Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Same diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

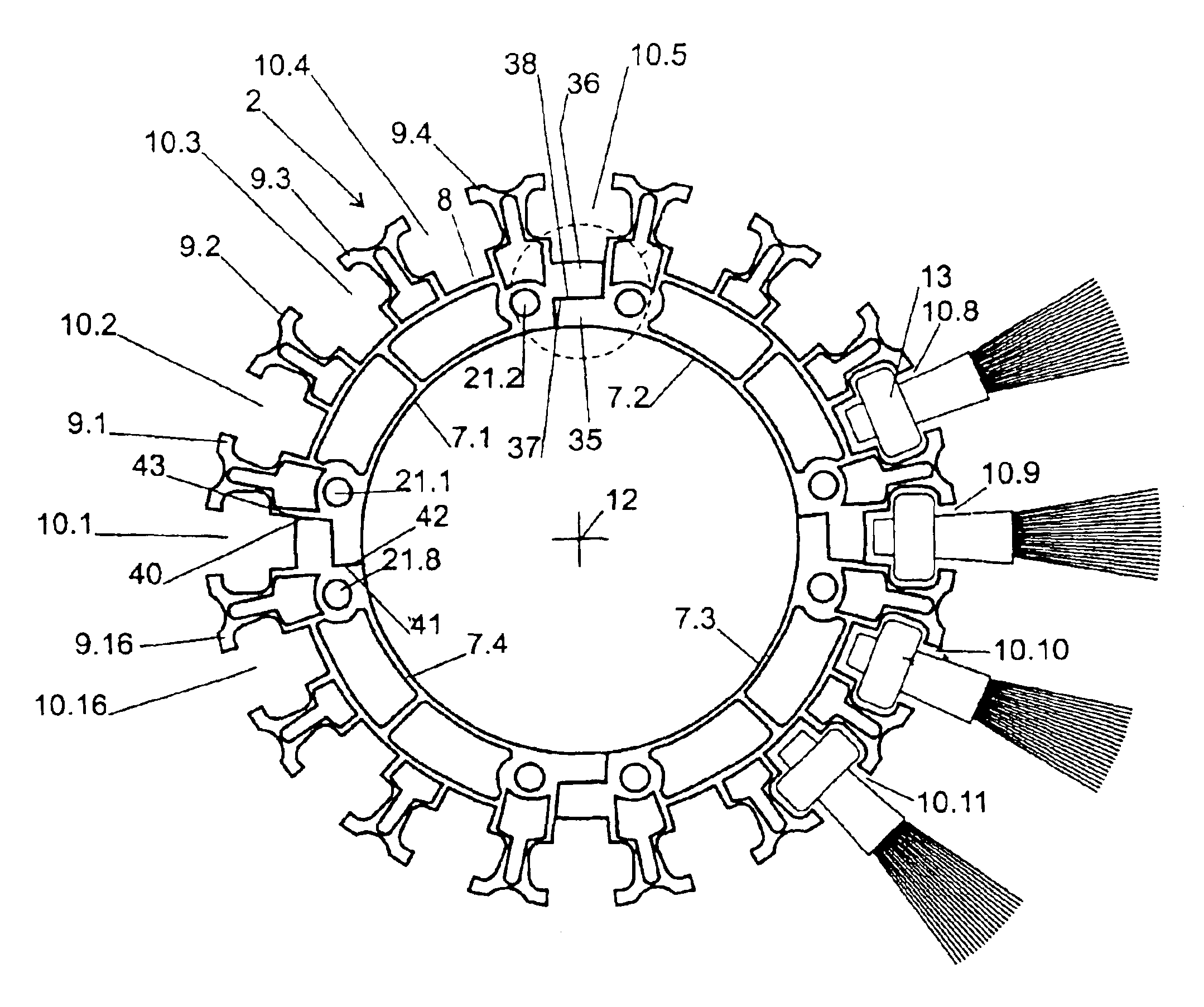

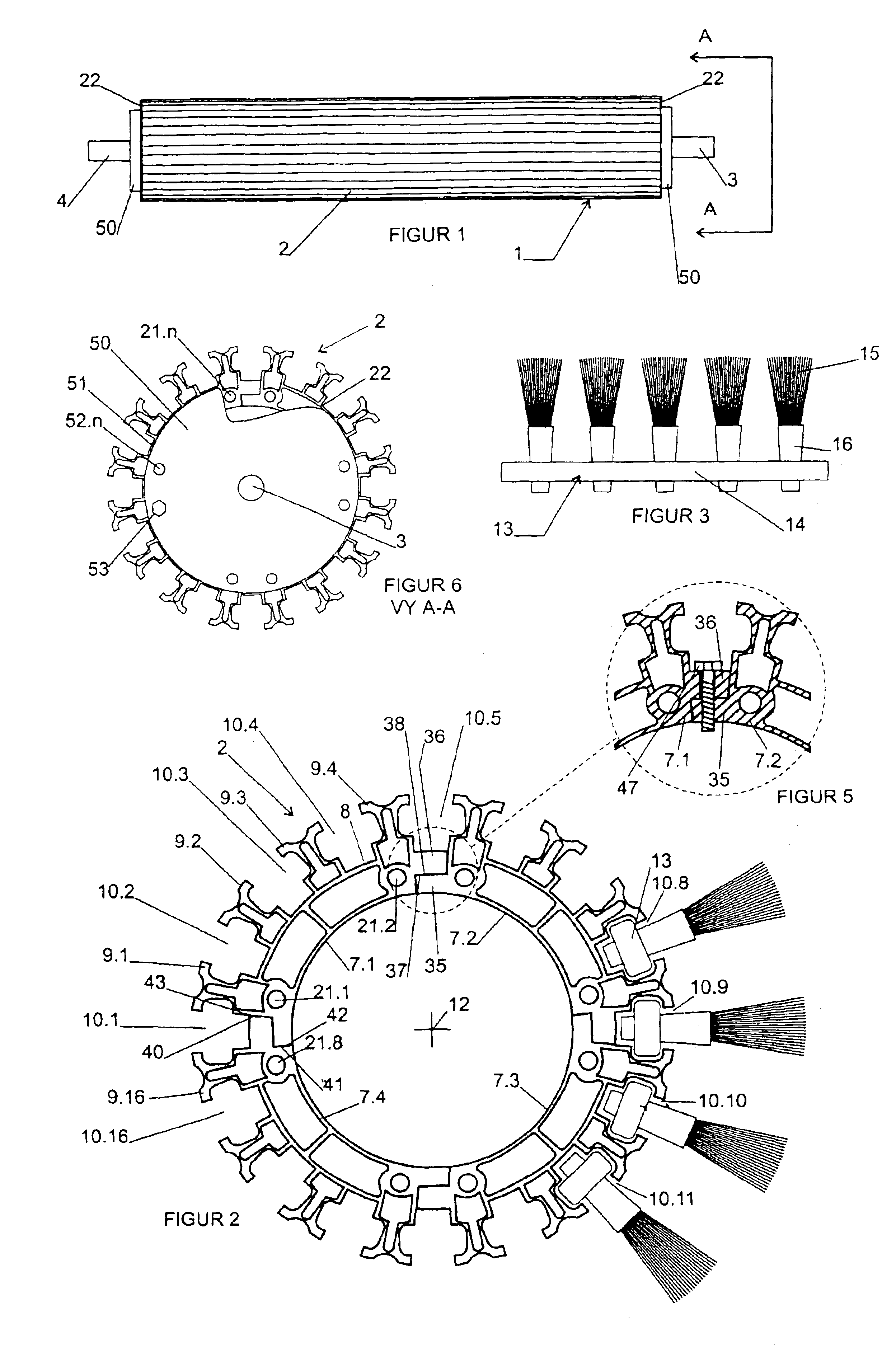

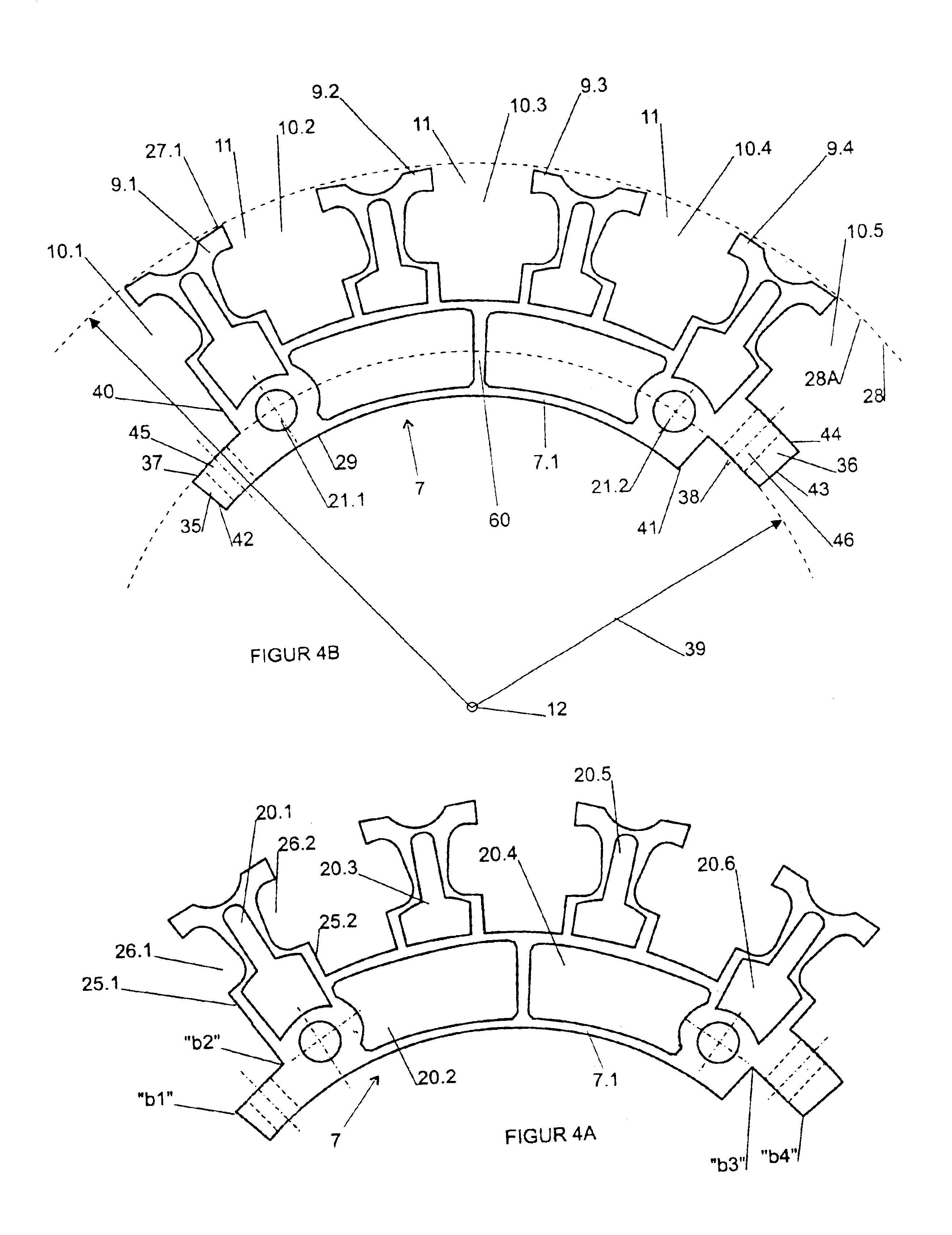

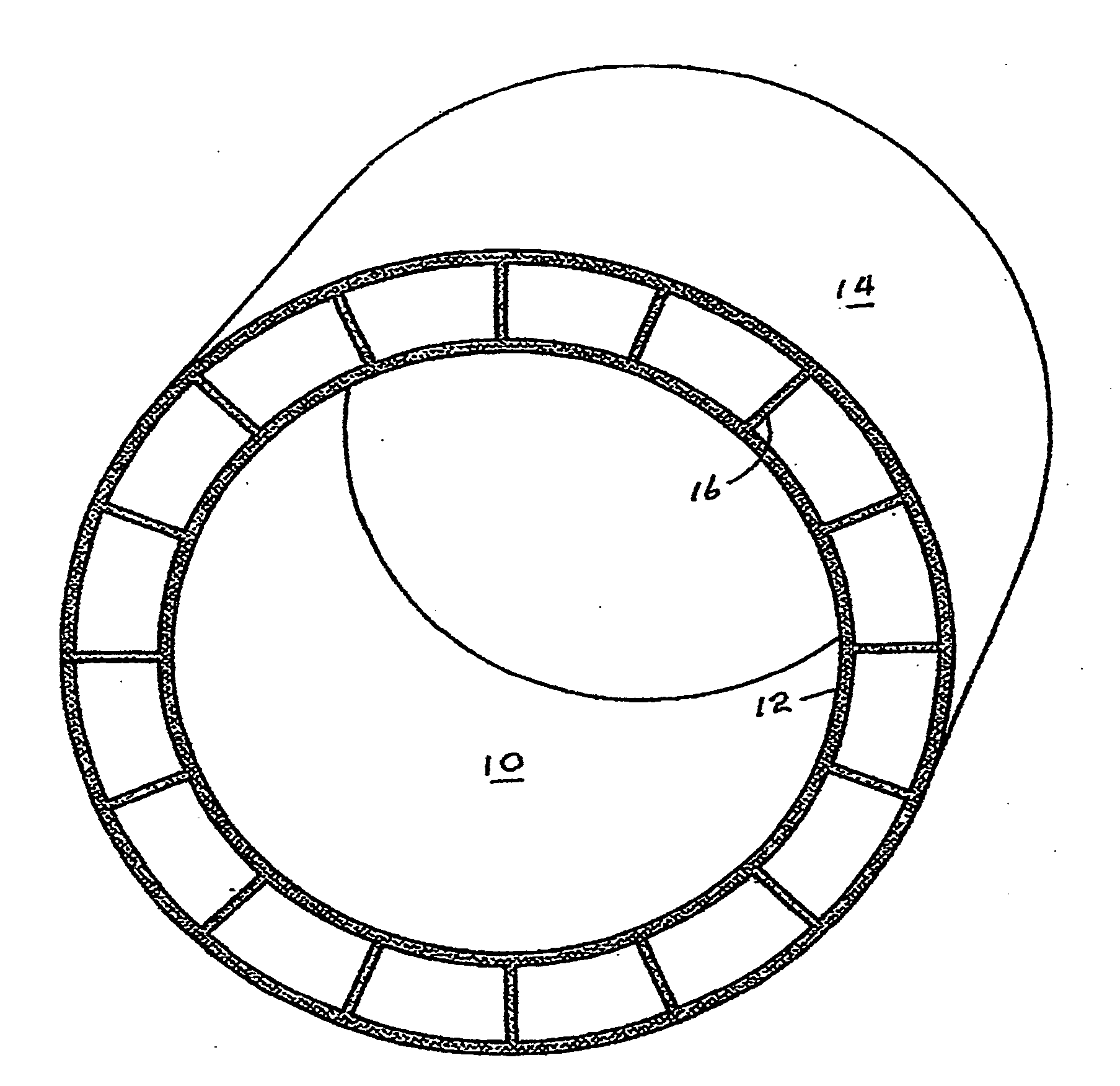

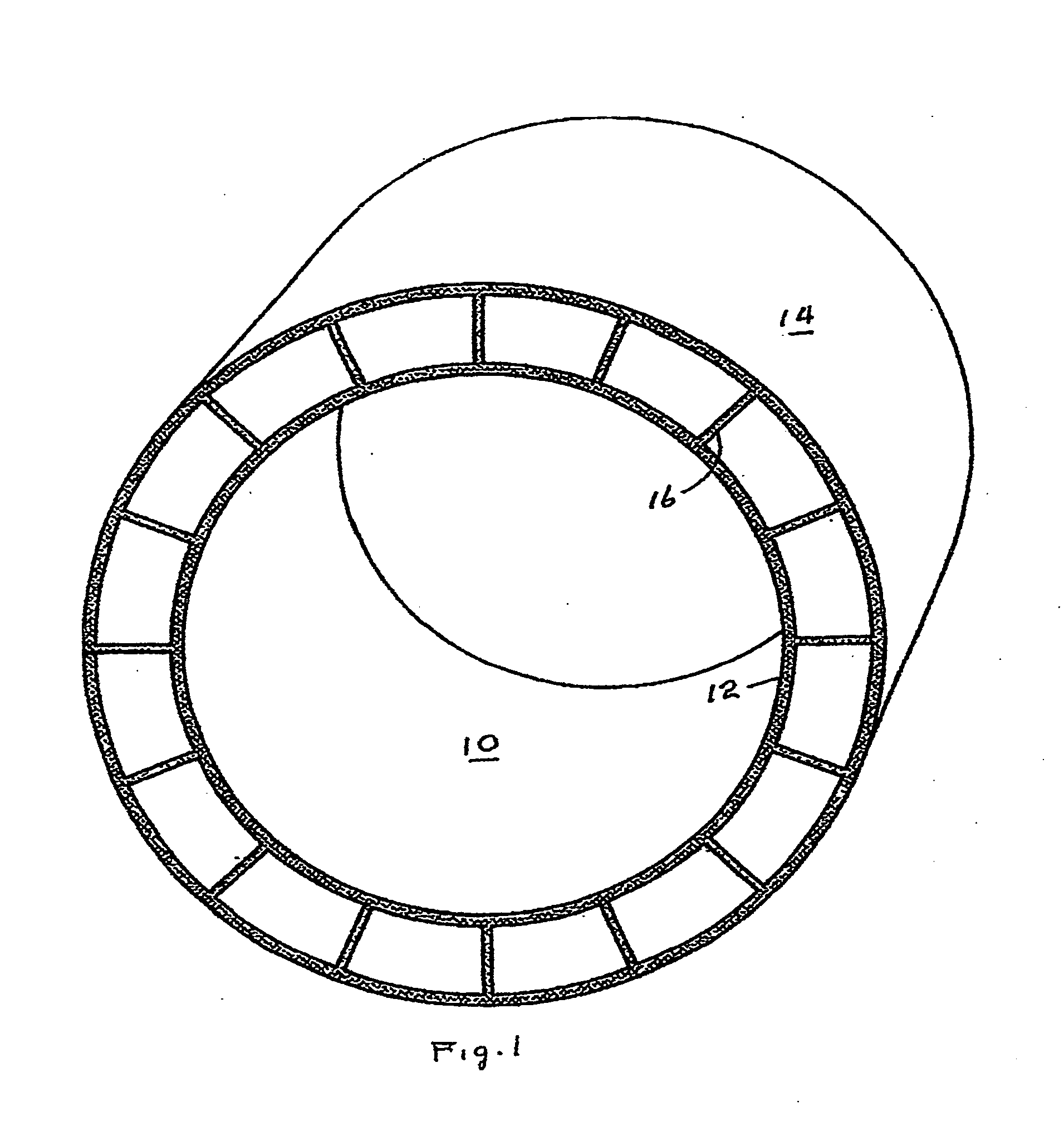

Method for mounting a drum as well as a drum and an axle for a brush roller

InactiveUS6817055B1Simpler and less-expensive to manufactureImprove stabilityBrush bodiesBristle carriersDouble wallEngineering

A drum for a brush roller comprised of a plurality of arcuate shaped segments with circumferentially projecting shoulders at their ends. The shoulders have outer edges that contact the adjacent segments and have respective inwardly and outwardly facing surfaces which in adjacent segments overlie and are attached together. Each segment has radially spaced double walls with sufficient rigidity and has reinforcement. The outward side of each segment is provided with a plurality of protruding beams defining U-shaped channels between them. An axle includes the drum with end plates and projecting shafts at each end. Also, a method of assembling the drum wherein the edges of the shoulders are brought against adjacent segments and the shoulders have their respective inwardly and outwardly facing surfaces overlying and fastening elements extend through the shoulders.

Owner:SVENSKA INDBORSTAR I VASTERAS

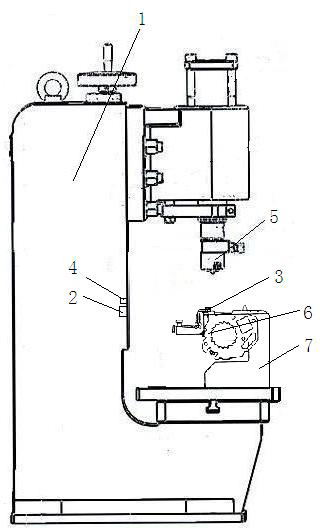

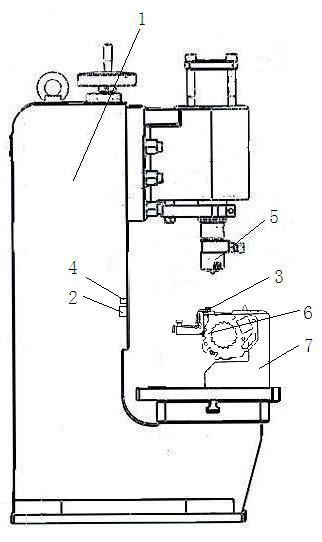

Riveting pressure detection device

InactiveCN102279418AReduce generationSame diameterOptical detectionUsing optical meansEngineeringLaser light

The invention discloses a riveting pressure detection device, which is characterized in that it includes a laser sensor arranged on a fixed frame at the riveting station, the laser light emitted by the laser sensor points to the position of the rivet to be riveted, and the fixed frame There is also a sensor for detecting the height of the riveting point of the rivet after riveting, and the laser sensor and the sensor are both connected to a control unit. The riveting detection device of the present invention uses a laser sensor to detect whether the rivets are complete before riveting, and then starts riveting after they are complete. If there are no rivets, the workpiece will not be riveted, and the workpiece will be automatically transferred to the next step by the control device. Work station, re-enter the riveting process after the rivet is loaded, reducing the generation of waste products. After riveting, the height sensor is used to detect whether the height of the riveting point of the rivet is standard, so as to ensure that the diameter of the riveting point is consistent and the quality of the riveting product is guaranteed.

Owner:SIP GOLDWAY TECH

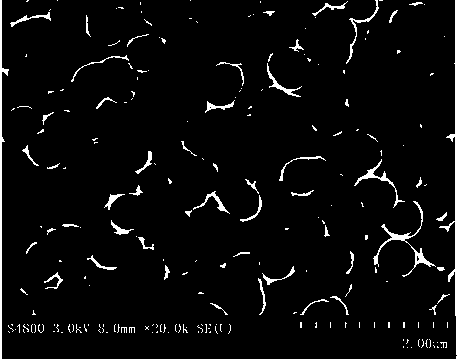

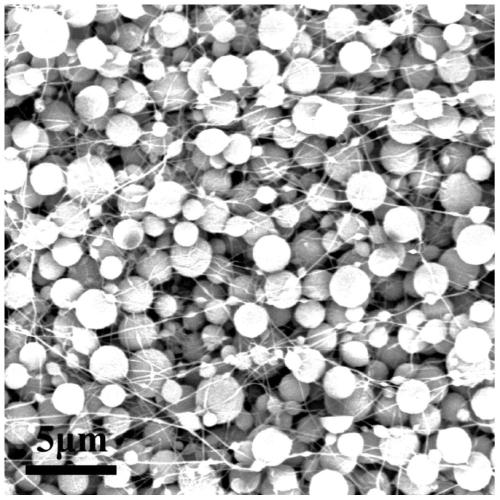

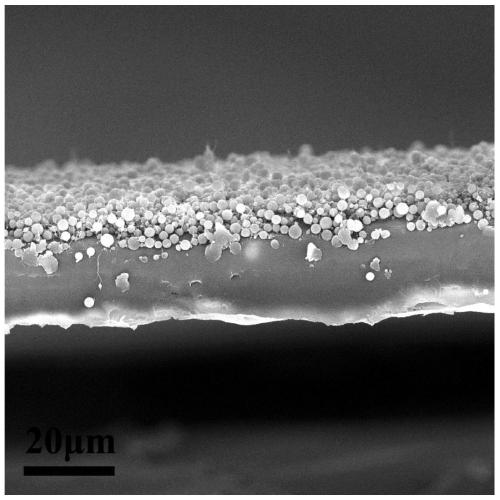

Polycrystal black silicon texturing process

ActiveCN108193281AGood lookingBlurred appearancePolycrystalline material growthAfter-treatment detailsMicro nanoSilver particles

The invention discloses a polycrystal black silicon texturing process. The polycrystal black silicon texturing process includes the following steps that 1), a polycrystalline silicon wafer is polishedthrough polishing liquid; 2), the polished silicone wafer is hole-dug through hole-digging treating liquid, and nano-holes are prepared in the surface of the silicone wafer; 3), the hole-dug siliconewafer is de-silverized, and silver particles on the silicone wafer are removed; 4), the de-silverized silicone wafer is chambered through chambering treating liquid, and micro-nano holes are preparedin the surface of the silicone wafer. According to the polycrystal black silicon texturing process, by means of control over the three key steps of polishing, hole-digging and chambering, the whole black silicone texturing process is controllable, polycrystal black silicon with the good appearance and high efficiency can be prepared, and the prepared polycrystal black silicon is fuzzy in appearance and is provided with uniform holes.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

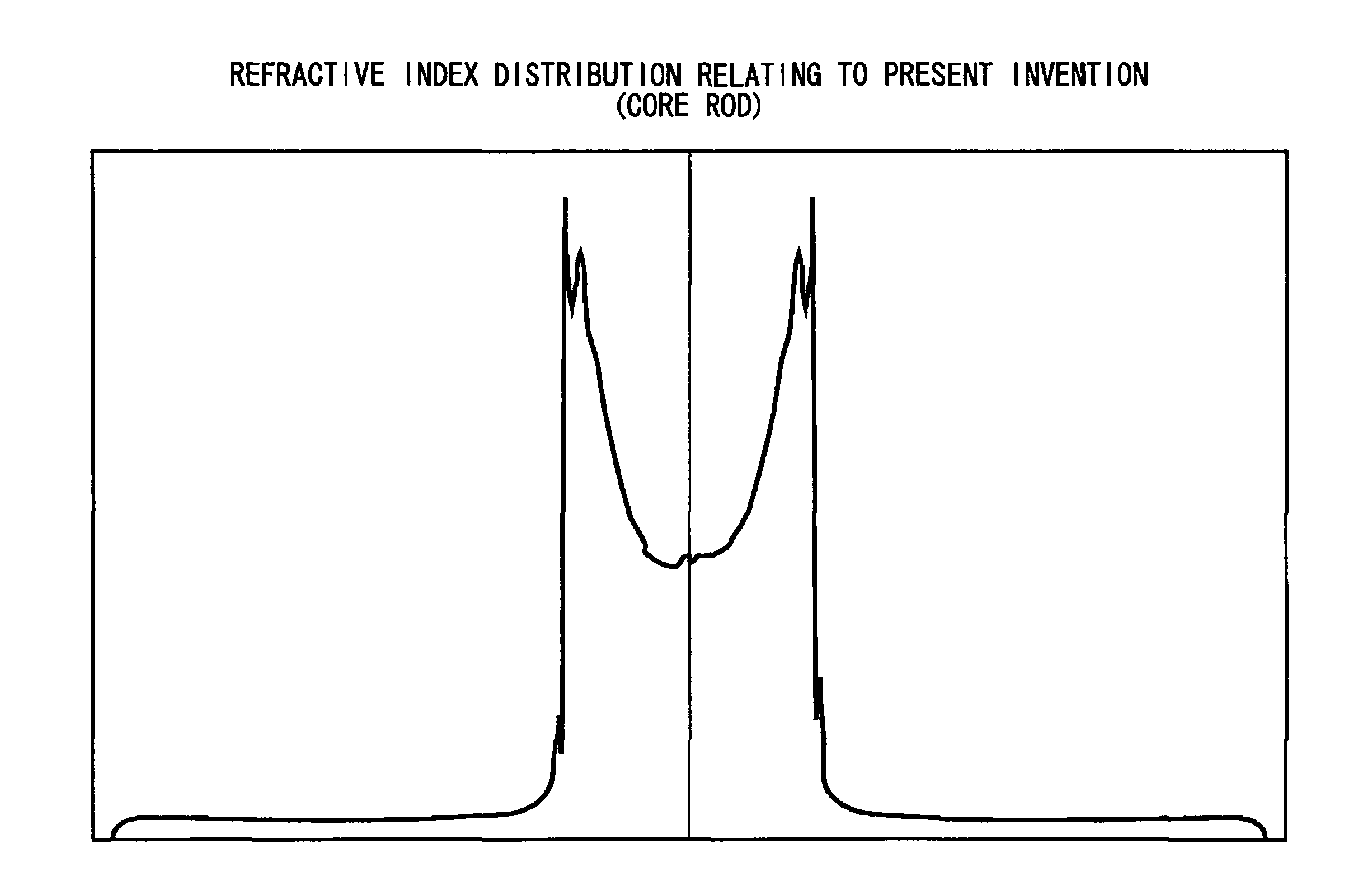

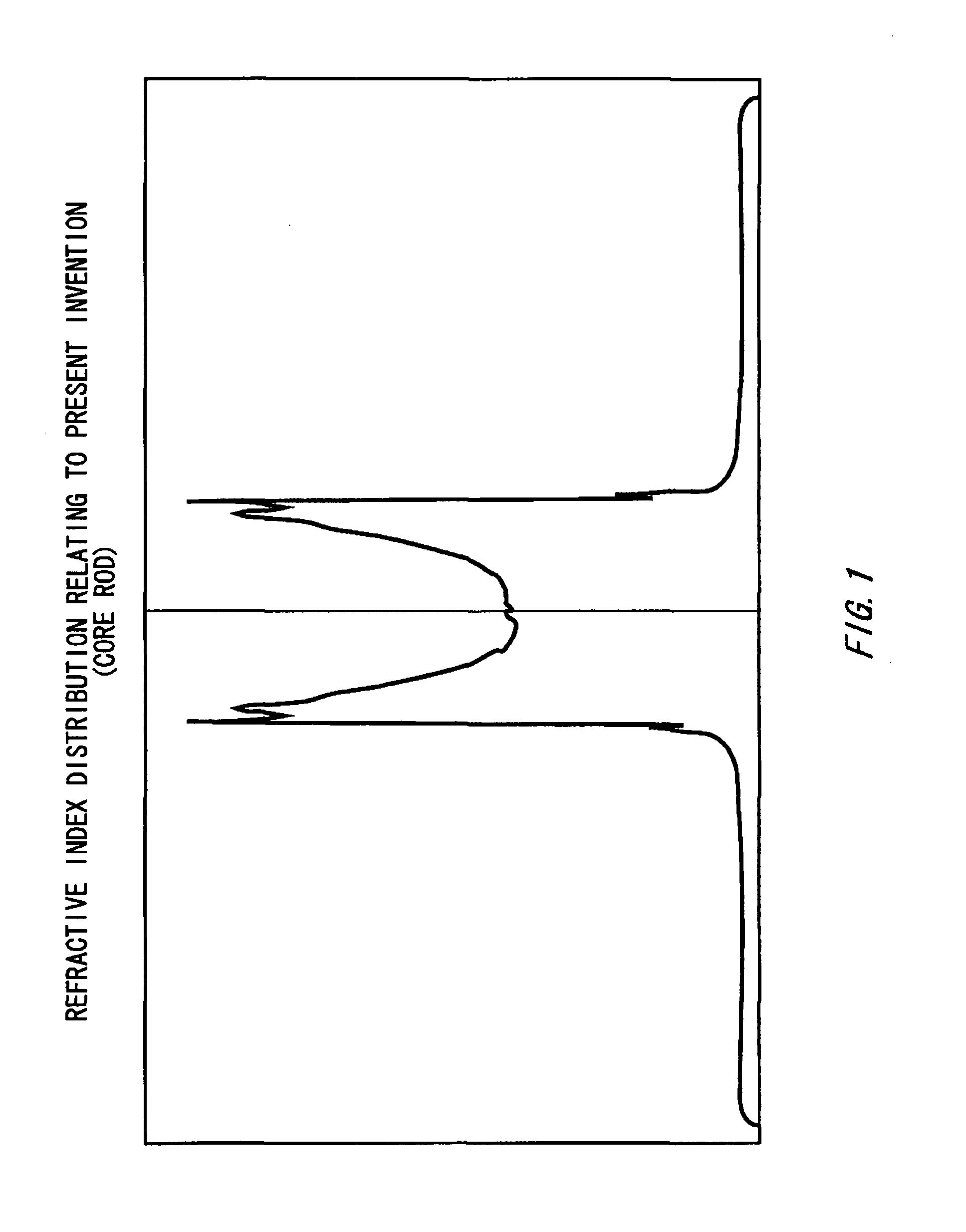

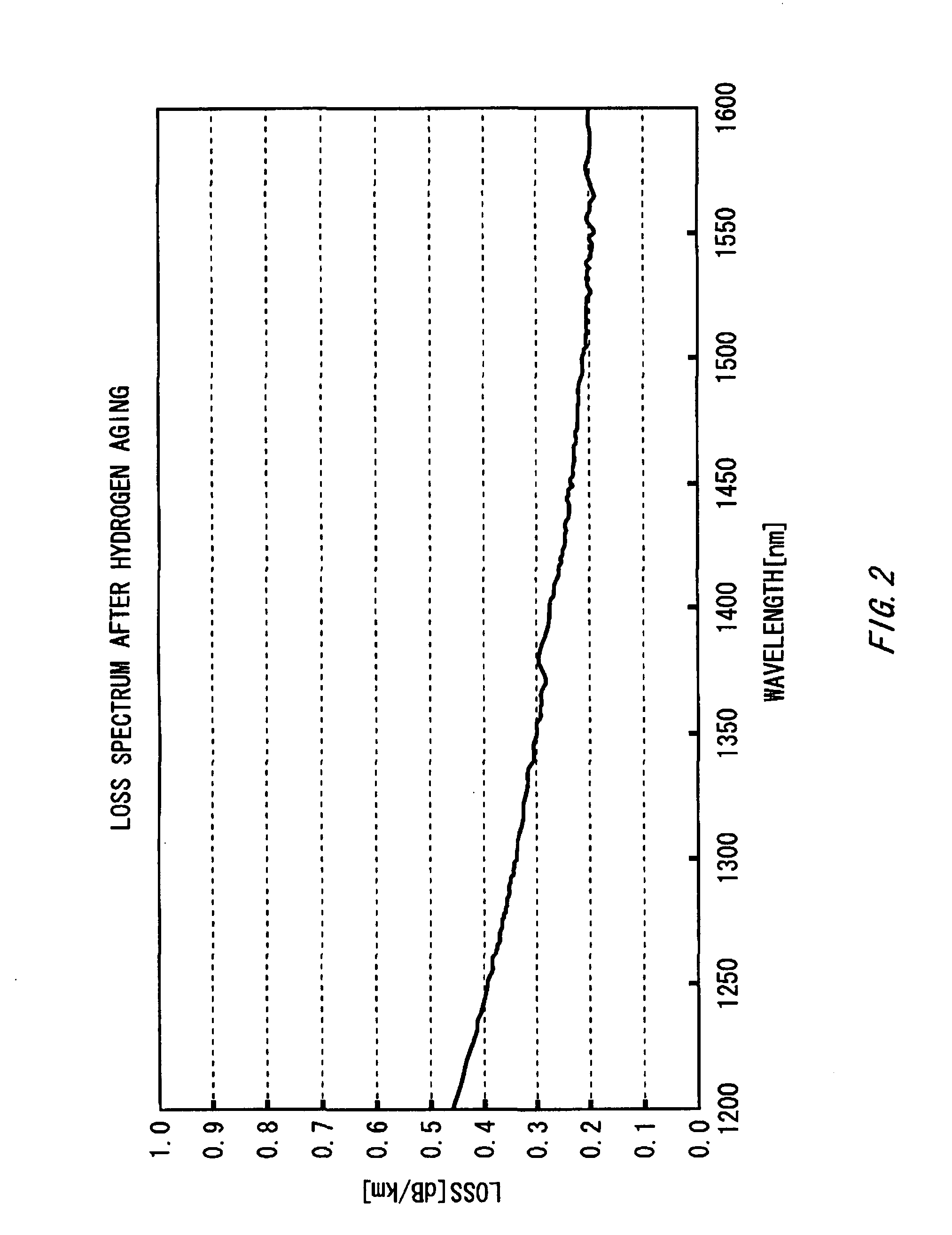

Optical fiber

ActiveUS7574087B2Low costSame diameterOptical fibre with graded refractive index core/claddingOptical waveguide light guideHydrogenRelative refractive index

Owner:SHIN ETSU CHEM CO LTD

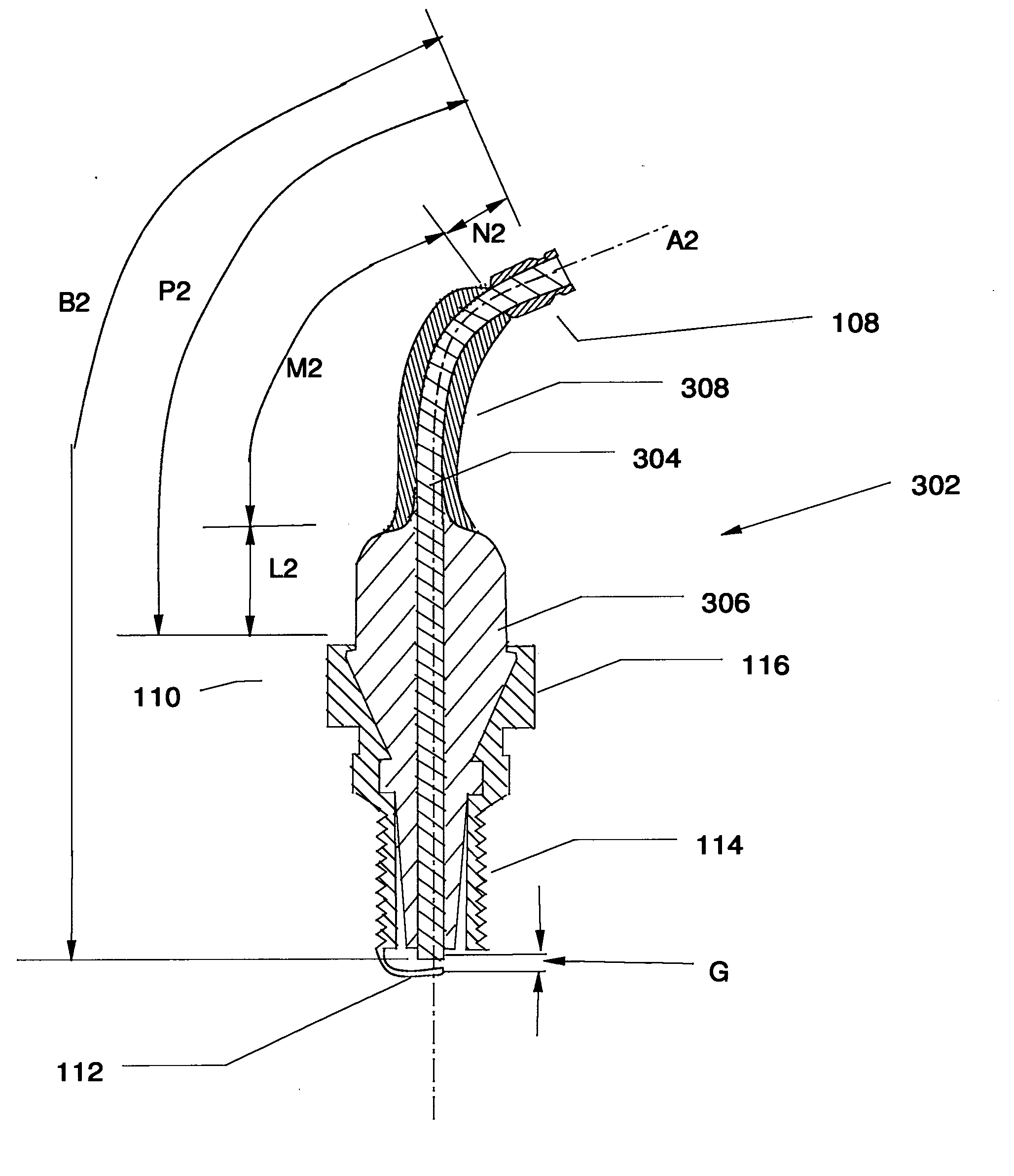

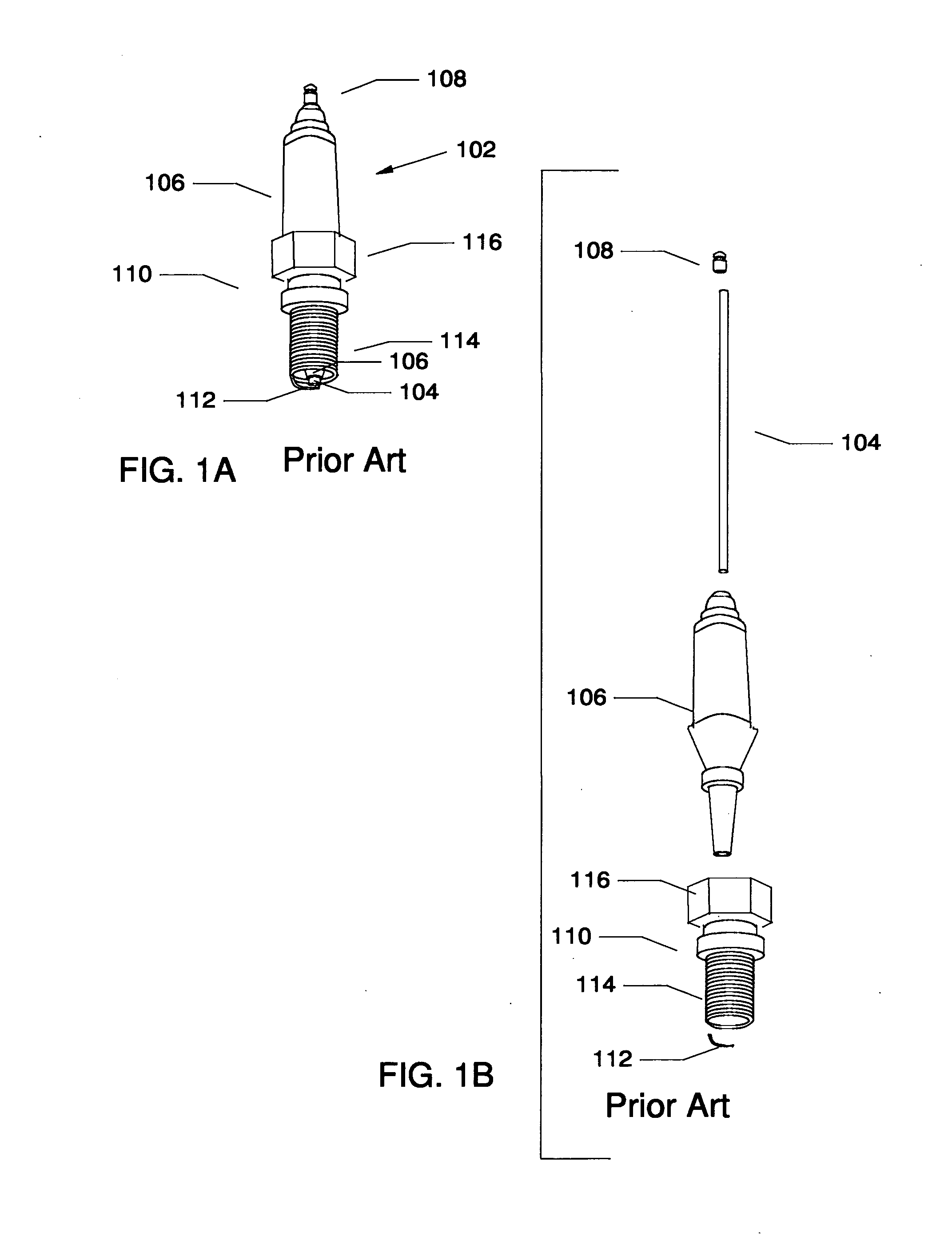

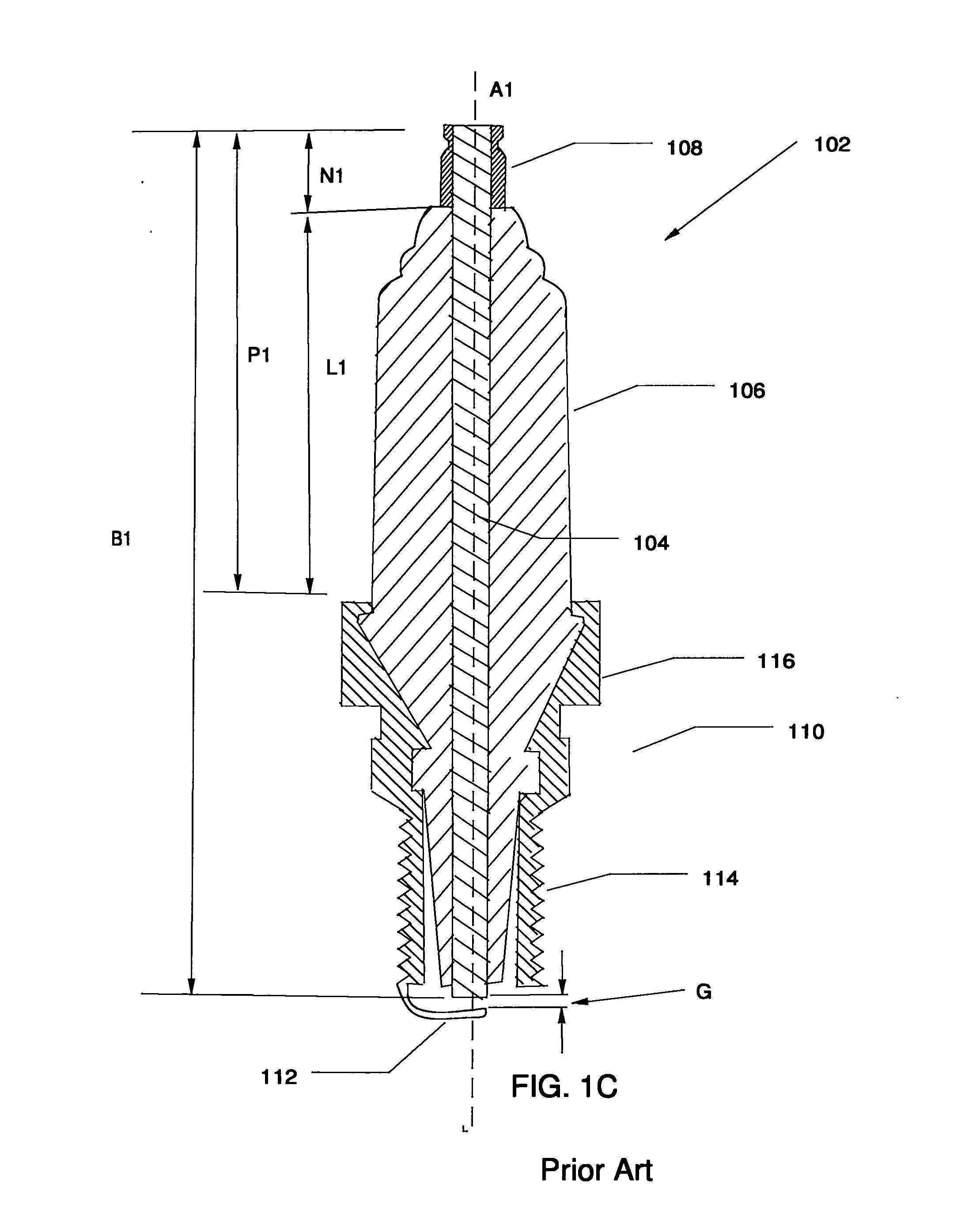

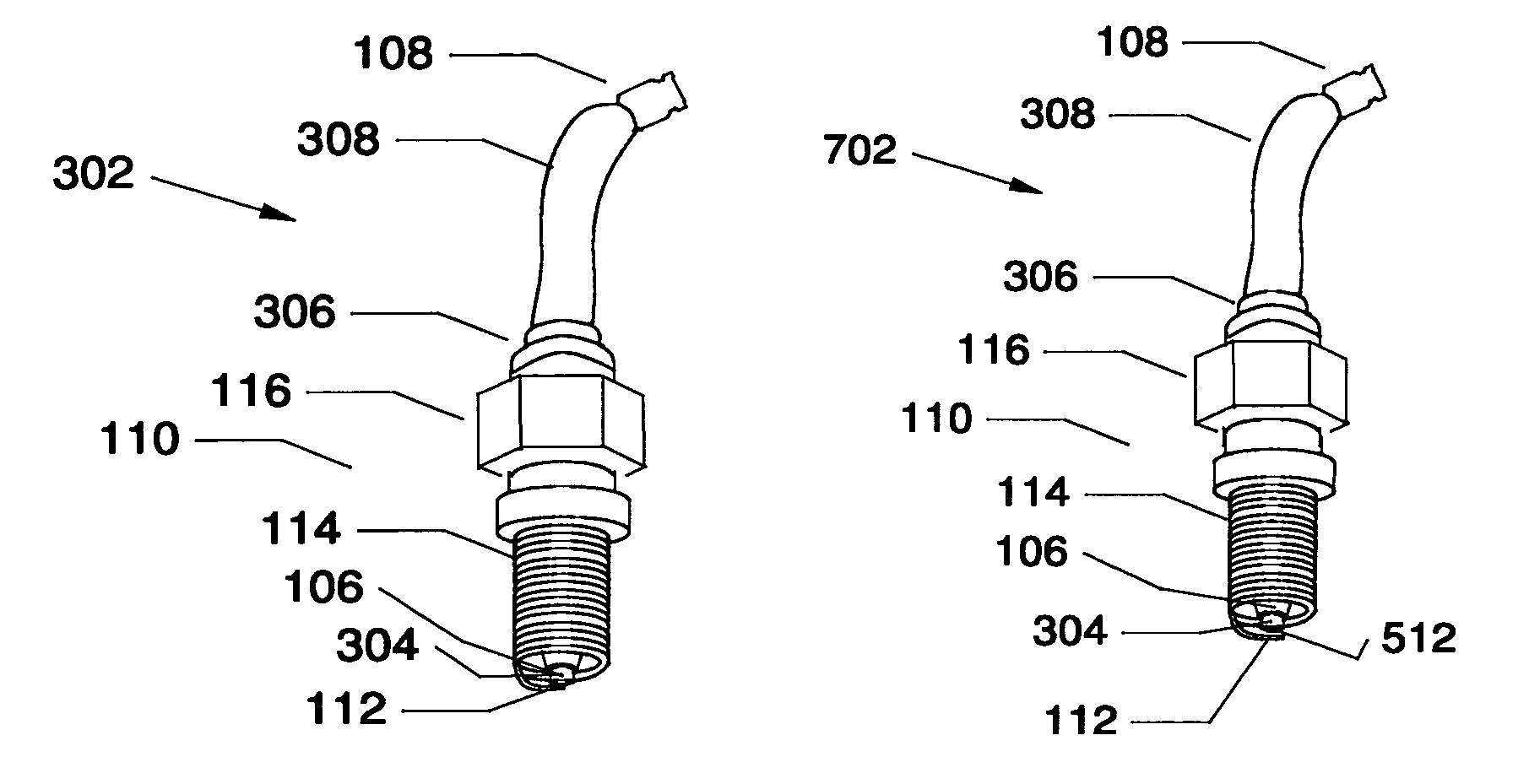

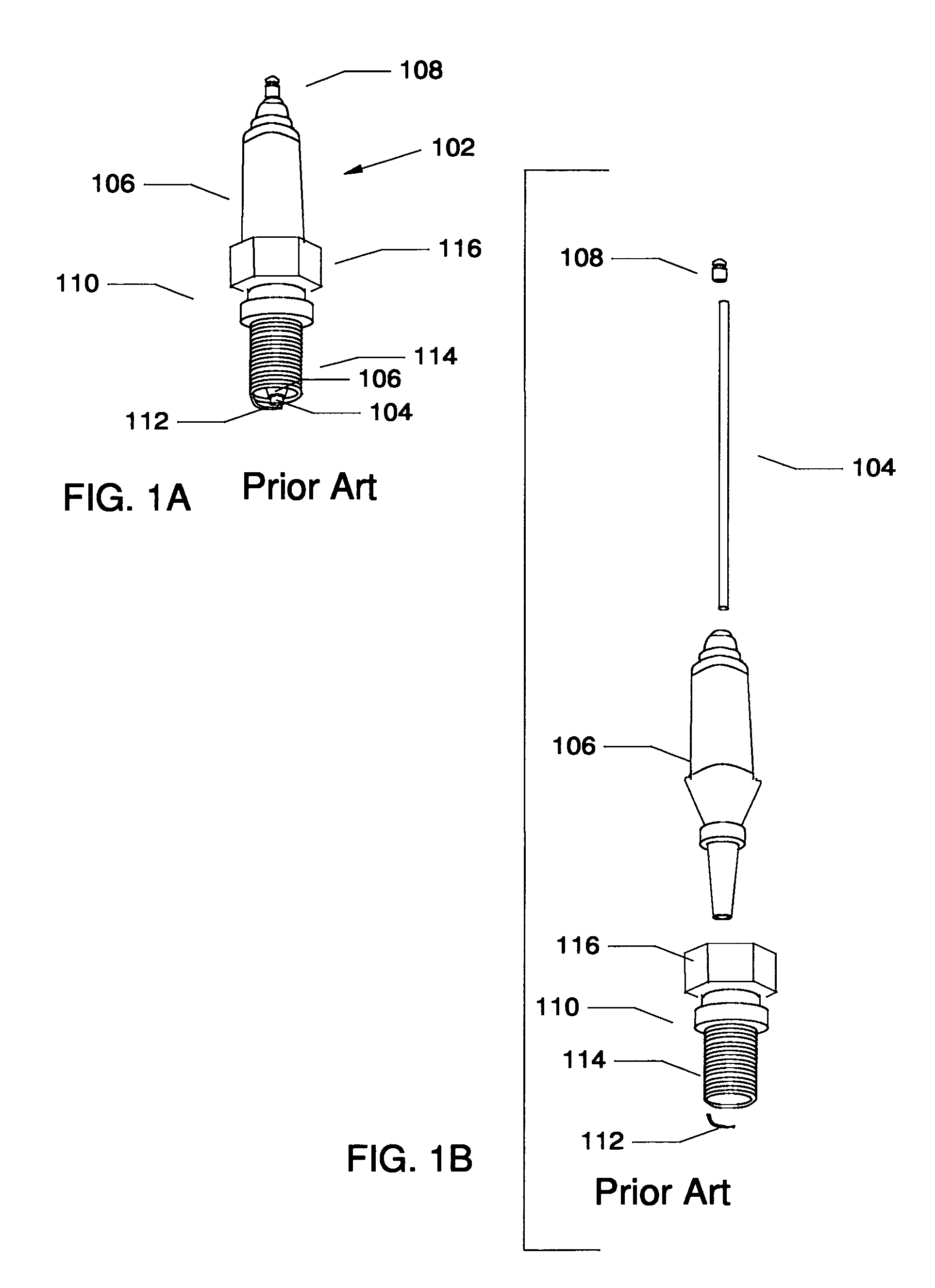

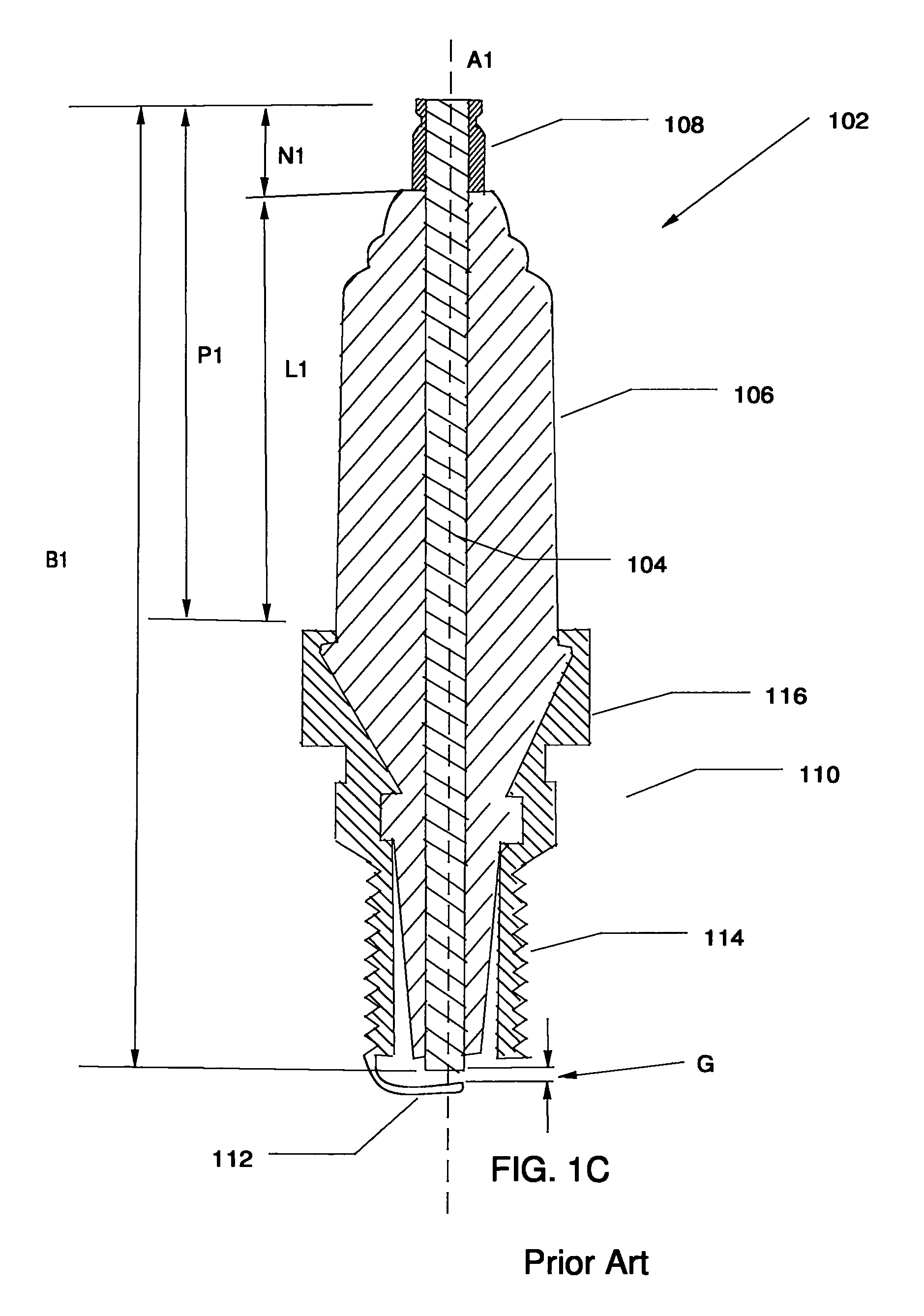

Flexible spark plug

A spark plug designed for fitting in tight spaces of an engine compartment is disclosed. The spark plug has a conductive terminal attached to one end of a flexible central electrode and has a ceramic insulator partially encasing the flexible central electrode. The part of the flexible central electrode between the ceramic insulator and the conductive terminal is encased in a flexible insulator. The flexible part of the central electrode may be bent away from the axis of the ceramic insulator accommodating both installation and servicing of the spark plug in tight spaces.

Owner:BISHOP BOBBY GLEN

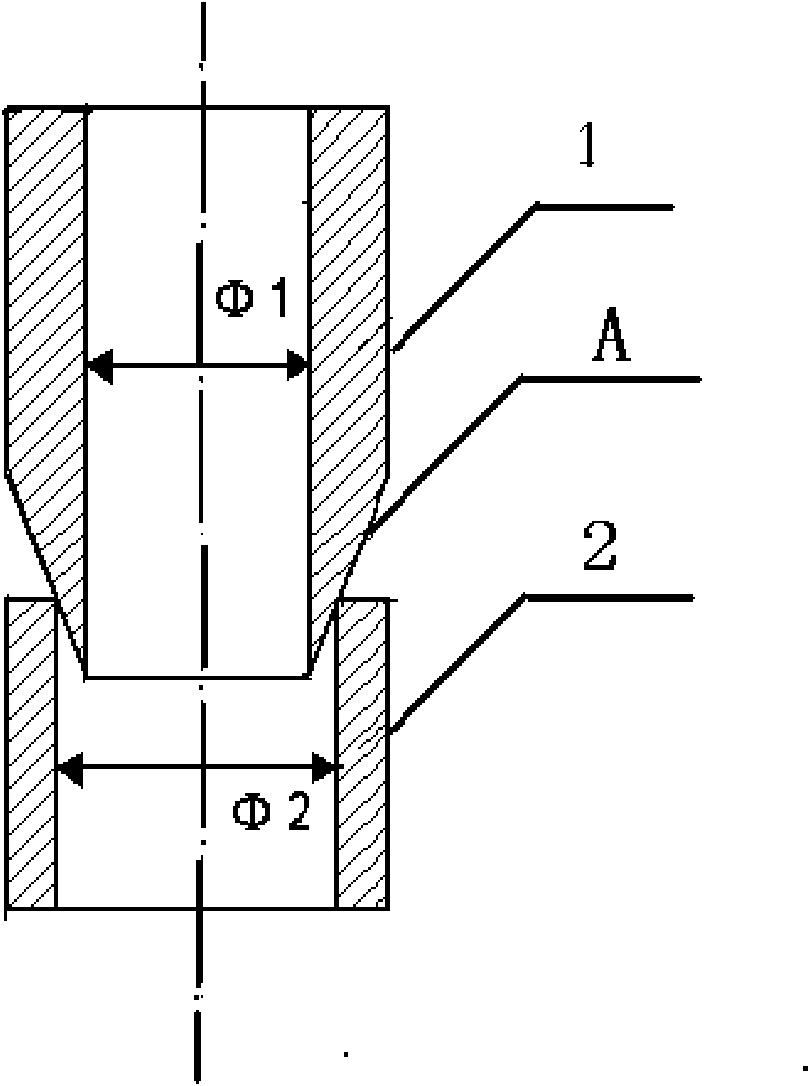

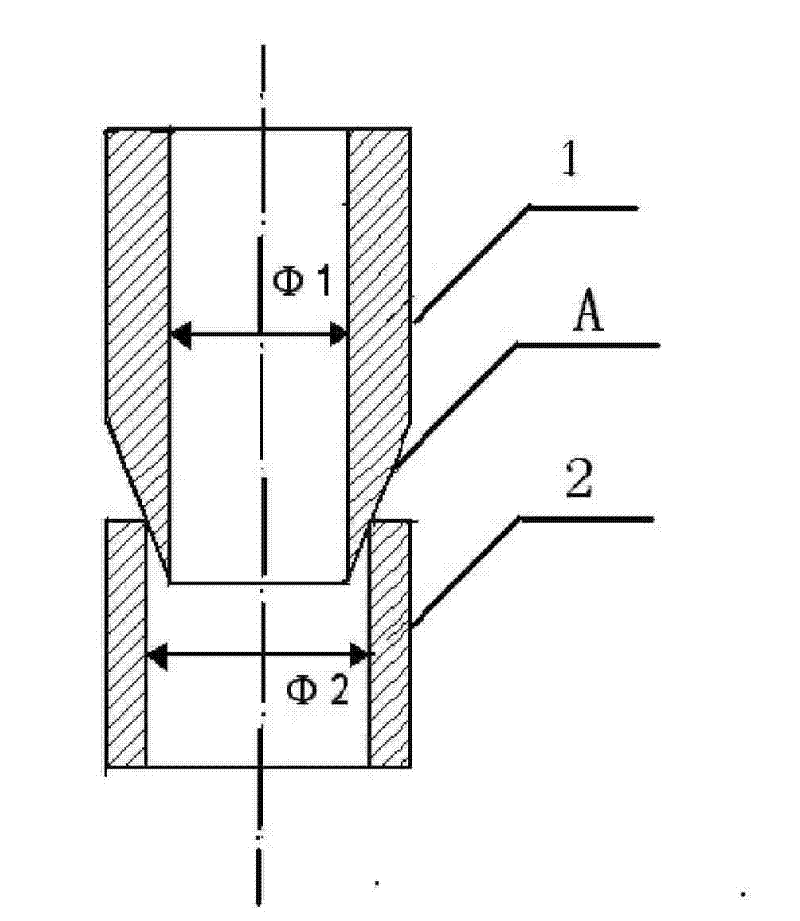

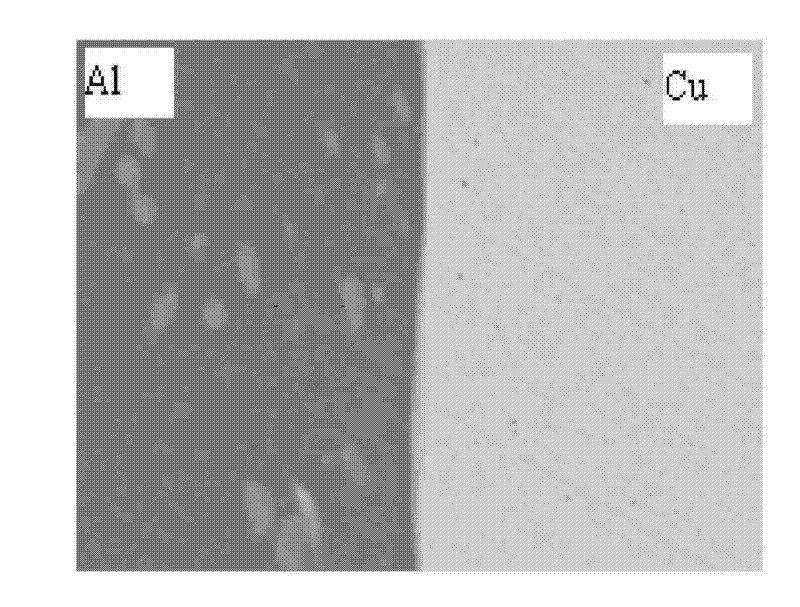

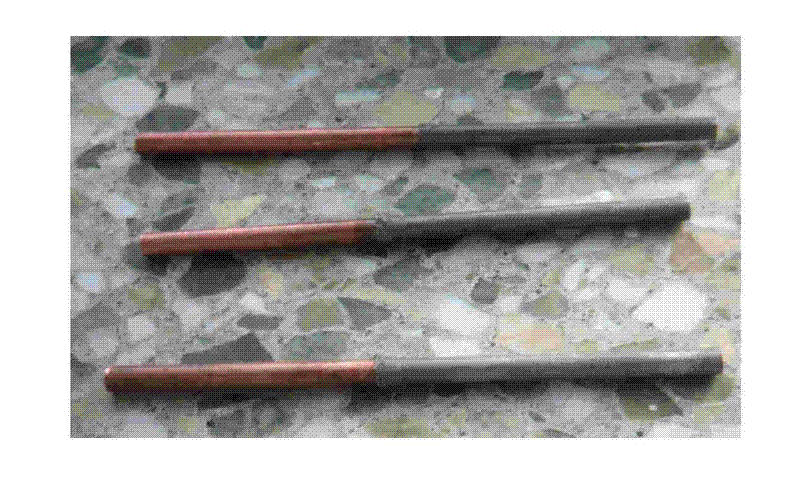

Method for the thermal compression welding of copper-aluminum combined pipeline fitting under the assistance of rotary friction

InactiveCN101642847AEfficient removalFacilitated DiffusionWelding/soldering/cutting articlesTubular articlesEngineeringRefrigeration

A method for the thermal compression welding of a copper-aluminum combined pipeline fitting under the assistance of rotary friction is disclosed, relating to the field of thermal compression welding process and solving the problem that the used aluminum pipe has an interior oxide film which is hardly removable and also has low production efficiency and high cost when professional welding equipmentis used to weld the copper-aluminum combined pipeline fitting in the prior art; the method comprises the steps that: the outer wall of one end of a copper pipe to be welded is processed into a tapered surface, the copper pipe is secured at a drill chuck of a drilling and milling machine while the aluminum pipe is secured on a clamp of the drilling and milling machine, one end with tapered surfaceof the copper pipe is inserted into one end of the aluminum pipe, and the sleeved section between the copper pipe and the aluminum pipe is heated up using an acetylene flame gun, when the temperaturereaches 400-500 DEG C, the copper pipe is rotated and the other end of the copper pipe is pressurized so that the copper pipe is inserted into the aluminum pipe, and heating is ceased to accomplish total welding between the copper pipe and the aluminum pipe. The method in the invention is applied to welding the combined pipeline fittings in refrigeration products.

Owner:HARBIN INST OF TECH

Extrusion apparatus

InactiveUS20070034274A1Improve consistencyImprove roundnessFlexible pipesHollow wall articlesMechanical engineeringMelt extrusion

An apparatus for simultaneously pulling and twisting a cylindrical extrudate as a whole into a helical configuration, that is, a cylindrical configuration that, as a whole, has longitudinal and circumferential vector components. The apparatus is adapted to act on a solidified extrudate by causing it to be pulled downstream in the direction of its longitudinal axis while simultaneously being rotated about its axis. A circumferential twisting and a downstream pulling are simultaneously applied to a cooled and solidified extrudate. This is accomplished with a single piece of apparatus as shown. Thus, by twisting the solidified extrudate downstream both a circumferential and an axial component are imparted to the solidified extrudate. This, in turn, imparts a longitudinal and a circumferential movement to the molten extrudate as it emerges from an extruder die before it is fully solidified. The thus twisted molten extrudate is the cooled and solidified in its twisted condition.

Owner:PROTEUS

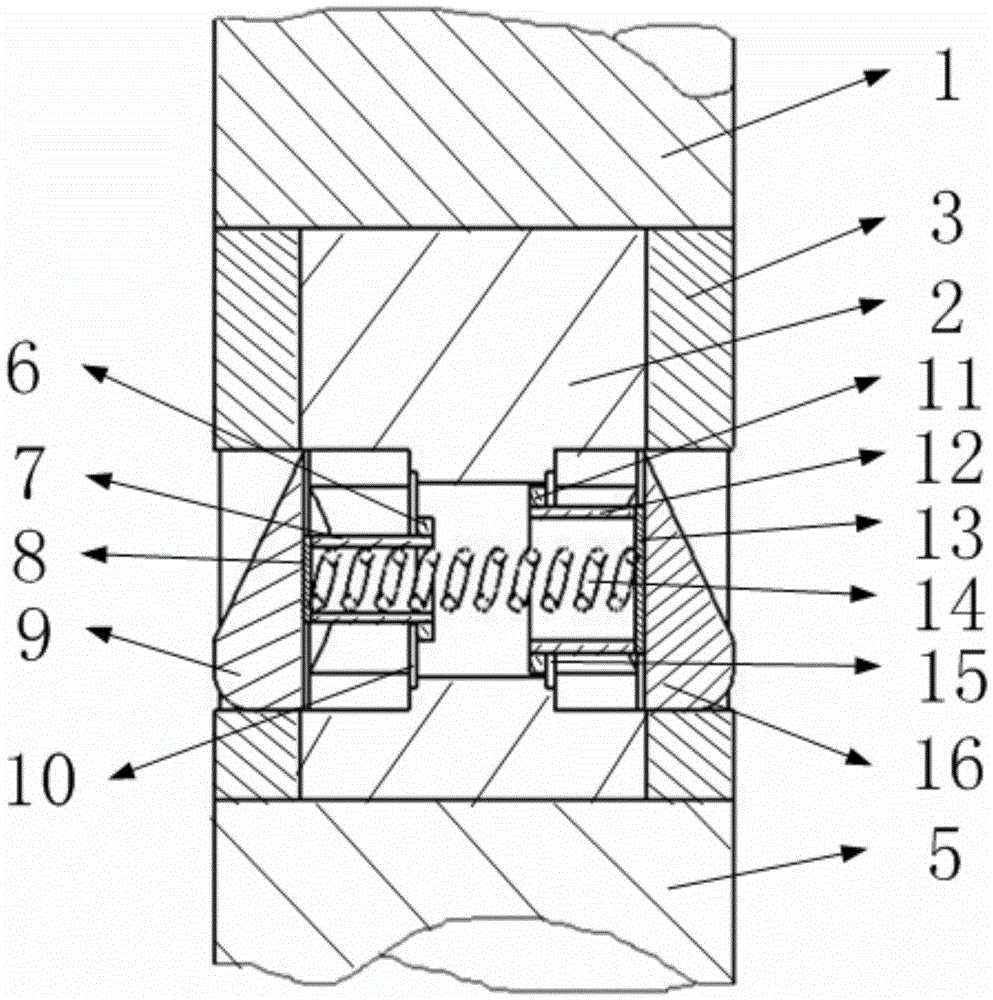

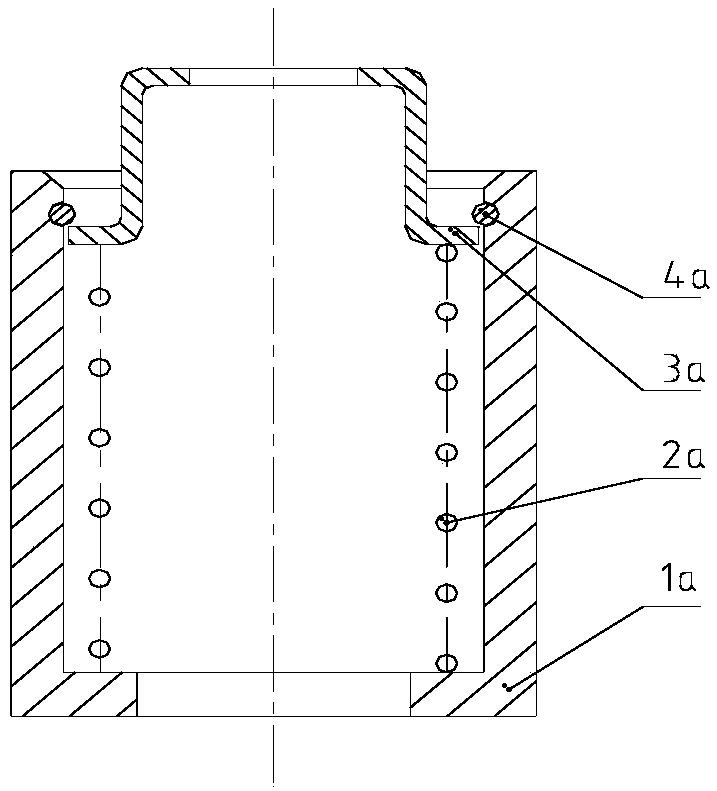

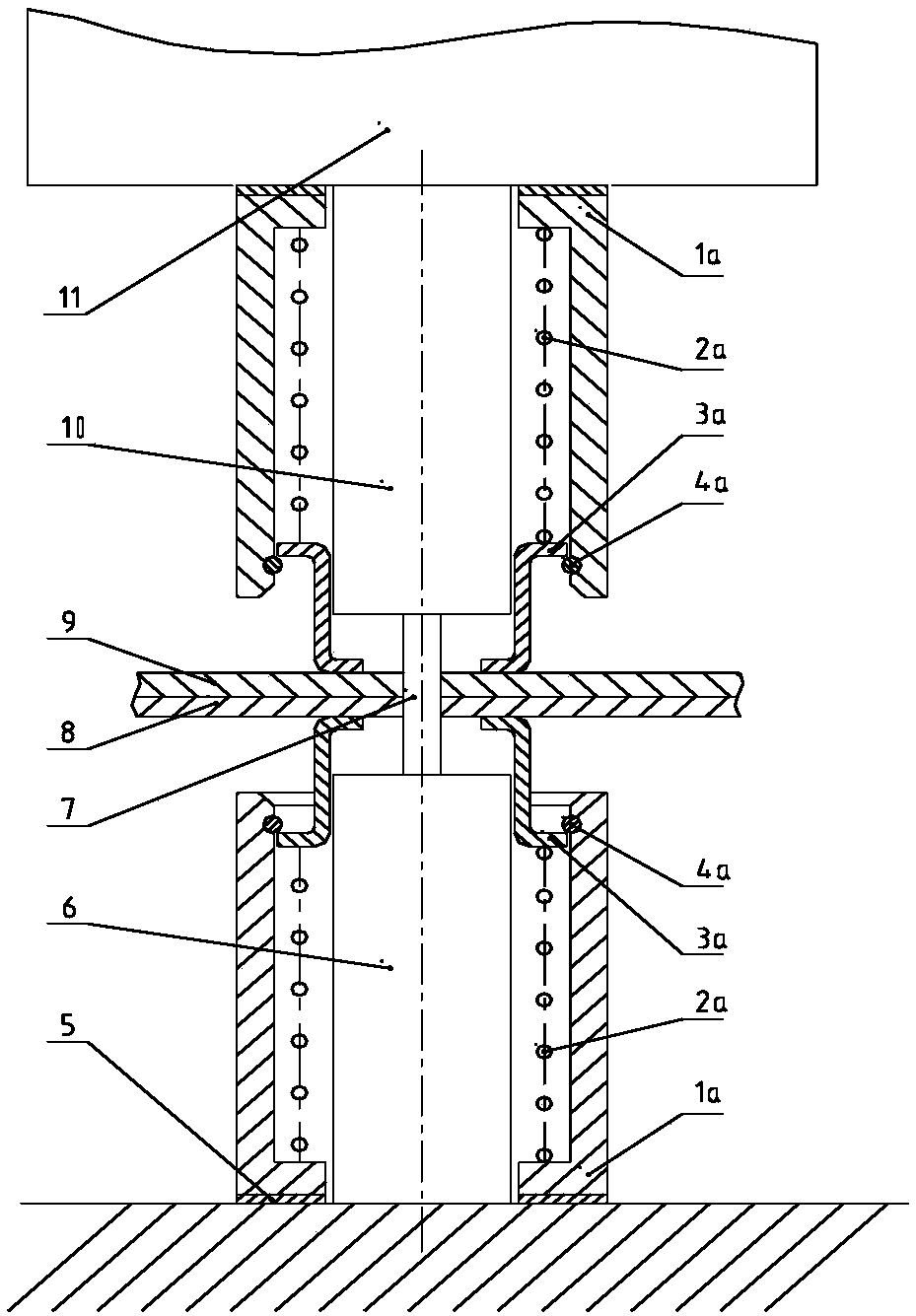

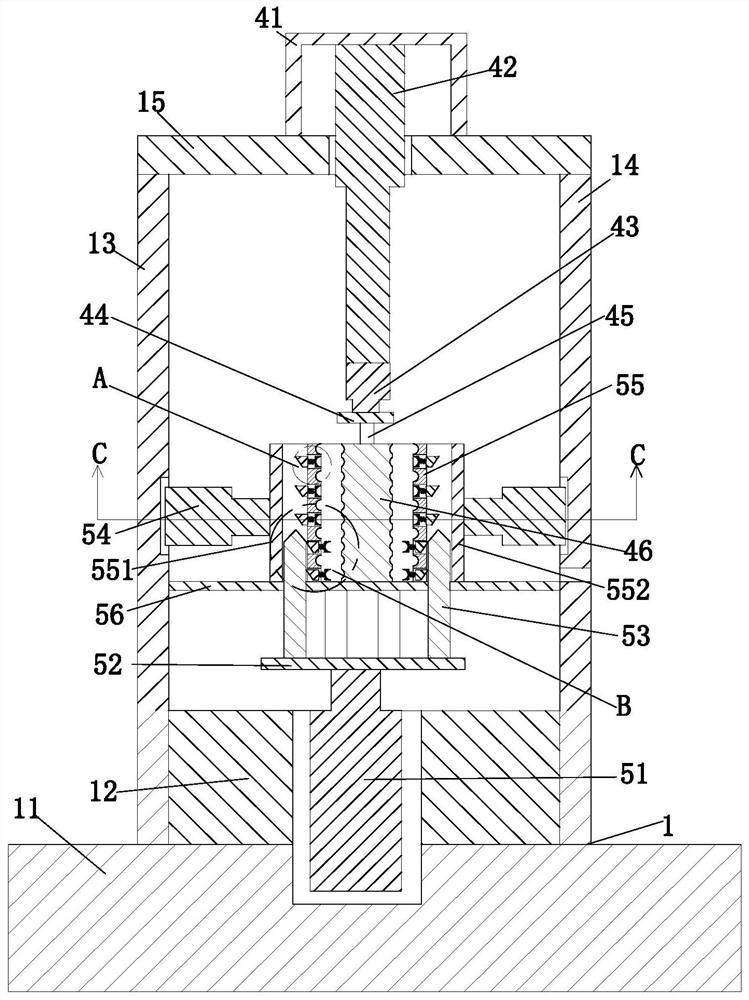

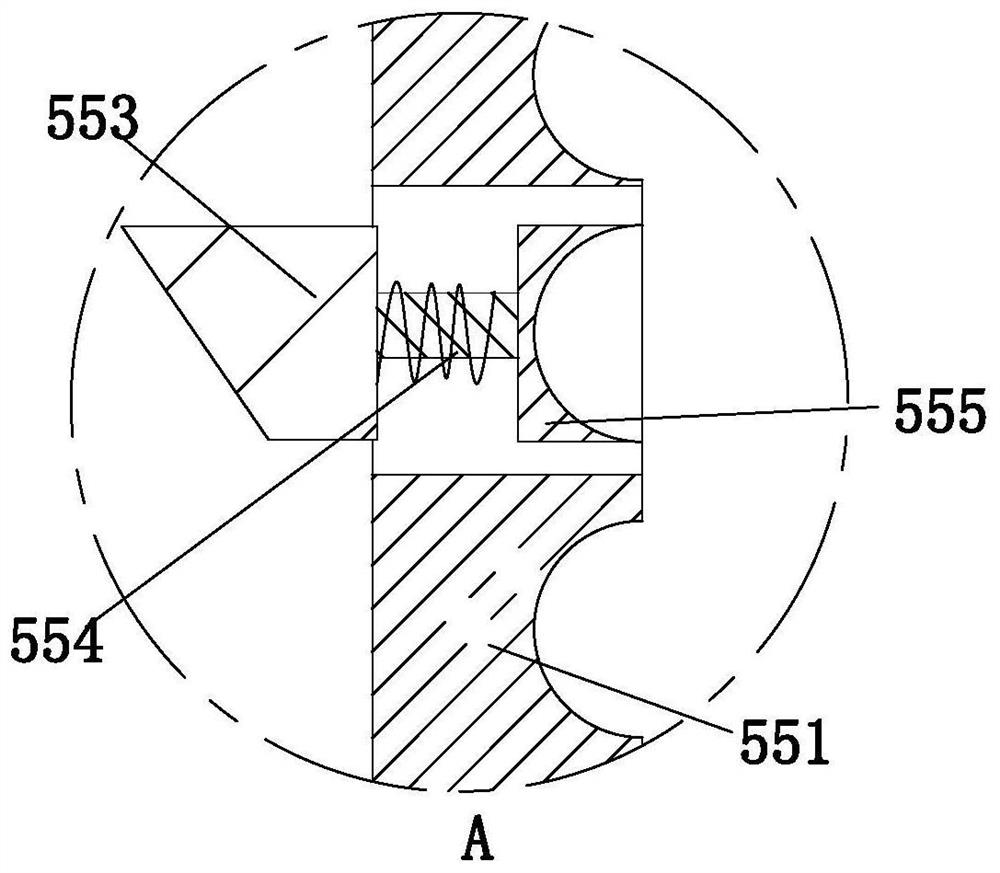

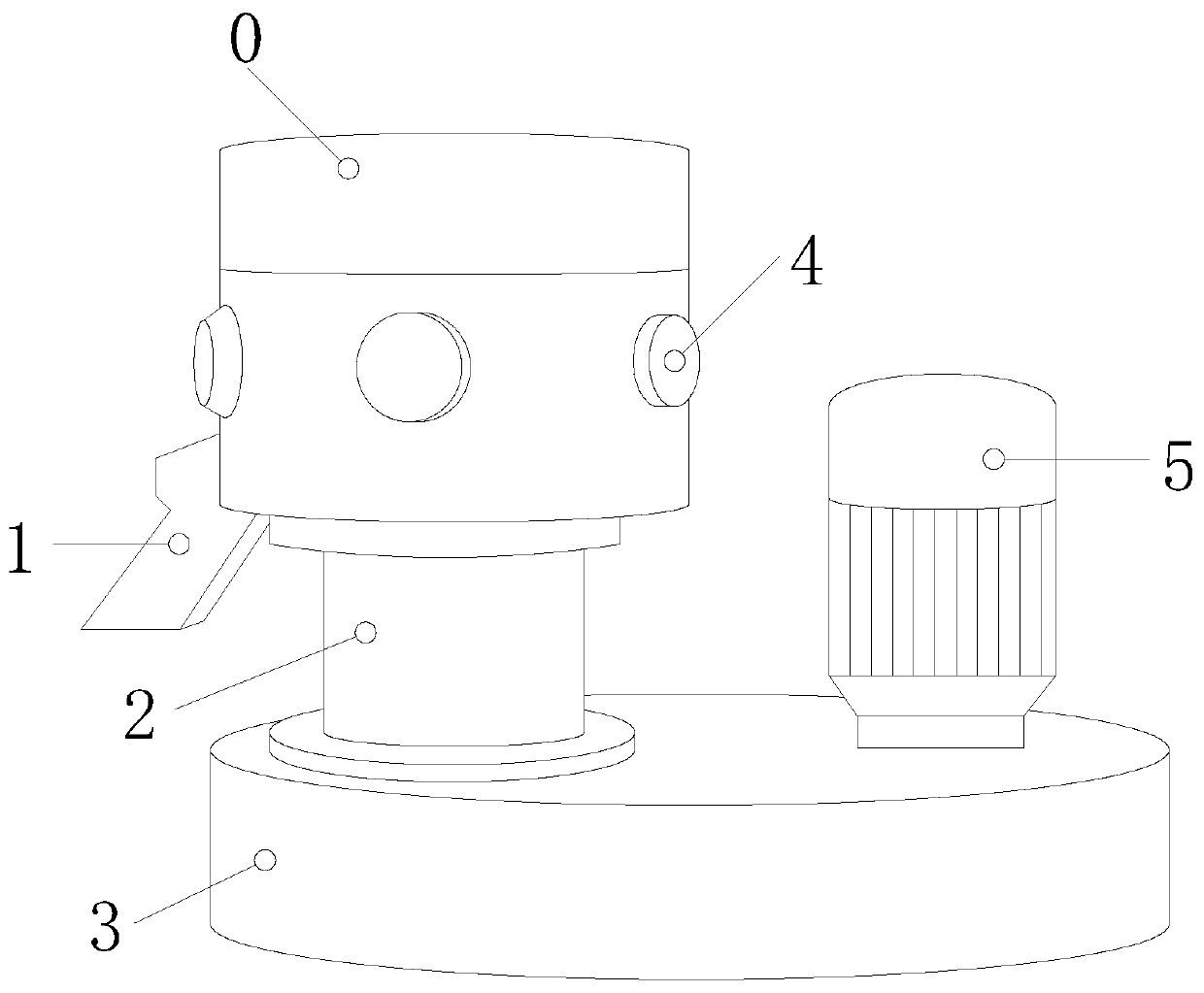

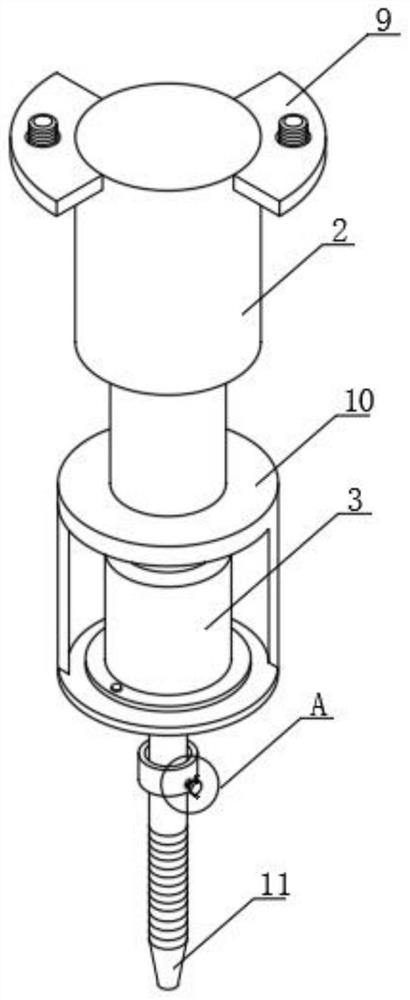

Over-well drill bit pressing mechanism for well drilling

ActiveCN105604502AExert pressurePlay a connecting roleDrilling rodsConstructionsWell drillingDrive motor

The invention belongs to the technical field of well drilling, and particularly relates to an over-well drill bit pressing mechanism for well drilling. The mechanism comprises a drill rod fixing mechanism sliding groove, a first rotary shaft, a second gear, a first gear, a threaded pressing mechanism, a drill rod body, a drill rod connecting structure, a drill rod fixing mechanism and a hollow driving rotary shaft, wherein the hollow driving rotary shaft and the drill rod body are connected through the drill rod fixing mechanism, the drill rod fixing mechanism can slide in the drill rod fixing mechanism sliding groove, and the hollow driving rotary shaft is in thread fit with a thread structure; a driving motor rotary shaft rotates to drive the first rotary shaft through the gear assembly to rotate, and the hollow driving rotary shaft moves downwards so as to press the drill rod while rotating under the driving of the first rotary shaft and the action of the thread structure. Furthermore, the drill rod connecting mechanism is compact in structure, it can be guaranteed that the diameter of the connection position is identical with that of the drill rod body, and damage of an oversized drill rod connecting structure to a borehole surface is avoided. The whole mechanism has a certain practical effect.

Owner:莱州市原野科技有限公司

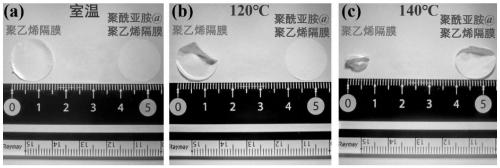

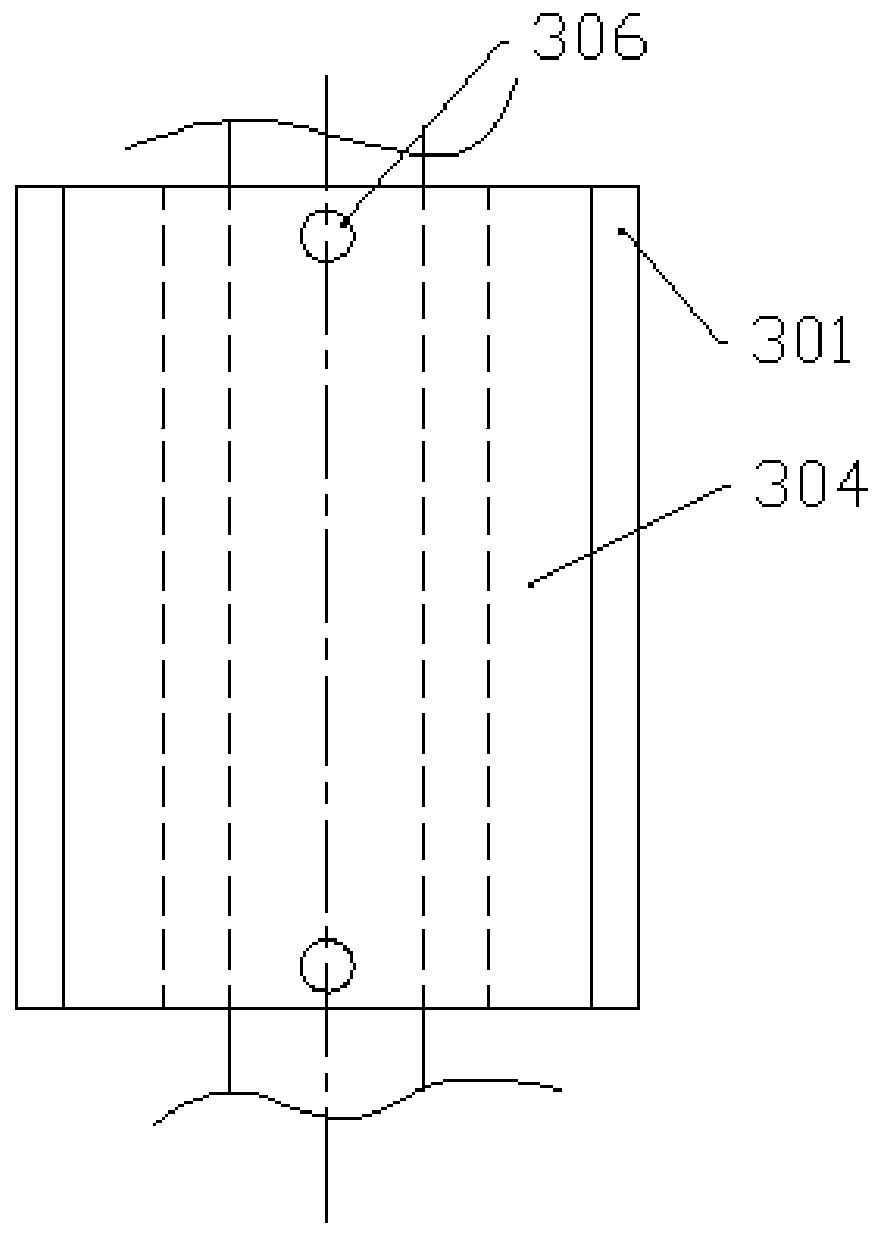

Method for modifying lithium battery diaphragm by temperature-resistant macromolecules and corresponding lithium battery diaphragm

InactiveCN111129396AImprove Coulombic efficiencyImprove Coulombic efficiency and prolong battery cycle lifeLi-accumulatorsCell component detailsElectrical batteryPhysical chemistry

The invention discloses a method for modifying a lithium battery diaphragm by using temperature-resistant macromolecules and a corresponding lithium battery diaphragm. The method comprises the steps of fully mixing and stirring a required temperature-resistant macromolecular material and an organic solvent to prepare a precursor solution with a certain mass fraction; cutting the lithium battery diaphragm to be modified, and fixing the cut lithium battery diaphragm on an electrostatic spinning spraying device; adjusting parameters such as the voltage of the electrostatic spinning spraying device, the rotating speed of a roller, the solution injection speed and the distance between a high-pressure needle head and a roller collecting device, and electrostatic spraying or spinning the precursor solution onto the lithium battery diaphragm; and turning off the electrostatic spinning spraying device at the arrival of the required time, flattening the lithium battery diaphragm, and carrying out vacuum drying to obtain the modified lithium battery diaphragm. The modified diaphragm provided by the invention can greatly improve the electrochemical performance and safety performance of the lithium metal battery.

Owner:杭州阳名新能源设备科技有限公司

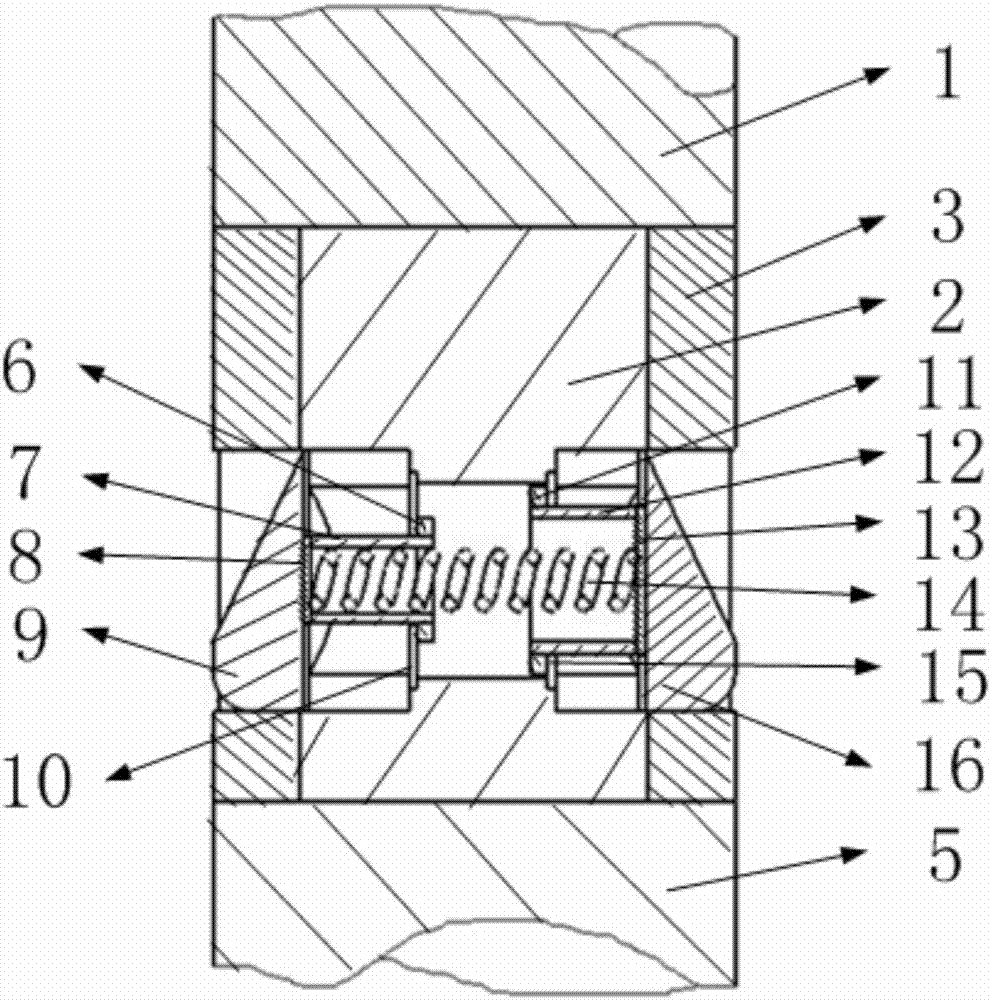

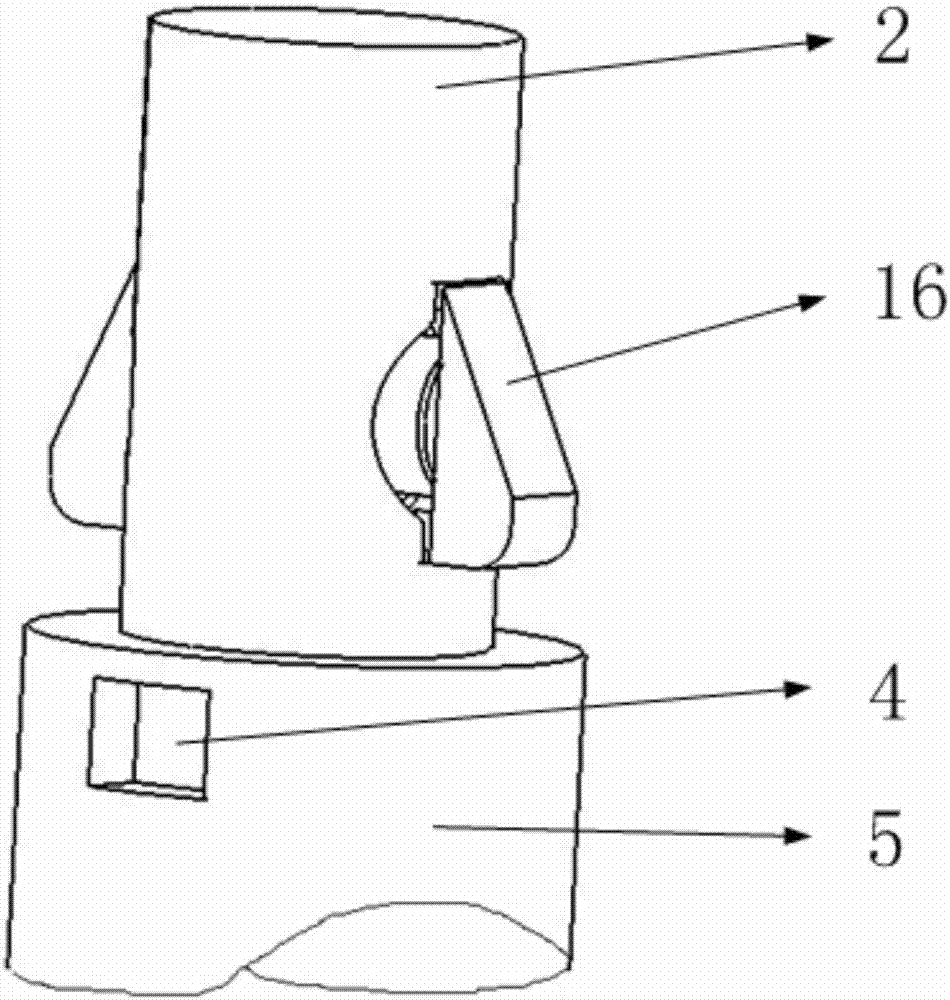

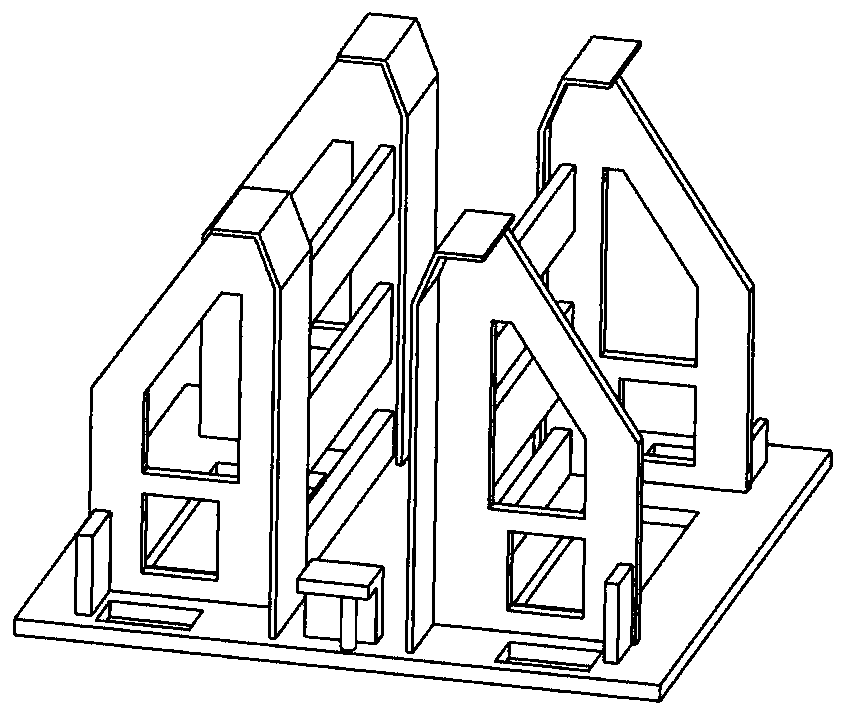

Pressing and riveting positioning tool for head-free rivets and application method

The invention relates to the technical field of riveting and assembling, particularly discloses a pressing and riveting positioning tool for a head-free rivet and a using method of the pressing and riveting positioning tool. The positioning tool comprises a base. A spring base is installed on the upper portion of the base. The spring base is fixedly connected with the base through a clamp spring.Two ends of the spring are limited by the bottom end of the base and the spring base respectively. The method comprises the following steps 1) of calculating the outer extension quantities of the head-free rivet; 2) of selecting a matched gasket; 3) of fixing a riveting positioning tool; 4) of adding a head-free rivet; 5) of controlling the riveting positioning tool to be in place; and 6) of carrying out riveting. The pressing and riveting positioning tool is suitable for the pressing and riveting of the head-free rivets. The outer extension quantities of the two sides of the head-free rivet in the initial state and the riveting process can be consistent through the symmetrically-arranged riveting positioning tool, so that the diameter and height of the upsetting heads on the two sides areconsistent after the head-free rivet pressing riveting is completed.

Owner:CAPITAL AEROSPACE MACHINERY +1

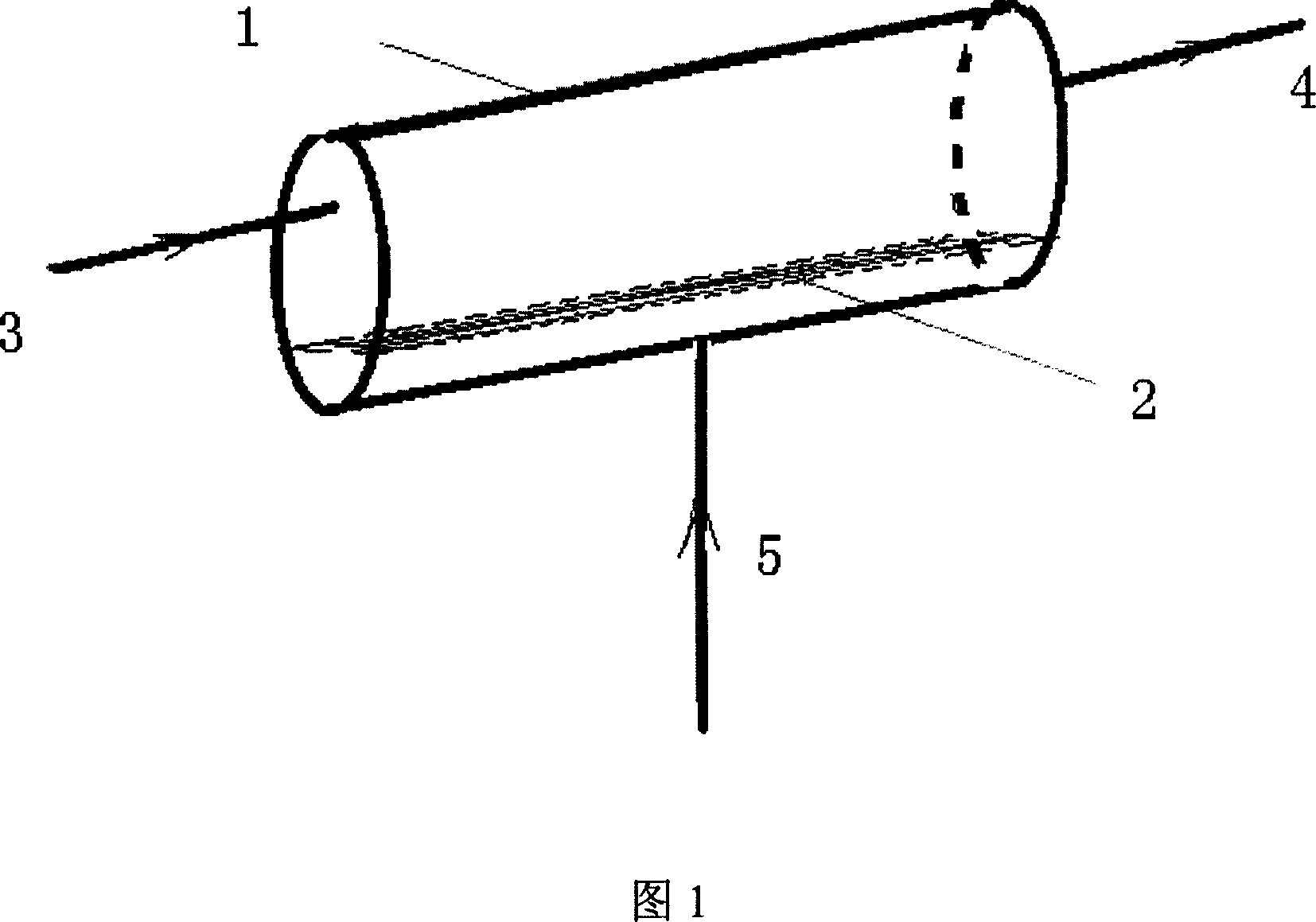

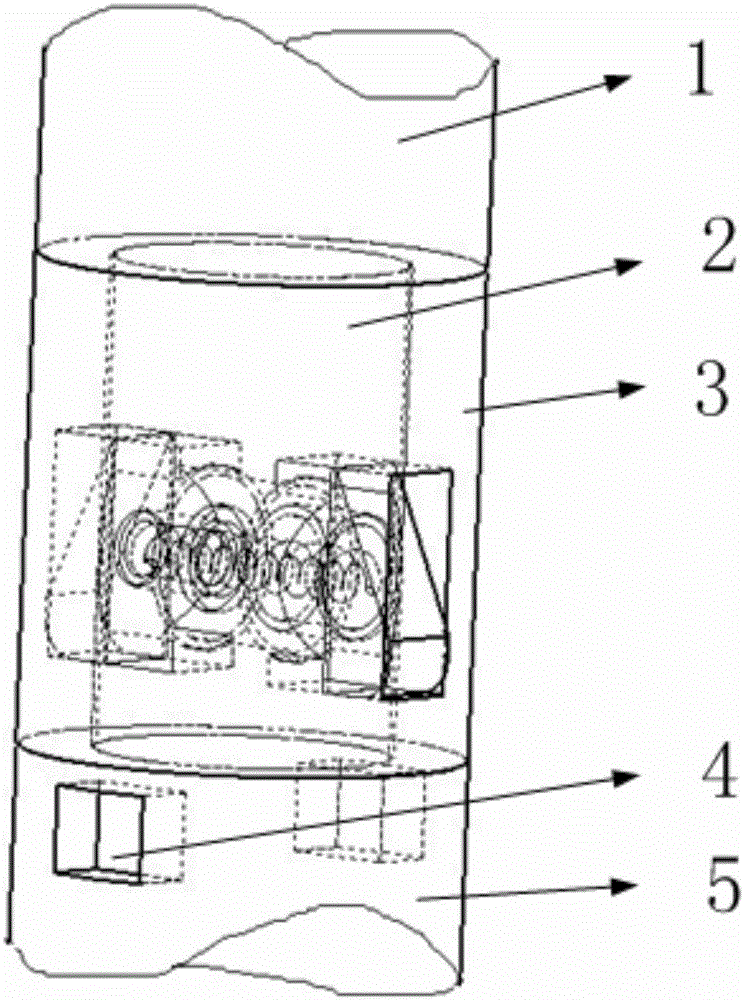

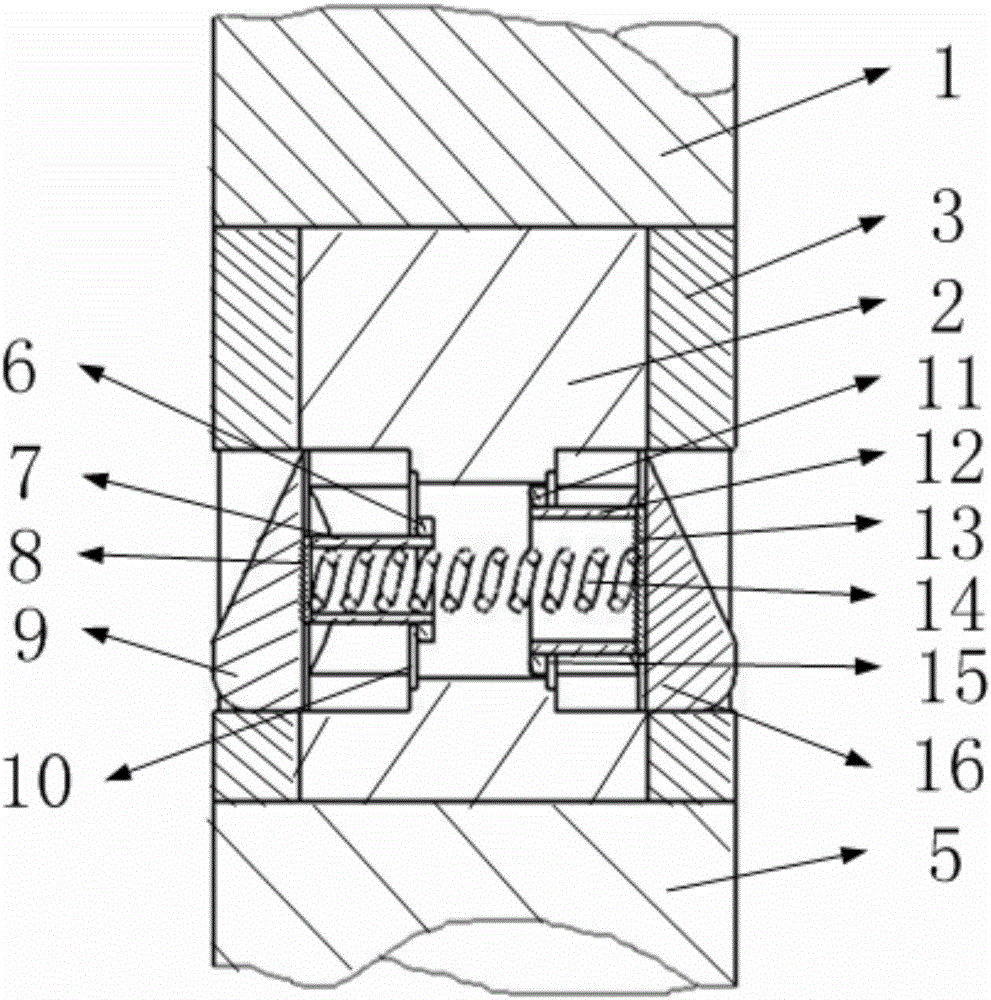

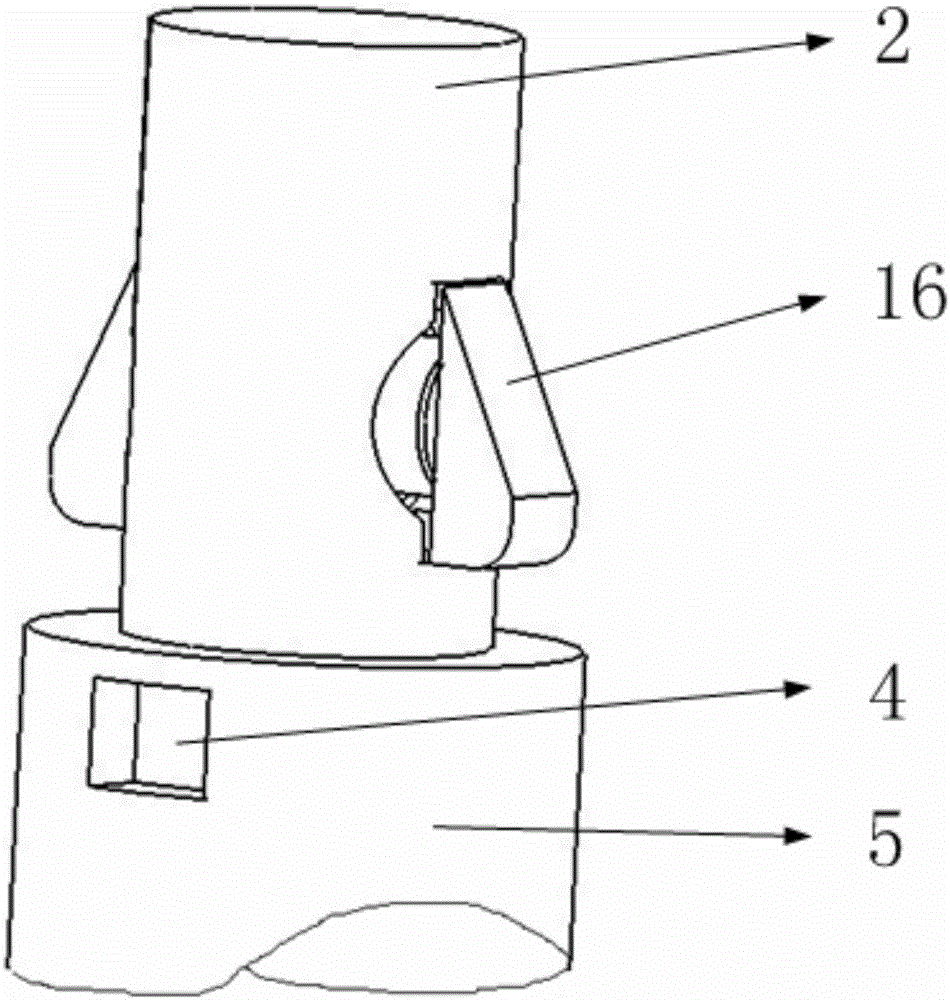

Method for preparing fibrous light cakium carbonate and reactor

ActiveCN1944263ASmall flow velocity disturbancePromote growthCalcium/strontium/barium carbonatesSlurryCarbonate

The present invention discloses process and reactor for preparing fibrous light calcium carbonate. The preparation process includes the following steps: heat the mixture of 1-5 % water slurry of Ca(OH)2 and MgCl26H2O in 2-4 times weight of Ca(OH)2 to 80-95 deg.C, carbonizing reaction of the slurry in a horizontal strip reactor and the introduced CO2 gas through one gas distributing member to carbonize the Ca(OH)2 in the slurry into fibrous calcium carbonate, and filtering and washing the effluent to obtain the fibrous light calcium carbonate. The said process has identical retaining time of Ca(OH)2 slurry inside the reactor and is favorable to the growth of fibrous light calcium carbonate to obtain fibrous light calcium carbonate in homogeneous size distribution.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

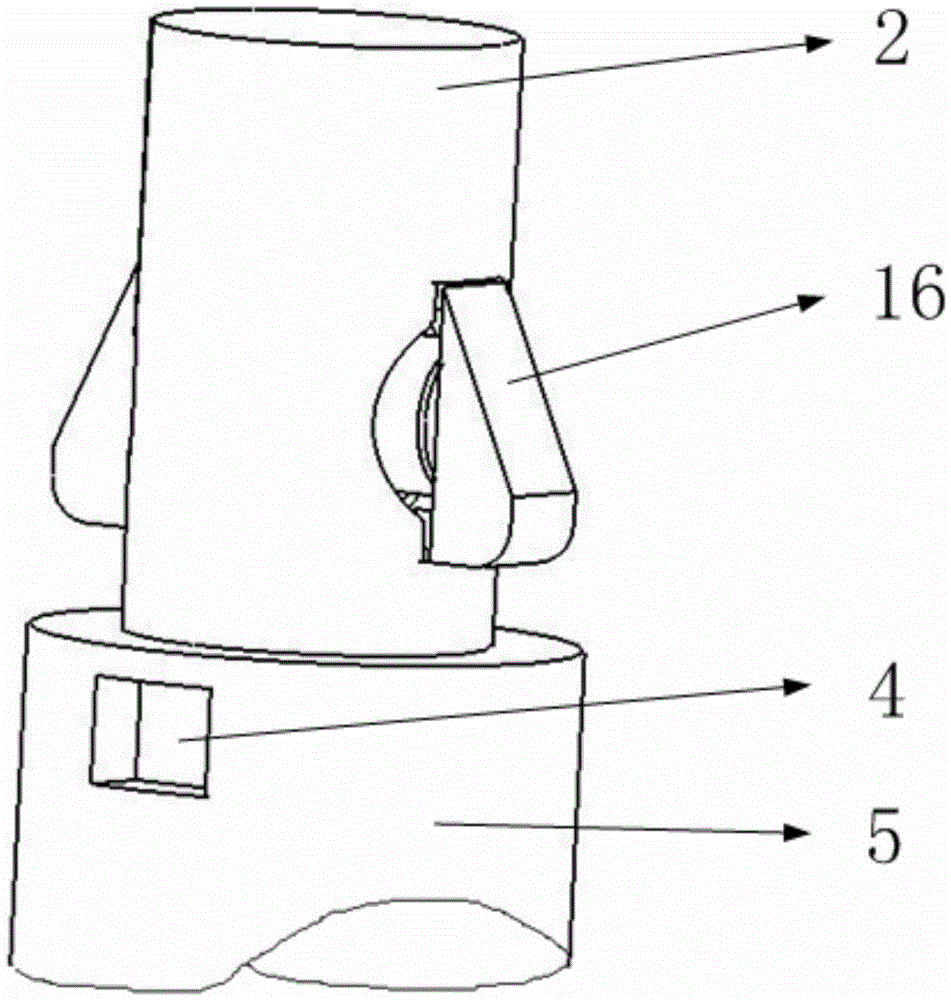

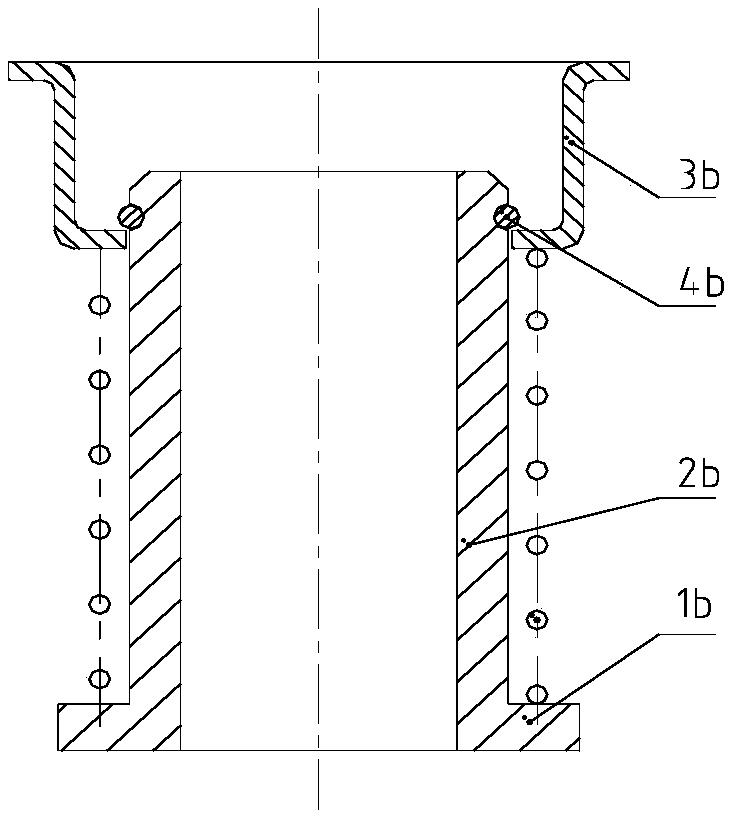

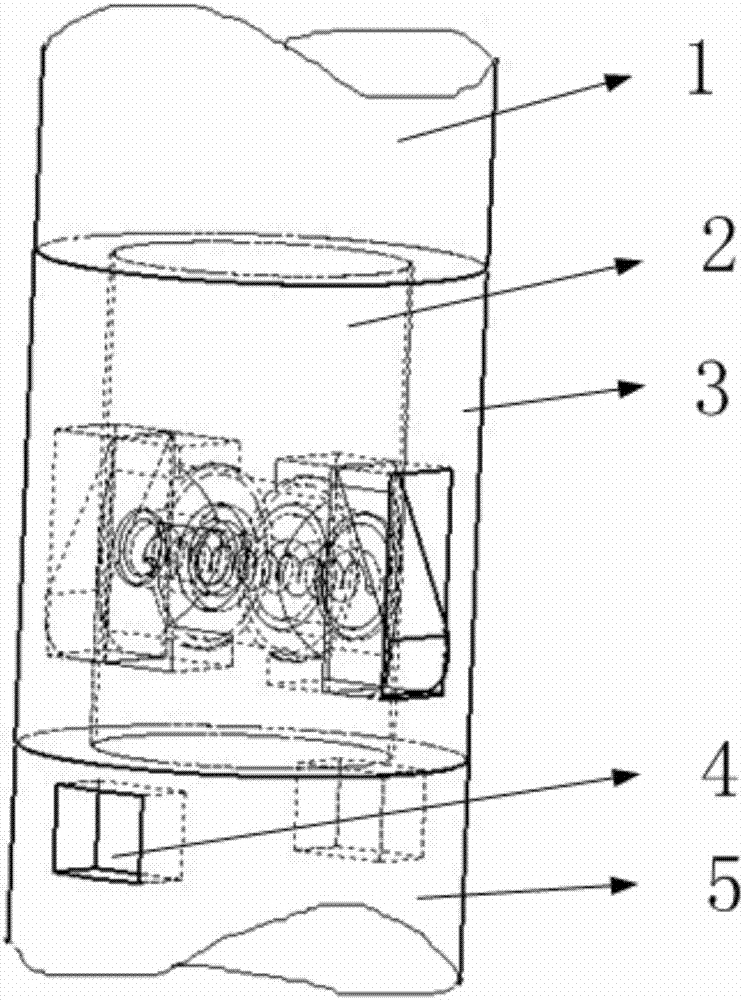

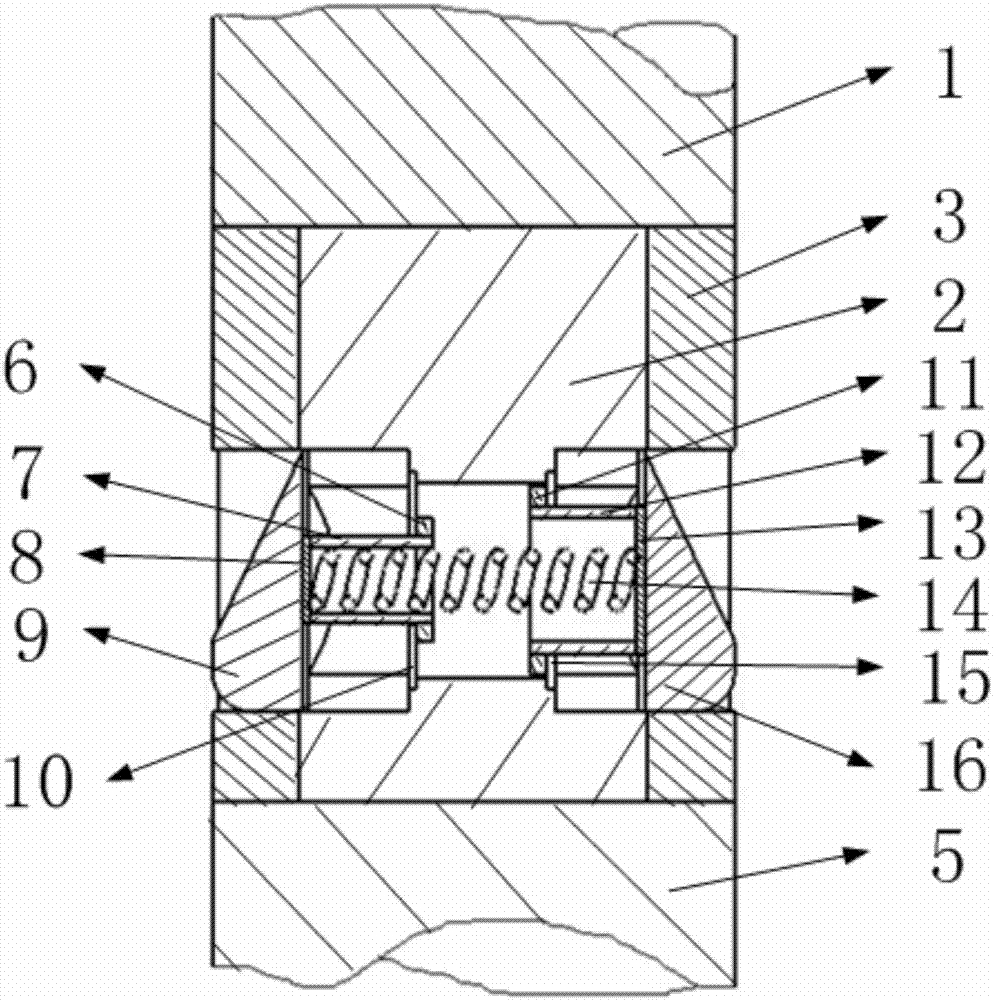

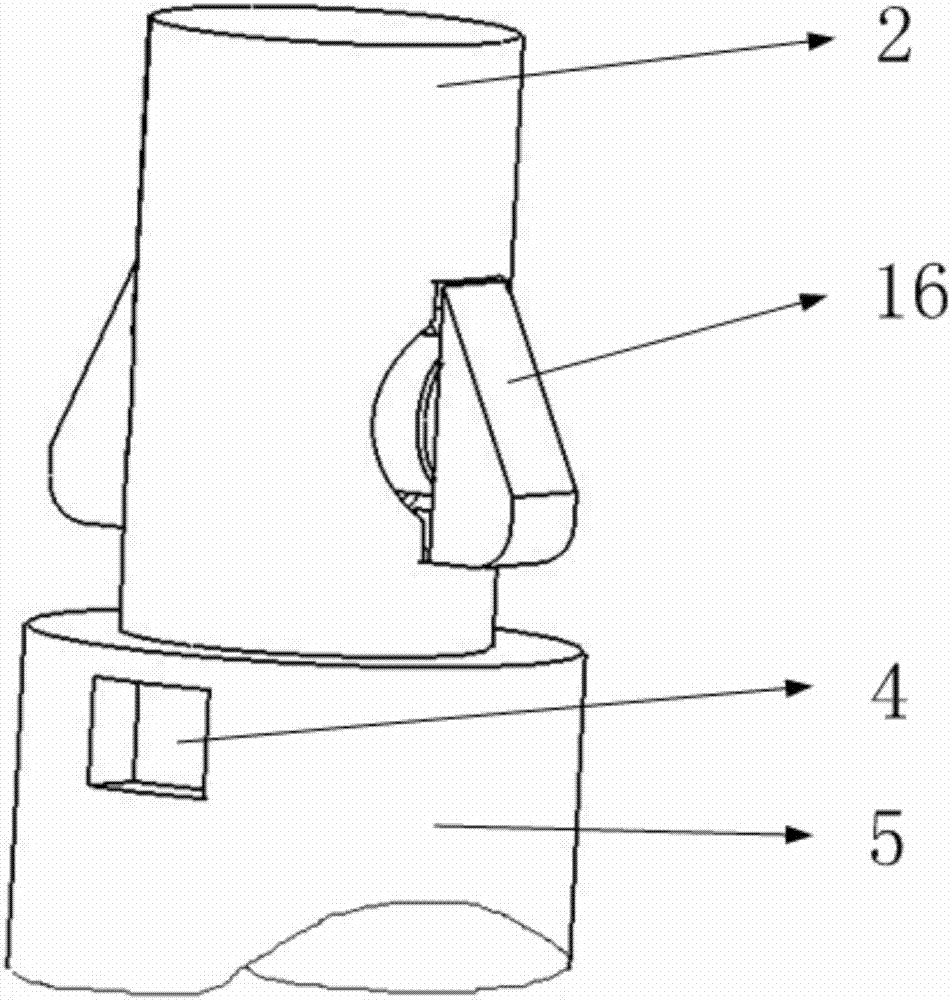

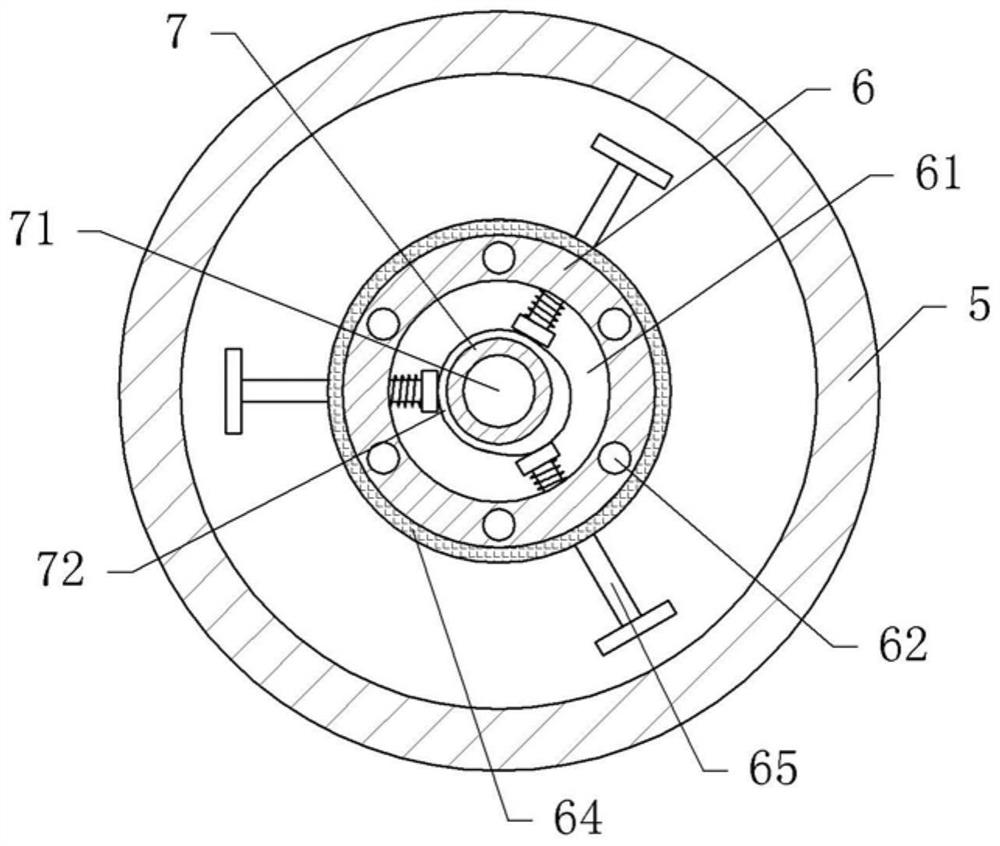

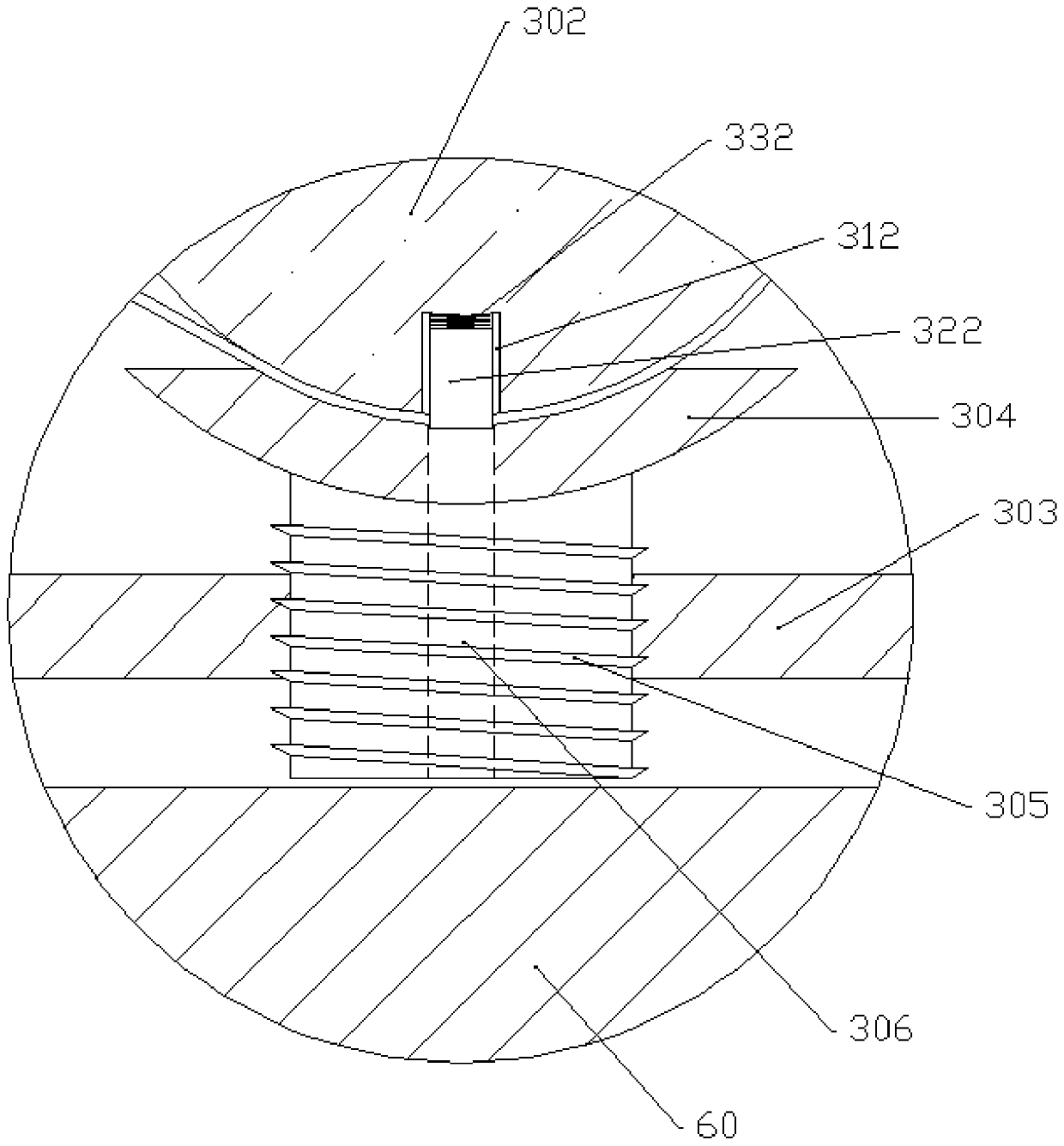

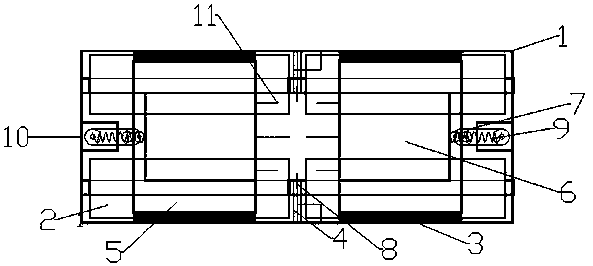

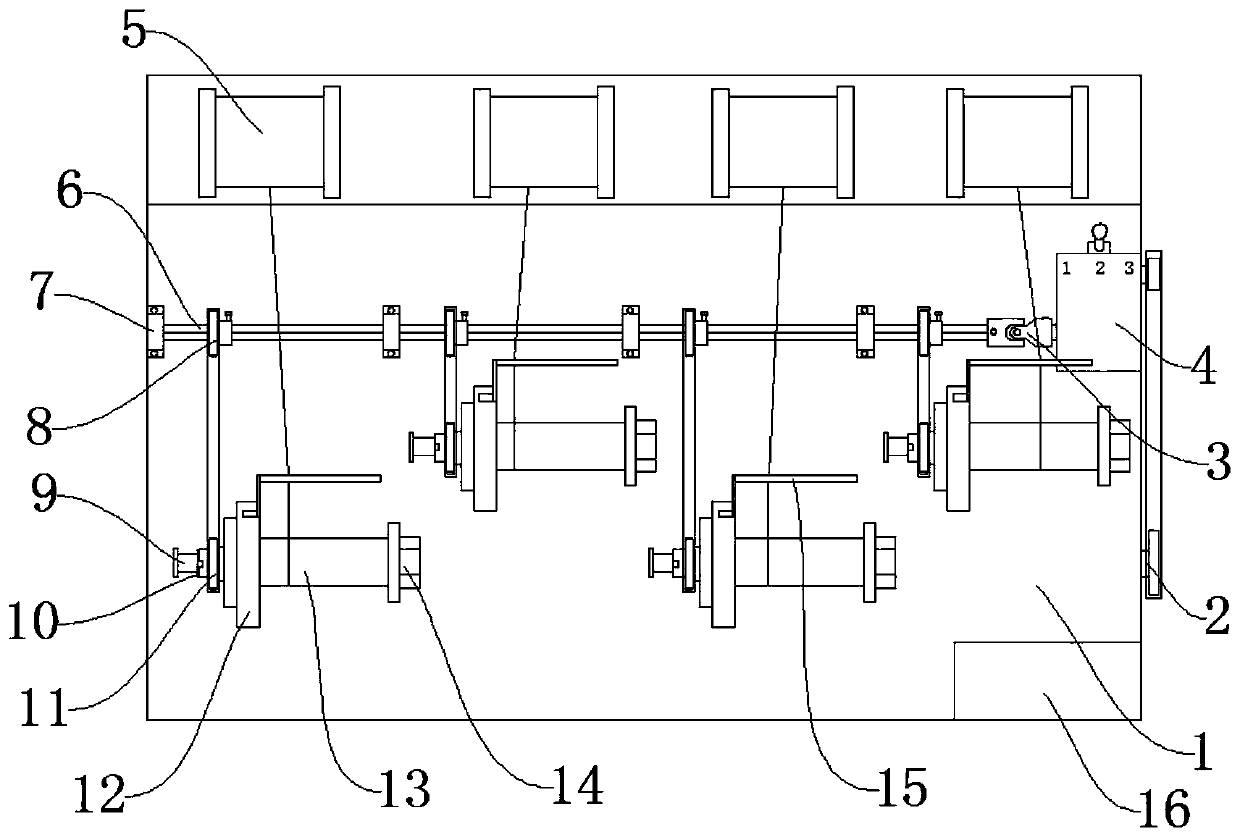

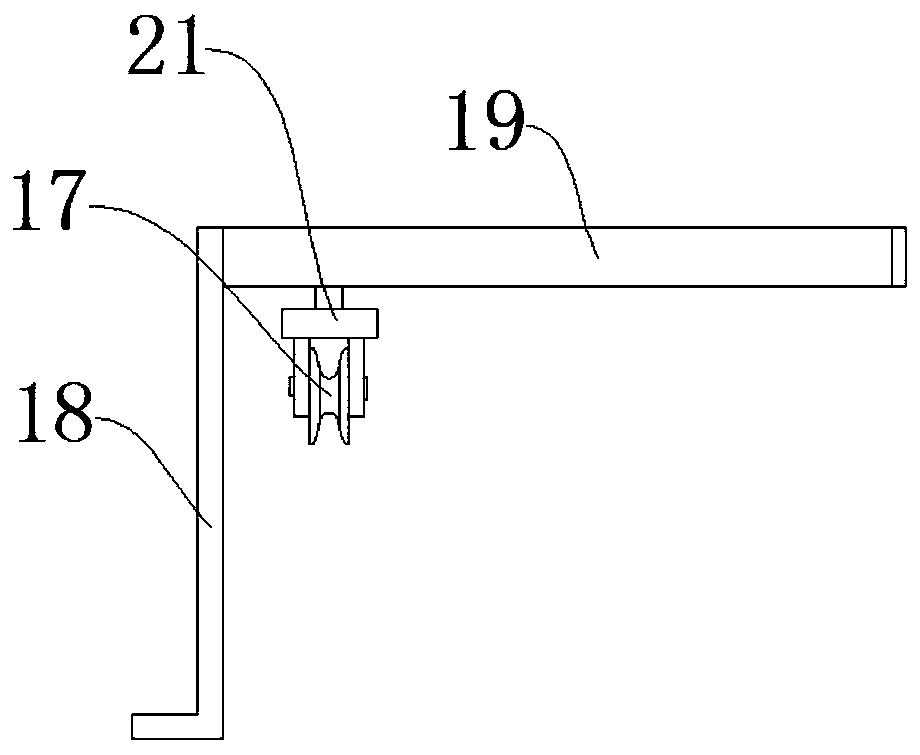

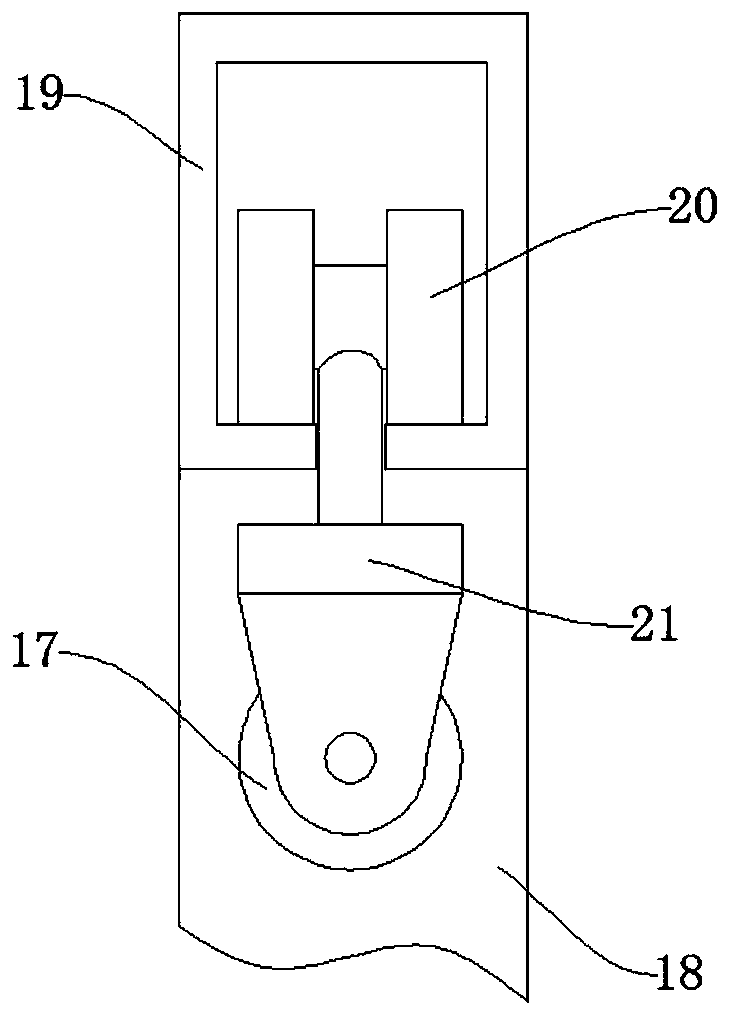

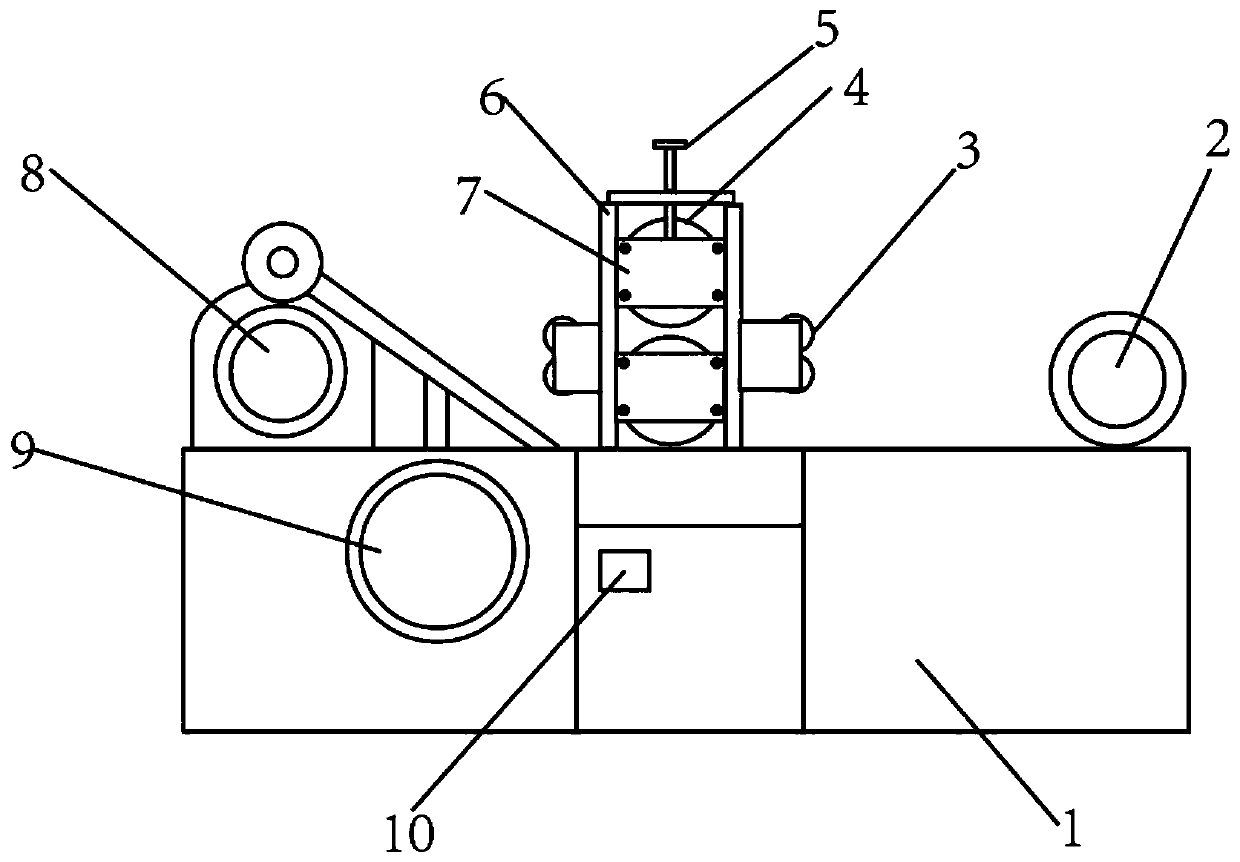

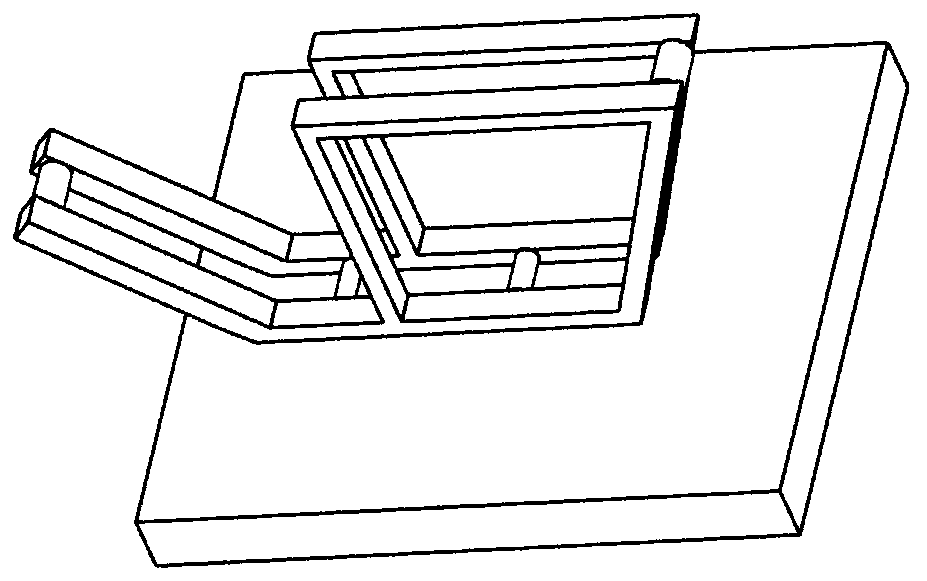

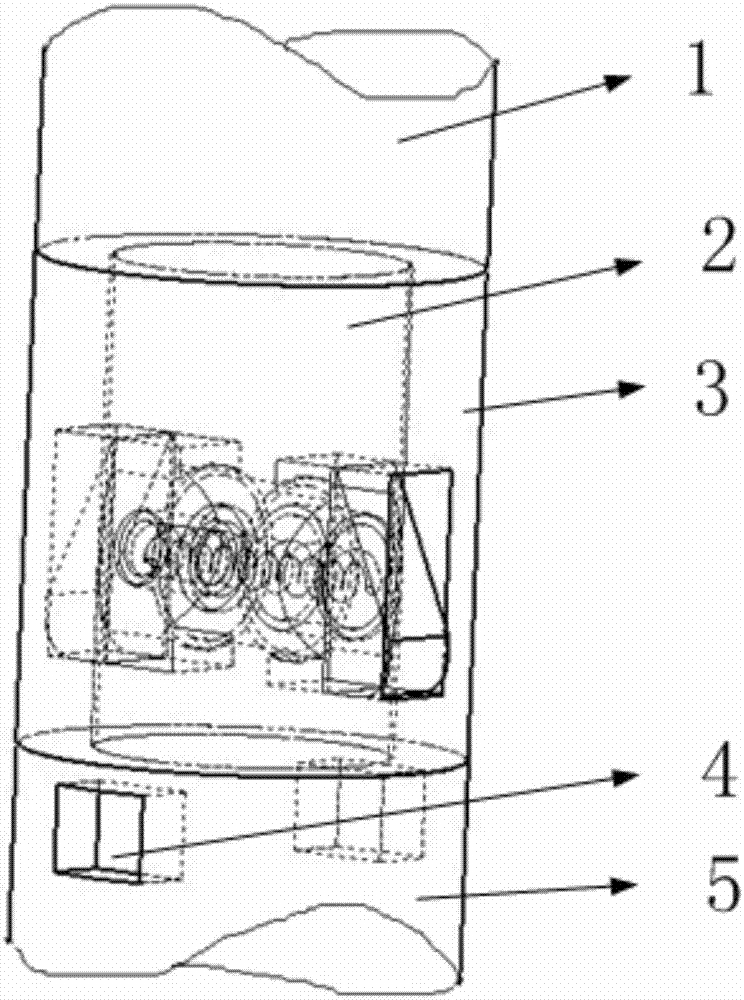

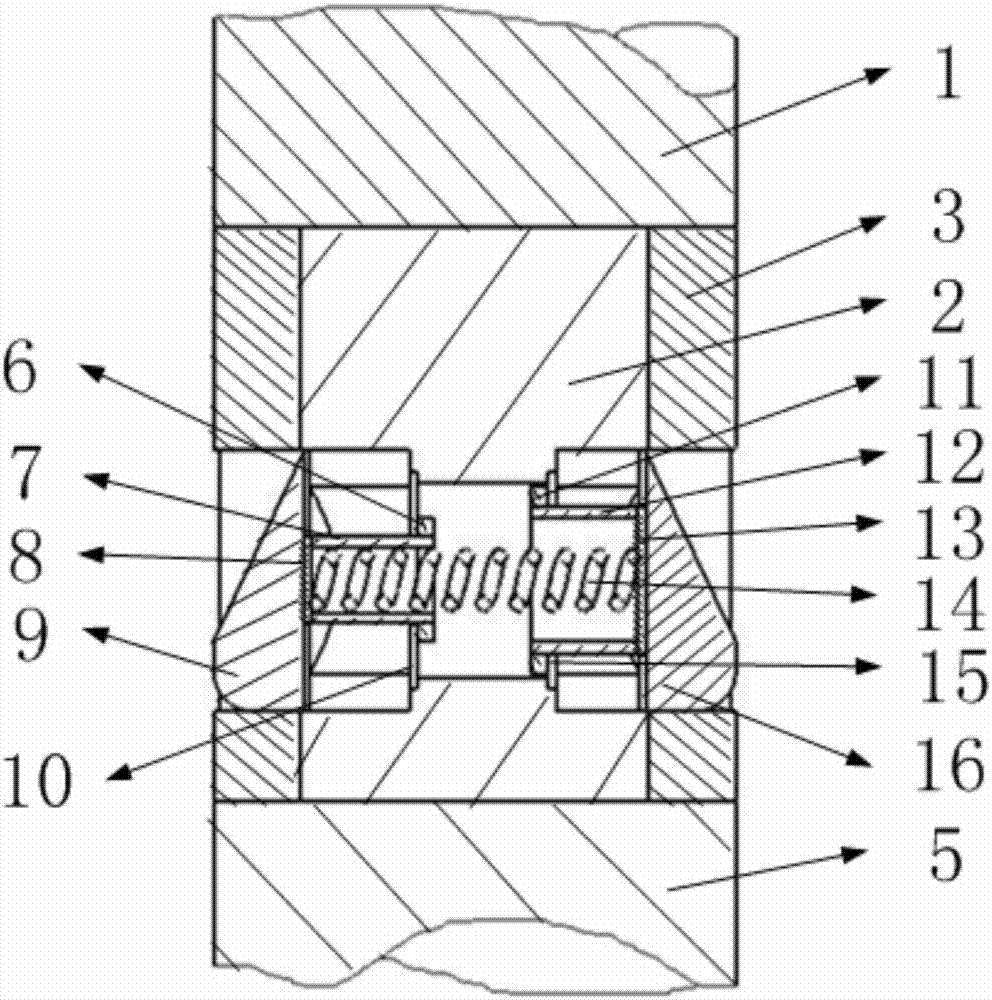

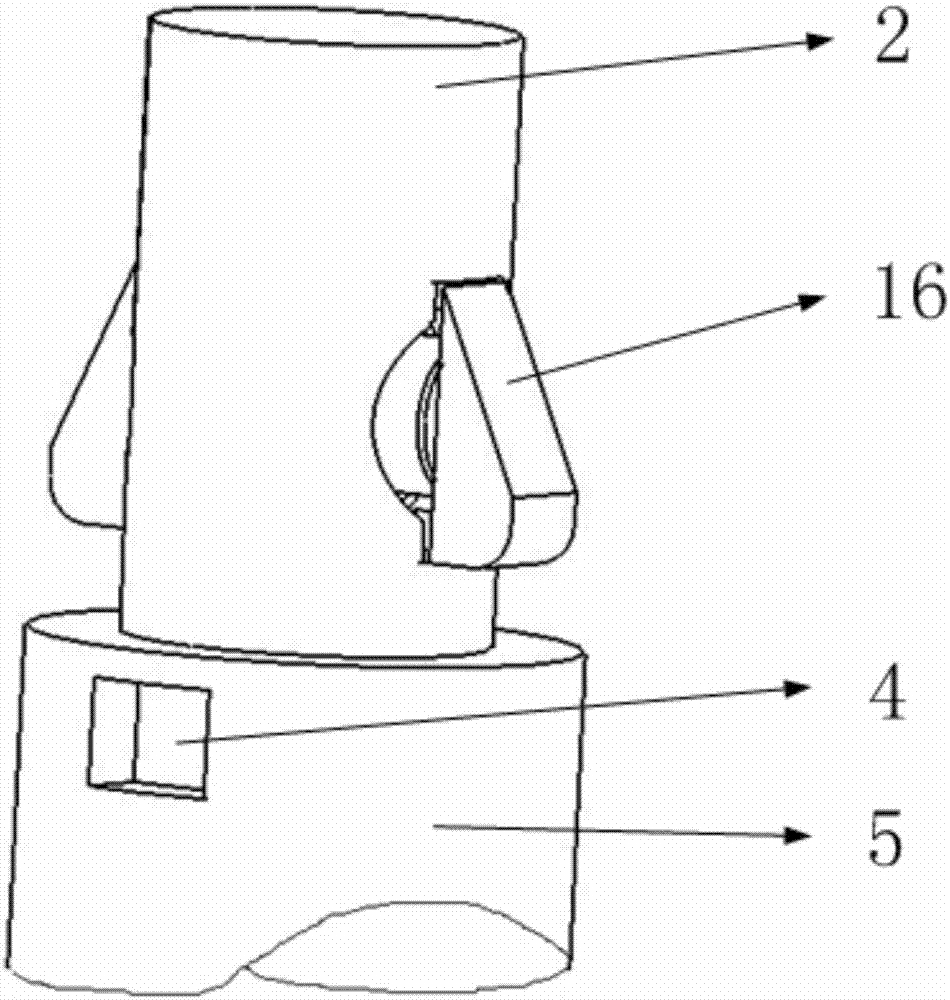

Rotary driving and pushing mechanism for well-drilling drill column

ActiveCN105781440AEnable connectivityRealize functionDrilling rodsBorehole drivesWell drillingEngineering

The invention belongs to the technical field of well drilling and specifically relates to a rotary driving and pushing mechanism for a well-drilling drill column. The rotary driving and pushing mechanism comprises a drill rod fixing mechanism, a driving motor, a pushing hydraulic rod, a hollow driving rotary shaft, a drill rod connection structure, a hydraulic rod fixing support and drill rod bodies. The driving motor is fixed to the hydraulic rod fixing support through the pushing hydraulic rod. Stretching-out and drawing-back of the hydraulic rod can drive the driving motor to move up and down. A rotary shaft of the driving motor is the hollow driving rotary shaft. The hollow driving rotary shaft can drive the drill rod bodies to rotate and move up and down through the drill rod fixing mechanism. The two drill rod bodies are connected together through the drill rod connection structure. The designed drill rod connection structure and the drill rod fixing mechanism are organically combined, so that the connection and driving functions of the drill rod are achieved. In addition, the drill rod connection structure is compact in structure, so that the effect that the diameter of the connection position is the same as that of the drill rod bodies can be ensured, and damage to a well drilling face due to a too large drill rod connection structure is avoided. The whole mechanism has a certain practical effect.

Owner:东营市虹田石油装备有限公司

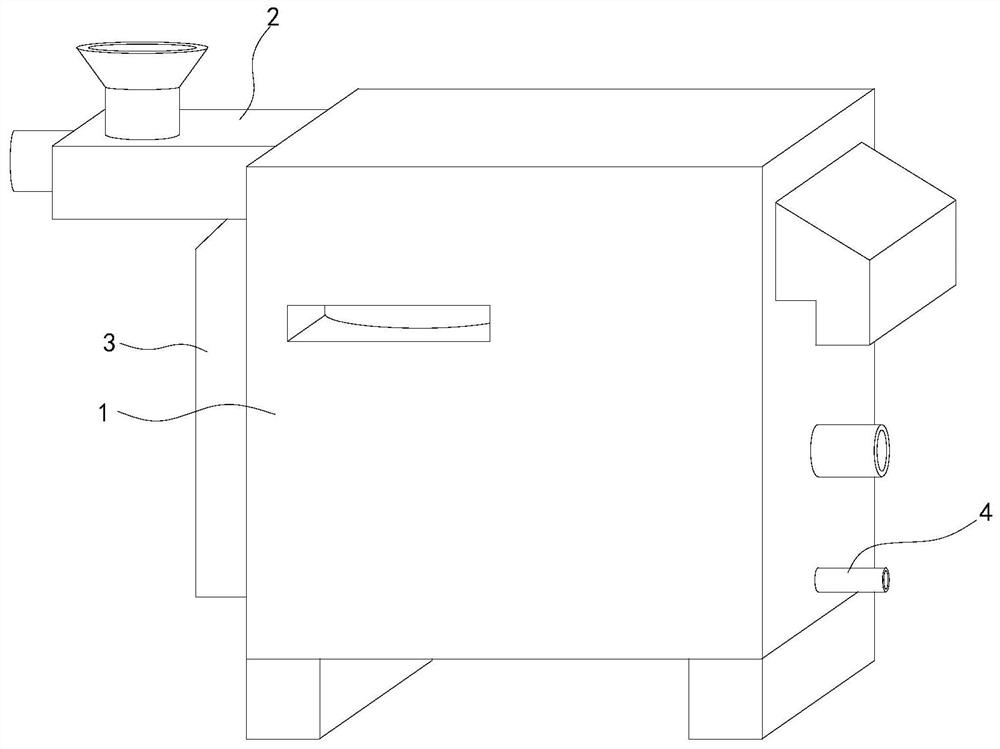

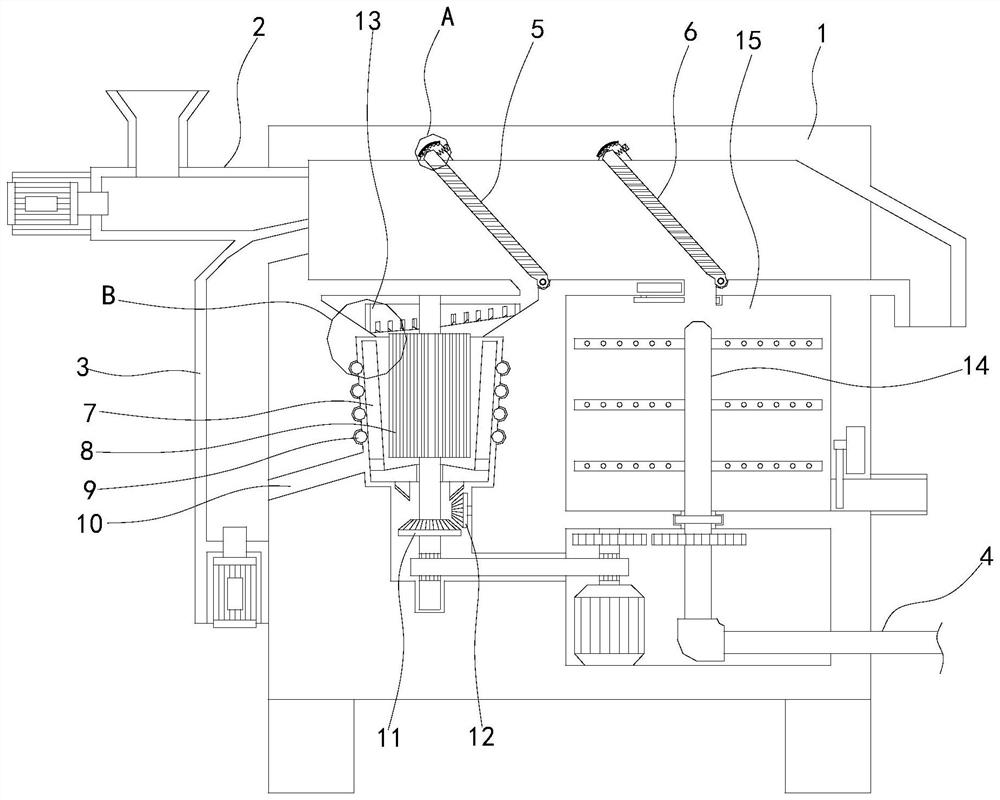

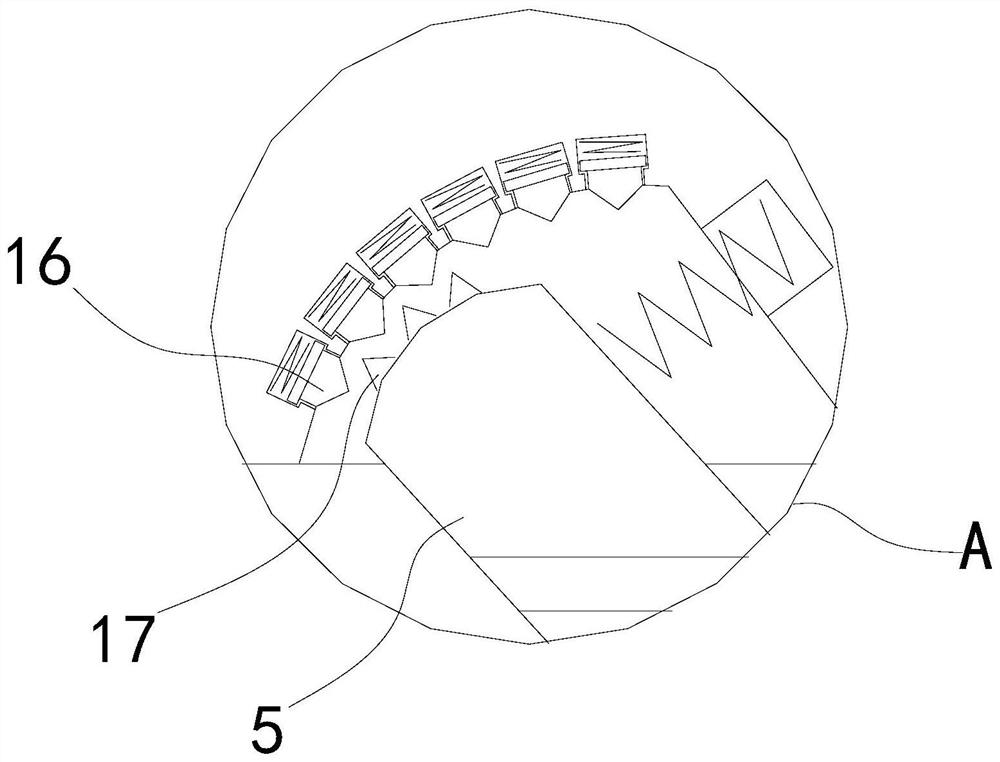

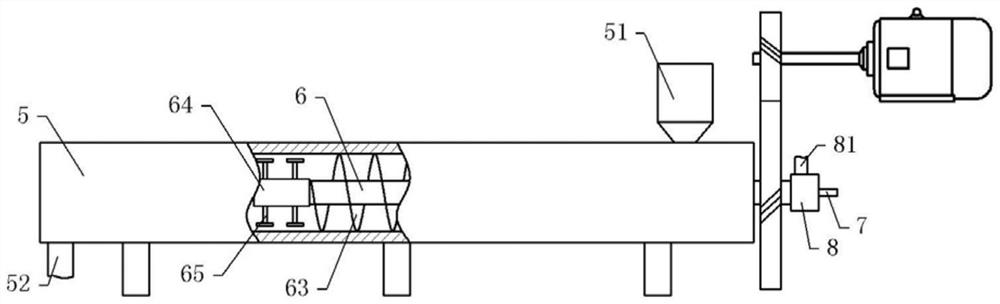

Plastic foam conveying equipment

InactiveCN111674956ASame diameterQuality improvementSievingRotary stirring mixersEngineeringMechanical engineering

The invention relates to the field of plastic foam production, in particular to plastic foam conveying equipment which comprises a device main body. A first filter plate is movably installed at the upper end inside the device main body, a rotating column is fixedly installed at the left side inside the device main body, a bead grinding cylinder is fixedly installed at the left side inside the device main body relative to the outer side of the rotating column, and a baffle plate is fixedly installed inside the device main body relative to the upper part of the rotating column. A convex block isfixedly installed at the upper end of the first filter plate, and an inner shrinkage block engaged with the convex block is movably installed inside the upper end of the device main body, so that when the first filter plate is used for a long time and some raw material beads are clamped in the first filter plate, the first filter plate is driven to rotate with the lower end as the center by increasing the air exhaust speed of a fan, then, the rotating speed of the fan is reduced, the first filter plate returns under the effect of a right spring, the convex block collides with the inner shrinkage block to produce vibration with the certain frequency, the clamped raw material beads are vibrated out, and an automatic cleaning effect is achieved.

Owner:杨志银

Flexible spark plug

Owner:BISHOP BOBBY GLEN

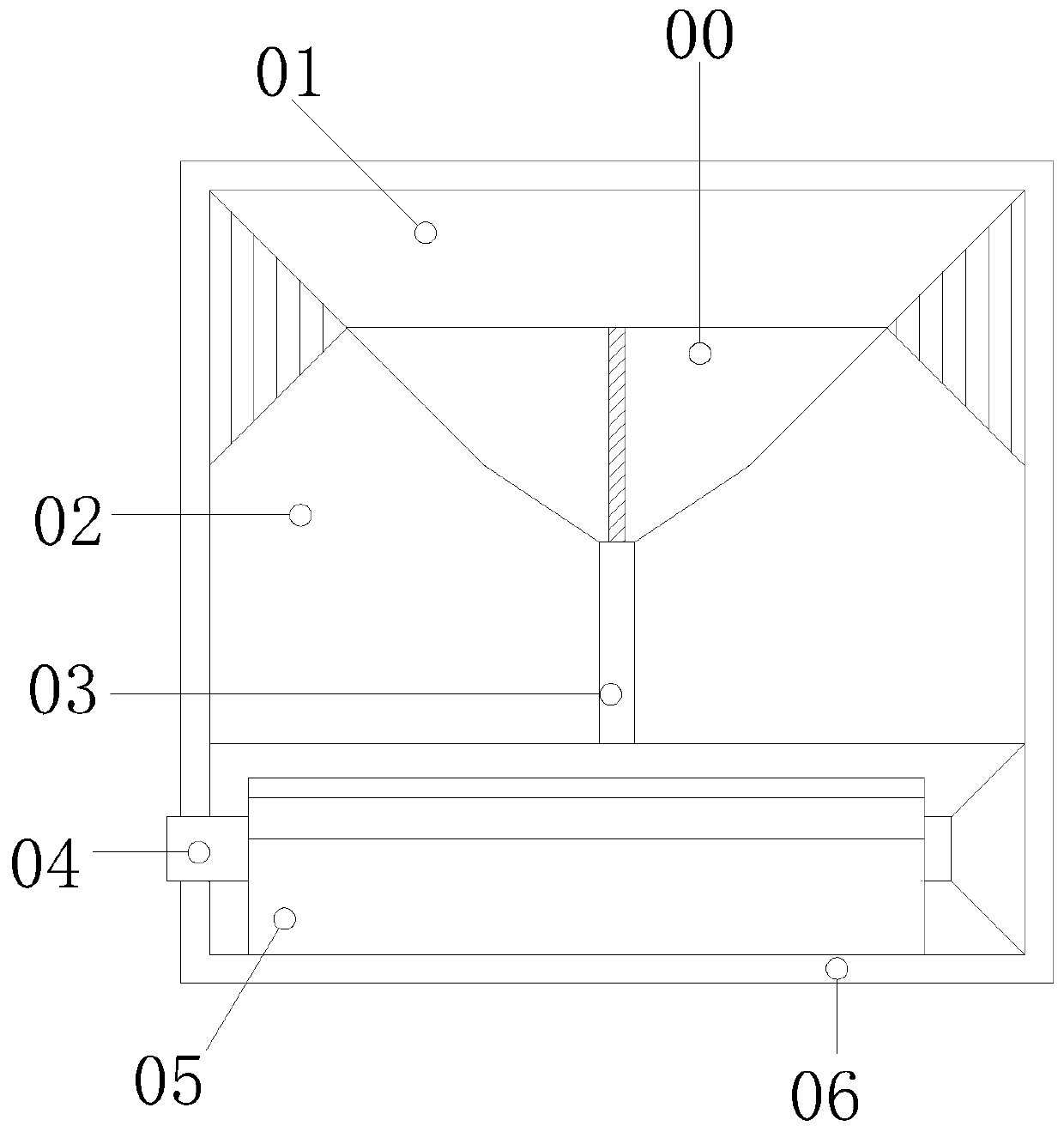

Fan coil forming machine

InactiveCN112045009APrevent up and down movementSame diameterHeat exchange apparatusMolding machineEngineering

The invention relates to a fan coil forming machine comprising a fixing base, mounting blocks, pushing air cylinders, a winding device and abutting devices. The mounting blocks are mounted at the rearend of the fixing base in a bilateral symmetry manner, the pushing air cylinders are mounted at the lower ends of the mounting blocks, the winding device is mounted in the middle of the upper end ofthe fixing base, and the abutting devices are symmetrically mounted at the lower end of the fixing base and the winding device. According to the fan coil forming machine, a spiral groove is formed inthe outer wall of a positioning column of the winding device, one end of a manufactured coil pipe is fixed in the spiral groove through a fixing pipe, the wound and formed coil pipes are prevented from moving up and down, the wound and formed coil pipes abut against one another in sequence through clamping blocks of the abutting devices, and when the coil pipes are completely wound and formed,theclamping blocks move towards the middle to extrude and form the coil pipes, so that it is guaranteed that the winding diameters of the coil pipes are the same, and gaps between the coil pipes are thesame.

Owner:欧阳福鑫

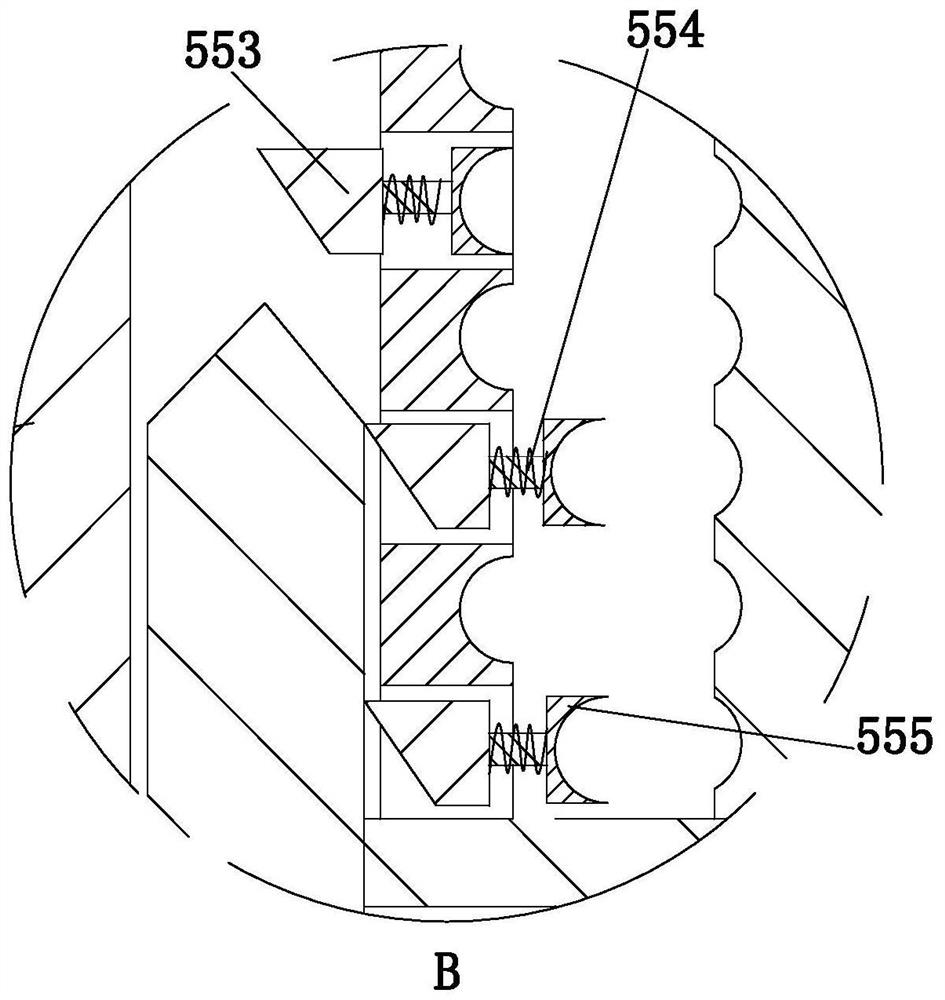

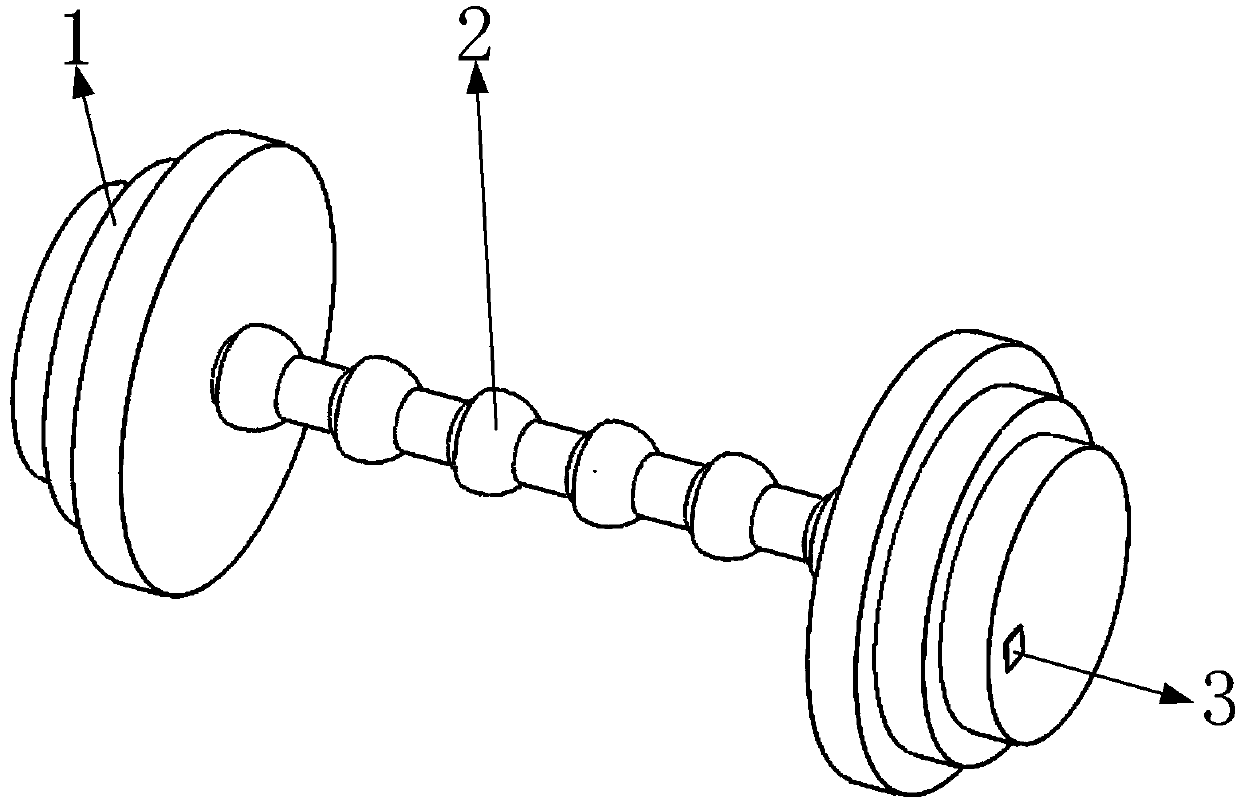

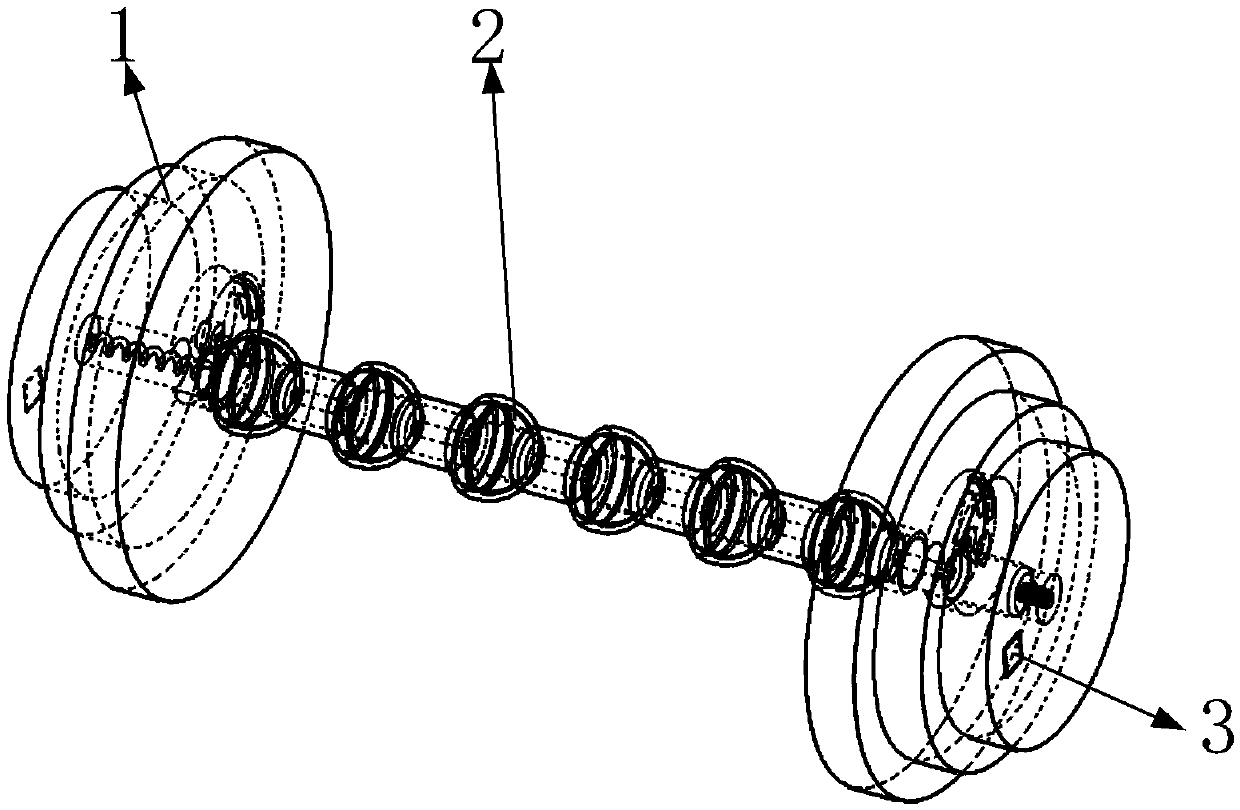

Share-based dumbbell

ActiveCN109091800ASame diameterSame apertureDumb-bellsApparatus for meter-controlled dispensingDumbbellComputer engineering

Owner:临沂兴创达知识产权运营有限公司

An uphole drill bit pressurizing mechanism for drilling

ActiveCN105604502BExert pressurePlay a connecting roleDrilling rodsConstructionsWell drillingElectric machinery

The invention belongs to the technical field of well drilling, and particularly relates to an over-well drill bit pressing mechanism for well drilling. The mechanism comprises a drill rod fixing mechanism sliding groove, a first rotary shaft, a second gear, a first gear, a threaded pressing mechanism, a drill rod body, a drill rod connecting structure, a drill rod fixing mechanism and a hollow driving rotary shaft, wherein the hollow driving rotary shaft and the drill rod body are connected through the drill rod fixing mechanism, the drill rod fixing mechanism can slide in the drill rod fixing mechanism sliding groove, and the hollow driving rotary shaft is in thread fit with a thread structure; a driving motor rotary shaft rotates to drive the first rotary shaft through the gear assembly to rotate, and the hollow driving rotary shaft moves downwards so as to press the drill rod while rotating under the driving of the first rotary shaft and the action of the thread structure. Furthermore, the drill rod connecting mechanism is compact in structure, it can be guaranteed that the diameter of the connection position is identical with that of the drill rod body, and damage of an oversized drill rod connecting structure to a borehole surface is avoided. The whole mechanism has a certain practical effect.

Owner:莱州市原野科技有限公司

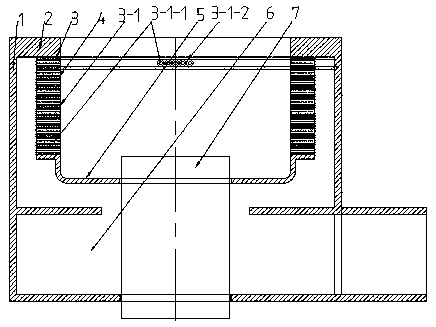

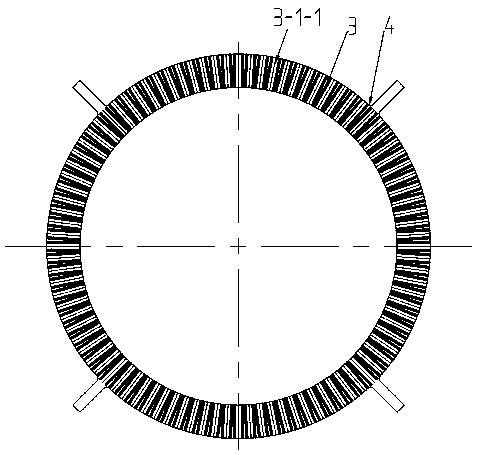

Double-fire-hole characteristic combustor formed by vertically stacking thin pipe annular row sets

InactiveCN110966595AFire hole diameter is the sameSame diameterGaseous fuel burnerCombustorCombustion chamber

The invention relates to the field of commercial kitchenware, in particular to a double-fire-hole characteristic combustor formed by vertically stacking thin pipe annular row sets. Thin pipes 2 are uniformly distributed on the surface of one surface of an annular partition plate 4 by a circle; the outlet of the thin pipes 3 faces a combustion chamber 5-1; the inlet of the thin pipes 3 faces a firedistribution chamber 1-1; a plurality of annular partition plates 4 on which the thin pipes 3 are distributed are stacked together to form a distributor 3-1 of the combustor; holes with the cross sections similar to triangles formed between the outer walls of every two adjacent thin pipes 3 and the surface of the annular partition plate 4 are auxiliary fire holes 3-1-2. The auxiliary fire holes 3-1-2, the inner holes of the thin pipes 3 and the main fire holes 3-1-1 jointly form double characteristic fire holes of the fire distributor 3-1, wherein the combustion chamber 5-1 is arranged in thecenter area of the fire distributor 3-1, a distribution chamber gland 2 is arranged on the fire distributor 3-1, a distribution chamber outer barrel 1 is connected to the lower part of the outermostperiphery of the distribution chamber gland 2. The gas combustor which is identical in size of fire hole diameter and excellent in combustion performance can be provided.

Owner:浙江惠厨节能科技有限公司

Method for removing the thermal compression welding of copper-aluminum combined pipeline fitting under the assistance of rotary friction

InactiveCN101642847BEfficient removalFacilitated DiffusionWelding/soldering/cutting articlesTubular articlesThermal compressionEngineering

A method for the thermal compression welding of a copper-aluminum combined pipeline fitting with the assistance of rotary friction to remove an aluminium tube oxidation film relates to the field of thermal compression welding process and solving the problem that the prior connection method of the conventional aluminum tube has poor connection compactness and low finished product ratio due to the compact oxidation film in the used aluminum tube. The method comprises the following steps: the outer wall of one end of a copper pipe to be welded is processed into a tapered surface, the copper pipe is secured at a drill chuck of a drilling and milling machine while the aluminum pipe is secured on a clamp of the drilling and milling machine, one end with tapered surface of the copper pipe is inserted into one end of the aluminum pipe, and the sleeved section between the copper pipe and the aluminum pipe is heated up using an acetylene flame gun, when the temperature reaches 400-500 DEG C, the copper pipe is rotated and the other end of the copper pipe is pressurized so that the copper pipe is inserted into the aluminum pipe, and heating is ceased to accomplish total welding between the copper pipe and the aluminum pipe. The method in the invention is applied to welding the combined pipeline fittings in refrigeration products.

Owner:HARBIN INST OF TECH

Steel wire gluing structure for tire

ActiveCN112934610ASame diameterEasy to usePretreated surfacesCoatingsRubber ringStructural engineering

Owner:重庆市九龙橡胶制品制造有限公司

Plastic crushing, mixing and granulating all-in-one machine with hybrid self-removing function

The invention discloses a plastic crushing, mixing and granulating all-in-one machine with a hybrid self-removing function. The machine structurally comprises a sundry cylinder, a discharging hopper,a transmission motor, a bottom frame, a pressure device, a speed reducer, wherein the speed reducer is vertically welded to the right end of the upper portion of the bottom frame, the transmission motor is vertically welded to the left end of the upper portion of the bottom frame and is in transmission connection with the speed reducer, mixture of metal and plastic product is placed in an inclinedbucket for melting, and when the temperature reaches a melting point of the plastic product, the mixture stops being added, so that the metal is left so as to be removed and recycled by the removed columns, the plastic product is changed into molten liquid to be prepared for cooling and granulating, energy wastage is avoided, the plastic product has high recovery rate, in a round upper ring and alower ring, round particles can be shaped, fixed space ensures the uniform size of the plastic particles, a cutting handle can perform point-to-point cutting, and a row of the cutting handles carriesout cutting at the same time, so that the size of the plastic particles is equal while the overall is higher, and the produced plastic particles are higher in quality.

Owner:南安市商宏机械科技有限公司

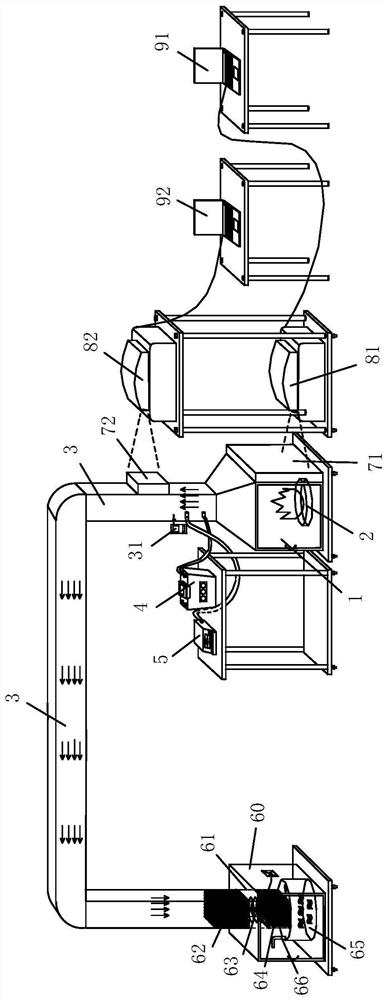

Flame and flue gas integrated spectrum identification and analysis platform

PendingCN114018774AImprove authenticity and accuracySame diameterWithdrawing sample devicesThermometers using electric/magnetic elementsPhysicsOptical spectrometer

The invention discloses a flame and flue gas integrated spectrum recognition and analysis platform which comprises a combustion chamber, a combustor is arranged in the combustion chamber, an outlet in the upper end of the combustion chamber is communicated with a flue gas exhaust pipeline, and an outlet of the flue gas exhaust pipeline is communicated with a flue gas treatment device; a first observation window is arranged on the combustion chamber, a first infrared spectrometer is arranged at the position right opposite to the first observation window, and the first infrared spectrometer is electrically connected with a first computer; a second observation window is arranged on the smoke exhaust pipeline, a second infrared spectrometer is arranged at the position right opposite to the second observation window, and the second infrared spectrometer is electrically connected with a second computer; the platform further comprises a smoke dust and flue gas tester and a particulate matter collector, and the smoke dust and flue gas tester and the particulate matter collector are respectively communicated with the smoke exhaust pipeline through sampling pipes. According to the invention, the whole process of releasing the smoke generated by the combustion flame is monitored, and finally, through coupling of the flame and the smoke, the relationship between the generation of the flame and the release of the smoke is explored as a basis for verifying a fire inversion model.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

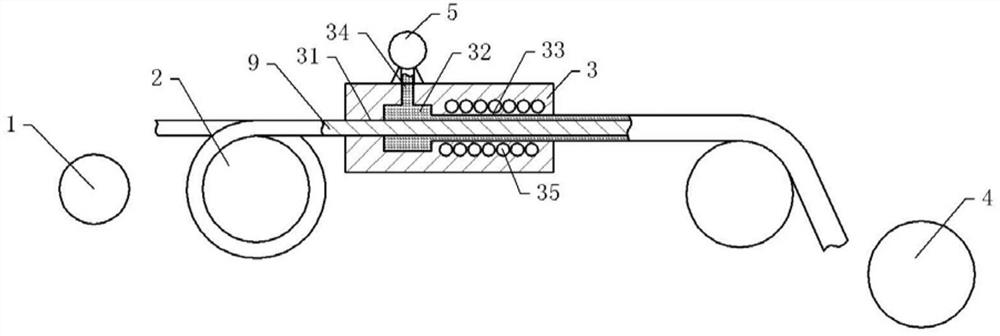

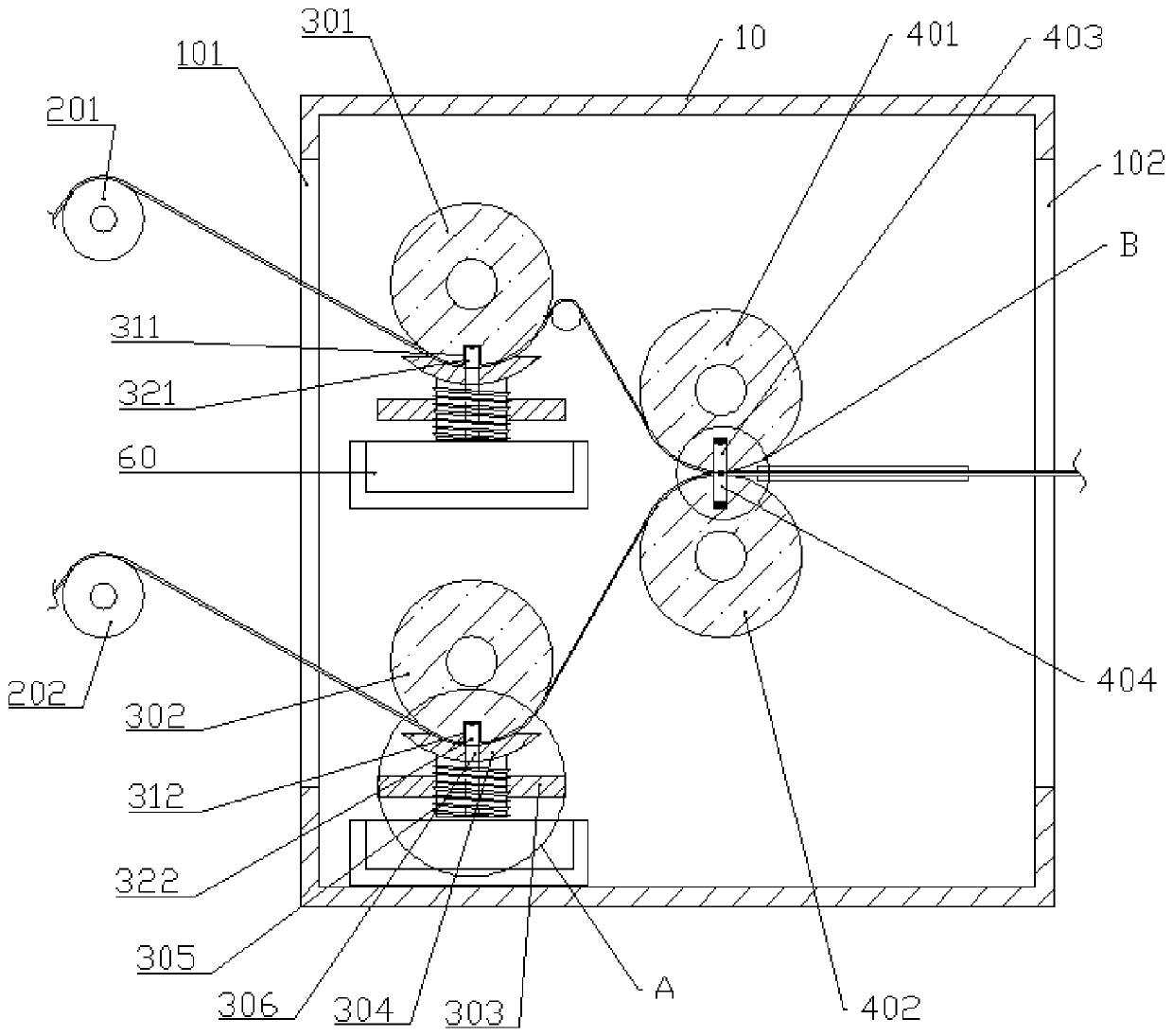

Receipt printing machine

InactiveCN108297547BAdjust delivery speedSame diameterRotary pressesPrinting press partsInvoiceEngineering

The invention relates to the field of printing, and in particular, discloses a bill printing machine. The bill printing machine comprises a detecting mechanism; the detecting mechanism comprises a first conveying roller, a second conveying roller, a first ejector rod, a second ejector rod and a circuit; the first ejector rod is elastically mounted on the side surface of the first conveying roller;the second ejector rod is elastically mounted on the side surface of the first conveying roller; the end, far from the first conveying roller, of the first ejector rod can be contacted with the end,far from the second conveying roller, of the second ejector rod; the diameters of the first printing roller, the second printing roller, the first conveying roller and the second conveying roller areconsistent; an indicating lamp is arranged in the circuit; an electric conducting first connecting block is arranged at the end, far from the first conveying roller, of the first ejector rod; an electric conducting second connecting block is arranged at the end, far from the second conveying roller, of the second ejector rod; and the first connecting block can be contacted with the second connecting block. The bill printing machine can perform punching positioning on multiple layers of bills before merging to improve the bill processing precision.

Owner:重庆华康印务有限公司

Wet-process groove type black silicon texturing method

InactiveCN110416353AReduce the impact of digging effectsUniform suedeFinal product manufactureSemiconductor/solid-state device manufacturingStop flowSmall hole

The invention discloses a wet-process groove type black silicon texturing method. The method comprises the following steps: carrying out surface treatment on a silicon wafer, and putting the silicon wafer into a primary treatment groove to remove line marks on the surface of the silicon wafer so as to obtain a primary silicon wafer with the smooth surface; performing hole digging and texturing onthe silicon wafer subjected to surface treatment, and putting the obtained primary silicon wafer into a secondary treatment groove for reaction for 180-220s to obtain a secondary silicon wafer with nanoscale small holes in the surface, wherein before the primary silicon wafer is put into the secondary treatment groove, a mixed solution in the secondary treatment groove stops flowing circularly 10-20s in advance until the hole digging is completed; carrying out hole expanding on the silicon wafer subjected to the hole digging and texturing, and putting the secondary silicon wafer subjected to the hole digging into a tertiary treatment groove for treatment for 85-95s to obtain a tertiary silicon wafer; and putting the obtained tertiary silicon wafer into a cleaning groove to obtain a siliconwafer with no metal ions on the surface, and drying the cleaned silicon wafer to obtain a finished silicon wafer. The obtained textured silicon wafer is same in hole size and good in uniformity.

Owner:阜宁苏民绿色能源科技有限公司

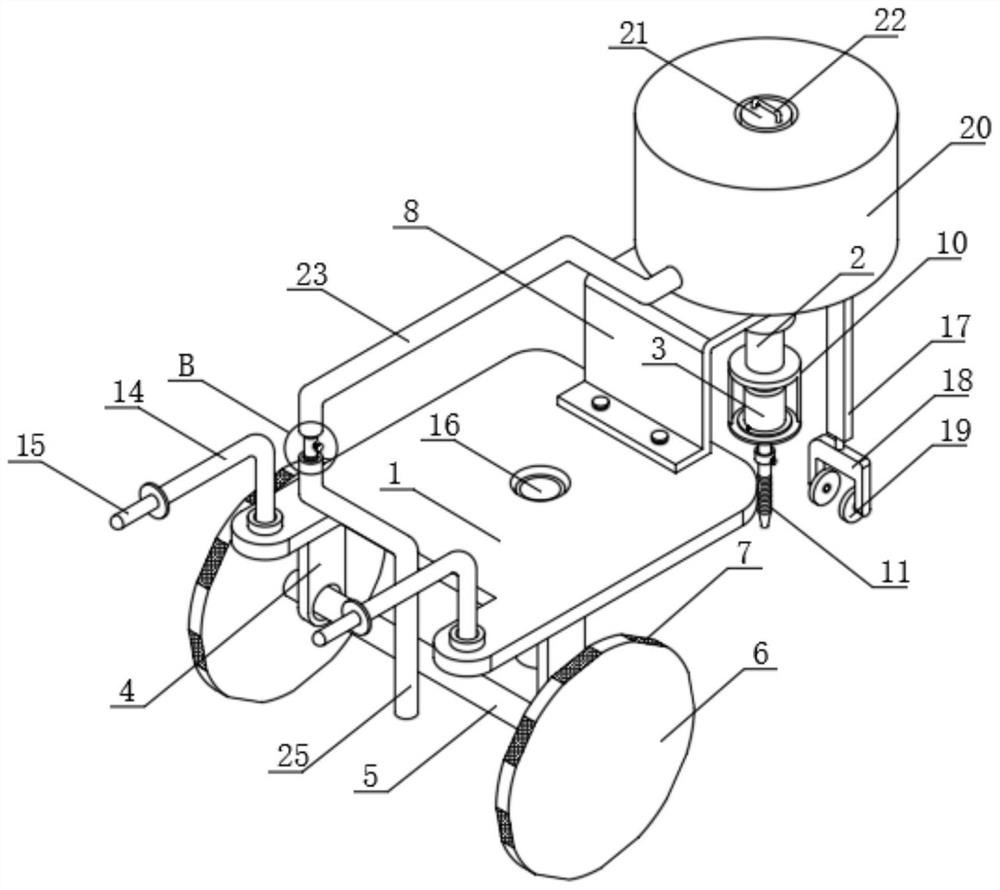

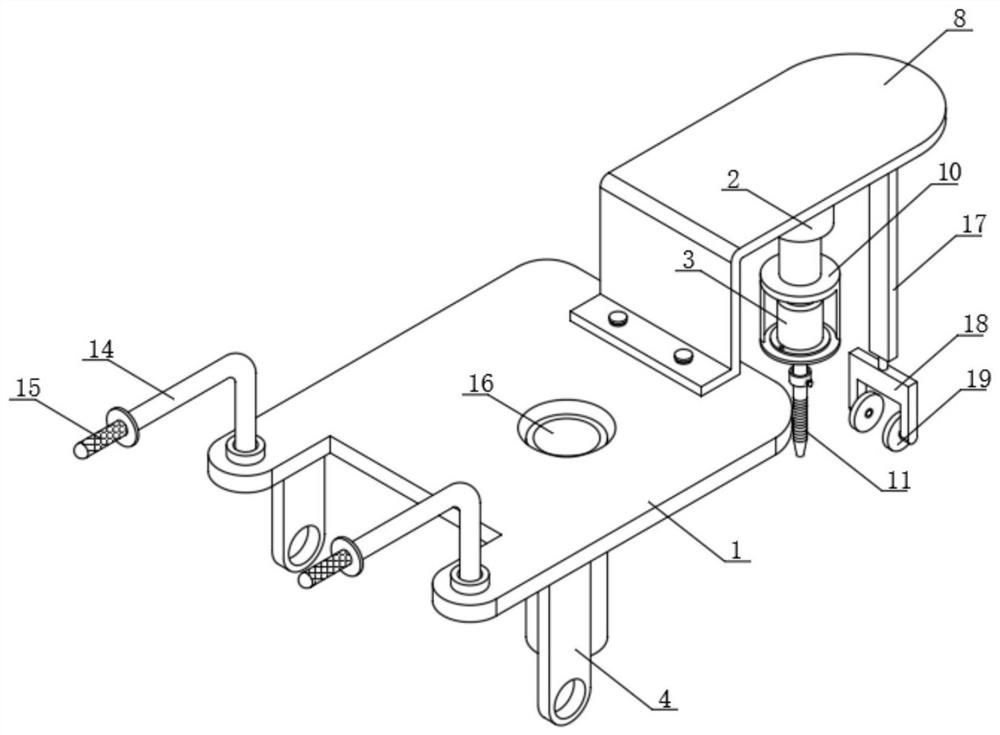

Agricultural product transplanting device

InactiveCN112243656ALow efficiencyShorten the timeWatering devicesTransplantingHydraulic cylinderAgricultural science

The invention relates to the technical field of transplanting equipment, and discloses an agricultural product transplanting device. The device comprises a placing plate, a lifting hydraulic cylinderand a motor, two side plates are fixedly connected to the lower surface of the placing plate, rotating shafts are movably connected to the inner walls of the two side plates, and wheels are installedat the two ends of each rotating shaft. The side faces of the two wheels are each provided with a plurality of sections, and one end of the upper surface of the placing plate is movably connected witha support through a bolt. According to the agricultural product transplanting device, crop cannot be smoothly thrown into pits by the transplanting device, so that the crop transplanting efficiency of the transplanting device is reduced, the advancing distances of the wheels each time can be equal through the combined arrangement of the wheels and the sections, and the problems that due to different advancing distances of the transplanting device each time, the transplanting device cannot smoothly put agricultural products into the pits through a putting cylinder, the agricultural product transplanting efficiency of the transplanting device is reduced, and the workload of a user is increased are effectively solved.

Owner:怀化市秀宝农业开发有限责任公司

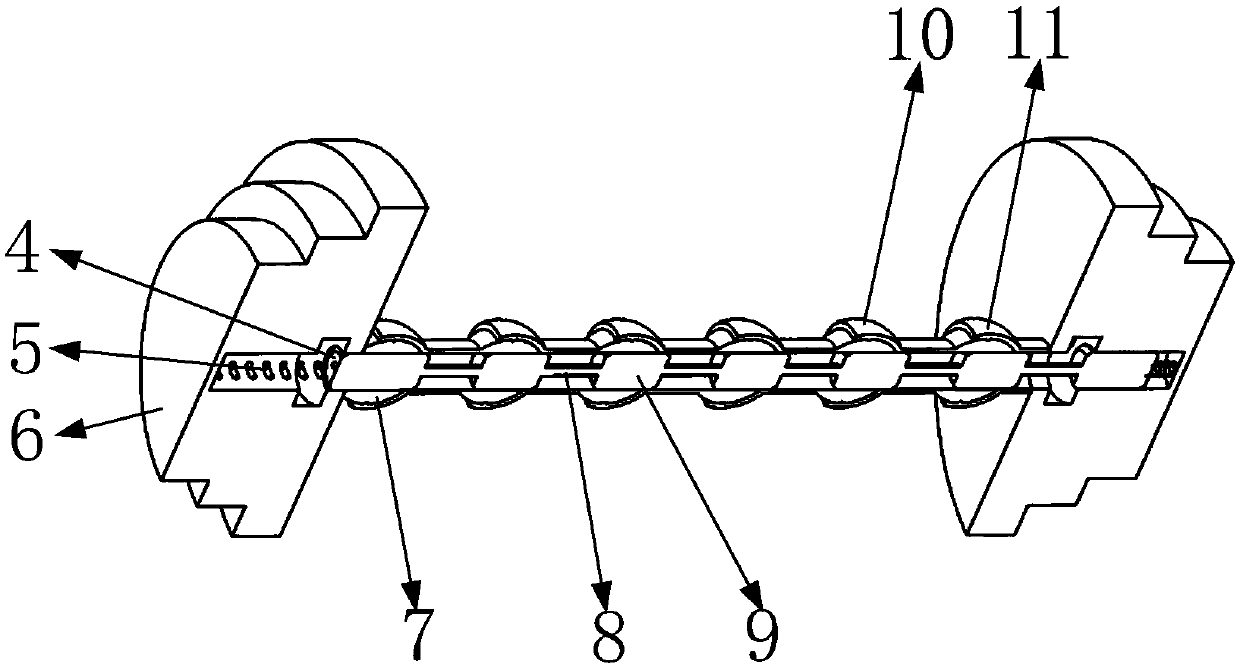

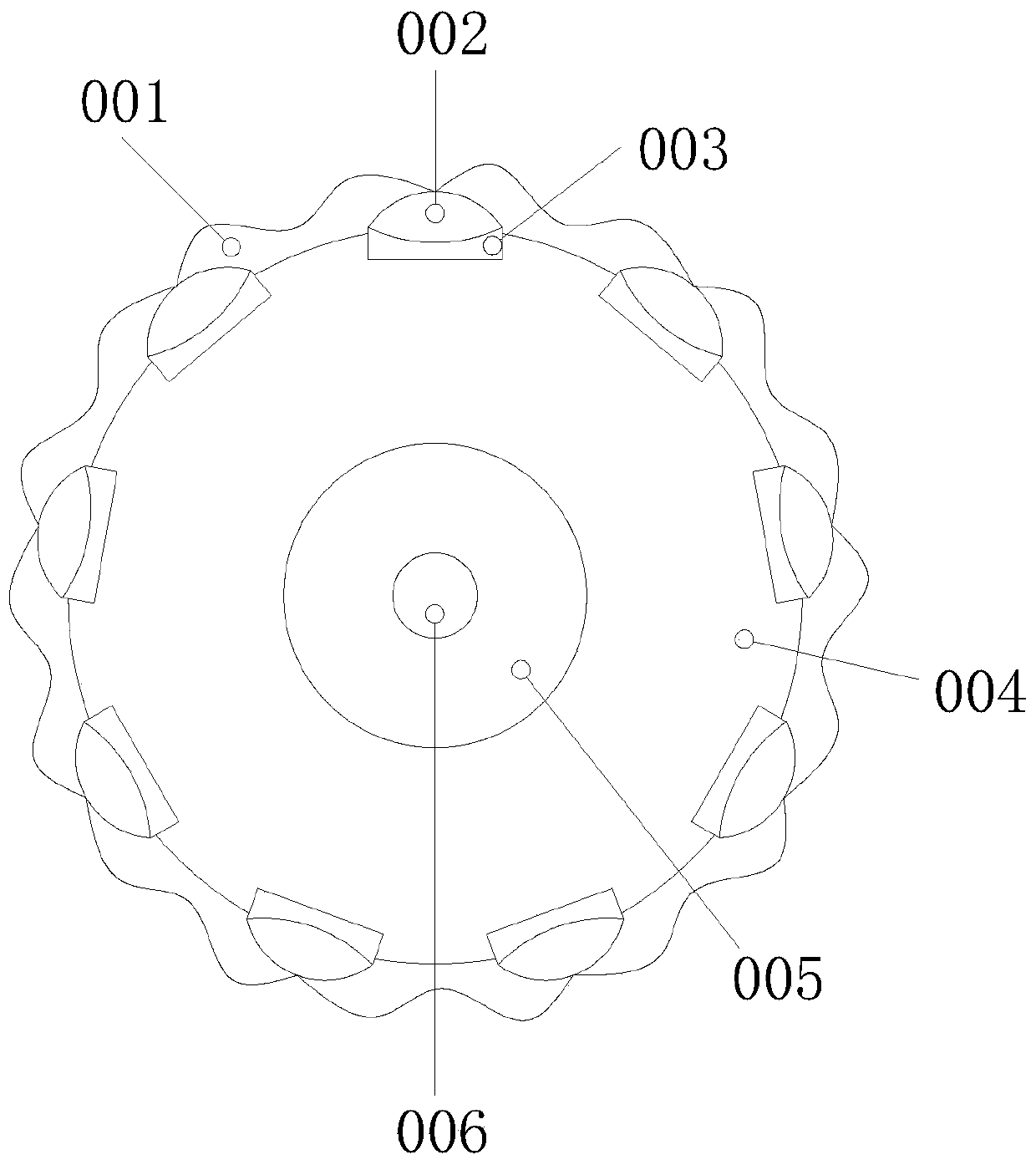

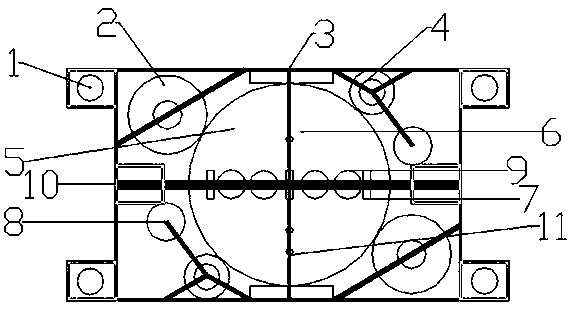

A precision peeling device for Gorgon fruit

The invention discloses a precision semen euryales shelling device which comprises a body, rotary shafts, support guide rails, a driving device, a pushing device, a cutting device and fixing ejector pins. The body is connected with the support guide rails, the support guide rails are symmetrically arranged inside the body, the rotary shafts are arranged on the inner sides of the support guide rails and comprise inner-circle rotary shafts and outer-circle rotary shafts, and the outer-circle rotary shafts and the inner-circle rotary shafts can rotate around a concentric circle. The precision semen euryales shelling device has the advantages that semen euryales can be mechanically automatically precisely shelled, accordingly, the shortcomings of severe damage on fruits and harm on the integral quality of existing semen euryales due to the traditional manual and partial mechanical shelling can be overcome, the semen euryales shelling success rate can be increased, the shelling speeds can be effectively increased, and the production values and the benefits can be greatly increased.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

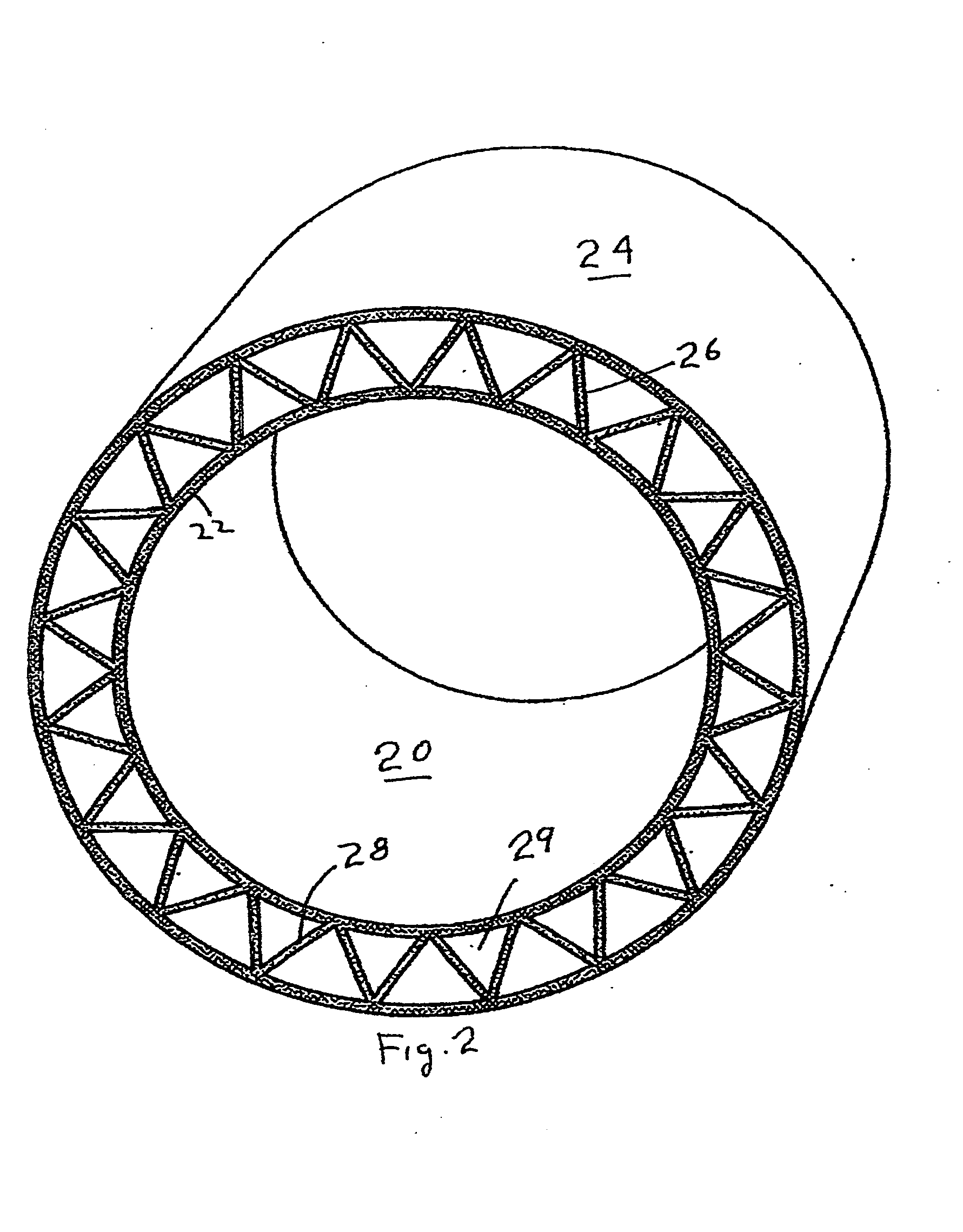

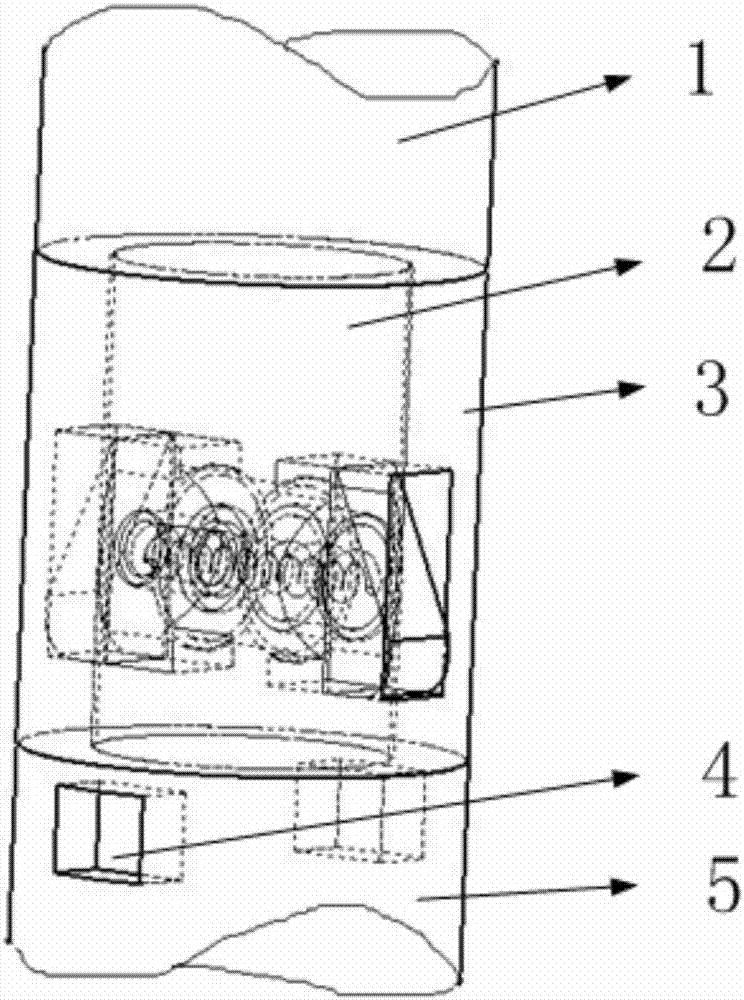

A kind of electric motor coil winding method

ActiveCN109217587BSame diameterImprove flatnessManufacturing dynamo-electric machinesWinding machineElectric machine

The invention discloses a high-efficiency motor coil winding method. Multiple wire wheels are fixed on multiple pay-off frames, and multiple coils that need to be wound are fixed on the rotating shaft through lock nuts and come out from the wire wheels. The wire passes through the guide wheel and is wound on the corresponding coil after being wound on it for a week; the motor drives the rotating shaft fixedly connected to the driven sprocket through the driving sprocket to rotate for automatic winding; the driven sprocket is adjusted through the sprocket locking device. Whether the sprocket is on the rotating shaft, and then select whether the rotating shaft rotates synchronously with the motor according to needs, thereby selecting the number of coils to be wound at the same time. The present invention drives a plurality of winding mechanisms to rotate through a transmission shaft, and simultaneously winds a plurality of coils, thereby improving the production efficiency of coils and motor products; The wire can drive the rolling wheel to slide back and forth on the transverse guide rail, thereby improving the flatness of the coil and saving the production cost.

Owner:XUZHOU DINGLI METAL ELECTROMECHANICAL

Rotary driving and pushing mechanism of drilling string

ActiveCN105781440BEnable connectivityRealize functionDrilling rodsBorehole drivesWell drillingDrive motor

The invention belongs to the technical field of well drilling and specifically relates to a rotary driving and pushing mechanism for a well-drilling drill column. The rotary driving and pushing mechanism comprises a drill rod fixing mechanism, a driving motor, a pushing hydraulic rod, a hollow driving rotary shaft, a drill rod connection structure, a hydraulic rod fixing support and drill rod bodies. The driving motor is fixed to the hydraulic rod fixing support through the pushing hydraulic rod. Stretching-out and drawing-back of the hydraulic rod can drive the driving motor to move up and down. A rotary shaft of the driving motor is the hollow driving rotary shaft. The hollow driving rotary shaft can drive the drill rod bodies to rotate and move up and down through the drill rod fixing mechanism. The two drill rod bodies are connected together through the drill rod connection structure. The designed drill rod connection structure and the drill rod fixing mechanism are organically combined, so that the connection and driving functions of the drill rod are achieved. In addition, the drill rod connection structure is compact in structure, so that the effect that the diameter of the connection position is the same as that of the drill rod bodies can be ensured, and damage to a well drilling face due to a too large drill rod connection structure is avoided. The whole mechanism has a certain practical effect.

Owner:东营市虹田石油装备有限公司

Novel slitting machine system

ActiveCN110899816AExact widthSame diameterShearing machinesShearing machine accessoriesVertical vibrationGear wheel

The invention belongs to the technical field of metal processing and discloses a novel slitting machine system. The system comprises a base, wherein an uncoiler is arranged at a right end of the base,a slitting machine detection module is arranged on a front side of the middle, a support and a slitting gear wheel are installed on an upper side through bolts, two cutter shafts are vertically arranged in the middle of the support in sequence, blades are installed on the cutter shafts, rotating shafts are vertically and sequentially installed on the left side and the right side of the support through bolts, carrier rollers are fixedly connected with the rotating shafts, a flattening device is arranged at a left end of the base, a lower right corner of the flattening device is only provided with a winding device on a front side of the base, and an outer side of the winding device is sleeved with a plastic sleeve. The system is advantaged in that through a carrier roller structure, vertical vibration of steel material conveying is reduced, and a phenomenon of tool shifting cannot be caused; limiting is conducted through the thickness of a plurality of rolled steel strips by means of aplastic sleeve on an outer side of the winding device, so the rolled steel strips are consistent in diameter and easy to store; by arranging pipe coil packing belt scissors and a longitudinal shearingpacking storage device, the sheared strip steels are easy to pack and store.

Owner:重庆兰羚天和科技股份有限公司

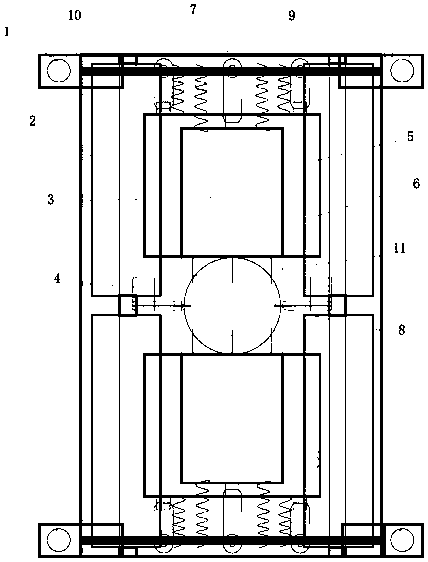

A Deep Well Drilling Mechanism Based on Uphole Pressure Applied Automatically Strengthening the Drill Bit

ActiveCN105804666BExtended service lifeCompact structureDrill bitsDrilling rodsWell drillingElectric machinery

The invention belongs to the technical field of well drilling and particularly relates to an over-well pressure applying deep well drilling mechanism based on an automatic reinforced drill bit. The over-well pressure applying deep well drilling mechanism comprises an over-well pressure applying mechanism, a drill rod positioning mechanism and the automatic reinforced drill bit. The drill rod positioning mechanism is installed on a drill rod of the over-well pressure applying mechanism. The automatic reinforced drill bit is installed at the bottom end of the drill rod of the over-well pressure applying mechanism. The over-well pressure applying mechanism applies pressure through thread fit of a threaded structure, and has the advantages of being small in size and easy to control. A drill rod connecting mechanism is compact in structure, the effect that the diameter of the junction is identical to that of a drill rod body can be guaranteed, and the situation that the surface of a drilled well is damaged due to an excessively large drill rod connecting structure is avoided. Three sets of extension bars are adopted by the drill rod positioning mechanism so the drill rod can be positioned in the center, and the well surface can be reinforced through pressing wheels. The automatic reinforced drill bit can automatically adjust reinforcing pieces through a control motor according to the hardness of rock, and accordingly the service life of the drill bit is prolonged. A whole well drilling platform has a good practical effect.

Owner:南通博鎏机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com