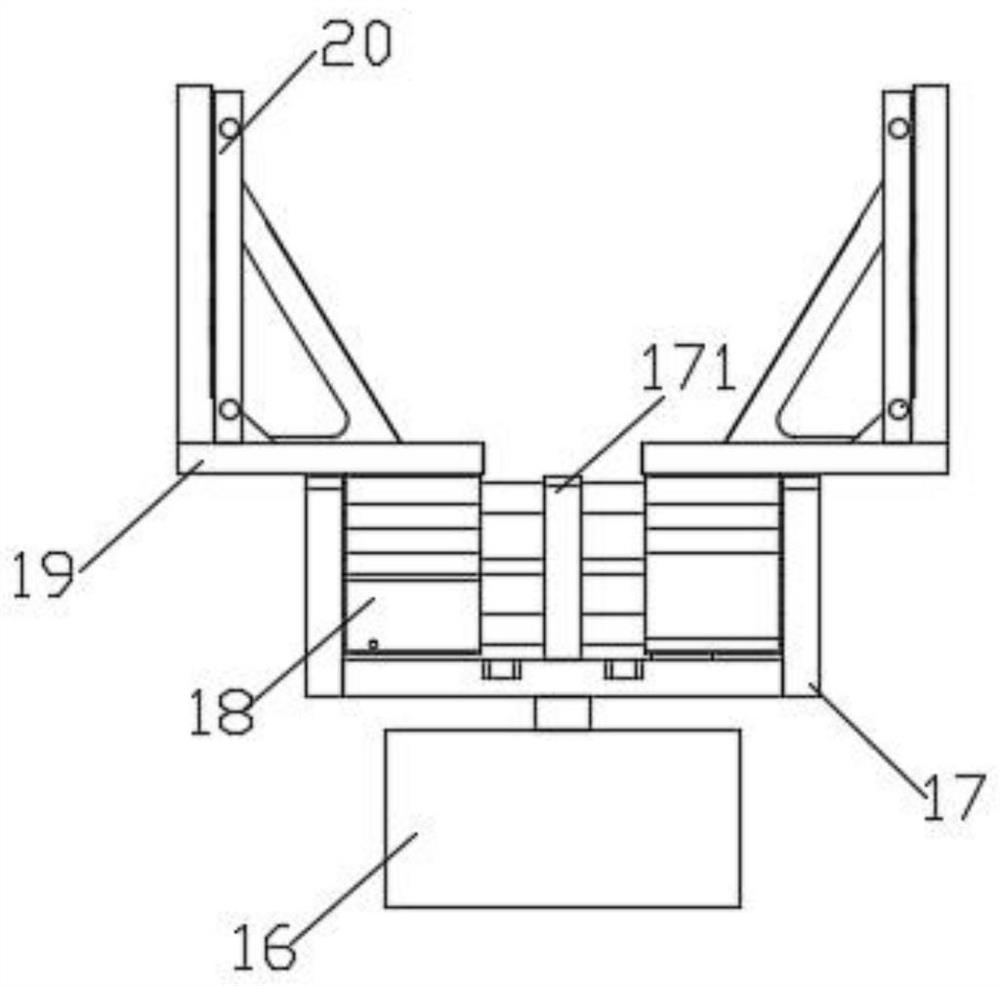

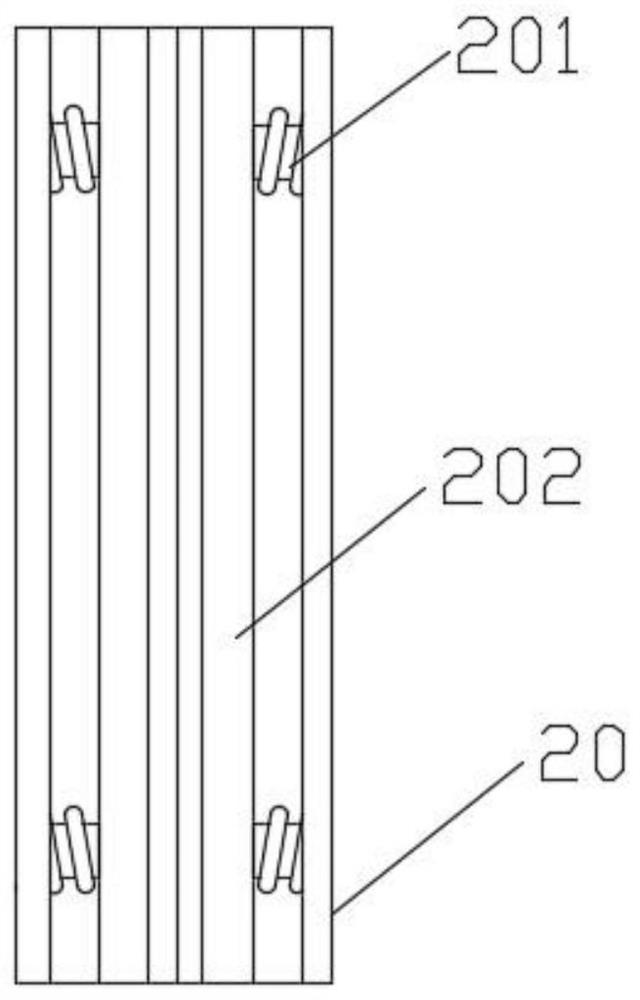

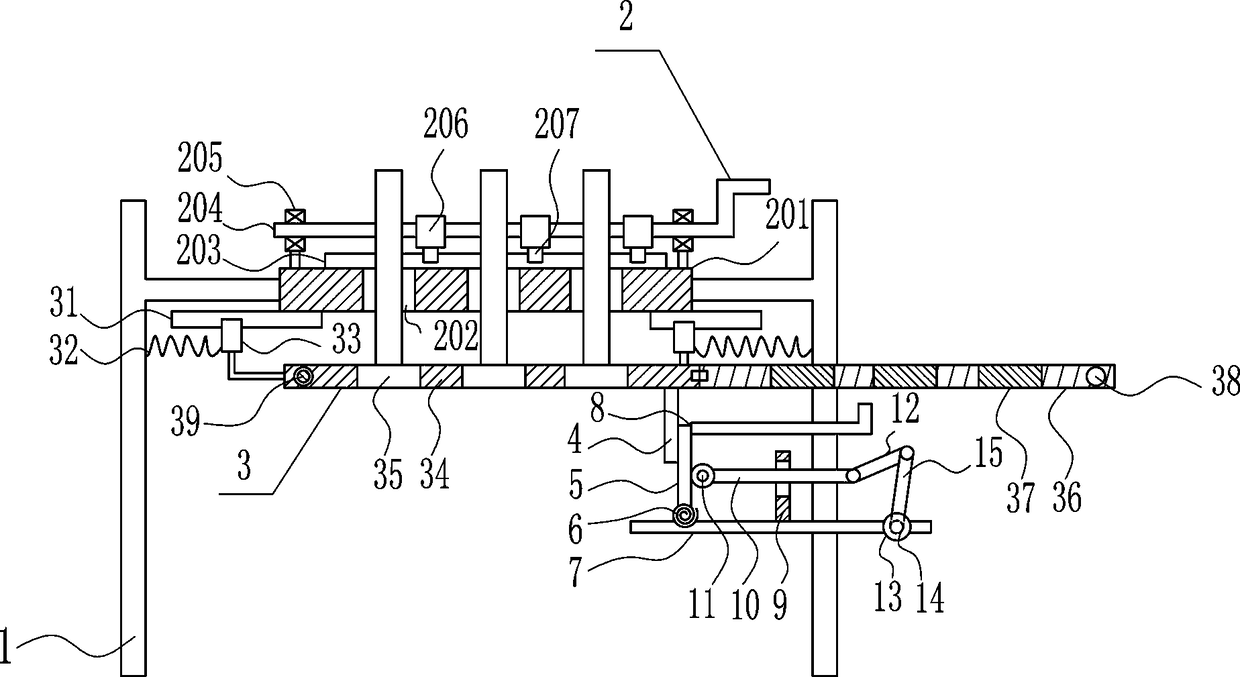

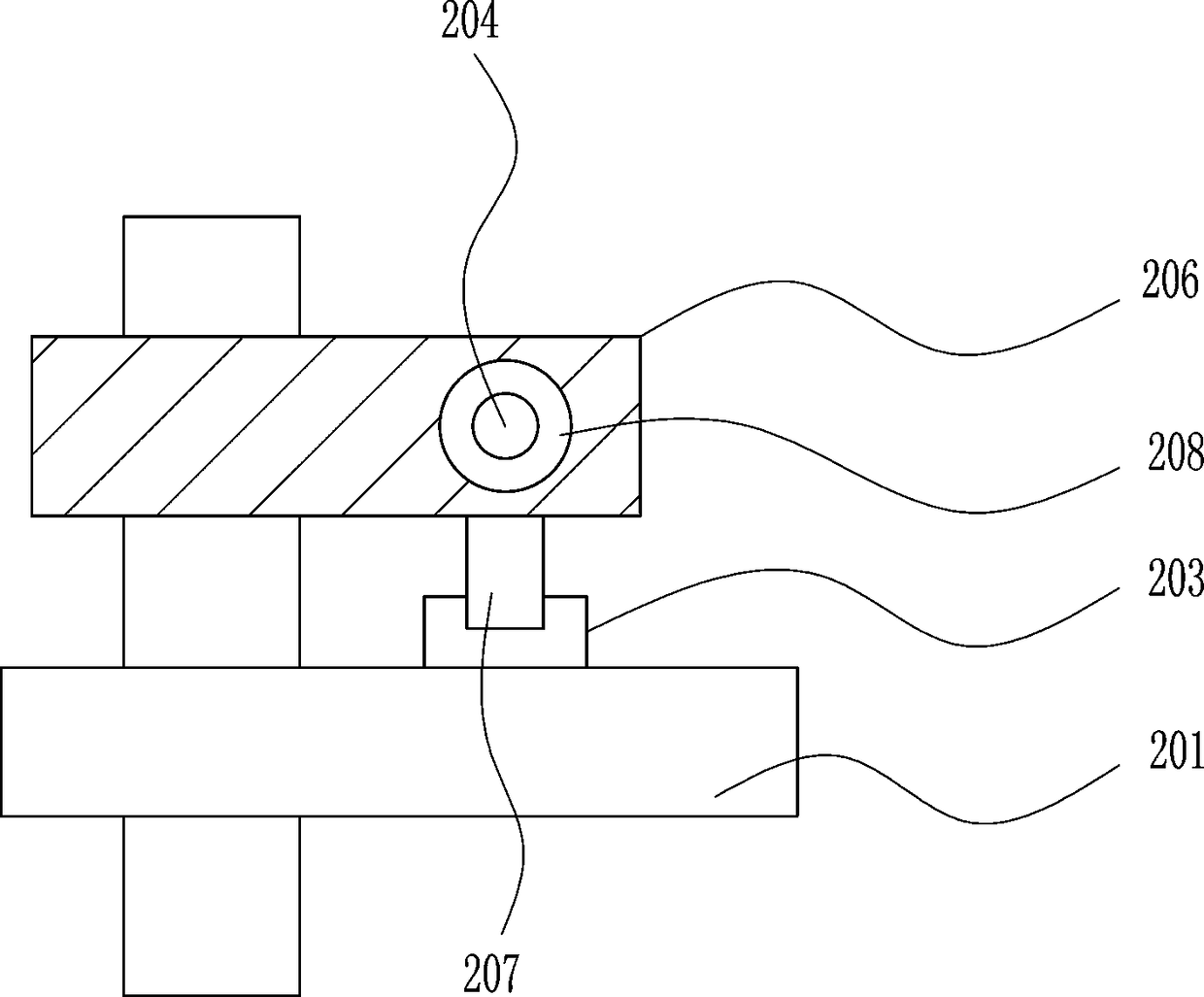

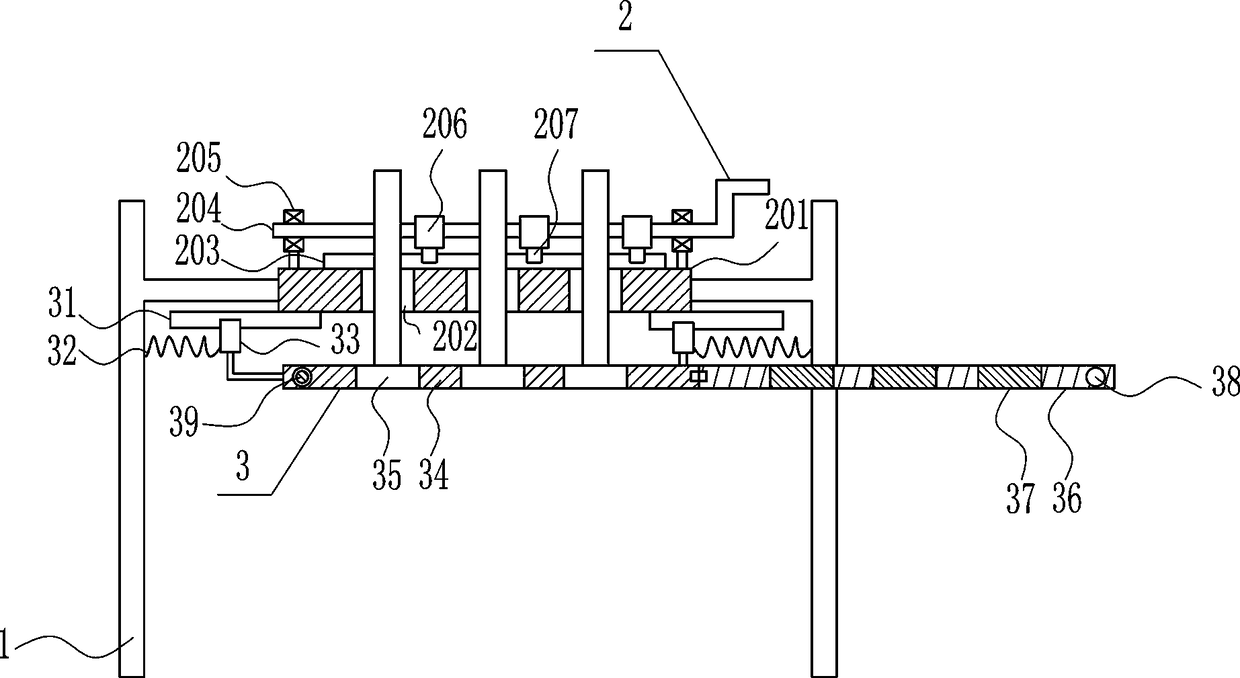

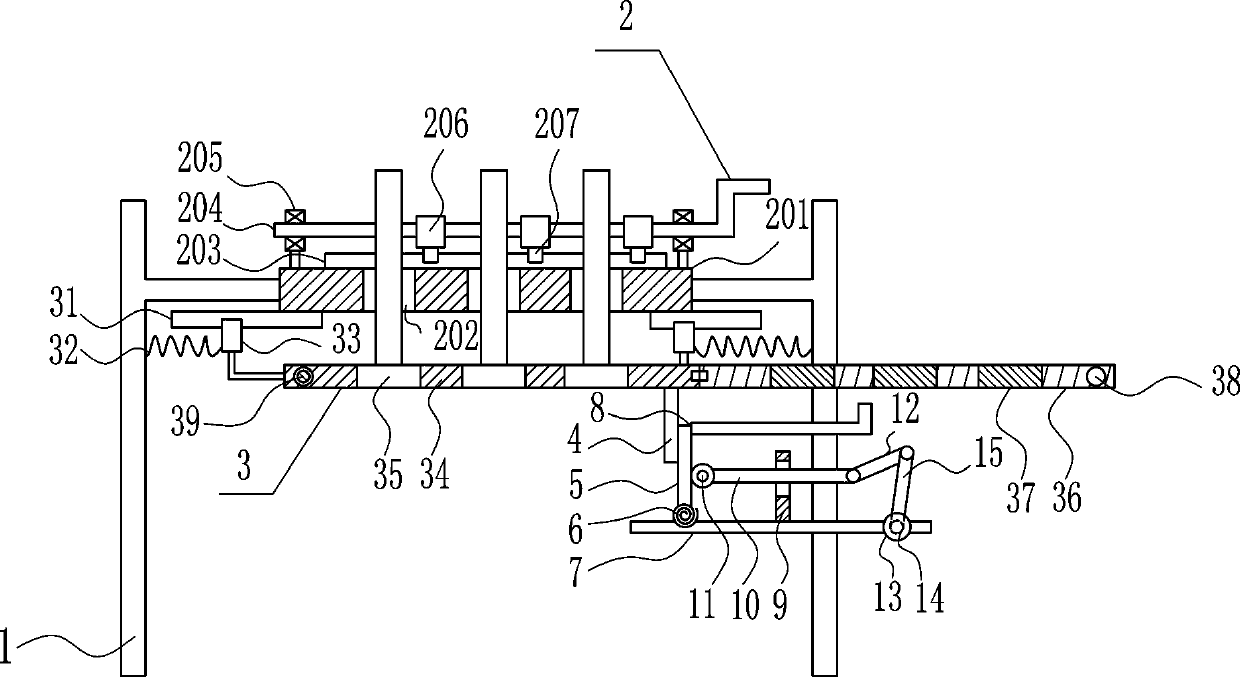

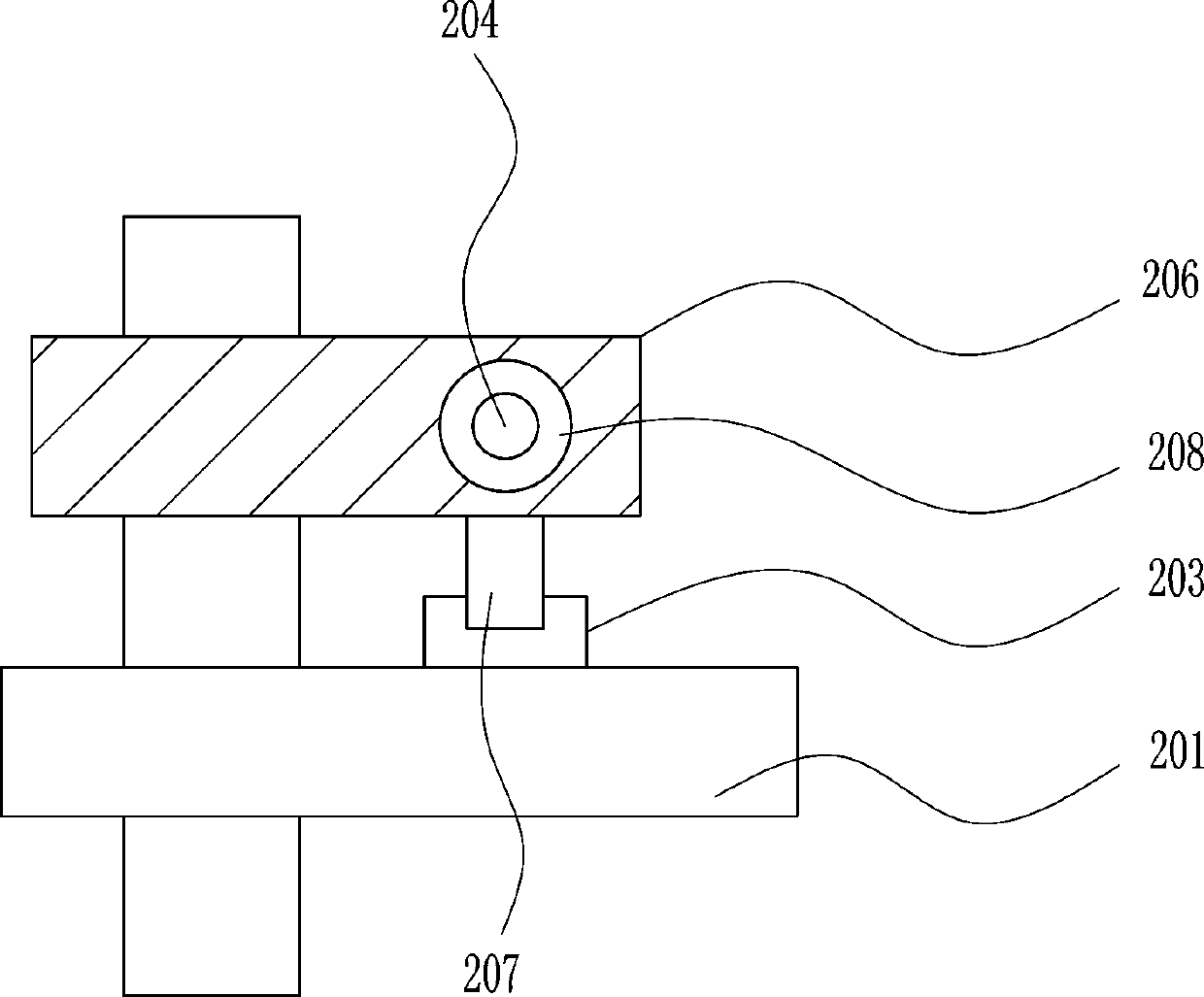

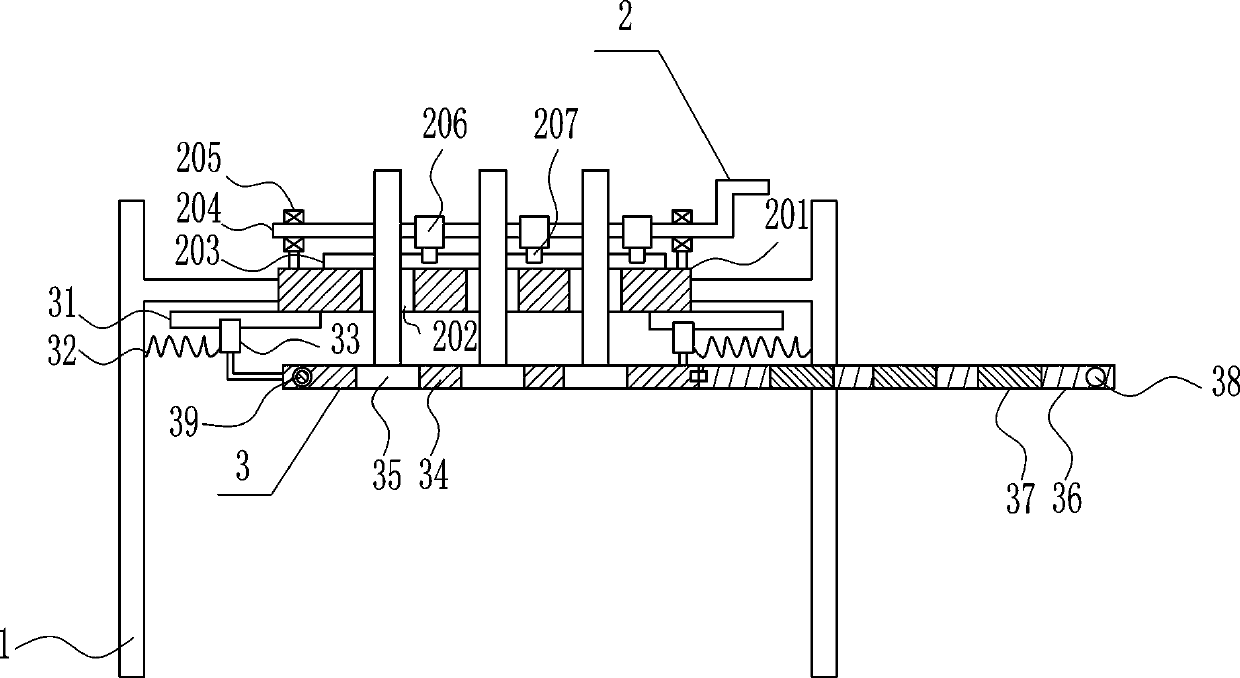

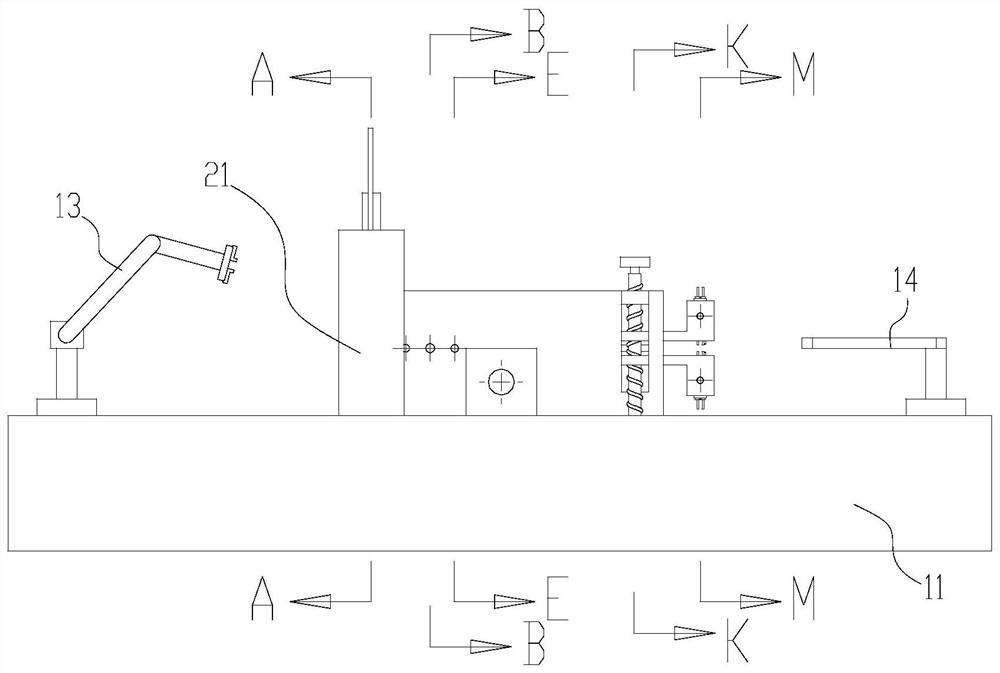

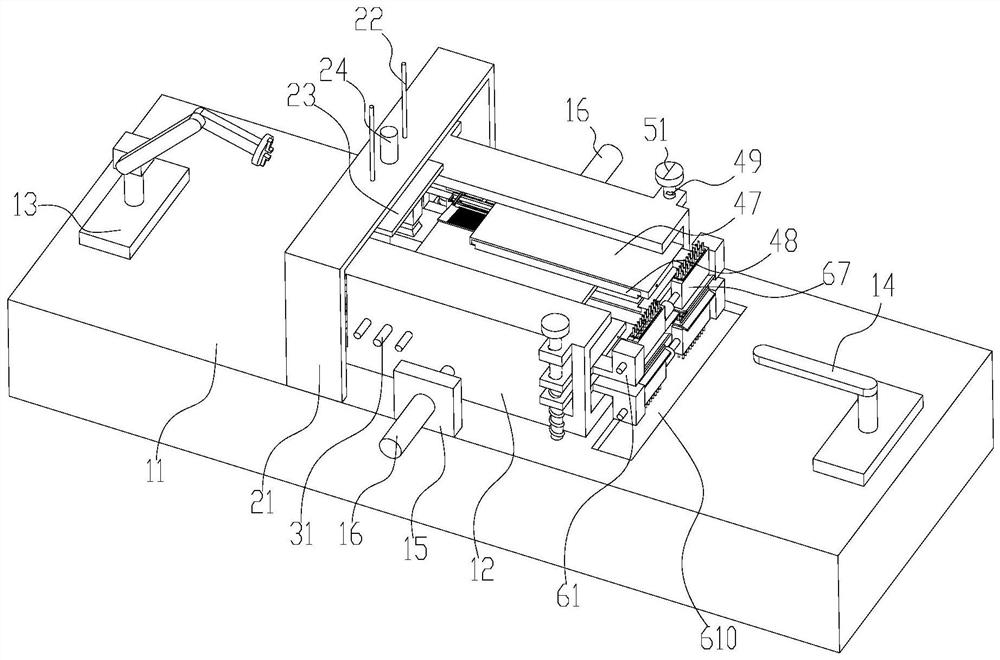

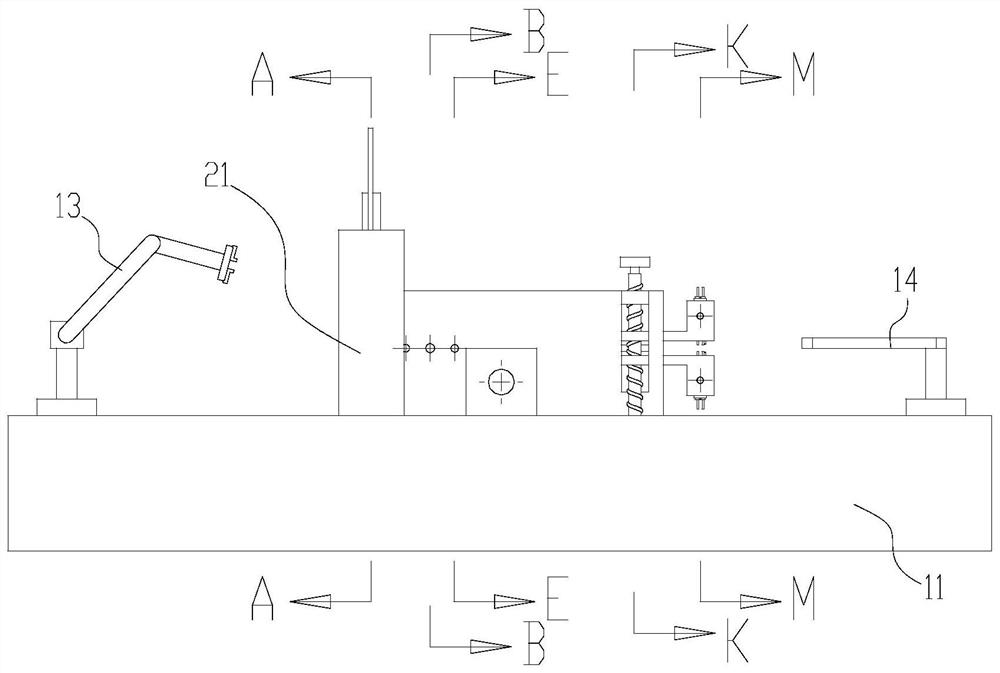

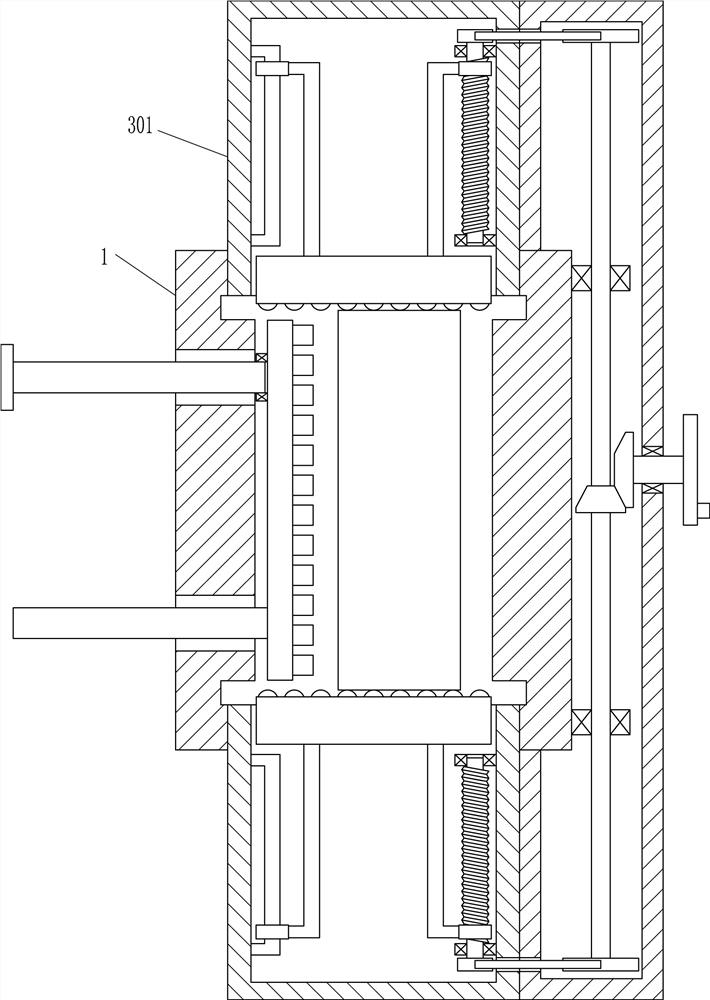

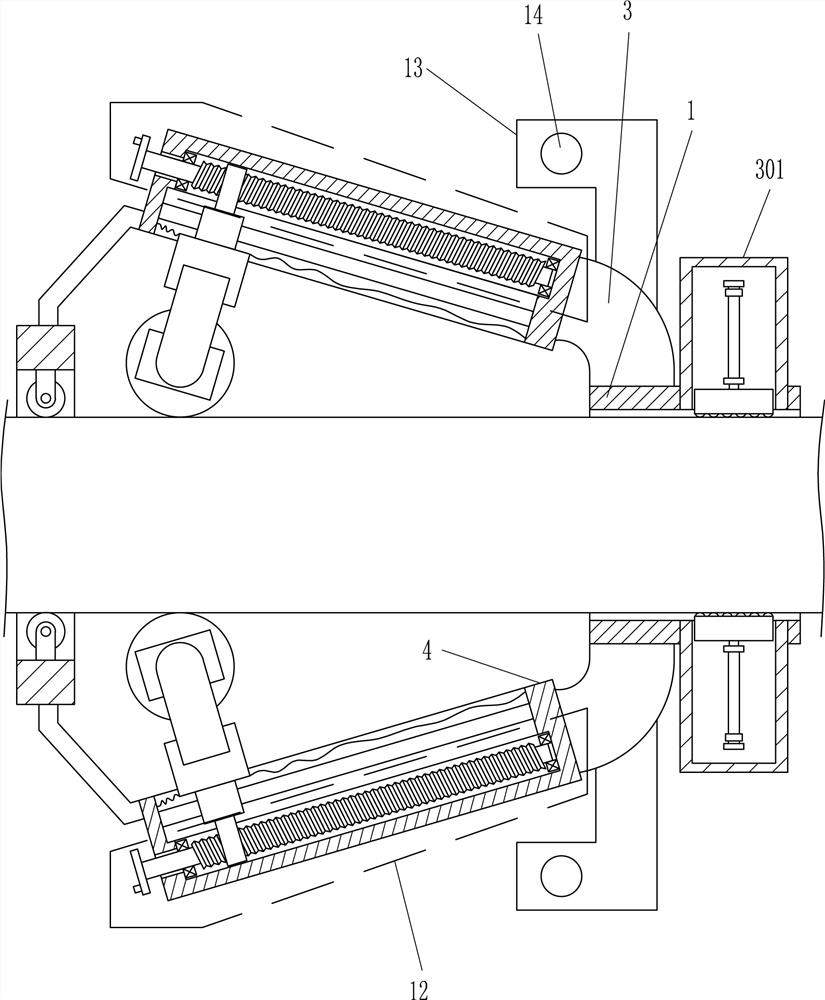

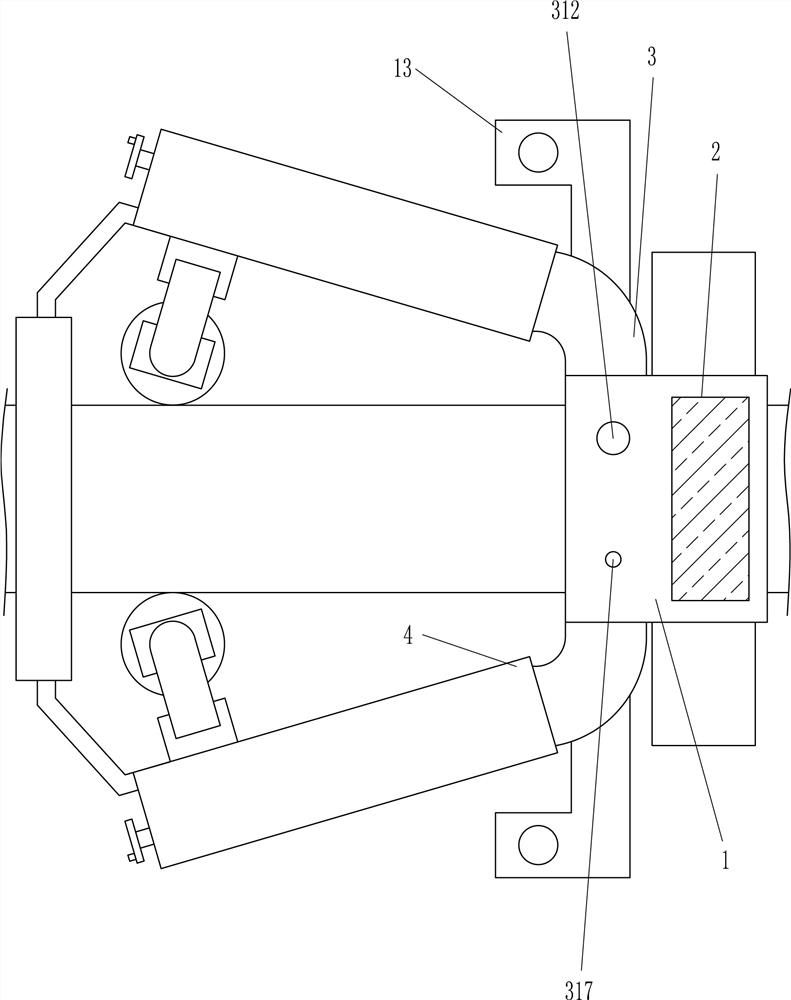

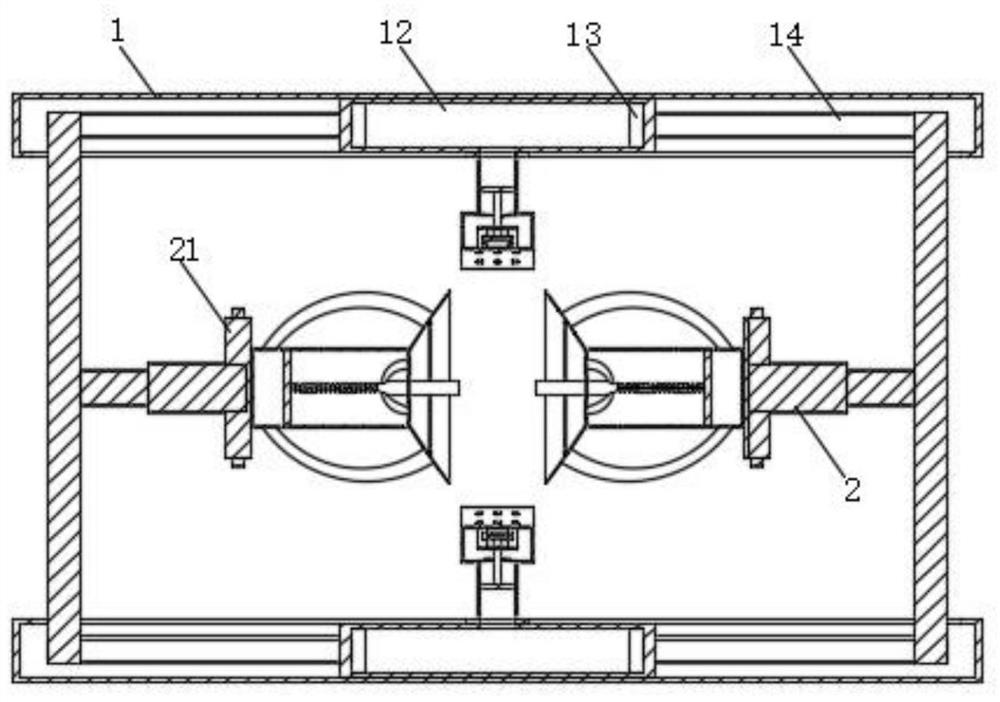

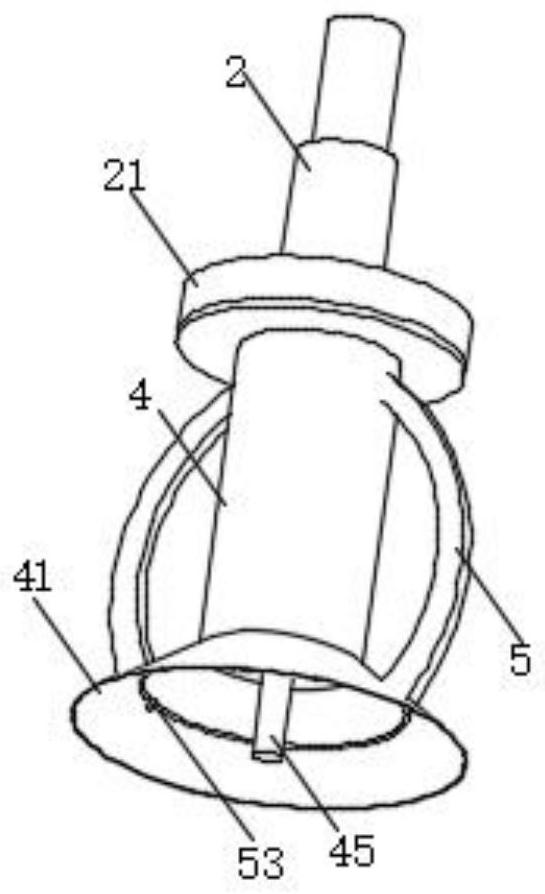

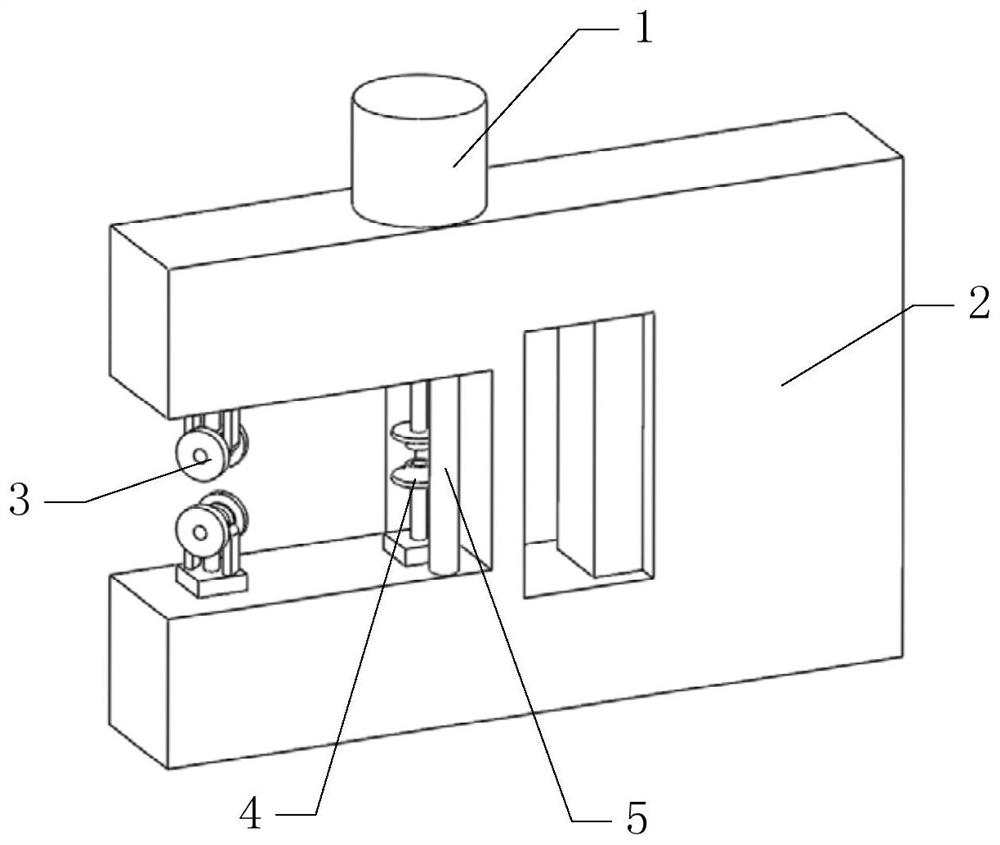

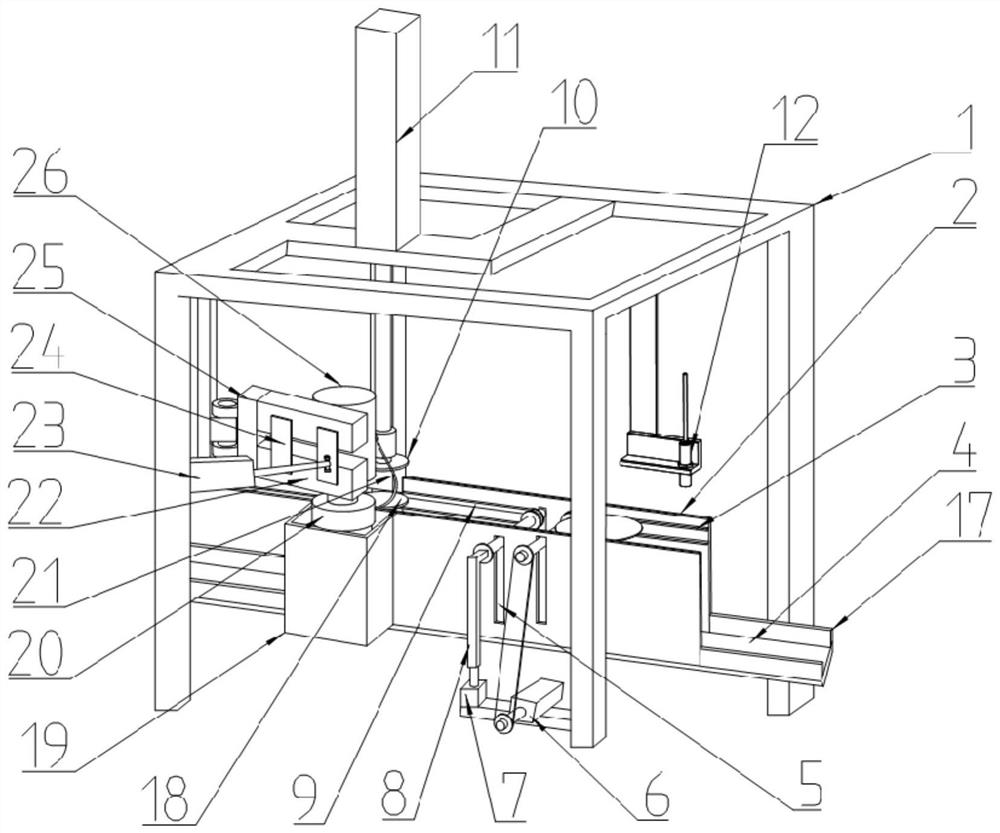

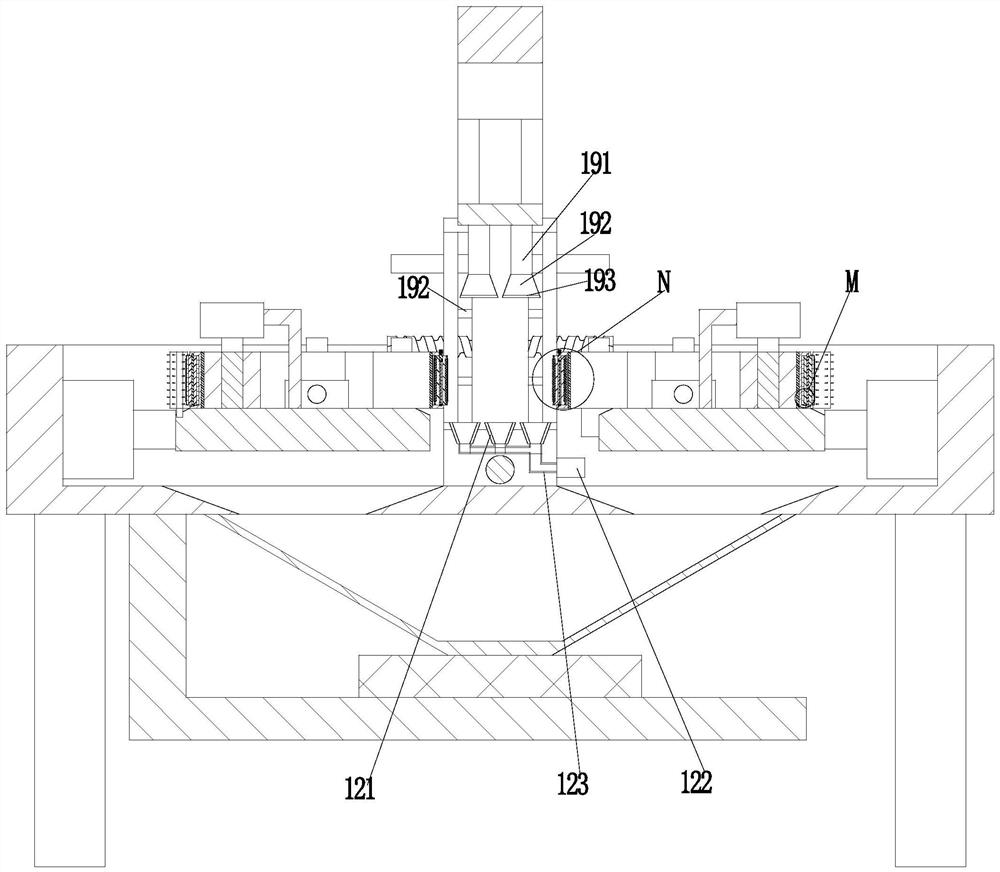

PCB double-sided board grinding device for electronic product and working method thereof

ActiveCN110900335ASanding effectReduce contact areaGrinding carriagesGrinding drivesPiston rodWheel drive

The invention discloses a PCB double-sided board grinding device for an electronic product and a working method thereof. The device comprises a machine table, wherein a clamping seat and a grinding table are arranged on the machine table, a chip collecting box is mounted on the grinding table, the clamping seat is of a rectangular box body structure, a fixing plate is mounted in the clamping seat,a first air cylinder is further arranged in the clamping seat, and a piston rod of the first air cylinder is connected with a connecting strip. According to the device, the first cylinder piston rodis contracted, so that one mounting plate is driven to move through the connecting strip, the mounting plate drives a rod sleeve to slide on a fixing rod, then a clamping strip drives a rotating wheeland a limiting rolling wheel to rotated, the rotating wheel drives the other clamping strip to move, the two clamping strips are driven to move towards each other, and then two moving side columns are driven to move towards each other through the two mounting plates, so that the technical problem that the PCB board grinding device is prone to be stuck due to the conventional screw rod adjusting clamping in the prior art is solved.

Owner:江苏百维能源科技有限公司

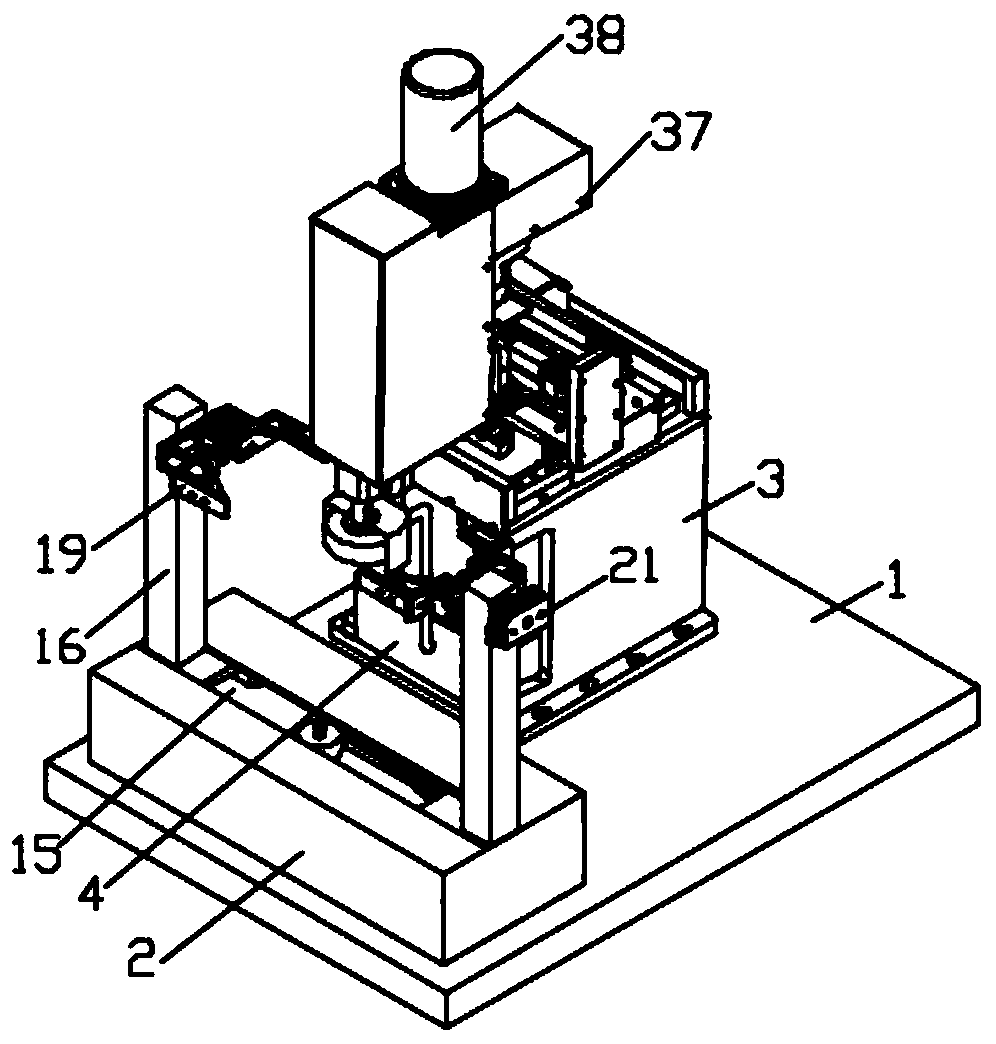

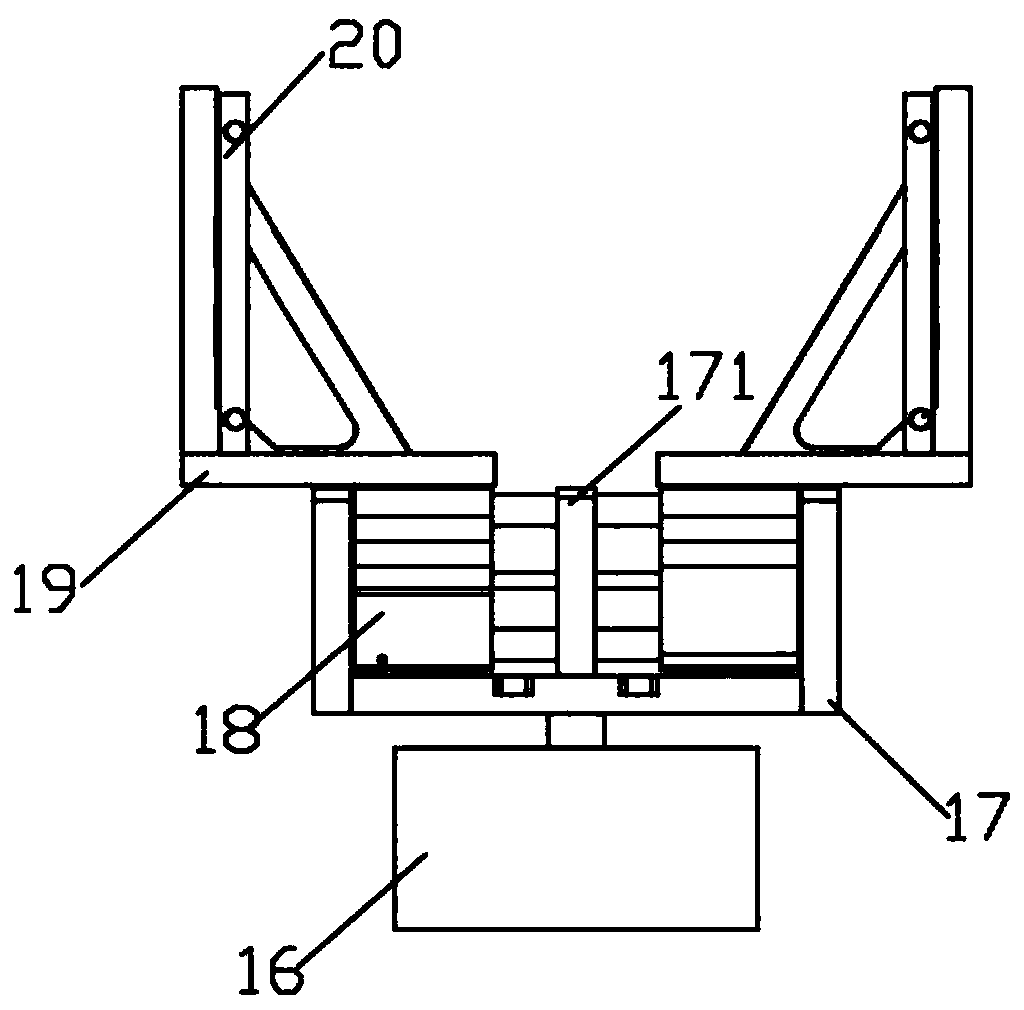

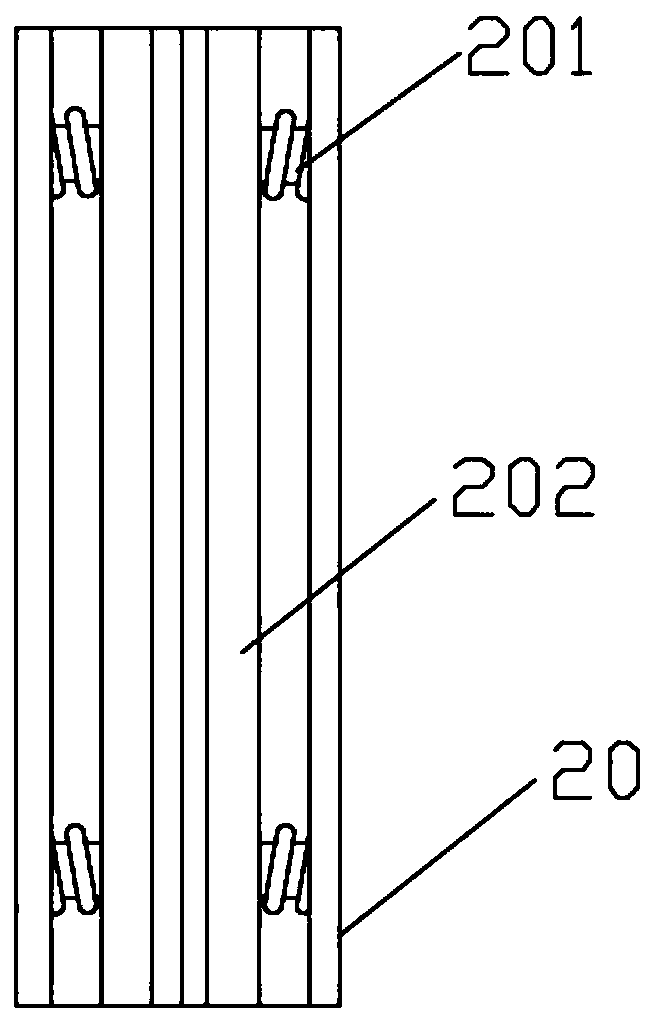

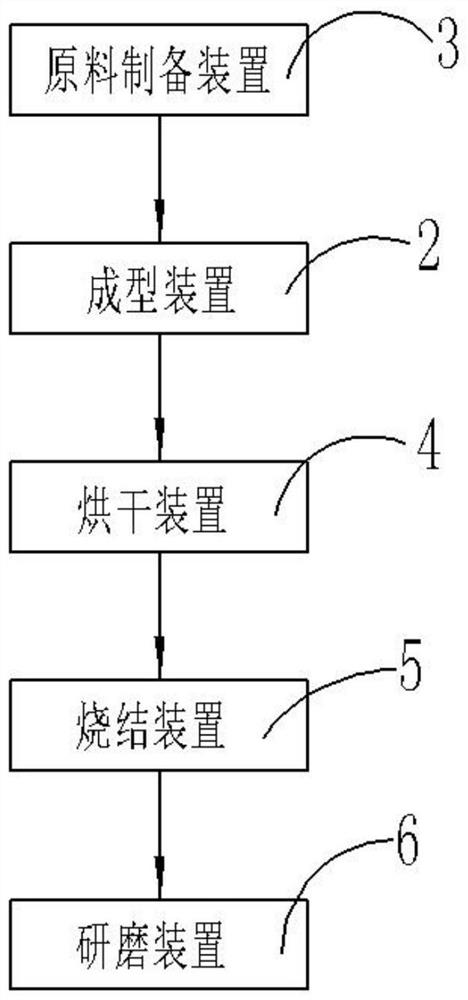

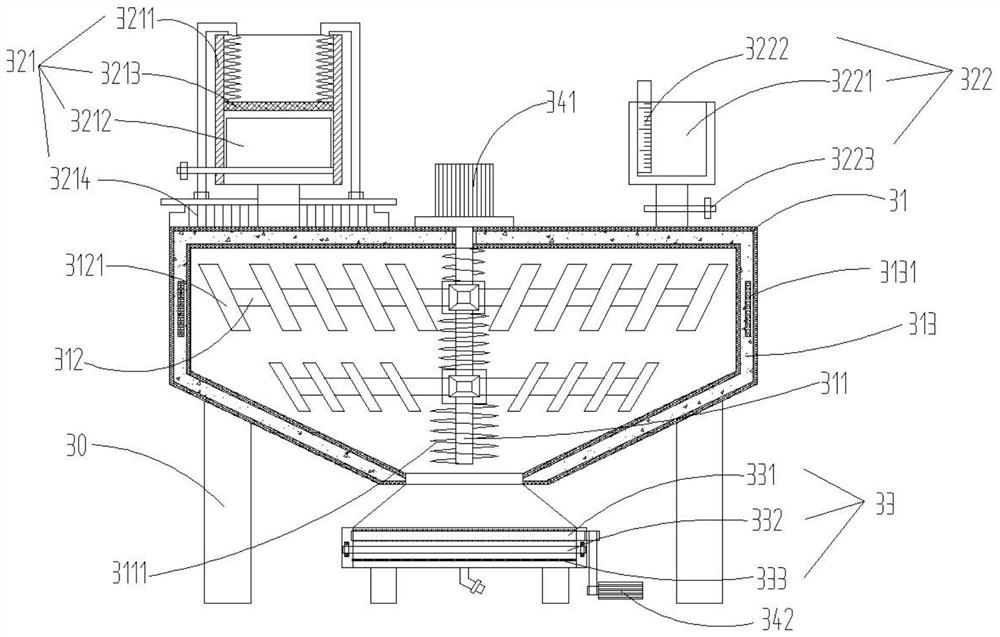

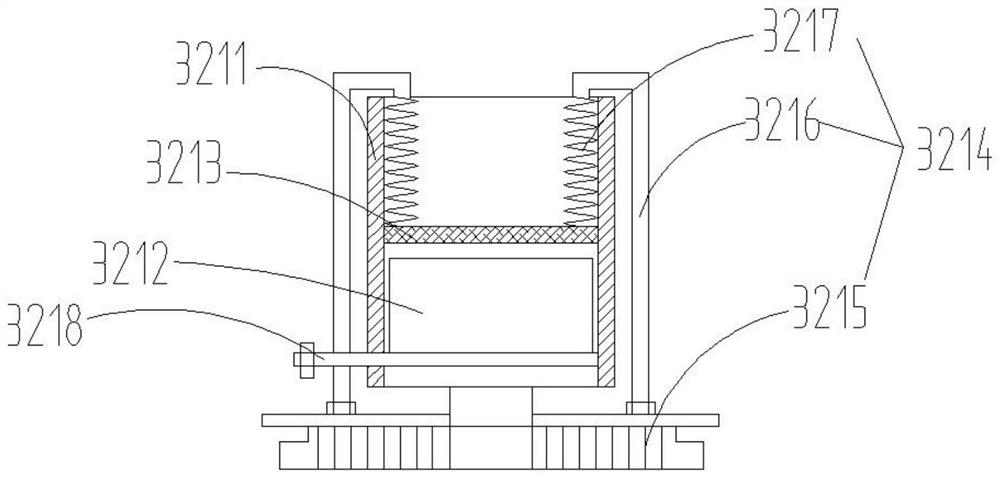

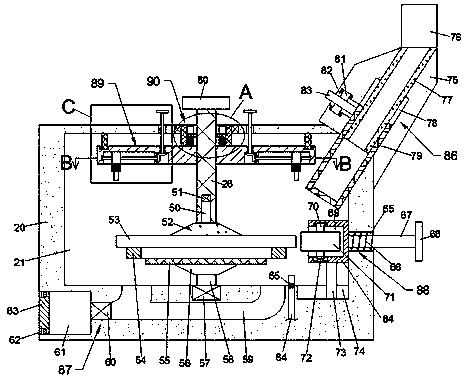

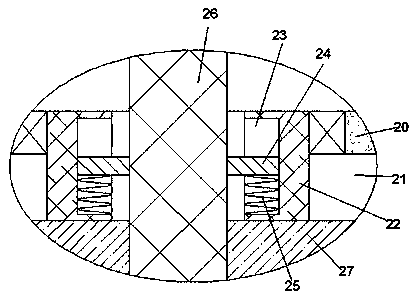

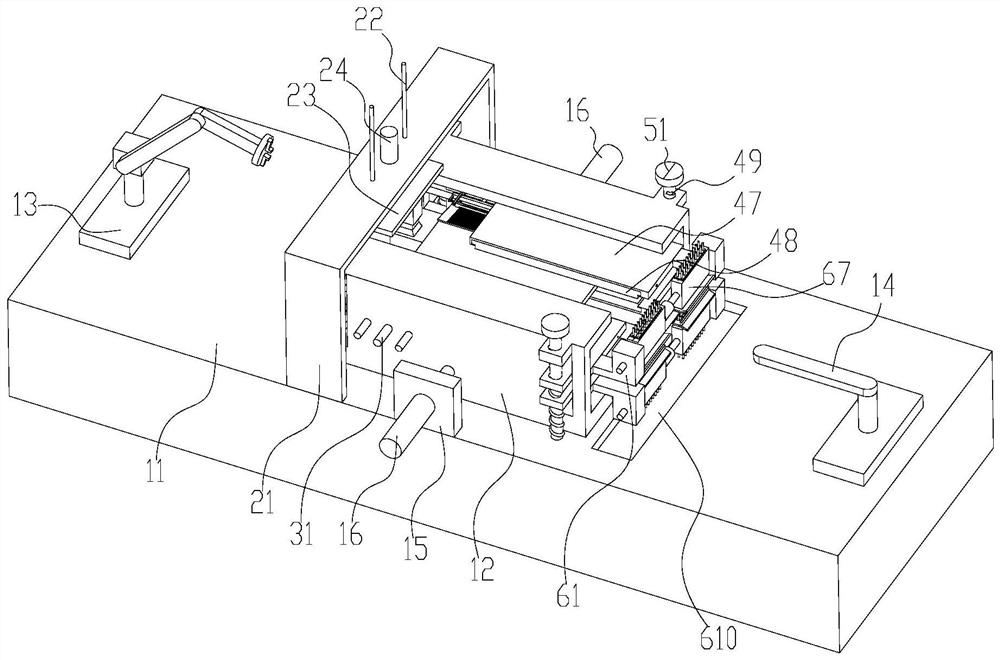

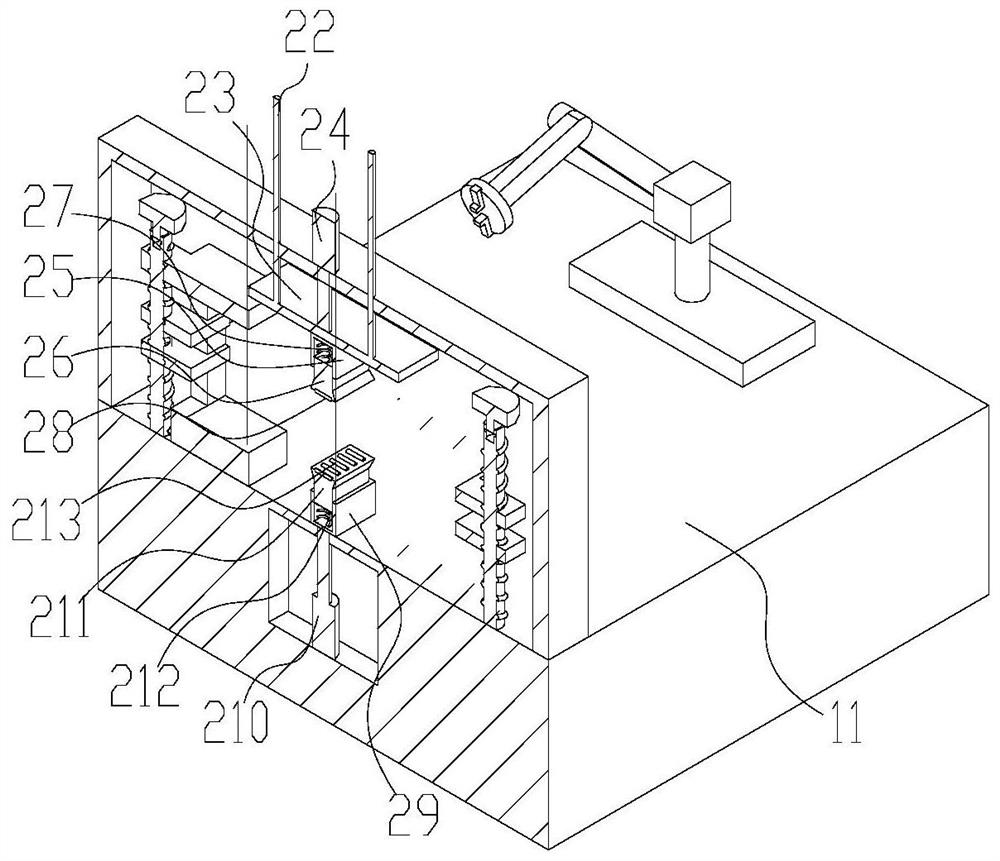

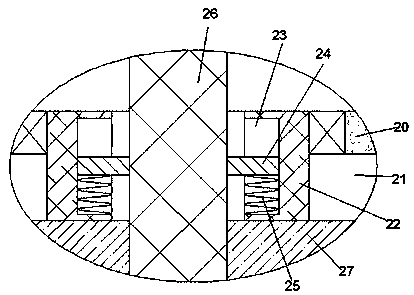

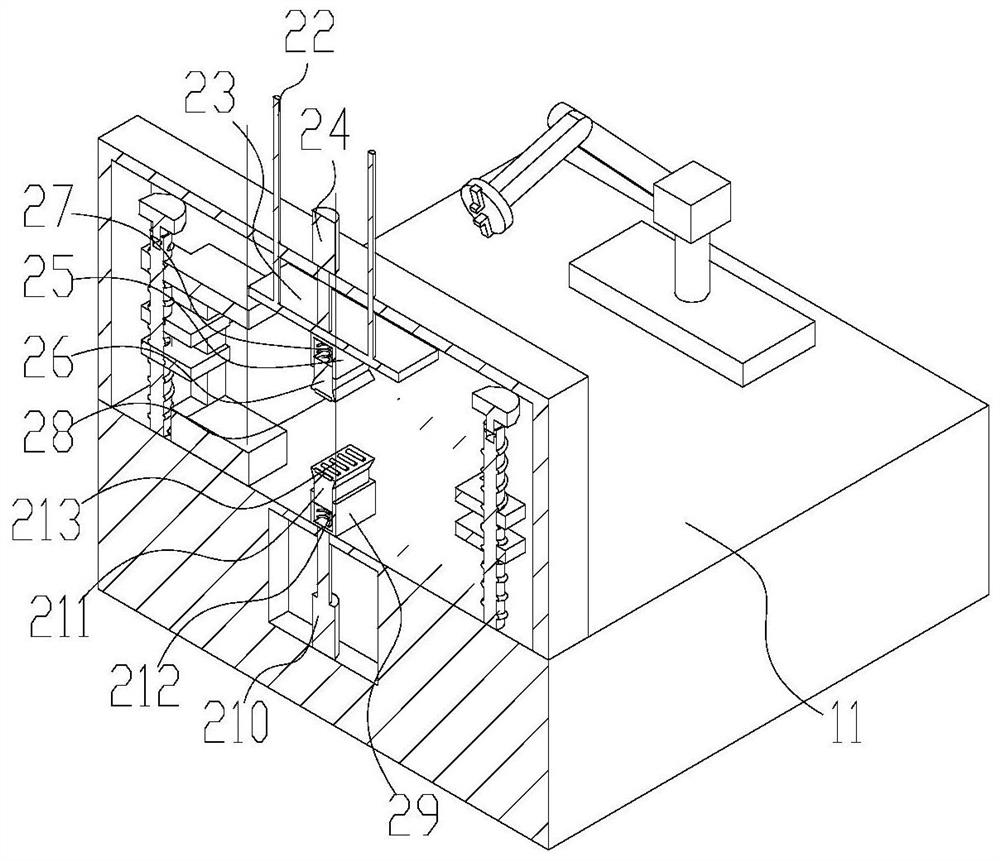

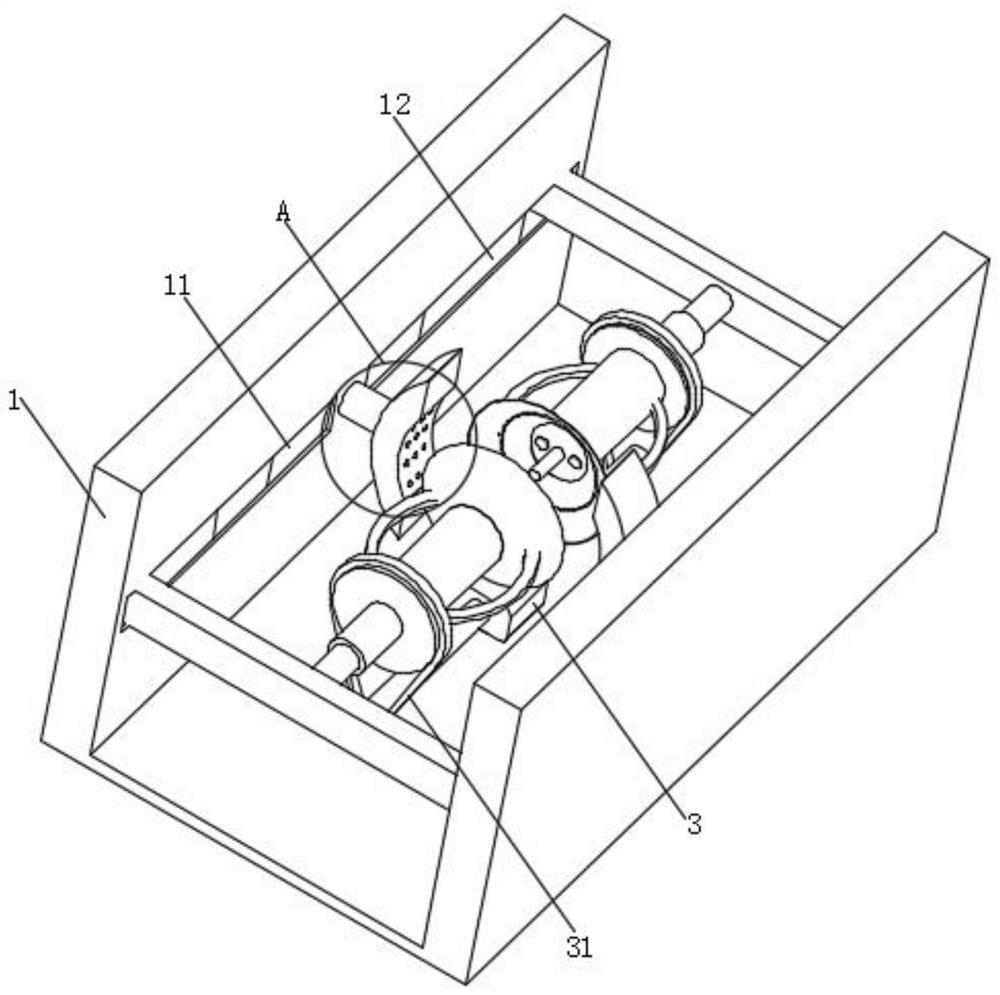

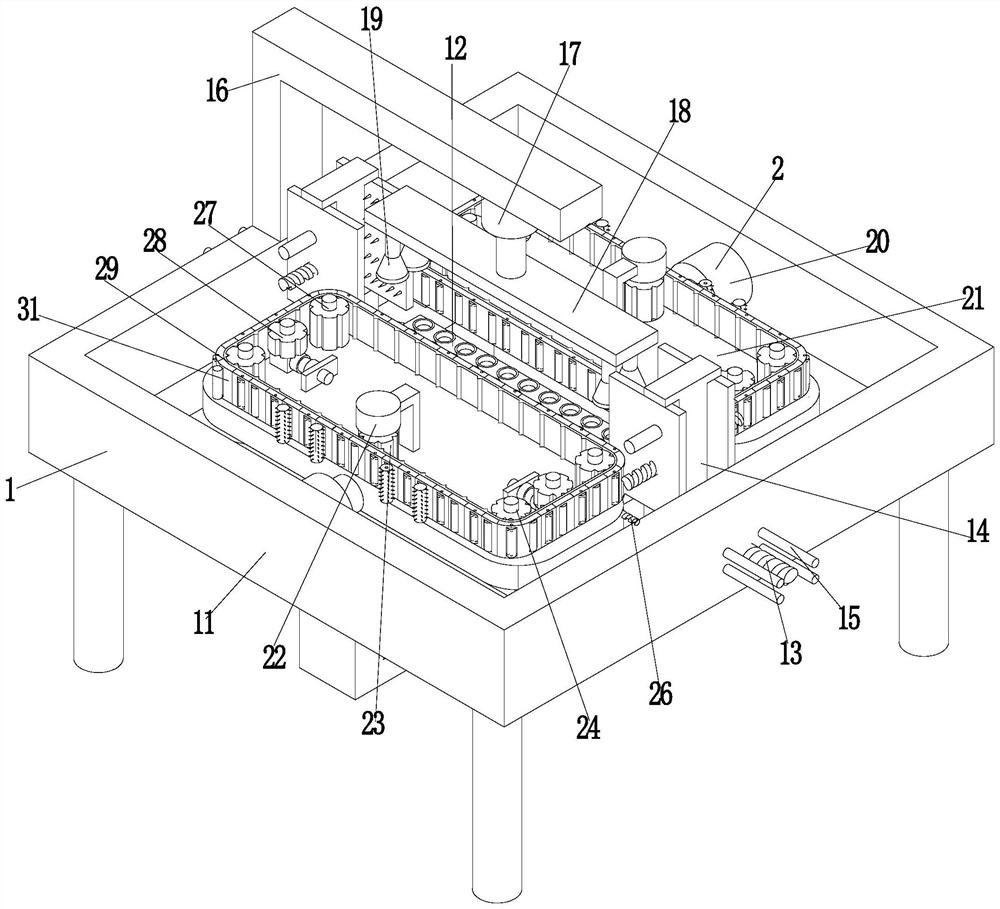

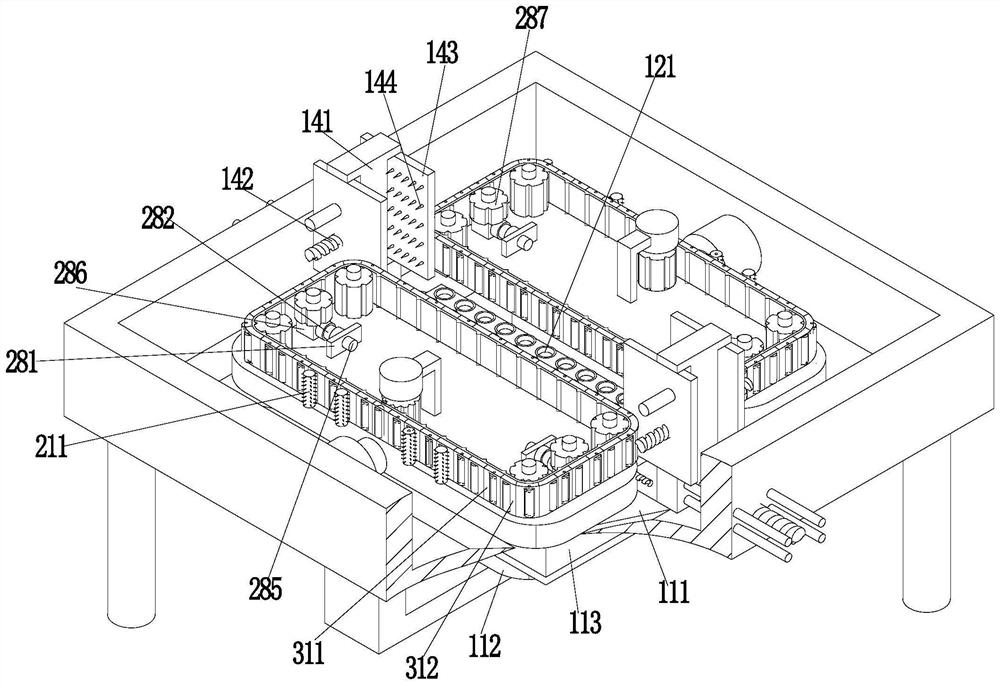

Electronic ceramic production system

ActiveCN111645182AReduce the possibilityGuarantee product qualityGrinding carriagesGrinding drivesMoulding deviceWhole systems

The invention relates to an electronic ceramic production system. According to the electronic ceramic production system, electronic ceramic processing is achieved by combining multiple devices, the whole system is reasonable in processing, firstly, the raw material preparation device is used for preparing high-quality ceramic slurry, then the high-quality ceramic slurry is put into the forming device for automatic forming, a green body is put into the drying device for drying after forming, the green body is preliminarily dried, in order to prevented cracks from being generated in the sintering process, the green body is placed in the sintering device after drying, by designing a feeding and taking structure of the sintering device, a user cannot be scalded in the using process, ceramic production is completed after sintering is completed, surface treatment of a ceramic product is carried out in the next step, the grinding device adopted for surface treatment is good in grinding effect, and meanwhile, dust generated in the grinding process is collected, so that dust pollution in a processing workshop is avoided; and electronic ceramics produced by using the whole system are high inquality, the whole system is used in the workshop, so that cleanliness of the workshop is guaranteed, and the safety production effect is improved.

Owner:新化县正能精细陶瓷有限公司

Safety steel plate grinding device

The invention discloses a safety steel plate grinding device and relates to the technical field of steel plate machining. The safety steel plate grinding device comprises a base and a cross beam whichare symmetrically arranged; a first support and a second support are connected between the base and the cross beam; the second support is connected between the base and the cross beam in a sliding manner; the first support and the second support are connected with a first grinding mechanism and a second grinding mechanism correspondingly; a clamping device, a protective device and a cleaning device are further arranged between the cross beam and the base; the first grinding mechanism and the second grinding mechanism are used for grinding a steel plate; the clamping device is used for clamping the steel plate; the protective device is used for isolating a grinding wheel and preventing disintegrating slag from splashing; and the cleaning device is used for cleaning the disintegrating slagon the steel plate. According to the safety steel plate grinding device, due to the design of the protective device, the grinding wheel is isolated from the outside environment, harm to people due tosplashing of the disintegrating slag generated during grinding is effectively prevented, and the safety of the device in work is improved; and due to the design of the cleaning device, the grinding effect is improved.

Owner:芜湖立普德机械科技有限公司

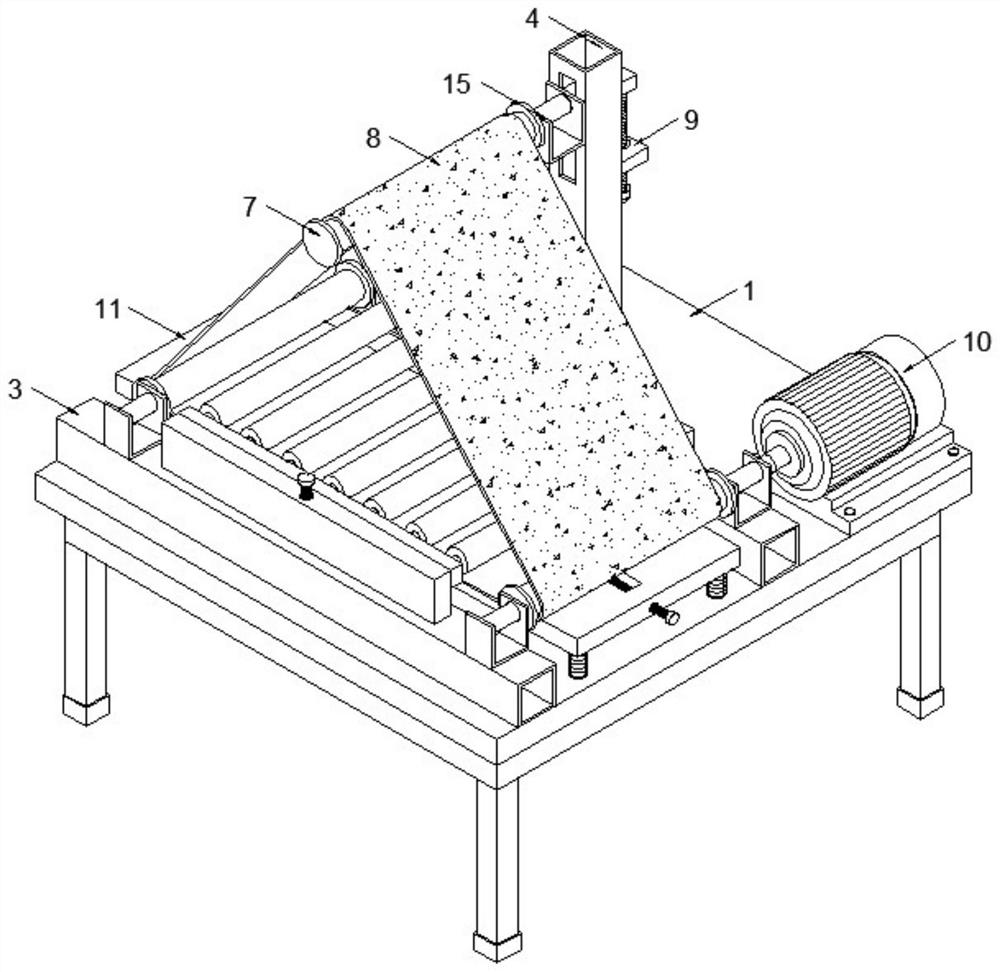

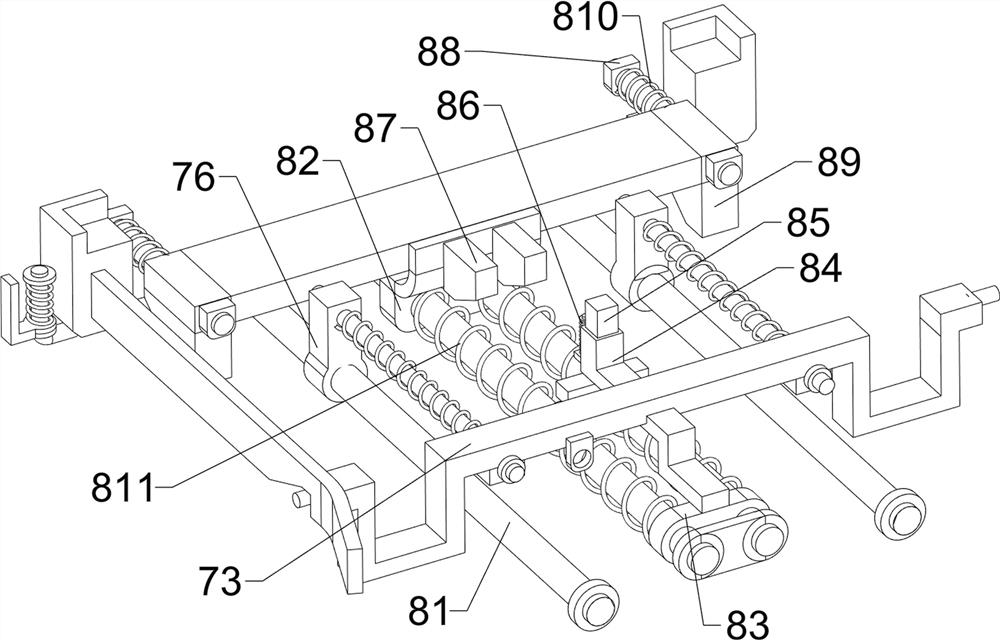

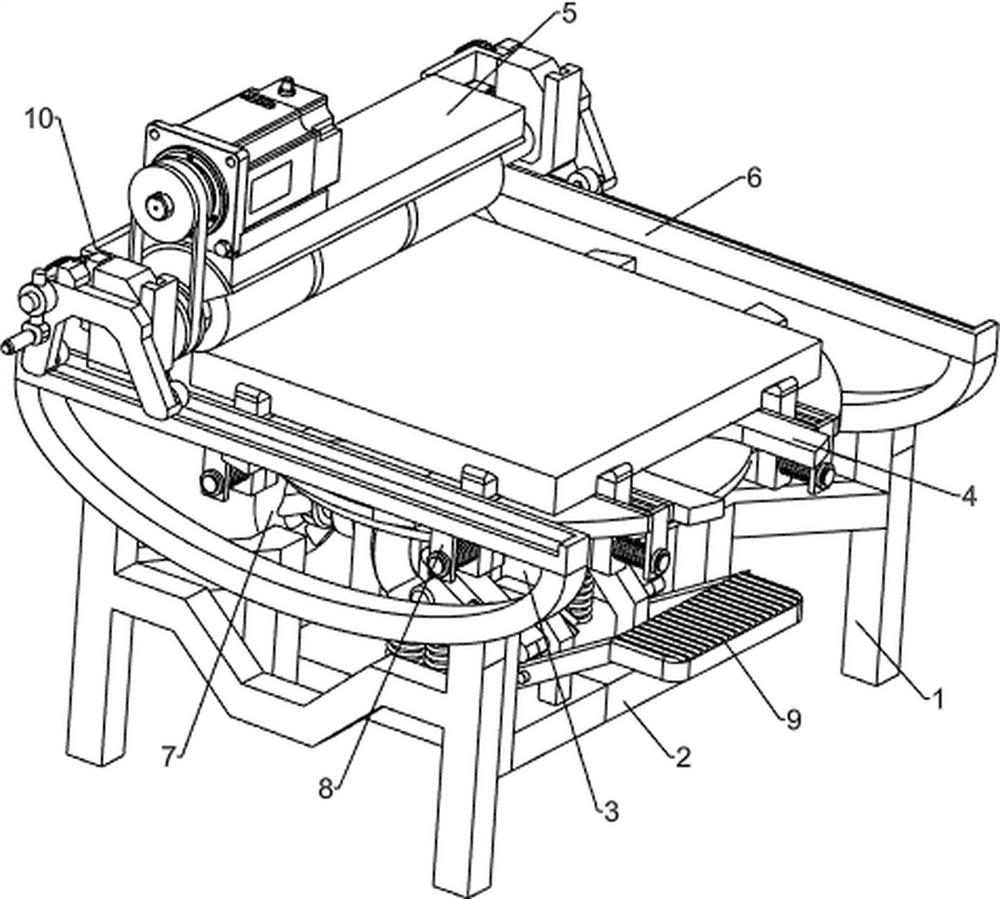

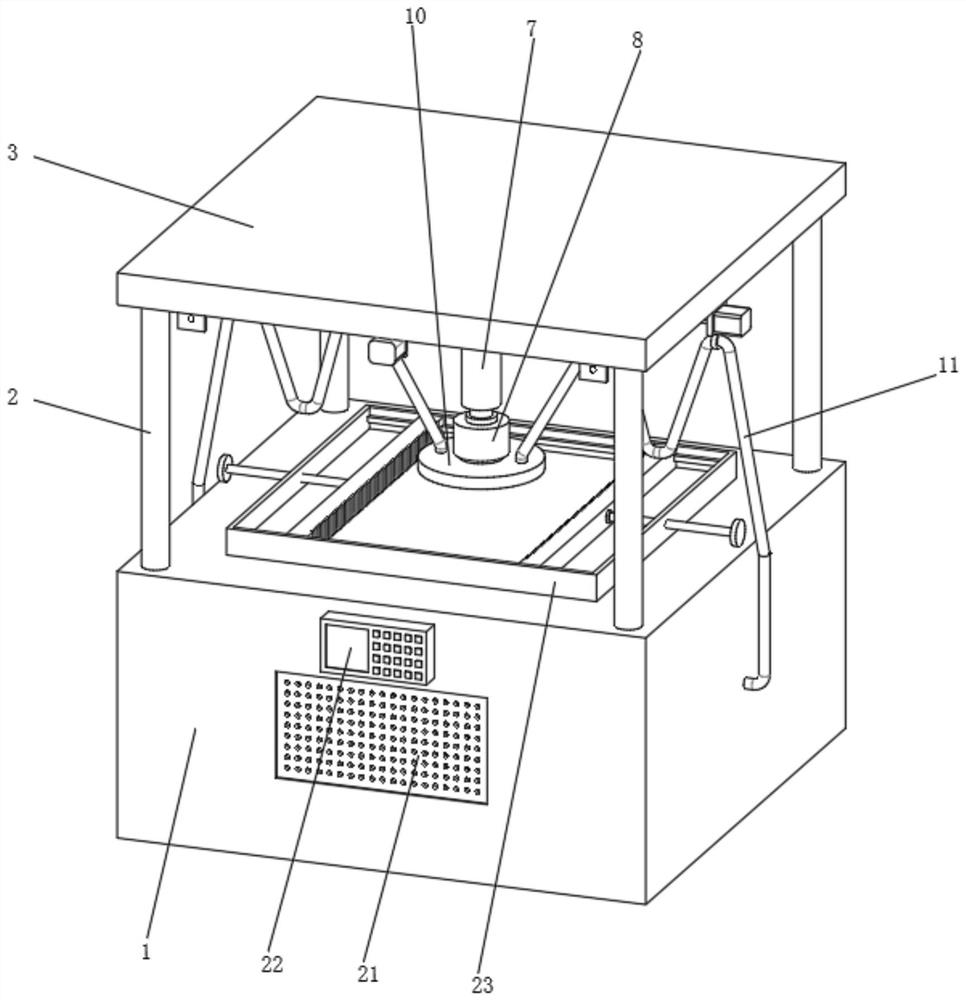

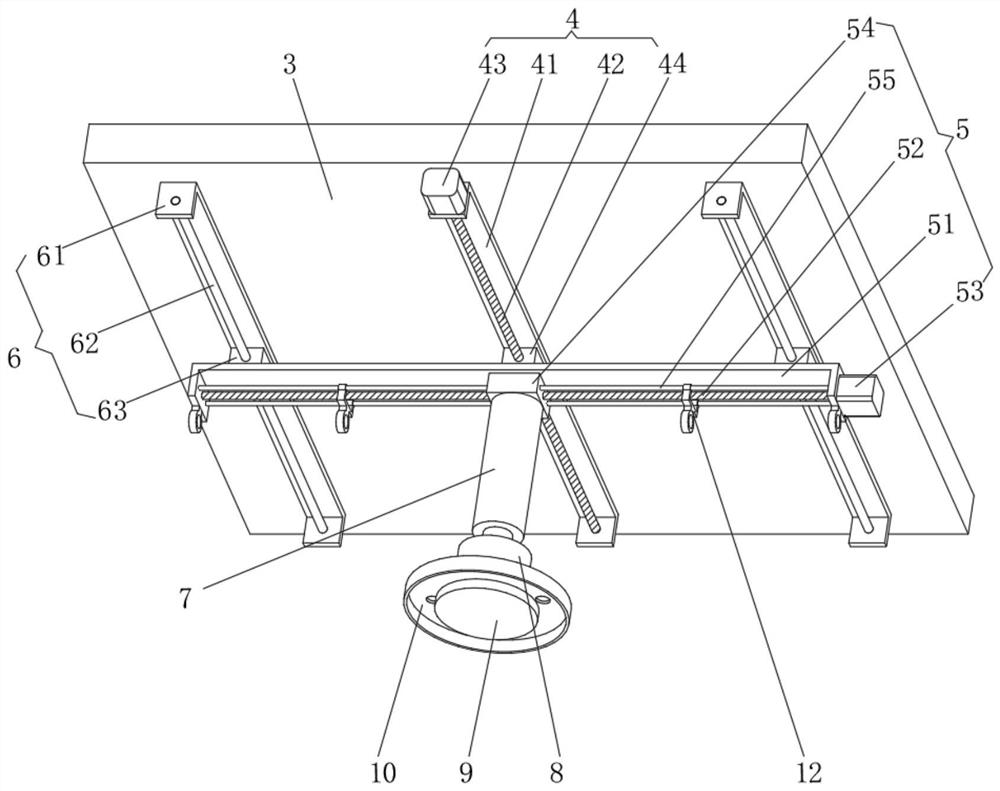

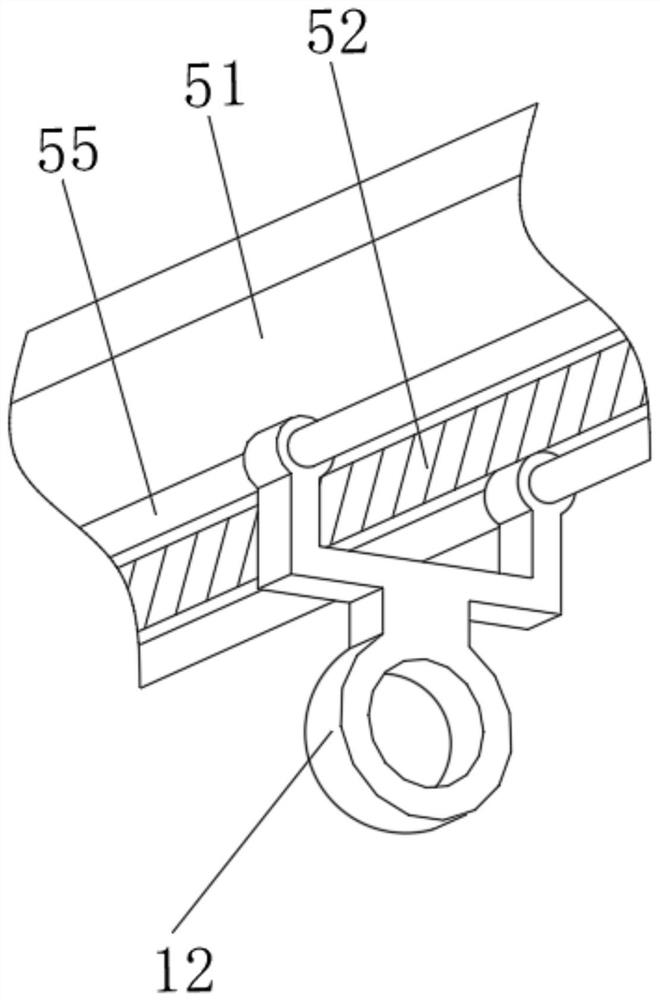

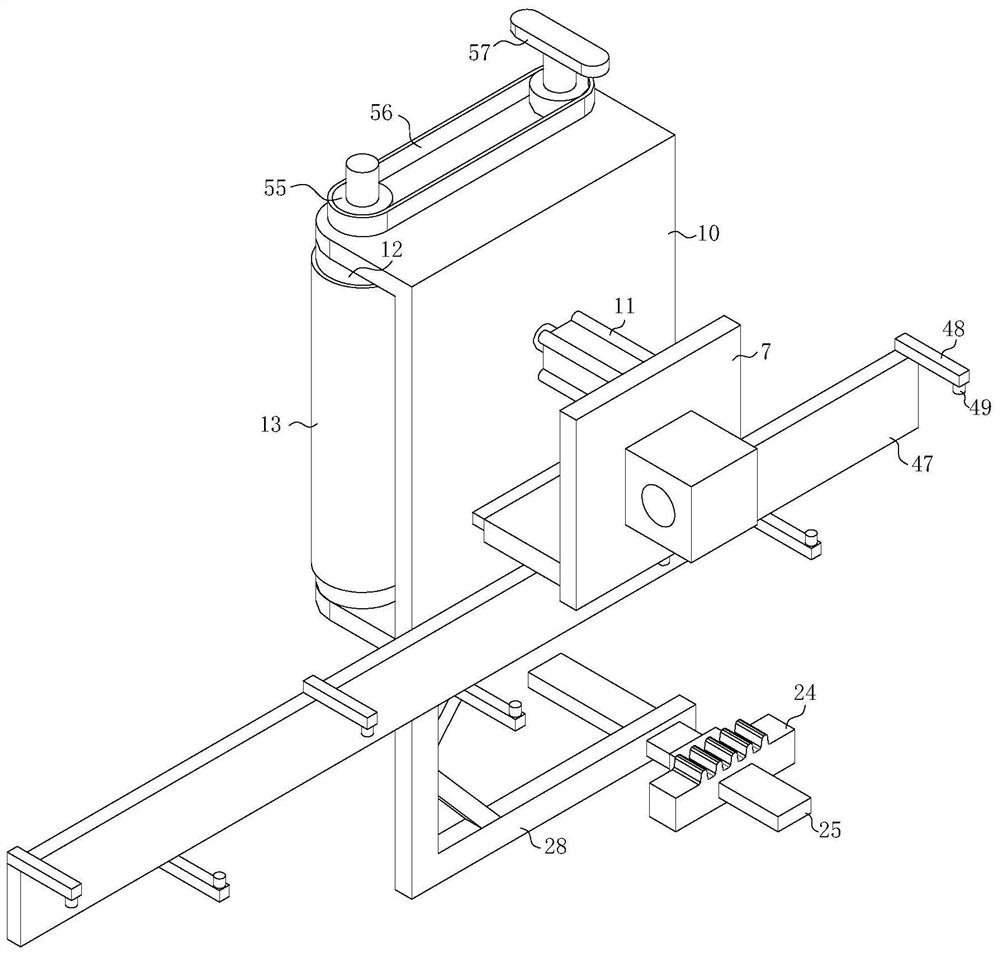

Floating type large plane polishing device for wood

ActiveCN111843756AImprove sanding effectIncrease tightnessBelt grinding machinesGrinding/polishing safety devicesHydraulic cylinderPolishing

The invention discloses a floating type large plane polishing device for wood. The device comprises a workbench, the two sides of the top end of the workbench are fixedly provided with fixing plates correspondingly, a base plate is fixedly arranged in the middle of one side of one of the fixing plates on the workbench, and the tops of the two fixing plates on the same side are provided with a samedriving belt wheel and a same driven belt wheel. According to the floating type large plane polishing device for the wood, a wood board to be polished is placed on a placing plate, two abutting plates move relative to each other to tightly fix the position of the wood board, then a hydraulic cylinder works to push the placing plate and the wood board to move upwards, the wood board is moved to abut against a sanding belt, at the moment, two threaded rods are simultaneously screwed to drive a sliding block to move downwards along a limiting groove, the sliding block moves to drive a pressing roller to move, and the pressing roller moves downwards to compress the sanding belt and the wood board, so that the attaching degree between the sanding belt and the wood board is improved, and the polishing effect on the wood board can be further improved.

Owner:HUNAN KUANGCHU TECH CO LTD

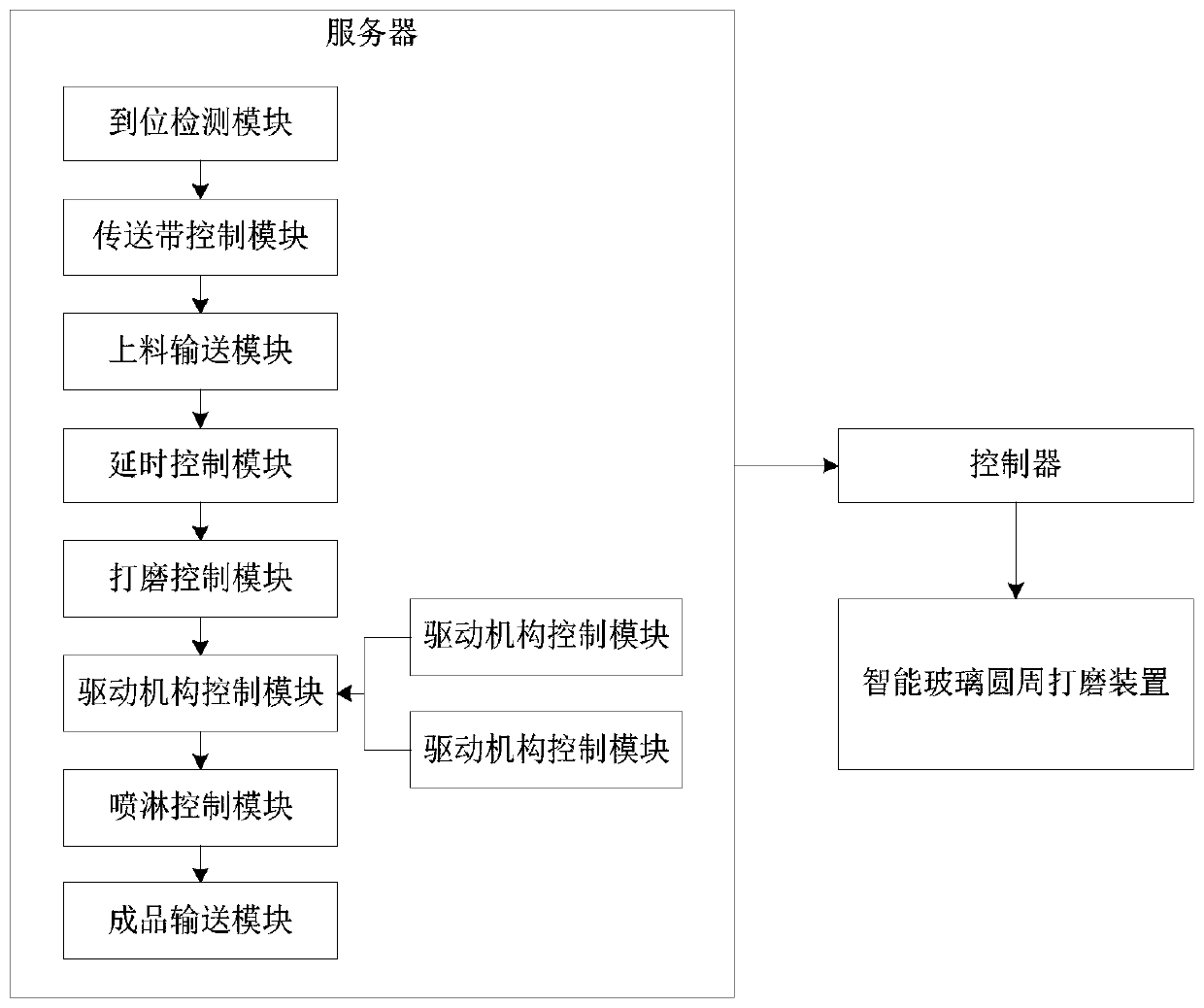

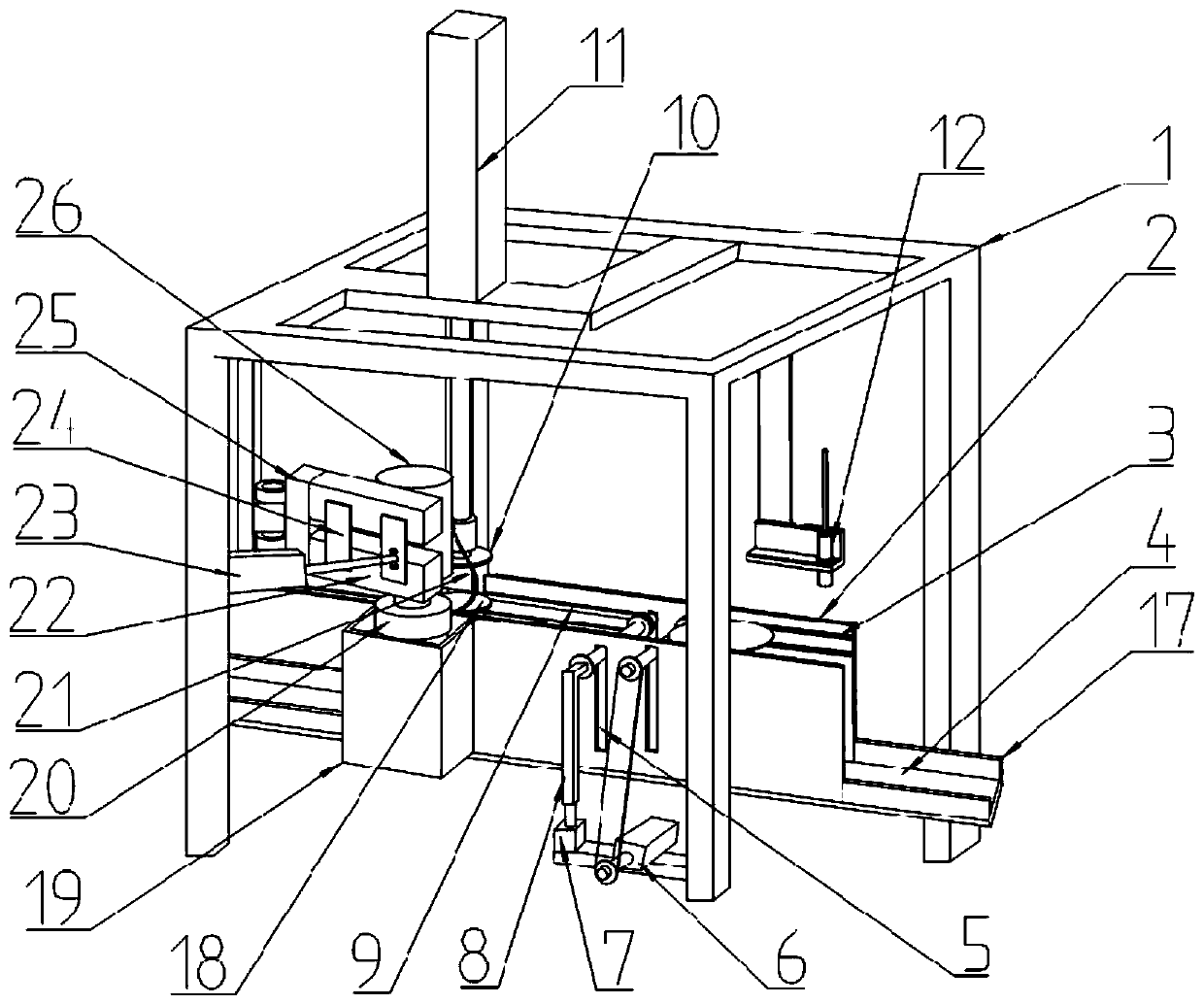

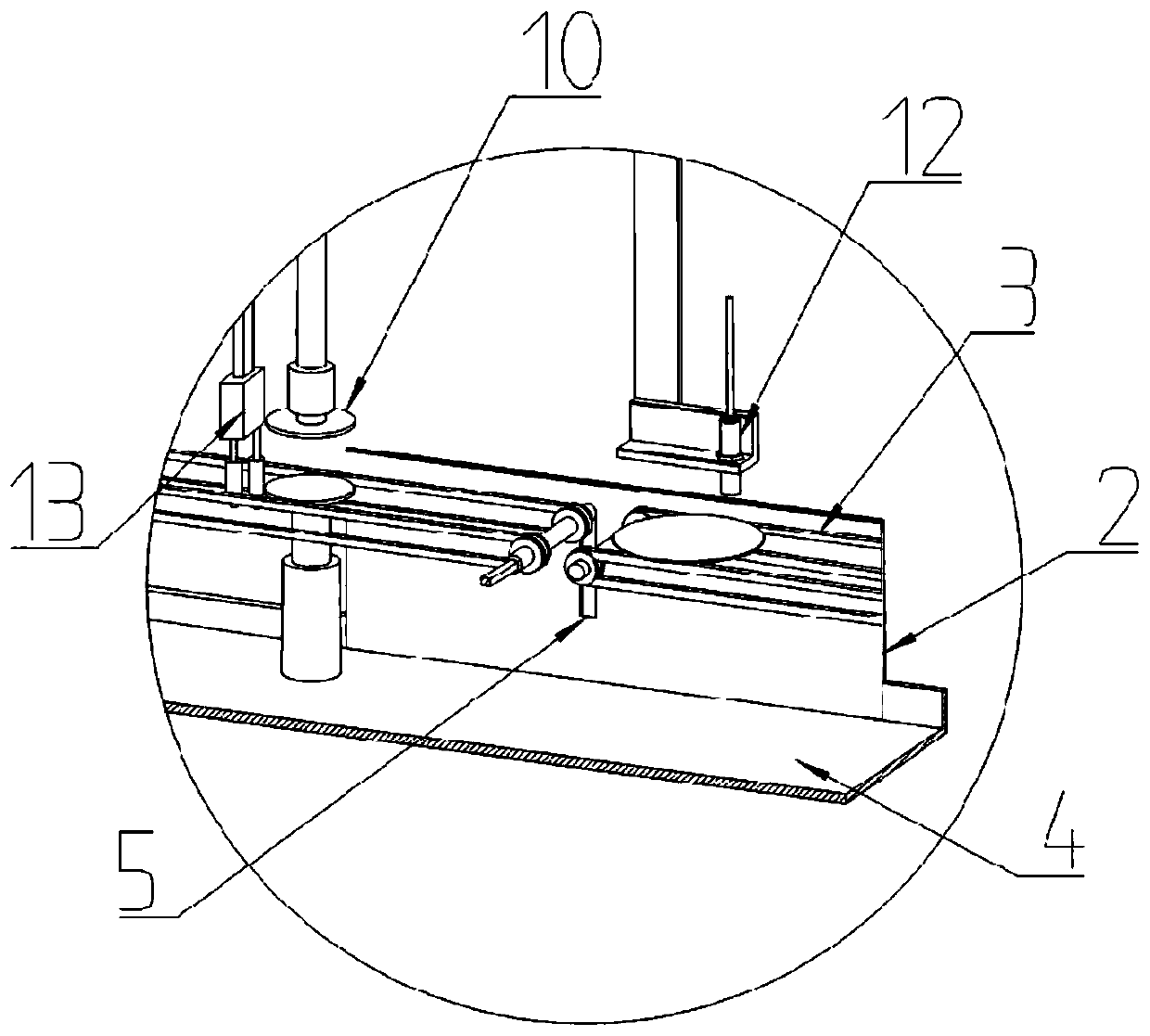

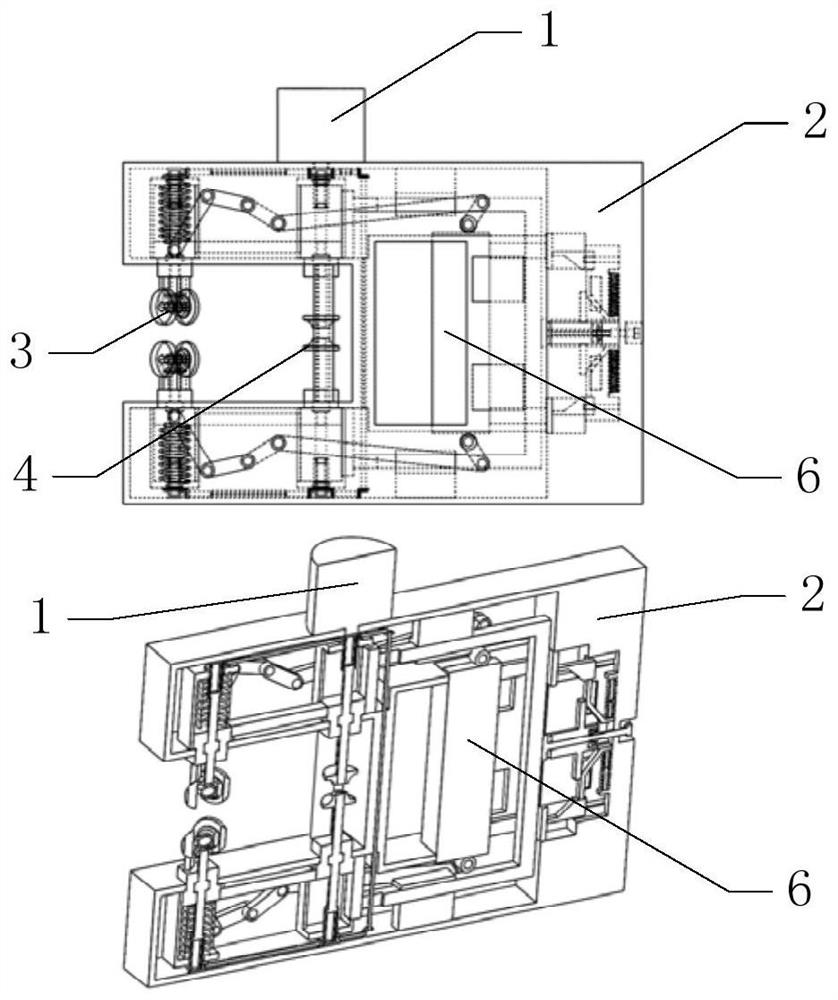

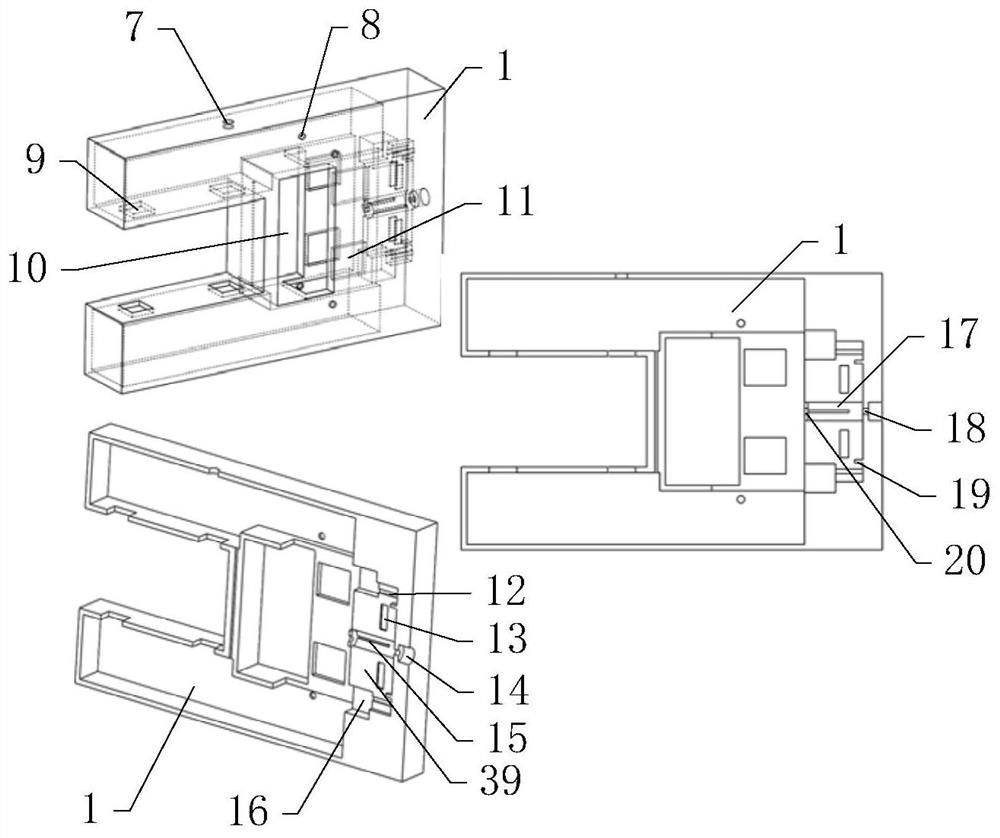

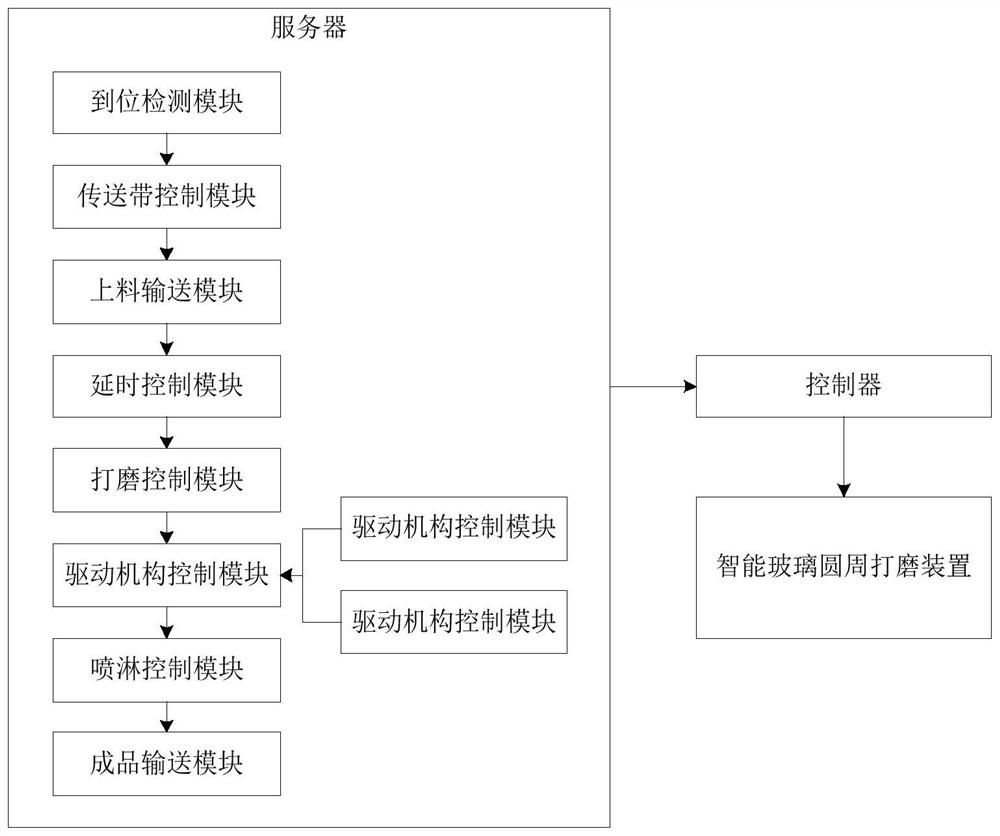

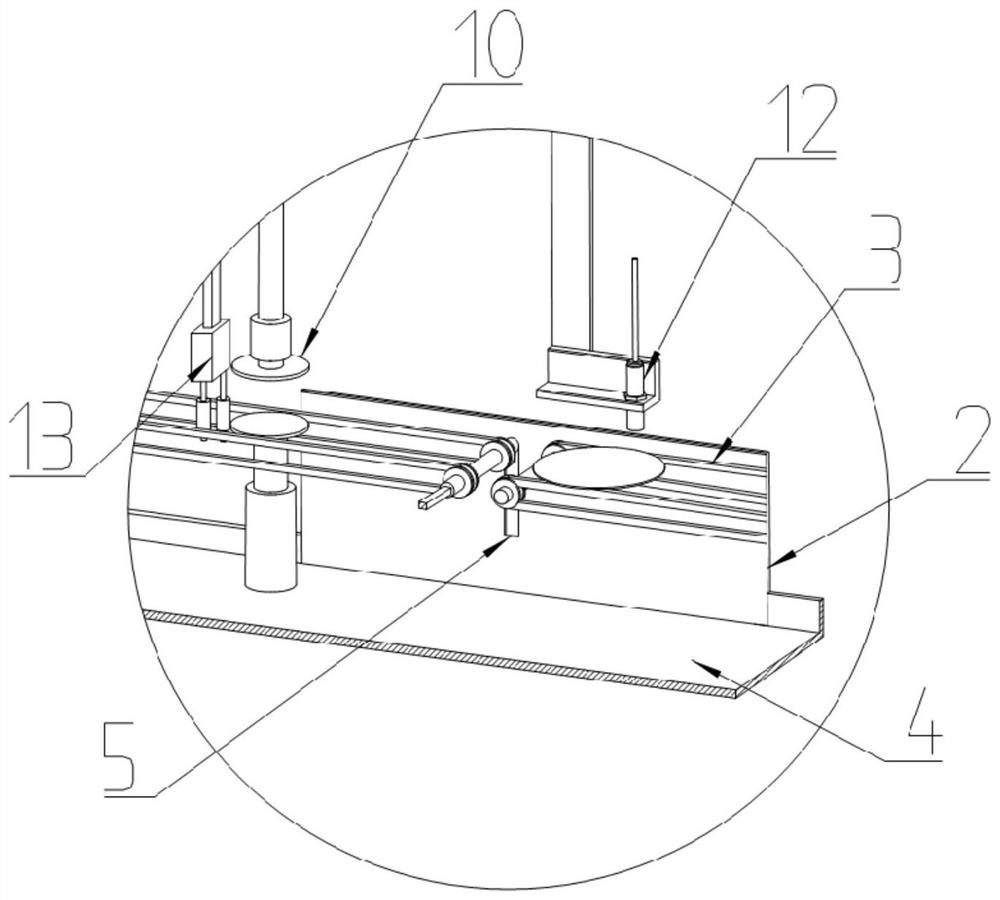

Circular glass polishing control system and method

ActiveCN111055184AEasy to holdRealize automatic clampingEdge grinding machinesGrinding drivesControl systemEngineering

The invention relates to the technical field of glass processing, in particular to a circular glass polishing control system and method. The circular glass polishing control system is applied to an intelligent glass circumference polishing device and comprises a controller and a server; the server comprises an in-place detecting module, a conveyor belt control module, a delay control module, a polishing control module and a finished product conveying module. The system is applied to the circular glass polishing control system and comprises the steps of in-place detection, conveyor belt control, delay control, polishing control and finished product conveying. The circular glass polishing control system solves the problems that circular glass polishing is low in efficiency and non-uniform.

Owner:重庆市耀城玻璃制品有限公司

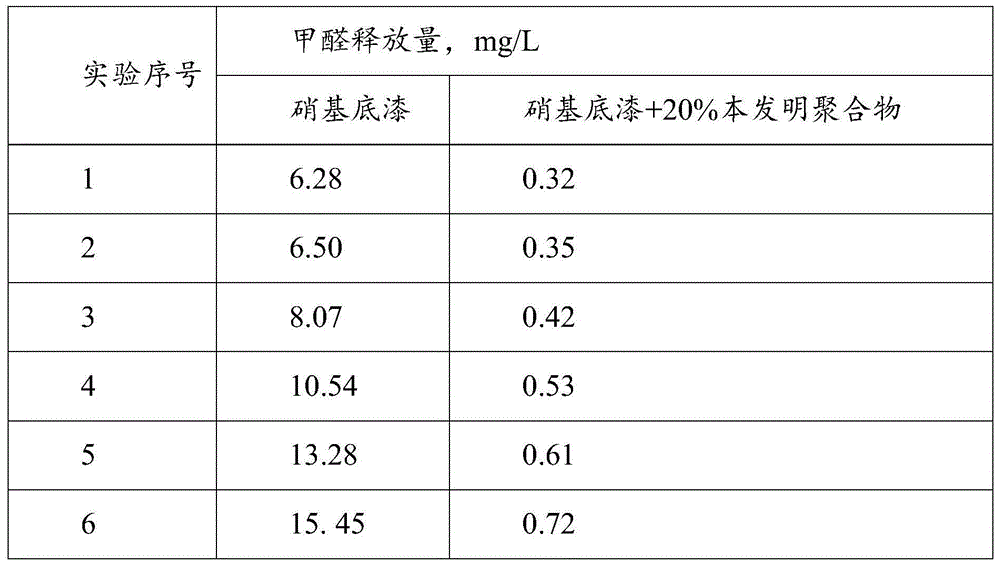

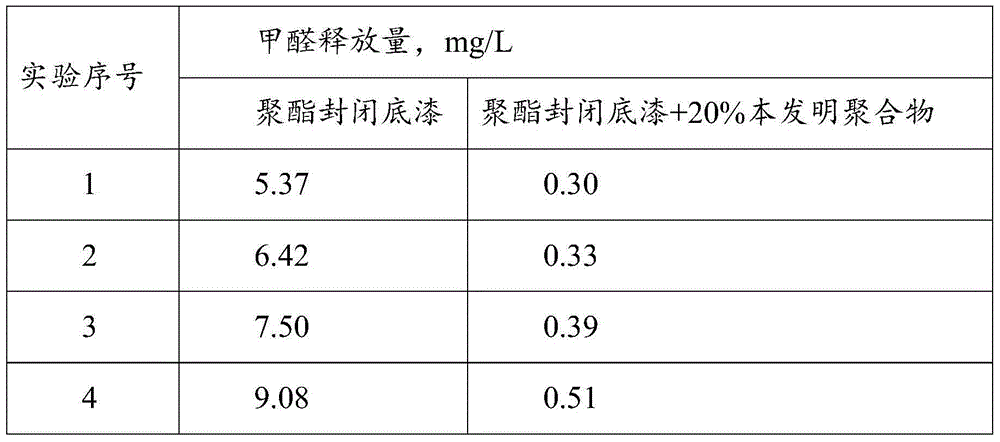

Seal primer added polymer with formaldehyde catching function and preparation method of polymer

InactiveCN104311737AObvious formaldehyde capture and removalLong-lasting formaldehyde capture and removalPolyurea/polyurethane coatingsEpoxy resin coatingsEmulsionPolyester

The invention discloses a seal primer added polymer with a formaldehyde catching function. The seal primer comprises acrylamide, an acrylate soft monomer, an acrylate hard monomer, an acrylate long-chain monomer, an initiator and an organic solvent. The invention further discloses a preparation method of the seal primer added polymer with the formaldehyde catching function. Resin prepared by adopting the seal primer added polymer with the formaldehyde catching function and the preparation method thereof has good compatibility with existing wooden ware primers (nitro wooden ware primer, polyester two-component wooden ware primer, acrylic emulsion type wooden ware primer, epoxy two-component wooden ware primer and the like); according to the formaldehyde content of a wooden ware base material, the polymer is added into the traditional wooden ware primer; and the wooden ware seal primer prepared by adding the polymer has obvious and lasting formaldehyde catching and clearing capability on the premise that obvious poor influence is not produced on the aspects of closure, adhesion, flexibility, polishing property and the like.

Owner:GUANGZHOU UNIVERSITY

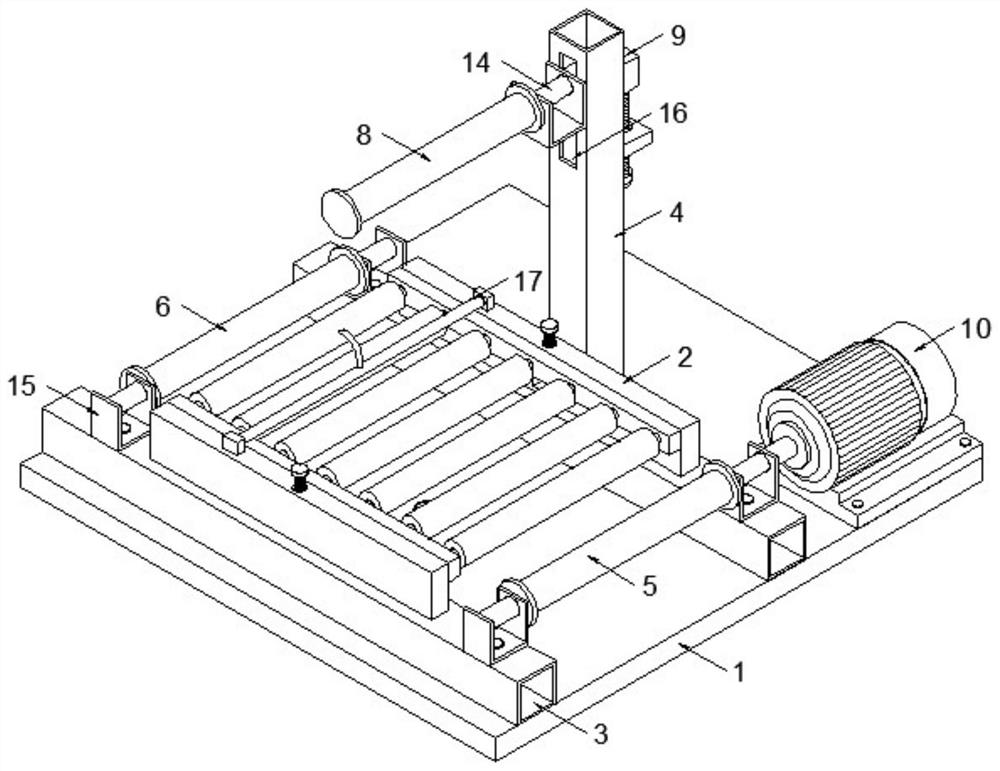

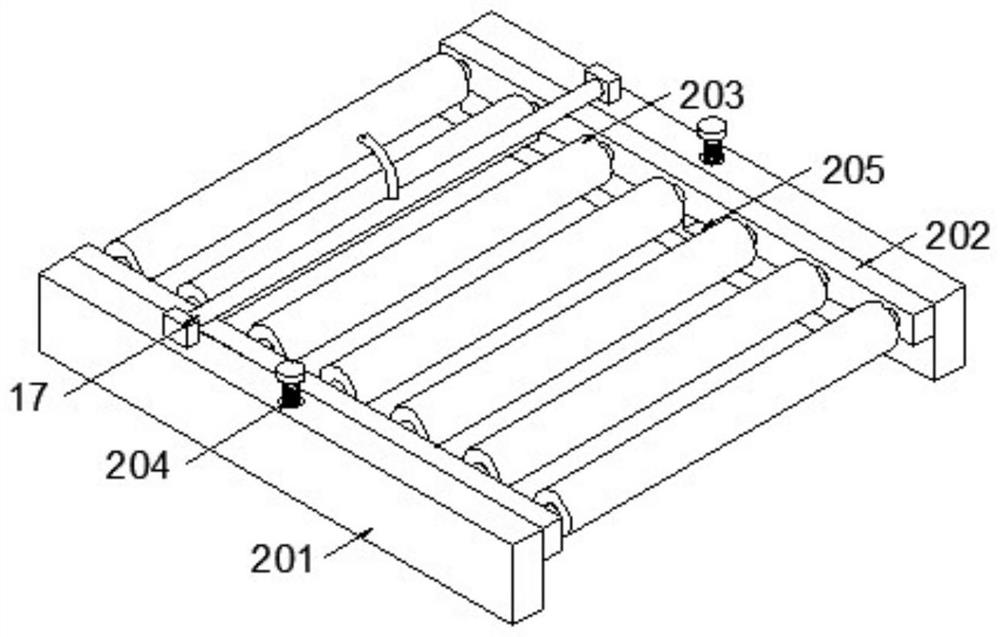

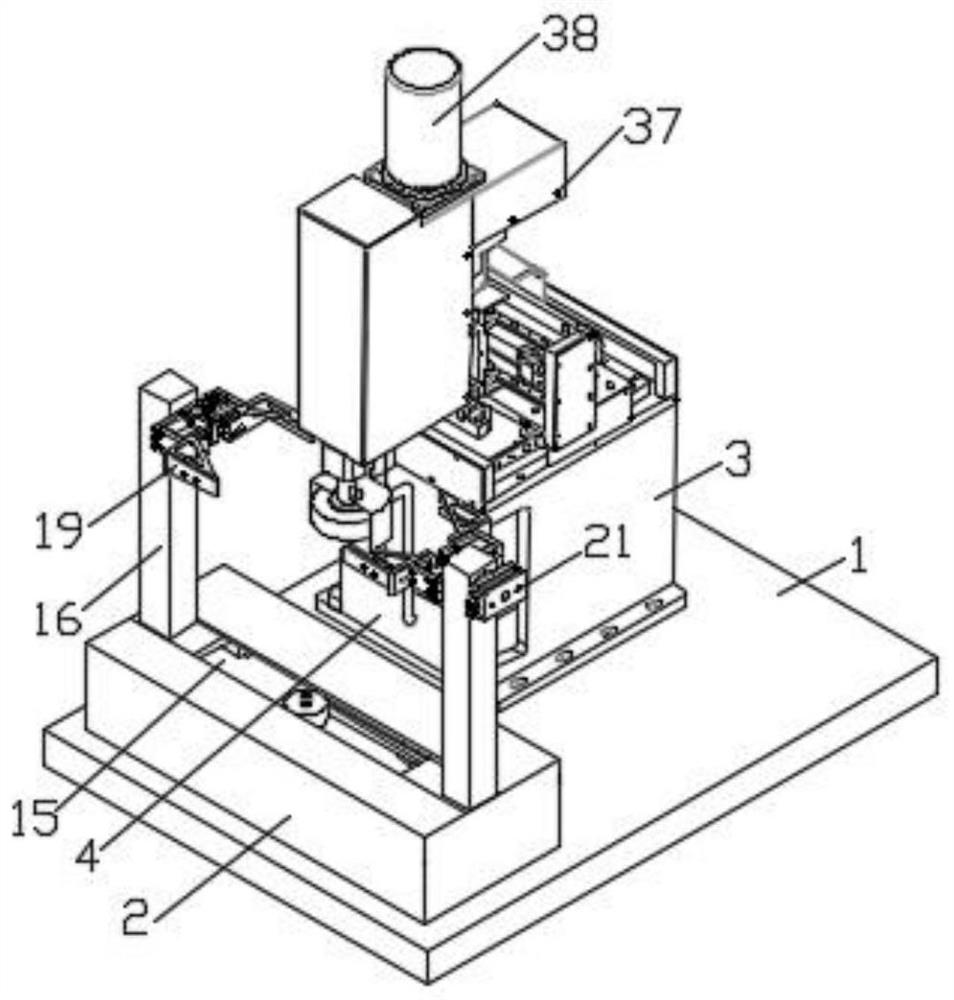

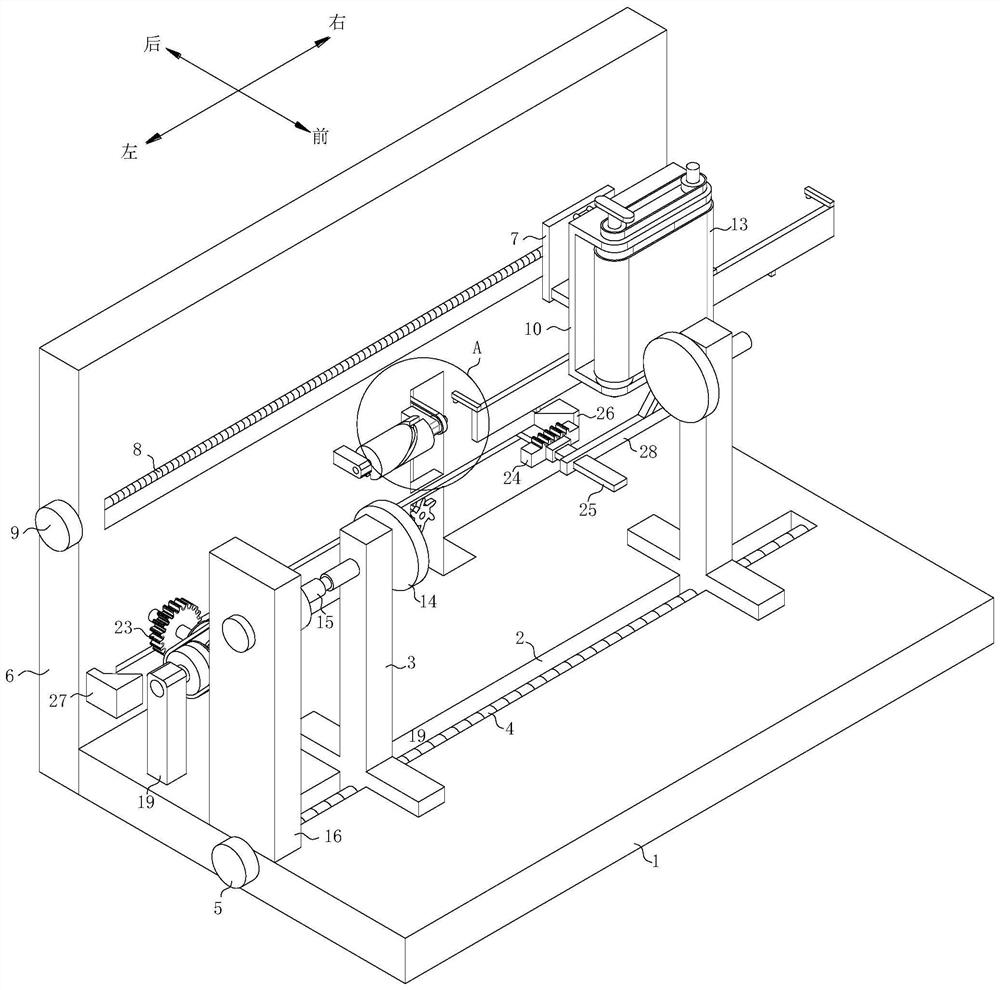

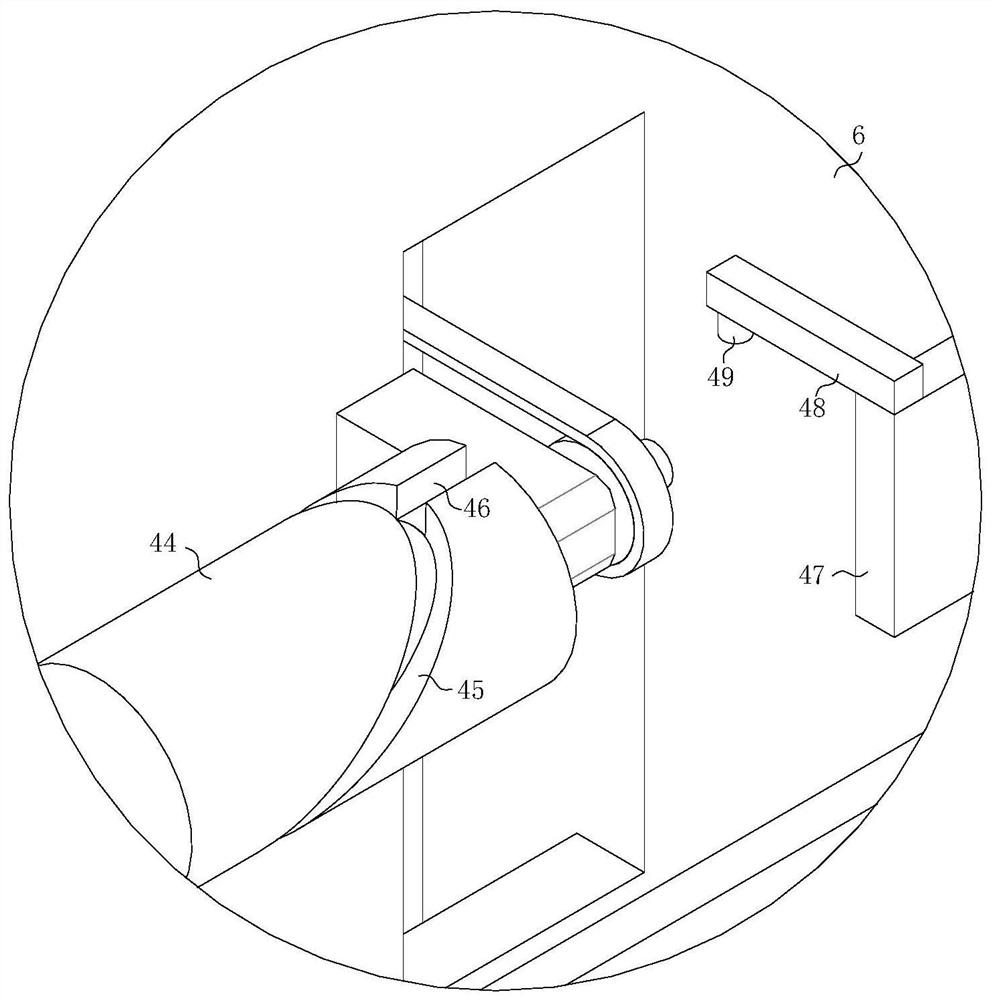

Material surface grinding equipment for high-end equipment manufacturing

ActiveCN113059454AEasily restrict locationPrecision grindingEdge grinding machinesPolishingElectric machinery

The invention relates to grinding equipment, in particular to material surface grinding equipment for high-end equipment manufacturing. To solve the technical problem, the invention provides the material surface grinding equipment for high-end equipment manufacturing; and according to the material surface grinding equipment for high-end equipment manufacturing, materials can be automatically pushed, grinding can be automatically and rapidly completed, the grinding position is accurately limited, guiding is provided for material movement, and the initial placing position of the materials is limited. The material surface polishing equipment for high-end equipment manufacturing comprises a workbench, a motor and a positioning mechanism, wherein a polishing mechanism is arranged on one side of the upper part of the workbench; the motor is arranged on one side of the first part of the polishing mechanism; and the positioning mechanism is arranged on one side of the workbench. According to the material surface polishing equipment for high-end equipment manufacturing, by starting an air cylinder to push a limiting frame to move leftwards, a side baffle is pushed to move upwards, so that materials move leftwards along the side baffle; and therefore, the effect of automatically providing guiding for material conveying is achieved, and the situation that the materials deviate in the moving process to affect polishing is avoided.

Owner:山东至信晟宇机械制造有限公司

Optical instrument for lens grinding

ActiveCN110640575AGuaranteed grinding accuracyGuaranteed clarityEdge grinding machinesGrinding/polishing safety devicesOptical instrumentEngineering

The invention discloses an optical instrument for lens grinding. The optical instrument comprises a machine body, a grinding cavity is formed in the machine body, a placing disc is rotationally arranged in the grinding cavity, a frame is placed on the placing disc, a lens is placed on the frame, a liftable stretching rod is arranged on the upper side of the lens through a telescopic device, the periphery of the stretching rod is of a spline-shaped structure, and a suction cup is mounted at the lower end of the stretching rod. According to the shape and sizes of the frame, a grinding trace lineis scribed on the lens through lasers, and the appearance precision during grinding is improved. The lens is ground through mutual cooperation of automatic constant-speed rotation of the lens and horizontal movement of an automatic rotating grinding wheel, and the grinding precision can be ensured by observing the grinding condition through an optical device in the grinding process. In addition,glass or resin slag generated during grinding is collected downwards through a recycling device, the observation clarity is guaranteed, grinding cannot be influenced because the slag cannot fly, one-time forming is achieved, and the grinding efficiency is high.

Owner:江西弘耀光学水晶有限公司

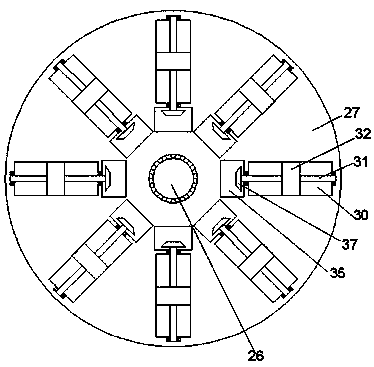

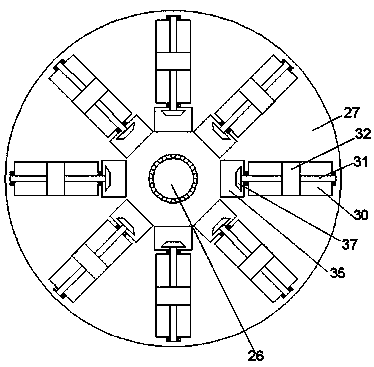

A cylindrical metal raw material burr grinding machine

ActiveCN109434600BSanding effectAvoid damageEdge grinding machinesGrinding work supportsPolishingElectric machinery

The invention relates to a polishing machine, in particular to a cylinder metal raw material burr polishing machine. According to the provided cylinder metal raw material burr polishing machine, the labor for polishing cylinder metal raw material is replaced, the working efficiency is high, and hands can be prevented from being stabbed. According to the technical scheme, the cylinder metal raw material burr polishing machine comprises a supporting frame, a circular plate, a handle, a 7-shaped plate, a rotating shaft, a bearing seat, a sleeve, a movable rod, a fastening bolt, a circular block,a blocking block and the like; and the circular plate is fixedly connected to the top of the supporting frame, an annular groove with a guiding function is formed in the middle of the top of the circular plate, and two annular sliding blocks are slidably arranged in the annular sliding groove. According to the cylinder metal raw material burr polishing machine, by placing a cylinder raw material into a placing hole to be in contact with a polishing block, a driving motor is started, burrs of the cylinder metal raw material can be cleared, the condition that a person clears the burrs of the cylinder metal raw material with a file is not needed, the working efficiency is high, and the hands can be prevented from being stabbed.

Owner:永康市晓诚电器有限公司

Cylinder metal raw material burr polishing machine

ActiveCN109434600AAvoid damageImprove cleanlinessEdge grinding machinesGrinding work supportsDrive motorMetal

The invention relates to a polishing machine, in particular to a cylinder metal raw material burr polishing machine. According to the provided cylinder metal raw material burr polishing machine, the labor for polishing cylinder metal raw material is replaced, the working efficiency is high, and hands can be prevented from being stabbed. According to the technical scheme, the cylinder metal raw material burr polishing machine comprises a supporting frame, a circular plate, a handle, a 7-shaped plate, a rotating shaft, a bearing seat, a sleeve, a movable rod, a fastening bolt, a circular block,a blocking block and the like; and the circular plate is fixedly connected to the top of the supporting frame, an annular groove with a guiding function is formed in the middle of the top of the circular plate, and two annular sliding blocks are slidably arranged in the annular sliding groove. According to the cylinder metal raw material burr polishing machine, by placing a cylinder raw material into a placing hole to be in contact with a polishing block, a driving motor is started, burrs of the cylinder metal raw material can be cleared, the condition that a person clears the burrs of the cylinder metal raw material with a file is not needed, the working efficiency is high, and the hands can be prevented from being stabbed.

Owner:永康市晓诚电器有限公司

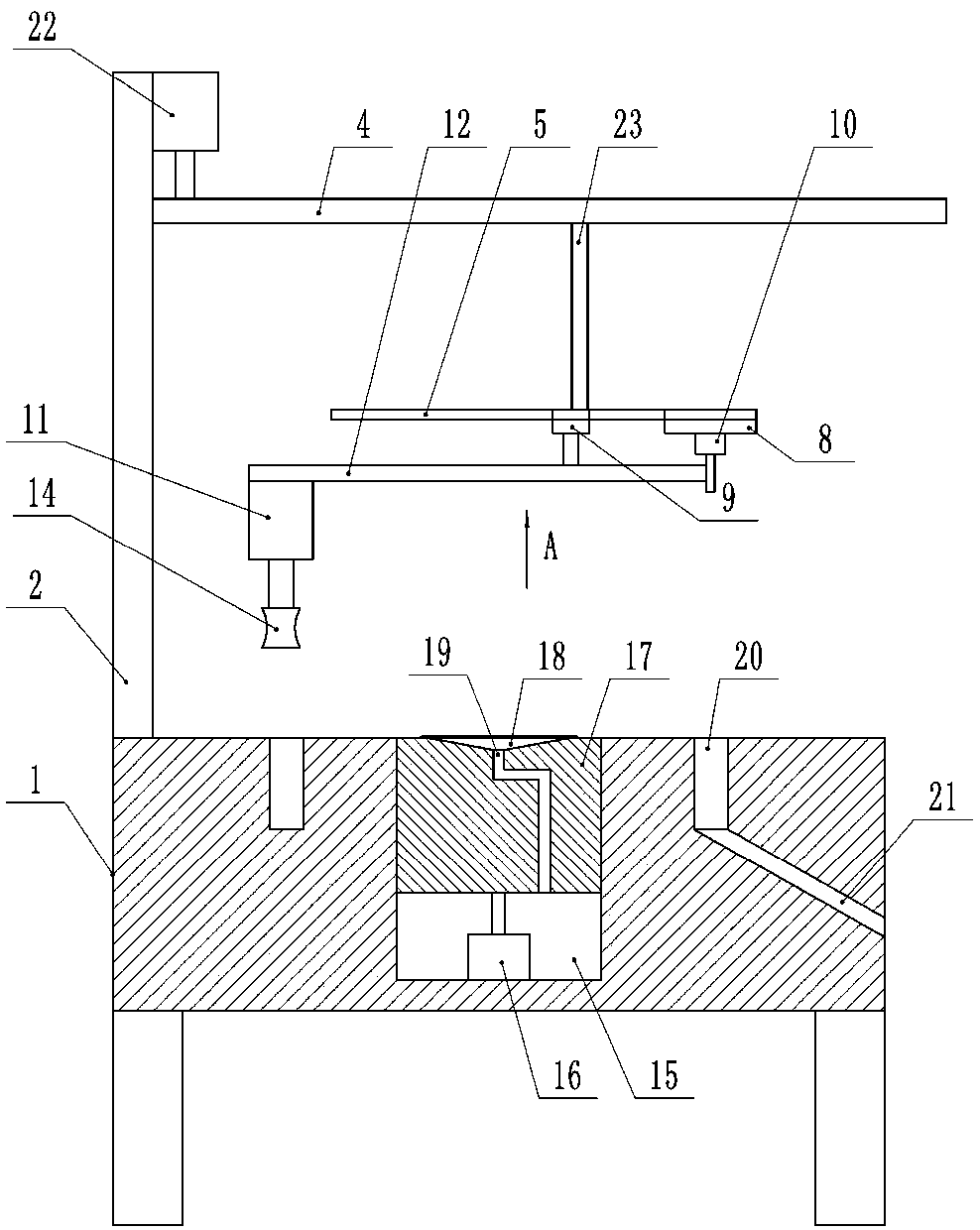

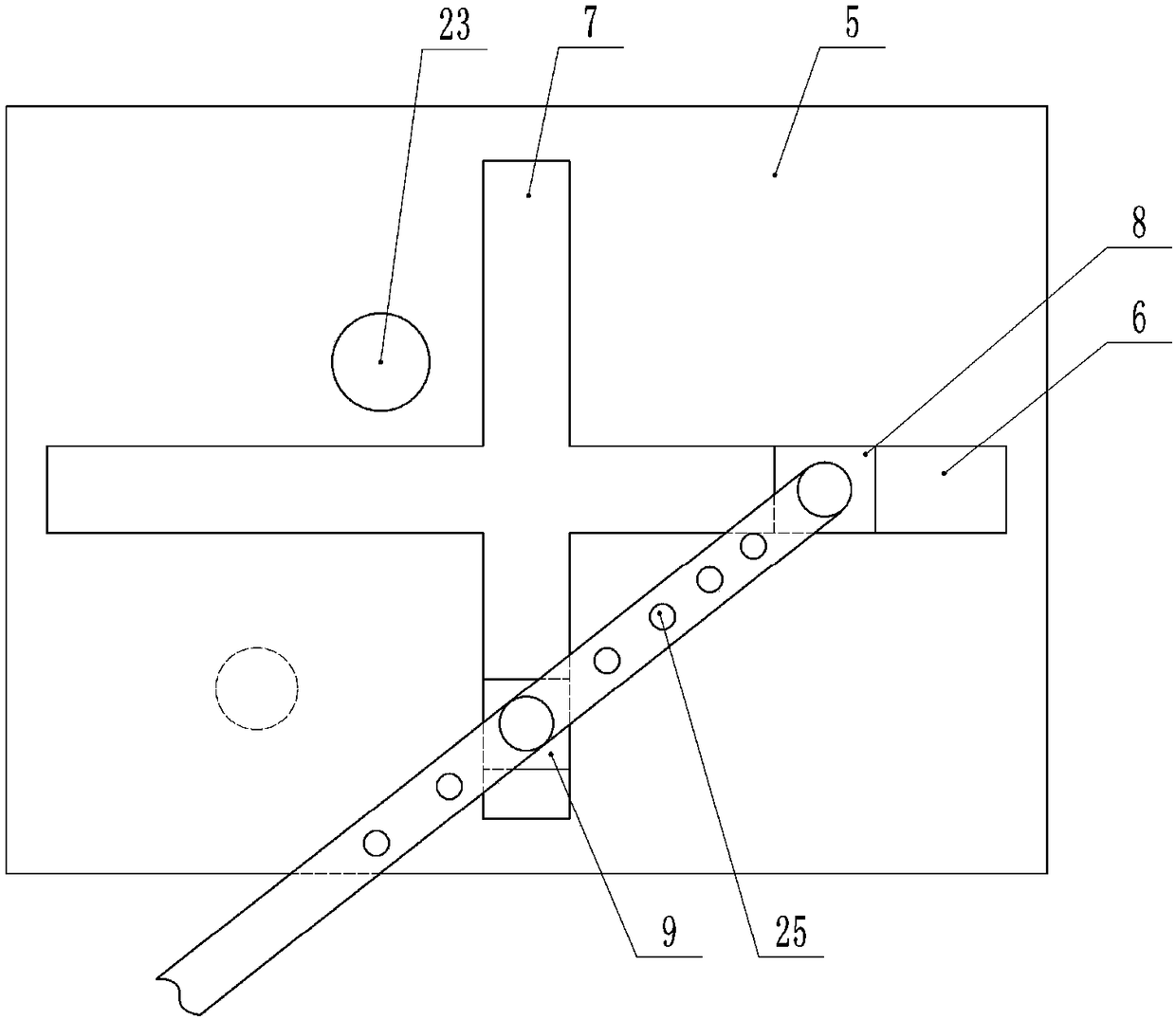

Plank polishing equipment

PendingCN108544327AQuick sandingImprove grinding efficiencyEdge grinding machinesGrinding carriagesBiochemical engineeringWood plank

The invention belongs to the technical field of plank processing equipment and particularly discloses plank polishing equipment. The plank polishing equipment comprises a workbench. A stand column isarranged on the workbench. A cross beam and a supporting plate are arranged on the stand column. A first through groove and a second through groove are formed in the supporting plate. A first slidingblock is arranged in the first through groove. A second sliding block is arranged in the second through groove. A first motor is arranged on the first sliding block. A guiding rod is connected with anoutput shaft of the first motor. A second motor is arranged on the guiding rod. A polishing wheel is arranged on an output shaft of the second motor. A fixing part is arranged on the workbench. The plank polishing equipment is mainly used for polishing plank, and the problems that during manual plank polishing, stress to planks is difficult to keep consistent by handholding polishing devices, consequently, unevenness of polished planks is liable to occur, and the polishing effect is poor are solved.

Owner:重庆草衣木食文化传播有限公司

Polishing device with dust removal function

ActiveCN113231899AReduce defective rateWith dust removal functionRevolution surface grinding machinesGrinding work supportsPolishingEngineering

The invention discloses a polishing device with a dust removal function, and relates to the technical field of dust removal. The polishing device with the dust removal function comprises a base, a hydraulic lifter and a placer are fixed to the top of the base, an output shaft of the hydraulic lifter is fixed to one end of an arc-shaped connecting strip, and the other end of the arc-shaped connecting strip is fixed to the top of a rotator. According to the polishing device with the dust removal function, in the polishing process of a polishing ball, a driving ball in a driving mechanism can intermittently and rapidly extrude a rubber air bag in a pneumatic dust removal mechanism, and in the deformation process of the rubber air bag, air in the rubber air bag can be blown out through a connecting pipe and an arc-shaped air blowing pipe; and air is blown to the inner side of a circular-ring-shaped machined part on an annular bearing piece, fine dust particles polished from the circular-ring-shaped machined part can be blown out, the fine dust particles remaining after the inner side of the circular-ring-shaped machined part is polished can be automatically removed, and manual cleaning is not needed.

Owner:肇庆维信实业有限公司

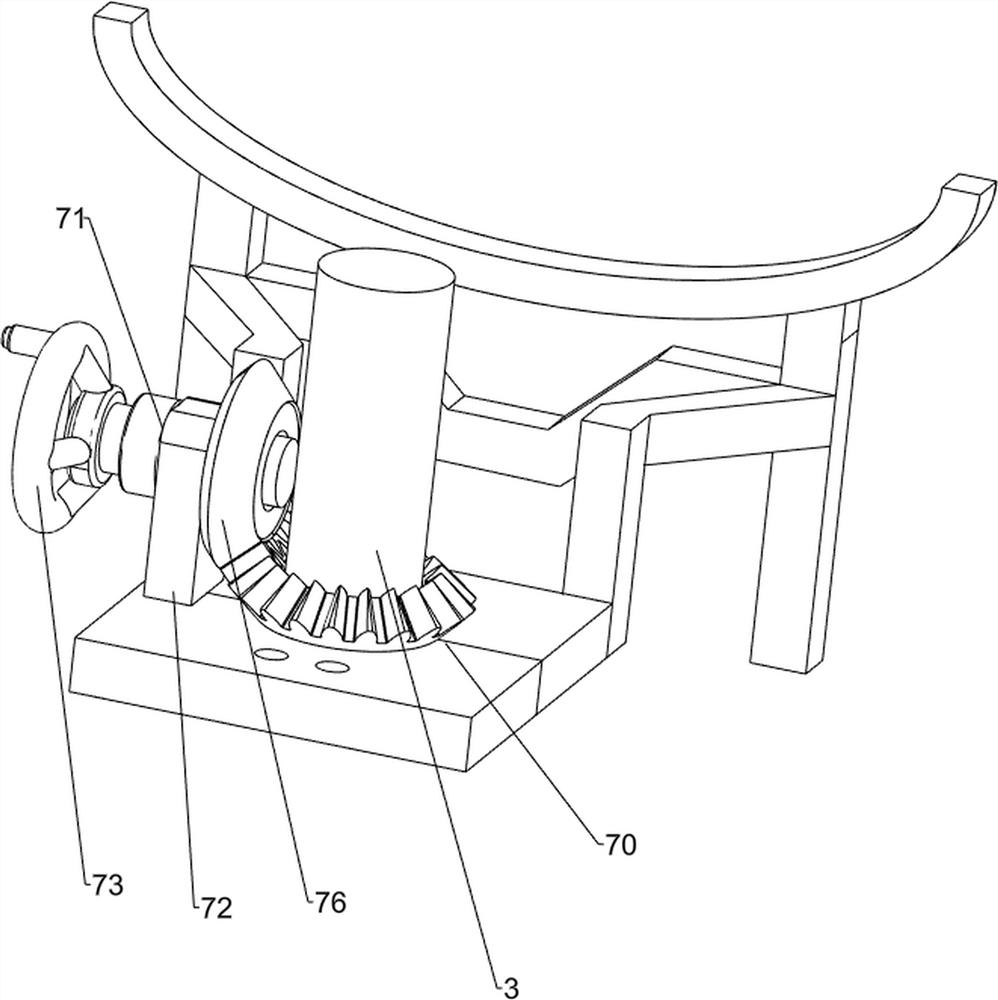

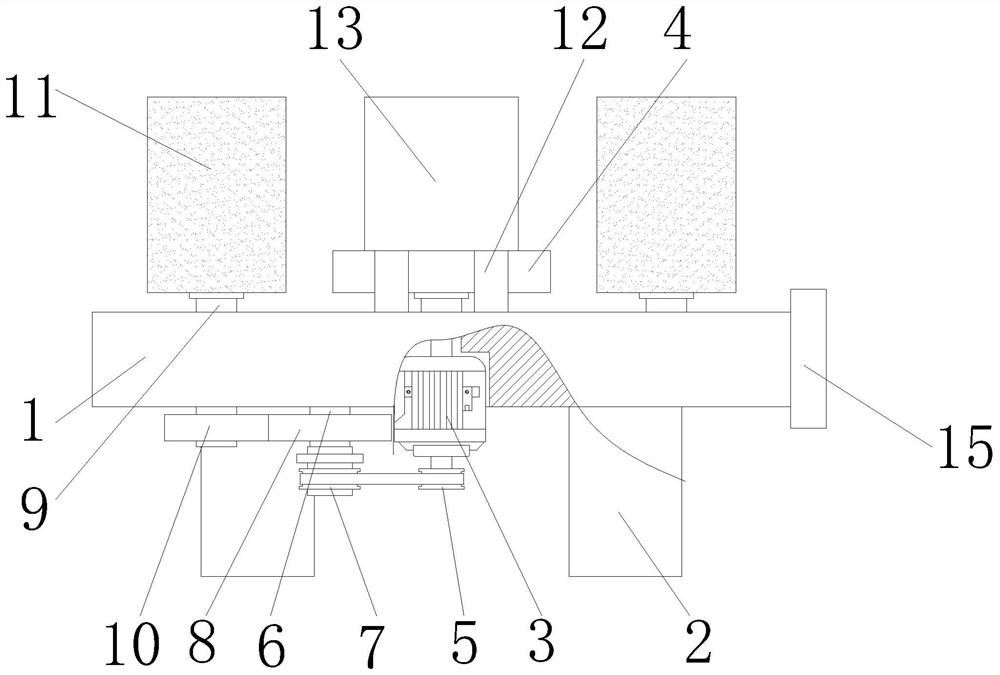

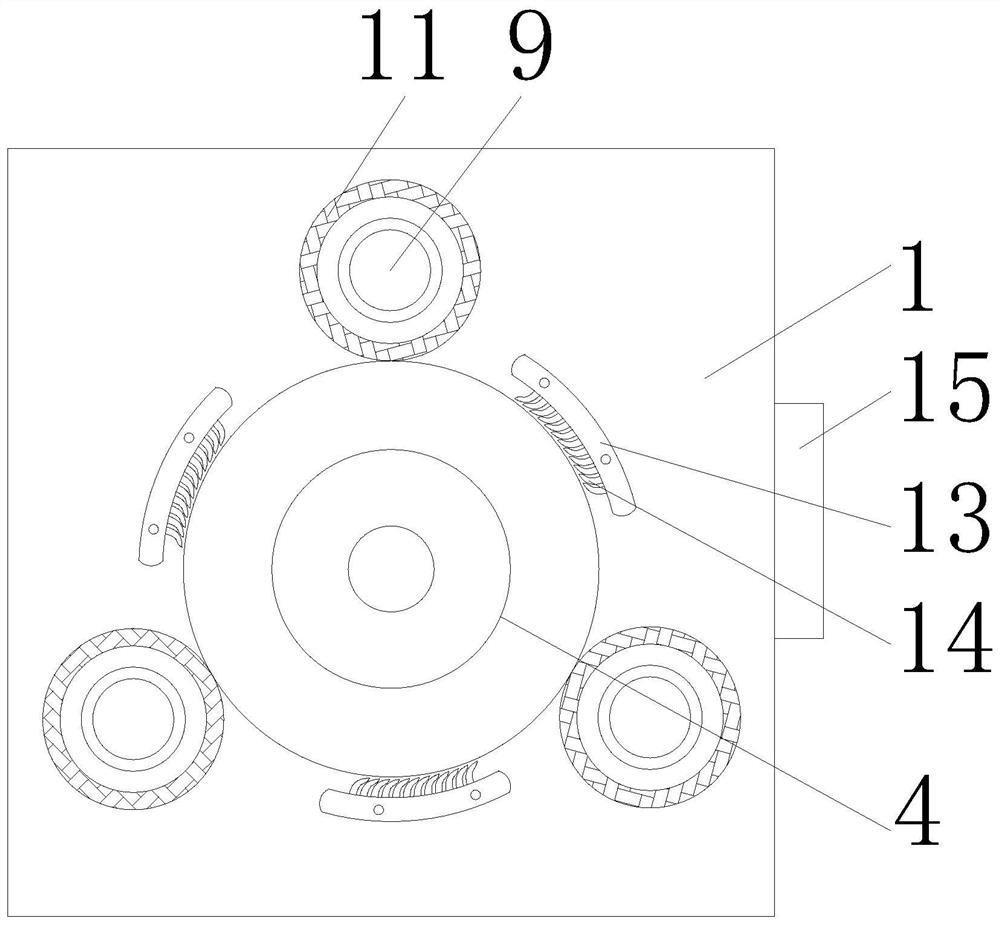

High-end equipment manufacturing steel plate surface grinding equipment

ActiveCN112720113AEasy effectSanding easilyGrinding drivesGrinding work supportsPolishingStructural engineering

The invention relates to polishing equipment, in particular to high-end equipment manufacturing steel plate surface polishing equipment. According to the high-end equipment manufacturing steel plate surface grinding equipment provided by the invention, the surface of a steel plate can be easily ground, the steel plate can be rotated to be fully ground, automatically clamped and fixed and easily unlocked and loosened, and rotation of the steel plate and movement of a grinding wheel are autonomously controlled. The high-end equipment manufacturing steel plate surface grinding equipment comprises supporting legs, a base, a rotating rod, a workbench, a transmission mechanism and a polishing mechanism, wherein the supporting legs are symmetrically arranged on the ground; the base is connected between the lower parts of the inner sides of the supporting legs; the middle of the upper part of the base is rotatably connected with the rotating rod; the upper side of the rotating rod is connected with the workbench; the transmission mechanism is arranged between the upper parts of the supporting legs; and the polishing mechanism is arranged on the transmission mechanism. According to the high-end equipment manufacturing steel plate surface grinding equipment provided by the invention, a pedal is treaded to drive a warping plate to rotate anticlockwise, a fixing rod and an arc-shaped supporting plate are pushed to move downwards, and a steel plate is loosened, so that the effect of unlocking and loosening the steel plate more easily and conveniently is achieved, and manpower is saved.

Owner:广东锐创图压力容器设备有限公司

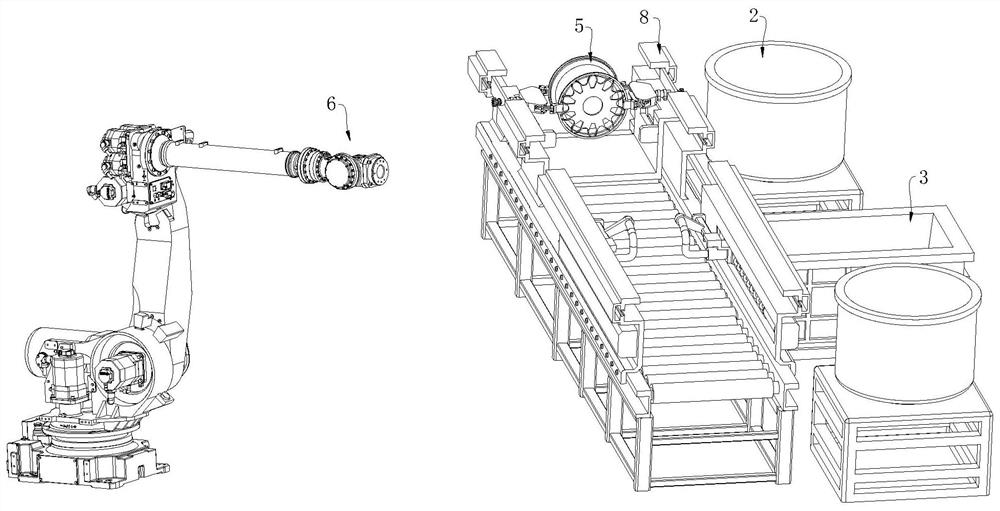

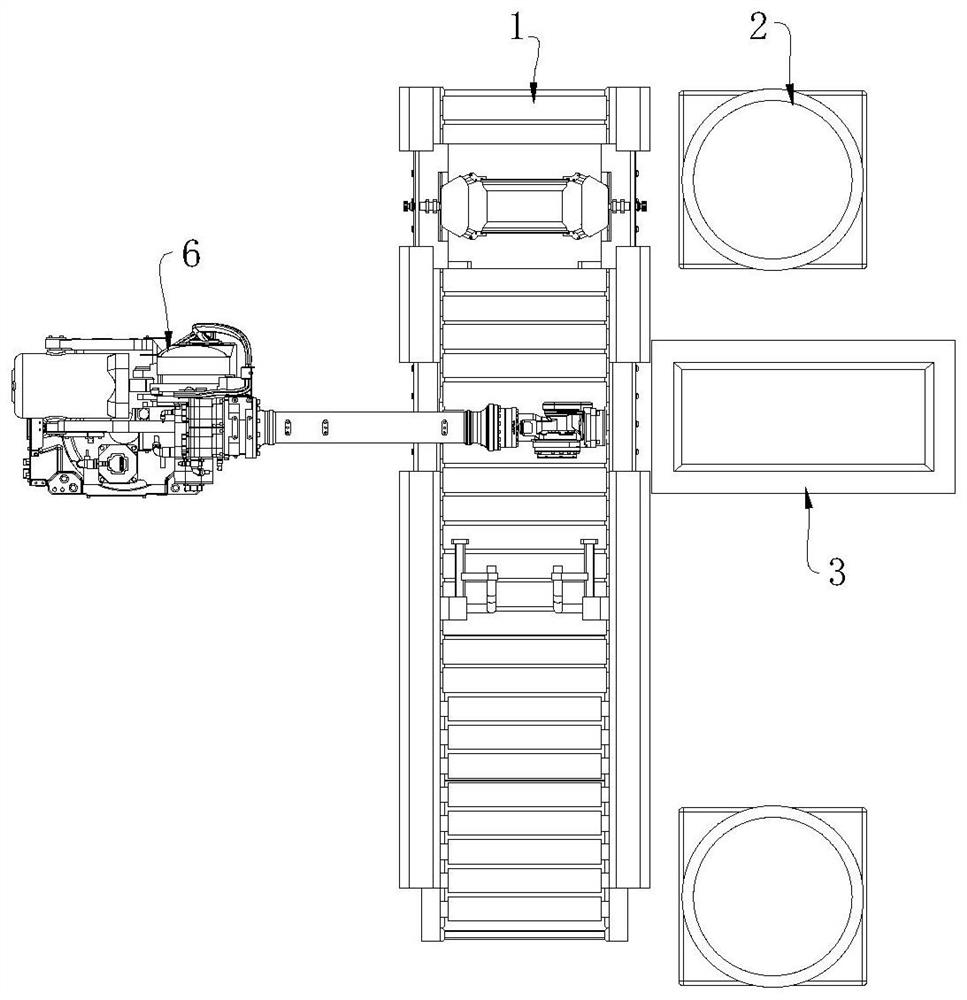

New energy automobile hub grinding device

ActiveCN114012566ASanding effectDry evenlyDrying gas arrangementsGrinding machinesNew energyTransmission belt

The invention discloses a new energy automobile hub grinding device. A roller conveying belt is mounted on the ground, a grinding machine body and a cleaning pool are arranged on one side of the roller conveying belt in parallel, a driving frame is arranged on the roller conveying belt, and a hub body is arranged on the driving frame; a mechanical arm used for grabbing the hub body is arranged on one side of the roller conveying belt; a fixing assembly is arranged on the driving frame and used for clamping the hub body, fixing frames are symmetrically arranged on the roller conveying belt, and drying pieces used for drying the cleaned hub body are arranged on the fixing frames; and an adjusting assembly is arranged on the fixing frame, and the adjusting assembly is used for changing the fixing angle of the hub body so that the concave surface with accumulated water in the hub body can be evenly dried through the drying piece. According to the new energy automobile hub grinding device, the hub body rotates at multiple angles through the fixing assembly and the adjusting assembly; and the wheel hub body is cleaned under the action of the drying piece.

Owner:张文鹏

A surface treatment equipment for anti-folding polymer new material

ActiveCN113714884BSanding effectImprove processing efficiencyEdge grinding machinesGrinding drivesPolymer scienceMaterials processing

The invention discloses a new polymer material surface treatment device for anti-stack marks in the technical field of new polymer material processing, which includes a bottom plate, a first chute is opened on the top of the bottom plate, and a first chute is slidably connected in the first chute. Two symmetrically arranged cross slides, and a two-way threaded rod is rotatably connected in the first chute, and the two cross slides are respectively threaded on both ends of the two-way threaded rod, and the left side wall of the bottom plate is fixedly connected with a second A motor, the output shaft of the first motor is fixedly connected to the left end of the two-way threaded rod; the present invention can realize automatic grinding of different faces of the new polymer material, can improve the processing efficiency of the new polymer material, and shorten the The processing time of molecular new materials.

Owner:鹤山市联拓工程塑料有限公司

Edge sealing strip handheld fastening and grinding robot

ActiveCN113523953AGuaranteed pressure effectImprove work efficiencyEdge grinding machinesGrinding carriagesElectric machineryDry glue

The invention belongs to the technical field of edge sealing strip fastening and grinding, and particularly relates to an edge sealing strip handheld fastening and grinding robot. The edge sealing strip handheld fastening and grinding robot comprises a motor, a shell, fastening mechanisms, grinding mechanisms and a trigger pressing block; an edge sealing strip is designed to be pressed by the handheld equipment; manual pressing is not needed, and the pressing effect is guaranteed; on the other hand, grinding is carried out under the action of pressing rollers in a non-dry glue pressing process; the two steps can be completed at the same time through the equipment designed by the invention, so that working efficiency is improved; a limiting mechanism is designed, and the limiting mechanism has the effect of ensuring that two second mounting sliding blocks for mounting two grinding wheels cannot slide relative to corresponding first guide sliding shells due to frictional resistance in the grinding process of the two grinding wheels; and the grinding of the grinding wheels on the corners of the edge sealing strip cannot be influenced.

Owner:SINOWOLF PLASTIC DEKOR

A pcb double-sided board grinding device for electronic products and its working method

ActiveCN110900335BSanding effectReduce contact areaGrinding carriagesGrinding drivesEngineeringMachine

The invention discloses a PCB double-sided board grinding device for electronic products and its working method. It includes a machine table, a clamping seat and a grinding table are arranged on the machine table, a chip collection box is installed on the grinding table, and the clamping seat is a rectangular box. Body structure, a fixed plate is installed in the clamping seat, a first cylinder is also arranged in the clamping seat, and a connecting bar is connected to the piston rod of the first cylinder. The invention shrinks the piston rod of the first cylinder, and then drives one of the mounting plates to move through the connecting bar, and the mounting plate drives the rod sleeve to slide on the fixed rod, and then drives the rotating wheel and the limit roller to rotate through the clip bar, and the rotating wheel drives the other The clamping strip moves, and the two clamping strips move towards each other, and then drive the two moving side columns to move towards each other through the two mounting plates, which solves the problem that the PCB board grinding device in the prior art is prone to jamming through conventional screw rod adjustment and clamping question.

Owner:江苏百维能源科技有限公司

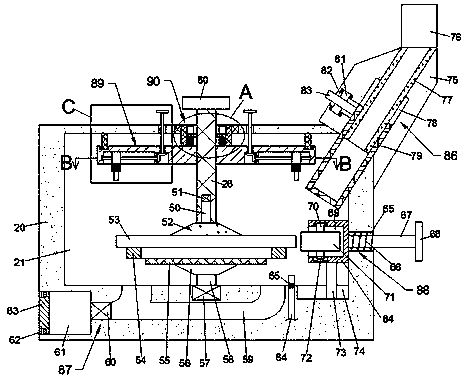

Mobile polishing equipment for cutting surface of building steel pipe

ActiveCN108857651AConvenient and labor-saving cutting surfaceReduce work intensityPlane surface grinding machinesGrinding/polishing safety devicesArchitectural engineeringTorsion spring

The invention relates to polishing equipment, in particular to mobile polishing equipment for cutting surface of a building steel pipe. According to the mobile polishing equipment for the cutting surface of the building steel pipe, the cutting surface of the steel pipe does not need to be polished manually, the polishing effect is uniform, and the work efficiency is high. The mobile polishing equipment for the cutting surface of the building steel pipe includes a machine frame and the like, a mounting mechanism is connected with the middle of the top of the machine frame, and a polishing mechanism is connected with the bottom of the mounting mechanism. By means of the mobile polishing equipment, the effect that the cutting surface of the steel pipe can be polished by only needing to move the polishing mechanism in a reciprocating left-to-right mode, and the cutting surface of the steel pipe is polished more conveniently is achieved, by arranging a moving plate, a swinging plate, a torsion spring, a mounting plate and a pushing rod, a polishing block can be pushed leftwards so that the cutting surface of the steel pipe is polished more simply, and the operation of the workers is more convenient.

Owner:徐州市瑞泰钢管有限公司

Surface grinding device for grinding tool standard part production and machining

InactiveCN113523917ASanding effectAvoid driftingGrinding carriagesGrinding devicesElectric machineryEngineering

The invention discloses a surface grinding device for grinding tool standard part production and machining, and relates to the technical field of grinding equipment, in particular to a surface grinding device for grinding tool standard part production and machining. The surface grinding device comprises a worktable, and a driving motor is arranged above the top of the worktable. The bottom of an output shaft of the driving motor is fixedly connected with a grinding disc, the outer portion of the grinding disc is covered with a dust suction cover, the top of the dust suction cover is fixedly connected with a dust suction pipe, the bottom end of the dust suction pipe extends into the worktable, the bottom end of the dust suction pipe is fixedly connected with a dust suction pump, and the right end of the dust suction pump is fixedly connected with a dust storage box. According to the surface grinding device for grinding tool standard part production and machining, the dust suction cover is arranged outside the grinding disc, chippings generated by grinding are covered with the dust suction cover, the chippings are prevented from freely drifting away, in the grinding process of the grinding disc, the chippings generated by grinding are sucked into a filter bag through the dust suction pipe, and the chippings are conveniently collected.

Owner:安庆皖台精密机械有限公司

A mobile grinding equipment for cutting surface of steel pipe for construction

ActiveCN108857651BEasy to operateSimple cutting surfacePlane surface grinding machinesGrinding/polishing safety devicesPolishingMachine

The invention relates to polishing equipment, in particular to mobile polishing equipment for cutting surface of a building steel pipe. According to the mobile polishing equipment for the cutting surface of the building steel pipe, the cutting surface of the steel pipe does not need to be polished manually, the polishing effect is uniform, and the work efficiency is high. The mobile polishing equipment for the cutting surface of the building steel pipe includes a machine frame and the like, a mounting mechanism is connected with the middle of the top of the machine frame, and a polishing mechanism is connected with the bottom of the mounting mechanism. By means of the mobile polishing equipment, the effect that the cutting surface of the steel pipe can be polished by only needing to move the polishing mechanism in a reciprocating left-to-right mode, and the cutting surface of the steel pipe is polished more conveniently is achieved, by arranging a moving plate, a swinging plate, a torsion spring, a mounting plate and a pushing rod, a polishing block can be pushed leftwards so that the cutting surface of the steel pipe is polished more simply, and the operation of the workers is more convenient.

Owner:徐州市瑞泰钢管有限公司

Automatic blade polishing mechanism

The invention discloses an automatic blade polishing mechanism which comprises a workbench, a sliding base arranged on the workbench, a first mechanical arm, a second mechanical arm, a fixing block arranged on the workbench, a first driving piece, a supporting mechanism, a blade back polishing device, a blade polishing device and a cleaning device. The blade polishing device comprises a second driving piece arranged on the sliding base, a first support arranged on a second driving piece, a first fixed shaft arranged on the first support, a polishing piece arranged on the first fixed shaft, a first twisting piece arranged on the first fixed shaft, a third driving piece arranged on the sliding base, a second support arranged on a third driving piece, a rotating roller arranged on a third support, a plurality of first limiting grooves formed in the rotating roller, clamping pieces arranged on the first limiting grooves, first elastic pieces arranged on the clamping pieces and a plurality of arc-shaped pieces and wiping assemblies arranged on the polishing piece.

Owner:SHANDONG IND TECH RES INST OF ZHEJIANG UNIV

An optical instrument for lens polishing

ActiveCN110640575BGuaranteed shape accuracyGuaranteed clarityEdge grinding machinesGrinding/polishing safety devicesEngineeringUniform rotation

The invention discloses an optical instrument for lens grinding, which comprises a body, a grinding cavity is arranged in the body, a placing plate is rotated in the grinding cavity, a picture frame is placed on the placing plate, and a picture frame is placed on the picture frame. A lens is placed, and the upper side of the lens is provided with a liftable stretching rod through a telescopic device. The outer periphery of the stretching rod is a spline structure, and a suction cup is installed at the lower end of the stretching rod. , use the laser to draw the grinding track on the lens to provide the shape accuracy during grinding, and grind the lens through the mutual cooperation of the automatic uniform rotation of the lens and the horizontal movement of the automatically rotating grinding wheel. During the grinding process, it can be observed through the optical device The grinding situation ensures the grinding accuracy. In addition, the glass or resin slag generated during grinding is collected downward through the recovery device to ensure the clarity of observation, and the slag will not fly and affect the grinding. It is formed once and the grinding efficiency is high.

Owner:江西弘耀光学水晶有限公司

A blade automatic grinding mechanism

Owner:SHANDONG IND TECH RES INST OF ZHEJIANG UNIV

A wall-mounted plank side grinding equipment

Owner:镭戈斯智能装备江苏有限公司

Intelligent corner polishing equipment based on circular lens

InactiveCN113843683AAchieve adsorptionAvoid abrasion damageEdge grinding machinesGrinding carriagesPolishingEngineering

The invention relates to the technical field of intelligent manufacturing equipment industry, and discloses intelligent corner polishing equipment based on a circular lens. The intelligent corner polishing equipment is characterized in that the interiors of the left and right side walls of a support frame are hollowed out, chutes are formed in the left and right side walls of the support frame, and first gas cavities are formed in middle shafts in the left side wall and the right side wall of the support frame correspondingly. According to the intelligent corner polishing equipment based on the circular lens, when the lens is clamped, an extrusion rod can move under the action of extrusion force, so that an arc-shaped rod is driven to enter a connecting cylinder, gas in a rubber suction cup can be drained under the condition that the arc-shaped rod moves, a vacuum negative pressure state is generated in the rubber suction cup, and the lens can be adsorbed according to the property characteristics of the state, so that the lens is prevented from being abraded and damaged during grinding and polishing.

Owner:李玉洁

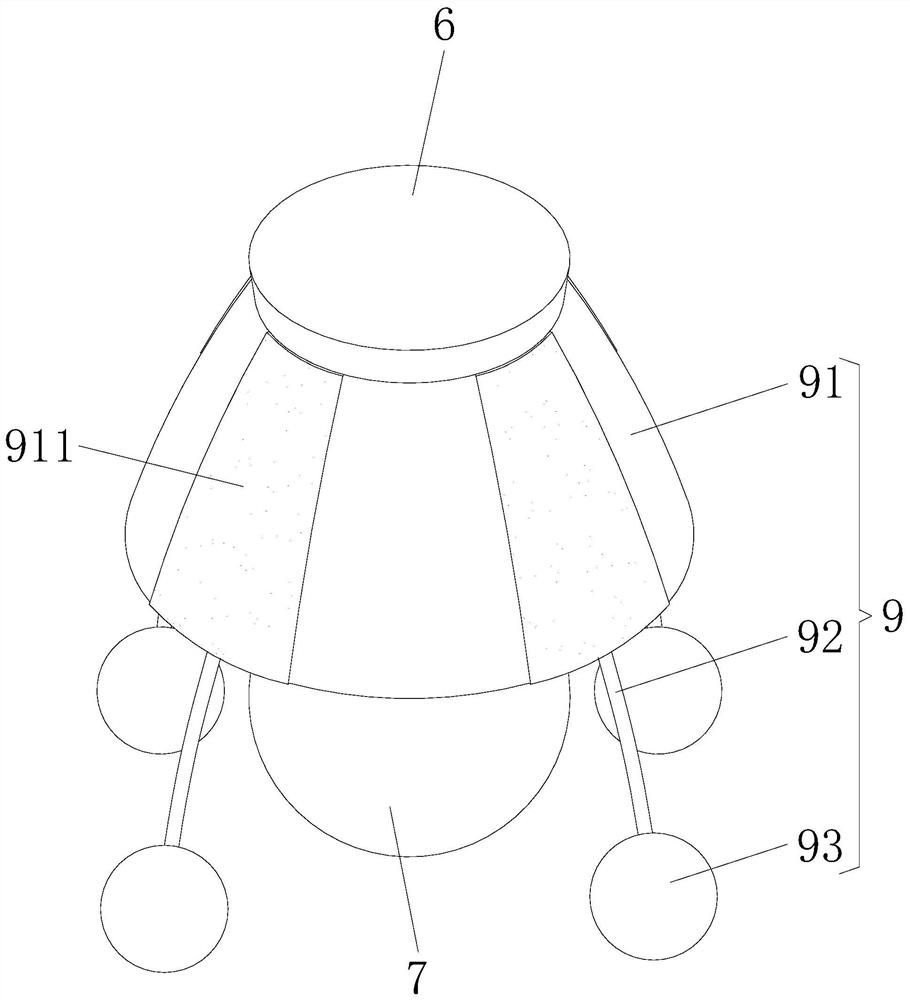

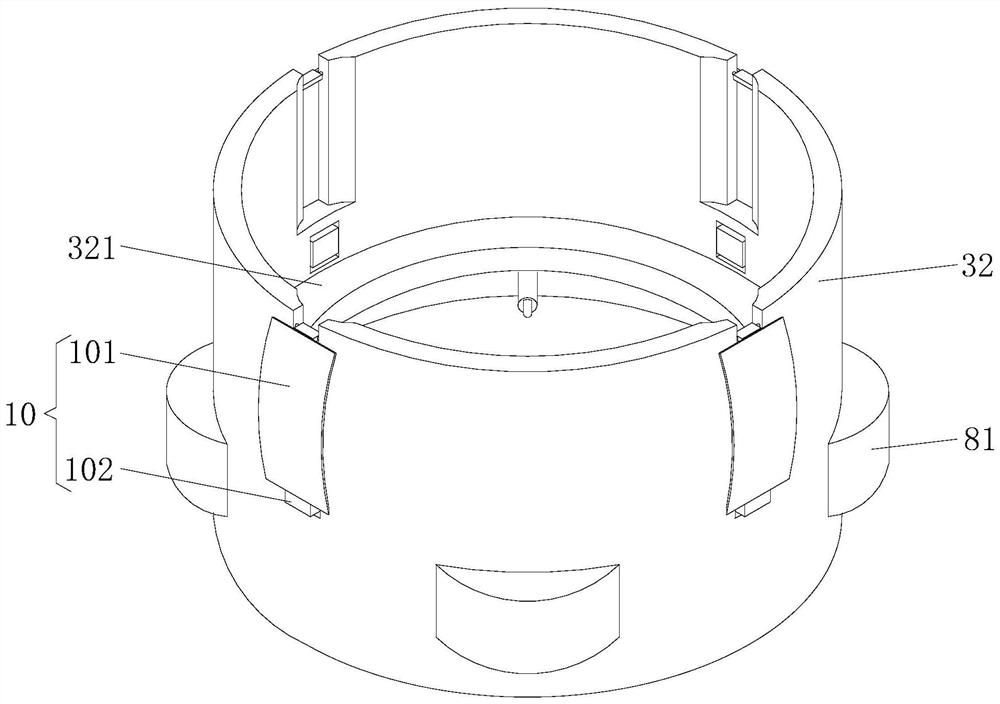

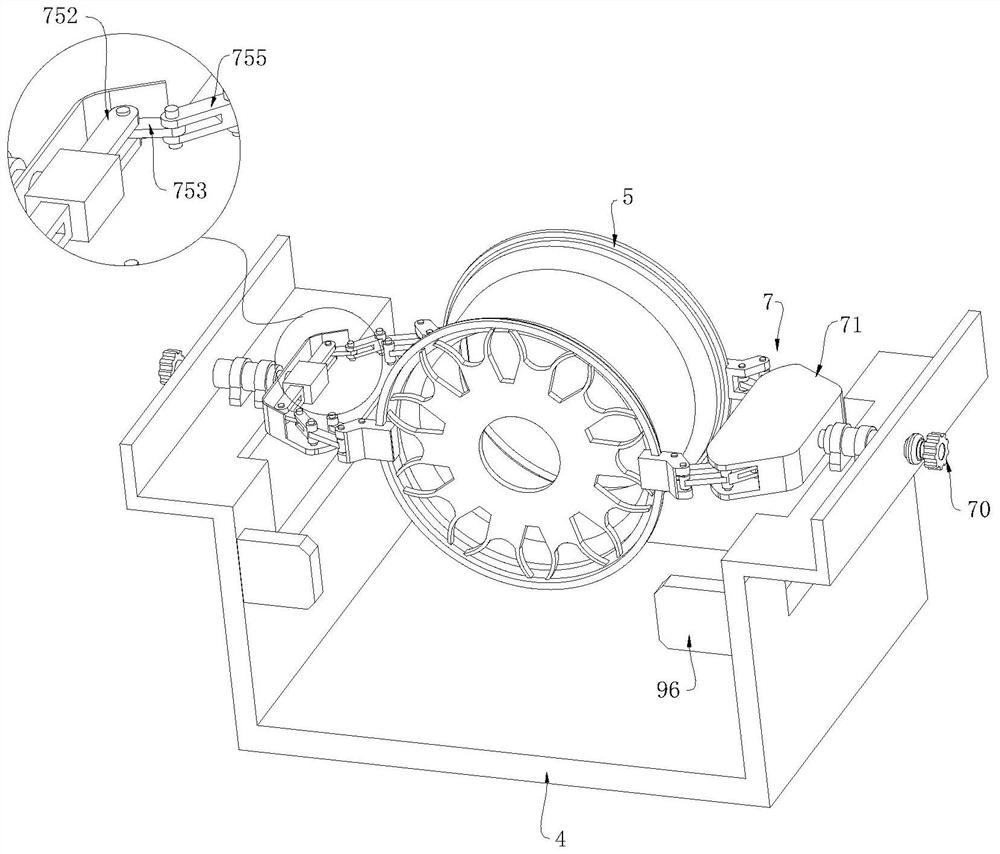

Side wall polishing device for filter machining

PendingCN112139913AImprove grinding efficiencySanding effectGrinding carriagesGrinding drivesElectric machineGear wheel

The invention relates to the technical field of filter machining equipment, in particular to a side wall polishing device for filter machining. The side wall polishing device comprises a workbench anda fixing frame at the bottom of the workbench, a double-shaft motor is installed at the middle position of the workbench, and a fixing seat for fixing a filter is fixedly installed at one end of an output shaft at the upper portion of the double-shaft motor. A first belt wheel is installed at one end of an output shaft at the bottom of the double-shaft motor, a rotating rod is installed at the left side position of the bottom of the workbench through a bearing, a second belt wheel is installed at the bottom position of the rotating rod, the first belt wheel and the second belt wheel are in transmission connection through a belt, and a first gear is installed on the outer wall of the rotating rod and located at the upper portion position of the second belt wheel. The polishing efficiency is high, and meanwhile the manufacturing and using cost is low.

Owner:安徽普蓝滤清器设备有限公司

A hand-held fastening and grinding robot for edge banding

ActiveCN113523953BGuaranteed pressure effectImprove work efficiencyEdge grinding machinesGrinding carriagesElectric machineryGrinding wheel

The invention belongs to the technical field of edge banding fastening and grinding, and in particular relates to a hand-held fastening and grinding robot for edge banding, which includes a motor, a housing, a fastening mechanism, a grinding mechanism, and a trigger block. In the invention, the edge banding The unique design of pressure exerts pressure on the hand-held device itself, and does not require artificial pressure, which ensures the effect of pressure exertion. On the other hand, in the process of applying pressure while the glue is not dry, grinding is carried out simultaneously under the action of the pressure roller, and the equipment designed by the invention can complete the two steps simultaneously, which improves the working efficiency. The present invention designs a limit mechanism, and the function of the limit mechanism is to ensure that the two second mounting sliders of the two grinding wheels will not be installed in the first guide sliding shell corresponding to the frictional resistance during the grinding process. Sliding affects the grinding of the edge of the edge strip by the grinding wheel.

Owner:SINOWOLF PLASTIC DEKOR

A circular glass grinding control system and method

ActiveCN111055184BSanding effectEasy to holdEdge grinding machinesUsing liquid separation agentControl systemControl engineering

The invention relates to the technical field of glass processing, in particular to a circular glass polishing control system and method. The circular glass polishing control system is applied to an intelligent glass circumference polishing device and comprises a controller and a server; the server comprises an in-place detecting module, a conveyor belt control module, a delay control module, a polishing control module and a finished product conveying module. The system is applied to the circular glass polishing control system and comprises the steps of in-place detection, conveyor belt control, delay control, polishing control and finished product conveying. The circular glass polishing control system solves the problems that circular glass polishing is low in efficiency and non-uniform.

Owner:重庆市耀城玻璃制品有限公司

Solid wood composite board manufacturing performance detection system

InactiveCN114563297APrevent movementReduce processCleaning using toolsInvestigating abrasion/wear resistanceSolid woodPulp and paper industry

The invention relates to the technical field of solid wood composite board performance detection, in particular to a solid wood composite board manufacturing performance detection system which comprises a fixing frame and a detection frame, and the detection frame is fixedly installed on the fixing frame. The surface of the solid wood composite board is ground through the detection frame, the grinding length range can be adjusted according to the actual size of the solid wood composite board, chippings on the surface of the solid wood composite board and the surfaces of grinding parts are cleaned in the grinding process, and the grinding efficiency is improved. According to the invention, the chippings are collected, the wear resistance of the solid wood composite board is judged according to the weight of the chippings, the solid wood composite board does not need to be additionally detected and weighed, the working procedures of a detection test are reduced, and the wear resistance detection efficiency is improved.

Owner:安雄飞

Anti-folding new polymer material surface treatment device

ActiveCN113714884ASanding effectImprove processing efficiencyEdge grinding machinesGrinding drivesPolymer scienceSlide plate

The invention belongs to the technical field of new polymer material processing, and discloses an anti-folding new polymer material surface treatment device. The anti-folding new polymer material surface treatment device comprises a bottom plate, a first sliding groove is formed in the top of the bottom plate, two symmetrically-arranged cross-shaped sliding plates are slidably connected into the first sliding groove, and a two-way threaded rod is rotatably connected into the first sliding groove; and the two cross-shaped sliding plates are in threaded connection with the two ends of the two-way threaded rod correspondingly, a first motor is fixedly connected to the left side wall of the bottom plate, and an output shaft of the first motor is fixedly connected with the left end of the two-way threaded rod. According to the device, different surfaces of the new polymer material can be automatically polished, the processing efficiency of the new polymer material can be improved, and the processing time of the new polymer material is shortened.

Owner:鹤山市联拓工程塑料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com