Circular glass polishing control system and method

A control system and glass technology, applied in grinding automatic control devices, separation methods, chemical instruments and methods, etc., can solve the problems of uneven grinding and low grinding efficiency of round glass, achieve uniform grinding and reduce manual participation. The effect of low degree and scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

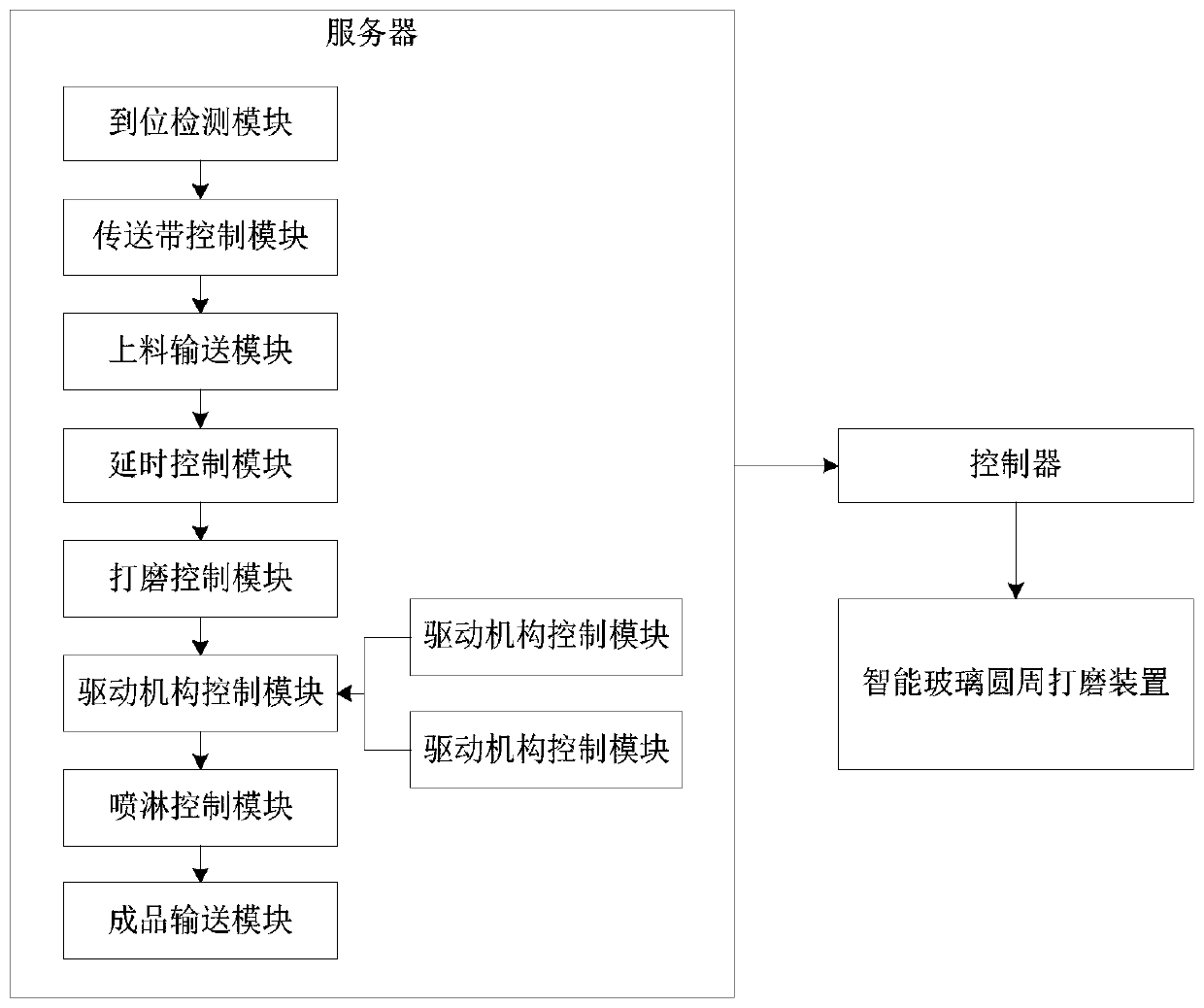

[0058] A circular glass grinding control system, basically as figure 1 As shown, it includes a controller and a server, the controller is connected to the smart glass circumference grinding device, and the server includes the following modules:

[0059] Explanation: The first round glass and the second round glass are round glasses to be processed and polished, and they are placed at equal intervals. The priority of the first round glass is higher than that of the second round glass.

[0060] In-position detection module: used to send an arrival instruction to the controller when the in-position detection sensor detects that the second round glass arrives at a designated position on the first conveyor belt;

[0061] Conveyor belt control module: used to control the first conveyor belt to stop through the controller after the controller receives the arrival instruction, and transport the first circular glass to the second conveyor belt set next to the first conveyor belt; becau...

Embodiment 2

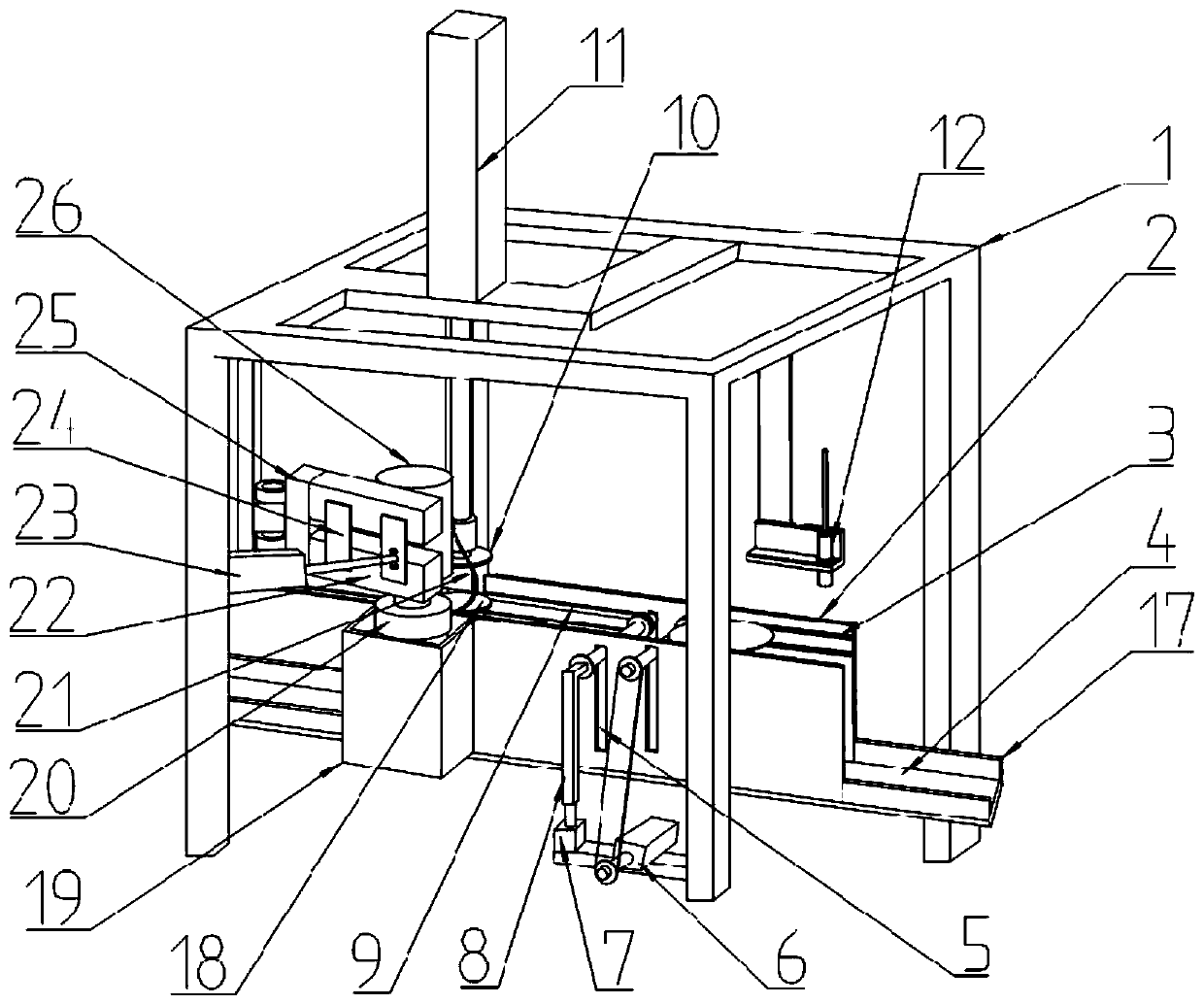

[0080] The difference between embodiment two and embodiment one is that it also includes a smart glass circumference grinding device, basically as figure 2 As shown, the workbench 4 is included, and a surrounding edge 17 is fixed around the workbench 4, so that the workbench presents a groove shape, and a frame is fixedly arranged outside the workbench.

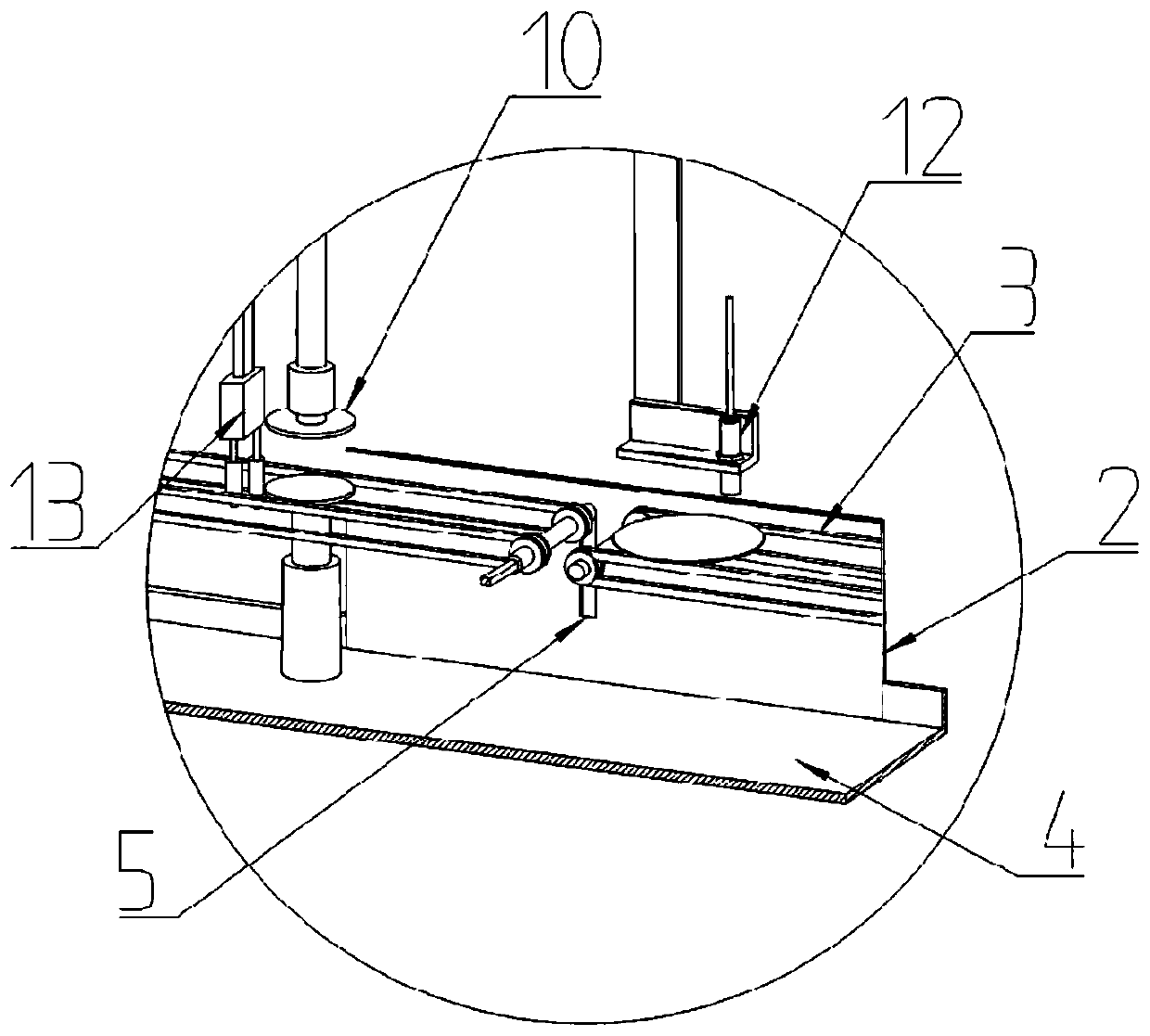

[0081] A conveyor belt is provided on the workbench, and the conveyor belt includes a first conveyor belt 3 and a second conveyor belt 9, and the first conveyor belt 3 and the second conveyor belt 9 run to the right in the same direction and are arranged next to each other.

[0082] The first conveyor belt 3 includes a conveyor belt, a first driving wheel and a first driven wheel, and the first driving wheel is driven by a transmission motor 6 . The second conveyor belt 9 comprises a conveyor belt, a second driving wheel and a second driven wheel, and the conveyor belts of the first conveyor belt 3 and the second conveyor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com