Automatic blade polishing mechanism

A technology of grinding mechanism and blade, which is applied in the direction of grinding machine parts, grinding machine, grinding feed movement, etc. It can solve the problems of not being able to adjust the angle of grinding parts, reduce the production efficiency of tools, etc., and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

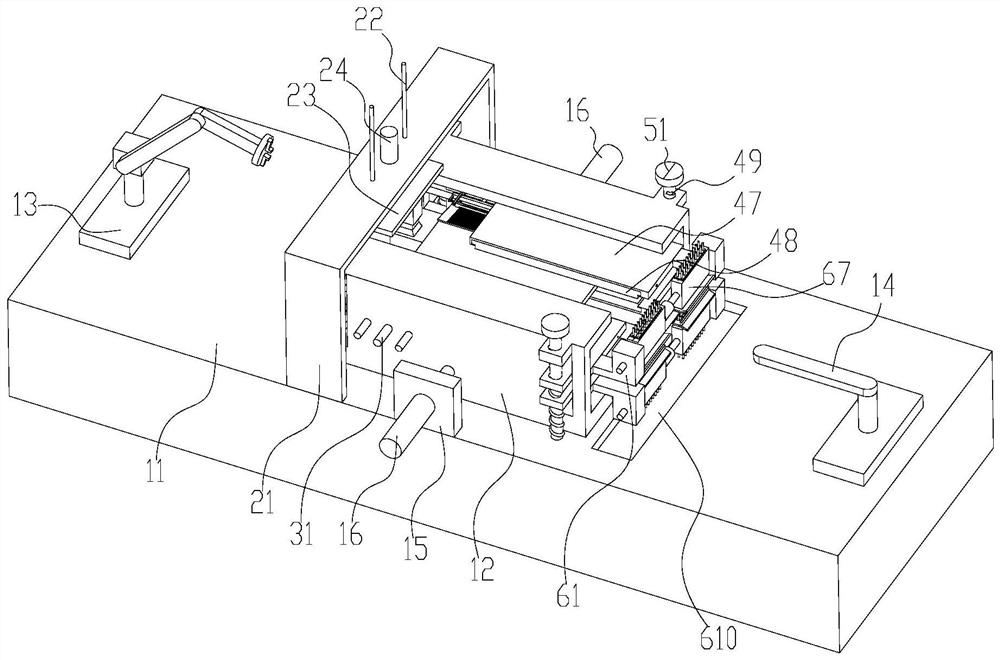

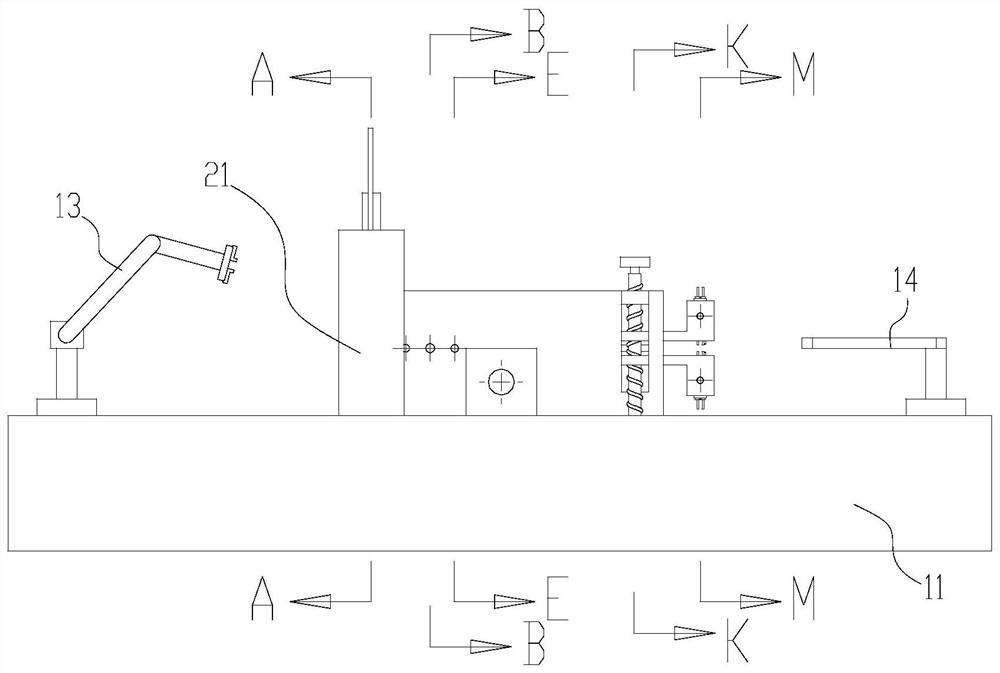

[0031] like Figure 1-16 As shown, a blade automatic grinding mechanism includes a workbench 11, a sliding seat 12, a first manipulator 13, a second manipulator 14, a fixed block 15, a first driver 16, a support mechanism, a knife back grinding device, a blade grinding device and Cleaning device; two sliding seats 12 are arranged symmetrically on the workbench 11 and can slide relative to the workbench 11; the first manipulator 13 is fixed on one side of the workbench 11; the second manipulator 14 is fixed on the workbench 11 ; Fixed block 15 is provided with 2, symmetrically fixed on the workbench 11;

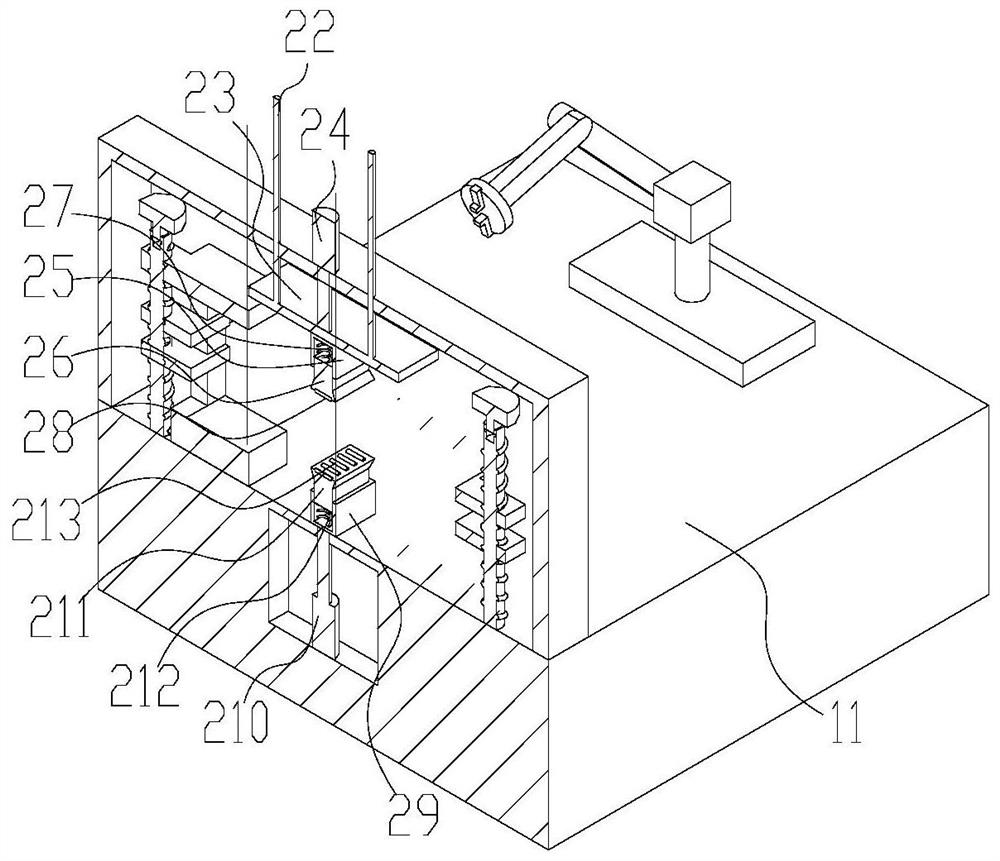

[0032] Further, the support mechanism includes a fixed frame 21, a limit rod 22, a lifting plate 23, a fourth driving member 24, a first fixed frame 25, a first pressing block 26, a first pressing spring 27, a first roller 28. The second fixed frame 29, the fifth driving member 210, the second pressing block 211, the second pressing spring 212 and the second roller 213; the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com