Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

167results about How to "Reliable formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

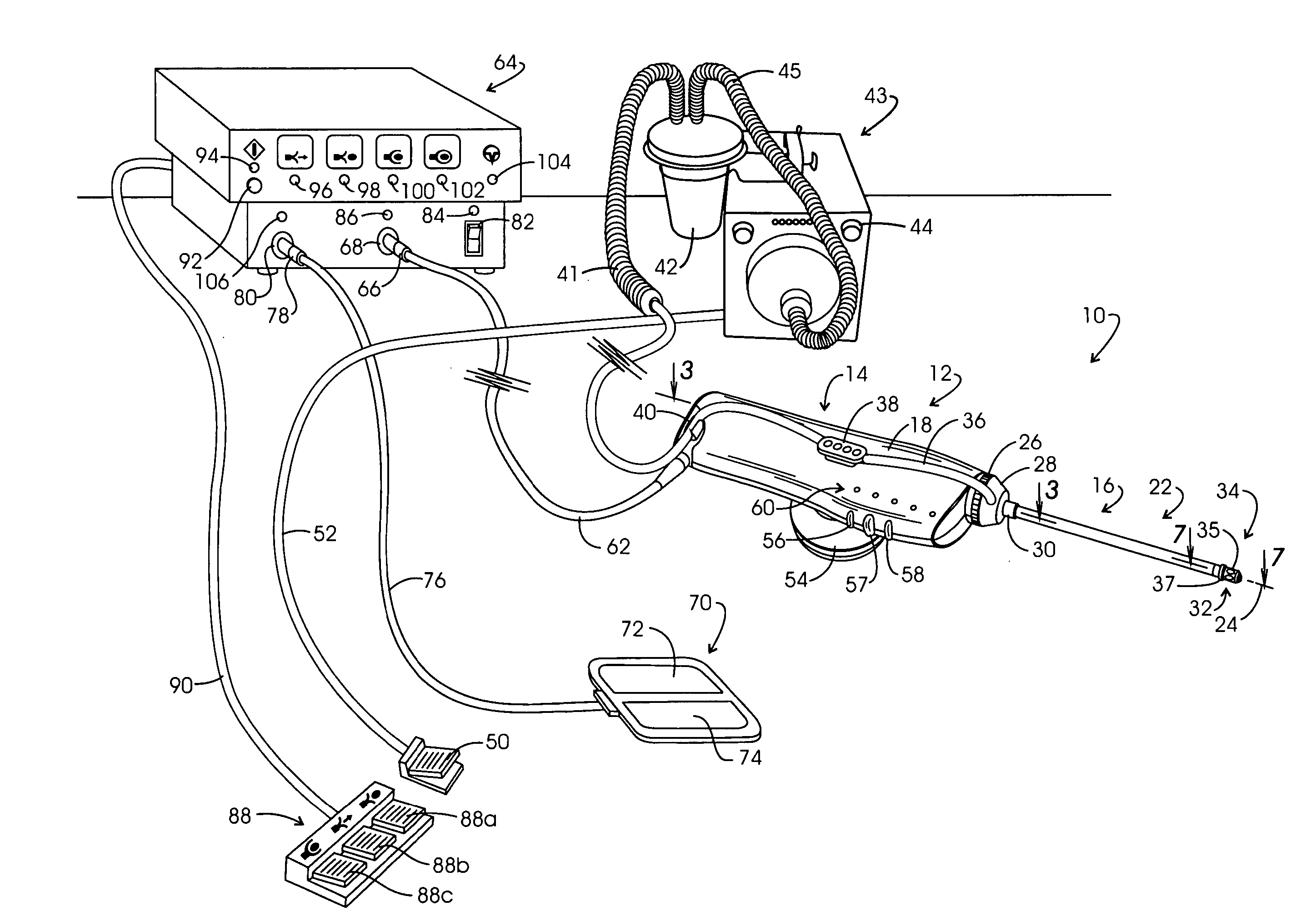

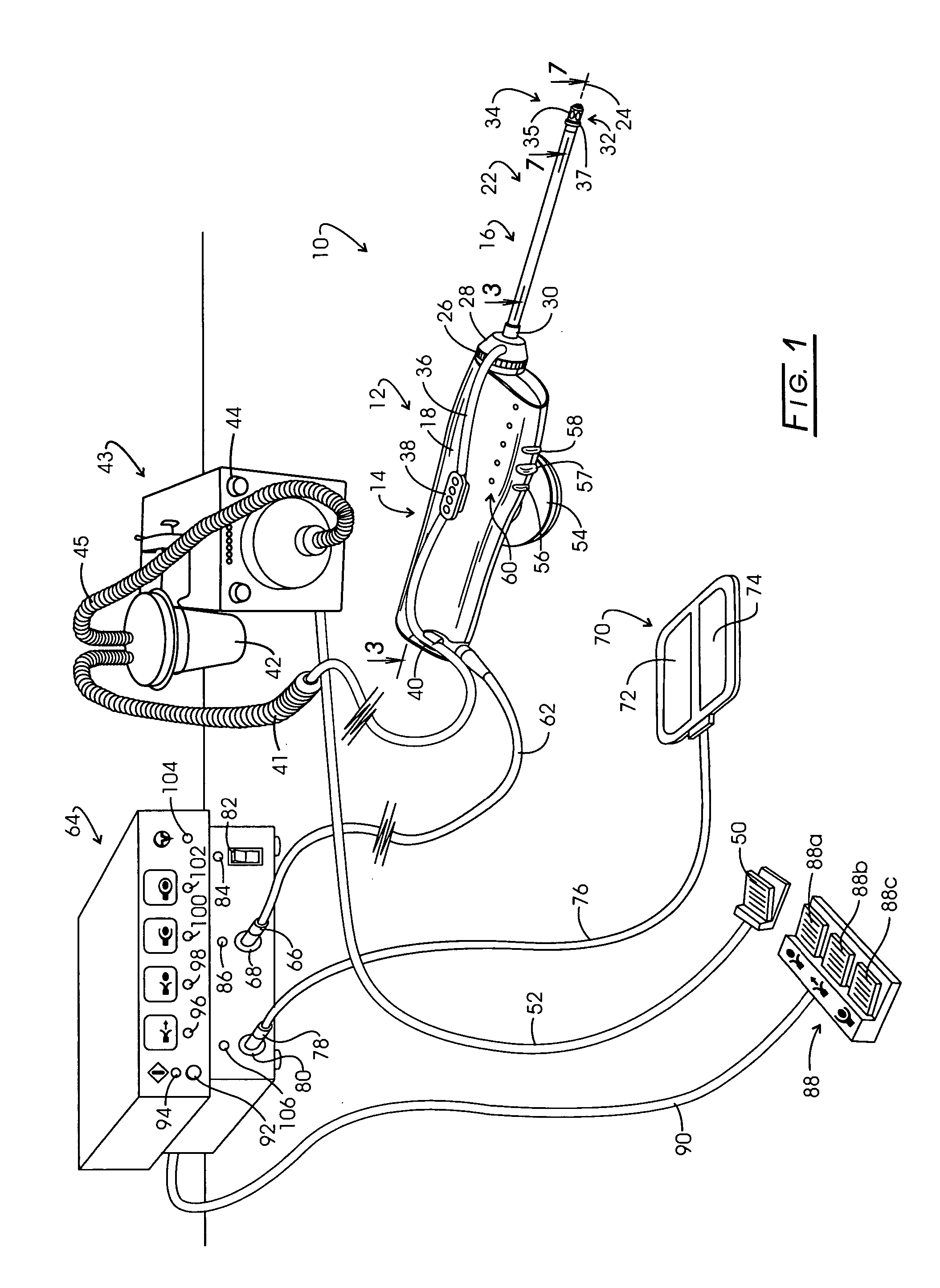

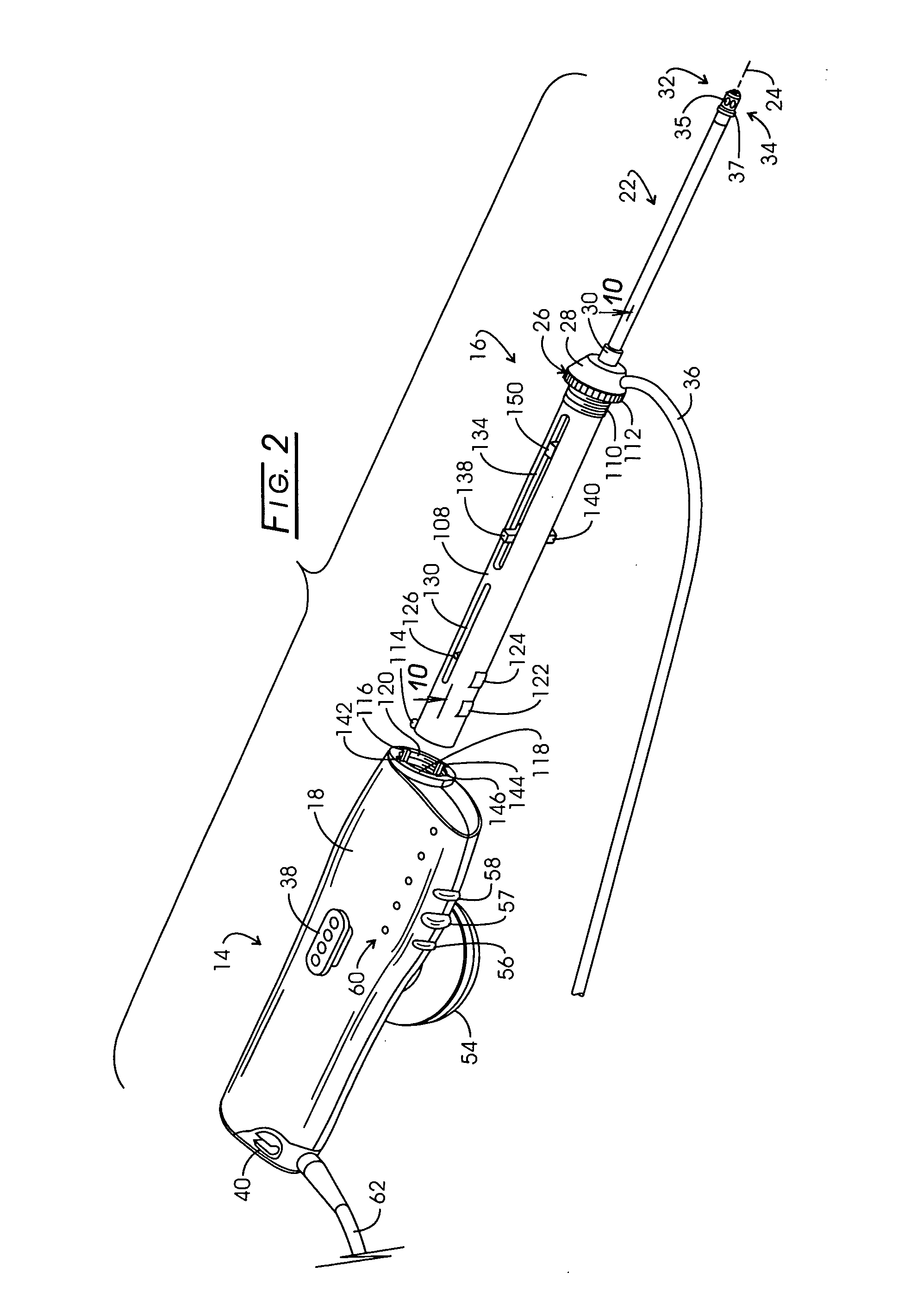

Electrosurgery with infiltration anesthesia

InactiveUS20050267455A1Reliable formationAnaesthesiaSurgical instruments for heatingElectrical resistance and conductanceElectrosurgery

Method for carrying out the recovery of an intact volume of tissue wherein a delivery cannula tip is positioned in confronting adjacency with the volume of tissue to be recovered. The electrosurgical generator employed to form an arc at a capture component extending from the tip is configured having a resistance-power profile which permits recovery of the specimen without excessive thermal artifact while providing sufficient power to sustain a cutting arc. For the recovery procedure, a local anesthetic employing a diluent which exhibits a higher resistivity is utilized and the method for deploying the capture component involves an intermittent formation of a cutting arc with capture component actuation interspersed with pauses of duration effective to evacuate any accumulation or pockets of local anesthetic solution encountered by the cutting electrodes.

Owner:INTACT MEDICAL

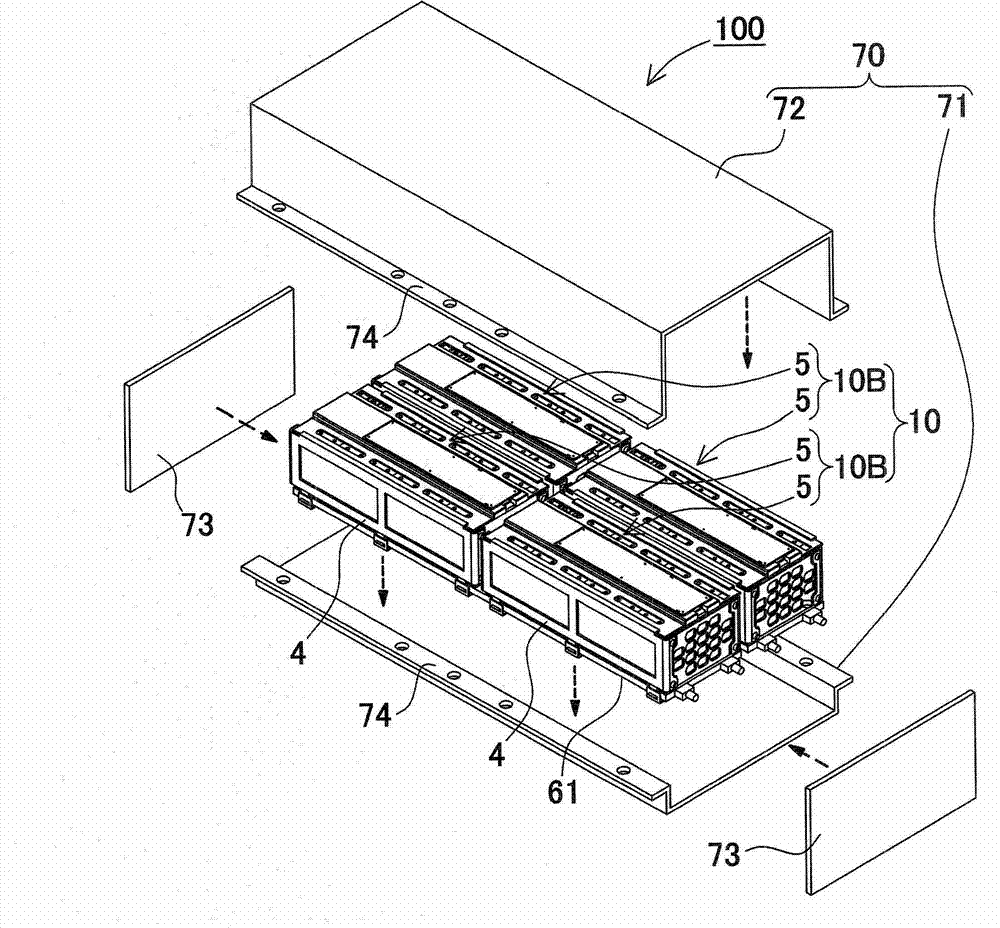

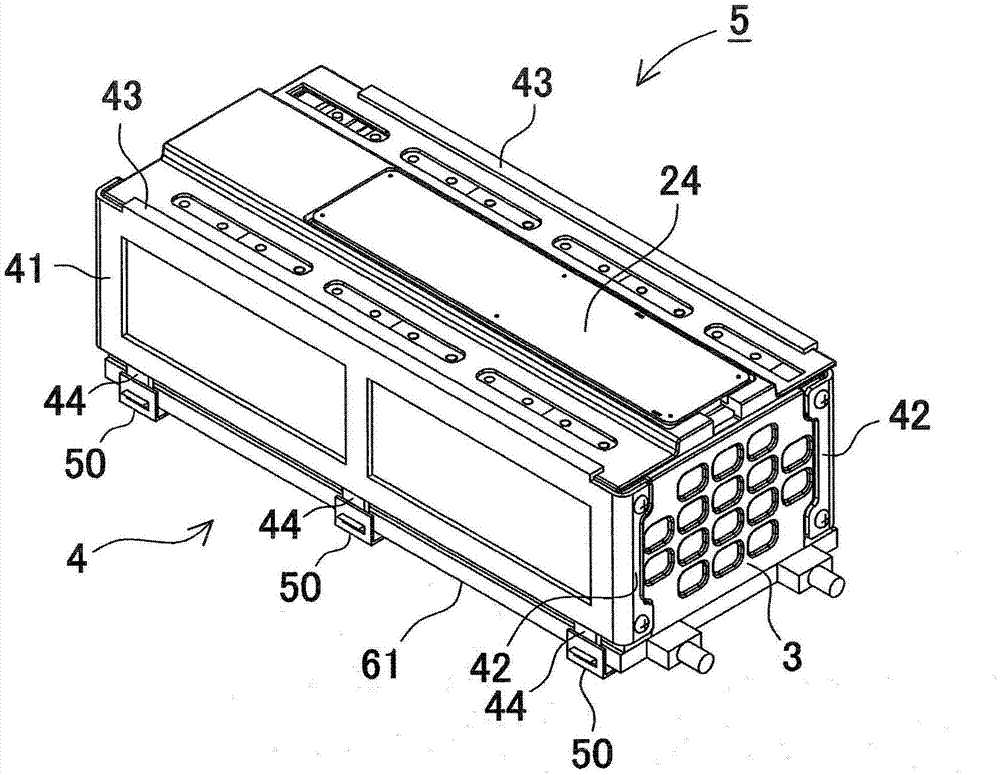

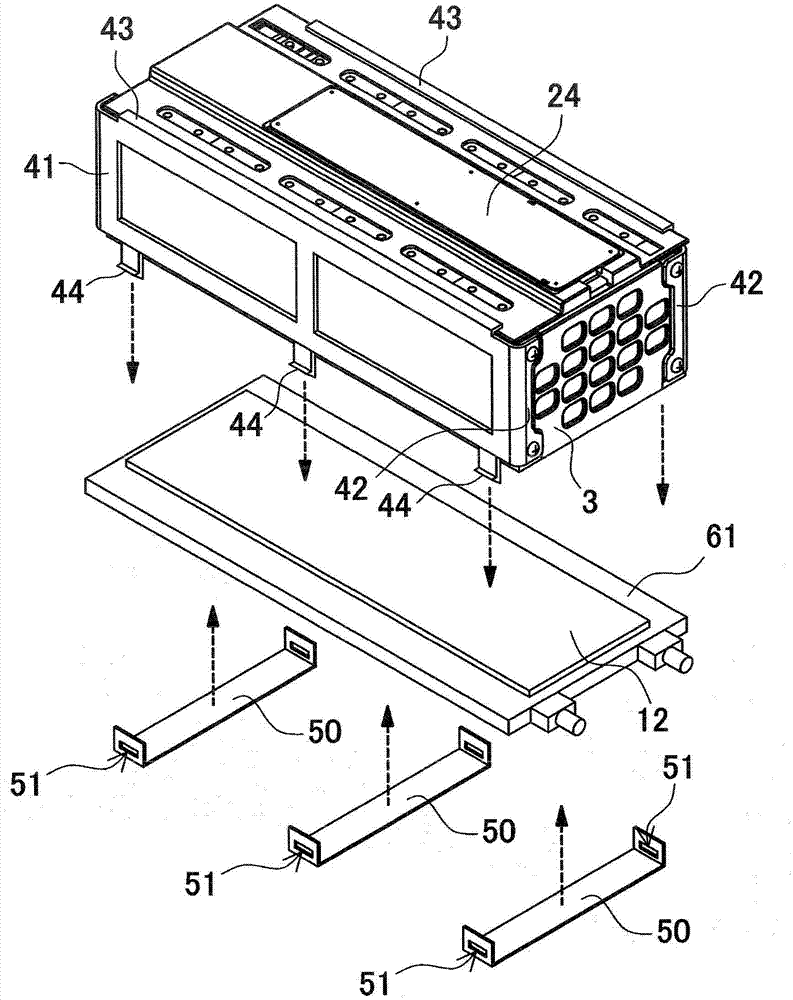

Power supply device and vehicle including the same

InactiveCN102856516AReduce gapReliable formationCell temperature controlBattery isolationMoisture condensationEngineering

The invention provides a power supply device and a vehicle including the same, the condition of moisture condensation at the surface of a battery unit can be prevented, and thermal coupling of the battery unit and a cooling plate (61) can also be maintained. The power supply device includes a battery assembly (5), a box-shaped cover case (16), a cooling plate (61), and a waterproof sheet (19). The battery assembly (5) includes rectangular battery cells (1) arranged side by side. Exterior surfaces of the battery assembly (5) are covered with surfaces of the cover case (16) other than the local of one surface. The cooling plate (61) is thermally coupled to one surface of the battery assembly (5). Coolant flows through the cooling plate (61) whereby transferring heat from the battery assembly (5) to the coolant. The waterproof sheet (19) covers the one surface of the battery assembly (5). Gaps between the battery assembly (5) and the cover case (16) are filled with a sealing material so that a sealing layer (18) is interposed between them. The waterproof sheet (19) is fastened by the sealing layer (18).

Owner:SANYO ELECTRIC CO LTD

Fastening strip and fastening network framework

ActiveCN101457572AGuaranteed pouringSolve the problem of convenient and quick fixWallsForms/shuttering/falseworksFloor slabStructural element

The invention relates to a blocking strip and a blocking net framework. The blocking strip comprises at least two strip sides, at least one of which is provided with convex teeth that are provided with breaches, the breaches are internally provided with agnails or barbs. The blocking net framework can be made by applying the blocking strip, and is formed by connecting keels, the blocking strip and a steel screen in a combining way. The keels are section steel parts and are arranged in parallel according to certain spacing; the blocking strips are vertical to the keels, arranged in parallel according to certain spacing and are fixed at one side or two sides of the keels to form a steel frame; the steel screen is distributed with a longitudinal convex rib as well as fish scales holes or meshes on the surface; the steel screen is attached to the outer surface of the steel frame, and is firmly and conveniently blocked and connected with the blocking strip. The invention solves the problems of composition and construction of a steel screen concrete member as well as the reinforcement of a steel screen concrete wall body. Meanwhile, the invention realizes large-scale and mechanized production, and is suitable for various building structural elements, especially for the structures of multilayer and high residential building wall bodies and floor slabs.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +1

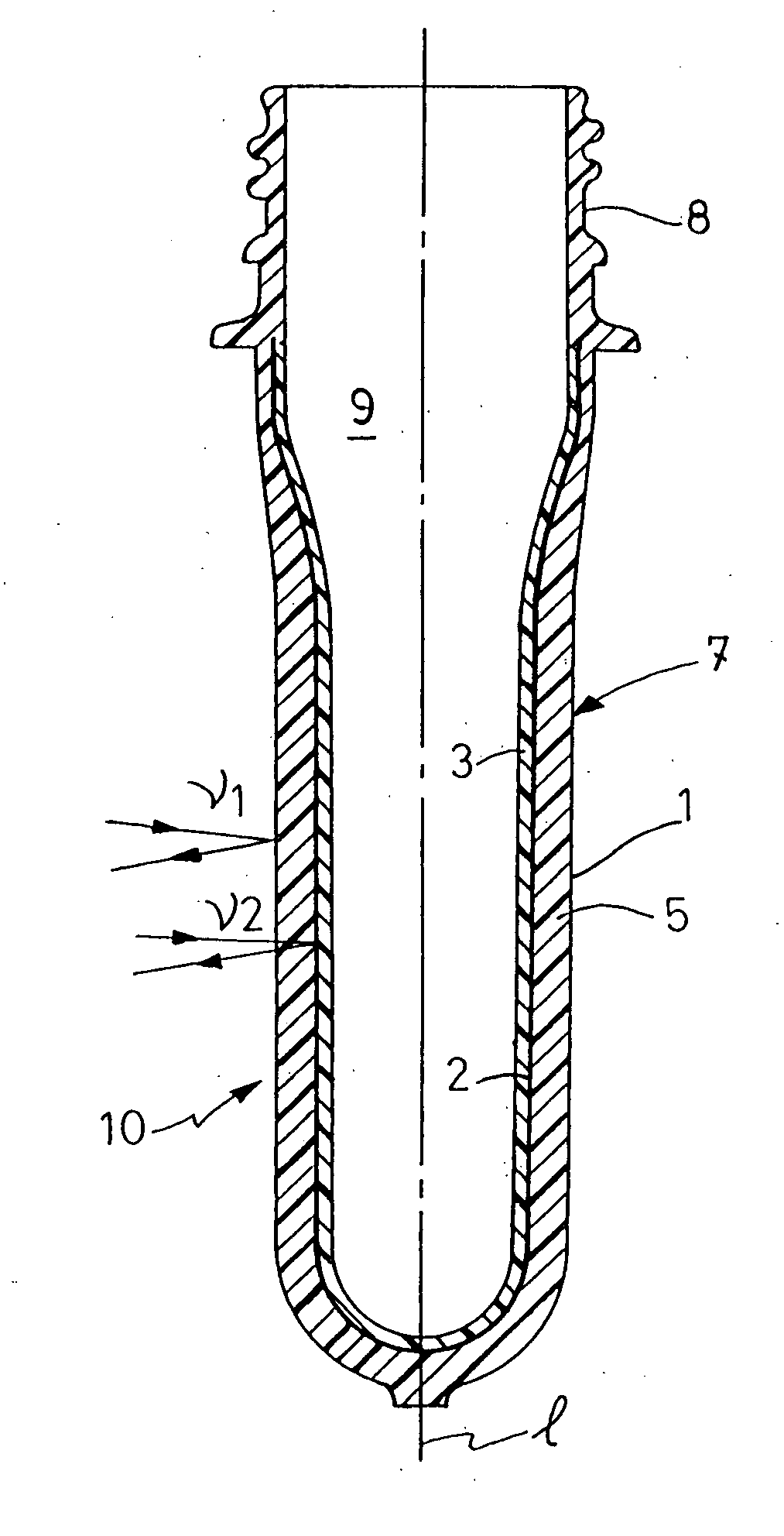

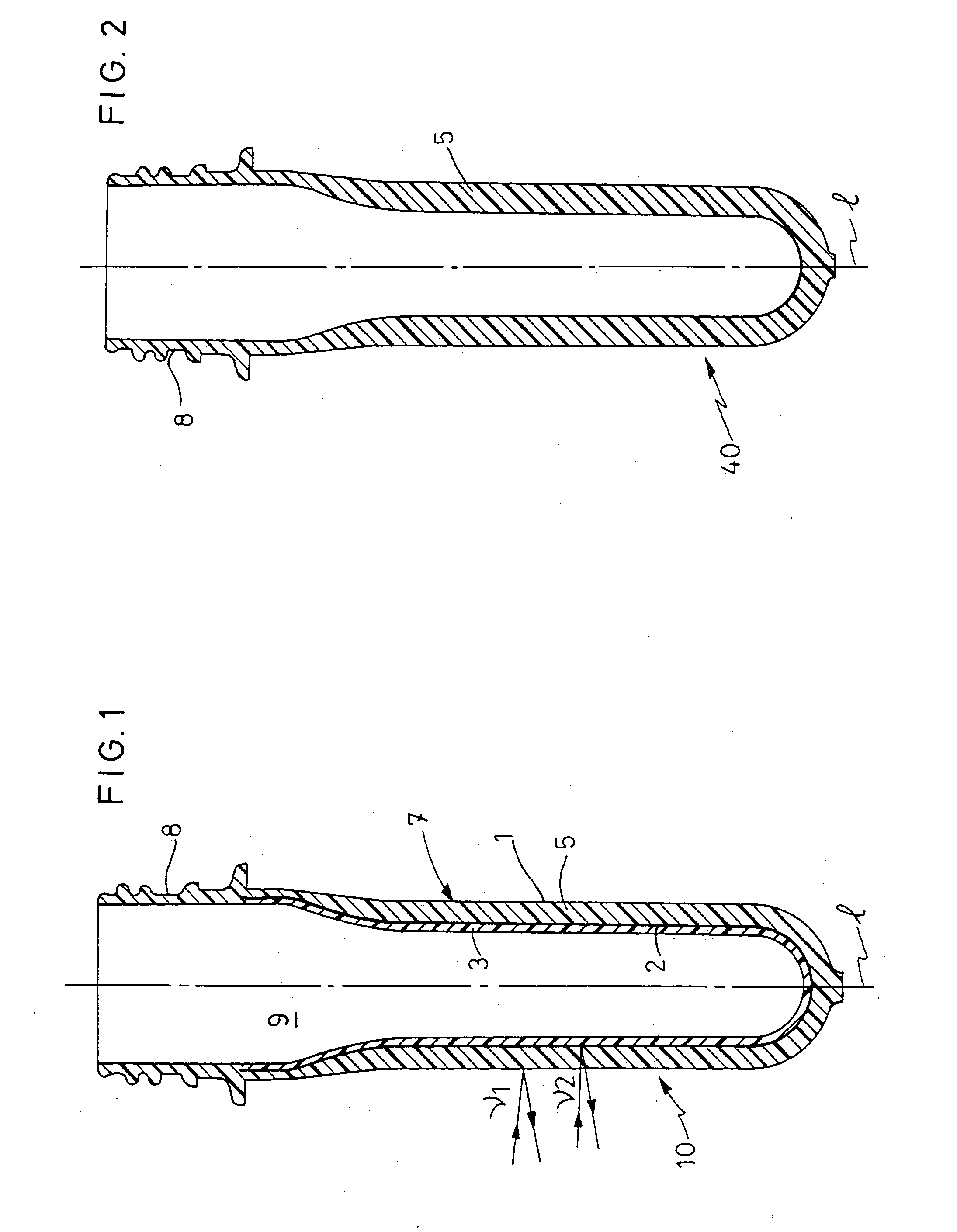

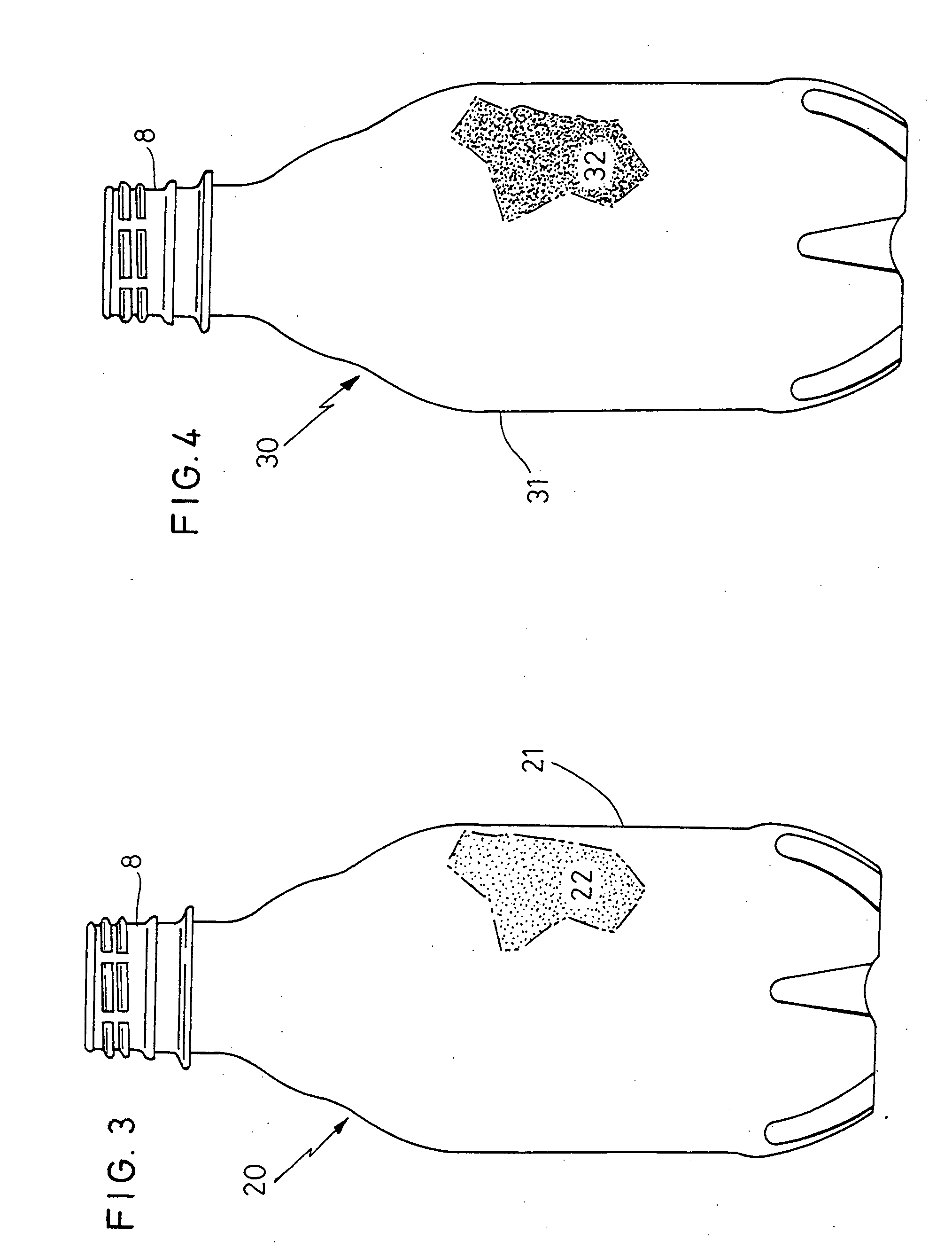

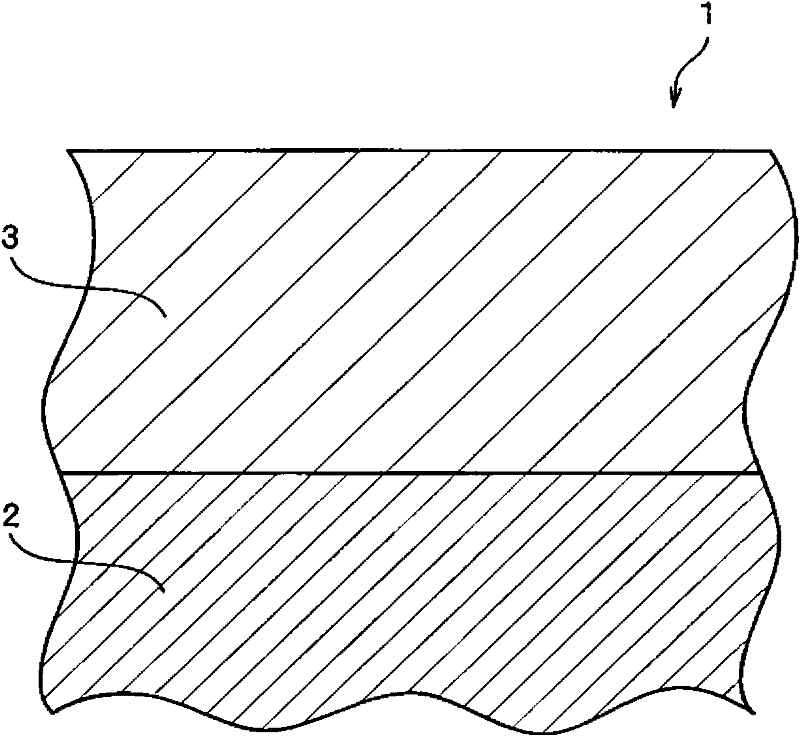

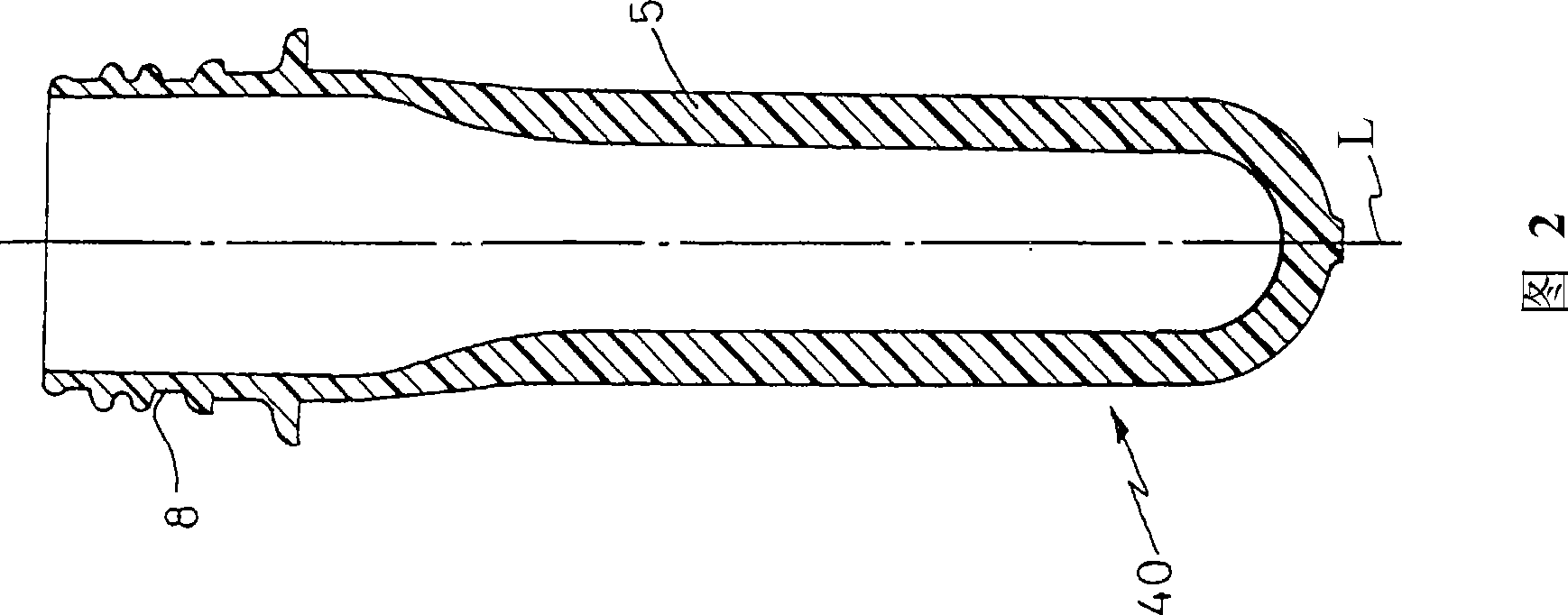

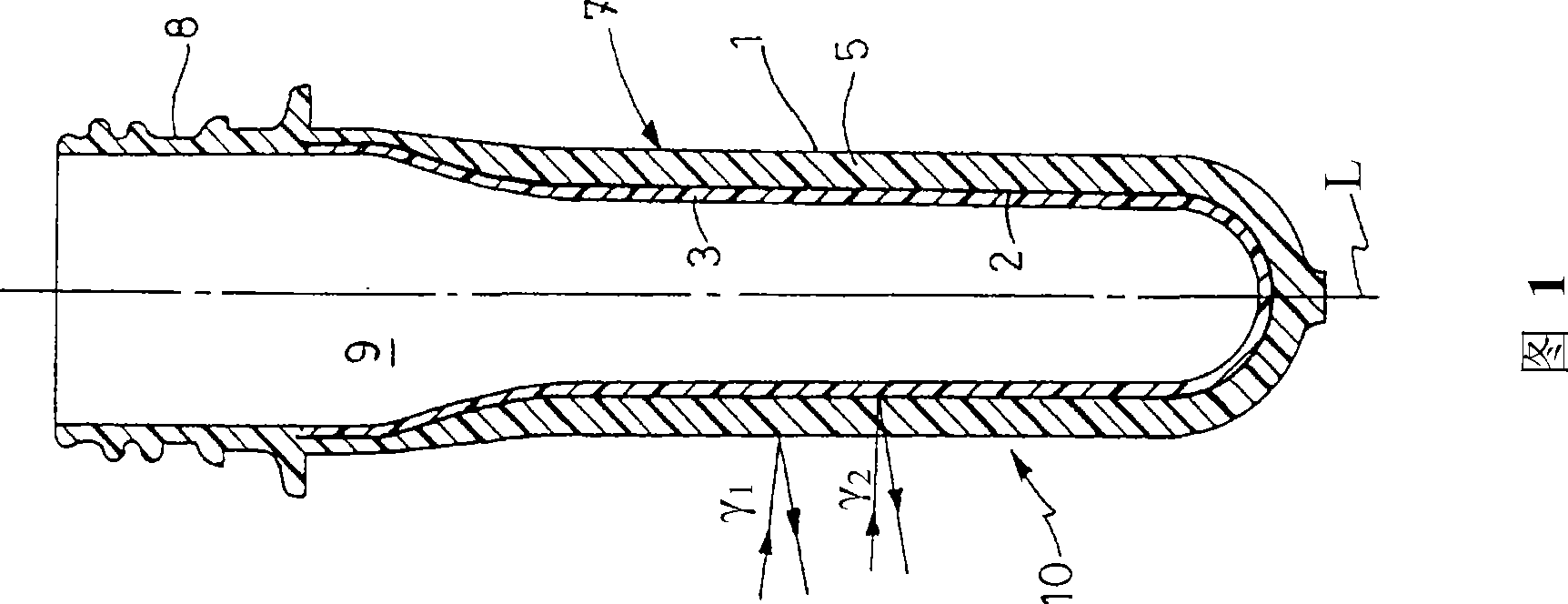

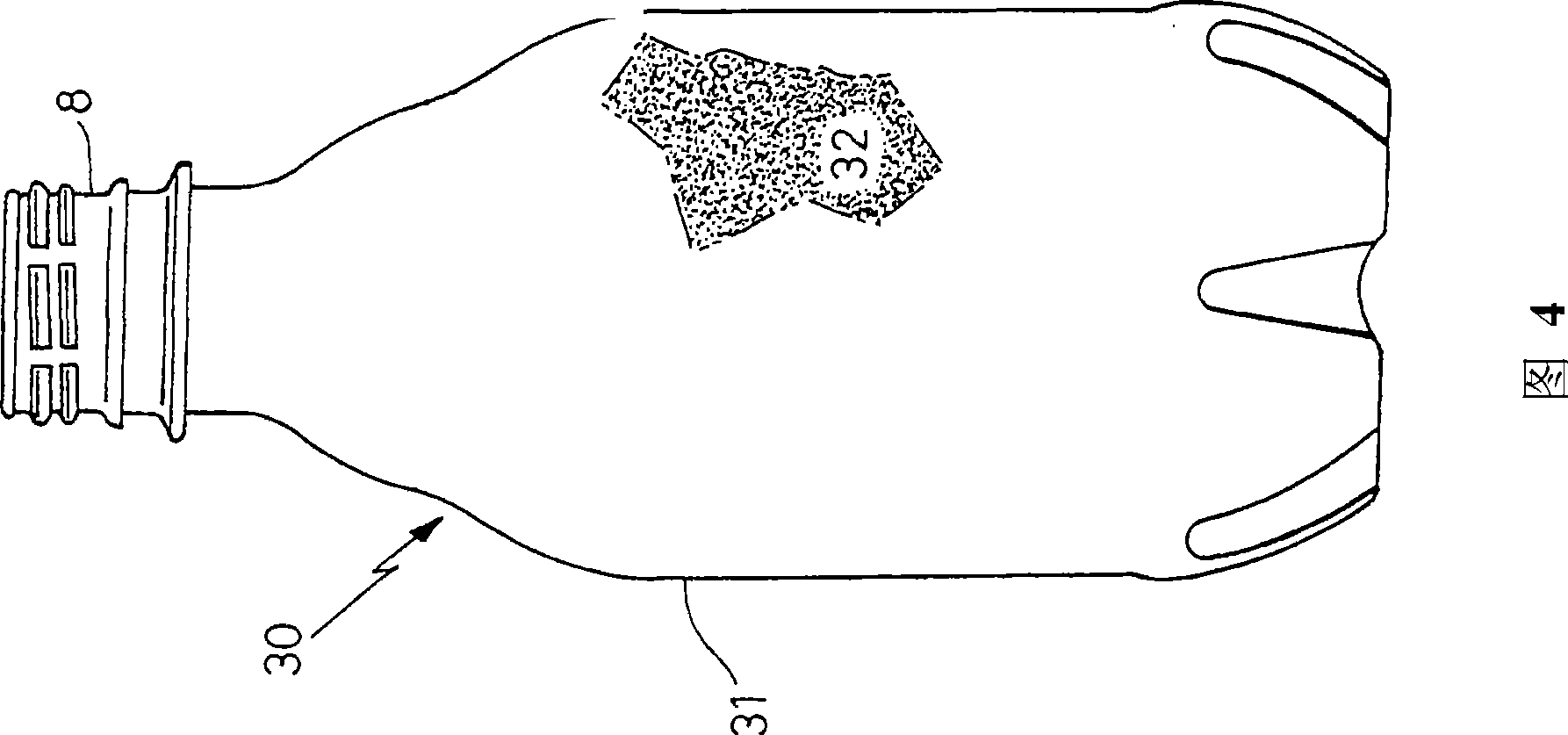

Preform and Container for Radiosensitive Products and Method for the Manufacturing Thereof

InactiveUS20090169786A1Easily and directly convertedEfficient light barrier propertyHollow wall articlesBeltsBiomedical engineeringRadiation

Preform, serving as a semi-finished product, for a container intended for containing products therein that are sensitive to radiation in particular light sensitive and food and dairy products, consisting of at least one base layer (1) made of a primary plastic base material, with a certain amount of additives (5) incorporated in it (1), characterised in that said preform (10, 20) is opaque over virtually the whole extent thereof, wherein a relatively low percentage of plastic additives (5) is incorporated to generate sard opaque appearance (22), so as to protect the inner space (9) thereof which is delimitated by it against external radiation (V1, V2) particularly electromagnetic radiation, more particularly light, under normal pressure condition.

Owner:RESILUX NV

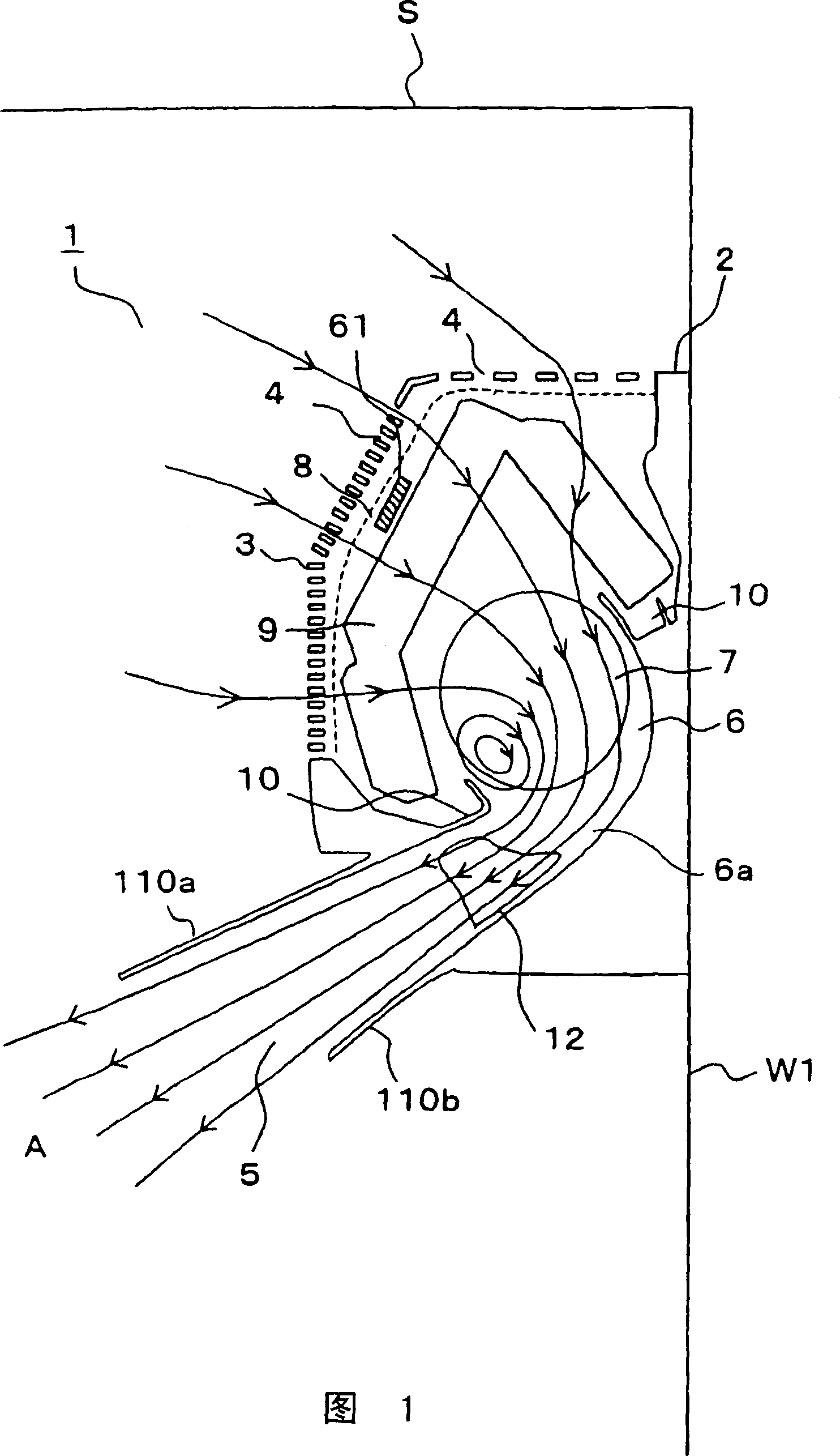

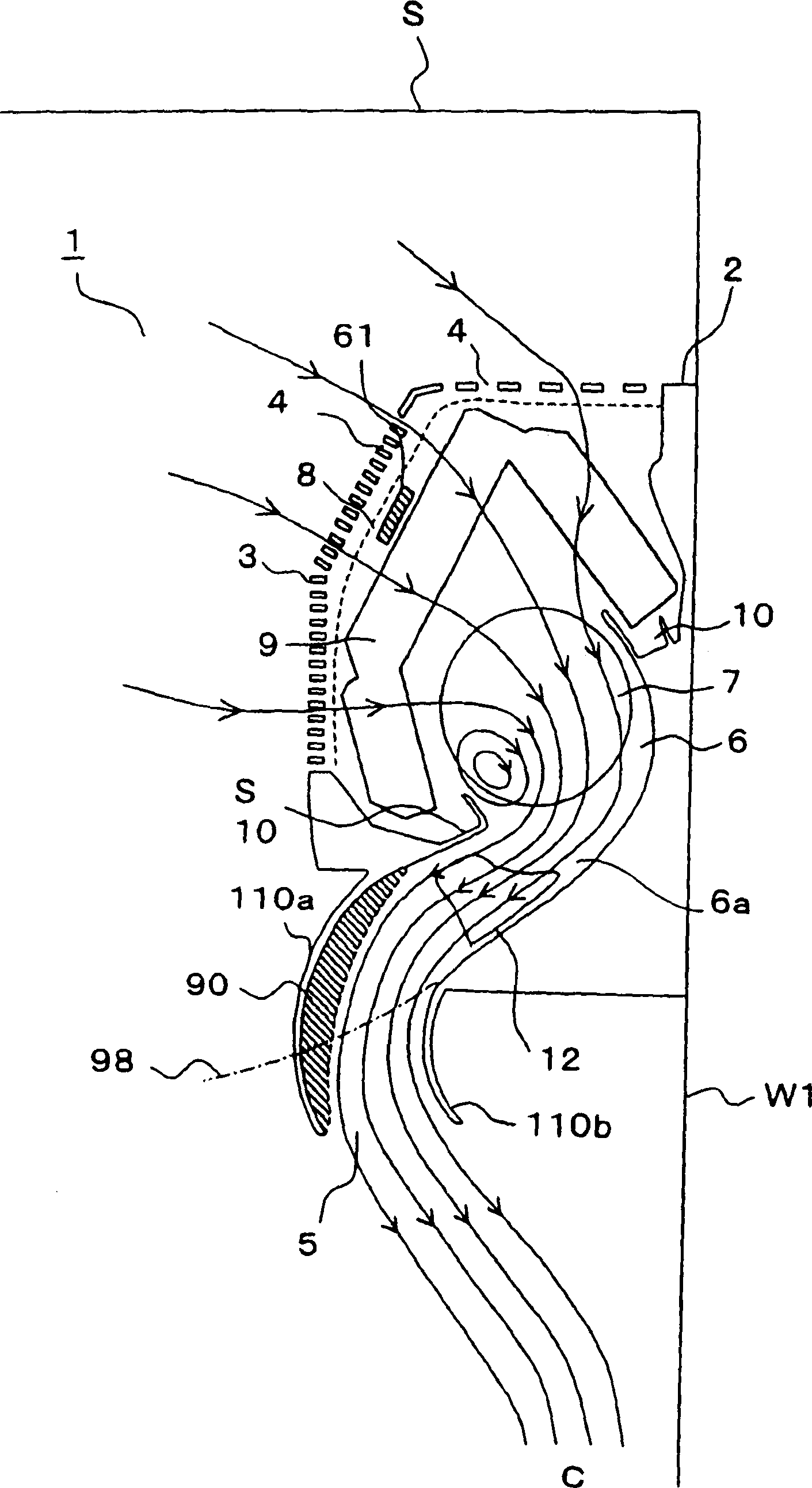

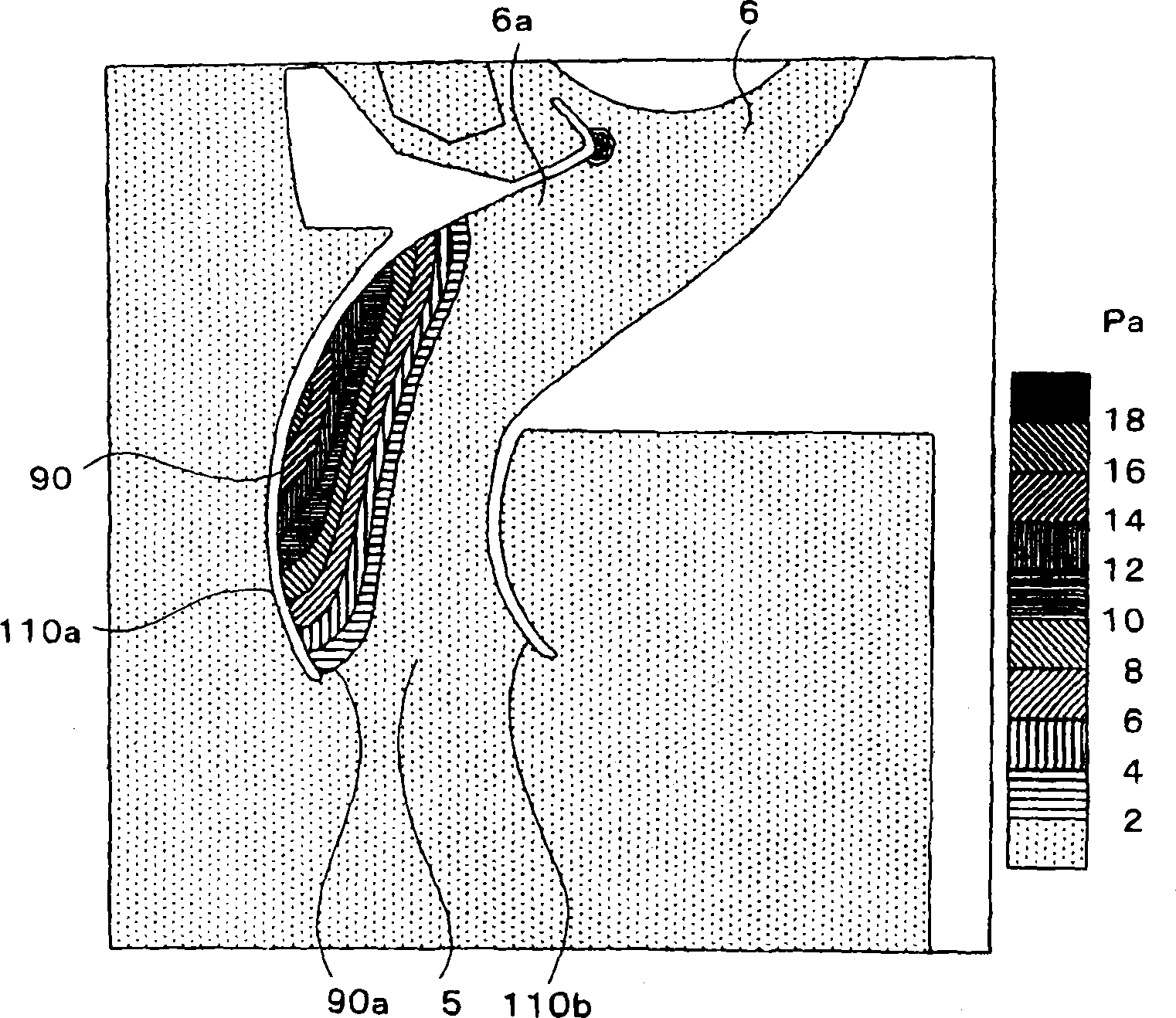

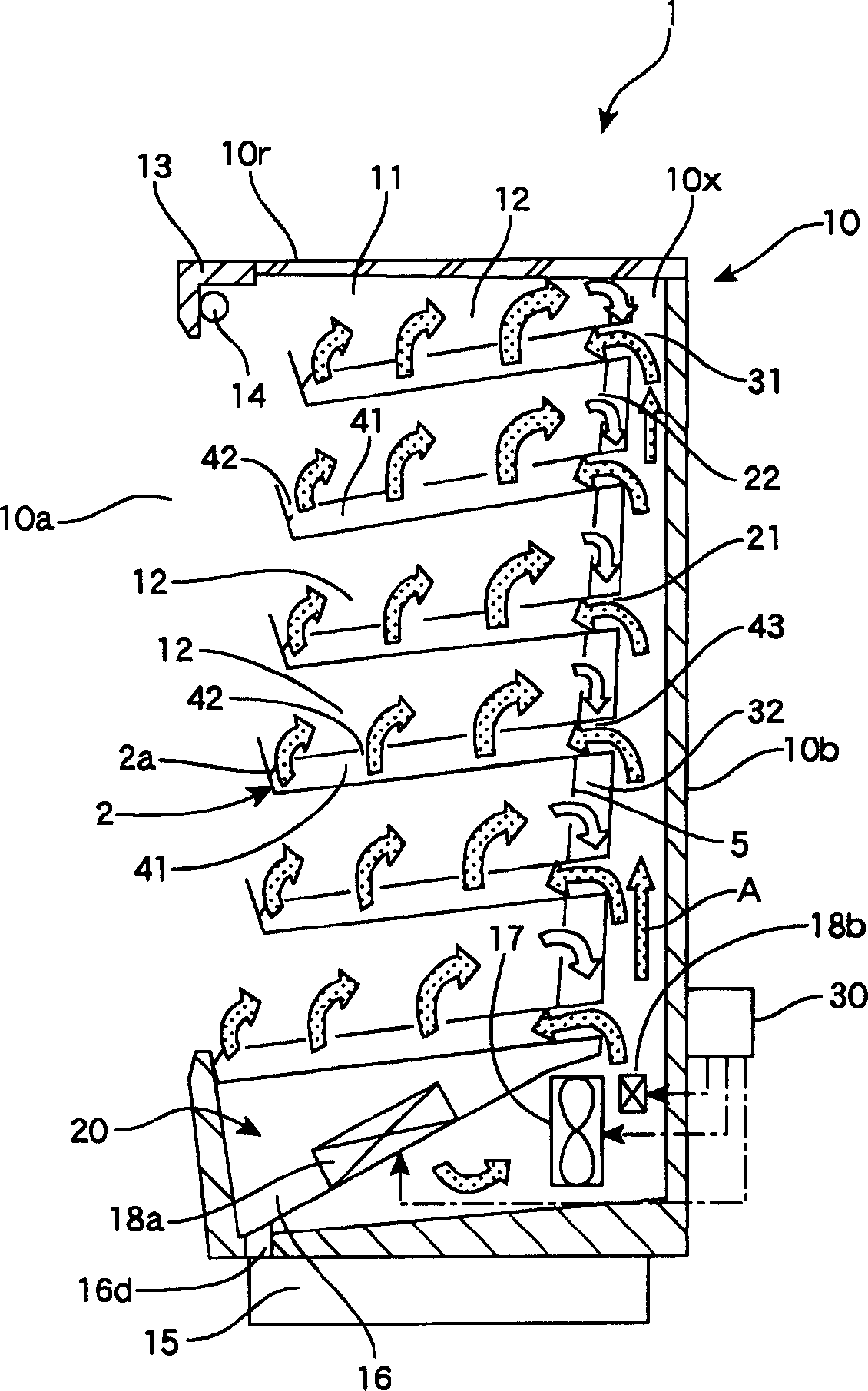

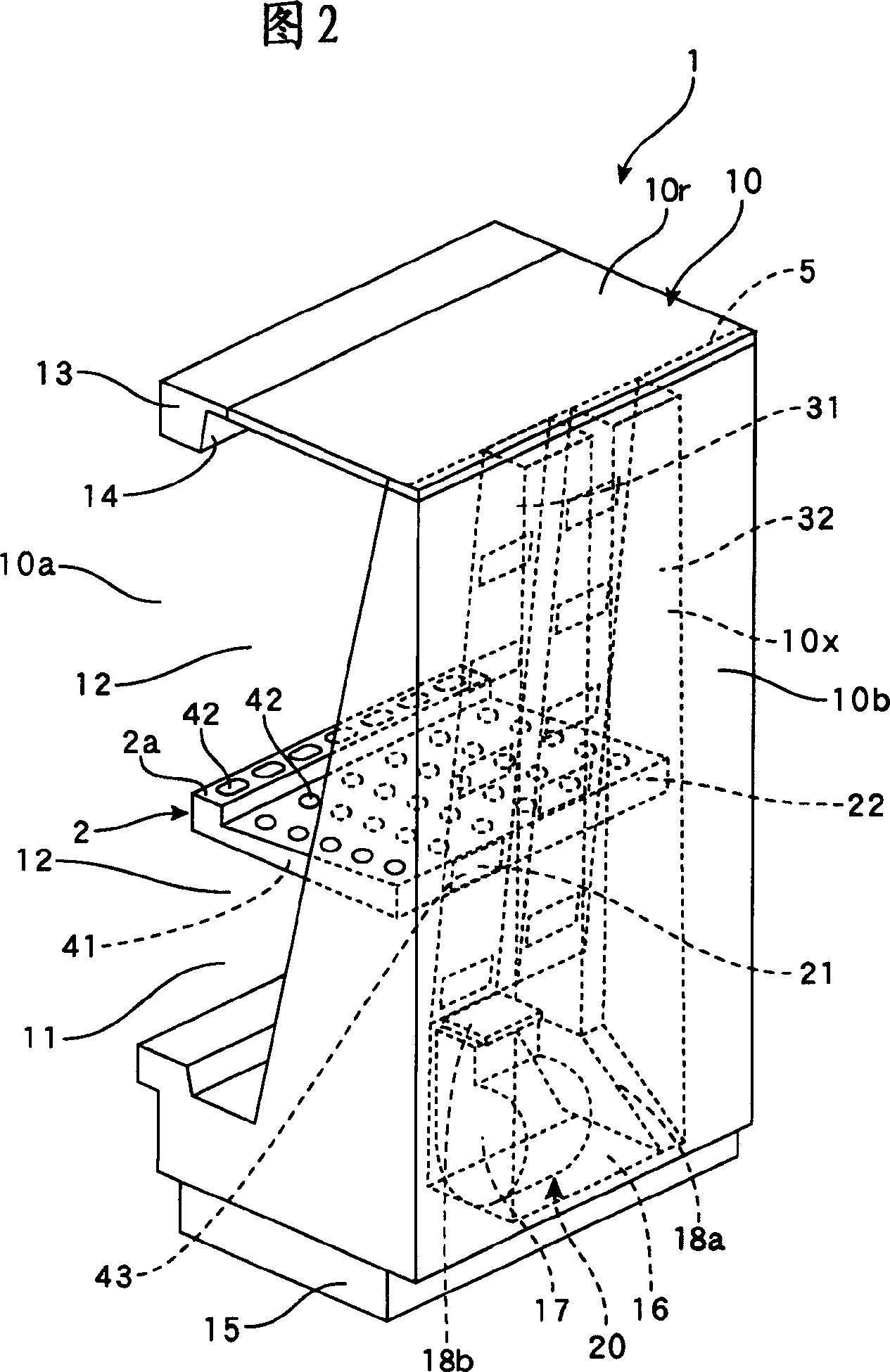

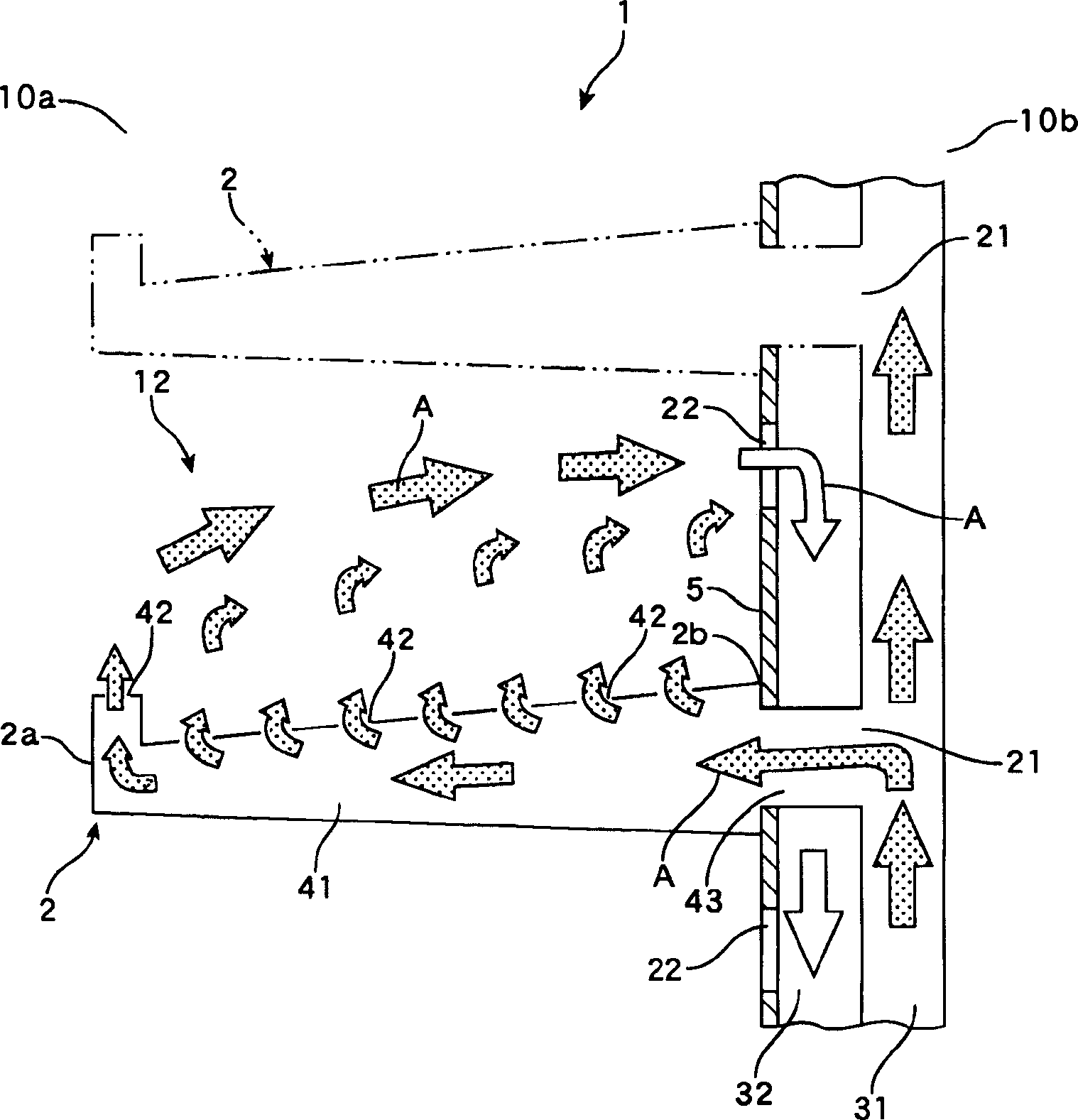

Air conditioner

ActiveCN1906447AEasy to change the wind directionSmall pressure lossDucting arrangementsLighting and heating apparatusEngineeringAir conditioning

Owner:SHARP KK

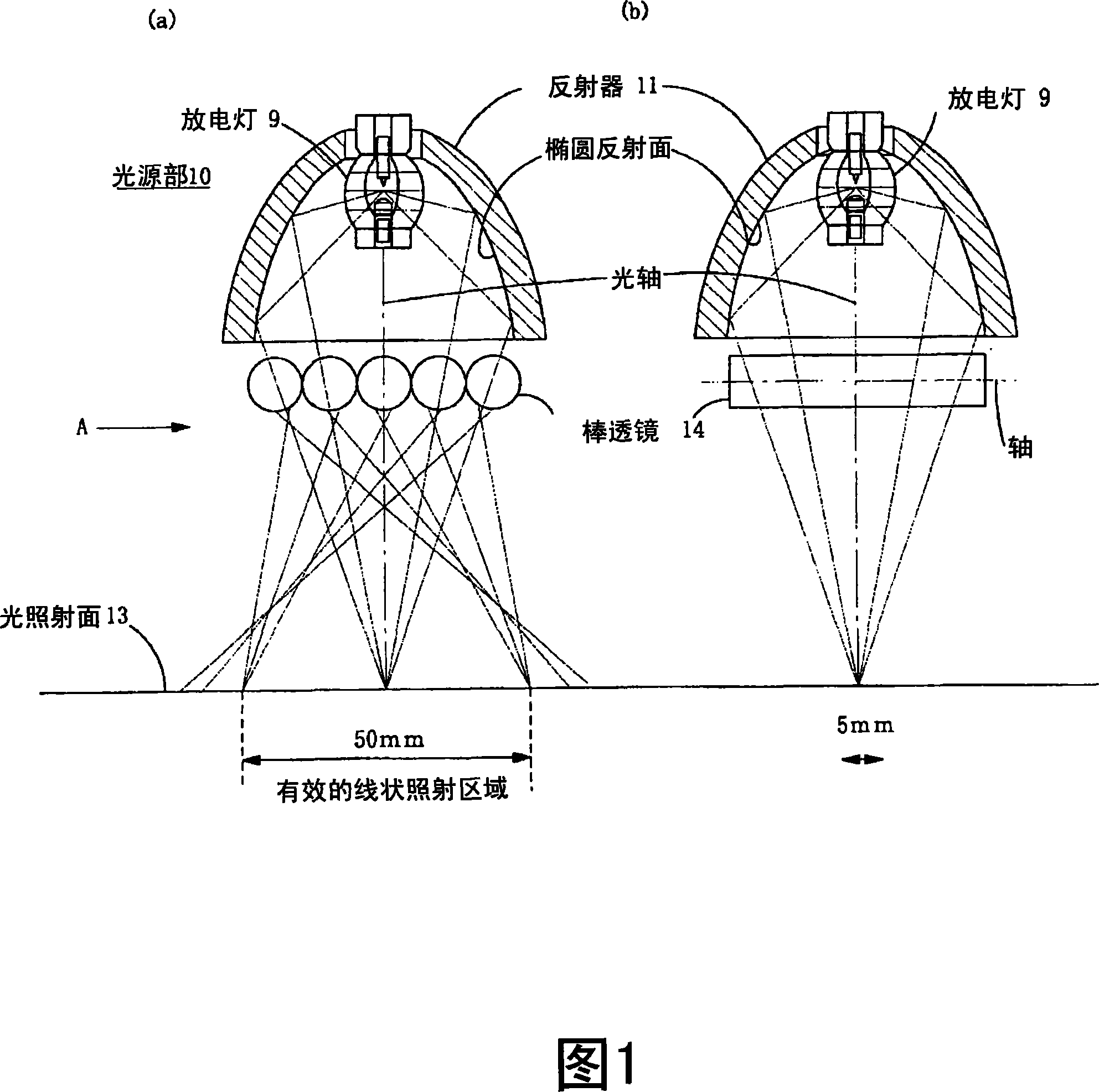

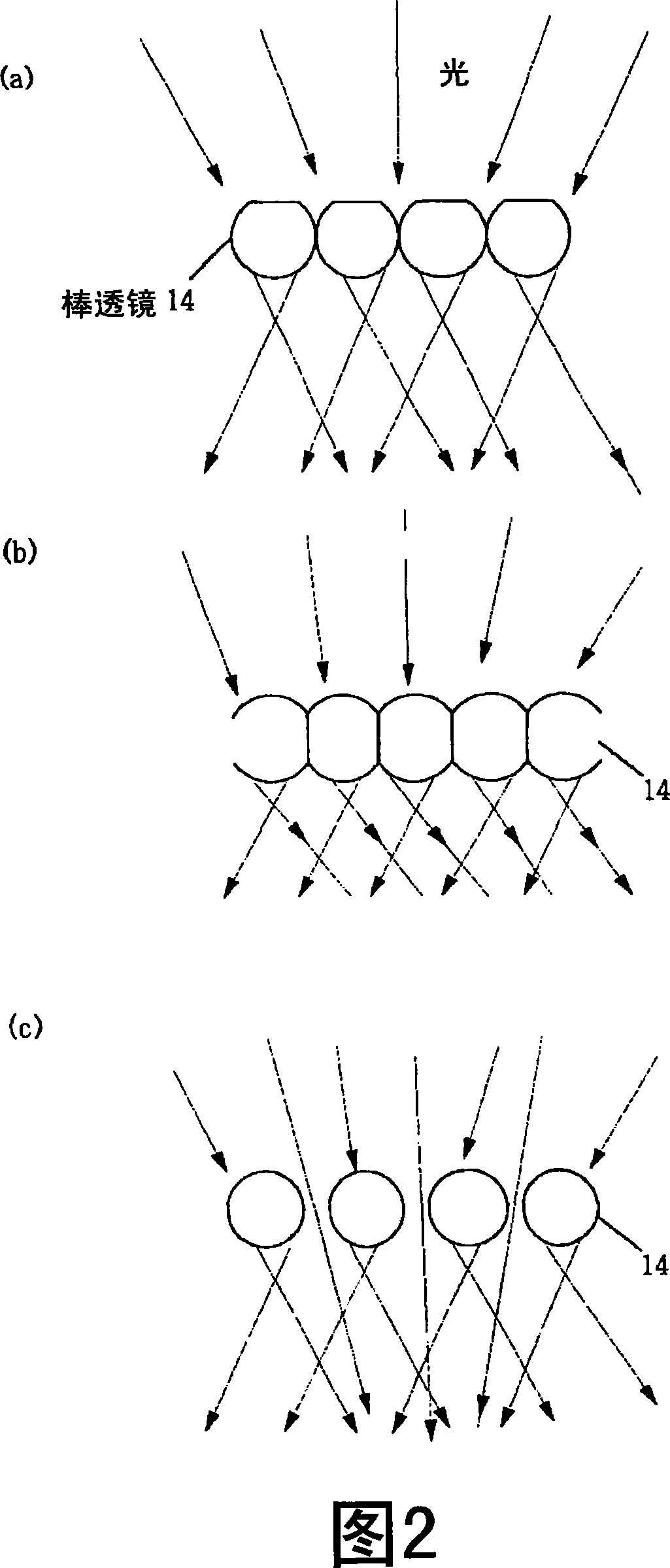

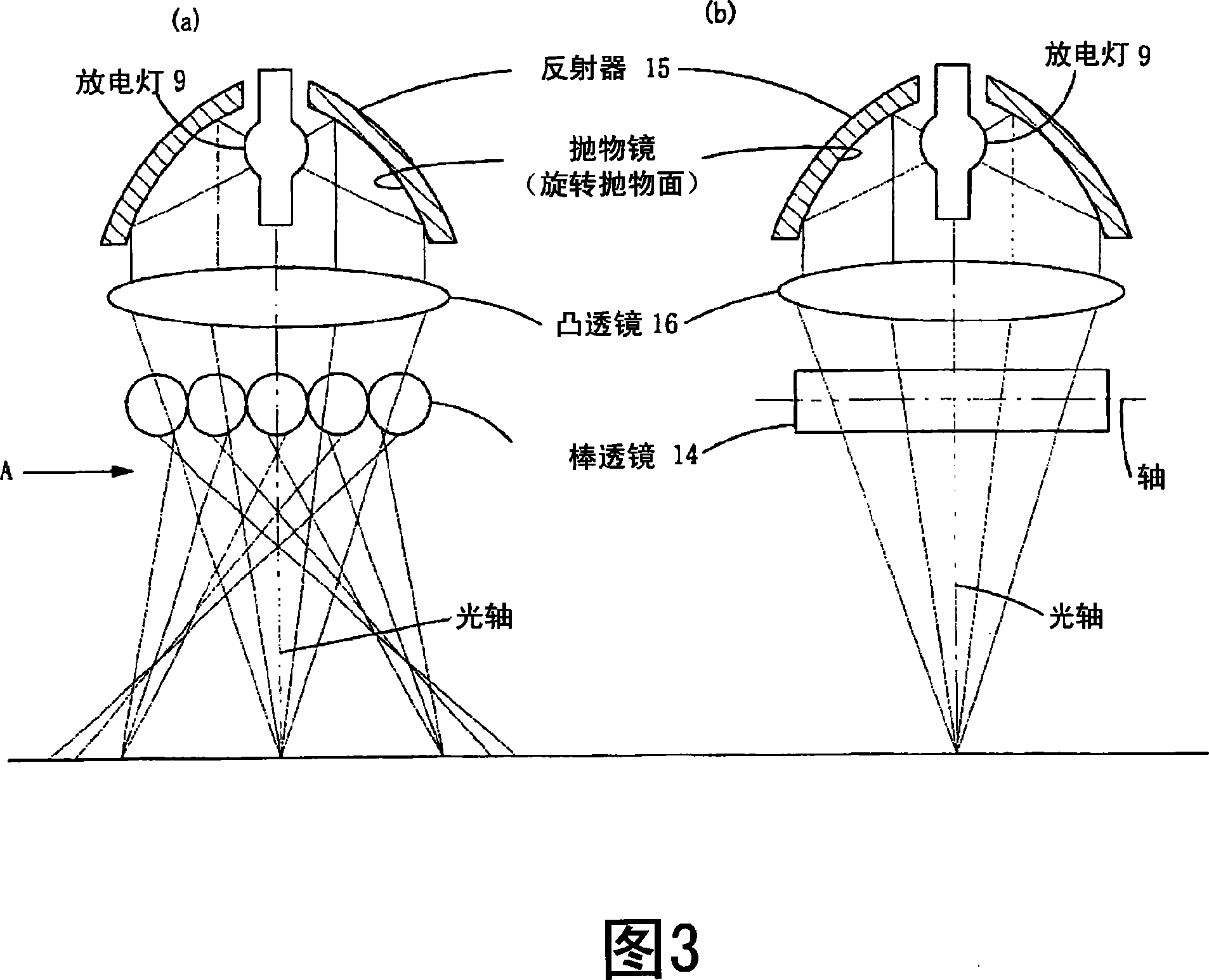

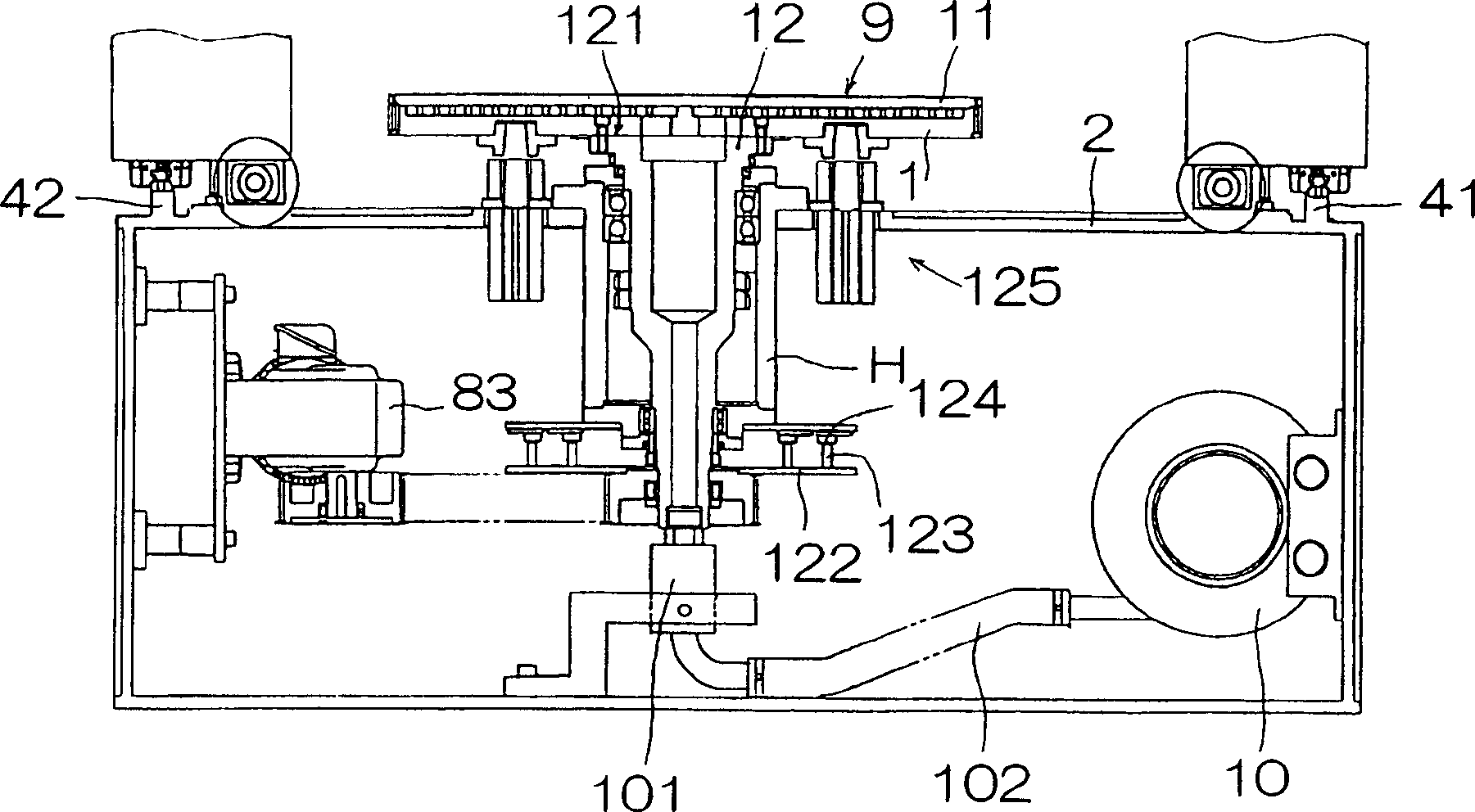

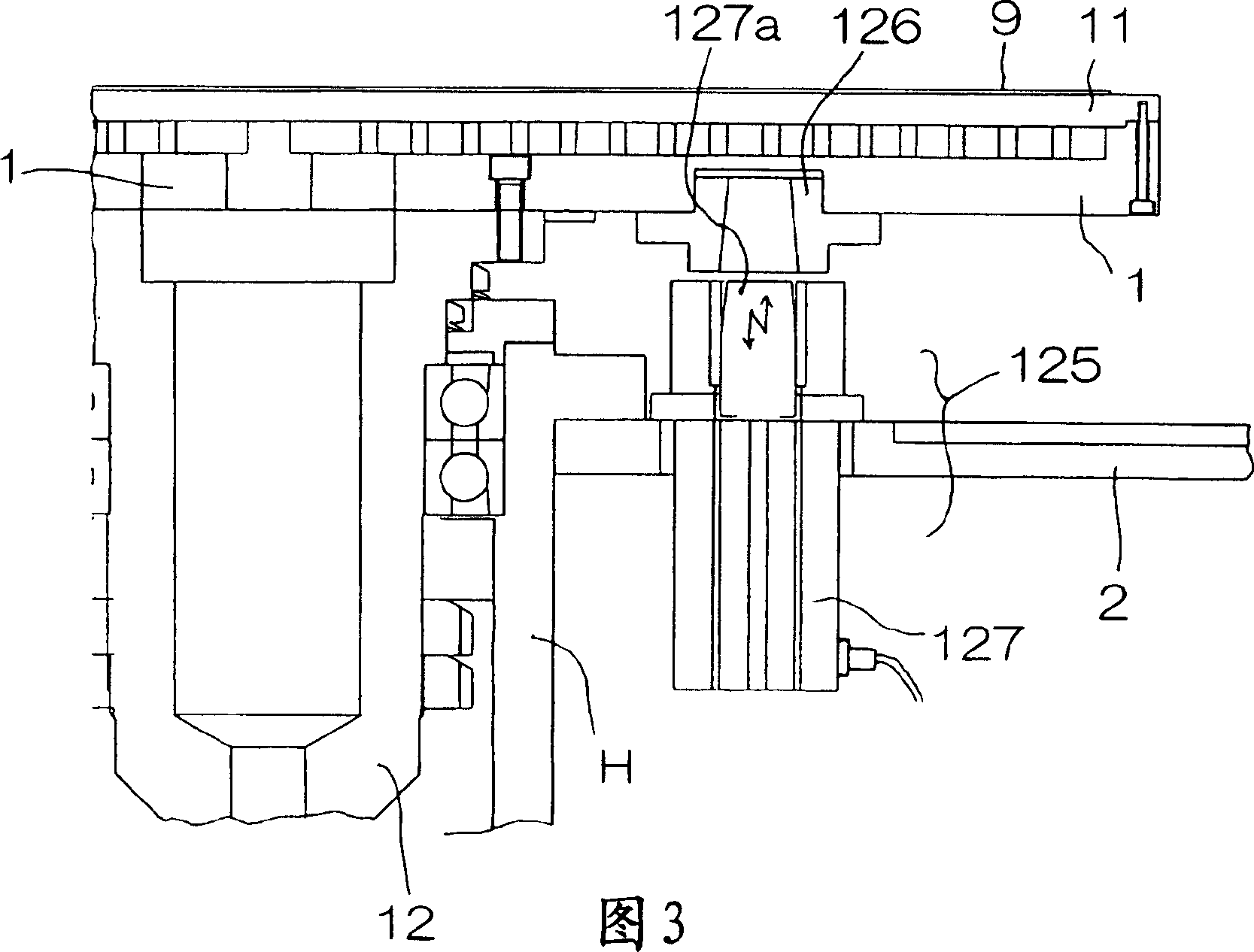

Light irradiation device and inkjet printer

ActiveCN101152784AAchieve smallAchieve lightweightPoint-like light sourceOther printing apparatusLight irradiationIlluminance

A light irradiation device that is capable of good irradiance uniformity in the lengthwise direction and that is applicable to an inkjet printer. A light-emitting portion of a short-arc type discharge lamp is positioned at the first focal point of a reflector that has a reflecting surface in the shape of an ellipsoid of revolution, and the light from the discharge lamp is reflected by the reflector and is focused at the second focal point; after which the light is incident on multiple, columnar rod lenses 14 . Of the light that is incident on the rod lenses, the light along the axial direction is focused at the second focal point of an elliptical reflector without being affected by the rod lenses, and the light along the direction perpendicular to the axial direction is focused by the rod lenses and then spreads and irradiates the light irradiation surface.

Owner:USHIO DENKI KK

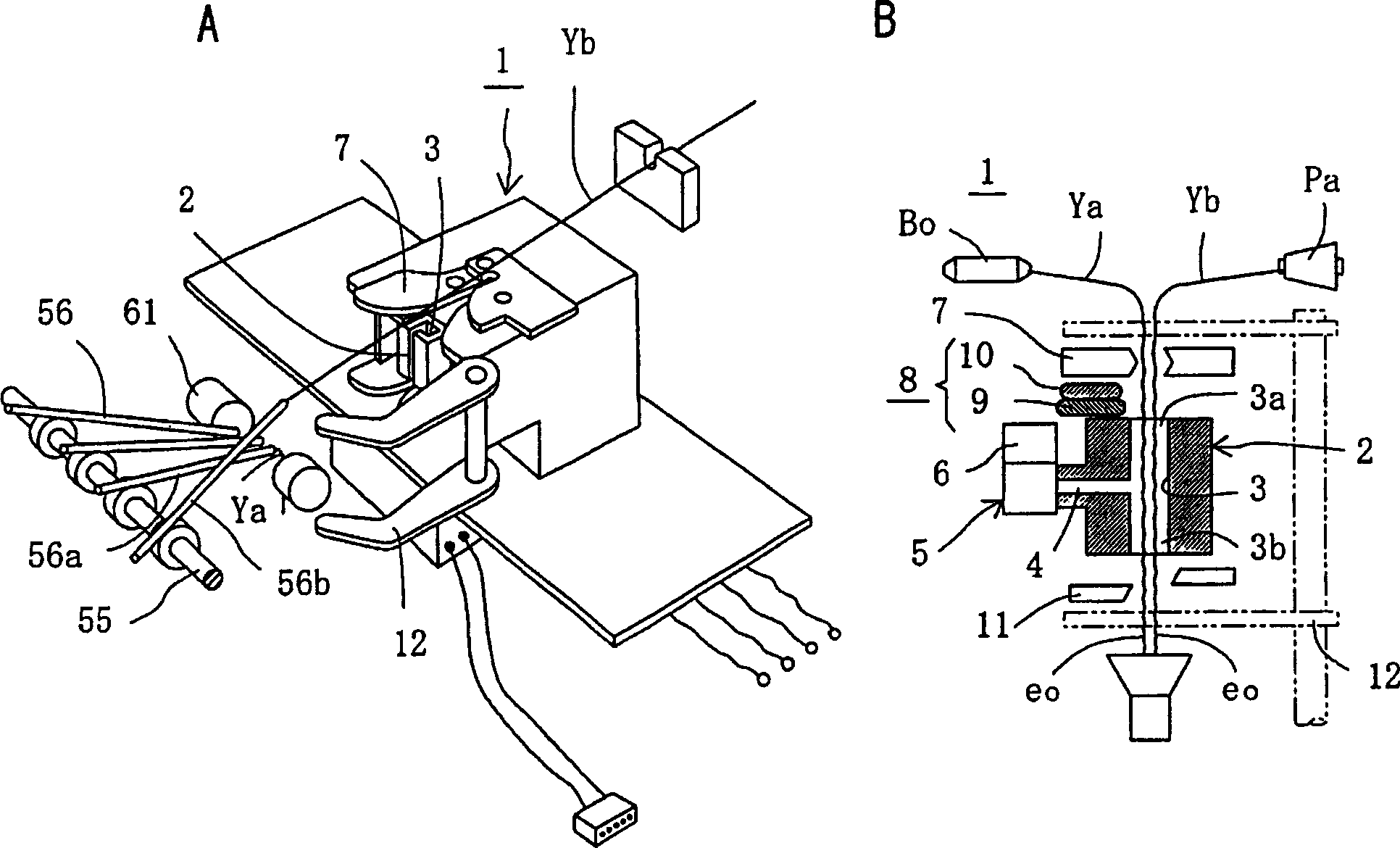

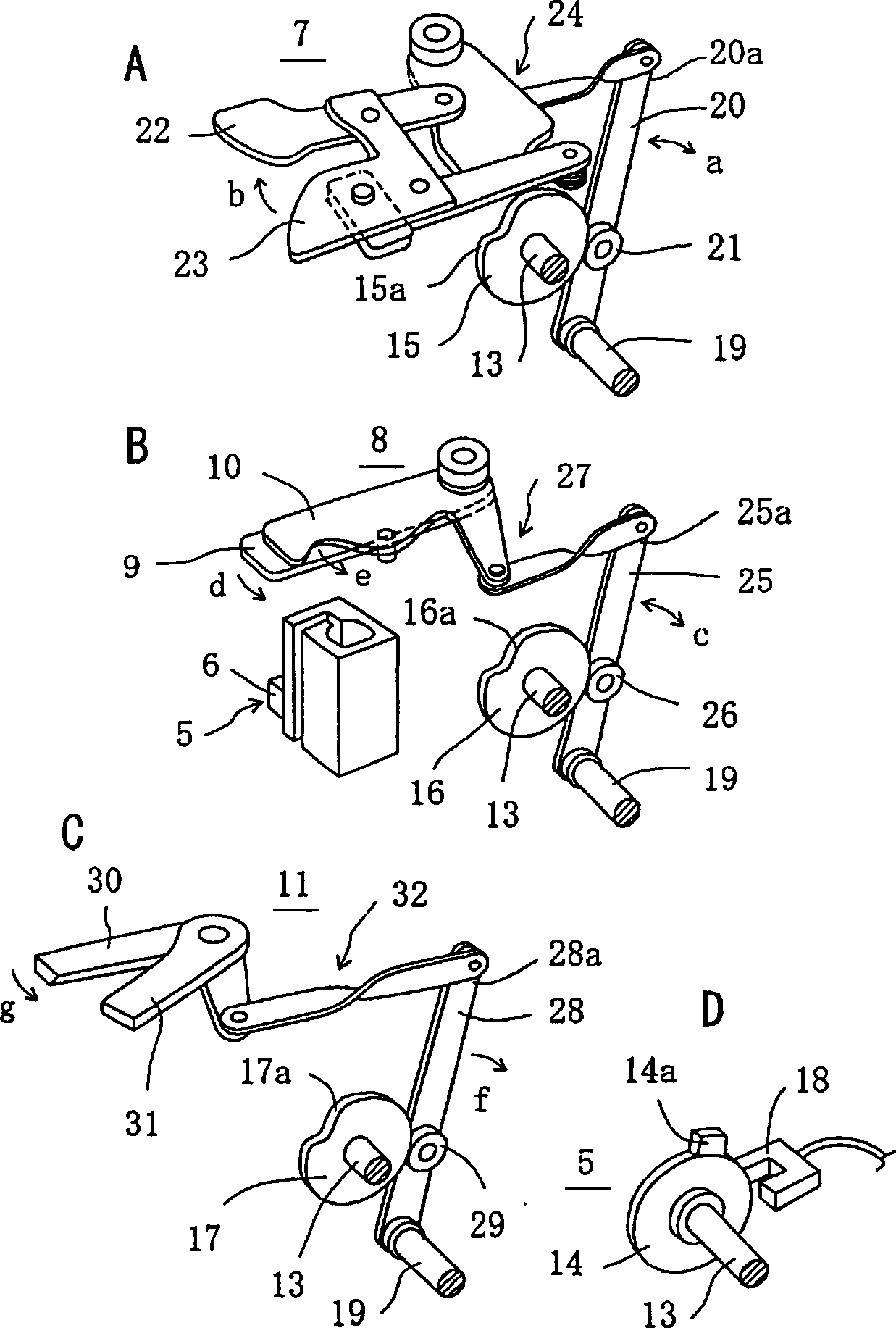

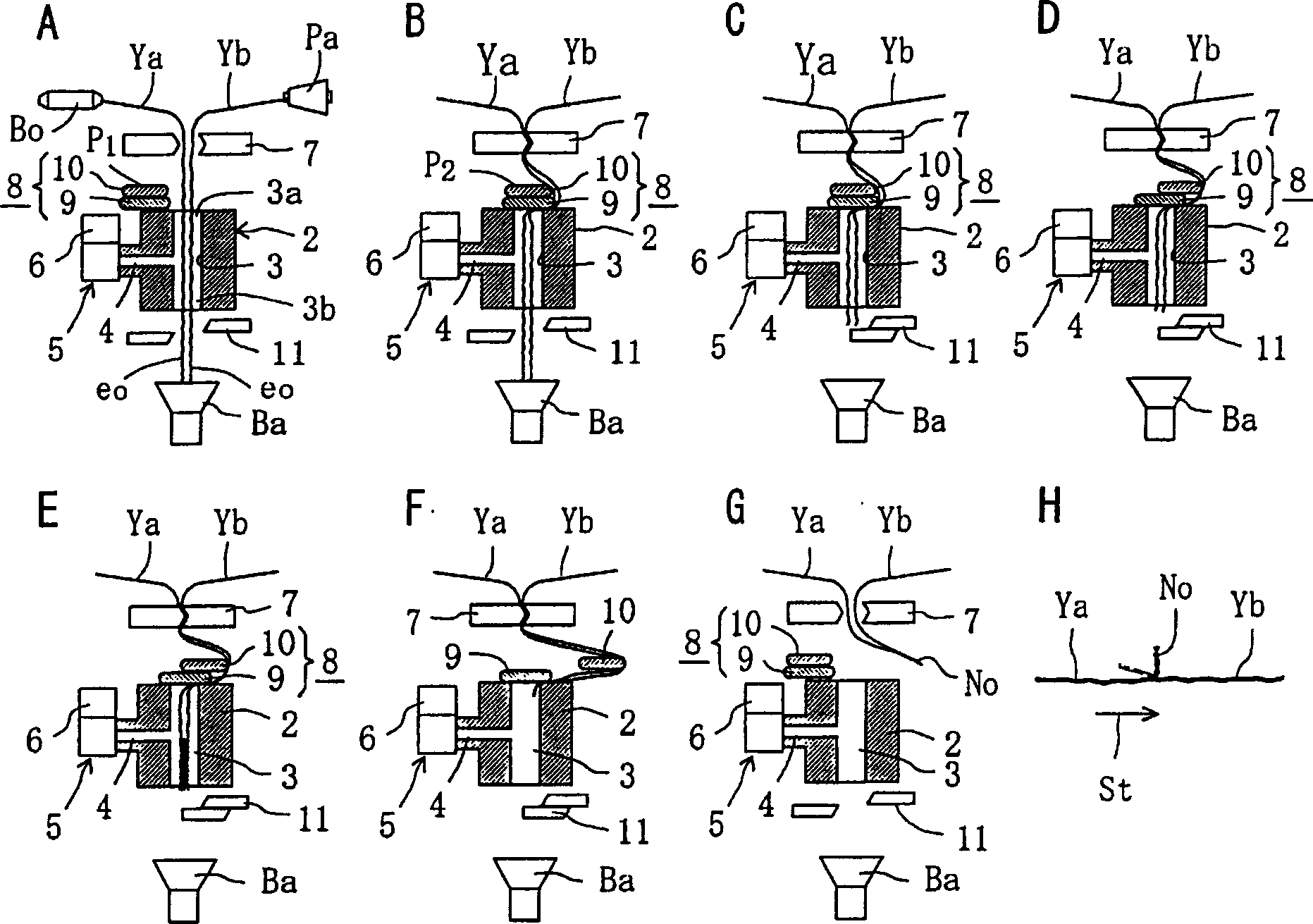

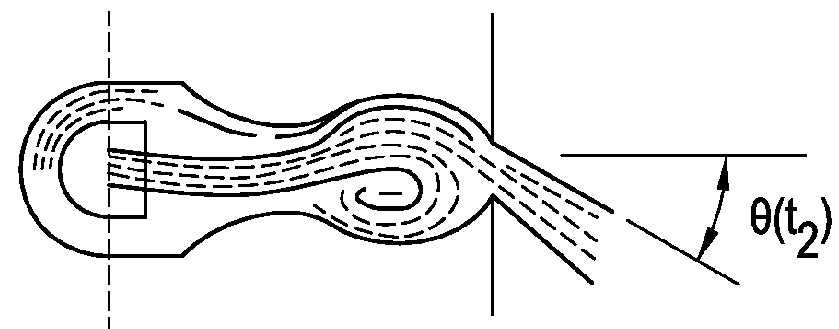

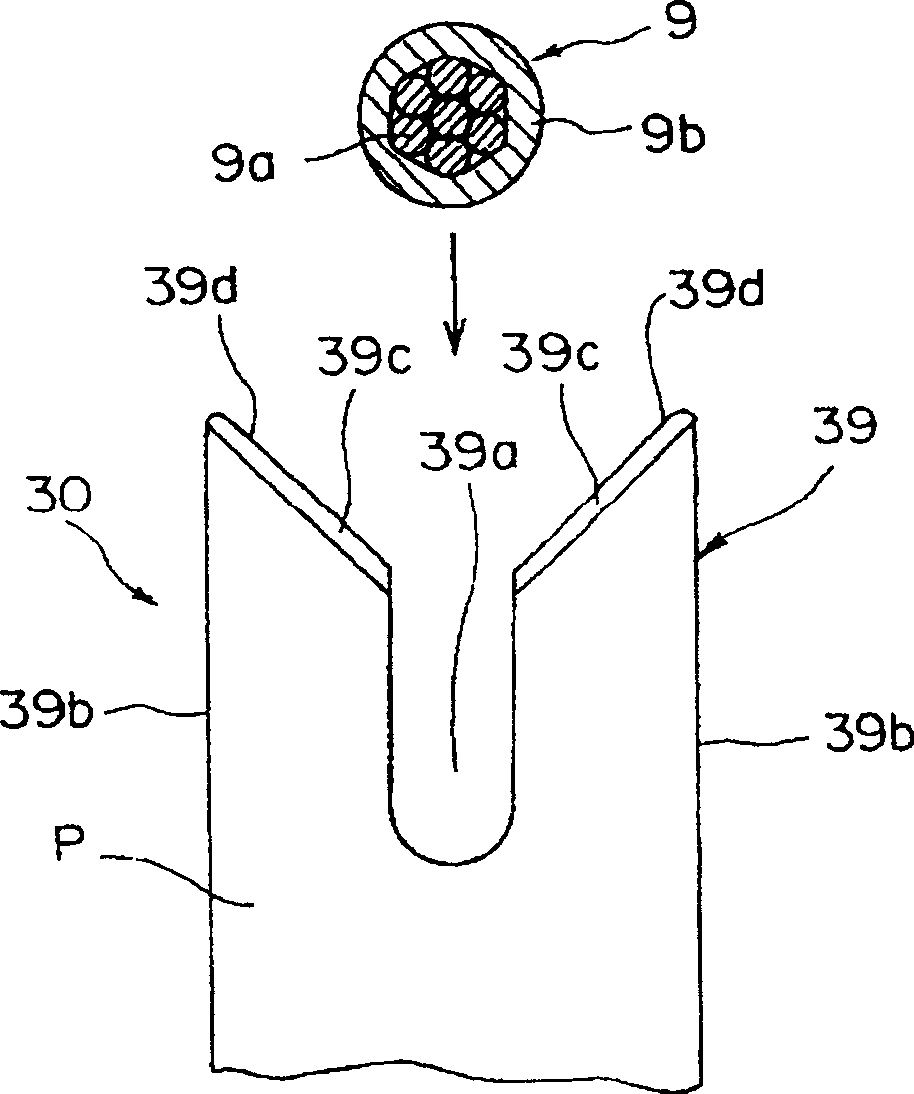

Yarn joining device and handy splicer

InactiveCN1676698AEffortless and easy untwistingLabor-saving and easy to untwistPiercing arrangementsFilament handlingYarnNozzle

The present invention provides a yarn joining device for joining two yarns (Ya,Yb) with the tail ends (eo) thereof aligned in the same direction. The yarn joining device reduces the size of the joint portion of the yarns even if the yarn joining is successively performed, and also adjusts the yarn joining length, and thereby forms the joint portion of yarns uniformly and reliably. In the yarn joining device for joining tail ends of two yarns with the tail ends aligned in the same direction, loosening and twining of the tail ends of the yarns is performed successively by a single air jet nozzle (2).

Owner:MURATA MASCH LTD

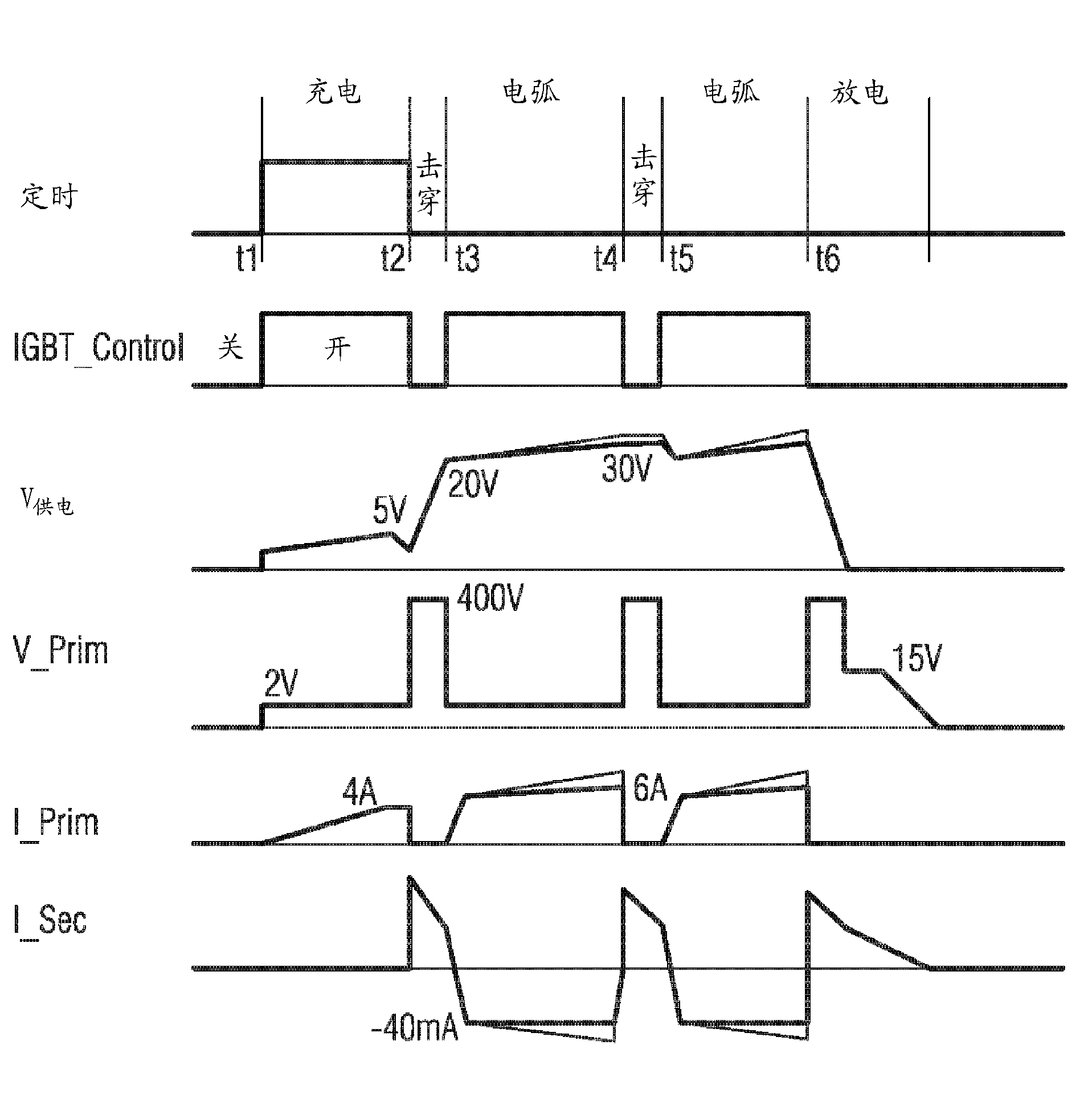

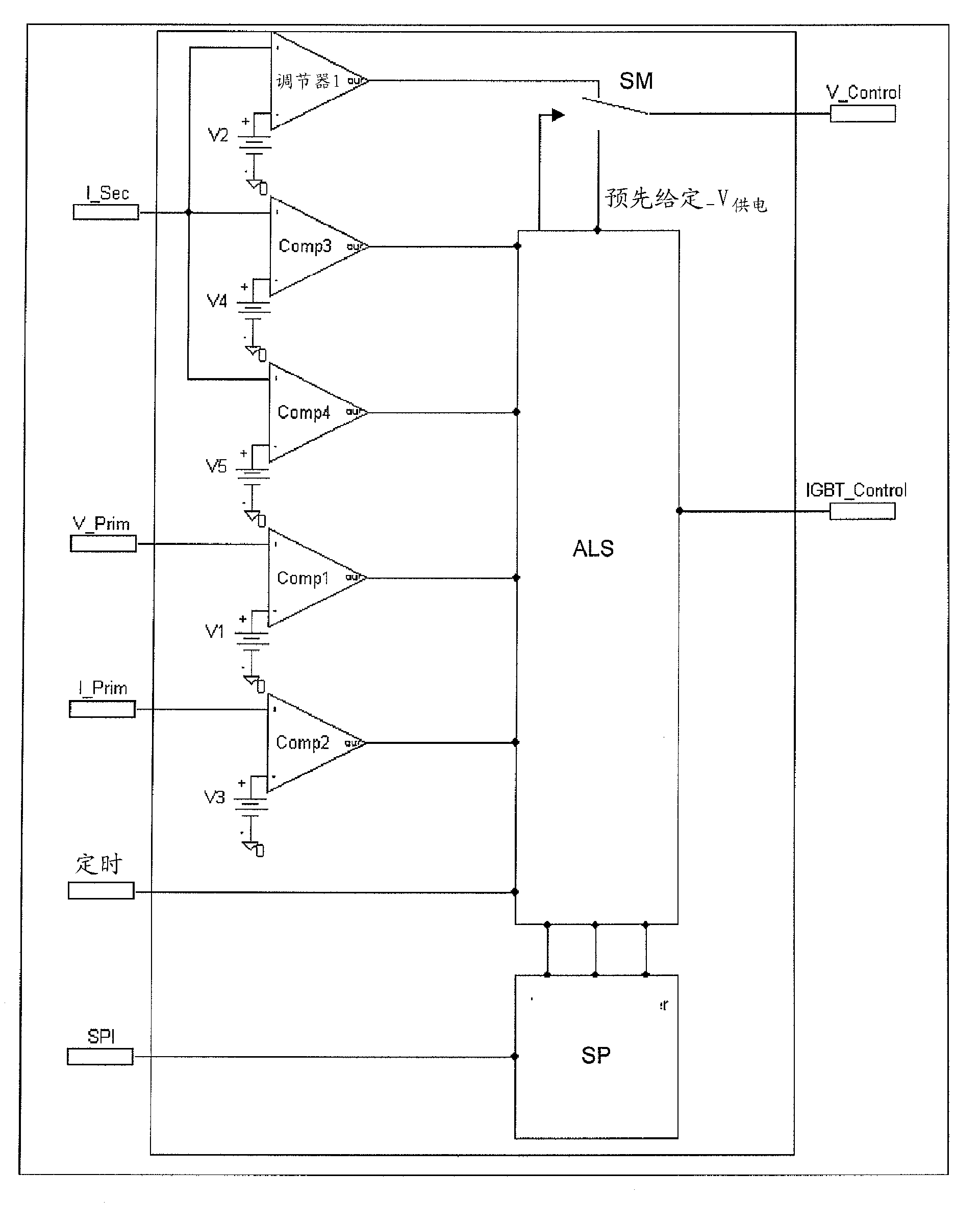

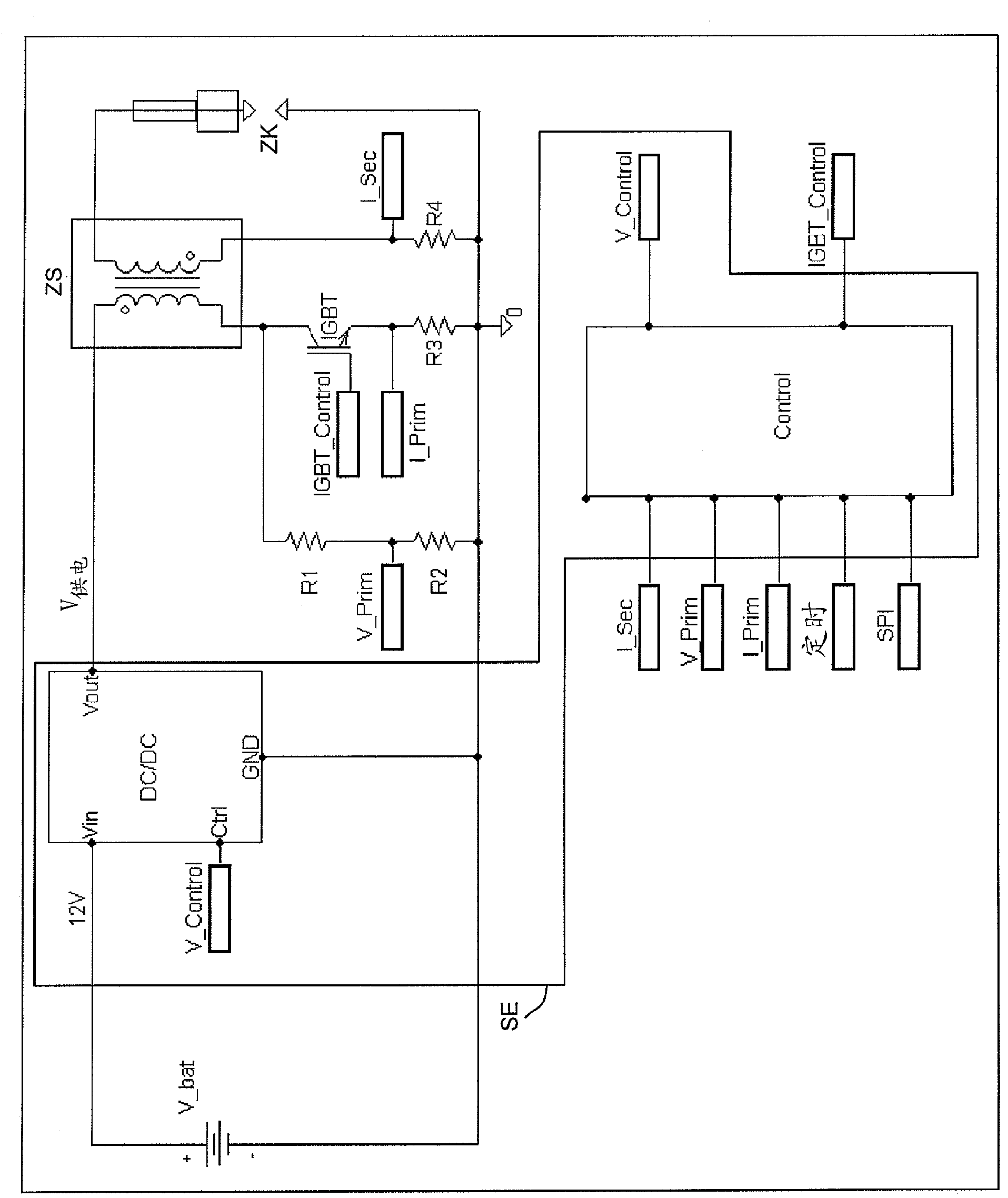

Method for operating an ignition device for an internal combustion engine, and ignition device for an internal combustion engine for carrying out the method

ActiveCN102741544AImprove ignition safetyReduce manufacturing costElectrical controlMachines/enginesTransformerIgnition coil

The invention relates to a method for operating an ignition device for an internal combustion engine, which ignition device is formed with an ignition coil (ZS) which is configured as a transformer, a spark plug (ZK) which is connected to the secondary winding of the ignition coil (ZS), an actuable switching element (IGBT) which is connected in series to the primary winding of the ignition coil (ZS), and a control unit (SE) which is connected to the control input of the switching element (IGBT), wherein the control unit (SE) provides an adjustable supply voltage (Vsupply) for the ignition coil (ZS) and an actuating signal (IGBT_Control) for the switching element (IGBT) as a function of the currents (I_Prim, I_Sec) through the primary and the secondary windings of the ignition coil (ZS) and the voltage between the connecting point of the primary winding of the ignition coil (ZS); to the switching element (IGBT) and the negative terminal of the supply voltage (GND), as a result of which firstly operation of the spark plug (ZK) by way of alternating current is possible and secondly regulation of said current is possible, which leads to more reliable ignition with a lower wear of the spark plugs.

Owner:CONTINENTAL AUTOMOTIVE GMBH

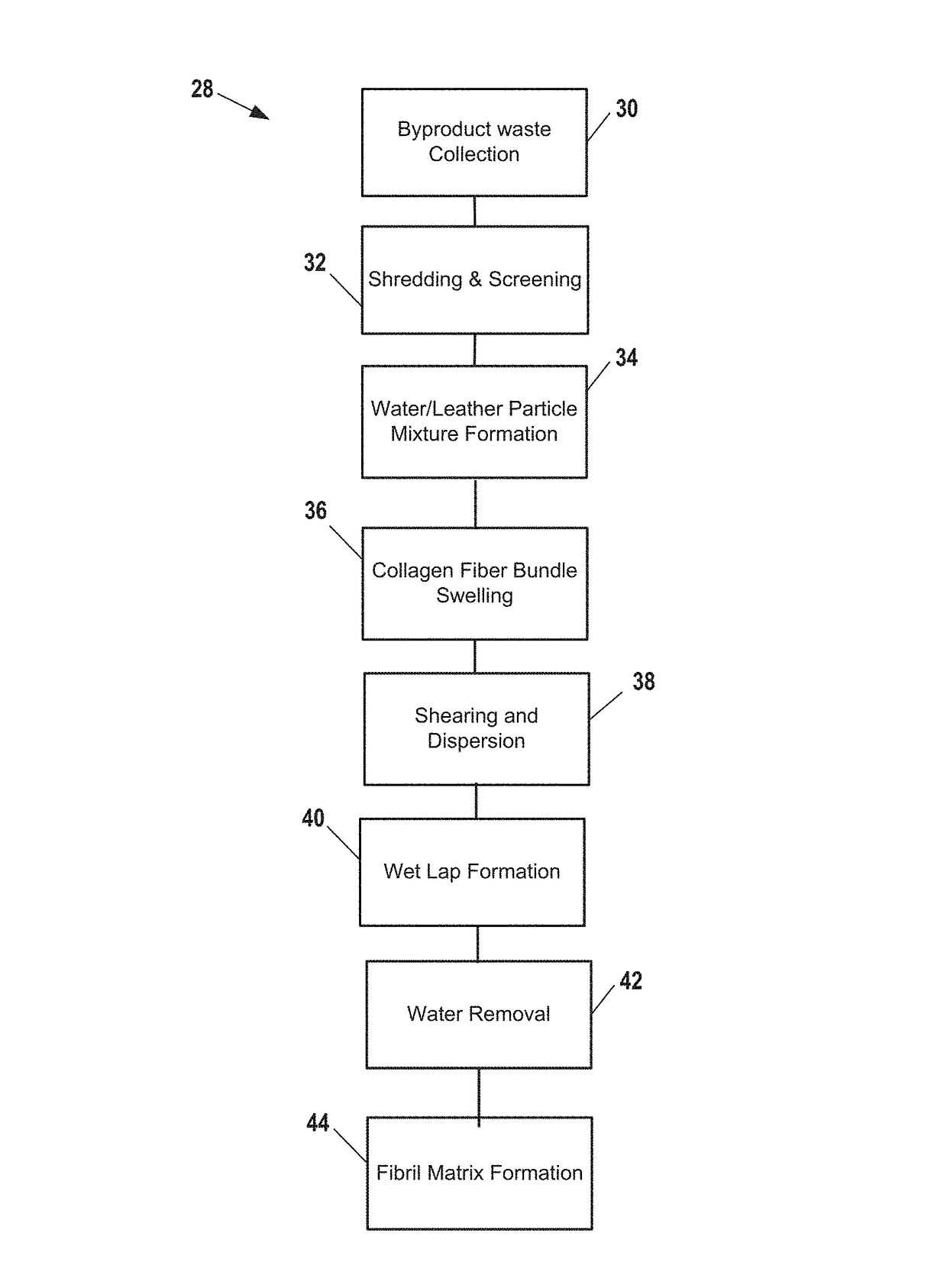

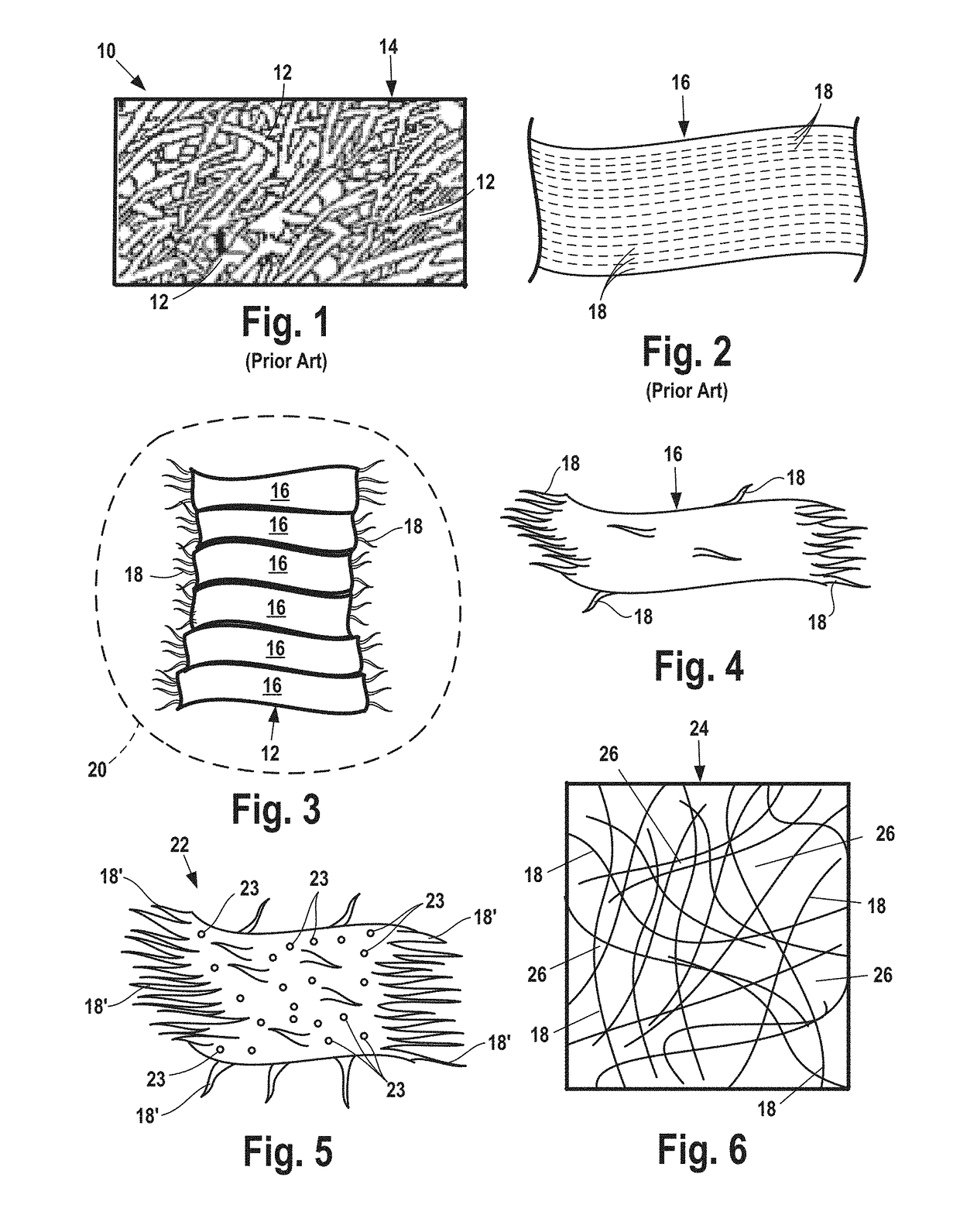

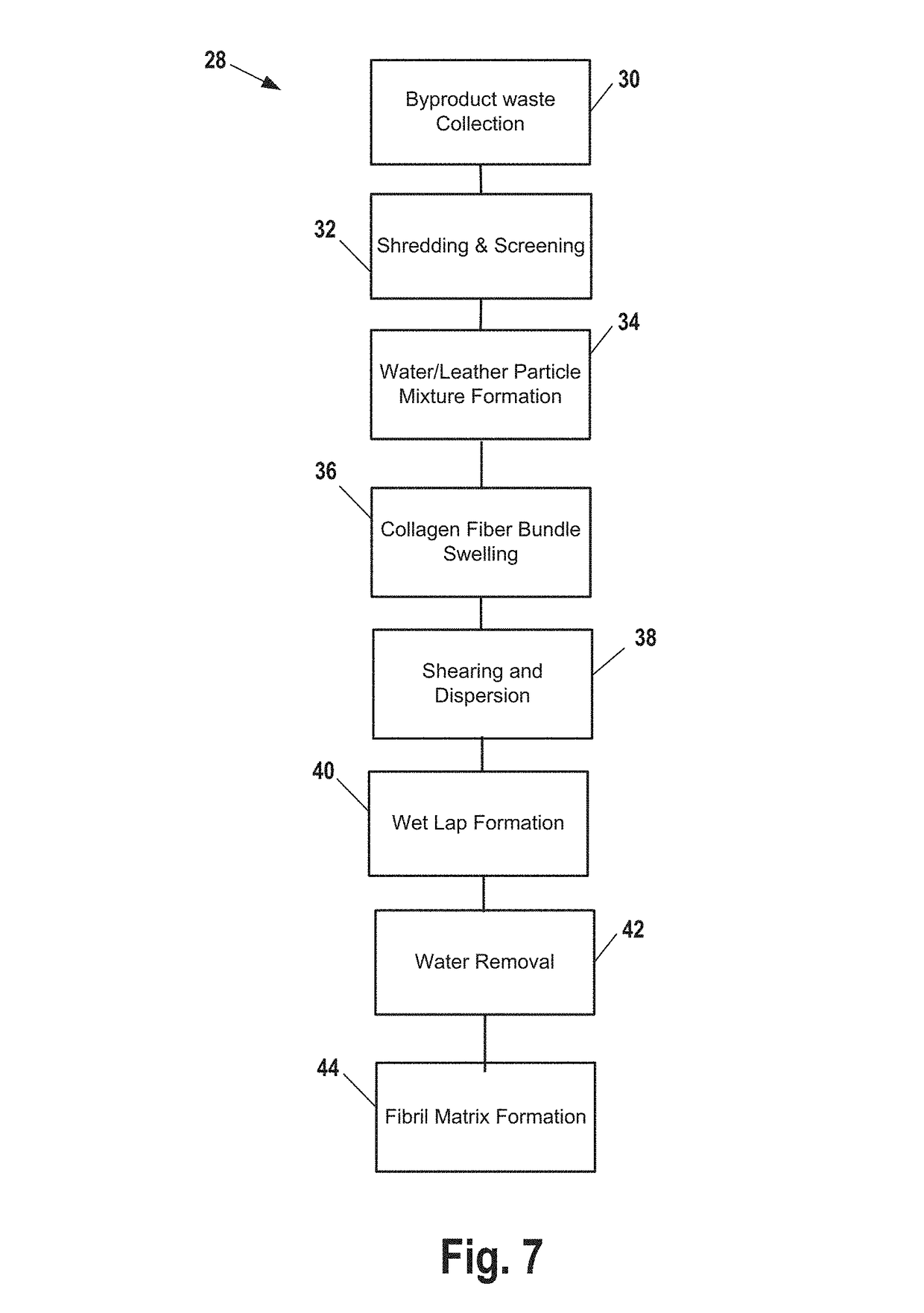

High strength leather material

ActiveUS10124543B1Improve tear resistanceLower-strength end-productComposite leathersFlat articlesFiberHigh intensity

A leather substrate formed from waste leather and its method of production, particularly a leather substrate made up substantially of a collagen fibril matrix.

Owner:SUSTAINABLE COMPOSITES LLC

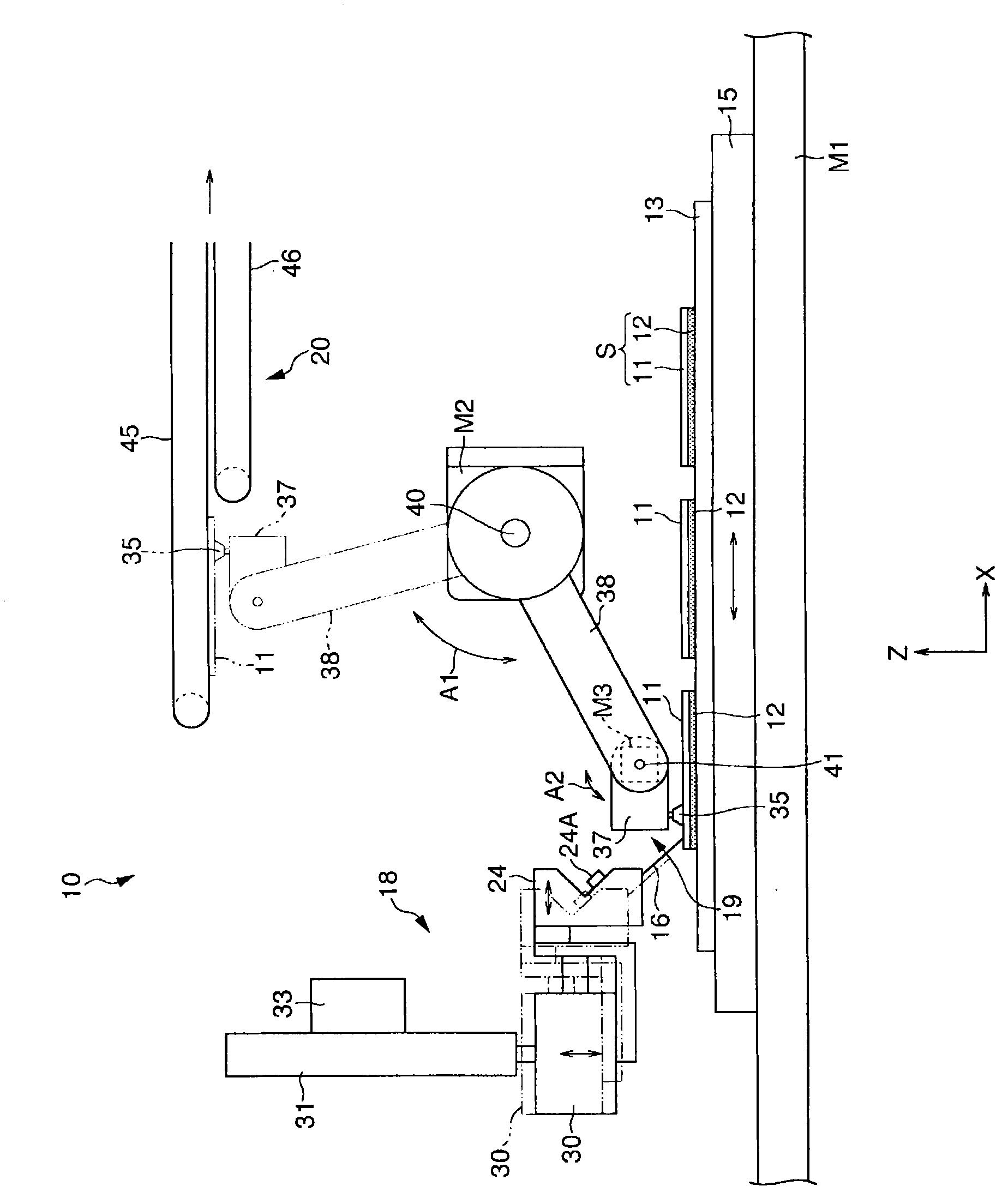

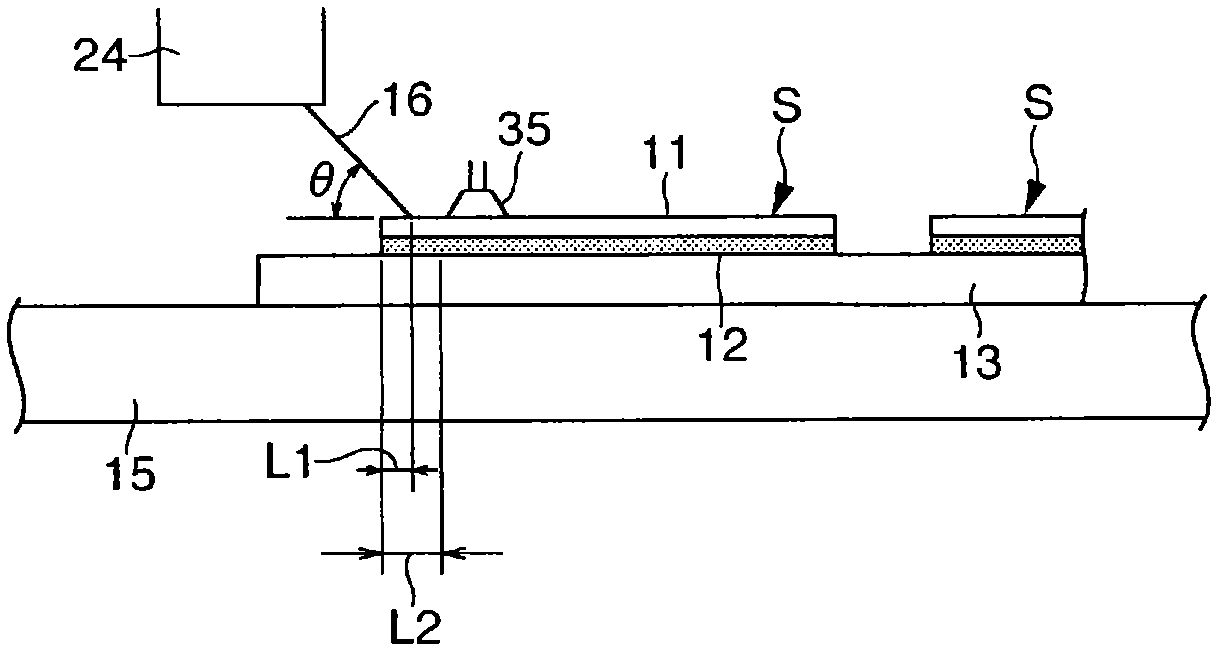

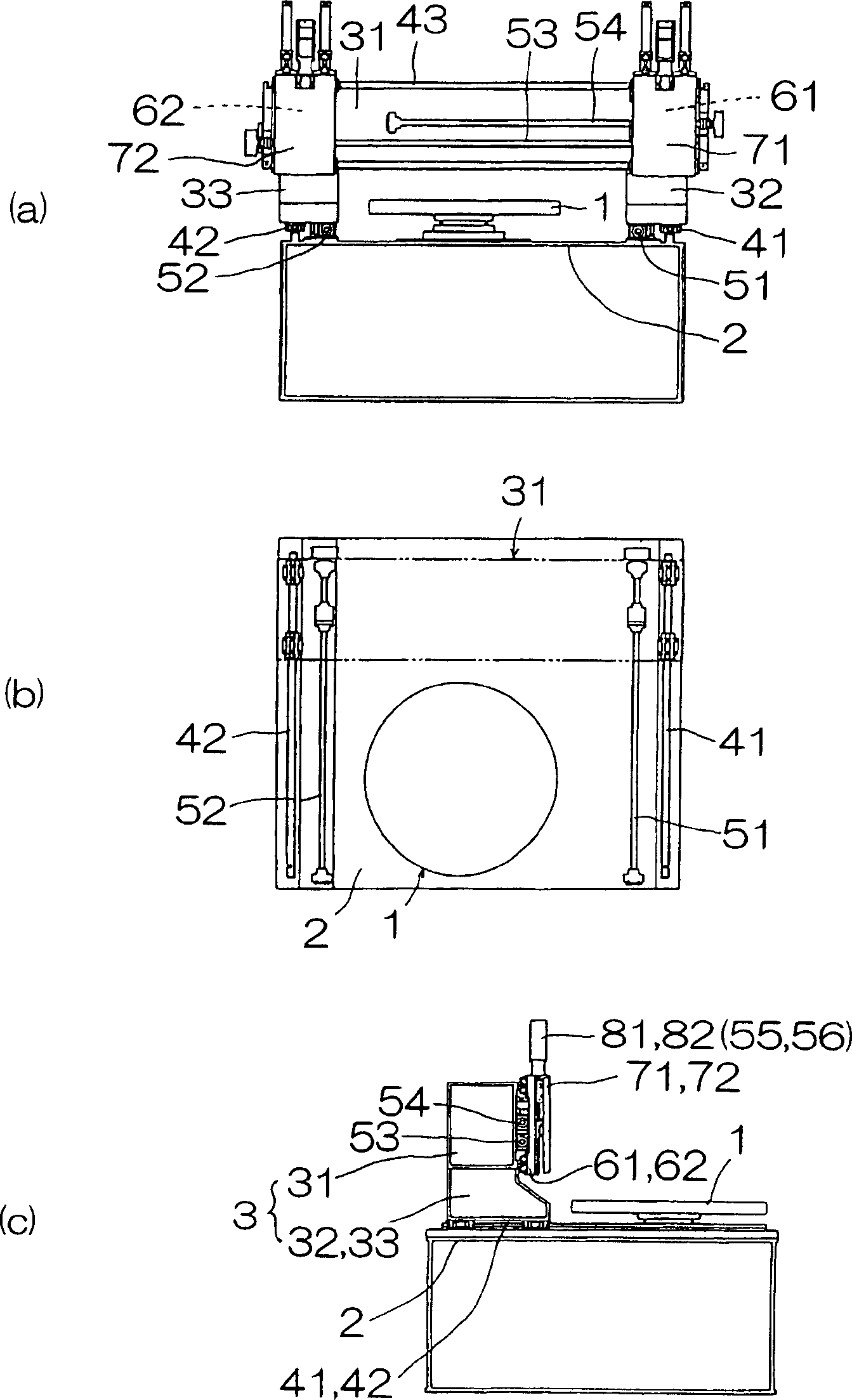

Detachment device and detachment method

ActiveCN102666333AHigh peel resistanceReliable formationLayered productsLaminationBiomedical engineeringMental detachment

Given an adhesive sheet (S) attached to a substrate (13), the disclosed detachment device (10) detaches a separator (11) from an adhesive layer (12). Said device is provided with: a table (15) that supports the substrate (13); a needle (16) that pierces the separator (11) from the top surface thereof; a support means (18) that moves the needle (16) to form a detachment-starting region (11A); and a suction pad (35) that applies suction to the separator (11). When forming the detachment-starting region (11A), the suction pad (35) applies suction to the separator (11), and then with the detachment-starting region (11A) formed, the suction pad (35) is rotated away from the substrate to detach the separator (11).

Owner:THREEBOND FINE CHEM CO LTD

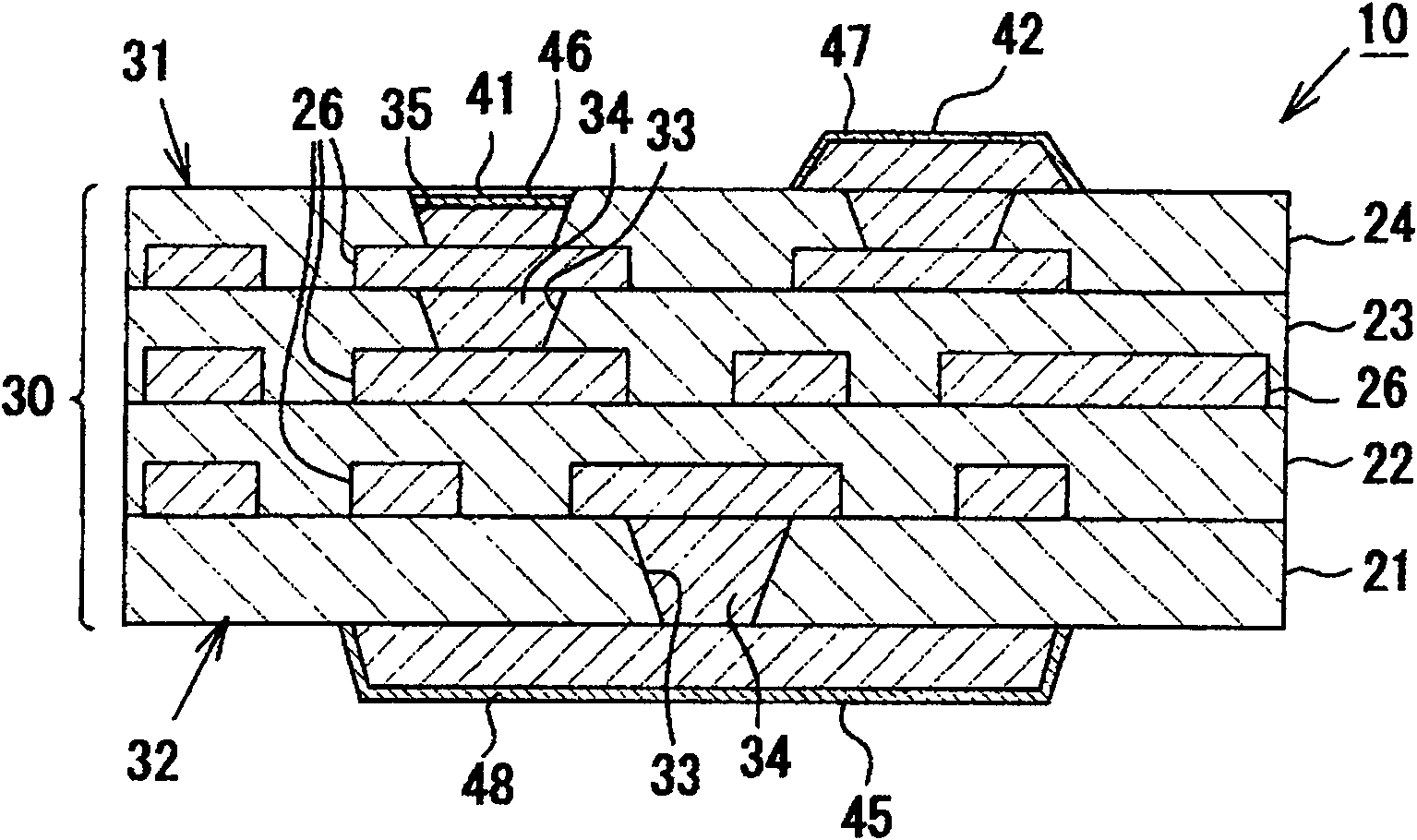

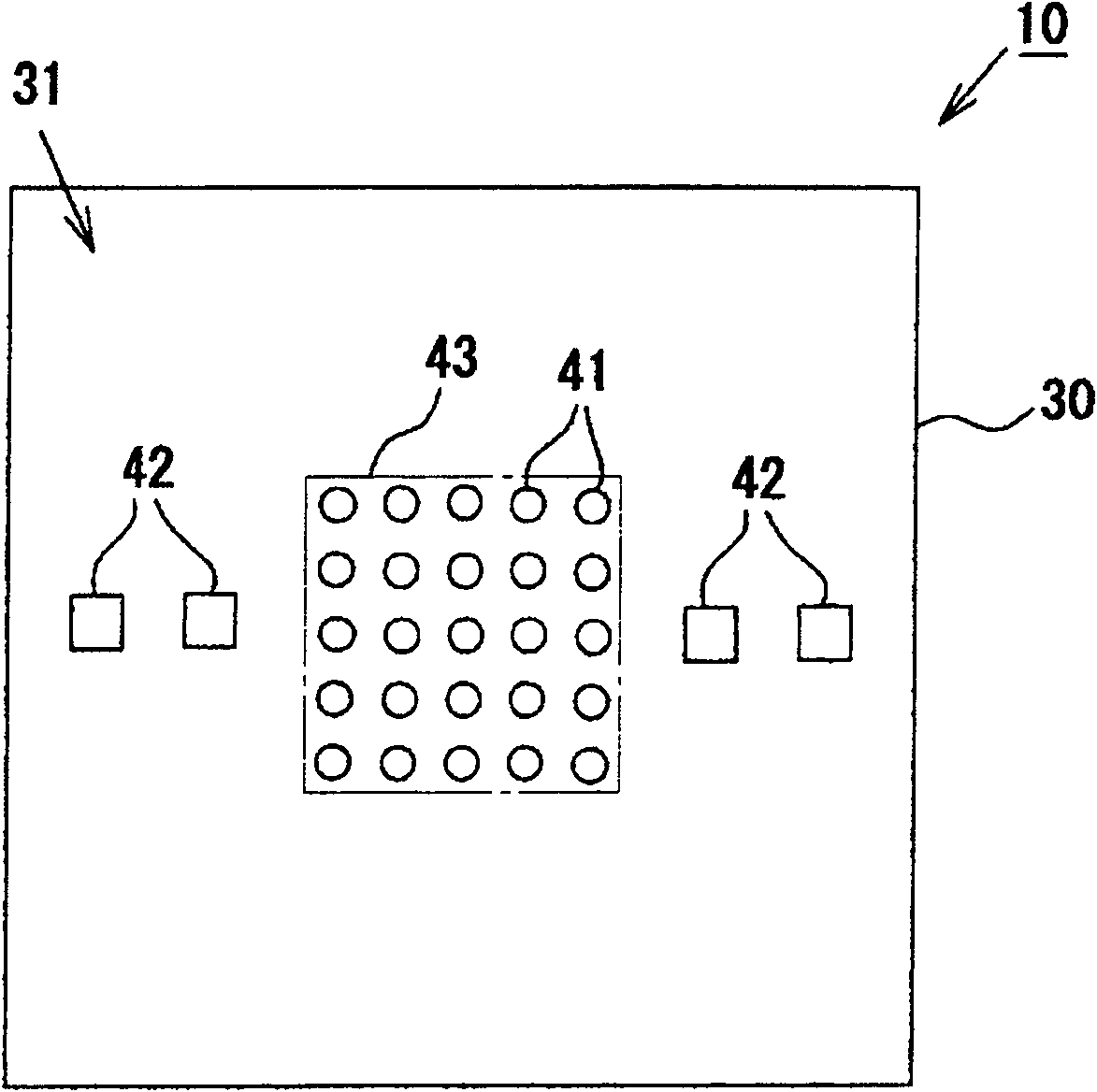

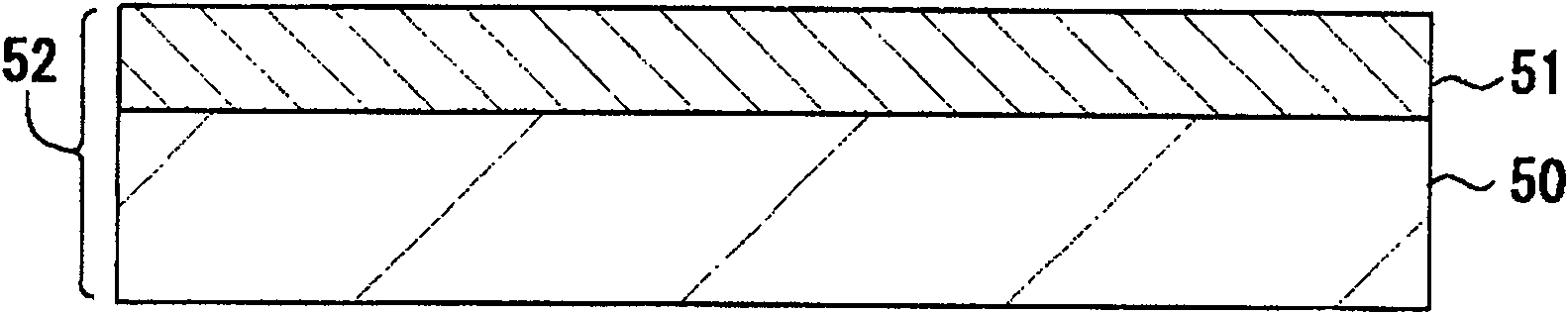

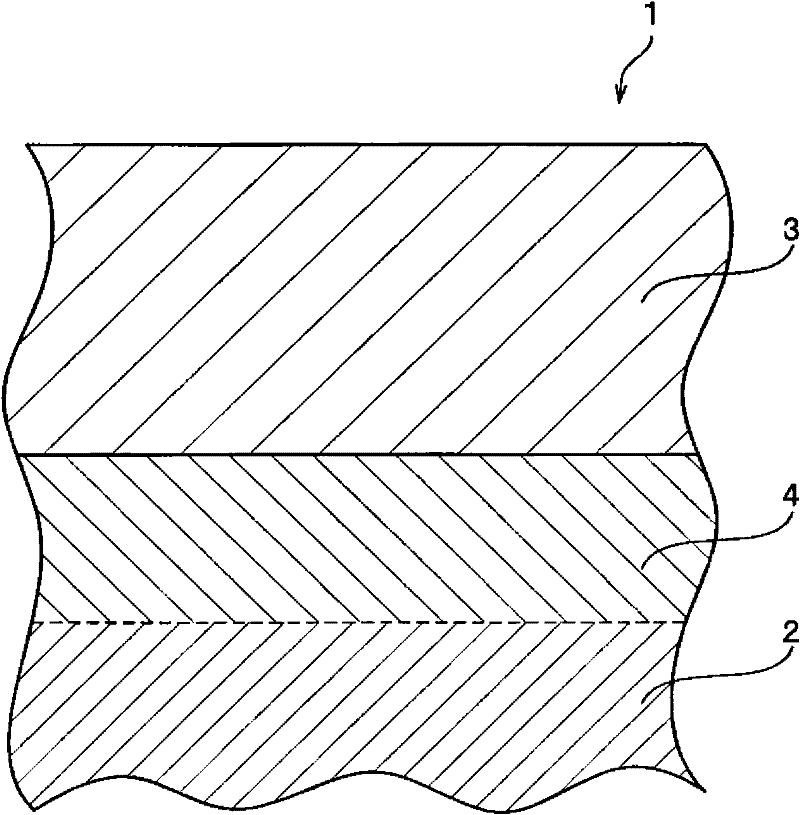

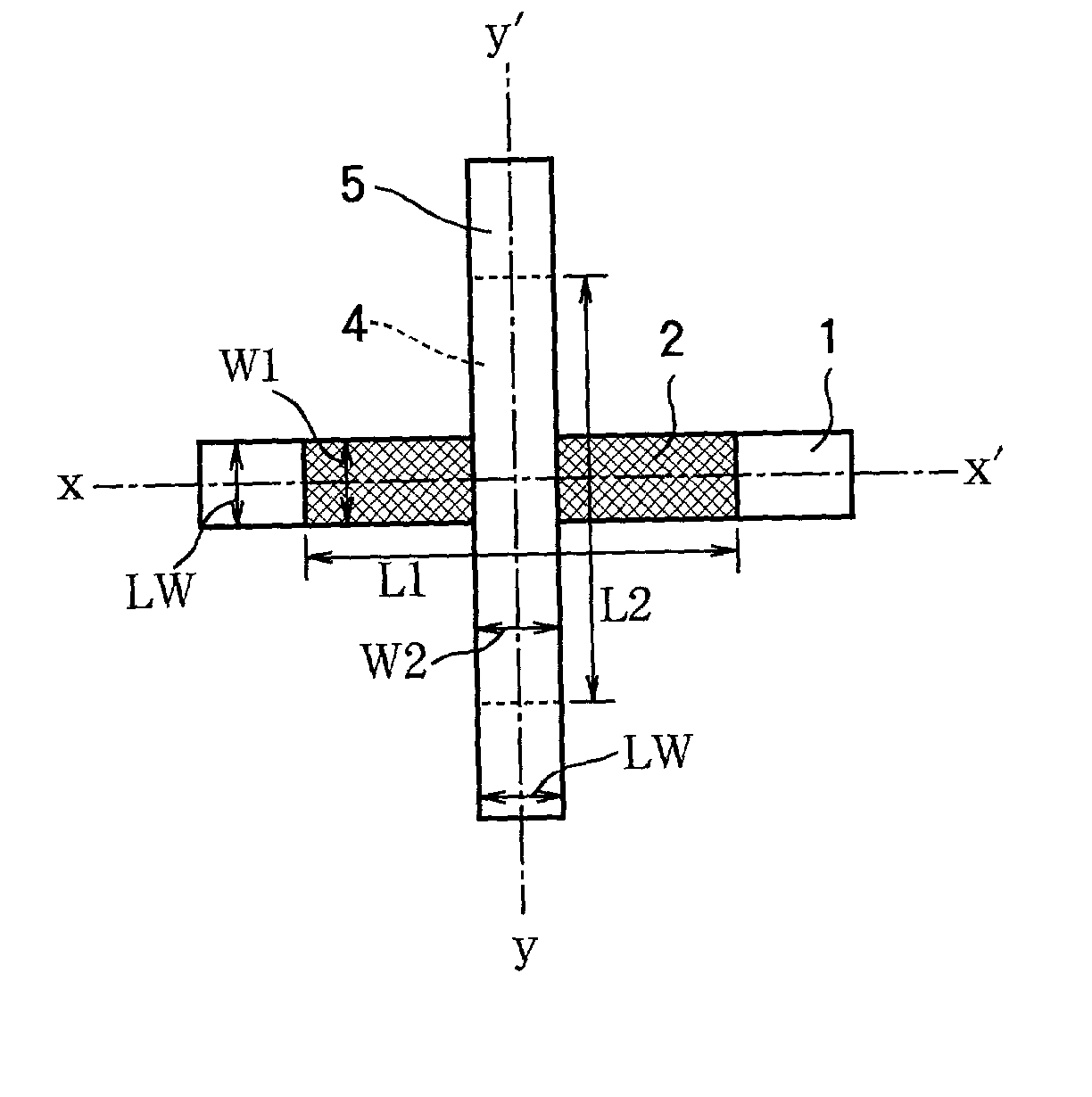

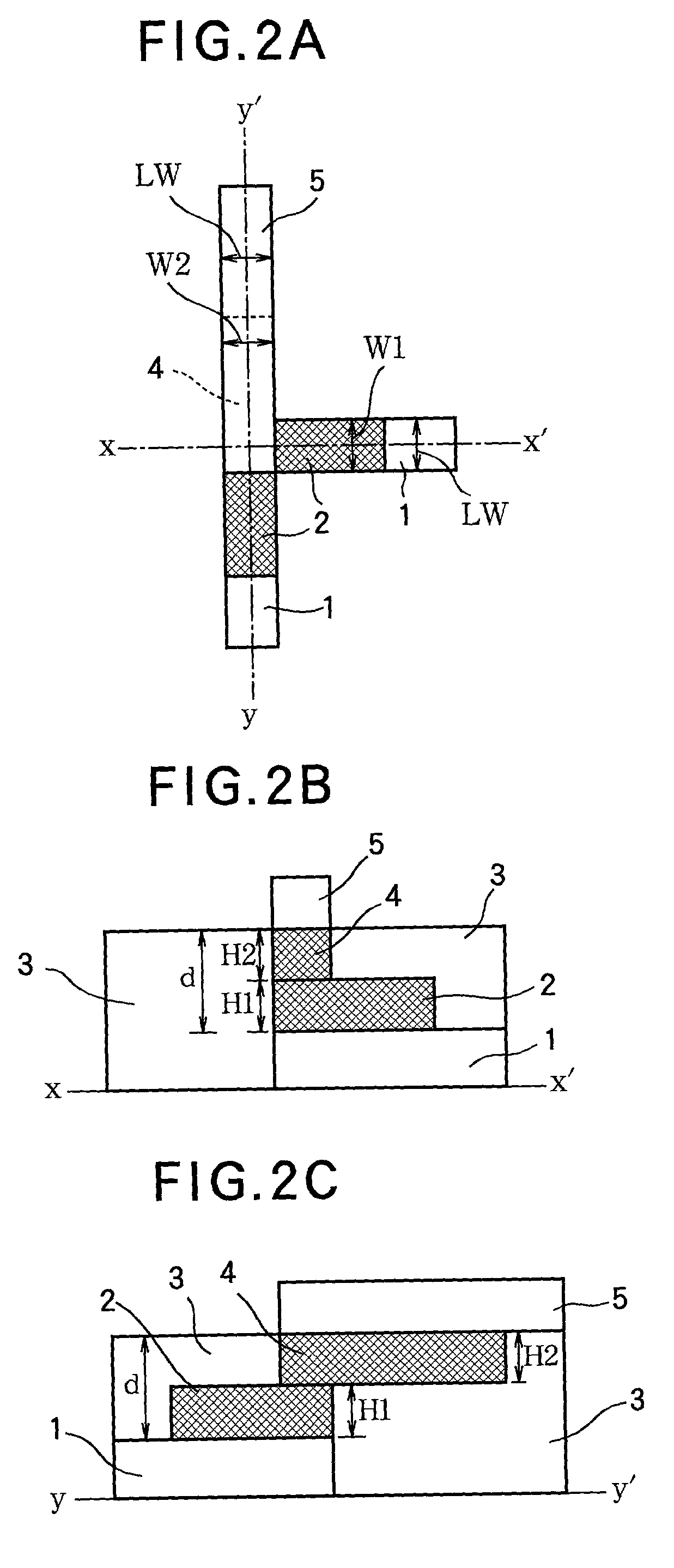

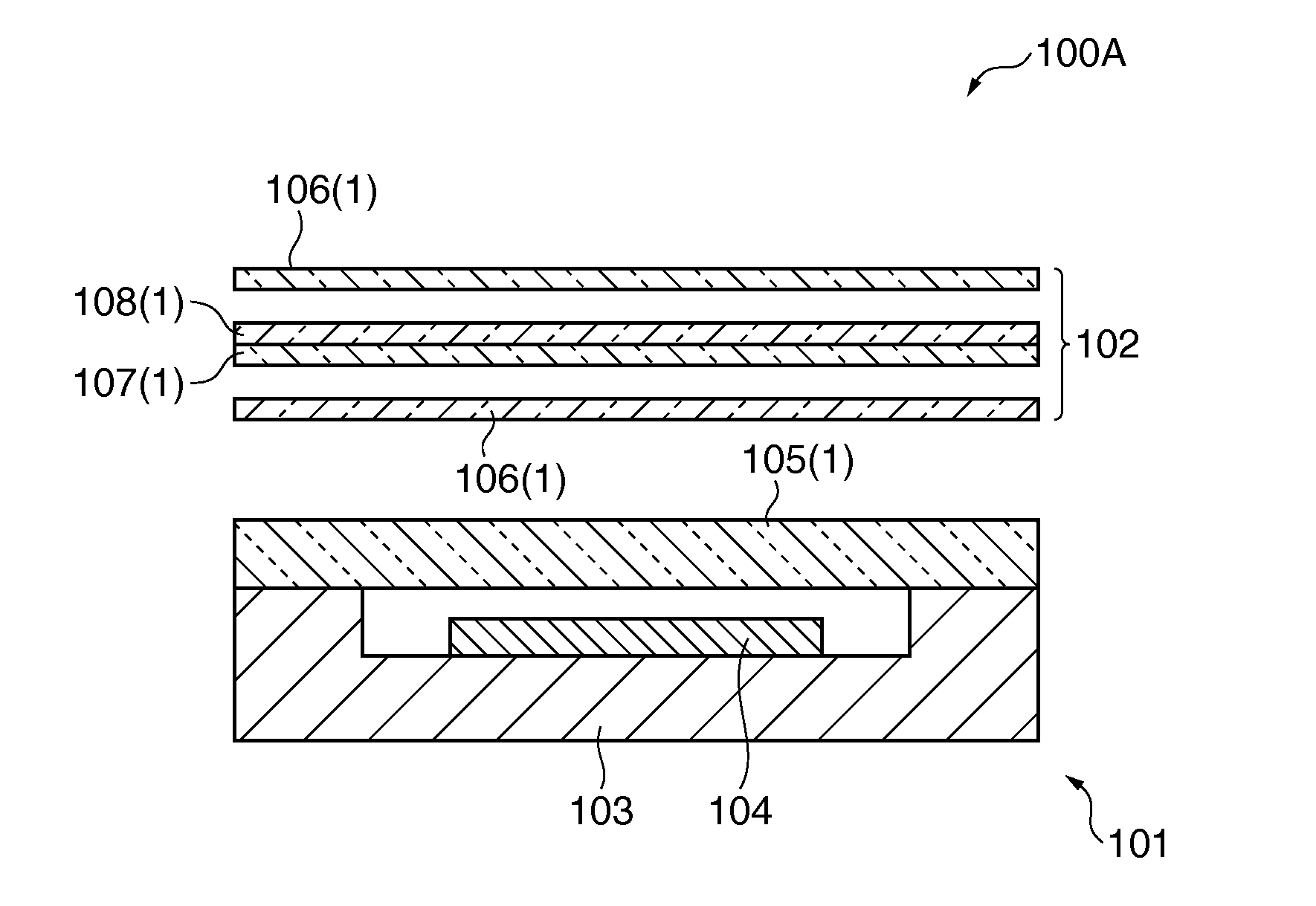

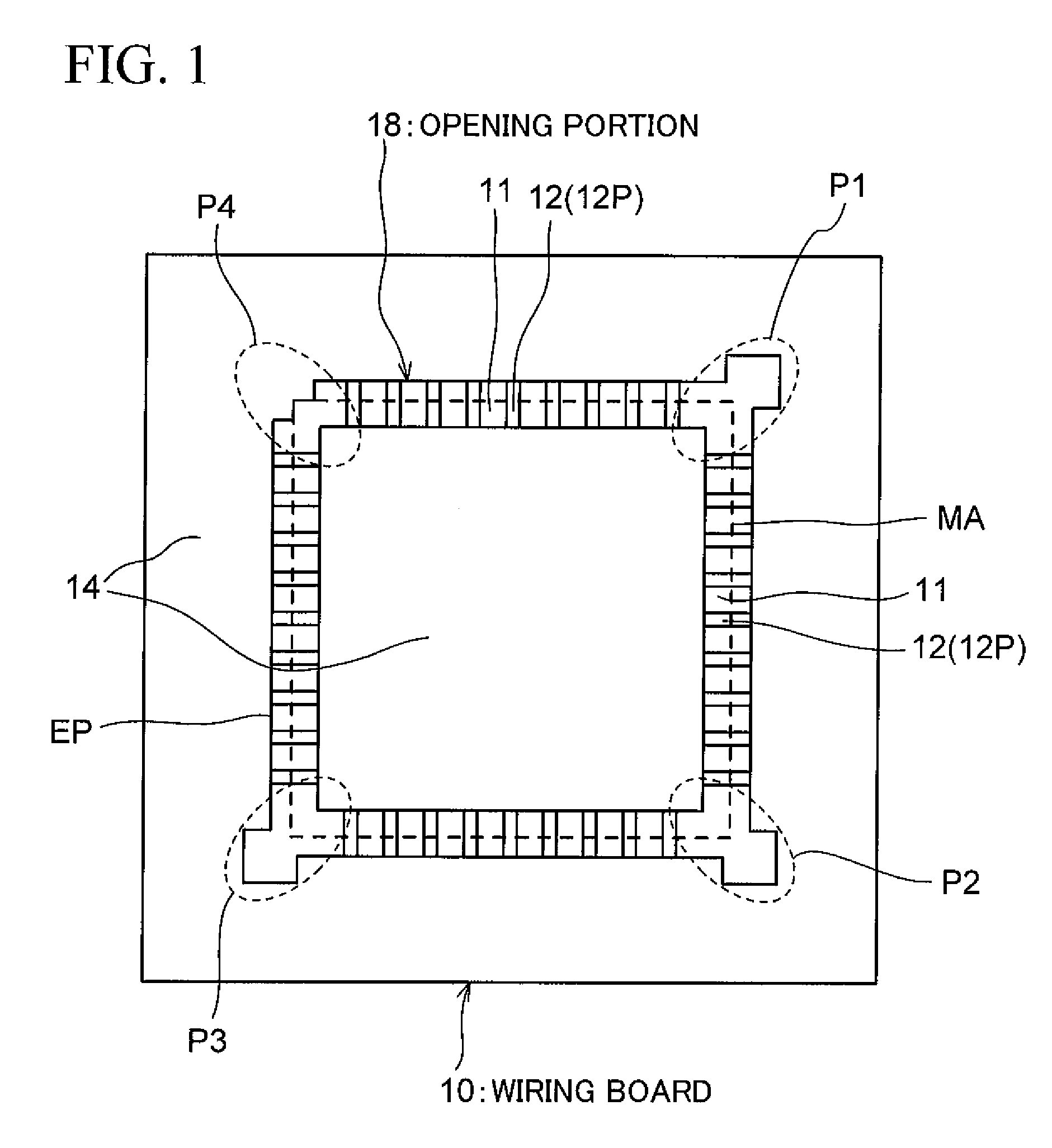

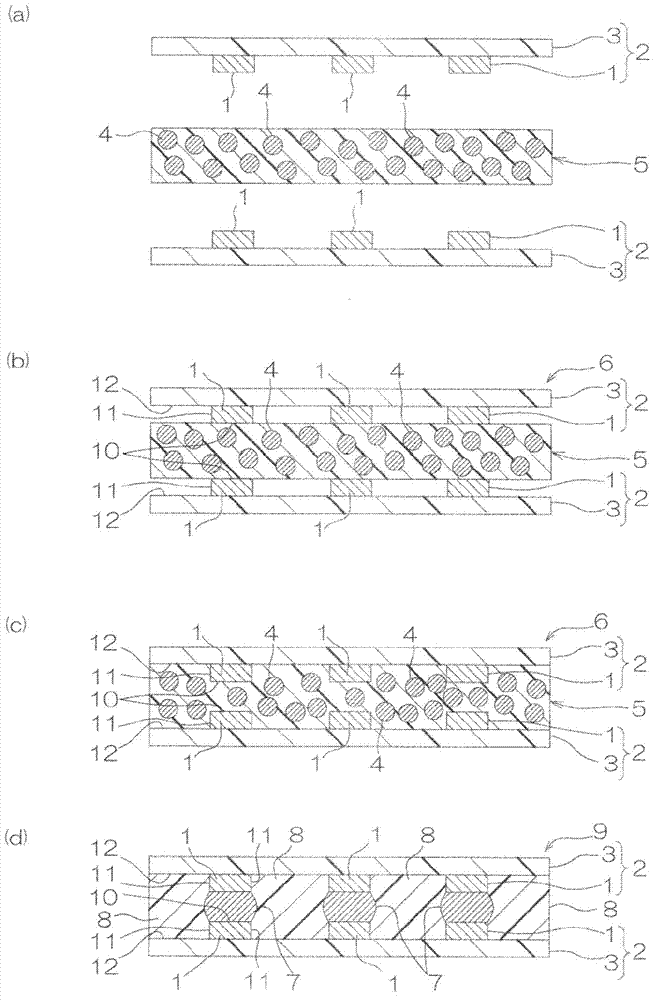

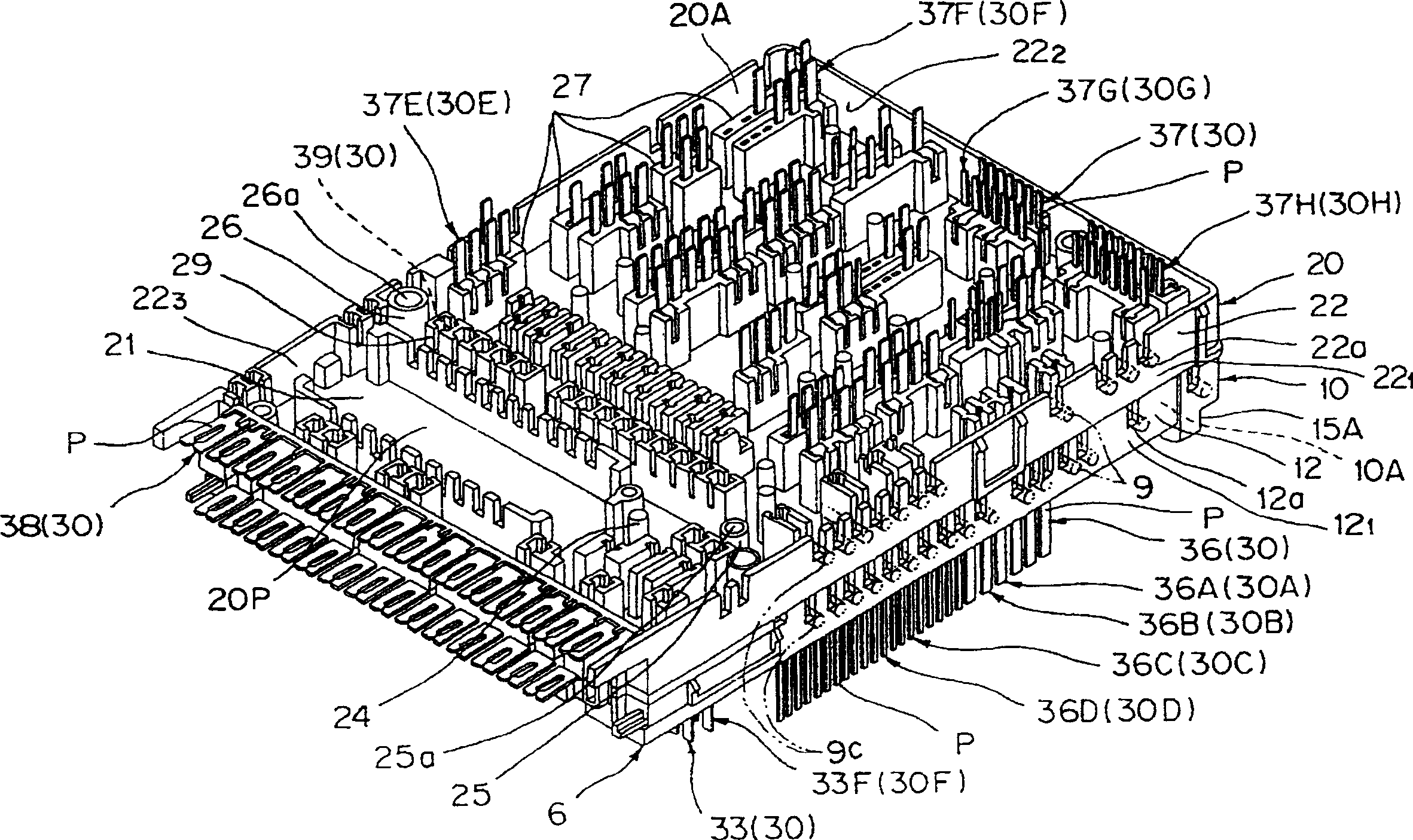

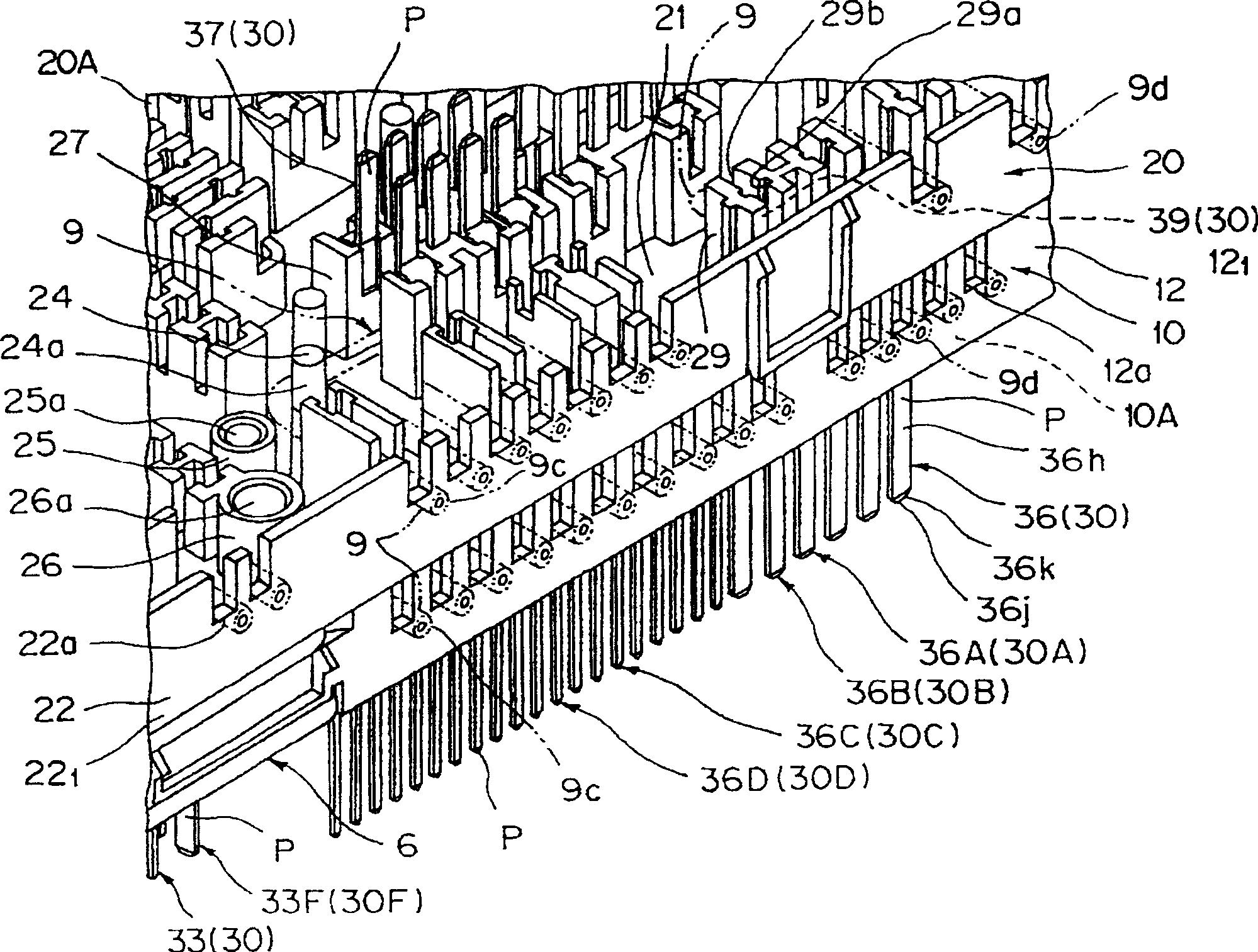

Multilayer wiring substrate

InactiveCN102111952AUniform depthReliable formationPrinted circuit detailsPrinted circuit aspectsInsulation layerElectrical conductor

A multilayer wiring substrate can reliably connect a plurality of connecting objects of different types. The multilayer wiring substrate is provided with a multilayer laminated structure (30) laminated alternately by a plurality of resin insulation layers (21-24) made primarily of the same resin insulation material, and a plurality of conductive layers (26), wherein on the upper surface (31) side of the laminated structure (30) there are provided an IC chip connector for connecting to IC chips, a capacitor connector (42) for connecting capacitors. The capacitor connector (42) is higher than a reference surface, and the IC chip connector (41) is lower than the reference surface, while the surface of the outermost resin insulation layers (24) exposed from the upper surface (31) of the laminated structure (30) is used as the reference surface.

Owner:NGK SPARK PLUG CO LTD

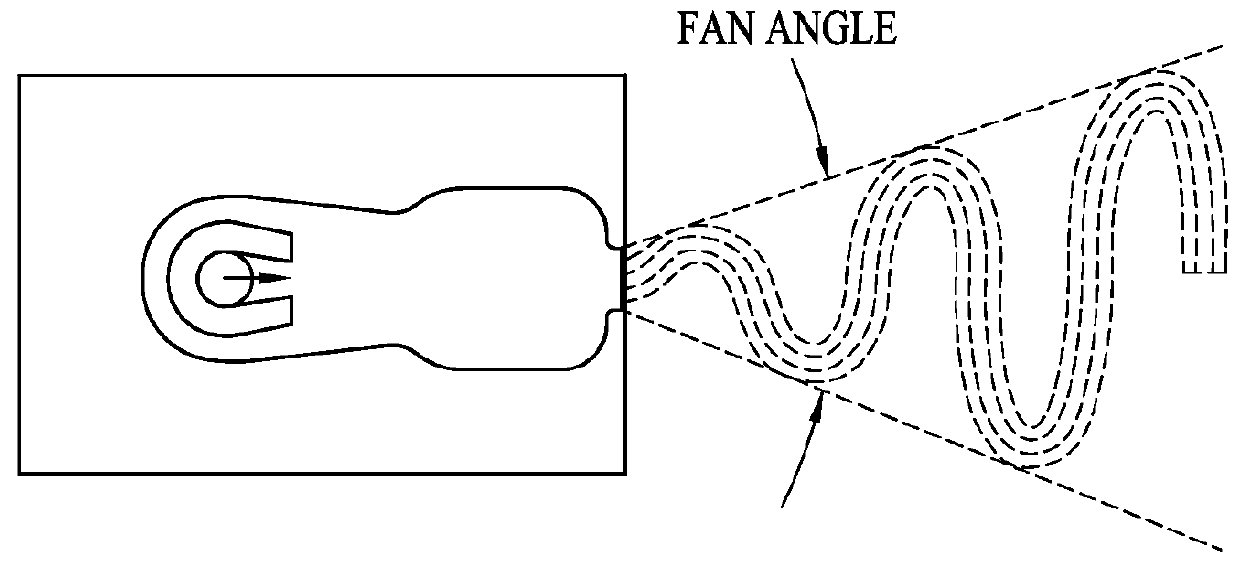

Owl, Double-bowl and slot-bump fluidic oscillator circuits, improved fluidic nozzle assemblies and methods for generating sprays with enhanced cold performance

ActiveUS20160030954A1Cost-effectiveBroaden dynamic and cold performance envelopeSpray nozzlesFluid dynamicsEngineeringFluid pressure

A fluidic circuit configured to spray an oscillating pattern of fluid droplets, having an inlet in fluid communication with a source and including a power nozzle with an oscillation chamber having a fluid jet steering section in fluid communication with the power nozzle and having either (a) a first fluid pressure accumulating volume opposite a second fluid pressure accumulating volume or (b) a first fluid jet attachment feature opposing a second fluid jet attachment feature. The fluid jet steering section is in fluid communication with and emits a fluid jet into an oscillation inducing interaction region with opposing first and second side wall ears or features which define an oscillation inducing interaction region in the oscillation chamber for causing the jet of fluid to rhythmically sweep back and forth between the sidewalls in the oscillation chamber and create a distally projecting oscillating spray.

Owner:DLHBOWLES INC

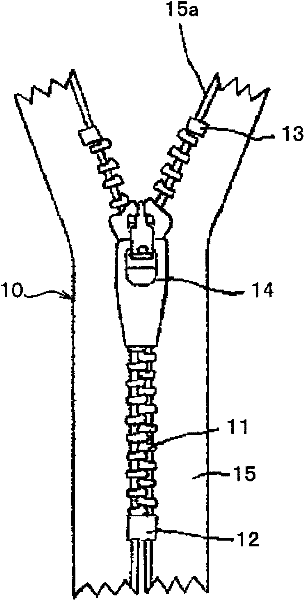

Zipper component and slide zipper, and method for producing zipper component

ActiveCN102665473ADifficult or no crackingLittle or no crackingSlide fastenersMaterials scienceMetal

A zipper component (1) comprising a component body (2) made of a metal and a metal plating film (3) provided on the surface of said component body. In this zipper component (1), at least a part of said component body (2) has been thermally treated before bending and thus said metal plating film (3) has a recrystallized structure wherein at least a part thereof has been recrystallized. Since the ductility of the metal plating film (3) can be improved thereby, when the zipper component (1) is bent, the metal plating film (3) can be deformed to follow the deformation of the component body (2). Therefore, the occurrence of crevicing or cracking in the metal plating film (3) can be prevented.

Owner:YKK CORP

Semiconductor device with elongated interconnecting member and fabrication method thereof

InactiveUS20020185736A1Reliable formingReduced dimensionSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

In a semiconductor device with multiple wiring layers, to connect a conductive line in a lower wiring layer to a conductive line in an upper wiring layer, two conductive members are formed in the space between the upper and lower conductive layers, one conductive member in contact with each conductive line. The two conductive members meet in the space between the two conductive layers to form an electrical path between the two conductive lines. One or both of the conductive members may have a rectangular bar shape extending lengthwise along the conductive line with which it makes contact. The conductive members can have a reduced height and enlarged area that enables interconnections to be formed with greater stability and reliability than by conventional methods.

Owner:LAPIS SEMICON CO LTD

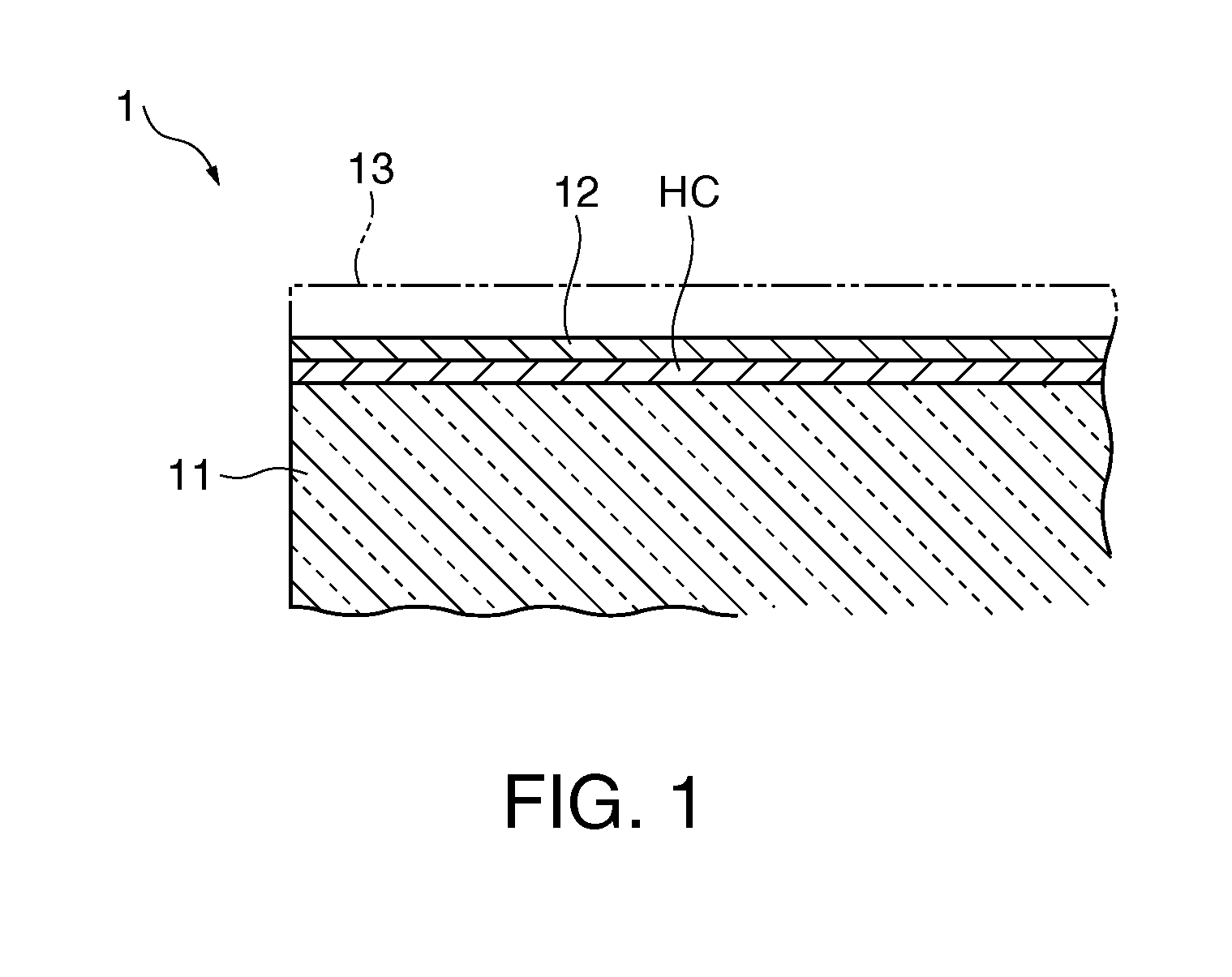

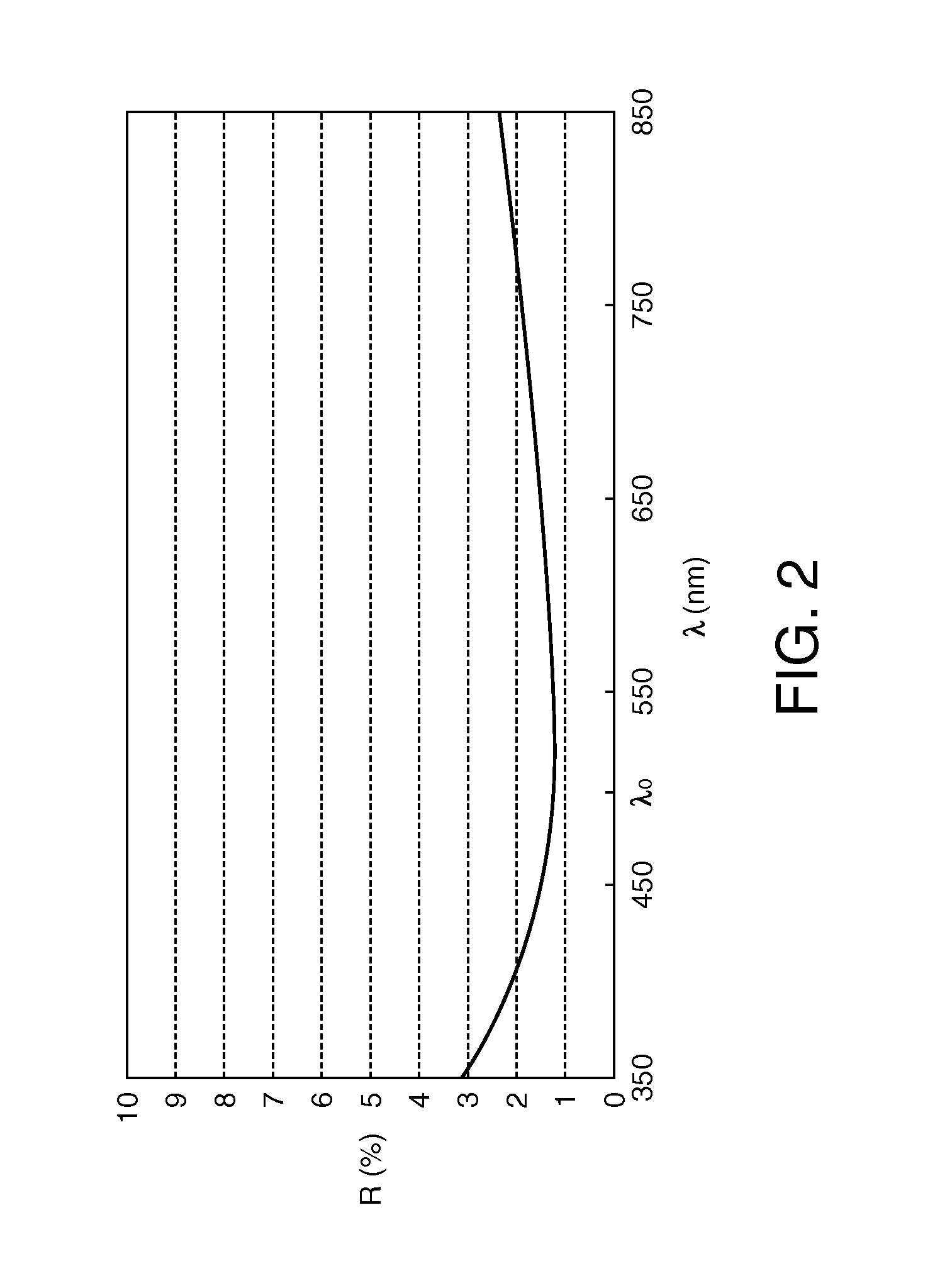

Optical device, image-capturing apparatus, electronic apparatus, and method for producing optical device

InactiveUS20130265477A1High-quality antireflection layerWell formedTelevision system detailsSolid-state devicesEpoxySimple Organic Compounds

An optical device includes an inorganic light-transmissive base material, a hard coat layer, which is provided on a principal surface of the light-transmissive base material and is harder than the light-transmissive base material, and an organic antireflection layer, which is provided on a principal surface of the hard coat layer and contains an organosilicon compound, an epoxy group-containing organic compound, and hollow silica. The hard coat layer and at least one of the organosilicon compound and the epoxy group-containing organic compound are covalently bonded to each other. The occurrence of a defect in the organic antireflection layer can be prevented. The organic antireflection layer has a higher dust-proof effect than an inorganic antireflection film, and therefore, dirt, dust, etc. hardly adhere thereto.

Owner:SEIKO EPSON CORP

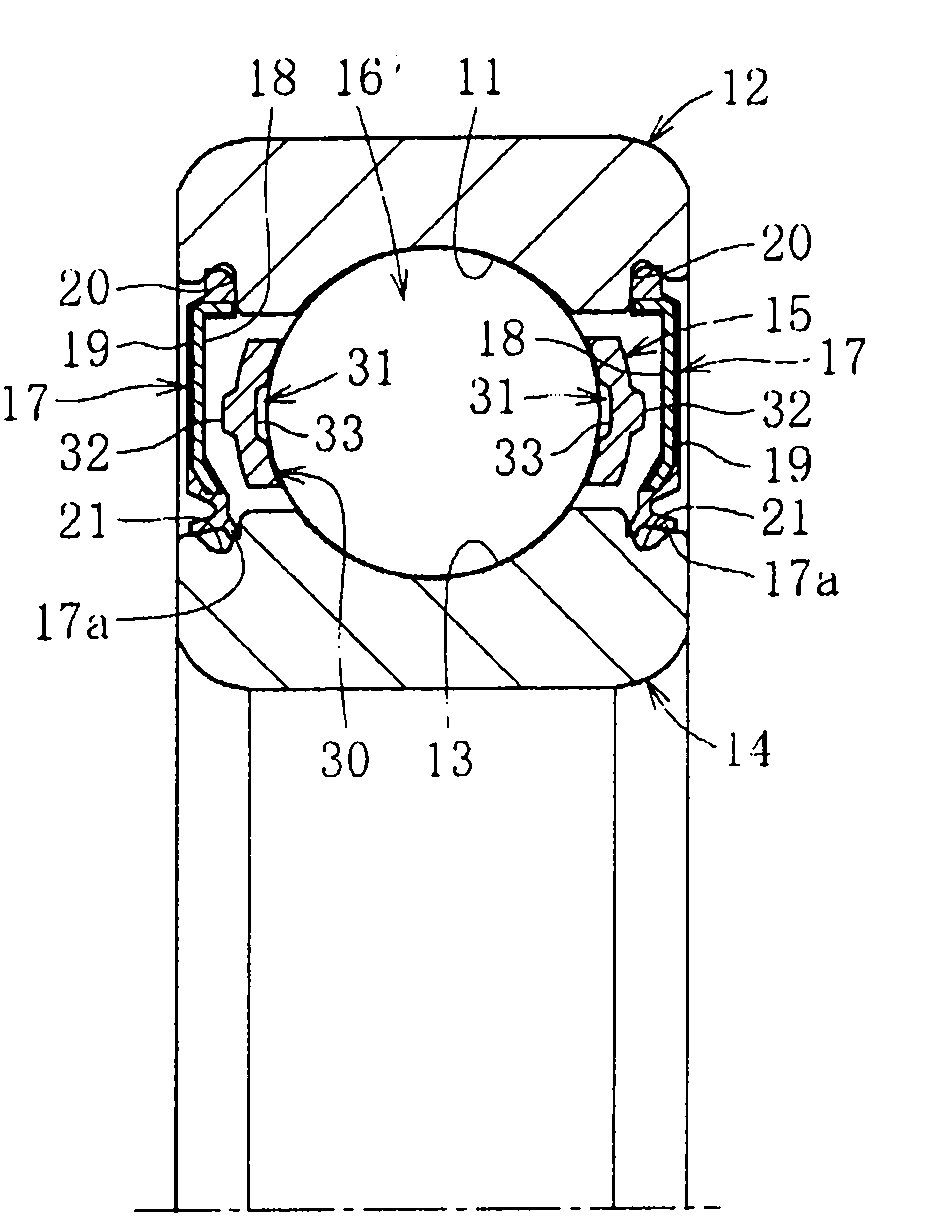

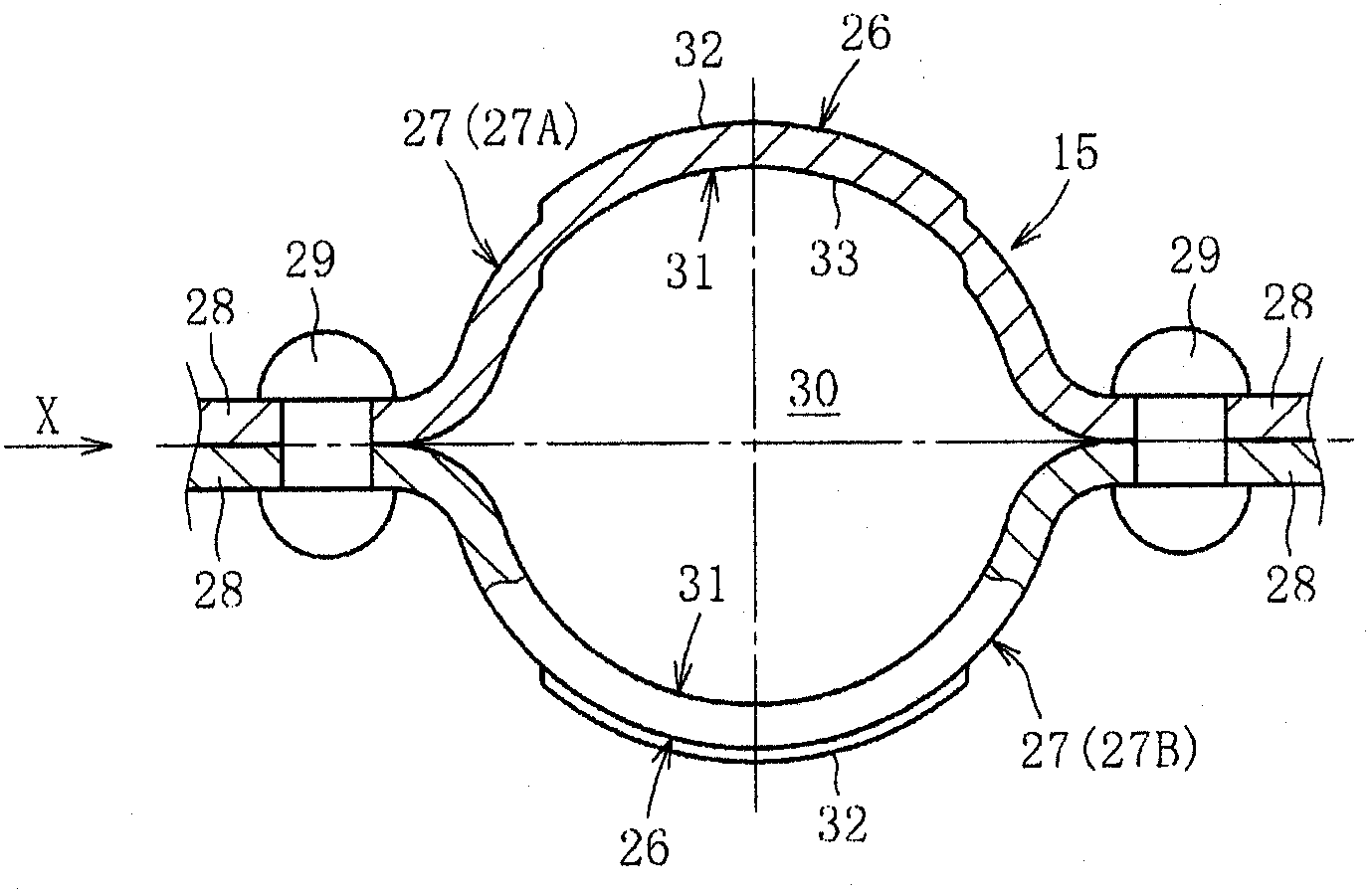

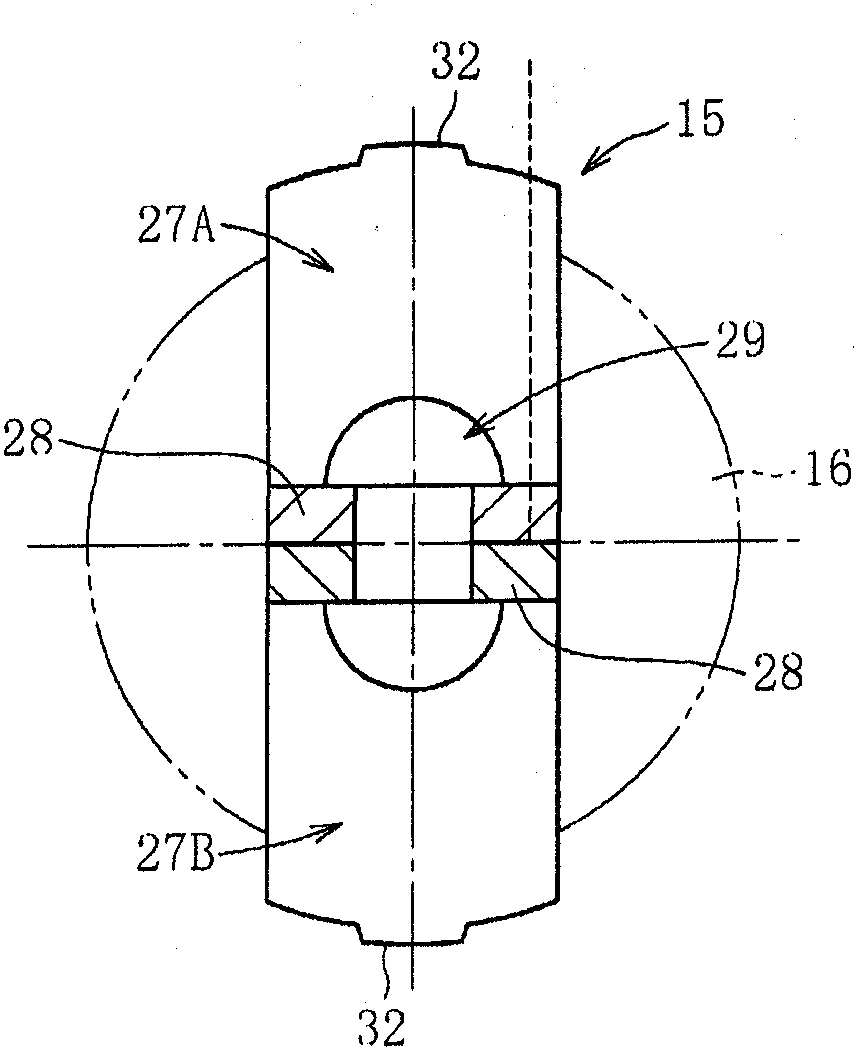

Retainer, deep groove ball bearing, and bearing with seal

ActiveCN102066786AReduced oil filmReliable formationBall bearingsBearing componentsForeign matterBall bearing

Provided are a retainer achieving low torque, a deep groove ball bearing using the retainer, and a bearing equipped with a seal, capable of preventing entry of foreign matter into the bearing and having sufficiently reduced seal torque. The retainer is formed by combining two annular holding plates (27A, 27B) each having hemispherical protrusions (26) circumferentially arranged at predetermined intervals. Pockets (30) for retaining balls (16) are formed by opposed hemispherical protrusions (26, 26). Contactless sections (31) with which a ball (16) does not make contact are formed on those surfaces of each pocket (30) which face the ball. The area of contact of each pocket (30) with the ball (16) is set less by 15% to 30% than the area of contact of the pocket (30) with the ball (16) when the contactless sections (31) are not provided. A seal member (17) is a contact seal in which a seal lip (17a) makes contact with the other raceway ring. The material of at least the front end of the seal lip (17a) is an easily wearable high wear material.

Owner:NTN CORP

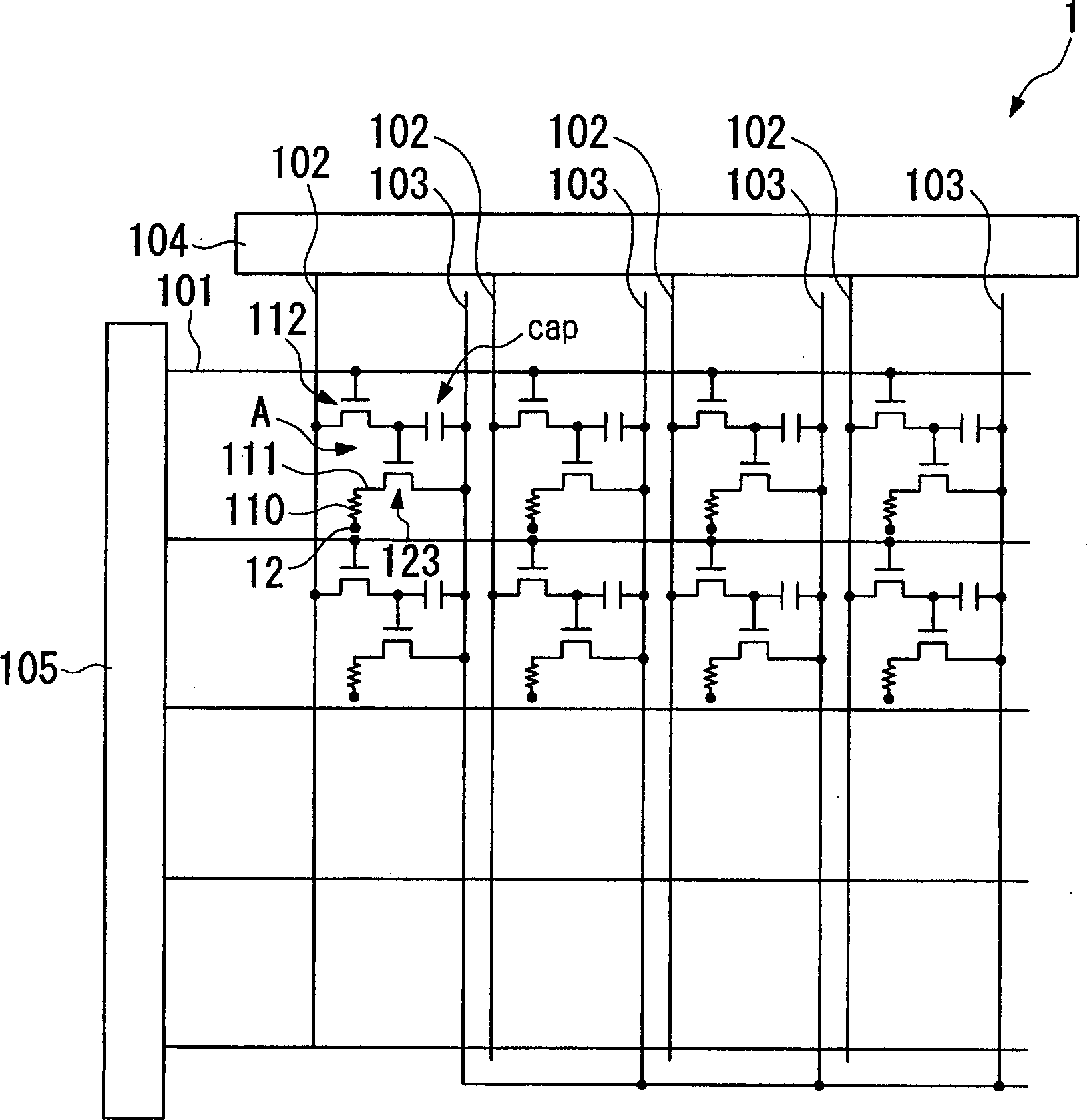

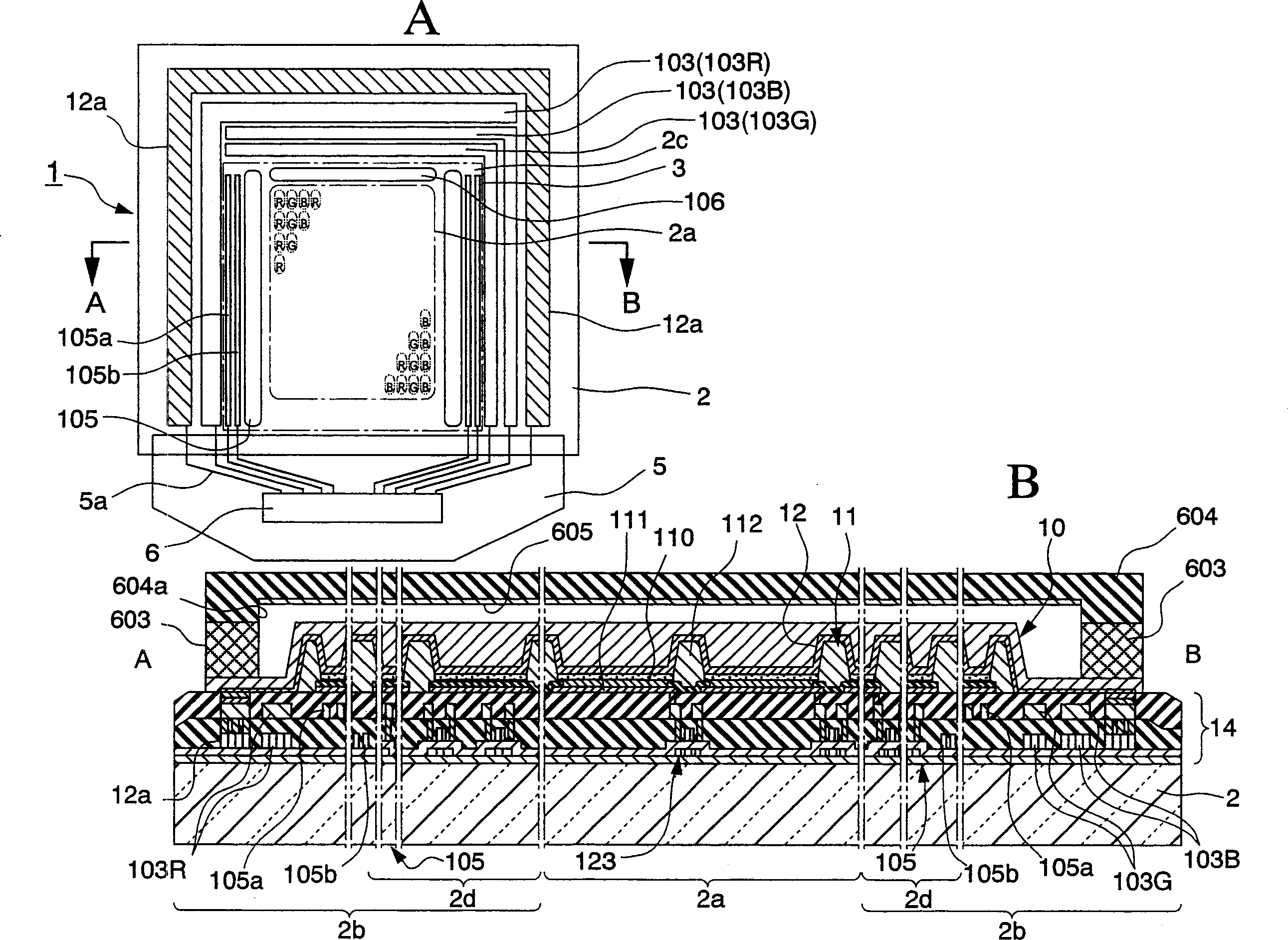

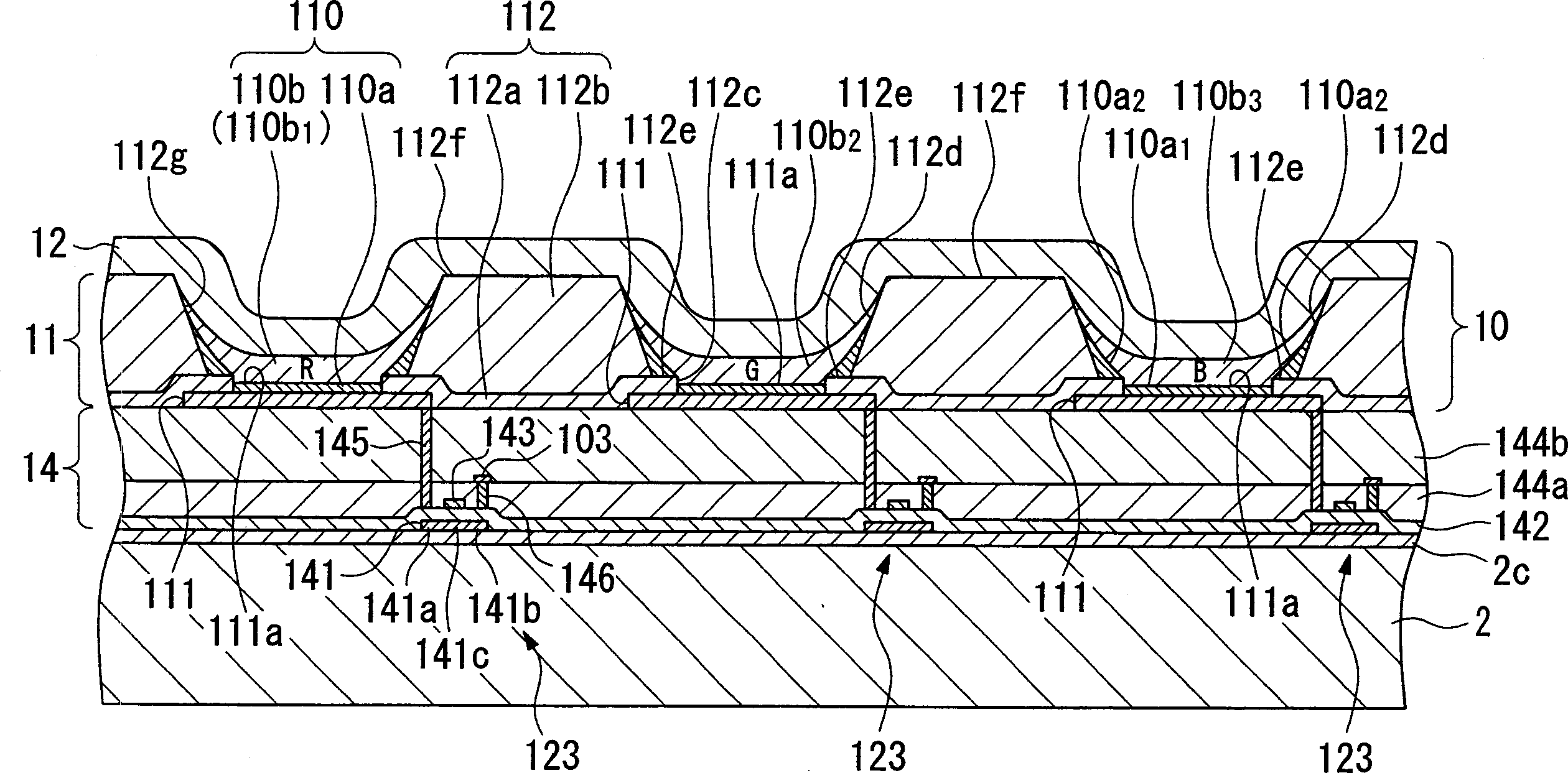

Display device, electronic apparatus and method for mfg. display device

InactiveCN1426894ALight evenlyRegular shapeElectroluminescent light sourcesSolid-state devicesTransport layerDisplay device

The present invention provides a display apparatus in which there is no shorting between the electrodes and cathode, and there is little variation in the amount of emitted light within a single luminescent layer. A display apparatus is employed in which first and second bank layers are extended to the peripheral edge section of electrodes, the first bank layer is extended farther towards the center of electrodes than the second bank layer, a first laminated section is formed on the first bank layer, an opening is provided in the bank sections, functional layers are composed of a positive hole injection / transport layer and a luminescent layer, and the positive hole injection / transport layer is composed of a flat section formed on the electrodes and a peripheral edge section formed on the first laminated section of the first bank layer.

Owner:ELEMENT CAPITAL COMMERCIAL CO PTE LTD

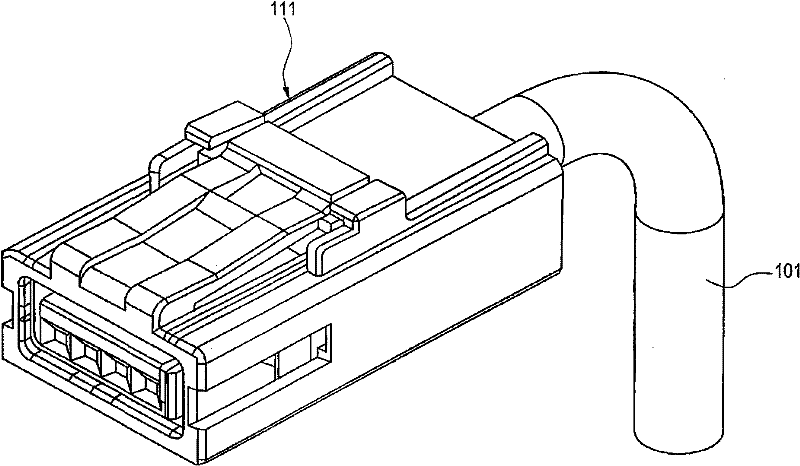

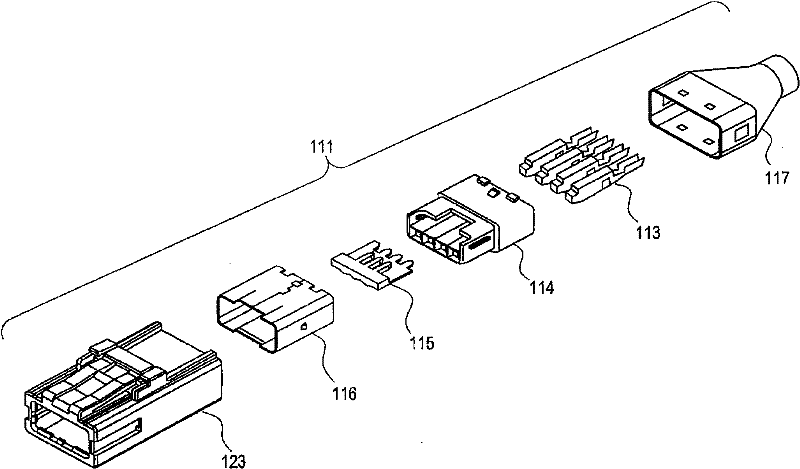

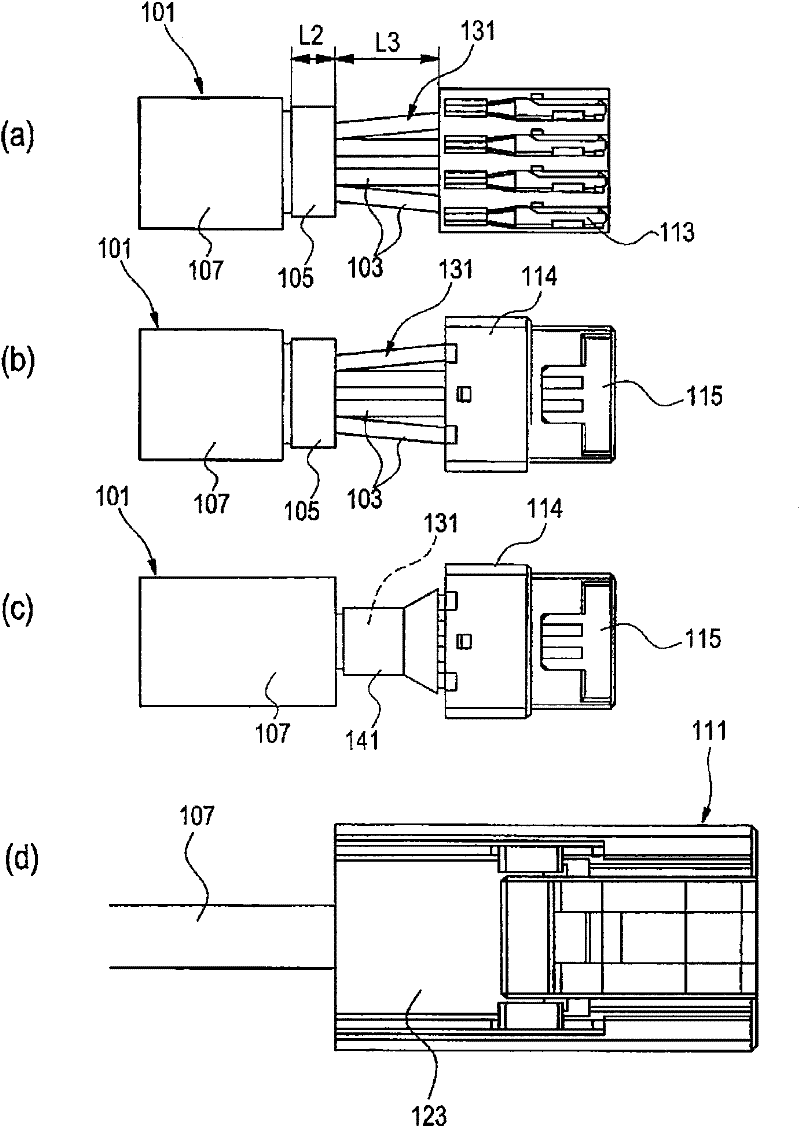

Shielded cable connecting structure and shielded cable connecting method

ActiveCN102394446AReliable formationSave man hoursLine/current collector detailsElectrically conductive connectionsShielded cableElectromagnetic shielding

There is provided a shielded cable connecting structure comprising a shielding layer removed portion where a plurality of covered wires are exposed for connection of connecting terminals to a shield connector and a conductive heat-shrinkable tube which is fittingly mounted on an end portion of an electromagnetic shielding layer which lies adjacent to the shielding layer removed portion and the shielding layer removed portion so as to bind together the plurality of covered wires through heat shrinkage.

Owner:YAZAKI CORP

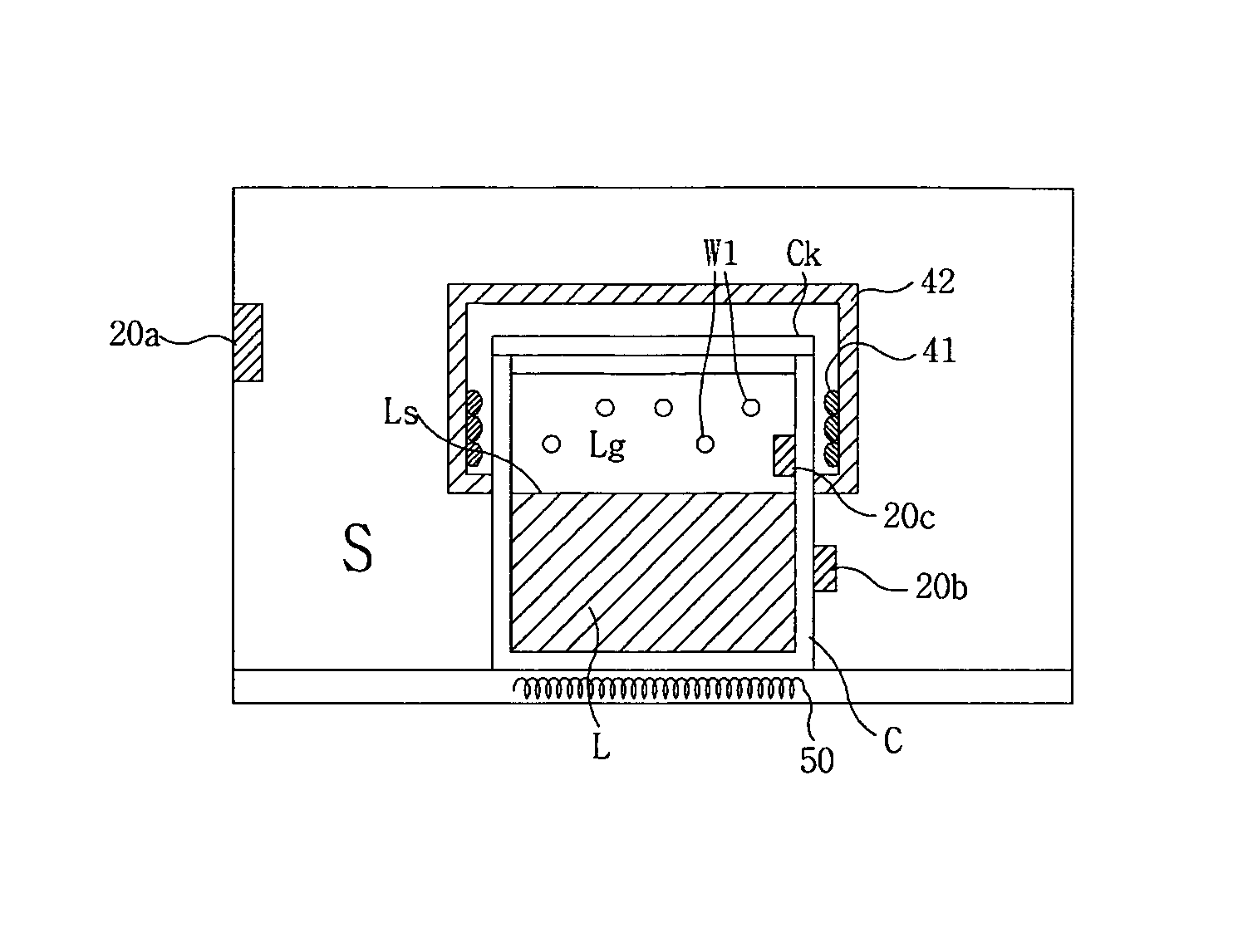

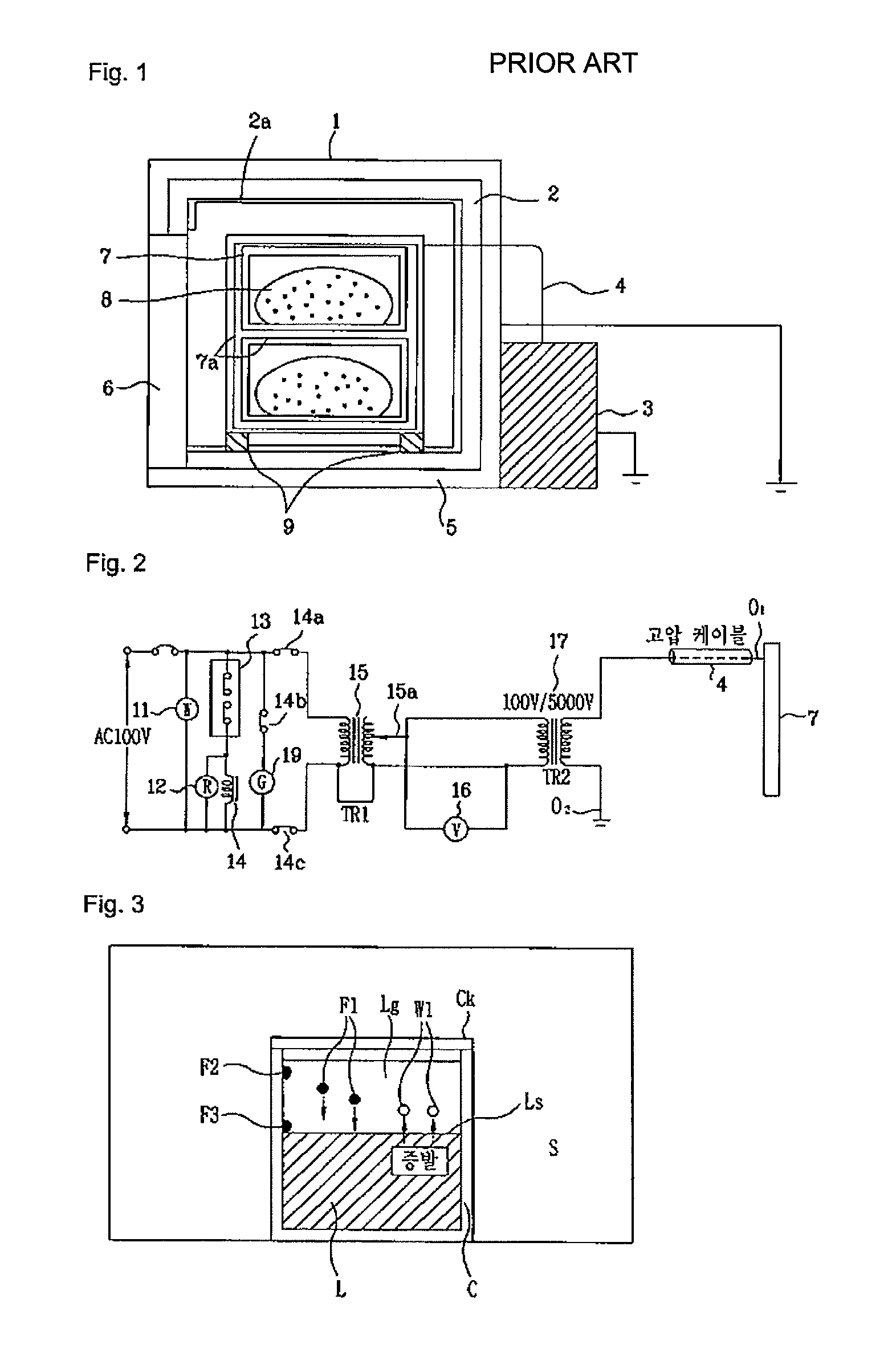

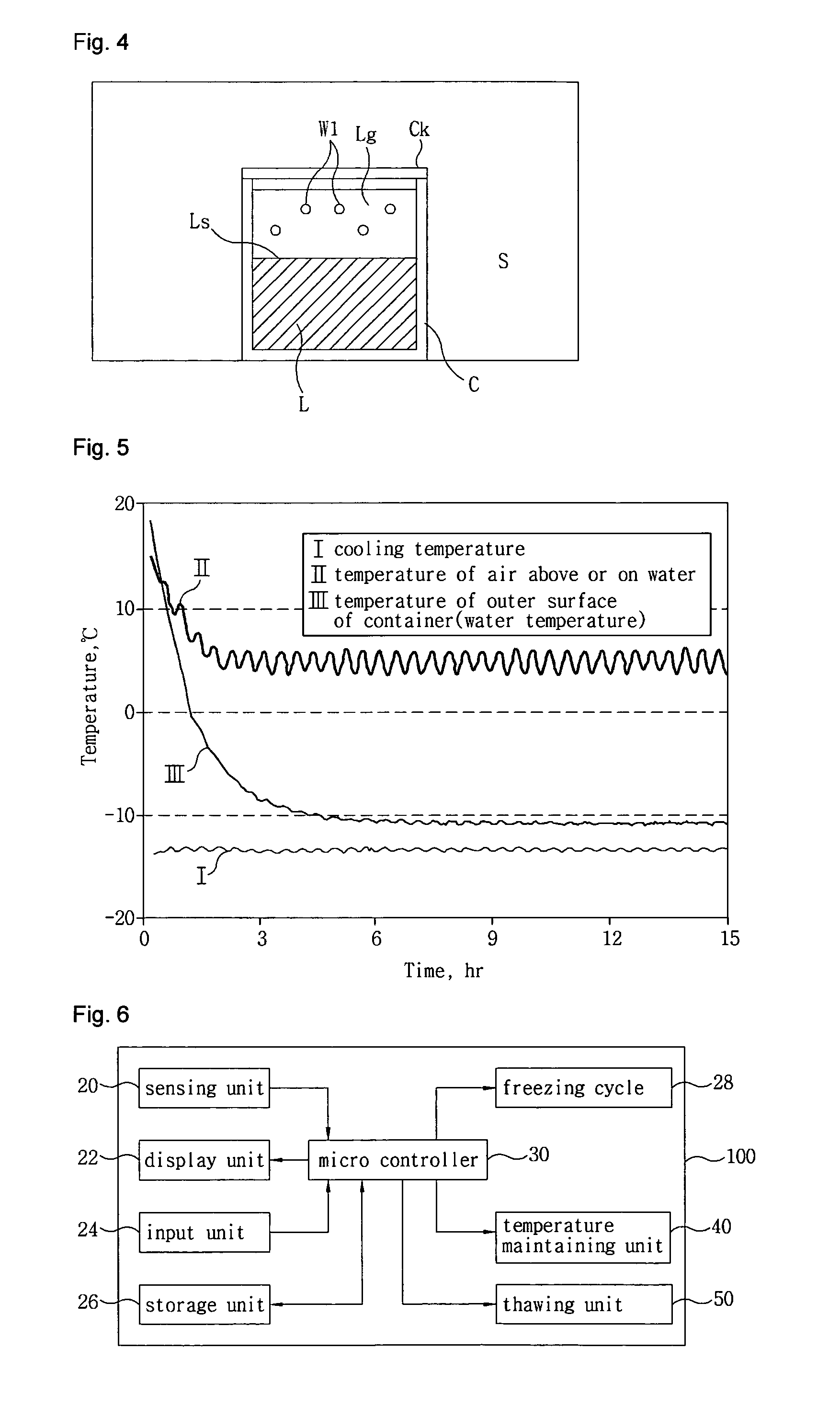

Supercooling apparatus

ActiveUS8572990B2Maintain freshnessMaintain qualityIce productionDomestic refrigeratorsEngineeringSupercooling

Owner:LG ELECTRONICS INC

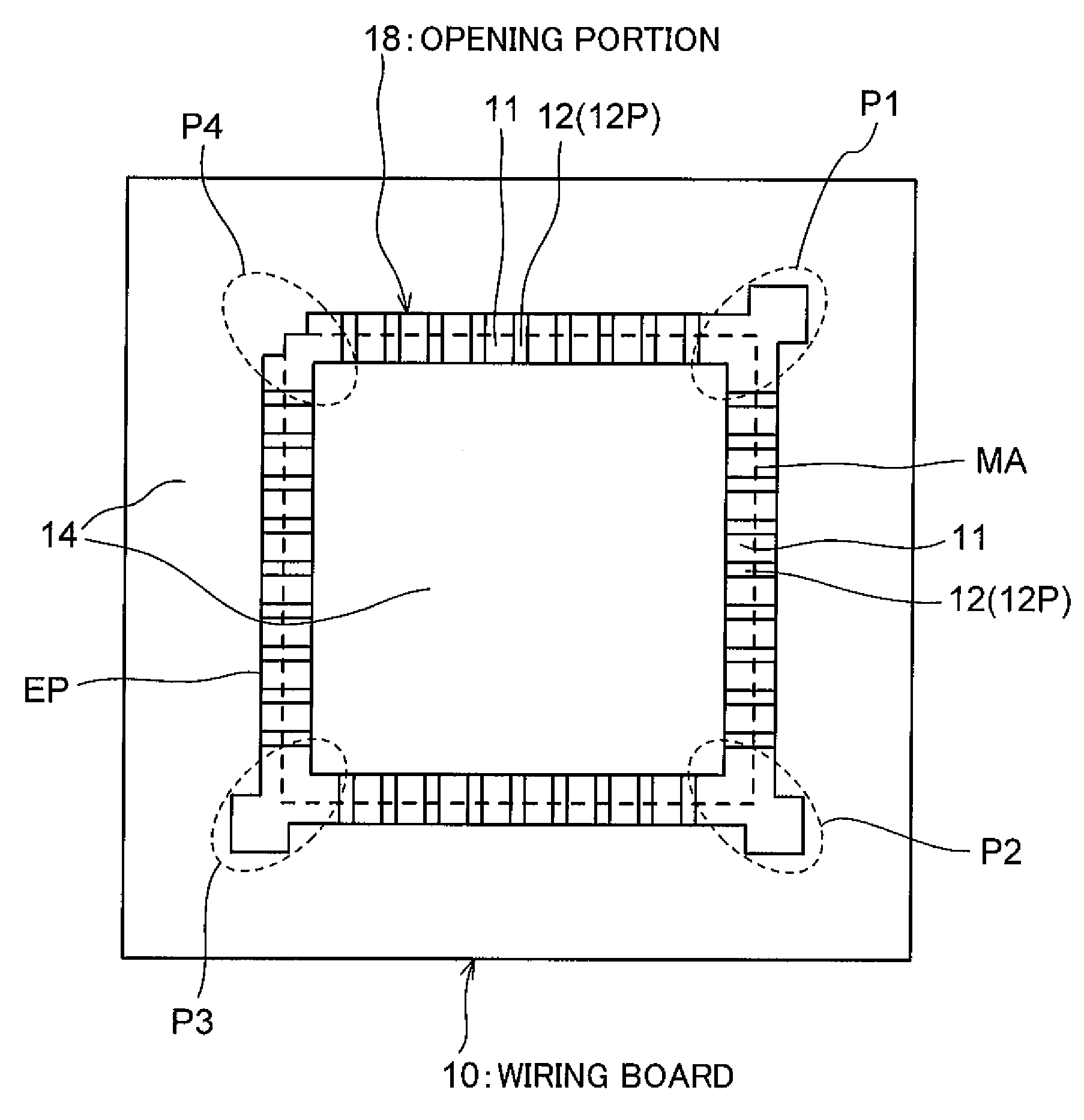

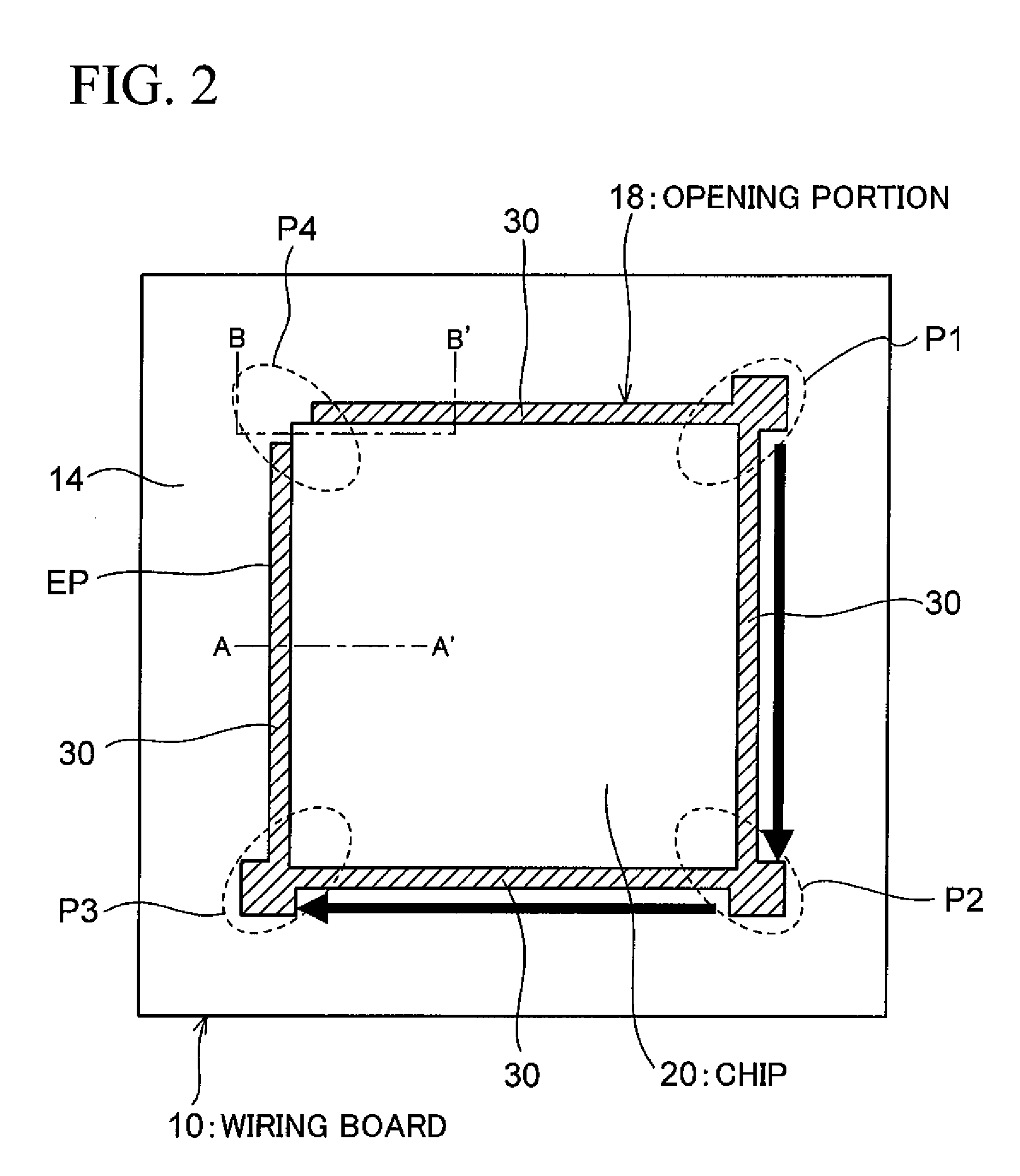

Wiring board

ActiveUS20090283317A1Reliable formationImprove liquiditySemiconductor/solid-state device detailsPrinted circuit aspectsElectrical conductorPower strip

A wiring board between which and a chip to be mounted a resin is filled includes: a substrate body on which a conductor portion to be connected to an electrode terminal of the chip is formed; and an insulating protection film formed on the substrate body and having an opening portion formed therein to expose the conductor portion. The opening portion is formed in such a manner that the edge thereof is positioned along and outside the outer shape of the chip except for a specific corner portion, and that the edge in the specific corner portion is positioned on a side of or inside the outer shape of the chip.

Owner:SHINKO ELECTRIC IND CO LTD

Preform and container for radiosensitive products and method for the manufacturing thereof

The present invention provides a prefabricated component which is used for container as intermediate product. The container is used for containing product therein. The product is food or milk product which is sensitive to radiation, especially to light. The prefabricated component is at least composed of a base layer (1) which is mainly composed of plastic-based material, and furthermore the base layer (1) is added with a certain amount of additive (5). The invention is characterized in that the prefabricated components (10, 20) are almost nontransparent in the whole area, wherein the plastic additive (5) with a relatively low percentage is introduced for generating nontransparent appearance (22) thereby protecting the confined inner space (9) from the external radiation (V1, V2) at the condition of normal atmosphere. The external radiation is specifically electromagnetic radiation, and more particularly the effect of light.

Owner:RESILUX NV

Method of machining semiconductor wafer-use polishing pad and semiconductor wafer-use polishing pad

InactiveCN1592955AReduce surface roughnessHigh dimensional accuracyPigmenting treatmentSemiconductor/solid-state device manufacturingWater insolubleSurface roughness

An object of the invention is to provide a processing method of a polishing pad for semiconductor wafer capable of forming a groove, a concave portion, a through hole and the like having a small surface roughness of the inner surface of the groove and the like of 20 mu m or less, a high dimensional accuracy and a uniform cross-sectional shape, and a polishing pad for semiconductor wafer. In the present processing method, a surface of a polishing pad comprising a water-insoluble matrix containing a crosslinked polymer and a water-soluble particle dispersed in the water-insoluble matrix is processed by cutting and the like. Additionally, when a groove and the like are formed, it is preferable that a polishing pad is placed on one surface side of a machining table having a sucking hole, the pad is fixed on the one surface side of the machining table by vacuuming sucking it from the other surface of the machining table, and then a groove and the like are formed.

Owner:JSR CORPORATIOON

Storage device

InactiveCN1608191ALighting means savedReduce outputShow cabinetsLighting and heating apparatusEngineeringLarge capacity

Provided is a storage device comprising: a display cabinet capable of dividing the interior into a plurality of storage areas; supply duct; exhaust duct connected to an exhaust outlet capable of drawing air from the storage area. With this storage device, air for conditioning such as cooling or heating is in a state of circulating in each storage area, and environmental conditions can be efficiently adjusted in a unit storage area. Therefore, the storage device provided with the open display cabinet can provide a storage device with a high storage capacity that can omit the air curtain covering the entire open surface.

Owner:GLOSTER

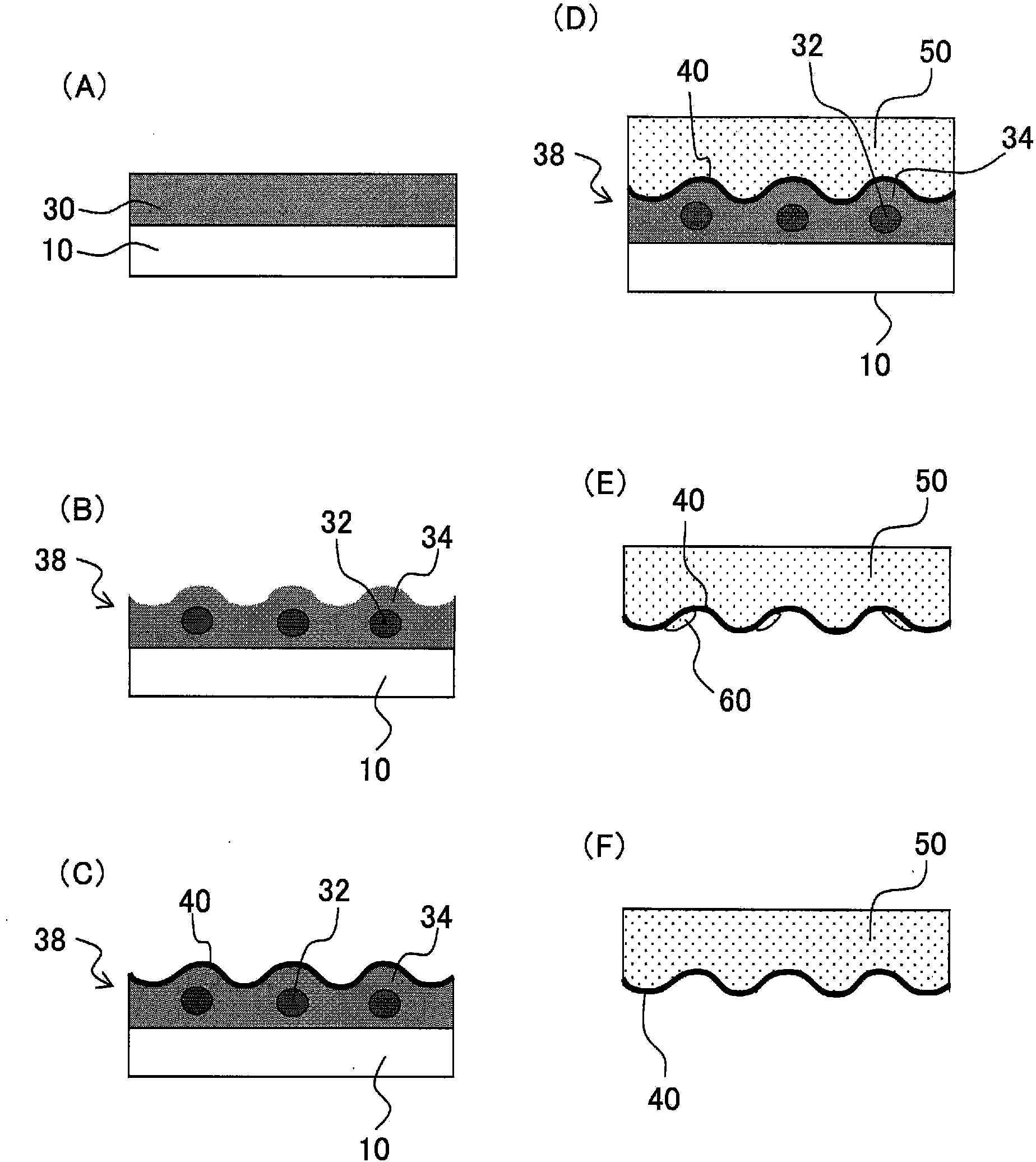

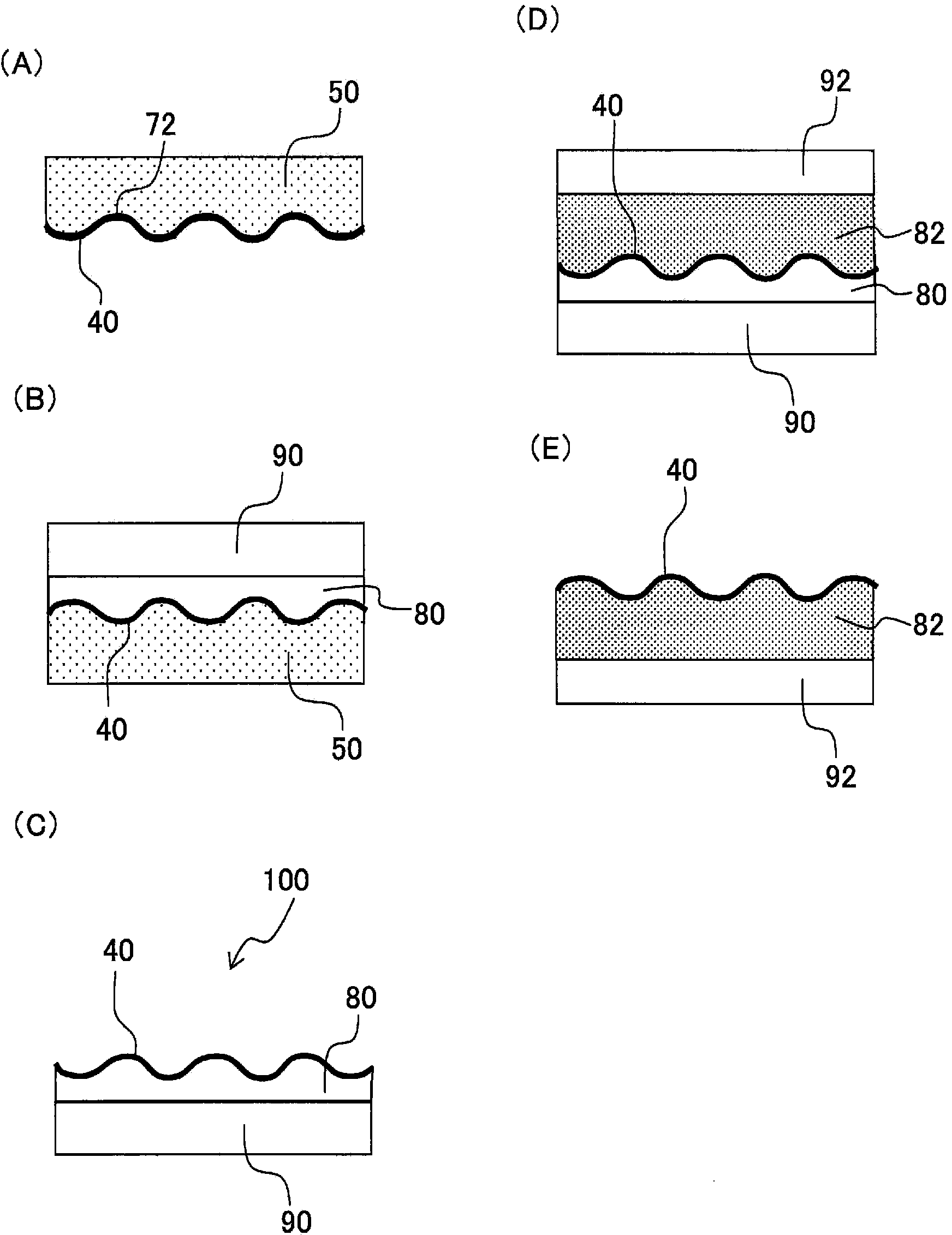

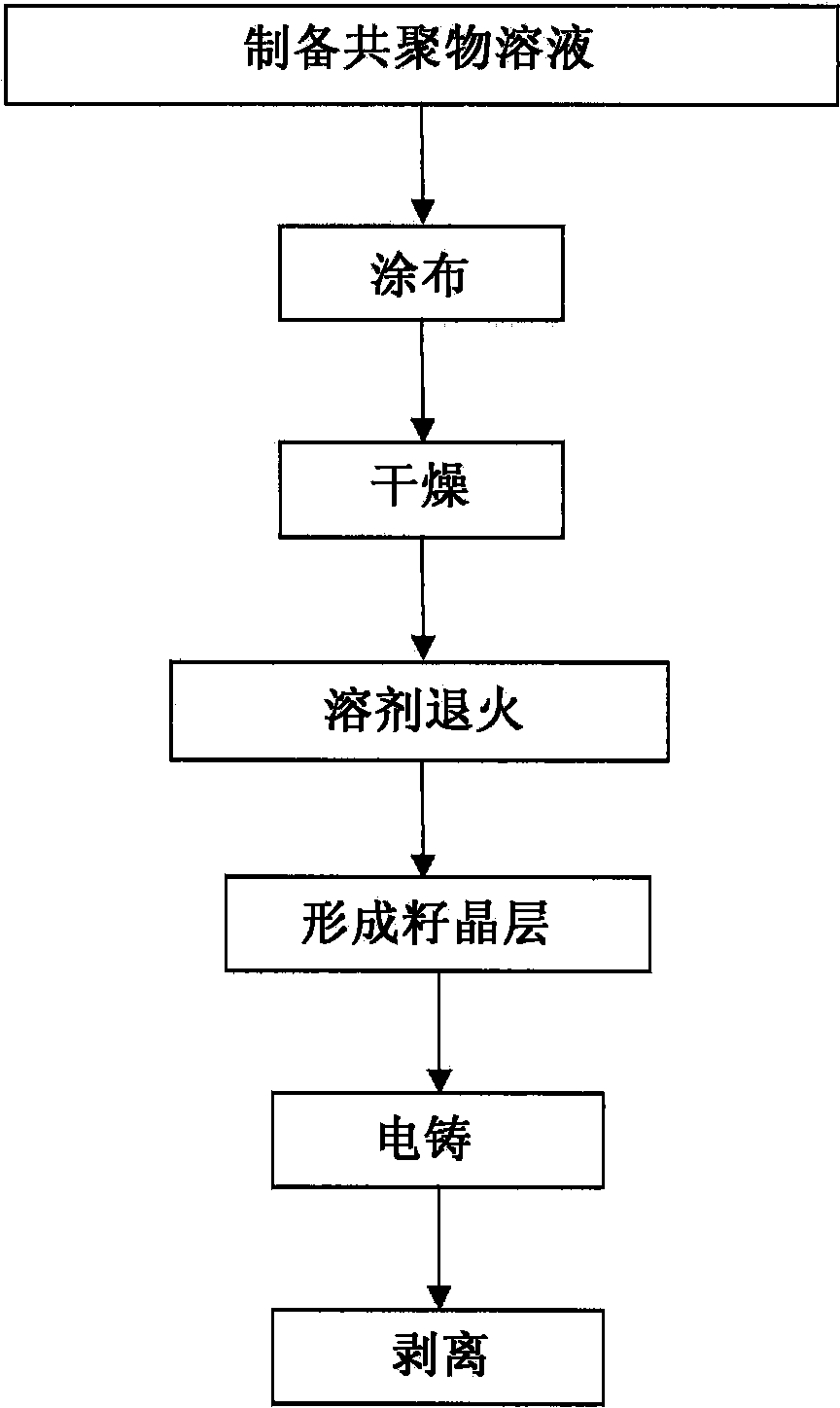

Method for producing mold for transferring fine pattern, method for producing substrate having uneven structure using same, and method for producing organic el element having said substrate having uneven structure

InactiveCN104254438AGood peeling effectLow costElectroluminescent light sourcesNanoinformaticsPolymer scienceOrganosolv

Owner:JX NIPPON OIL & ENERGY CORP

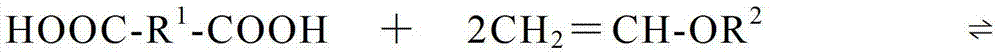

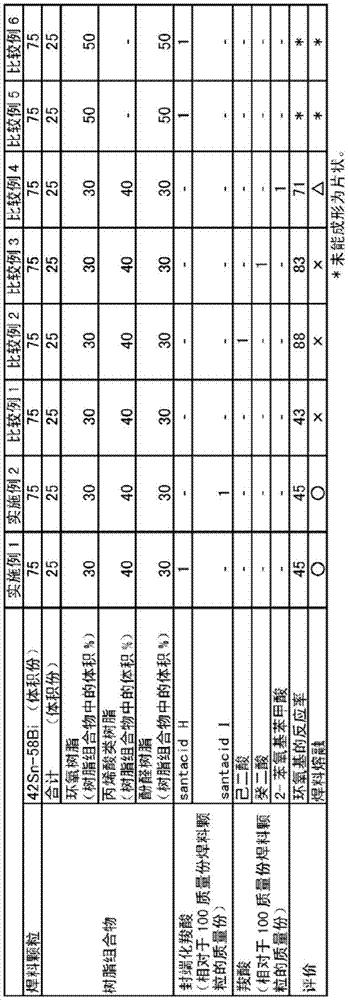

Joining sheet, electronic component, and producing method thereof

InactiveCN103372730AInhibitory responseEasy to shapePrinted circuit assemblingSolid-state devicesCarboxylic acidElectronic component

The invention provides a joining sheet, electronic component, and producing method thereof. The joining sheet contains solder particles, a thermosetting resin, a thermoplastic resin, and a blocked carboxylic acid.

Owner:NITTO DENKO CORP

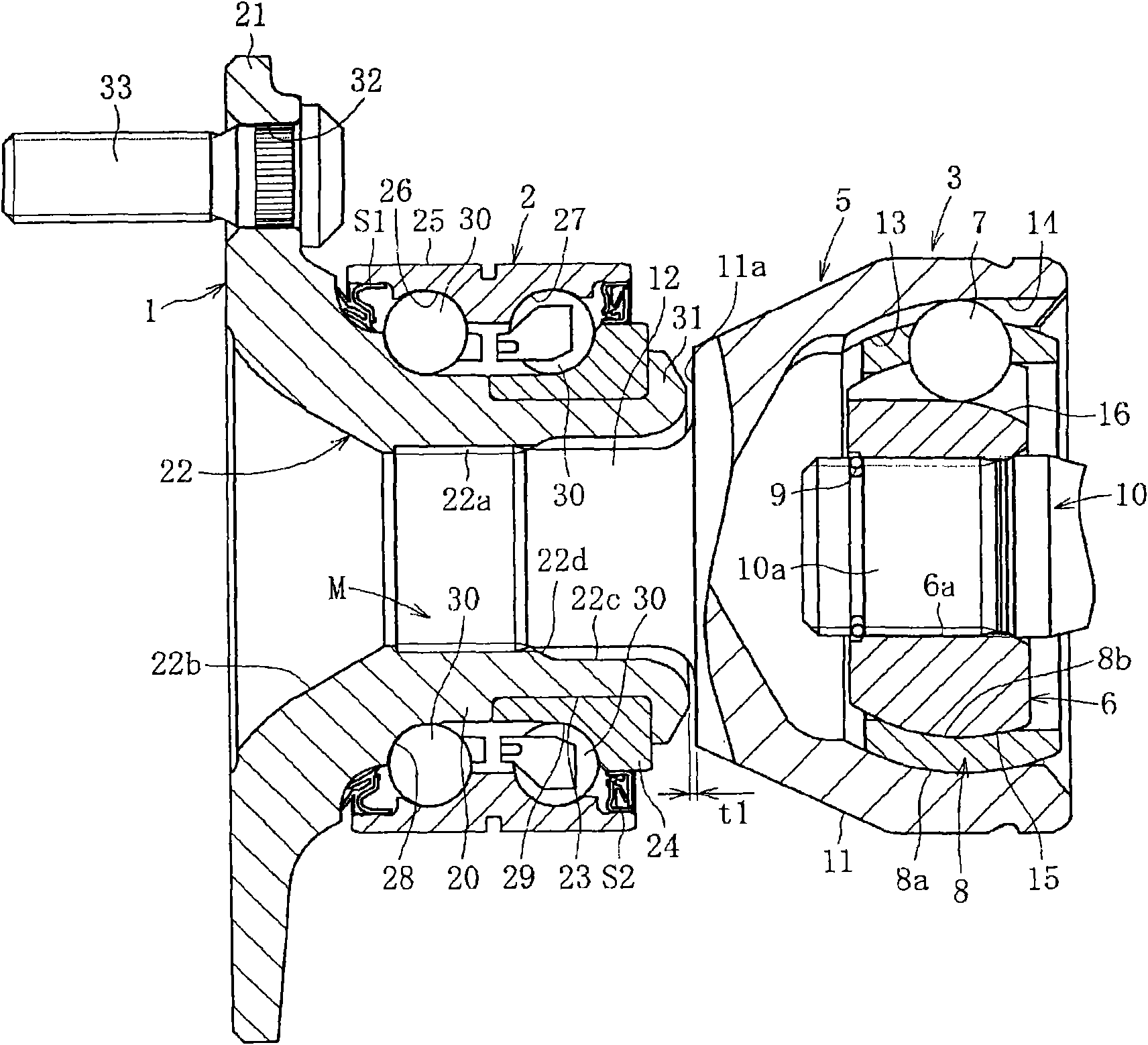

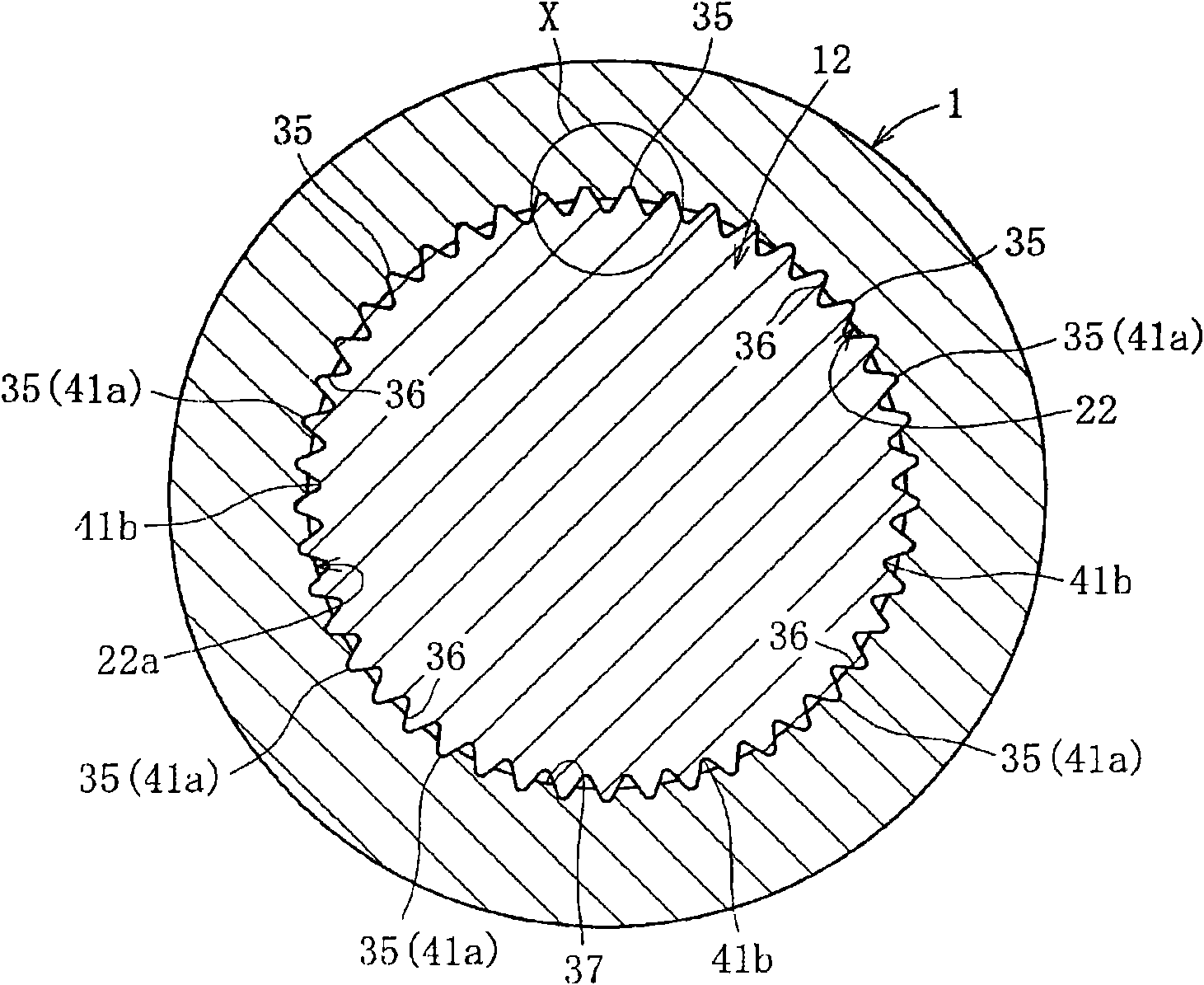

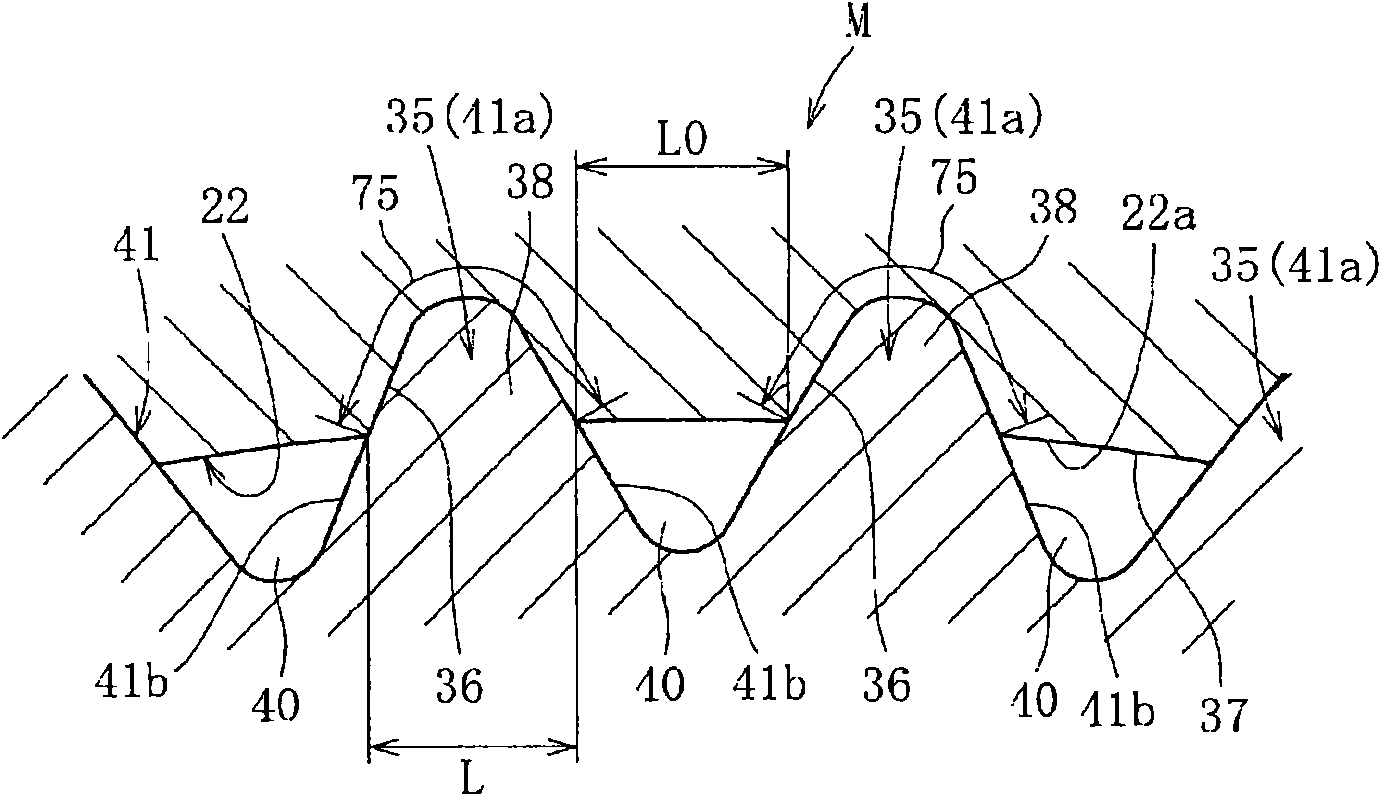

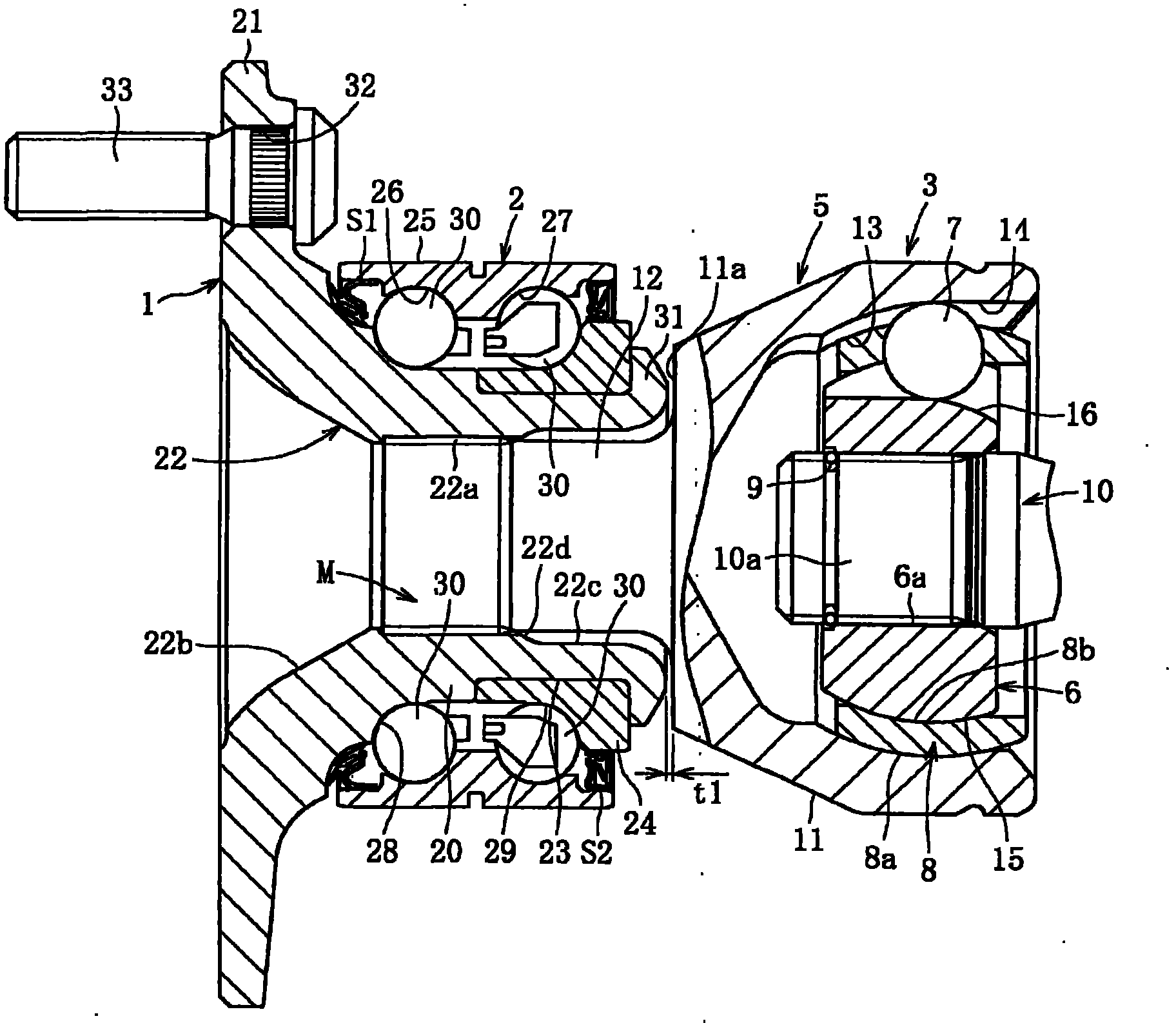

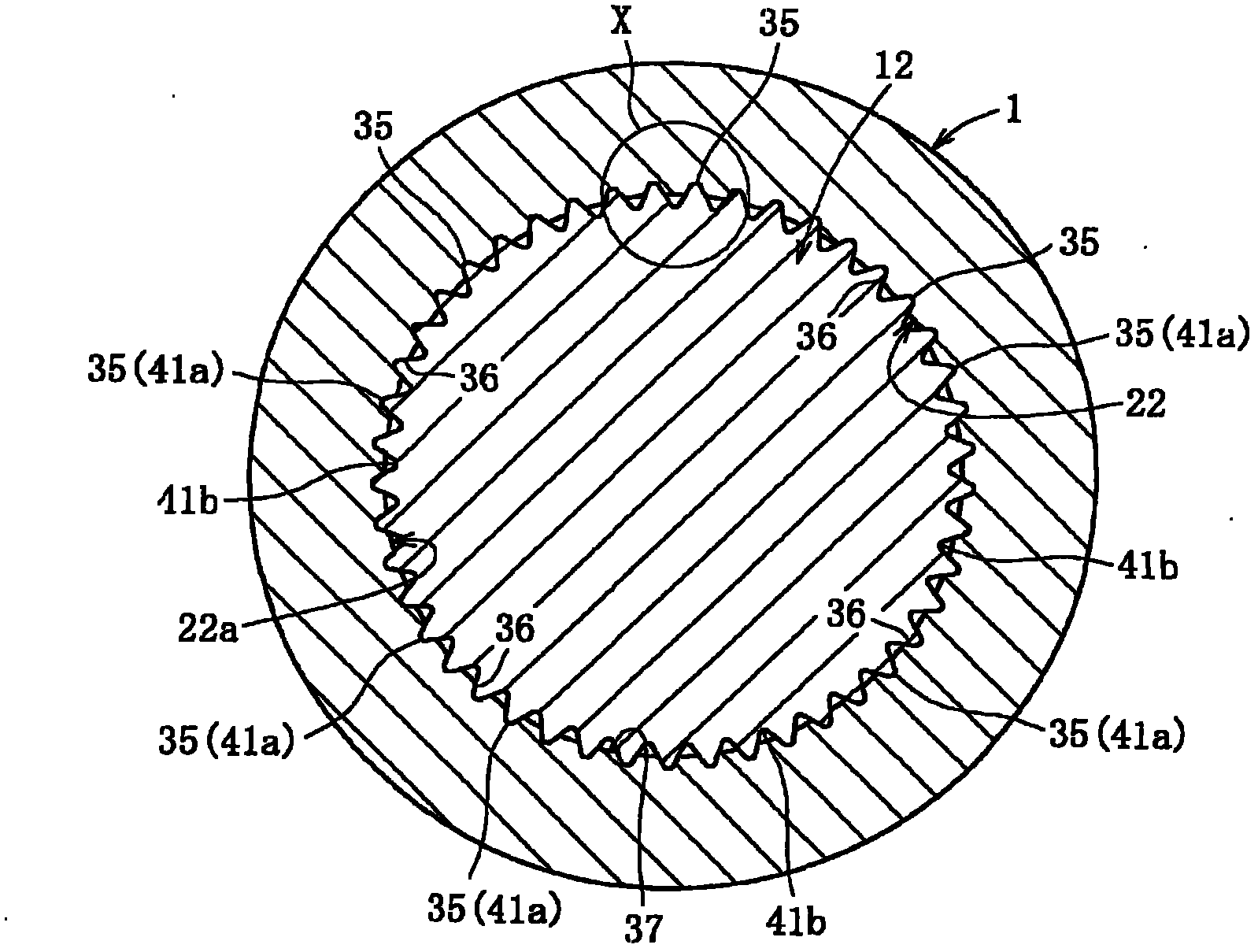

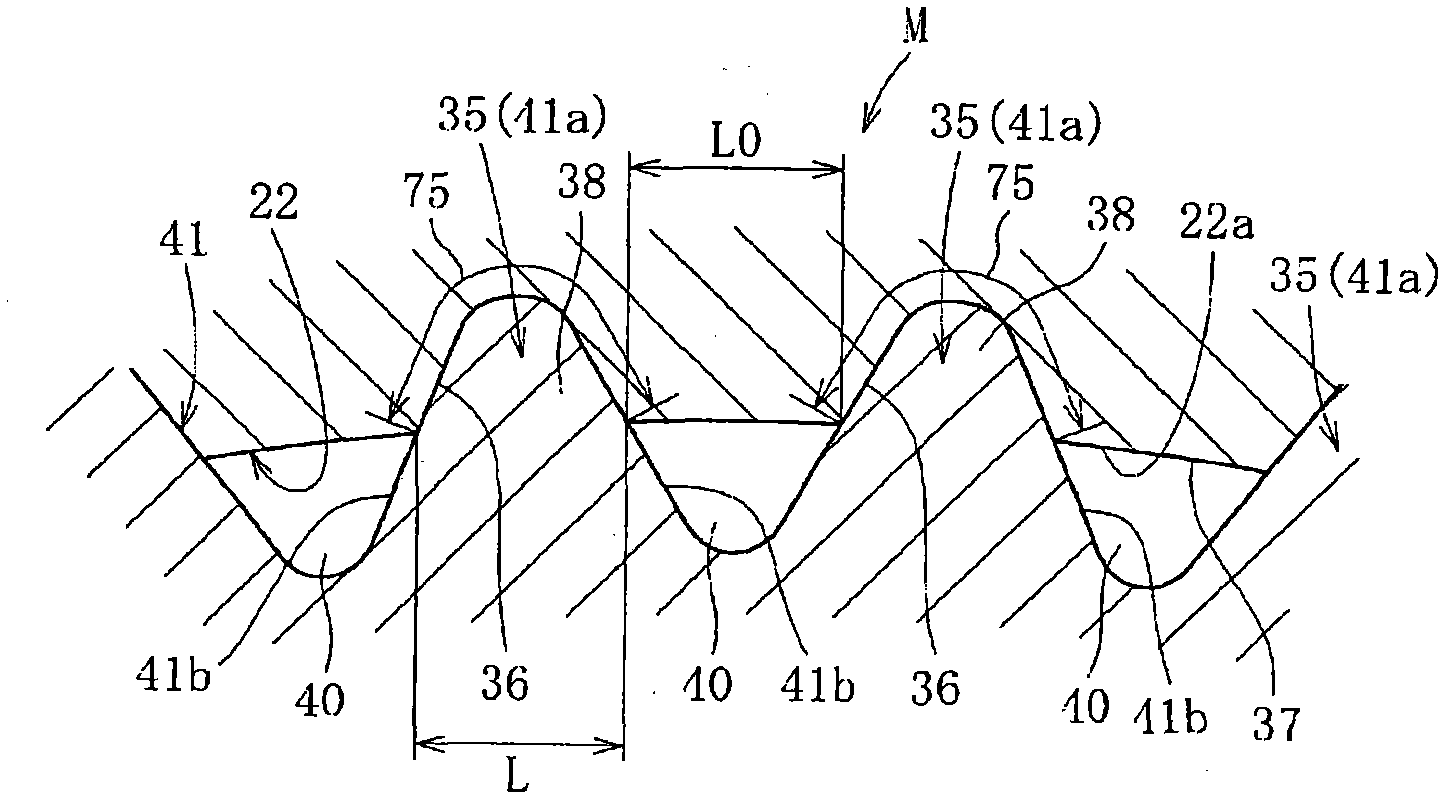

Bearing device for wheel

InactiveCN101641225ADoes not generate abnormal noiseHigh strengthRolling contact bearingsAxle unitsKnuckleEngineering

A bearing device for a wheel, in which circumferential play is suppressed, which facilitates connection between a hub ring and an outer coupling member, in which a reduction in NVH characteristics due to play at a joint between the hub ring and the constant velocity universal joint and by play between a bearing outer member and a knuckle is prevented, and which performs highly accurate transmission of rotational torque. The bearing device has a groove-ridge fitting structure (M) by which the hub ring (1) and a shaft section (12) of the outer coupling member of the constant velocity universal joint (3) are integrated together, and the shaft section (12) is fitted in a hole (22) of the hub ring (1). In the groove-ridge fitting structure (M), ridges (35) on the outer diameter surface of the shaft section (12) and grooves (36) in the inner diameter surface (37) of the hub ring (1) are fitted to each other in a fitting contact portion (38), and the ridges (35) and the grooves (36) are in intimate contact with each other in the entire fitting contact portion (38).

Owner:NTN CORP

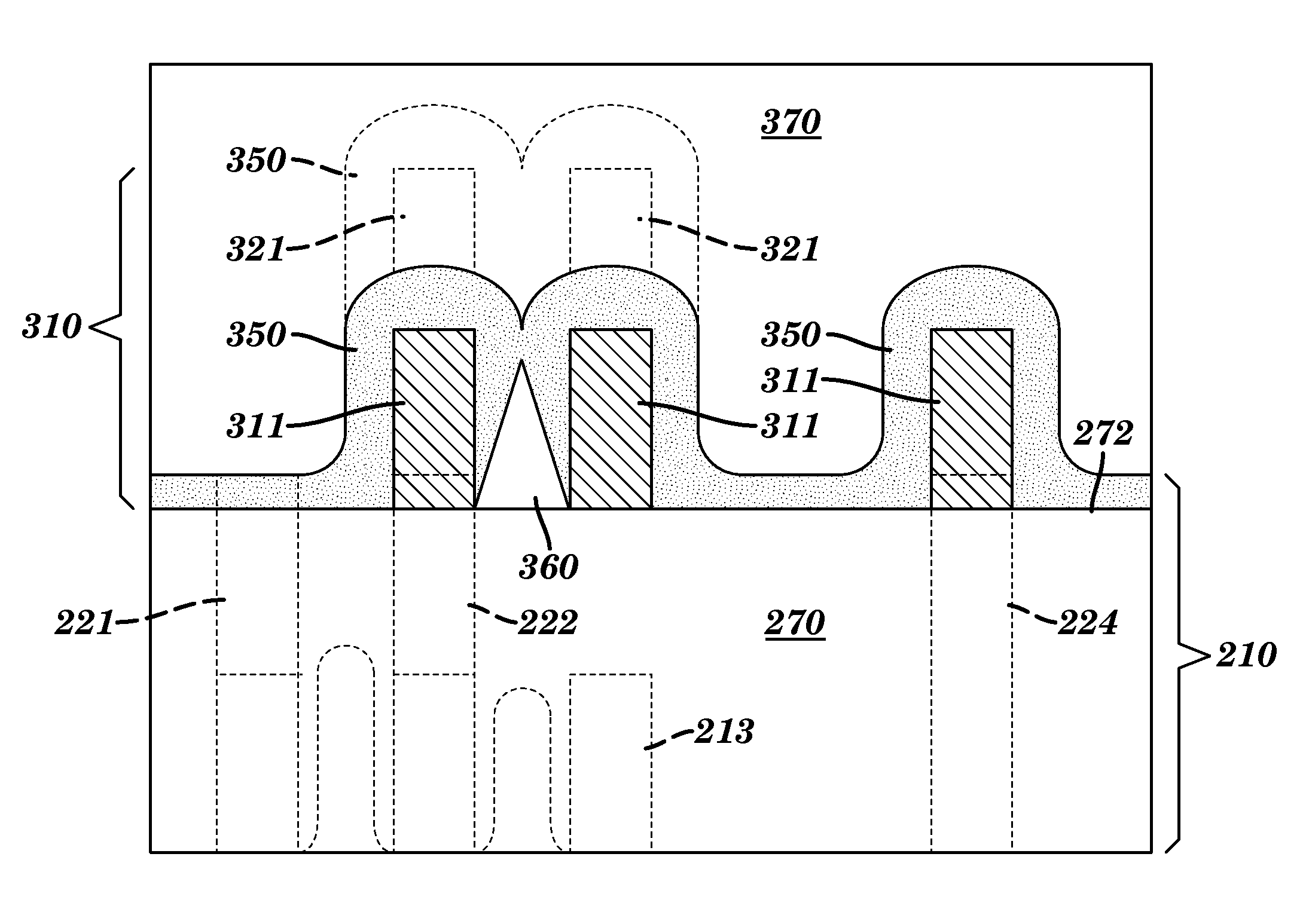

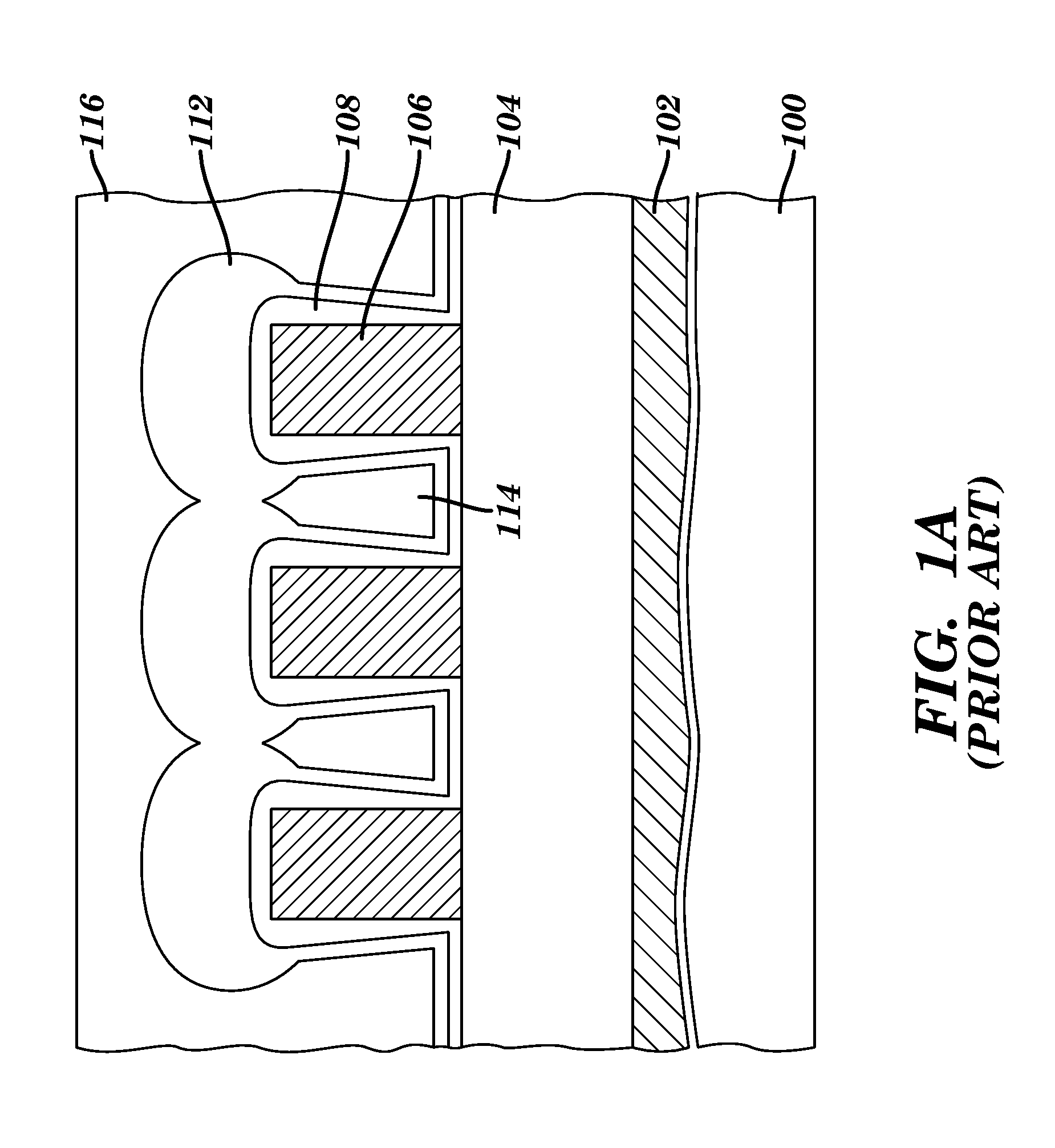

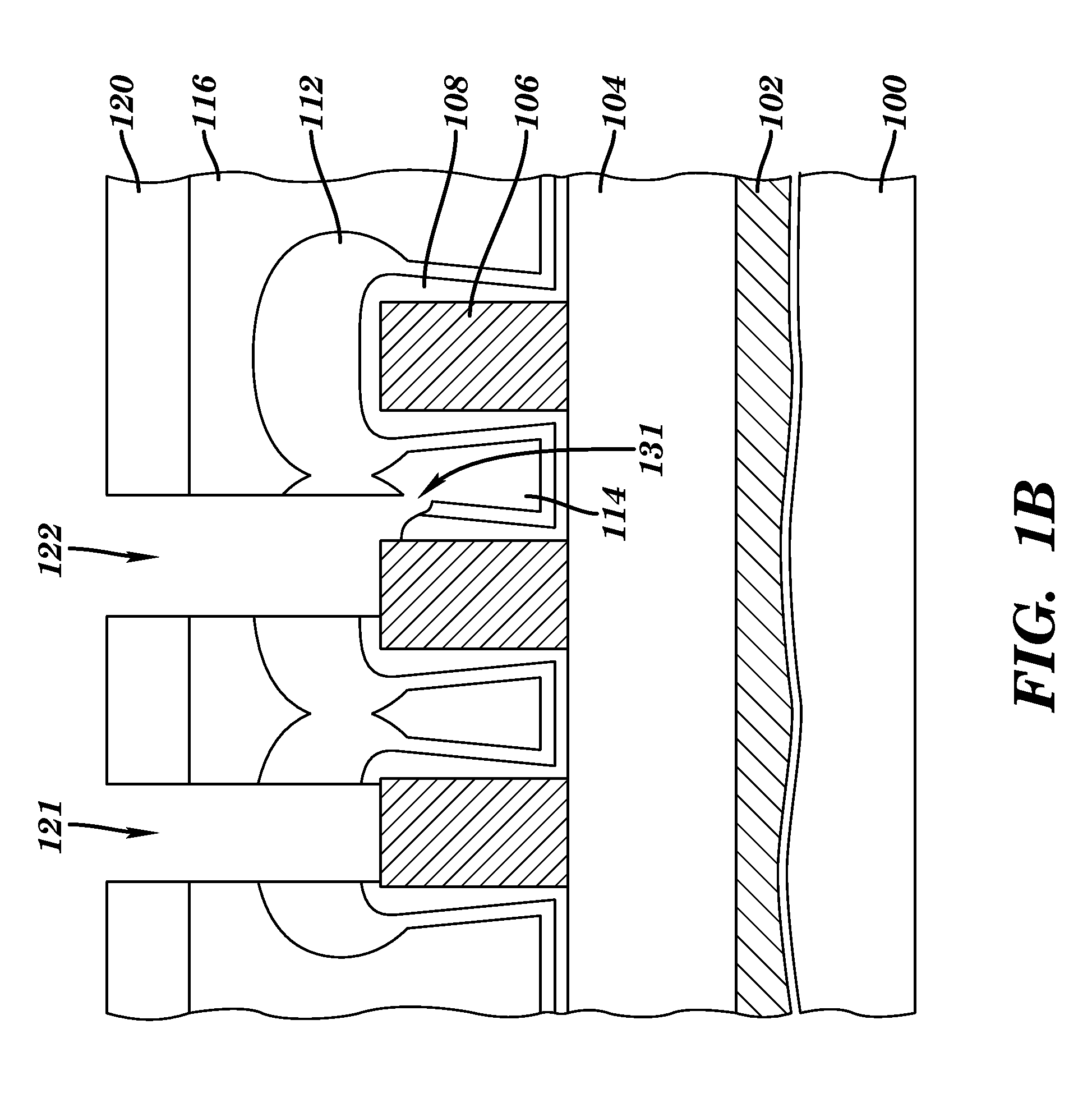

Air-dielectric for subtractive etch line and via metallization

ActiveUS8735279B2Reliable formationSemiconductor/solid-state device detailsSolid-state devicesDielectricCapacitance

A method and structure is disclosed whereby multiple interconnect layers having effective air gaps positioned in regions most susceptible to capacitive coupling can be formed. The method includes providing a layer of conductive features, the layer including at least two line members disposed on a substrate and spaced from one another by less than or equal to an effective distance, and at least one such line member also having a via member extending away from the substrate, depositing a poorly conformal dielectric coating to form an air gap between such line members, and exposing a top end of the via.

Owner:GLOBALFOUNDRIES U S INC

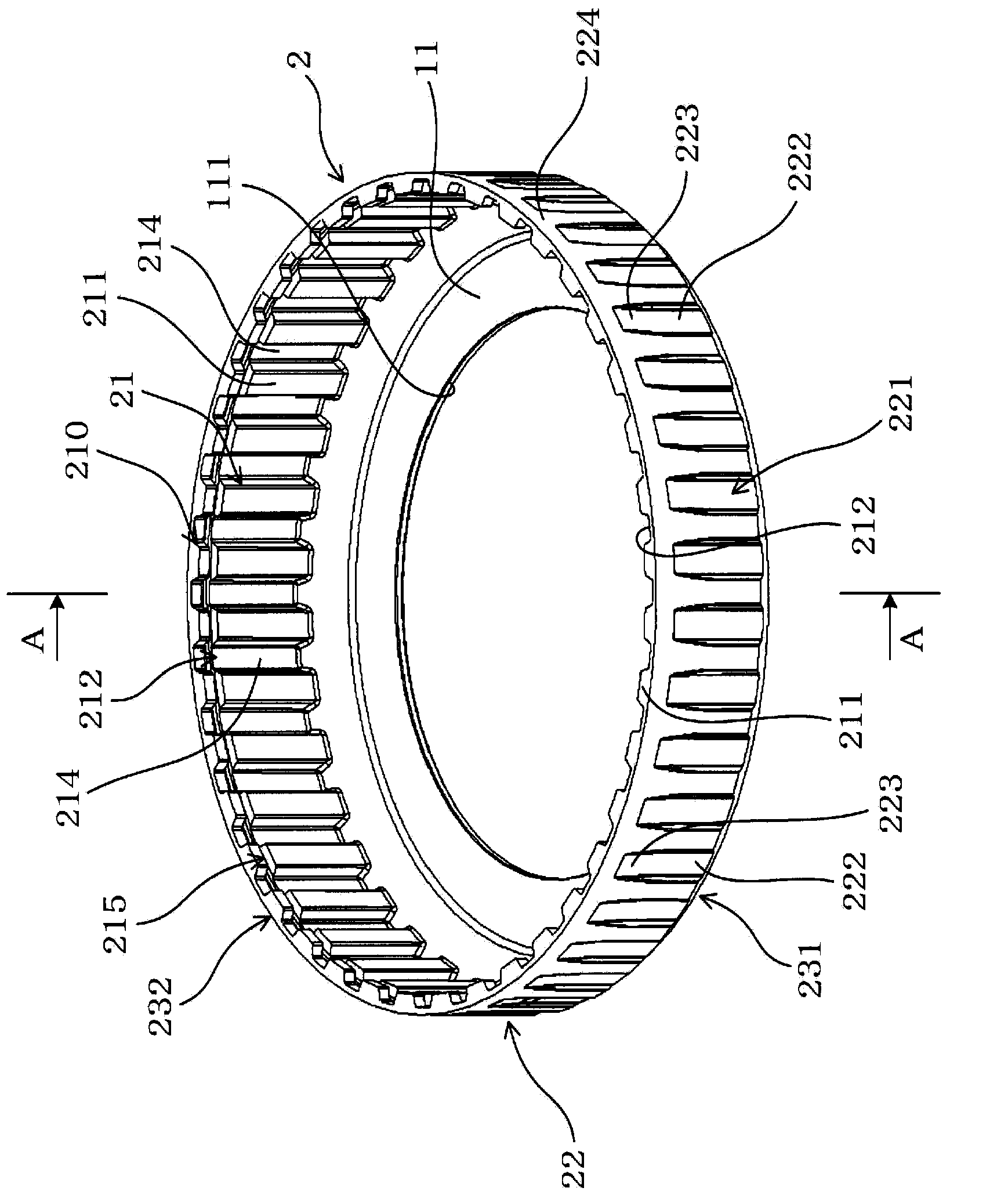

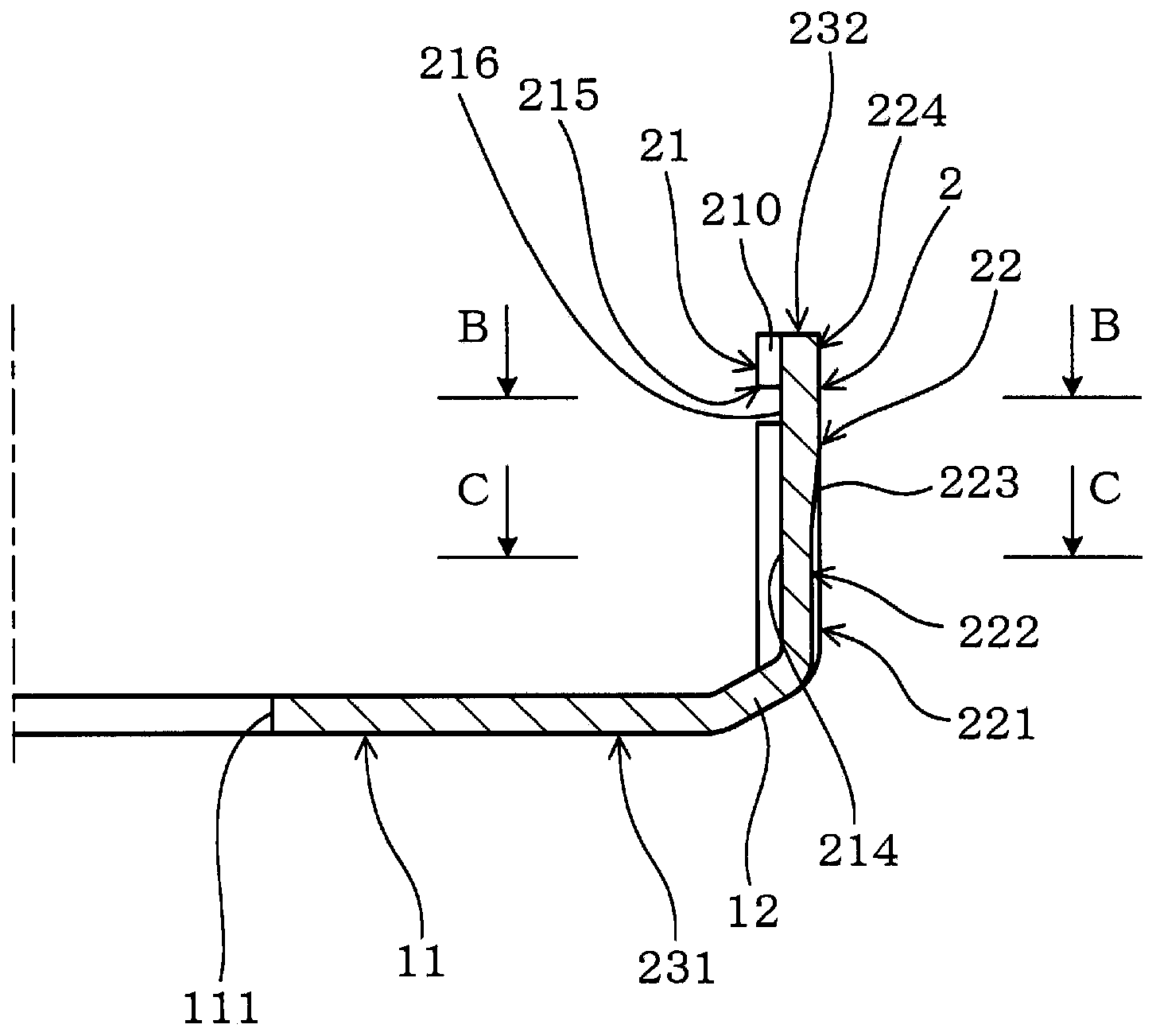

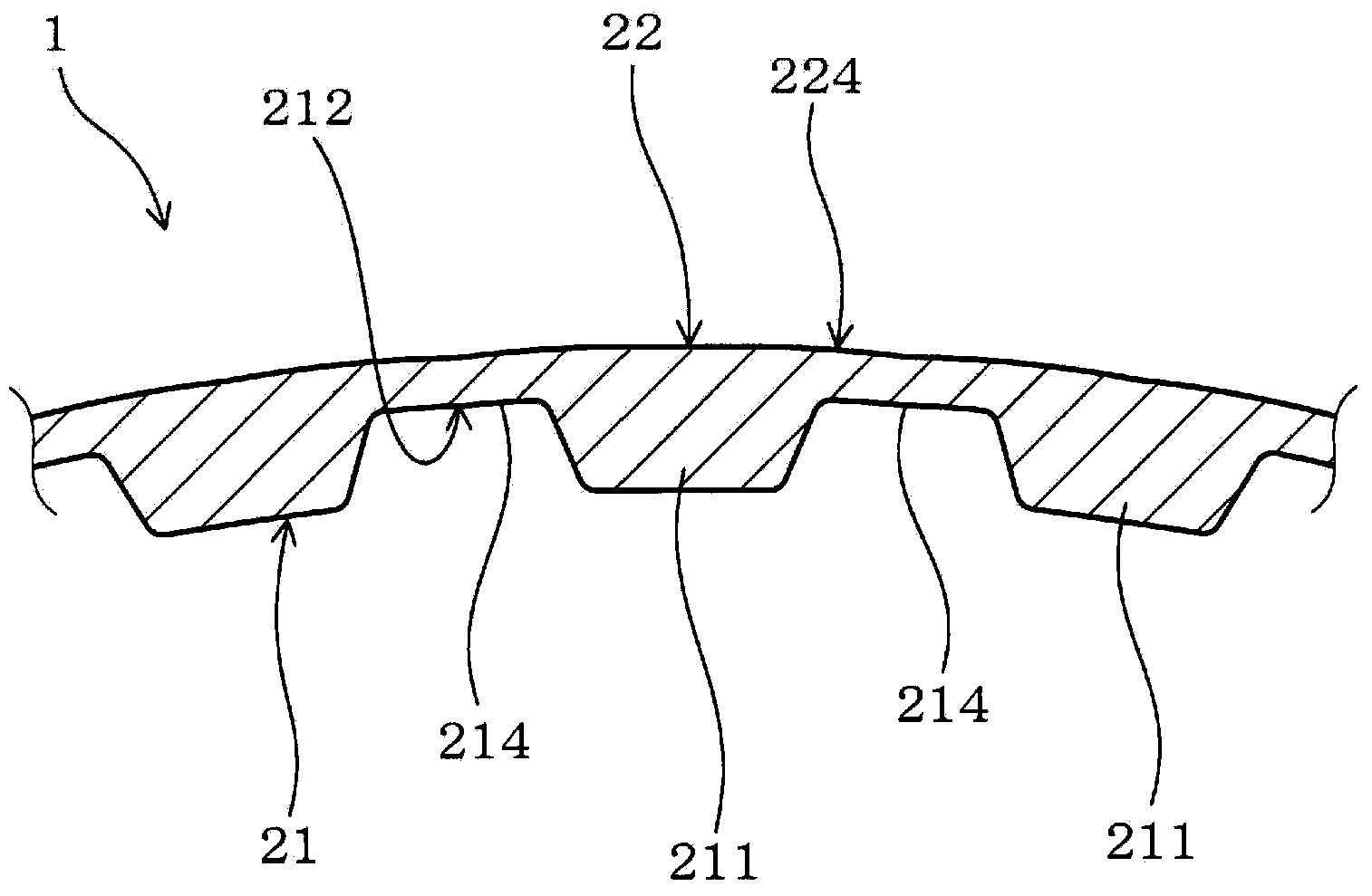

Cup-shaped part with inner peripheral uneven surface section, method for manufacturing cup-shaped part, and device for manufacturing cup-shaped part

InactiveCN103748376AHigh strengthReliable formationFriction clutchesGear wheelsEngineeringPeripheral

A cup-shaped part (1) having an inner peripheral uneven surface section (210) has a bottom section (11), a cylinder section (2), and the inner peripheral uneven surface section (210). The inner peripheral uneven surface section (210) has inner peripheral protrusions (211) and inner peripheral recesses (212), the inner peripheral protrusions (211) and the inner peripheral recesses (212) being formed on the inner peripheral surface (21) of the cylinder section (2). Outer peripheral recesses (221) formed by recessing the outer peripheral surface (22) of the cylinder section (2) toward the inside of the cylinder section (2) in the radial direction are formed on the base end (231) side of the outer peripheral surface (22) of the cylinder section (2). A smooth outer peripheral section (224), in which the outer peripheral recesses (221) are not formed, is formed on the opening end (232) side of the outer peripheral surface (22) of the cylinder section (2), the opening end (232) side being the side located opposite to the side on which the bottom (11) of the outer peripheral surface (22) of the cylinder section (2) is provided.

Owner:AISIN AW CO LTD

Wiring piece, block terminal and method for cutting wire

InactiveCN1489251AAvoiding the Problem of Failed Cutting WiresAvoid failureElectric/fluid circuitApparatus for joining/termination cablesEngineeringElectrical wiring

Owner:YAZAKI CORP

Bearing device for wheel

InactiveCN102152711AStable deliveryHigh strengthYielding couplingRolling contact bearingsUniversal jointTorque transmission

Provided is a bearing device for a wheel that can realize prevention of a backlash in a circumferential direction and is excellent in workability of connection of a hub wheel and an outer joint member of a constant velocity universal joint. Further, provided is a bearing device for a wheel that can prevent deterioration in NVH characteristics, which is caused by the backlash occurring in a joint section between the hub wheel and the constant velocity universal joint or between an outer member and a knuckle, and can perform rotation torque transmission with high accuracy. The bearing device includes a recess-projection fitting structure (M) in which the hub wheel (1) and a shaft section (12), which is fitted in a hole (22) of the hub wheel (1) of the outer joint member of the constant velocity universal joint (3) are unitized together. In the recess-projection fitting structure (M), entire fitting regions among projections (35) on the outer surface of the shaft section (12) of the outer joint member and recesses (36), which fit on the projections, are brought into intimate contact with each other.

Owner:NTN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com