Rotary driving and pushing mechanism for well-drilling drill column

A technology of rotary drive and push mechanism, which is applied to the driving device for drilling in the wellbore, drilling equipment, drill pipe, etc., which can solve the problems of trouble, damage to the well body, high manufacturing cost and high use cost of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

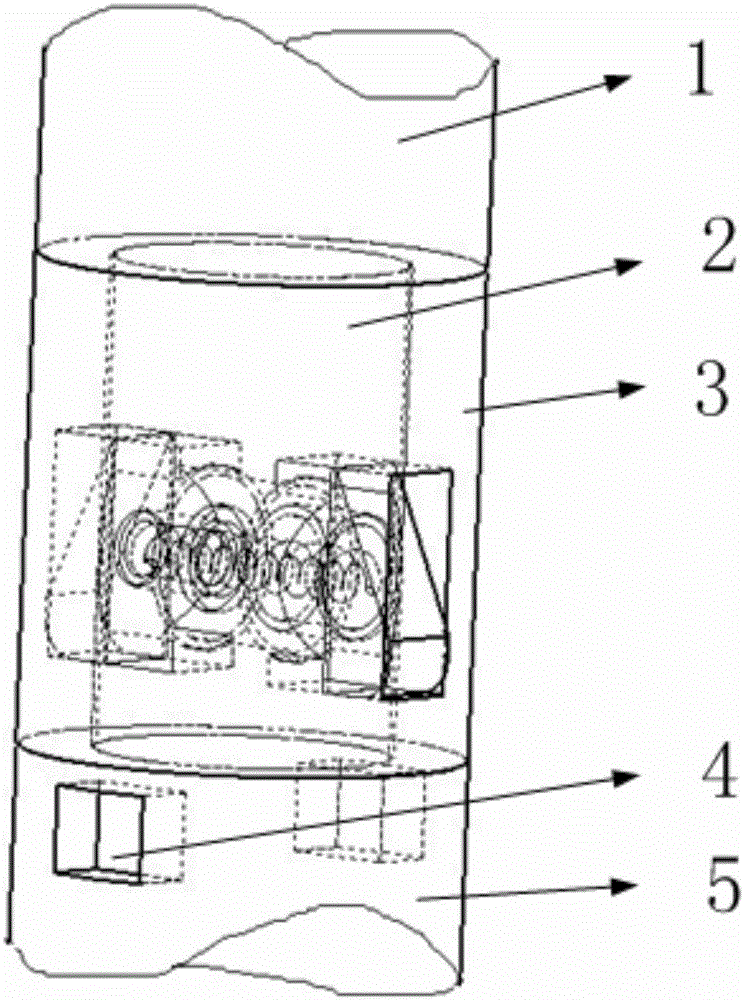

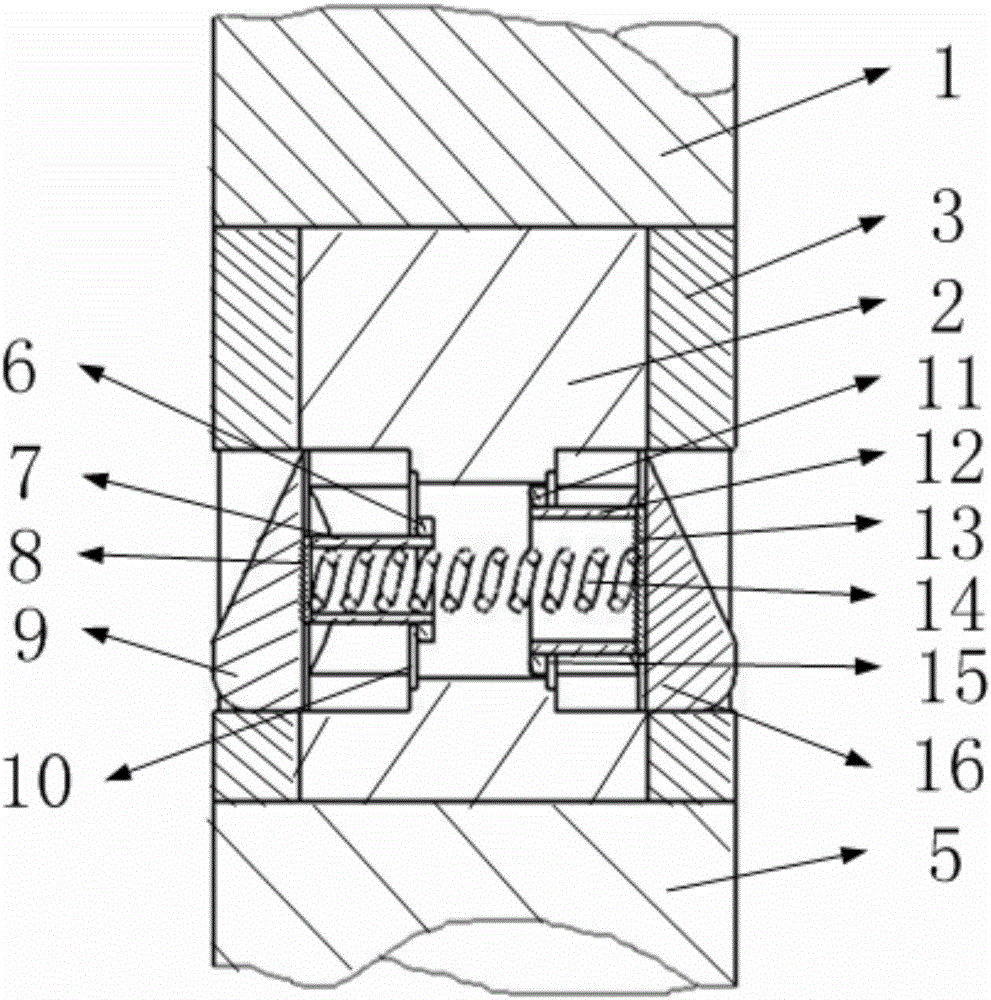

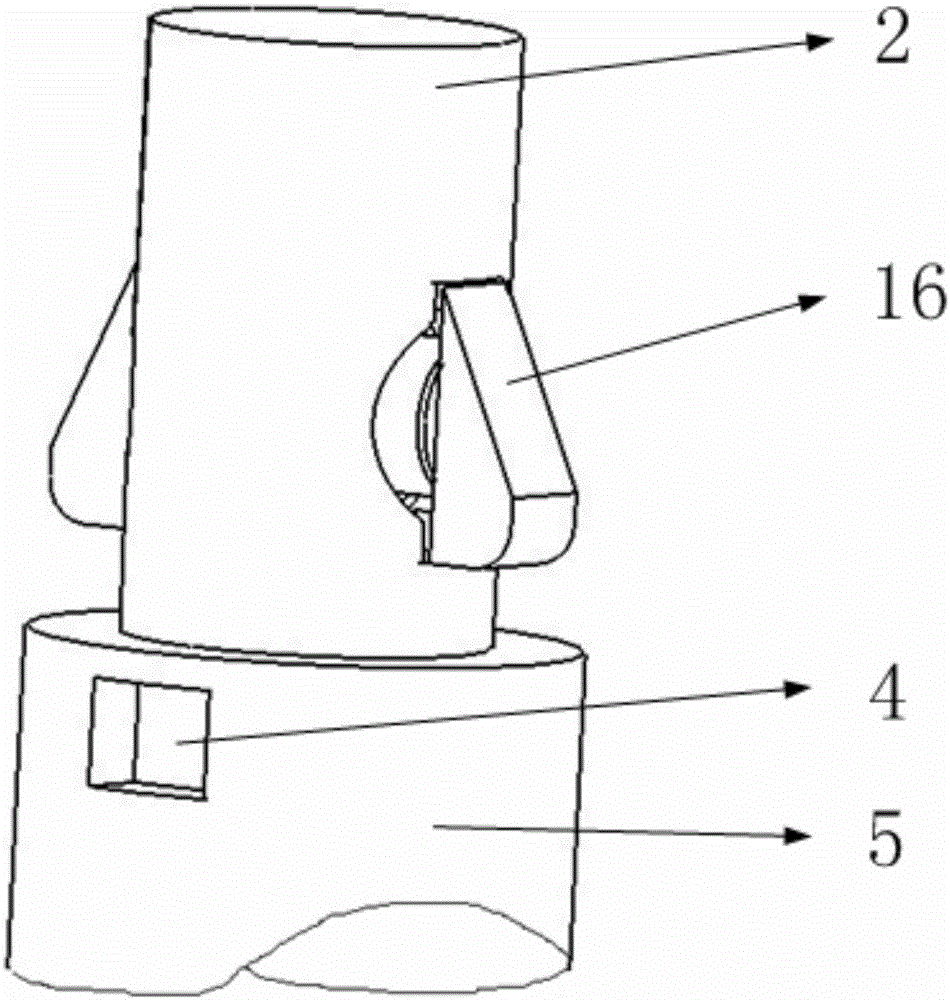

[0037] Such as Figure 11 As shown, it includes a drill pipe fixing mechanism, a driving motor, a driving motor fixing structure, a push hydraulic rod, a hollow drive shaft, a drill pipe connection structure, a hydraulic rod fixed support, and a drill pipe body. Two of the push hydraulic rods are installed in a complete manner. Similarly, for any one of them, one end of the push hydraulic rod is installed on the fixed support of the hydraulic rod fixed on the ground, and the other end of the push hydraulic rod is installed on the fixed structure of the drive motor; Figure 12 As shown, the two driving motor fixing structures are symmetrically installed on the driving motor. The rotating shaft of the driving motor is a hollow driving rotating shaft. Shorter; the above-mentioned drill pipe shafts are solid cylinders; any two drill pipe shafts are connected by a drill pipe connecting structure.

[0038] The above-mentioned two drill rod fixing mechanisms are symmetrically instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com