Novel slitting machine system

A slitting machine and a new type of technology, applied in shearing machine equipment, shearing devices, accessories of shearing machines, etc., can solve the problems of running knife, inaccurate width of cut material, and different diameters of steel strips. Achieve the effect of meeting cutting requirements, easy to pack and store, and accurate material width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0037] Aiming at the problems existing in the prior art, the present invention provides a novel slitting machine system. The present invention will be described in detail below in conjunction with the accompanying drawings.

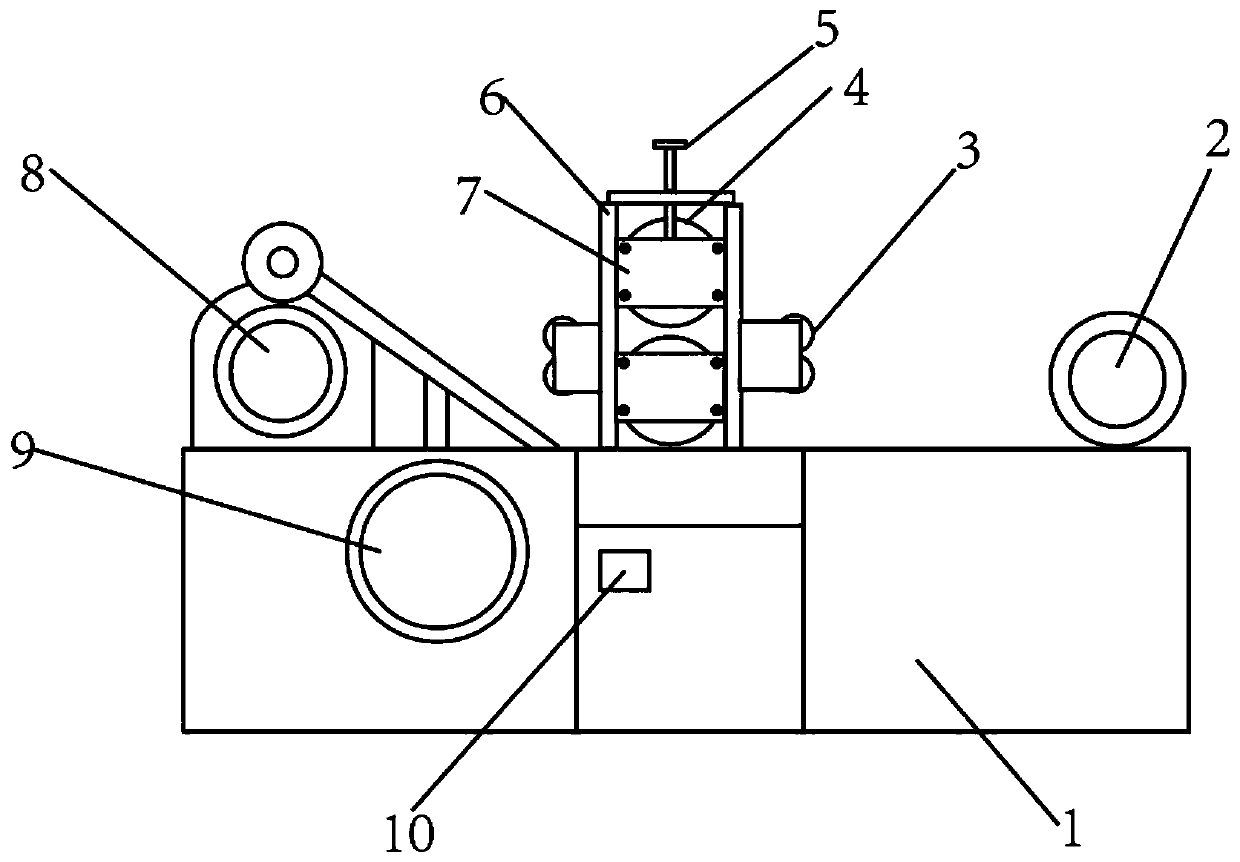

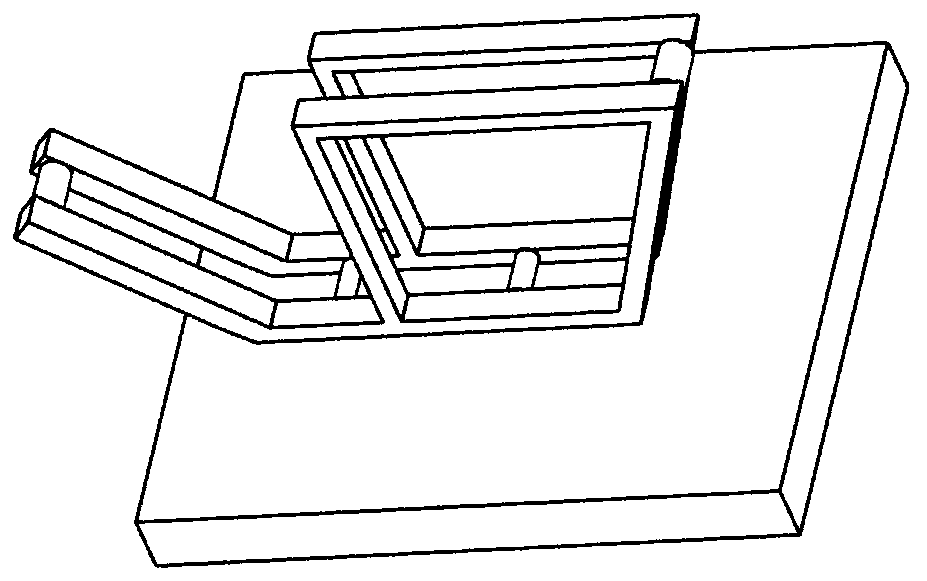

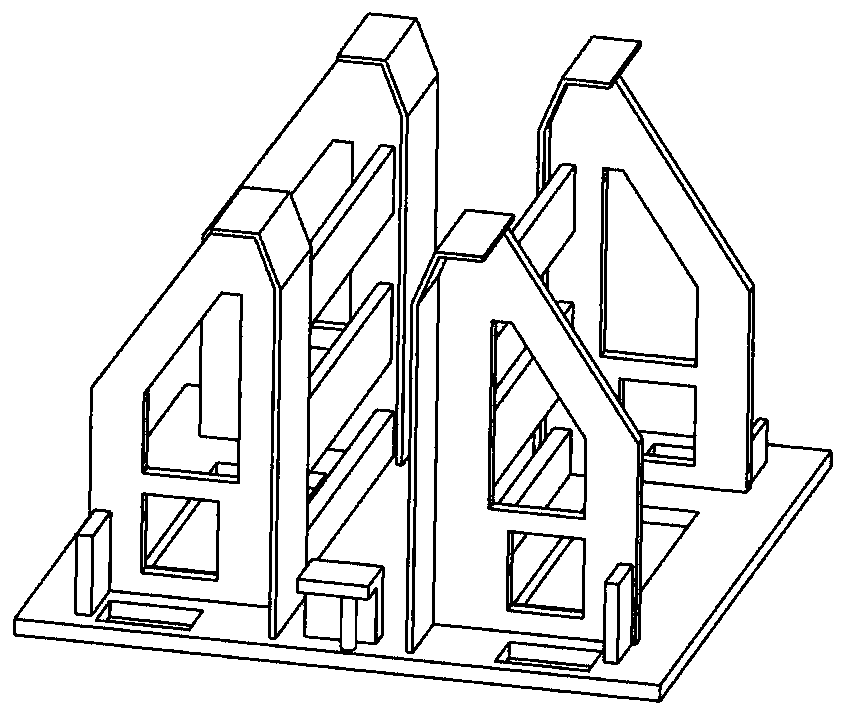

[0038] like Figure 1 to Figure 5 As shown, a new type of slitting machine system includes a base 1, an uncoiler 2 is arranged at the right end of the base 1; a slitting machine detection module 10 is arranged on the front side of the middle part, and a bracket 6 and a slitting machine are installed on the upper side through bolts. Gear wheel, the middle part of the support 6 is provided with two cutter shafts 4 up and down, blades are installed on the shaft, and the left and right sides of the support 6 are sequentially installed with ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com