Surface grinding device for grinding tool standard part production and machining

A technology for standard parts and abrasive tools, applied in grinding devices, grinding/polishing safety devices, grinding workpiece supports, etc. Randomly scattered, easy to collect, and unblocked

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

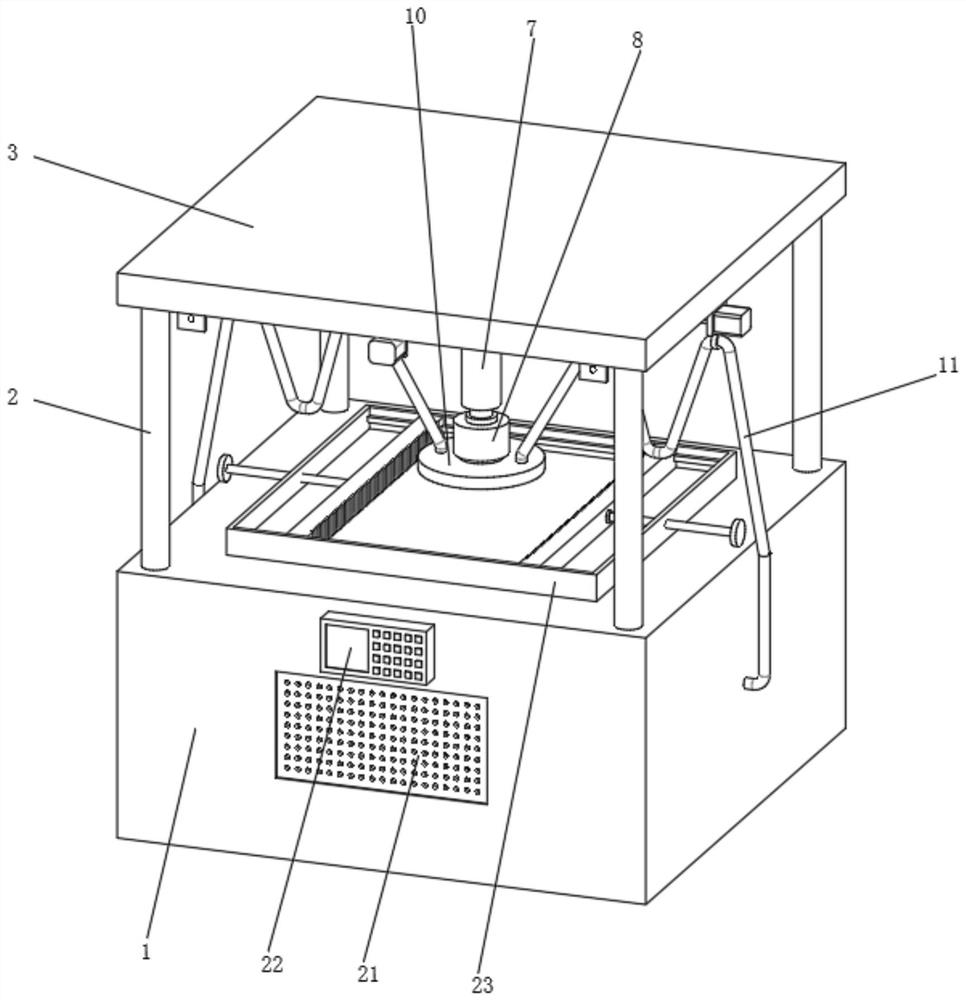

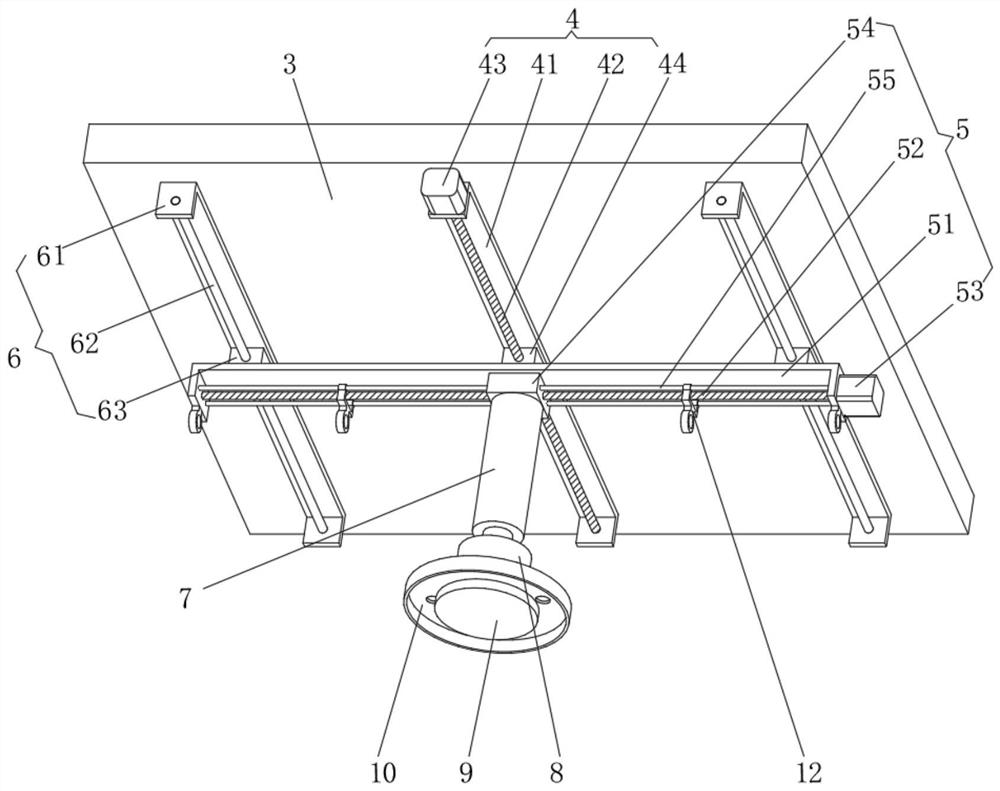

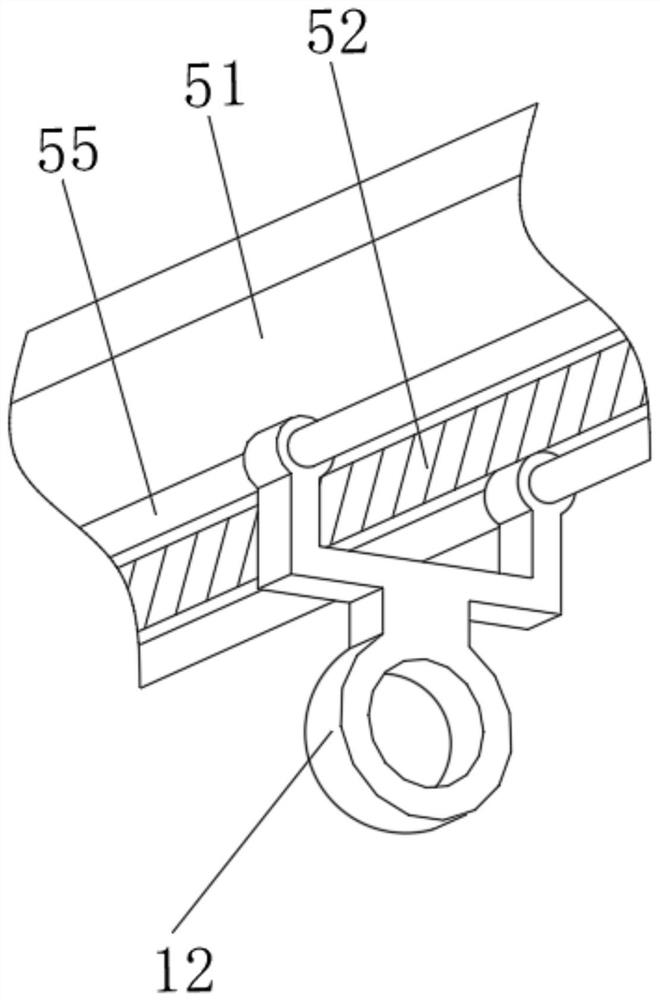

[0026] See figure 1 with figure 2 The present invention provides a technical solution: a surface grinding apparatus for producing processing for the production of abrasives, including a table 1, and the top fixed connection of the table 1 is supported 2, supporting the top of the support 2 fixedly mounted with top plate 3 The front and rear moving device 4 is attached to the bottom of the top plate 3, and the front and rear moving device 4 includes a housing one 41, and the housing 41 is fixedly mounted on the bottom of the top plate 3, and the internal activity of the housing 1 41 has a lead screw one 42 The front end of the housing 121 is fixedly mounted having a servo moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com