Riveting pressure detection device

A detection device and riveting technology, which is applied in the direction of measuring device, optical device exploration, optical device, etc., can solve the problems of wasting manpower, damage to the workpiece, single and boring work, etc., to ensure the quality of riveting products, consistent diameter, The effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

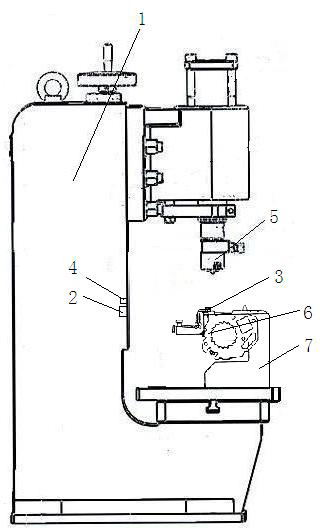

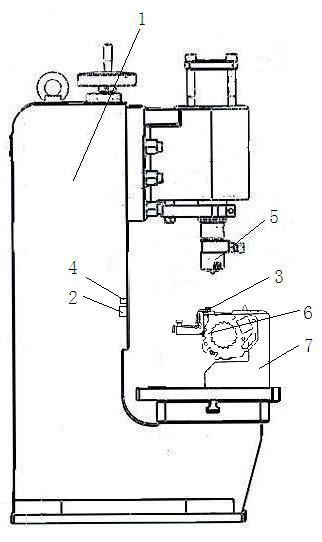

[0015] Such as figure 1 As shown, the riveting pressure detection device of the present invention includes a laser sensor 2 arranged on a fixed frame 1, and the laser light emitted by the laser sensor 2 points to the position of the rivet 3 to be riveted.

[0016] The fixed frame 1 is also provided with a sensor 4 for detecting the height of the riveting point of the rivet after riveting,

[0017] Both the laser sensor 2 and the sensor 4 are connected to a control unit. The signals detected by the laser sensor 2 and the sensor 4 are all transmitted to the control unit, and the control unit controls the flow direction of the press and the workpiece according to the detected signals.

[0018] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com