Plank polishing equipment

A wood board and equipment technology, applied in the field of wood board grinding equipment, can solve problems such as poor grinding effect and uneven grinding, and achieve the effect of consistent grinding thickness, good grinding effect and simple grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is further described in detail through specific implementation methods:

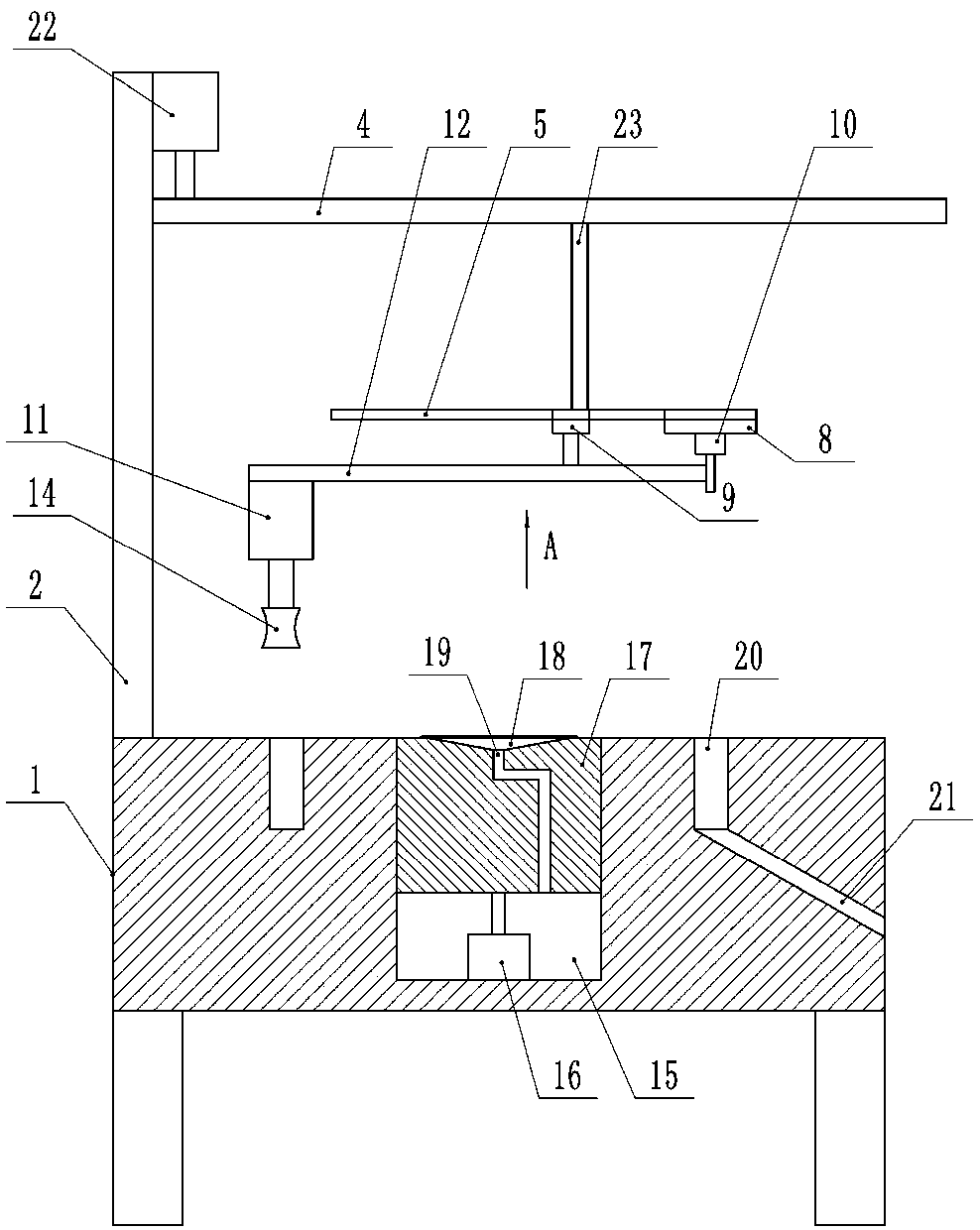

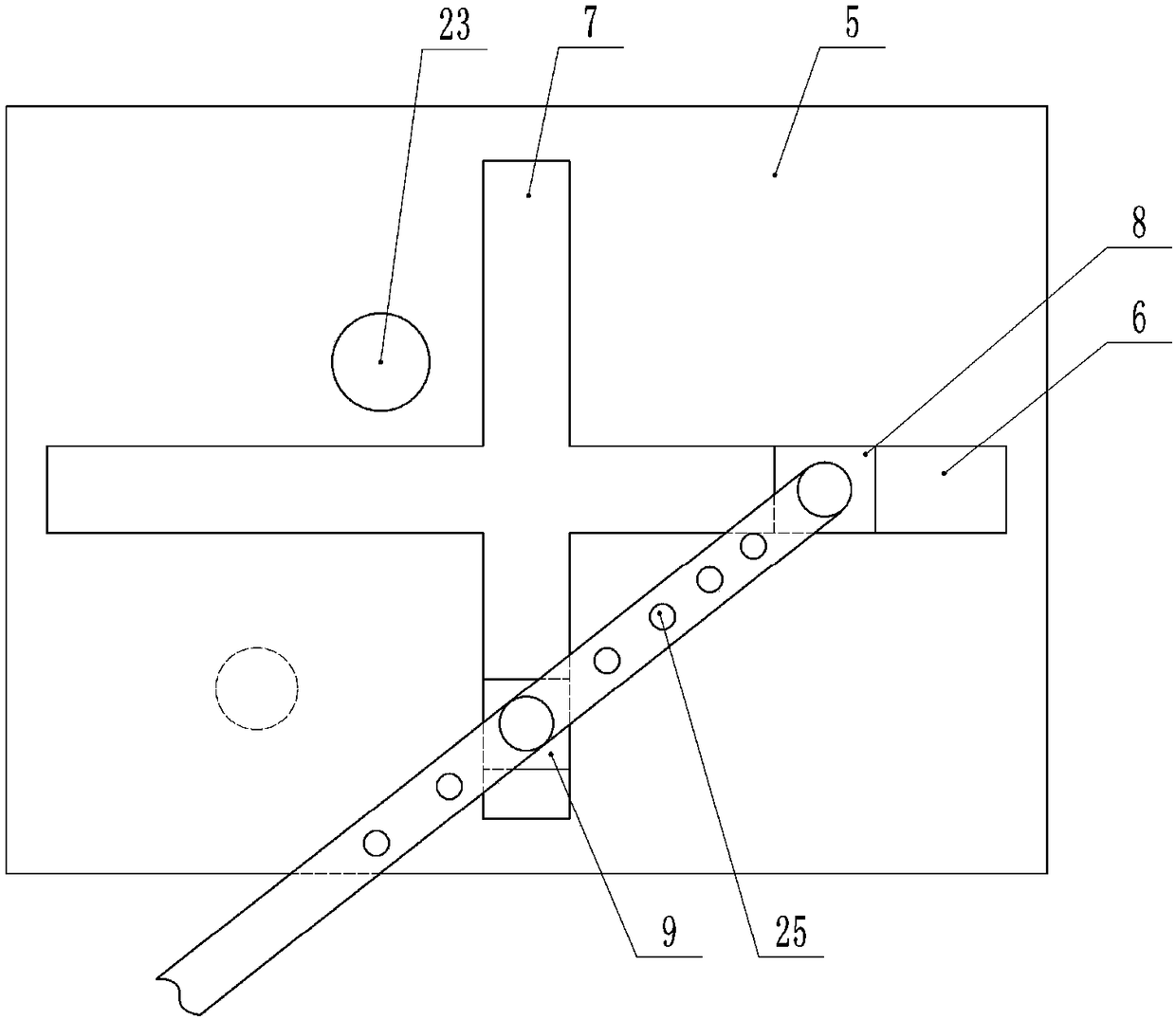

[0017] The reference signs in the drawings of the description include: workbench 1, column 2, beam 4, support plate 5, first through groove 6, second through groove 7, first slider 8, second slider 9, first Motor 10, second motor 11, guide rod 12, grinding wheel 14, cavity structure 15, second cylinder 16, top block 17, suction cup 18, suction hole 19, collection tank 20, material guide hole 21, third cylinder 22, vertical shaft 23, threaded hole 25.

[0018] Such as figure 1 As shown, a kind of plank grinding equipment includes a workbench 1, a vertical column 2 is installed on the left side of the workbench 1, a beam 4 and a third cylinder 22 with the output shaft arranged downward are installed on the upper part of the column 2, and the middle part of the column 2 is installed There is a vertical slide rail, the crossbeam 4 is slidingly connected with the slide rail, and the pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com