Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Reduced structure width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

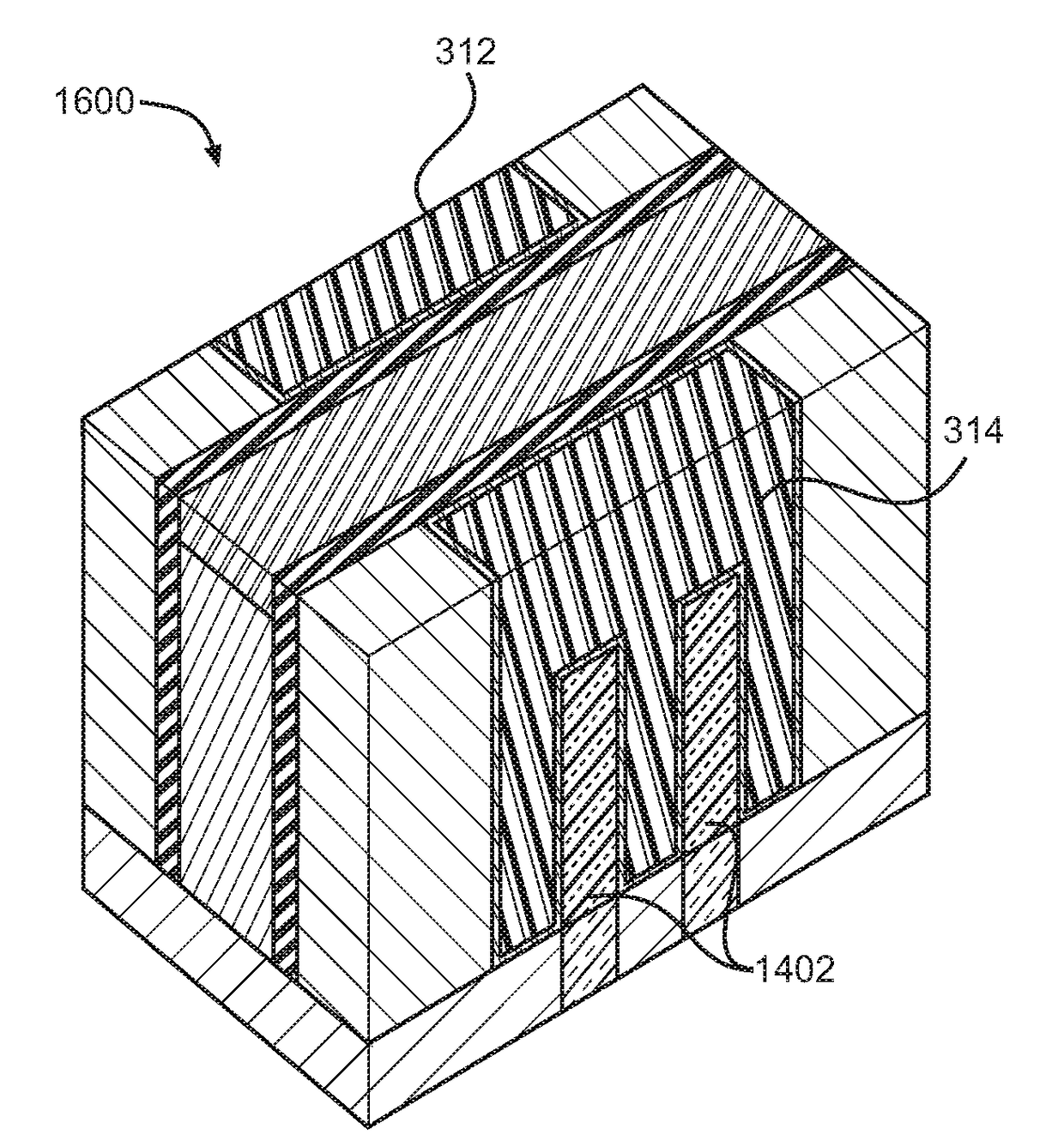

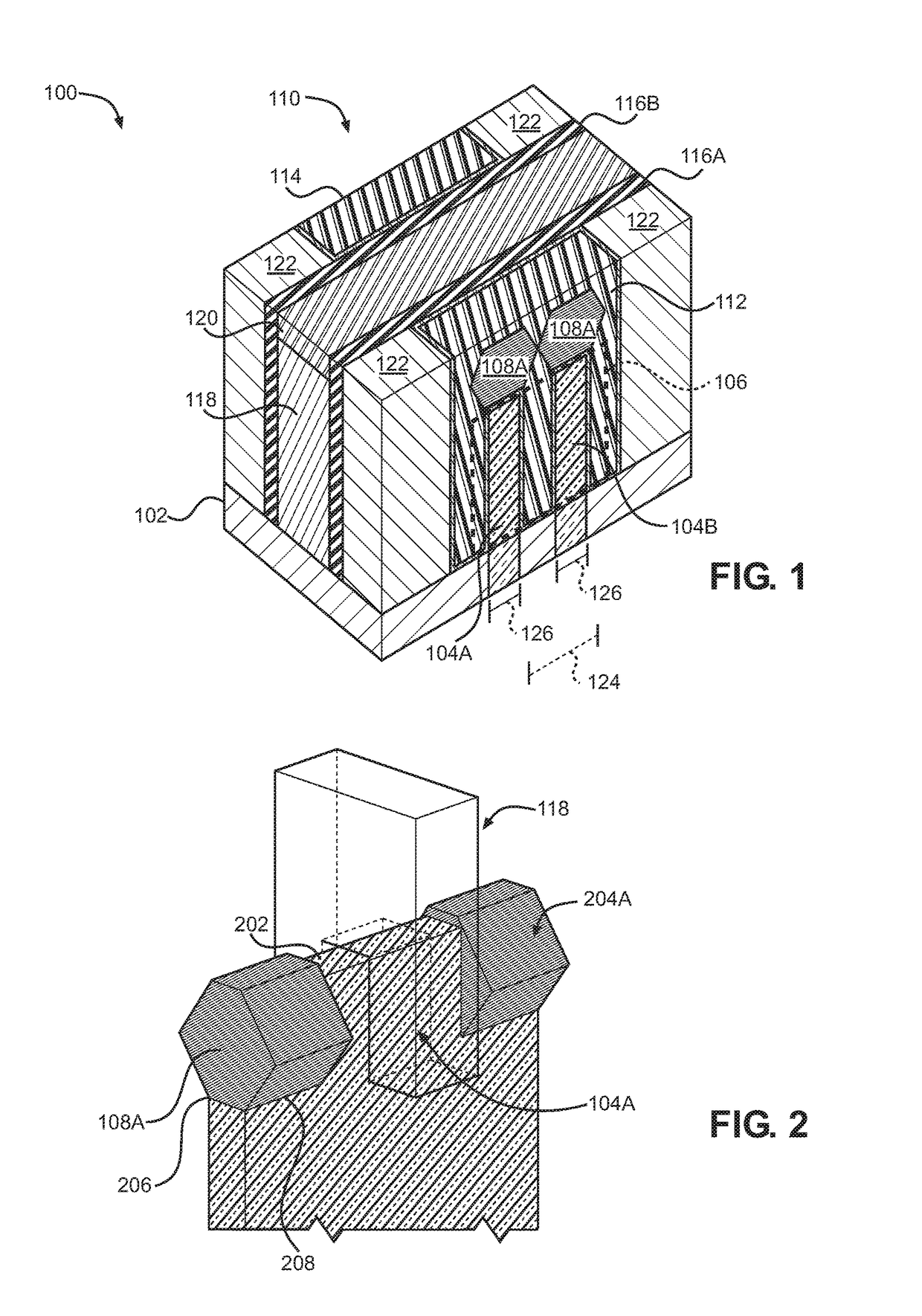

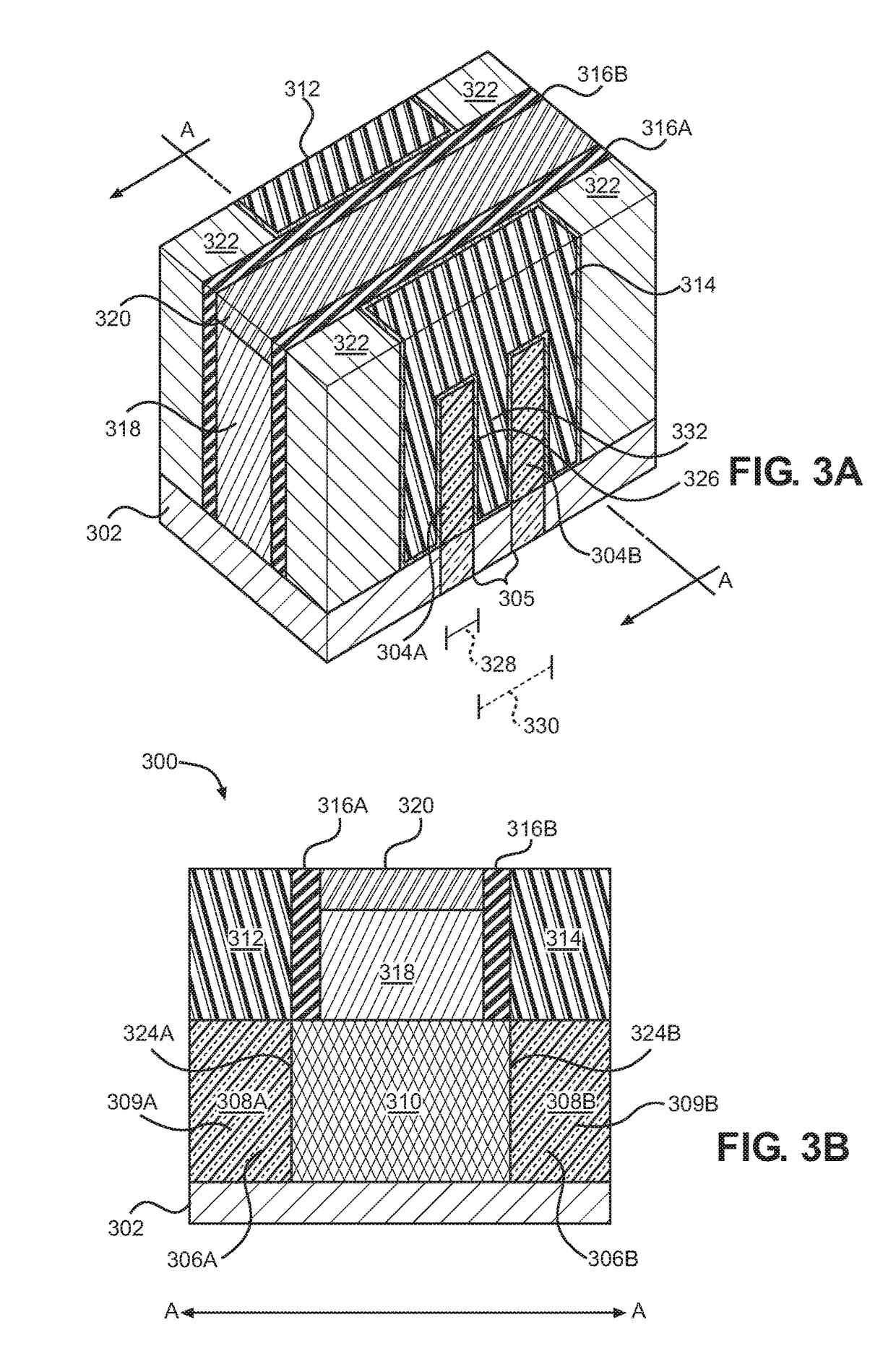

Complementary metal oxide semiconductor (CMOS) devices employing plasma-doped source/drain structures and related methods

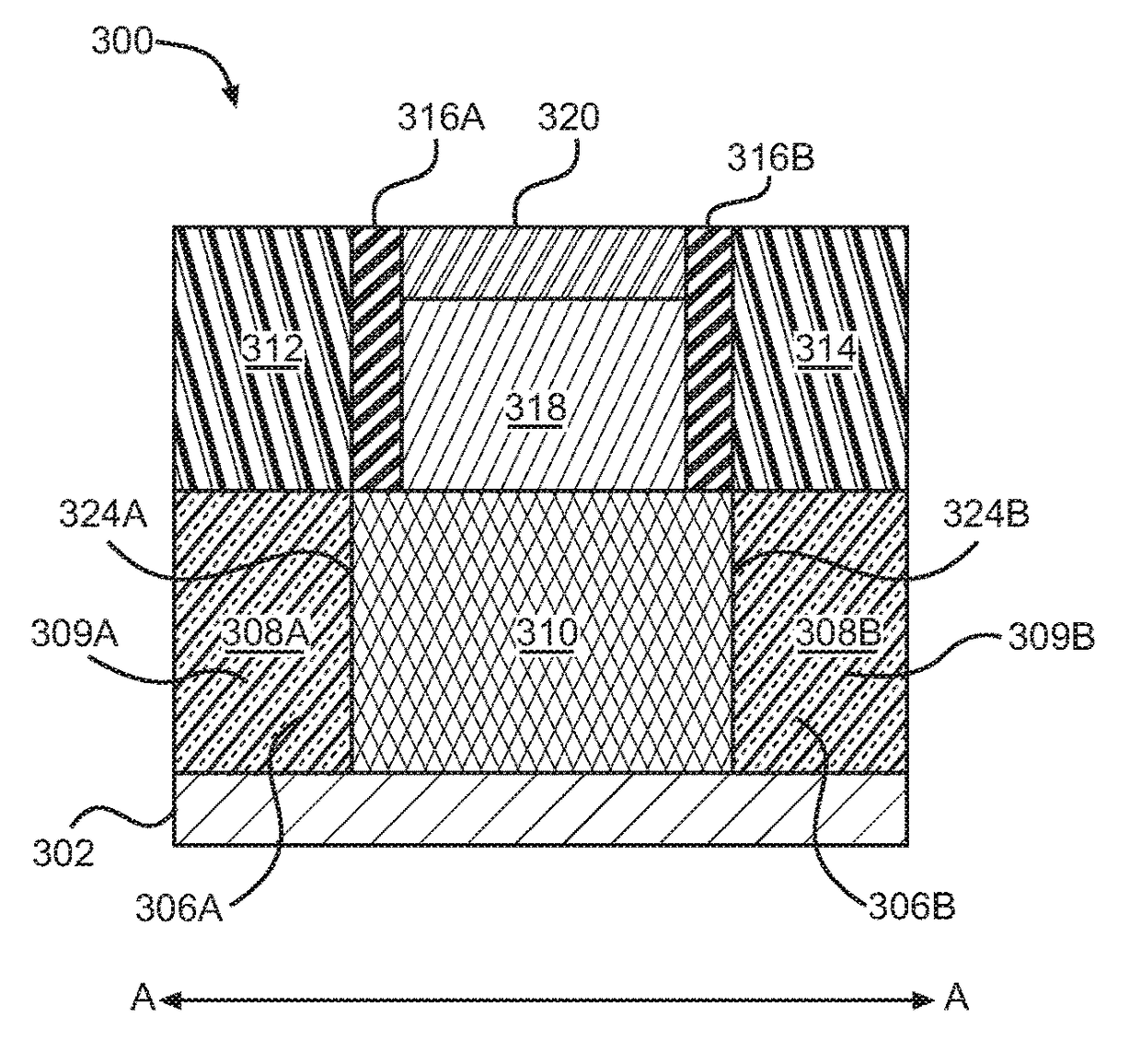

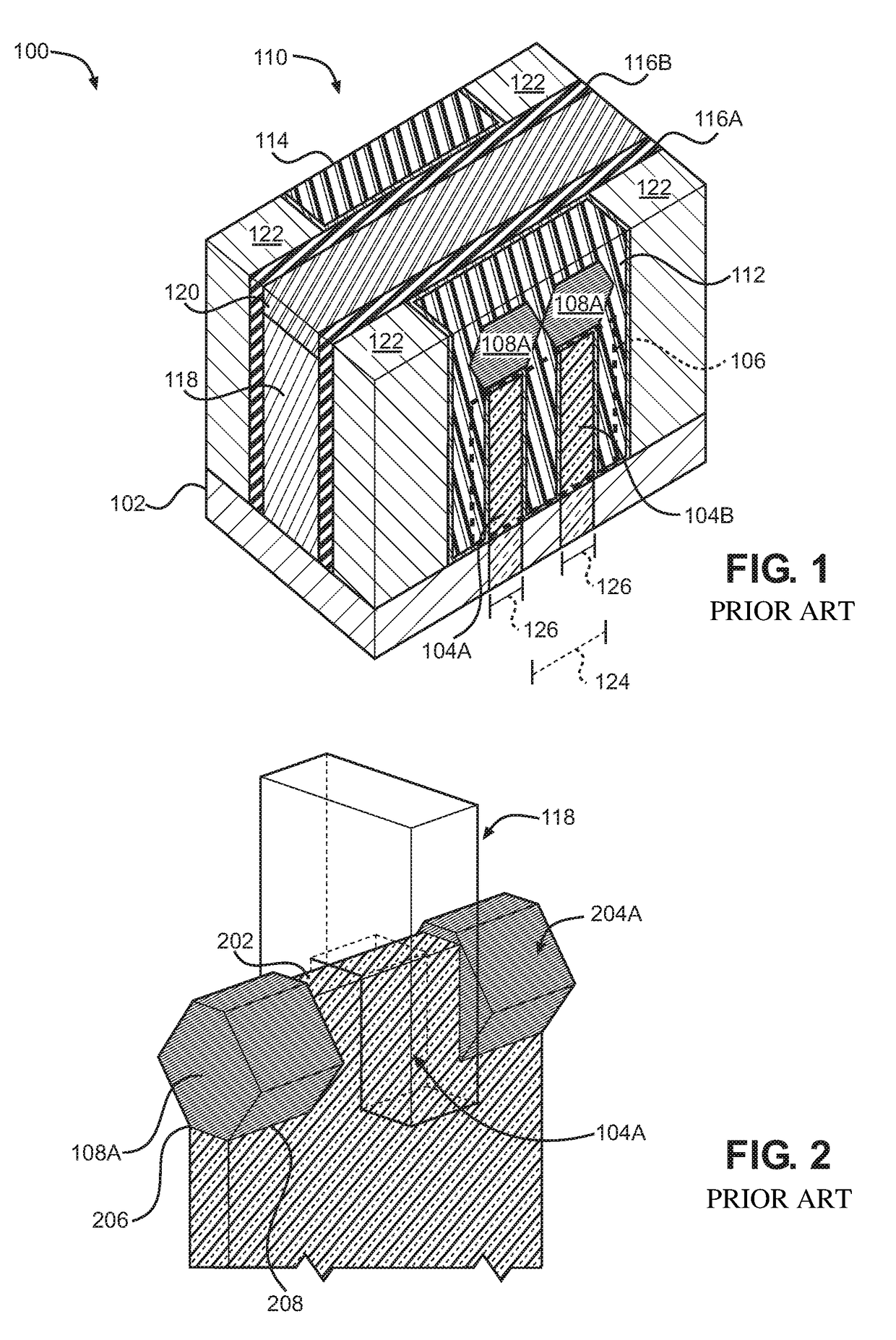

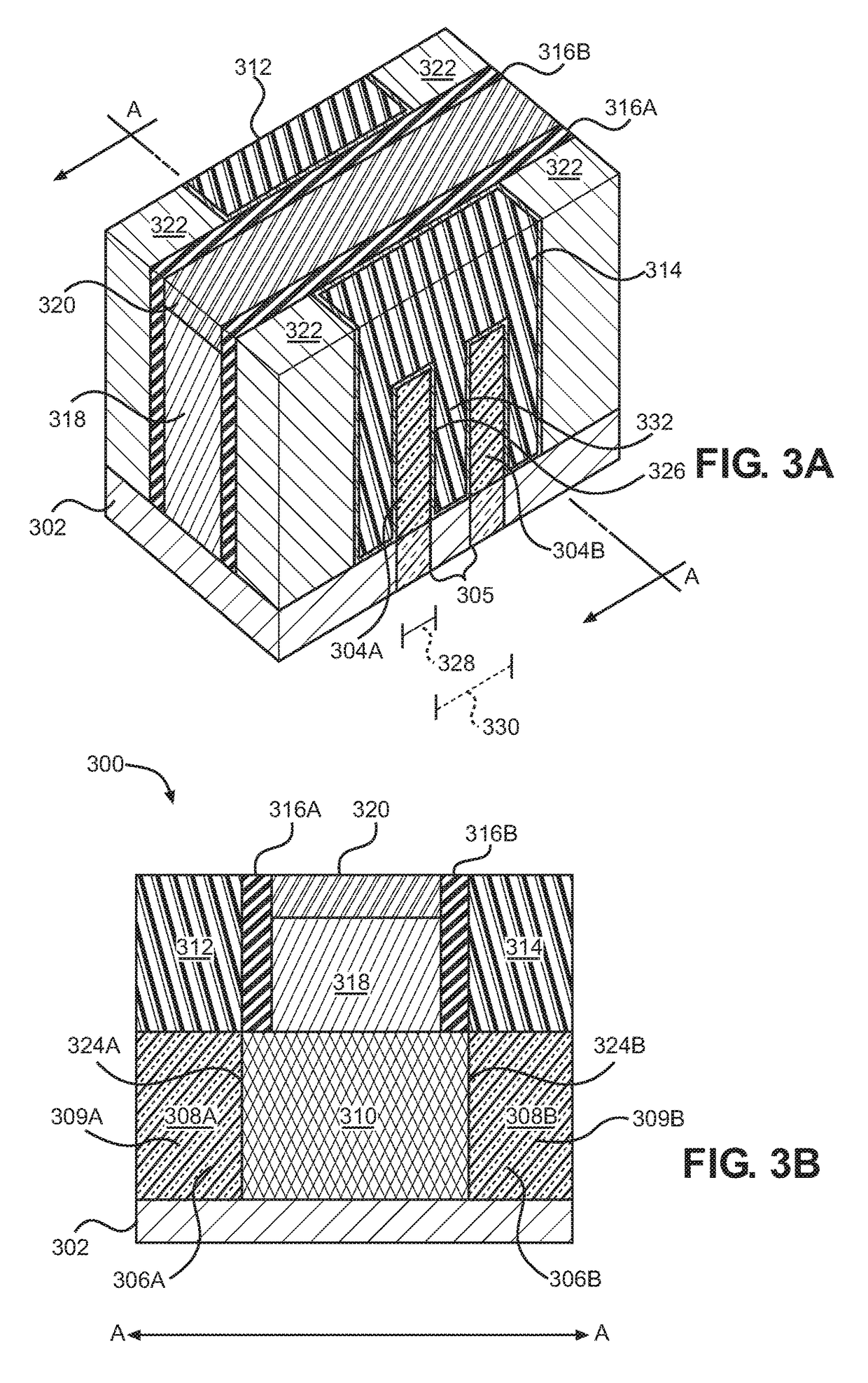

InactiveUS20170352662A1Channel contact resistanceReduced channel structure widthTransistorSolid-state devicesSolubilityEngineering

Complementary metal oxide semiconductor (CMOS) devices employing plasma-doped source / drain structures and related methods are disclosed. In certain aspects, a source and drain of a CMOS device are formed at end portions of a channel structure by plasma doping end portions of the channel structure above solid state solubility of the channel structure, and annealing the end portions for liquid phase epitaxy and activation (e.g., superactivation). In this manner, the source and drain can be integrally formed in the end portions of the channel structure to provide coextensive surface area contact between the source and drain and the channel structure for lower channel contact resistance. This is opposed to forming the source / drain using epitaxial growth that provides an overgrowth beyond the end portion surface area of the channel structure to reduce channel contact resistance, which may short adjacent channels structures.

Owner:QUALCOMM INC

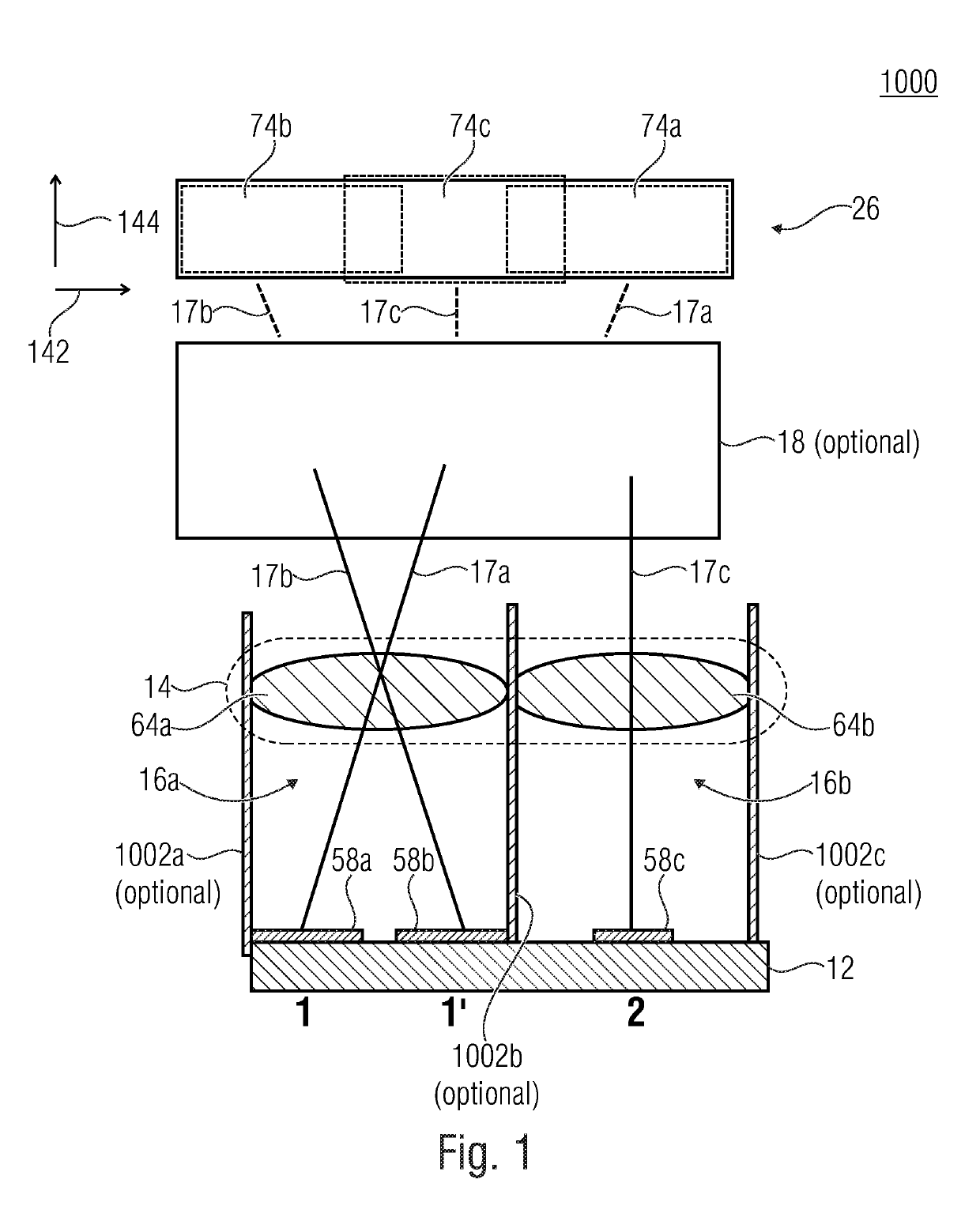

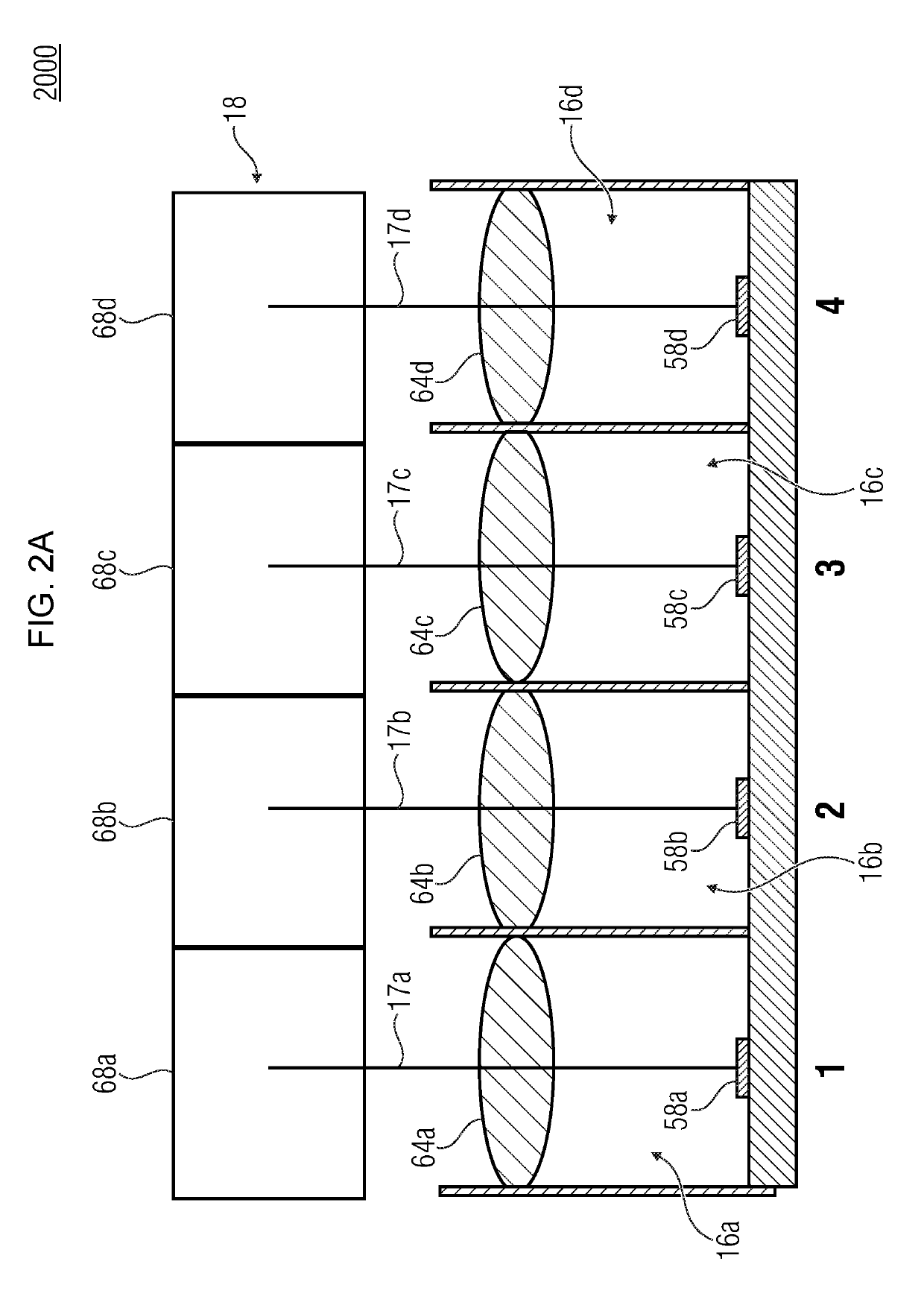

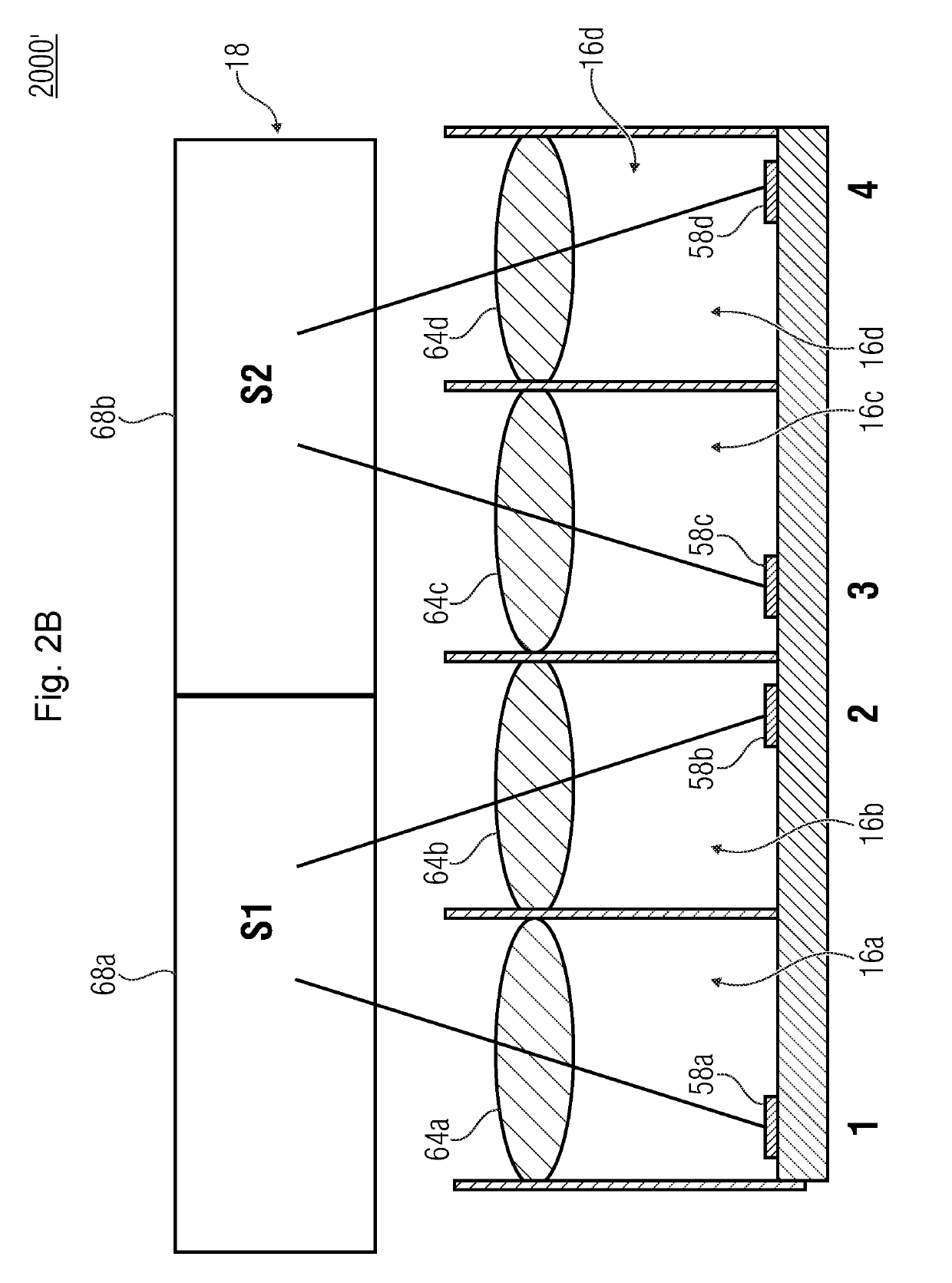

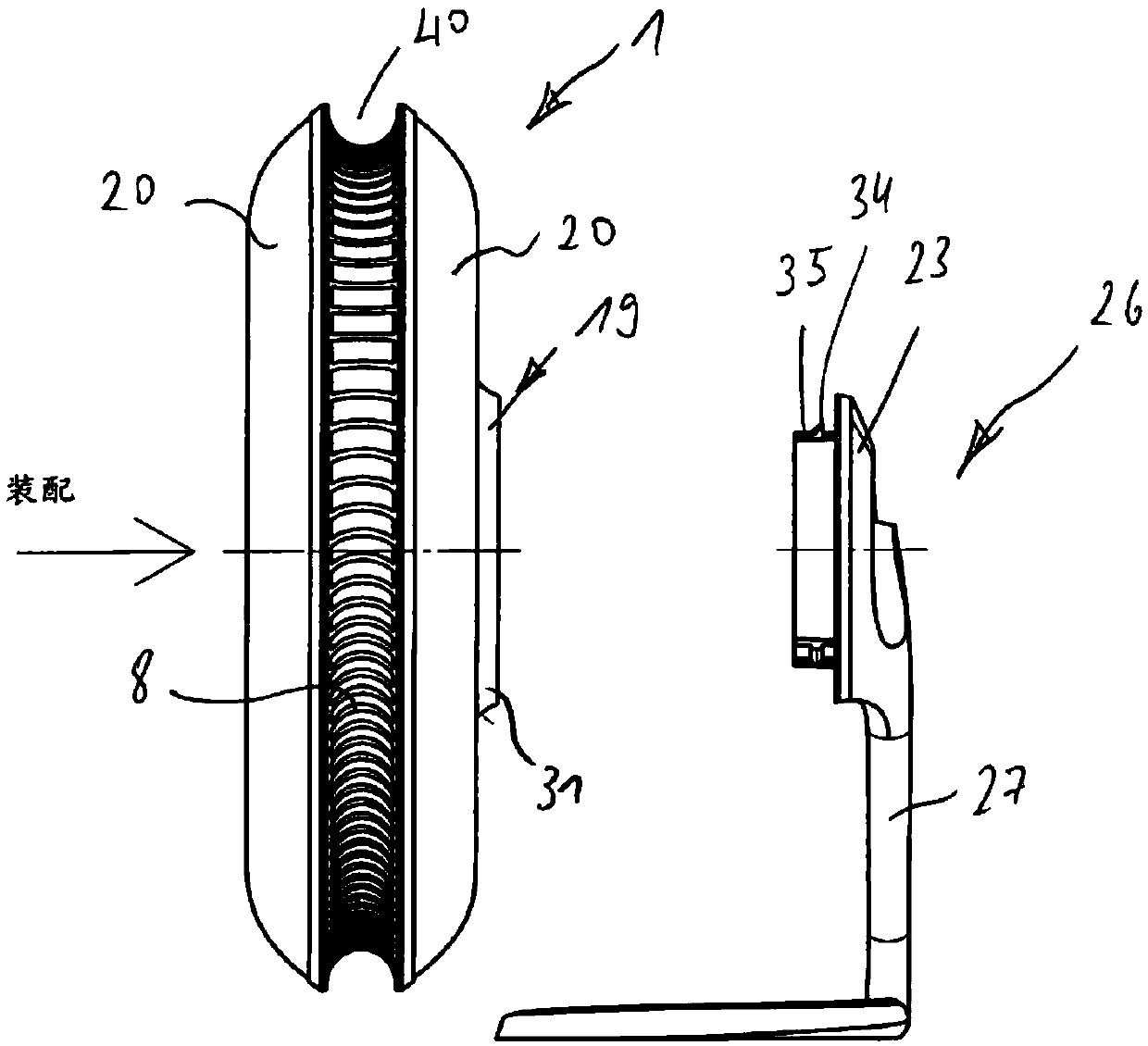

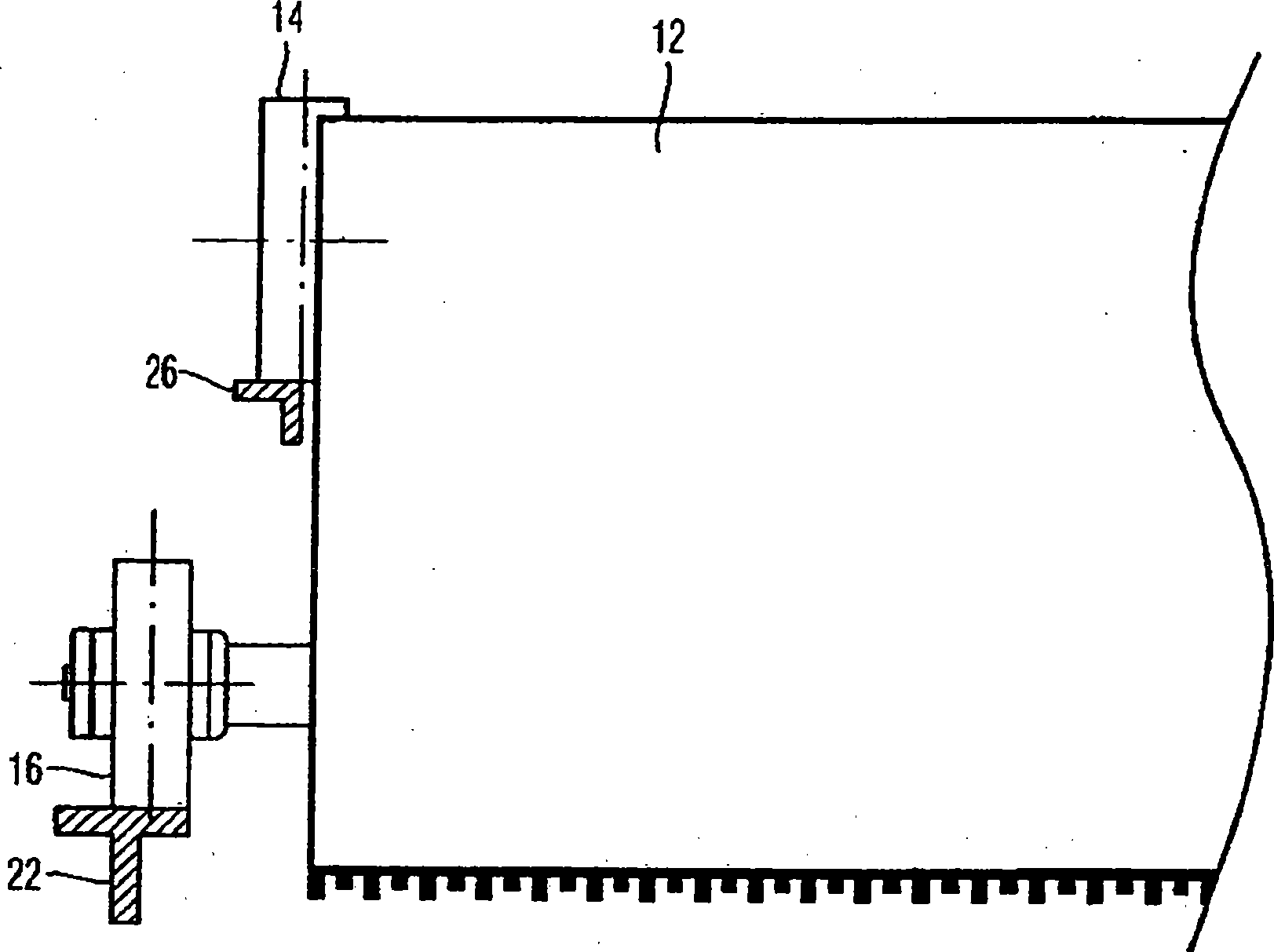

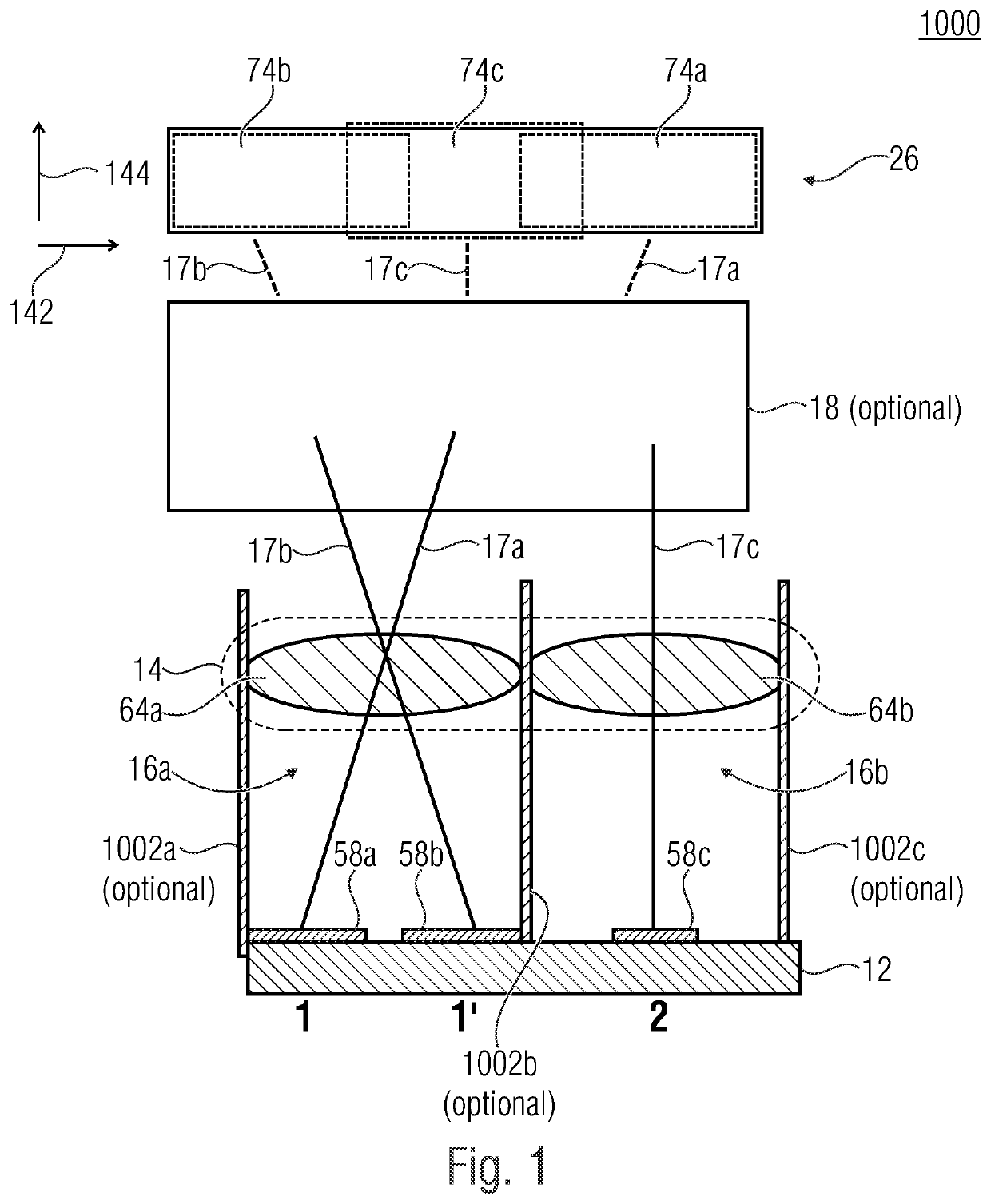

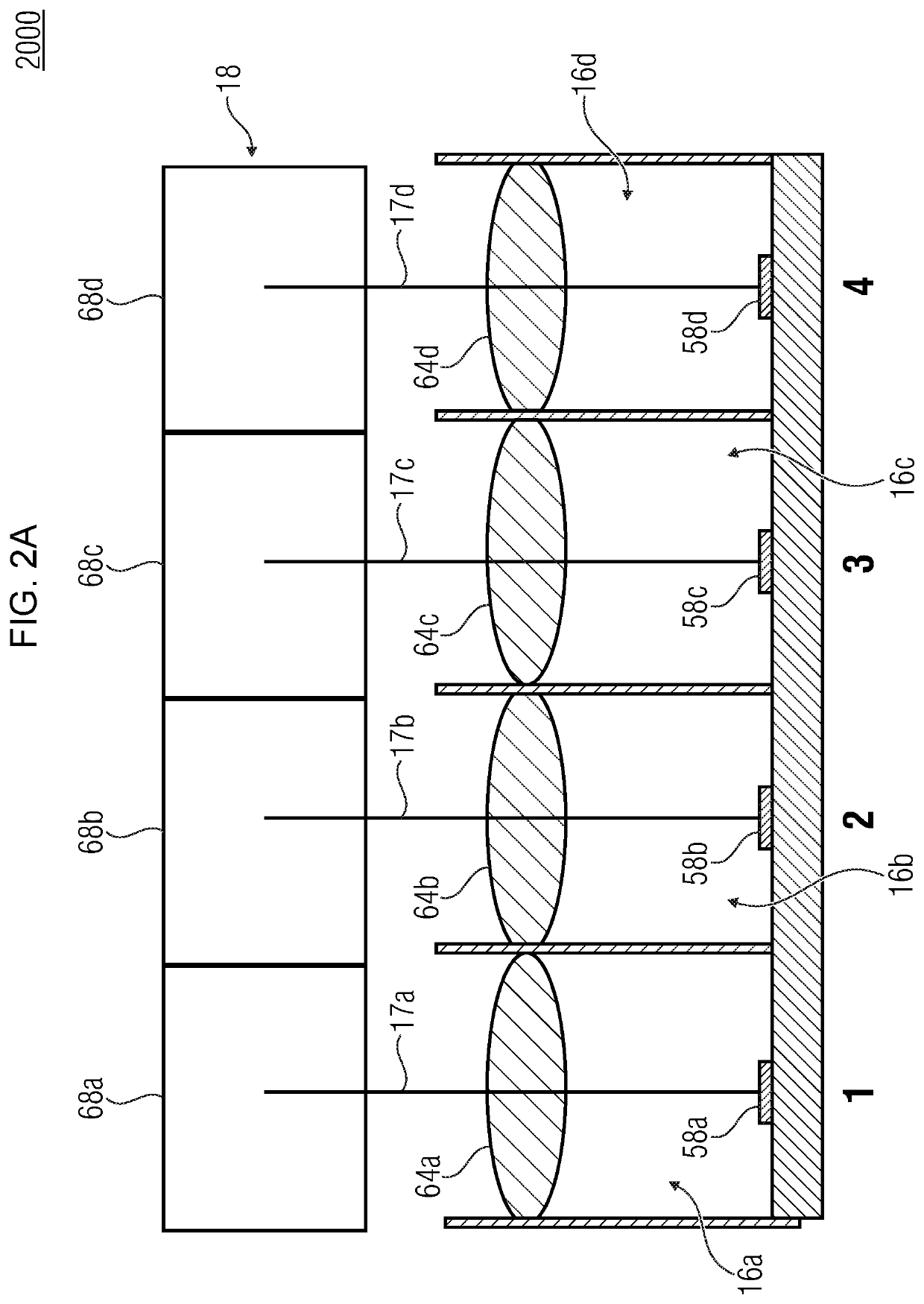

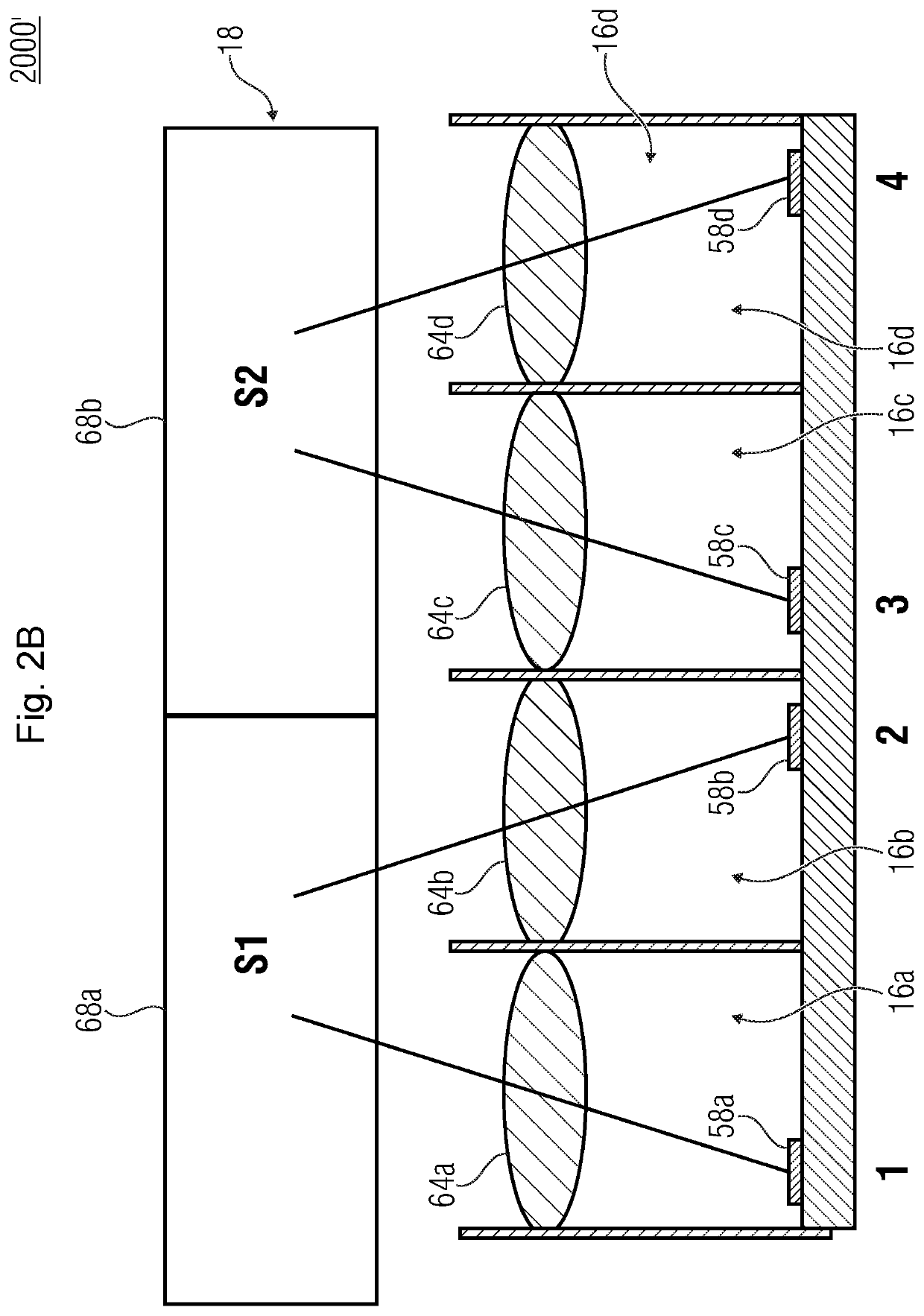

Multi-aperture imaging device, imaging system and method for capturing an object area

ActiveUS20190104242A1Minimum volumeReduce in quantityTelevision system detailsColor television detailsImage sensorImage system

A multi-aperture imaging device includes at least one image sensor and an array of juxtaposed optical channels. Each optical channel includes optics for imaging of projecting at least one partial area of an object area on an image sensor area of the image sensor. A first optics of a first optical channel is configured to project a first partial area of the object area on a first image sensor area and to project a second partial area of the object area on a second image sensor area. A second optics of a second optical channel is configured to project at least a third partial area of the object area on a third image sensor area. The first partial area and the second partial area are disjoint in the object area. The third partial area overlaps incompletely with the first partial area.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

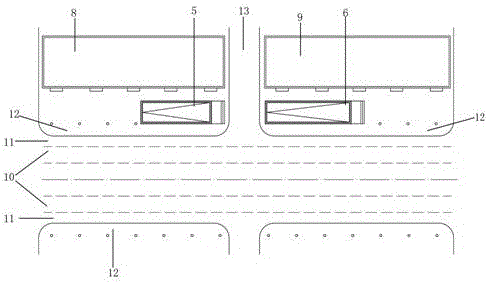

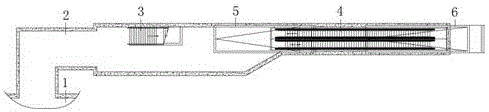

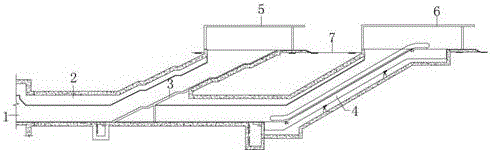

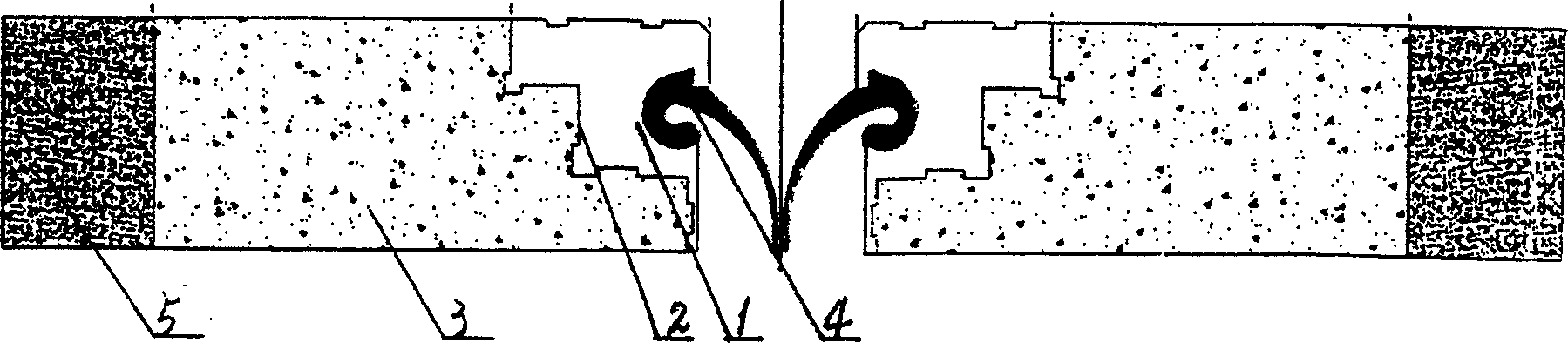

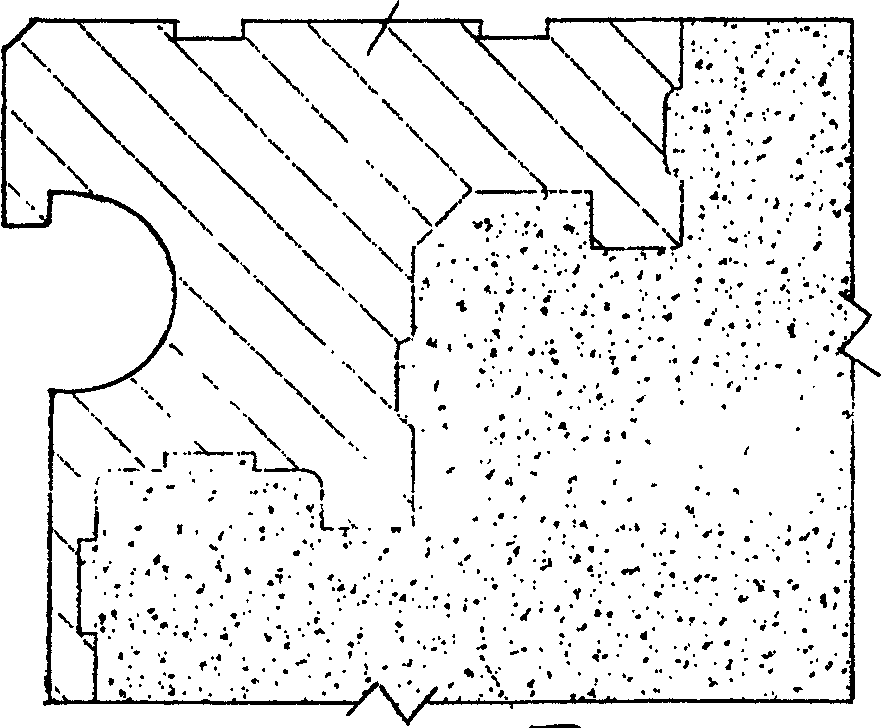

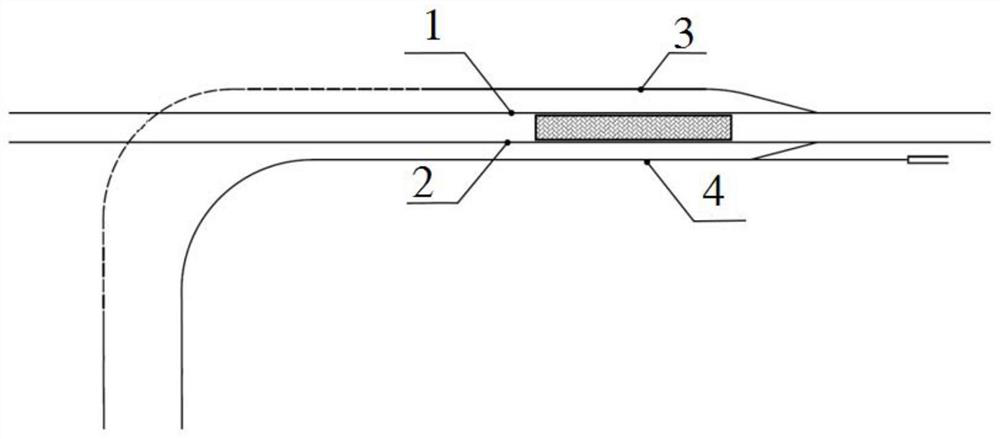

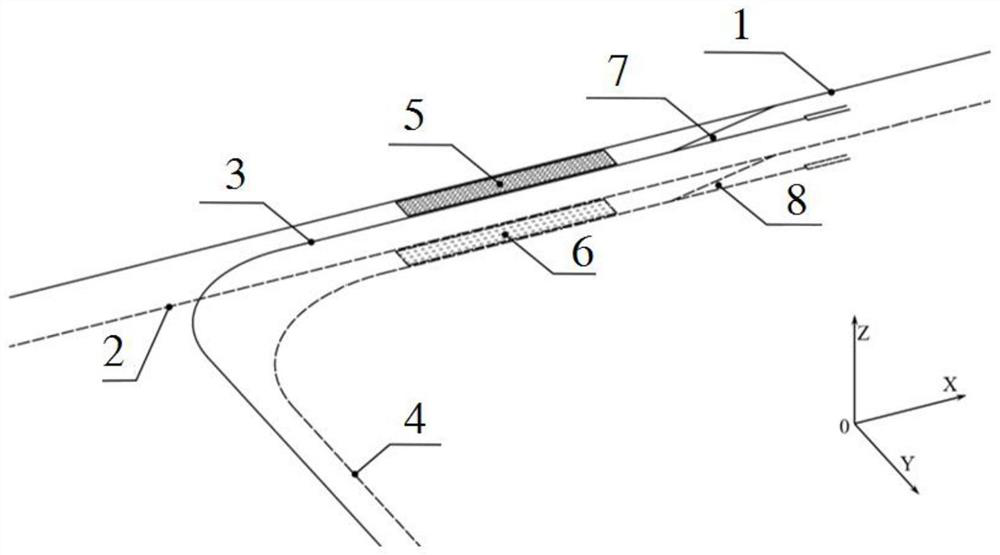

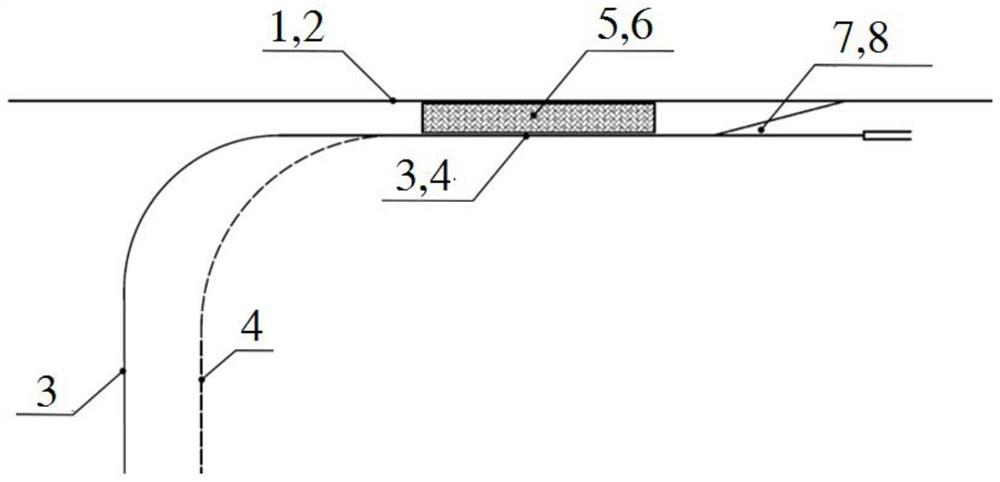

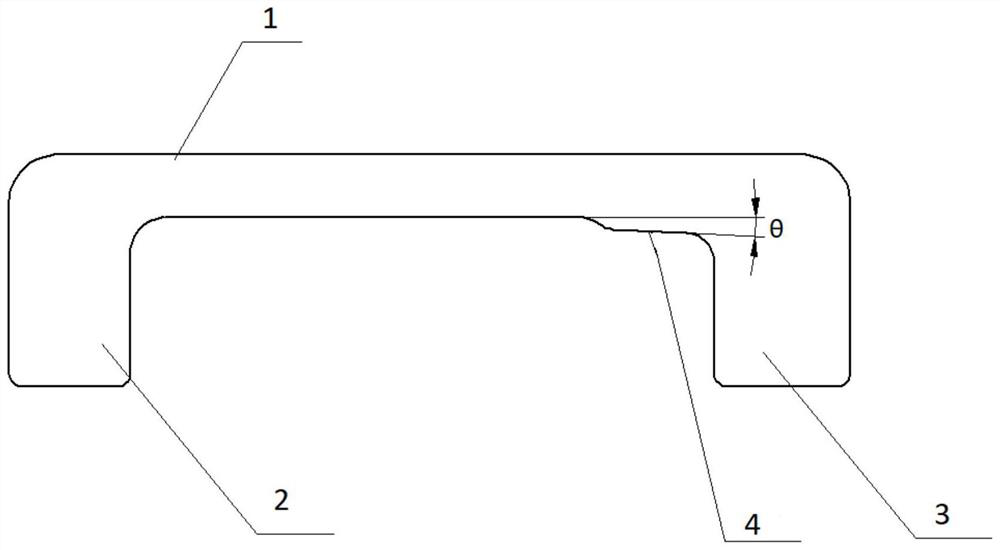

Design structure of subway station entrance-exit in narrow area of urban road

InactiveCN105696624ADoes not affect trafficGuaranteed functionArtificial islandsUnderwater structuresSubway stationEngineering

The invention belongs to the field of building structures, and in particular relates to a design structure for the entrance and exit of a subway station in a narrow area of urban roads. The entrance and exit passages are connected from the station hall floor and are connected to the independent first and second climbing sections after the underground section is separated. The first and second climbing sections are stair climbing sections or escalator climbing sections. After the first climbing section and the second climbing section reach the ground, independent ground pavilions are respectively set along one side of the road, and the ground pavilions are longitudinally arranged along one side of the road. The invention effectively reduces the width of the structure, realizes the arrangement of entrances and exits at narrow roads, satisfies the requirements of passenger use and accident evacuation, and improves the overall service level of the subway station.

Owner:CHINA RAILWAY TUNNEL SURVEY & DESIGN INST

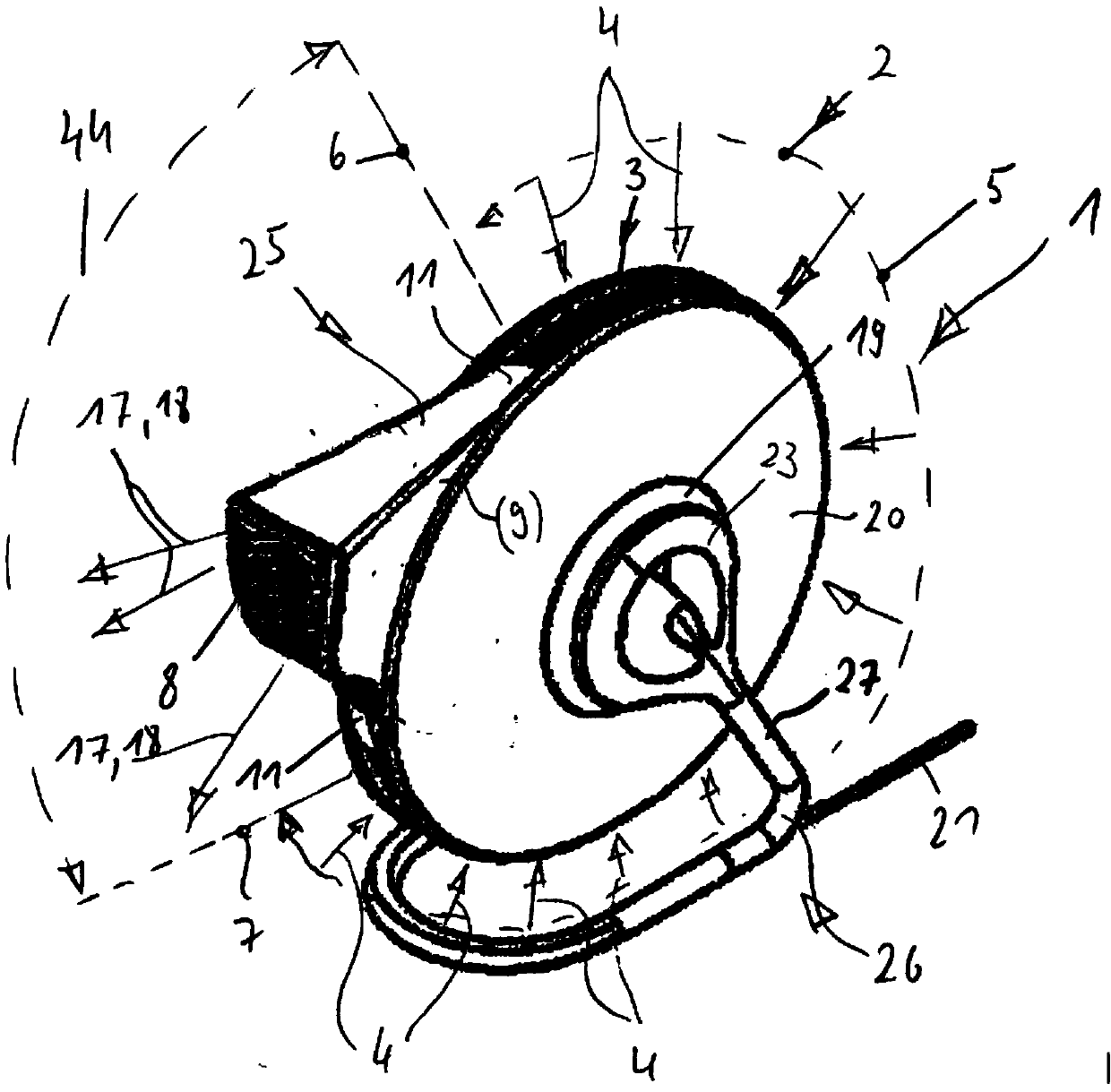

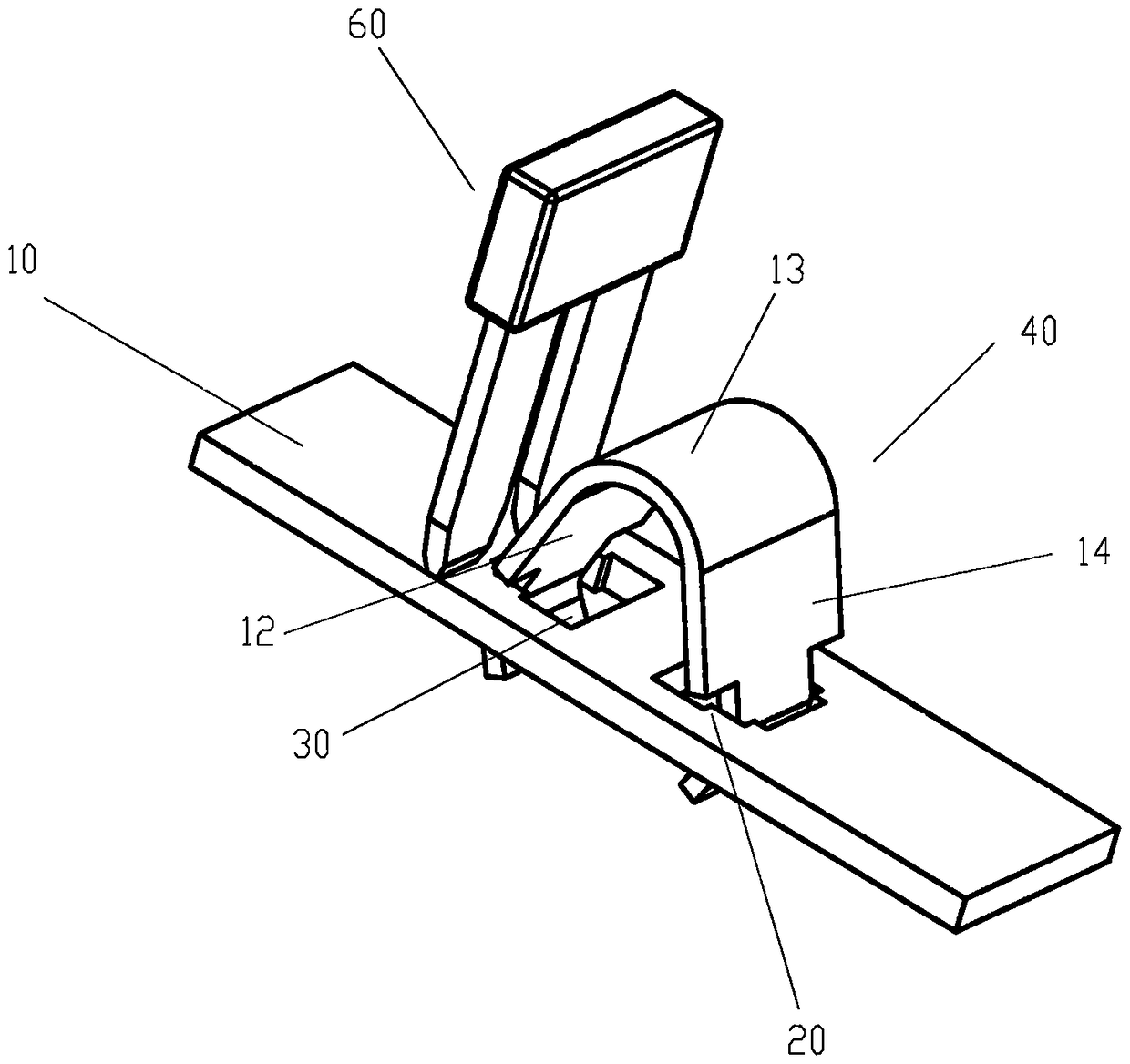

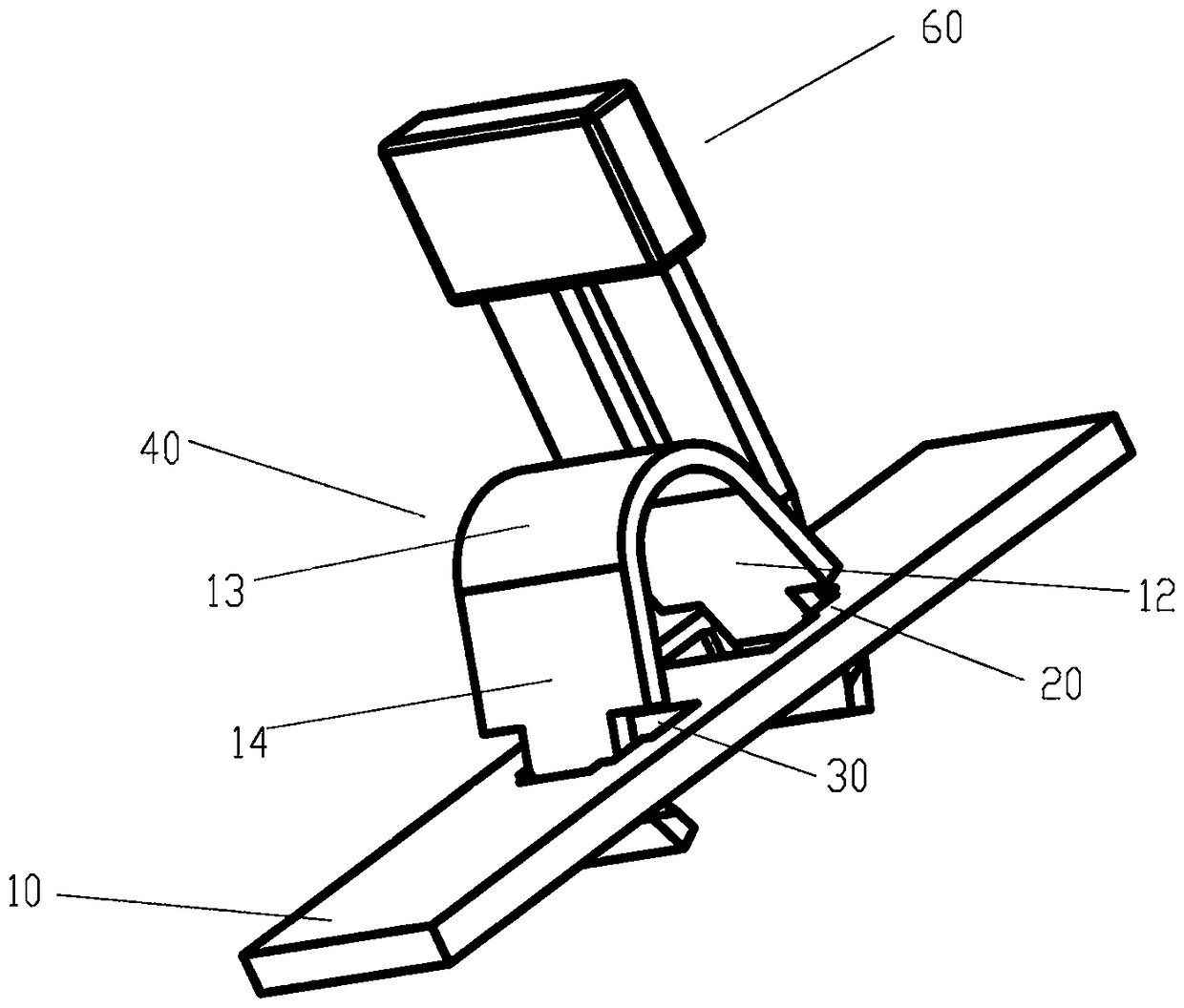

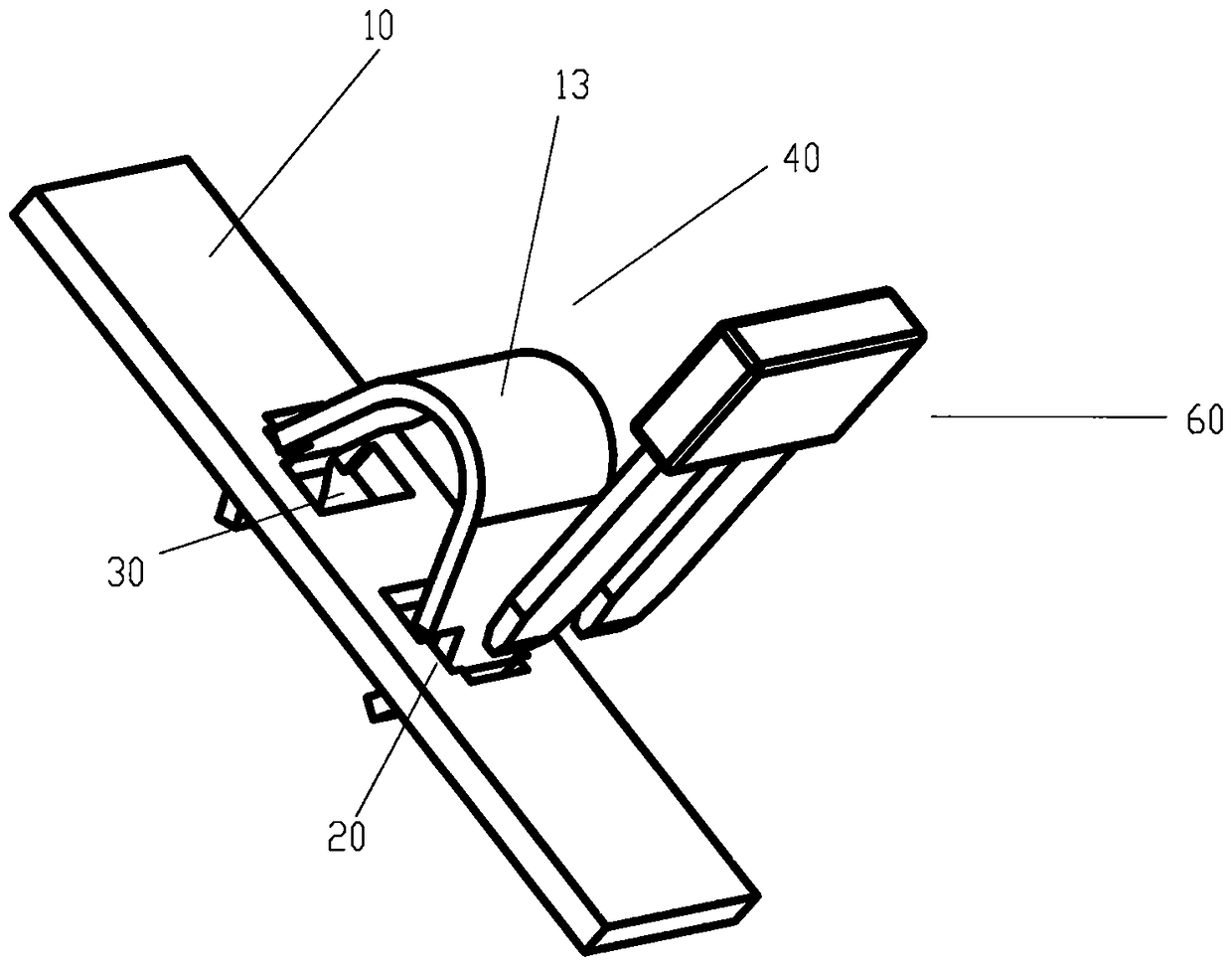

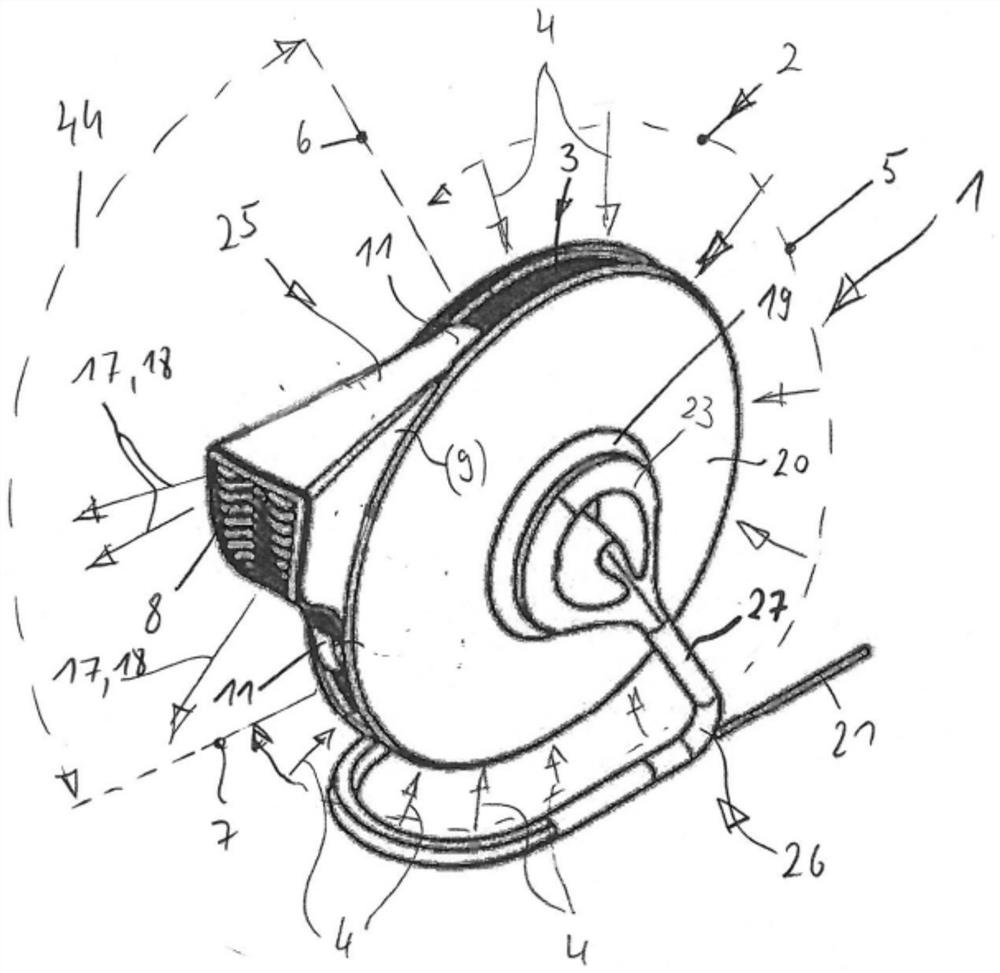

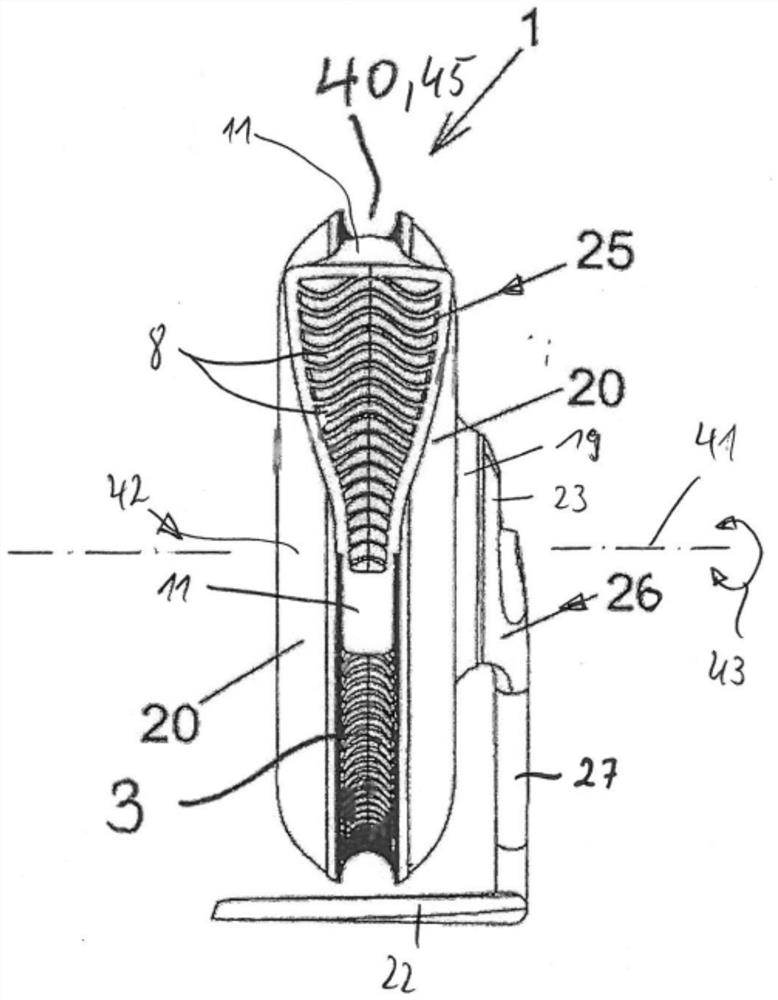

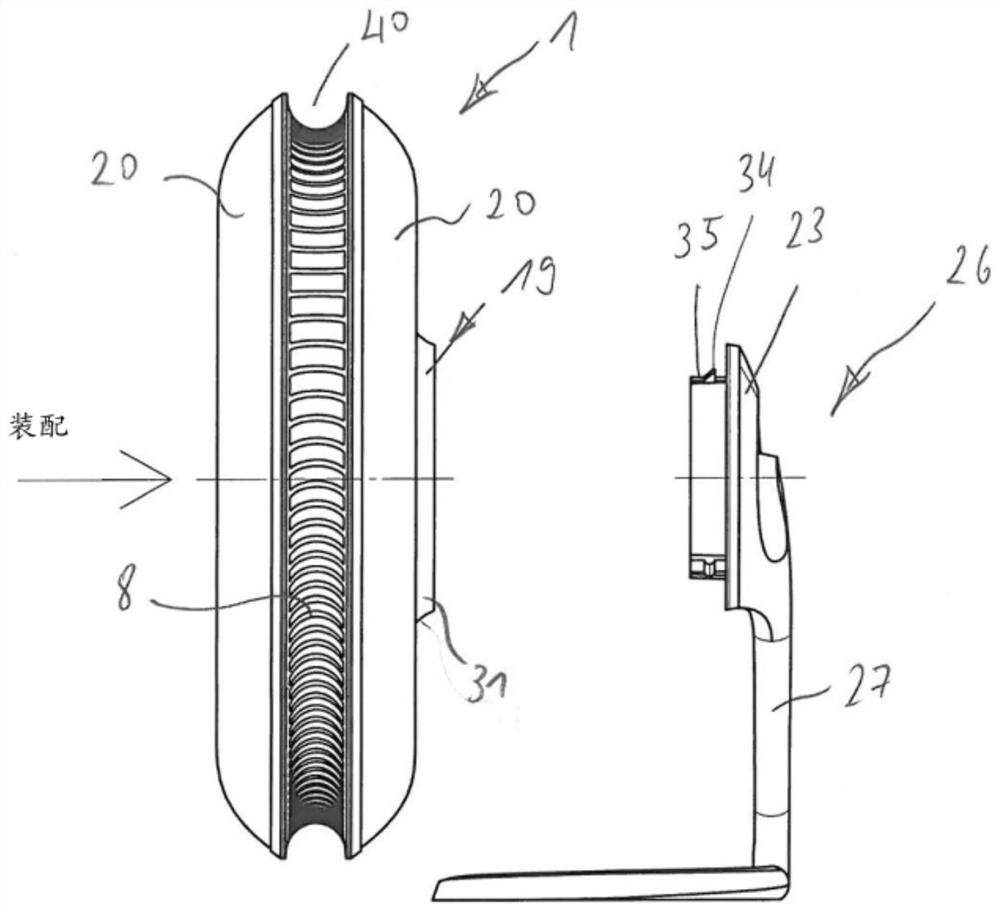

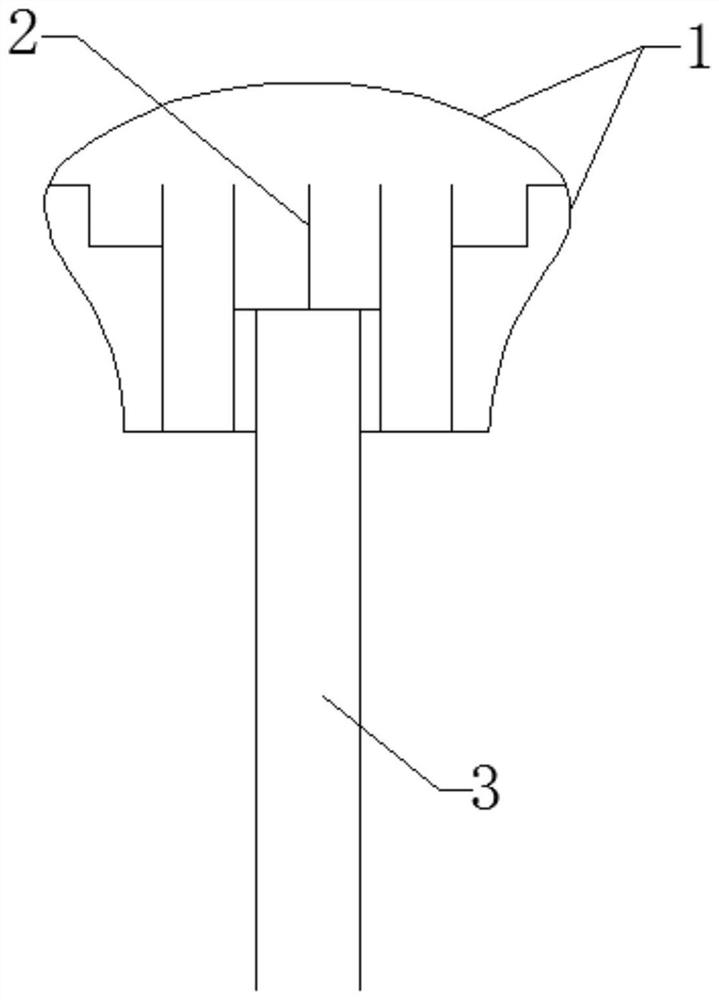

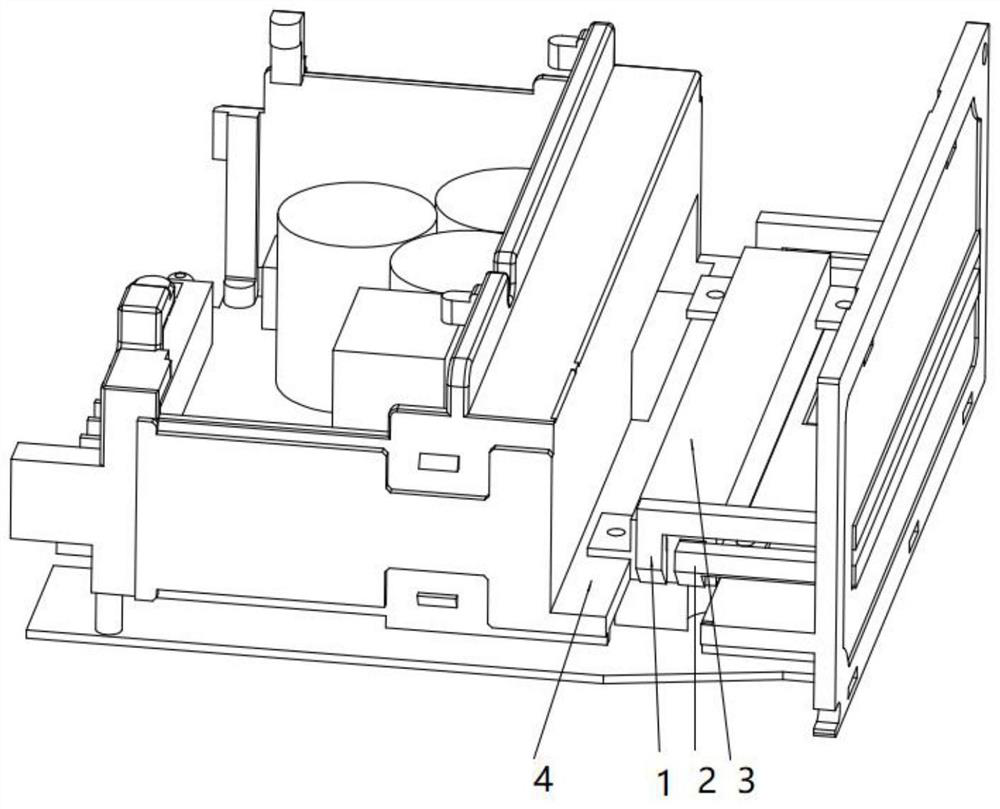

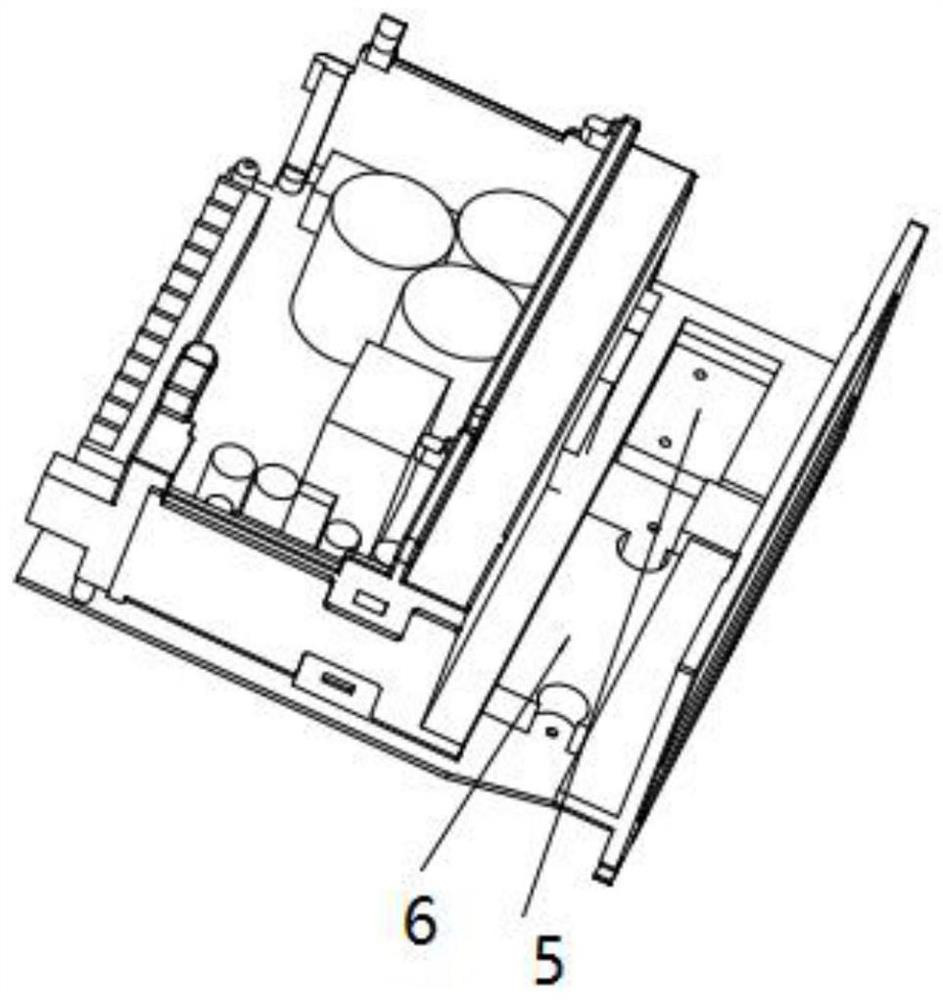

Personalised air purification device with a stand

ActiveCN109611962AReduced structure widthSmall sizeMechanical apparatusDispersed particle filtrationEngineeringAir purification

A personalized air purifying device (1) with a casing (42) having at least one air suction zone (5) for drawing air into the casing (42) and at least one for purifying An air blowing area (44) blown from the outer casing (42), wherein the purified blown air stream (17) is directed toward the body and especially toward the face of the user, wherein the air purifying device (1) is configured The table top device and the stand (26) are releasably secured at the outer casing (42).

Owner:IQAIR AG

Complementary metal oxide semiconductor (CMOS) devices employing plasma-doped source/drain structures and related methods

Owner:QUALCOMM INC

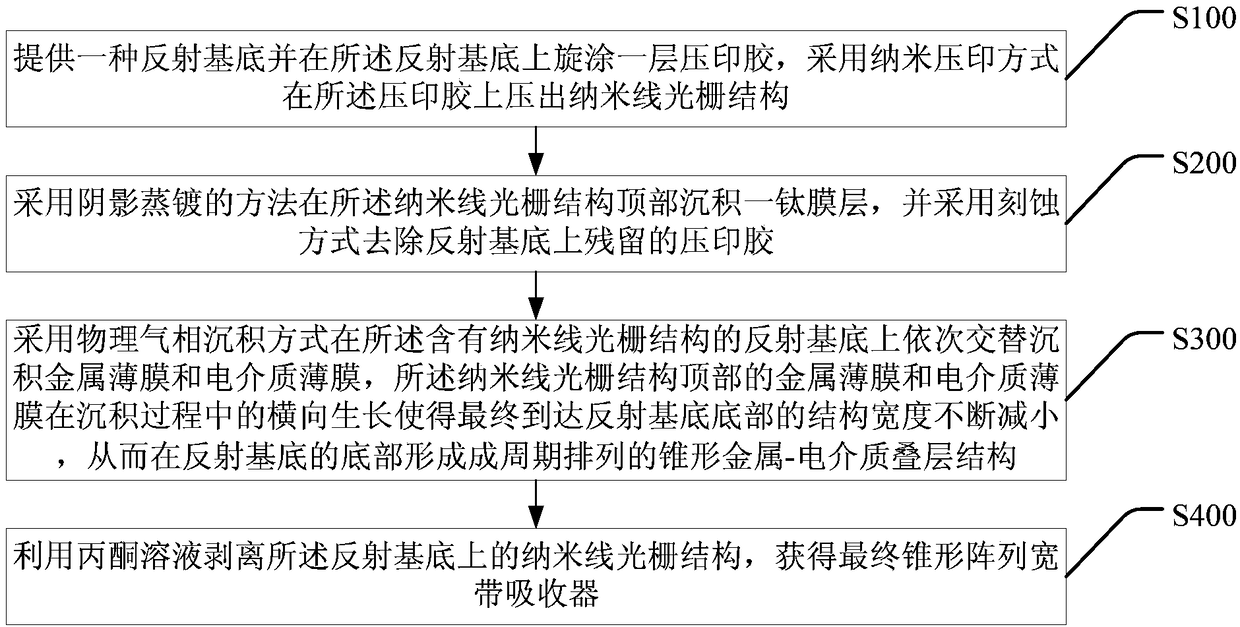

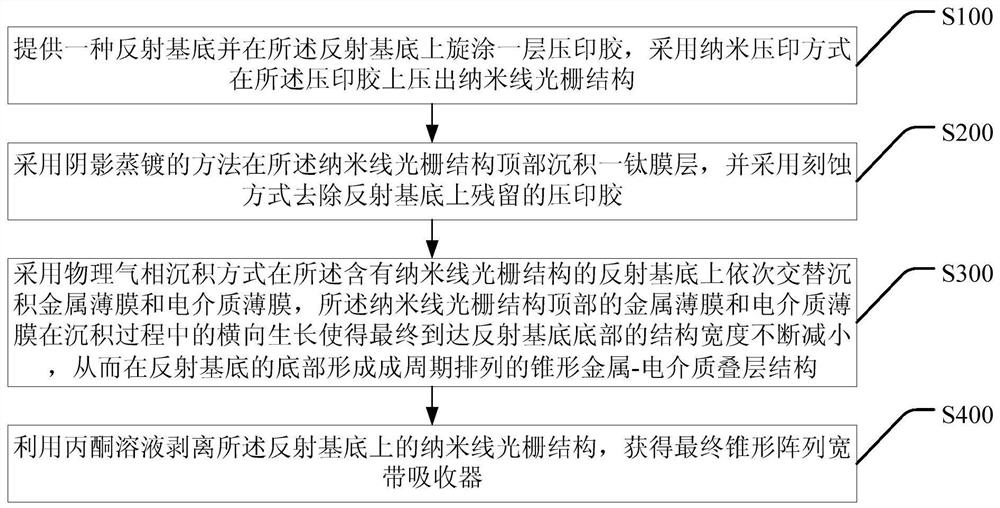

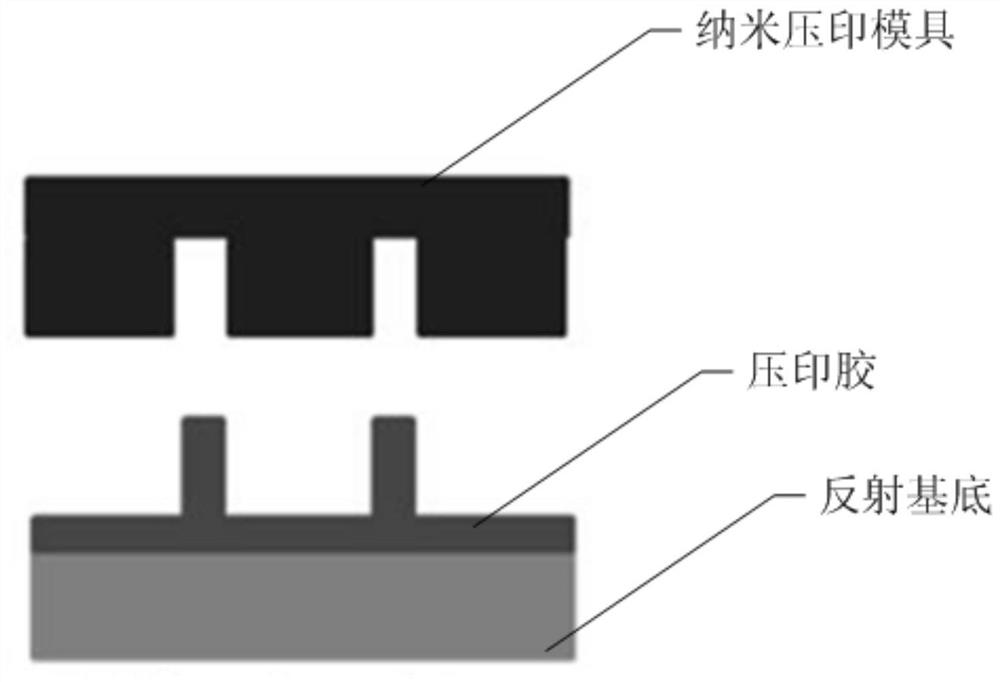

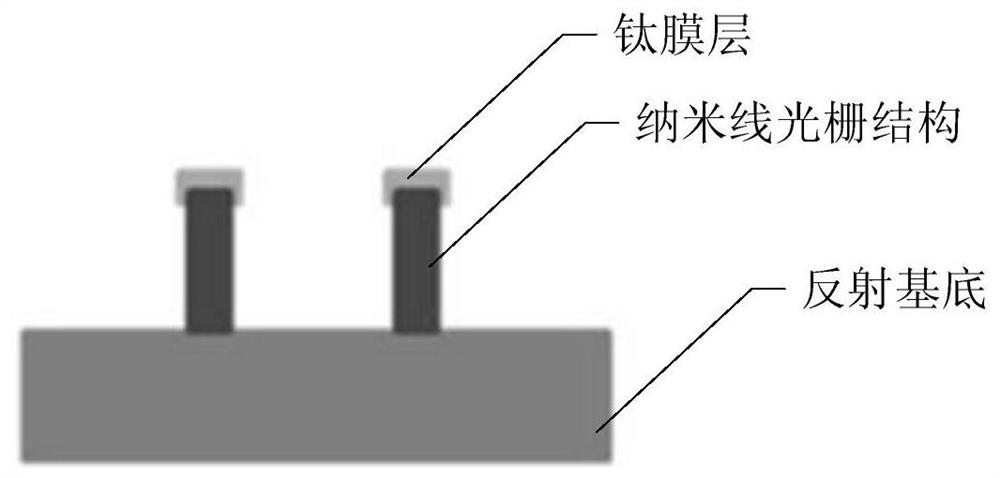

Conical array broadband absorber and preparation method therefor

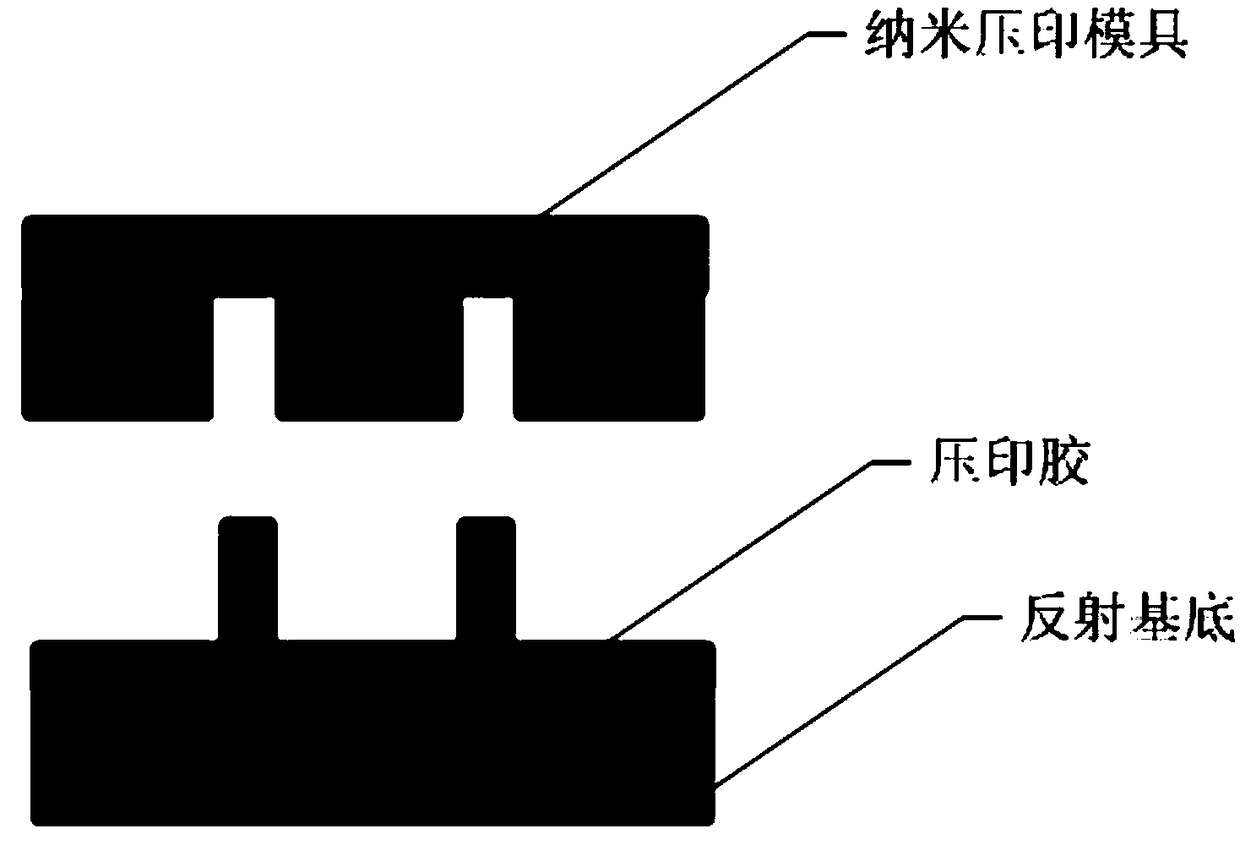

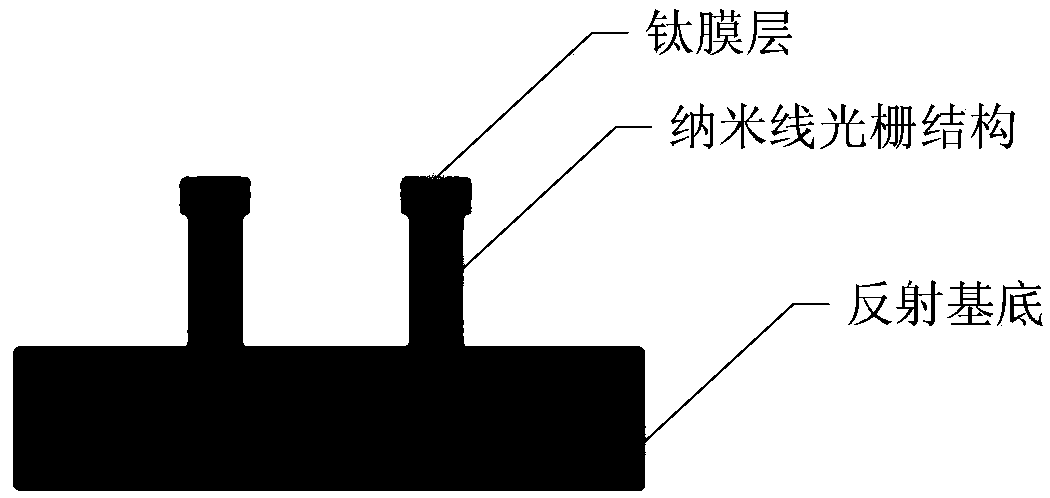

The invention discloses a conical array broadband absorber and a preparation method therefor. The method comprises the steps of: extrudeing a nanowire grating structure on imprint adhesive on reflection substrate by adopting nanoimprint way; depositing a titanium film layer on top of the nanowire grating structure to remove the residual imprint adhesive on the reflection substrate; alternately depositing a metal thin film and a thin dielectric film on the reflection substrate in sequence, and using the phenomenon of natural lateral growth of the metal film and dielectric film during the deposition process, so that structure width eventually reaching the bottom of the reflective substrate continues to decrease, thus a periodically arranged conical metal-dielectric stack structure is formedat the bottom of the reflective substrate; and finally stripping the nanowire grating structure on the reflection substrate by using acetone solution to obtain the conical array broadband absorber. The preparation method provided by the invention is simple, rapid, and suitable for processing of large-area devices, and broadband absorption in visible light and infrared ranges is realized by the conical array broadband absorber.

Owner:SHENZHEN INLIGHT TECH CO LTD

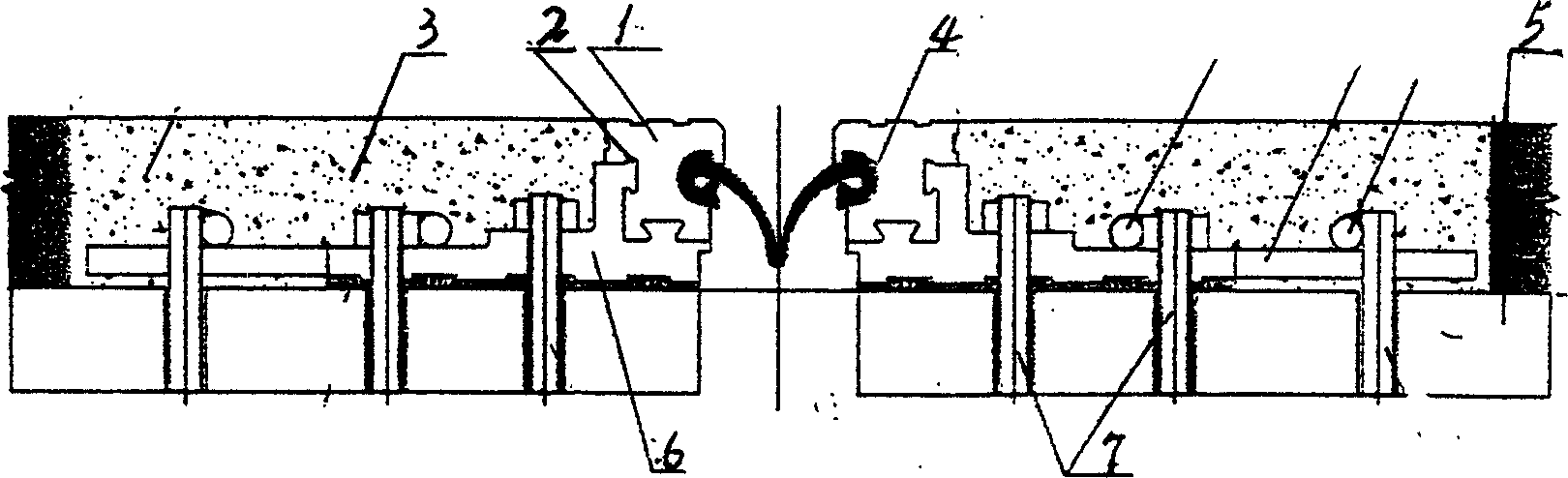

Aluminium alloy bridge expansion and cotraction device and its manufacturing method

InactiveCN1514065AIncreased durabilityCorrosion resistantBridge structural detailsHigh strength concreteExpansion joint

An Al-ally expansion joint for bridge is composed of the side beam to form the expansion slot of bridge, the transition concrete segment, and the anchor part for said side beam. It features that said side beam is made of Al-alloy for light weight, and high rigidity and anticorrosion performance, said transition segment is made of expoxy concrete or high-strength concrete, and the join interface between side beam and transition segment has concave-convex cross-section structure.

Owner:上海金环工程橡胶有限公司

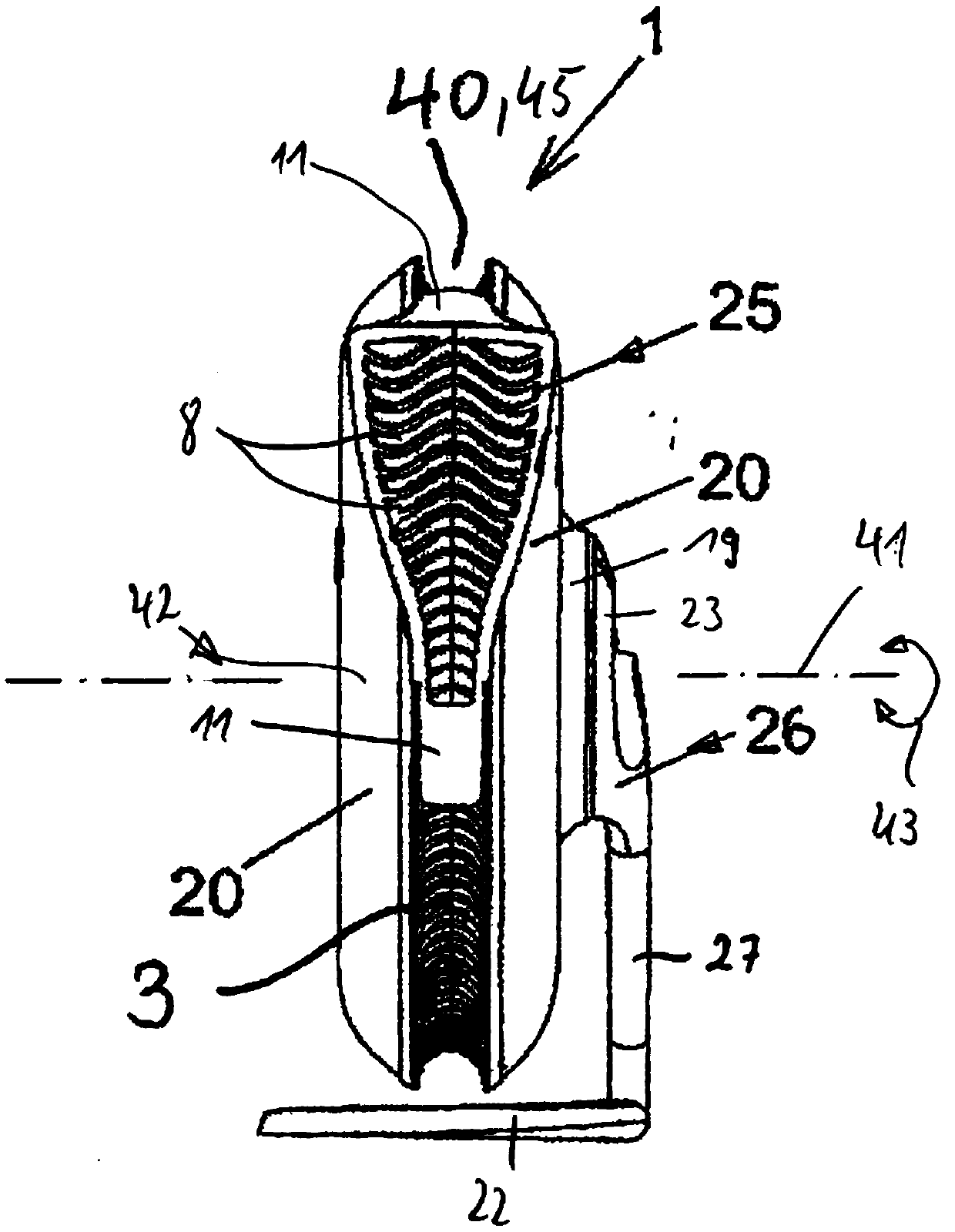

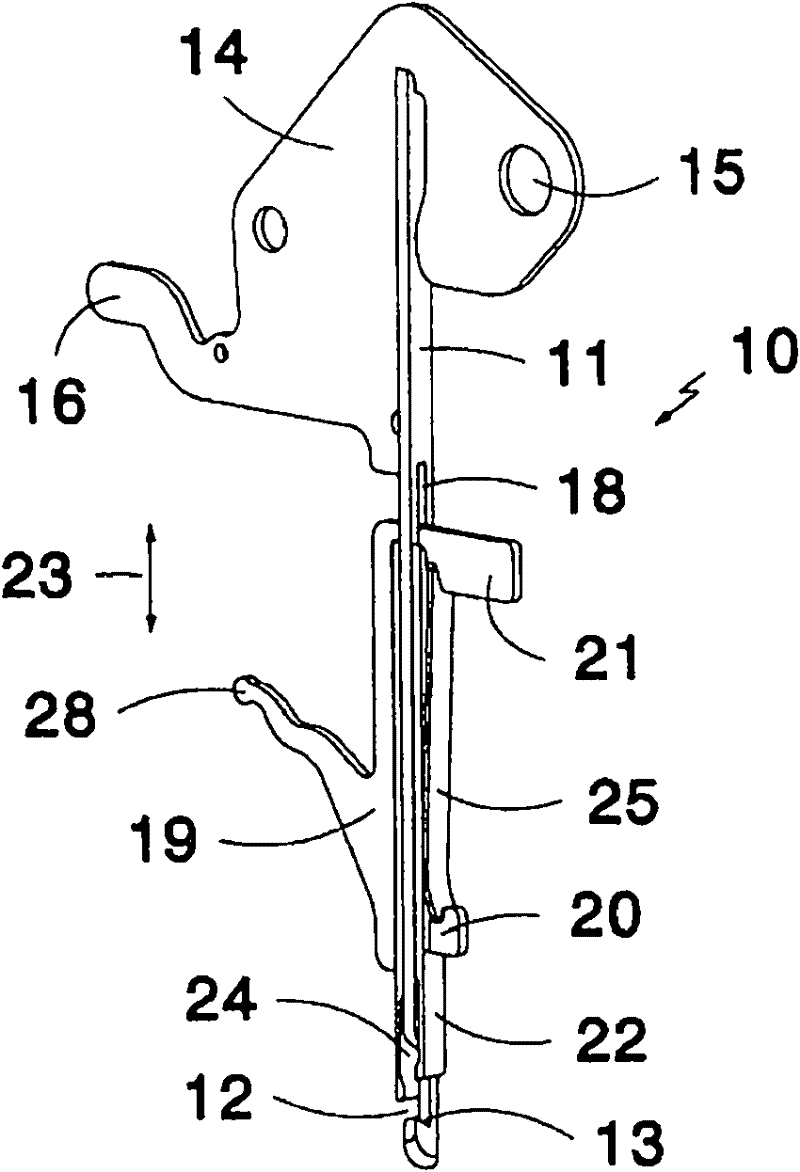

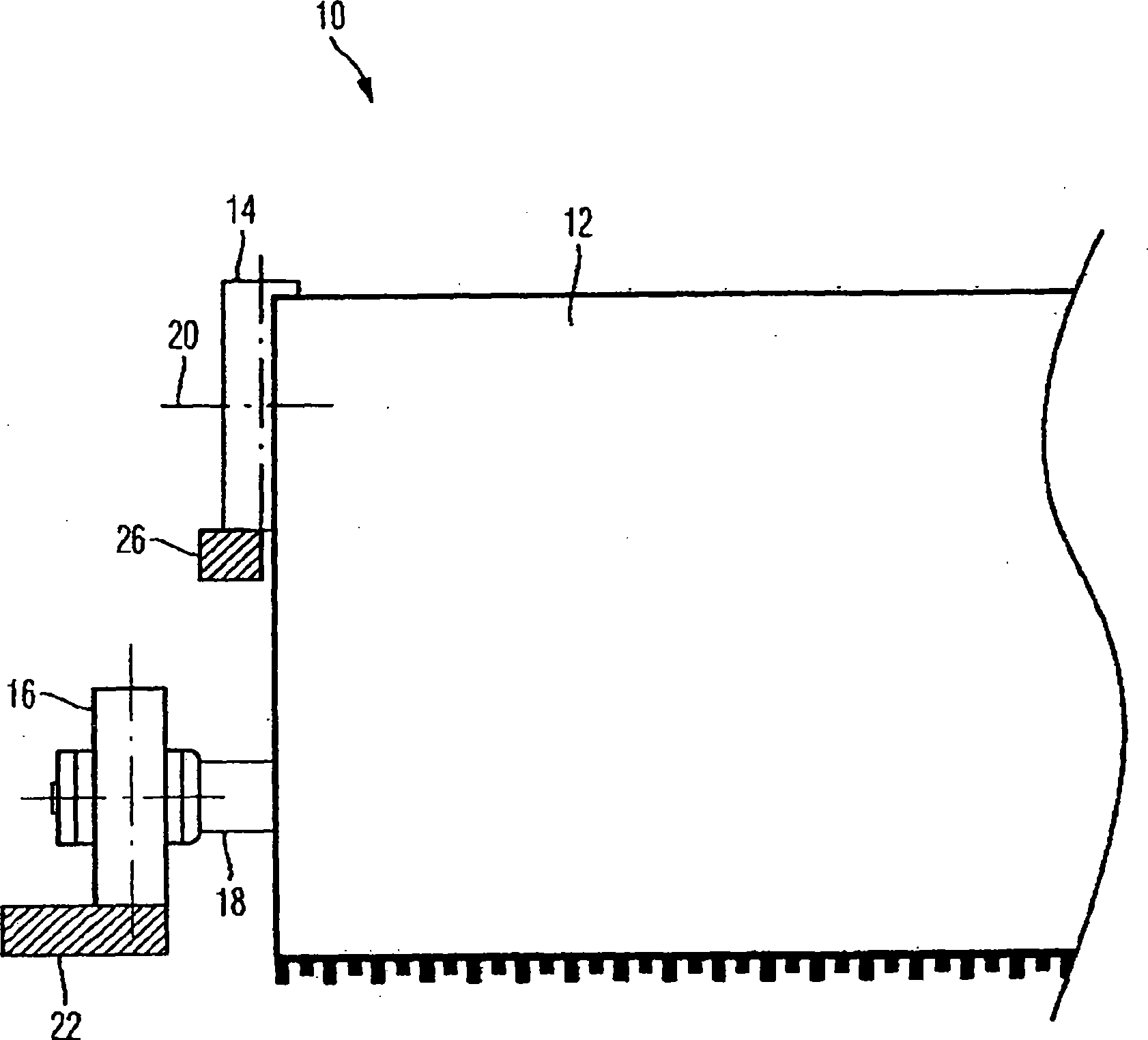

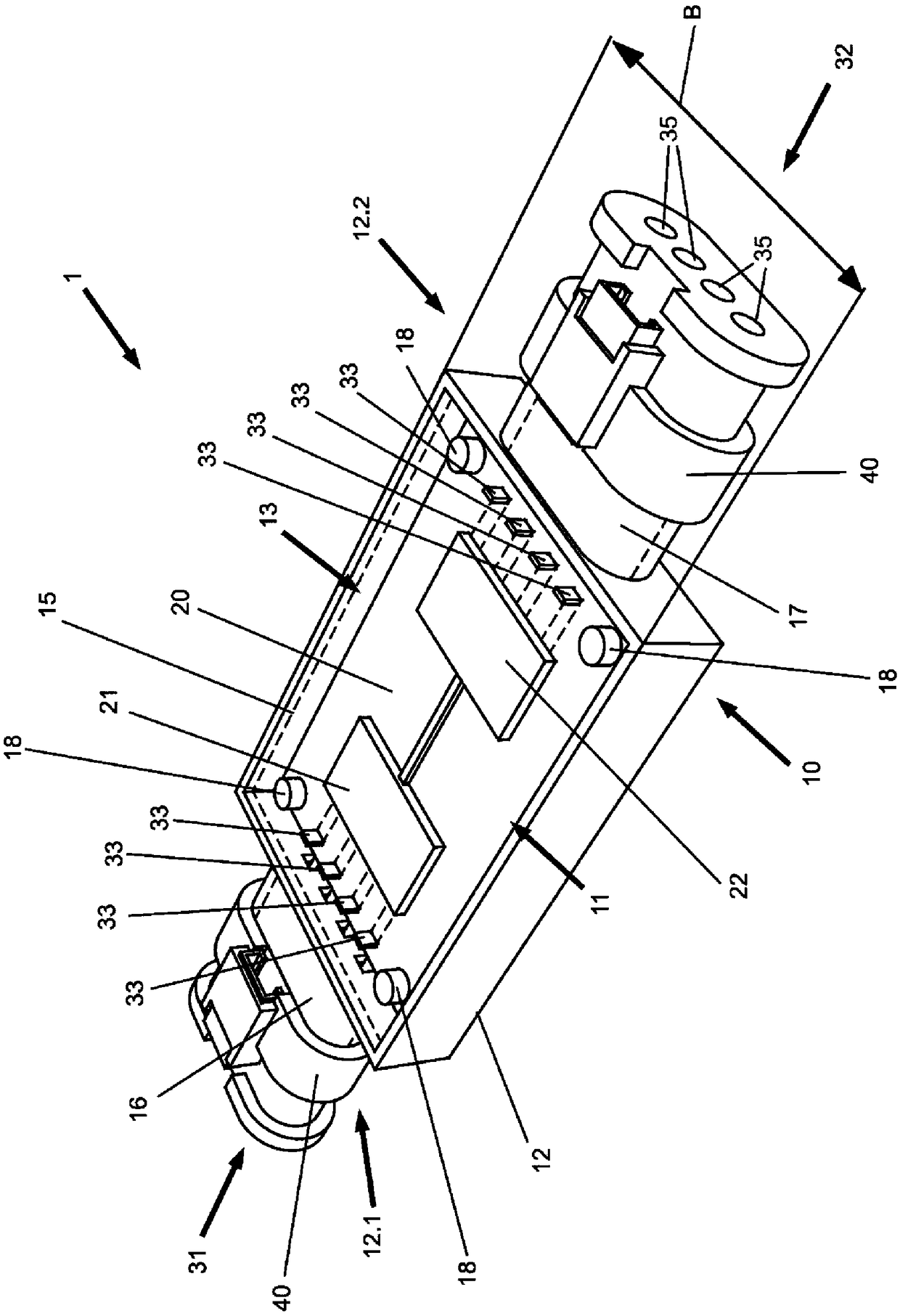

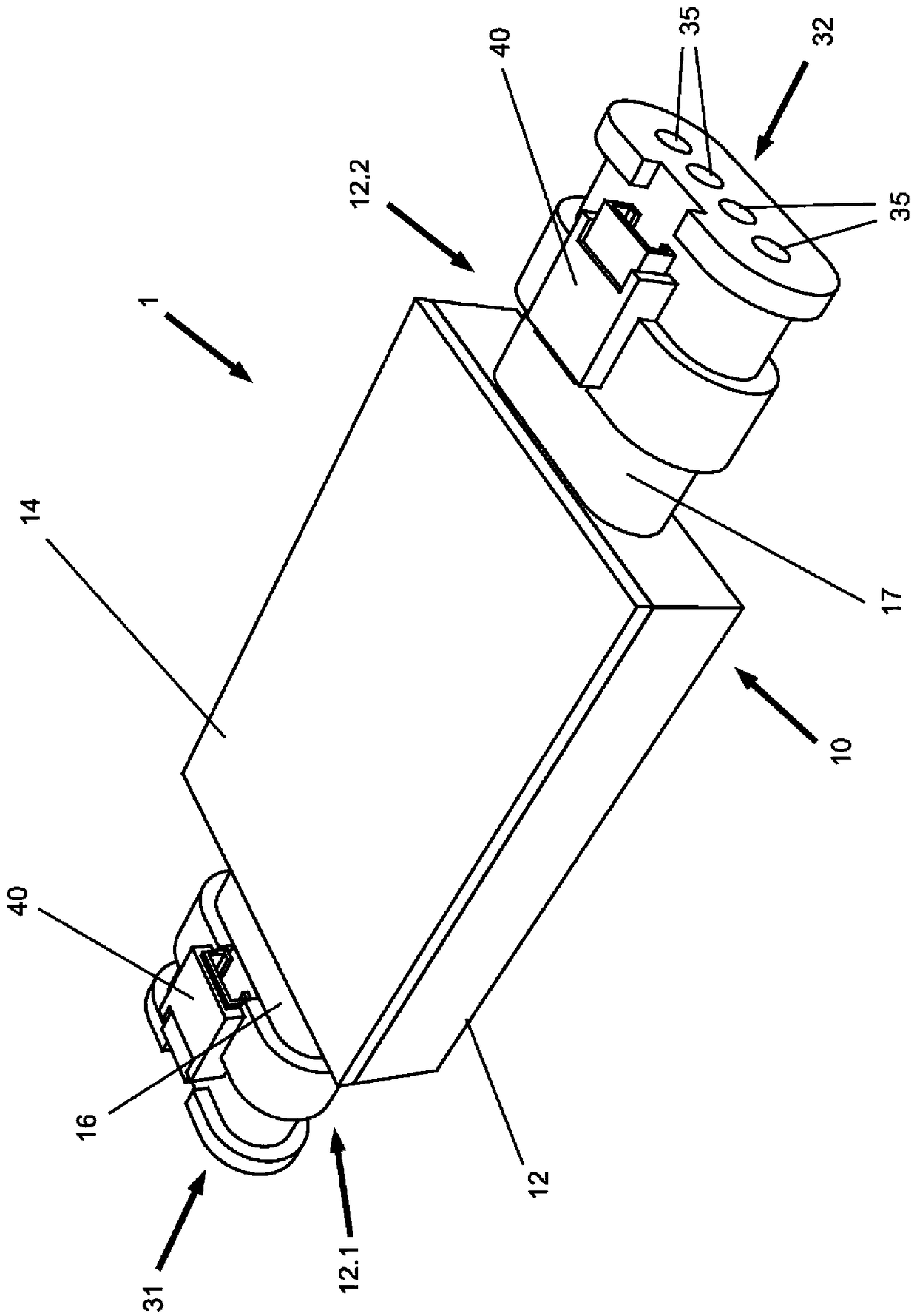

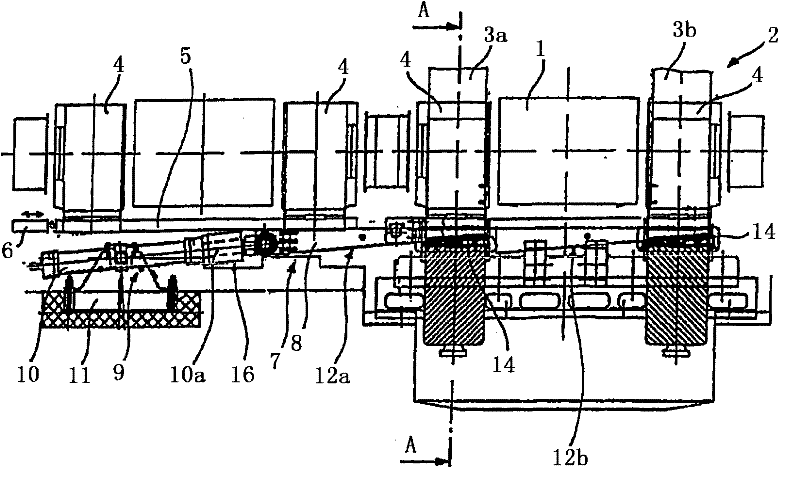

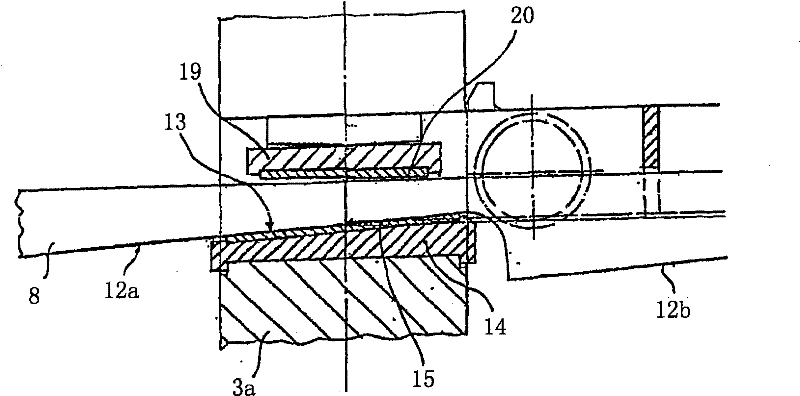

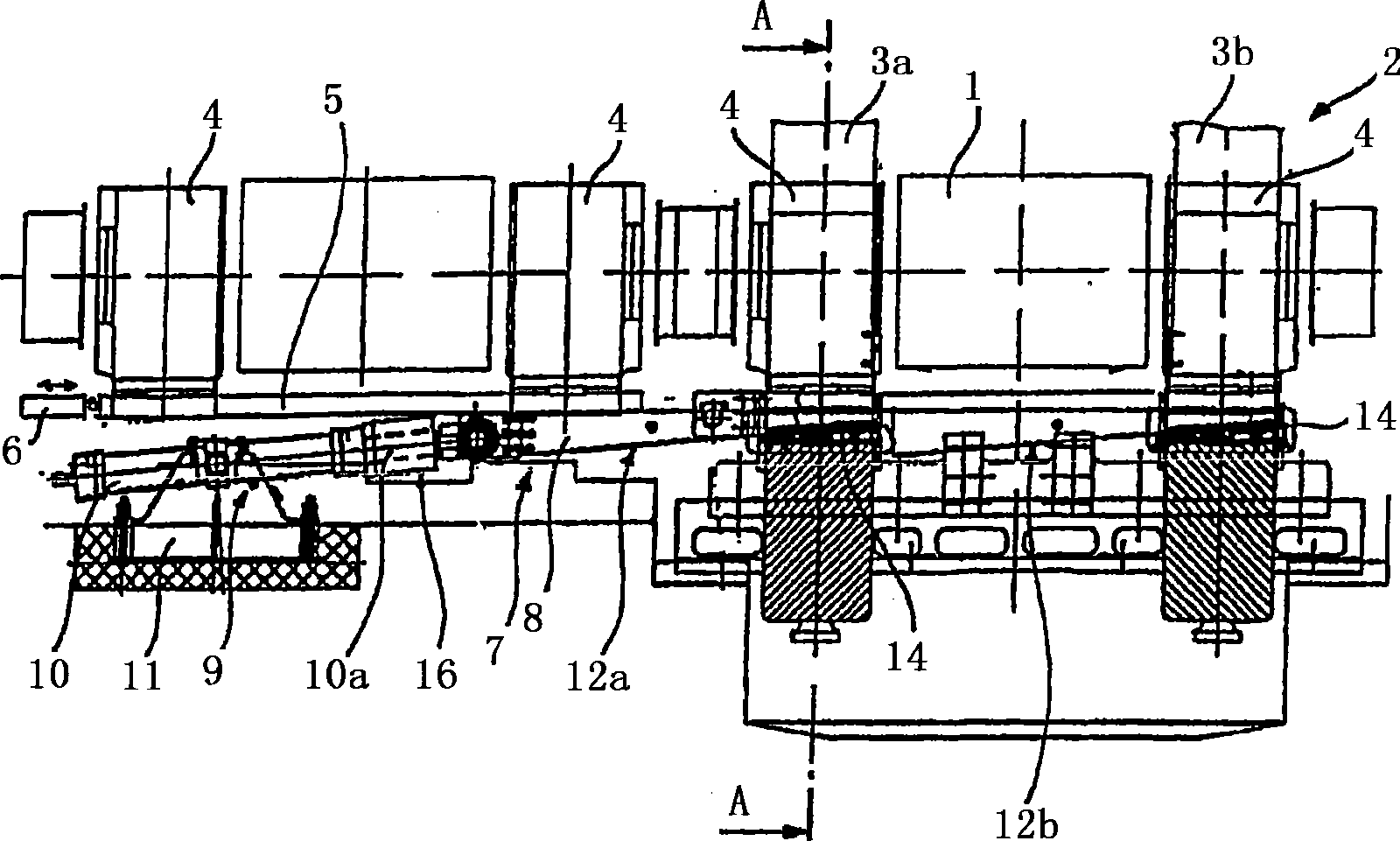

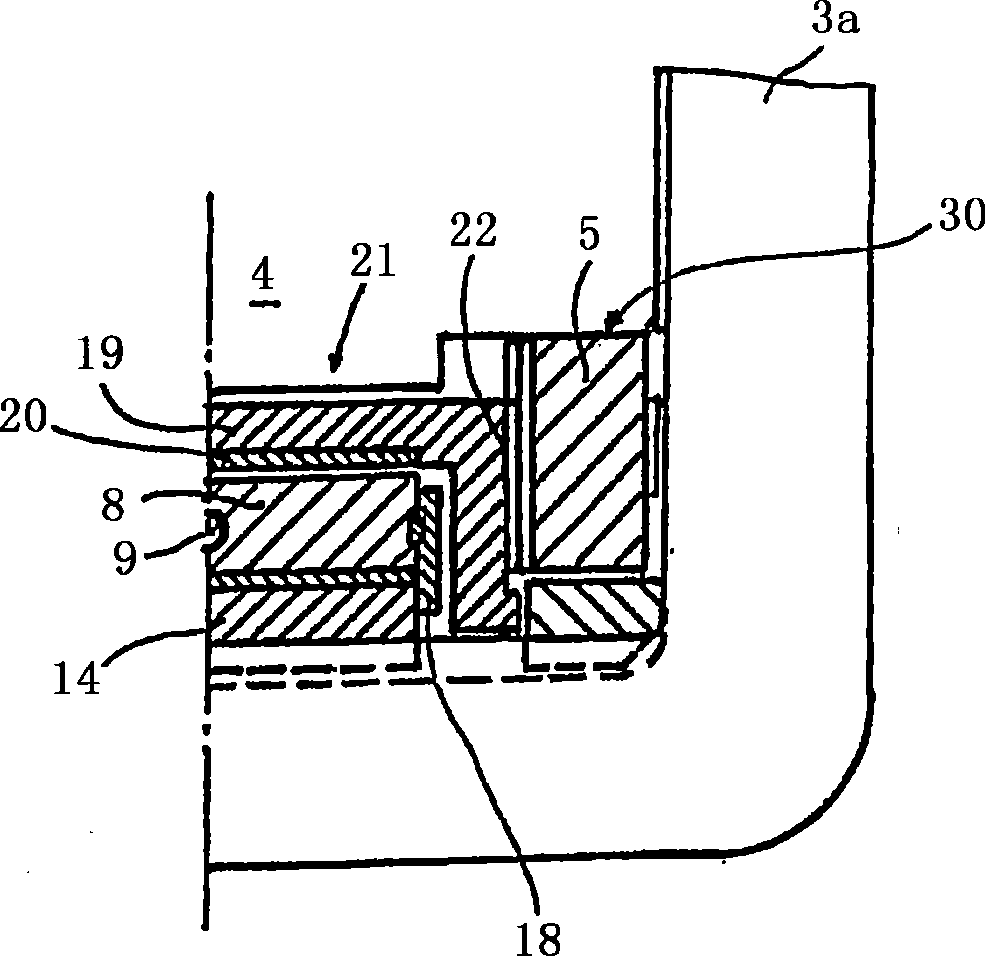

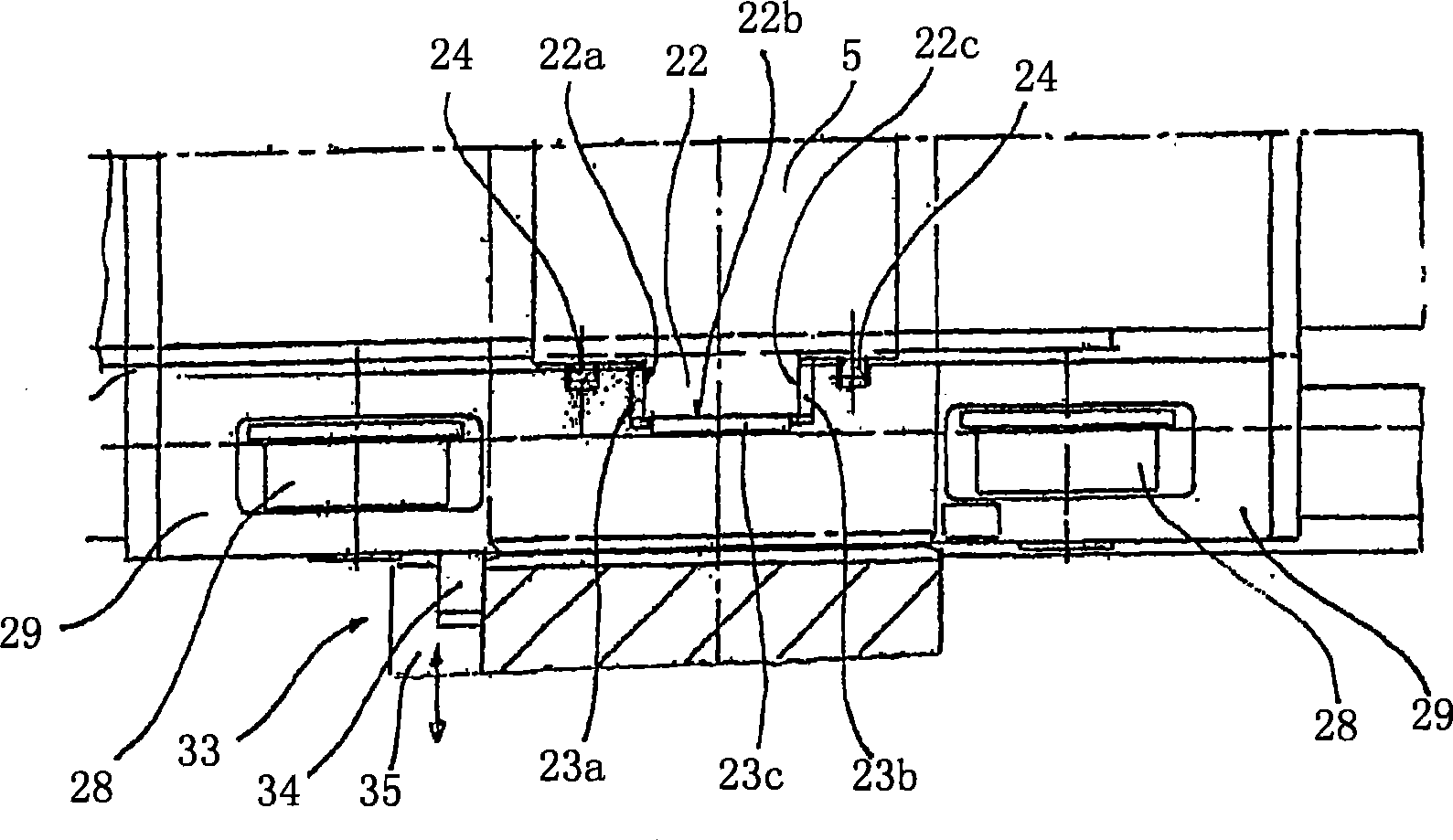

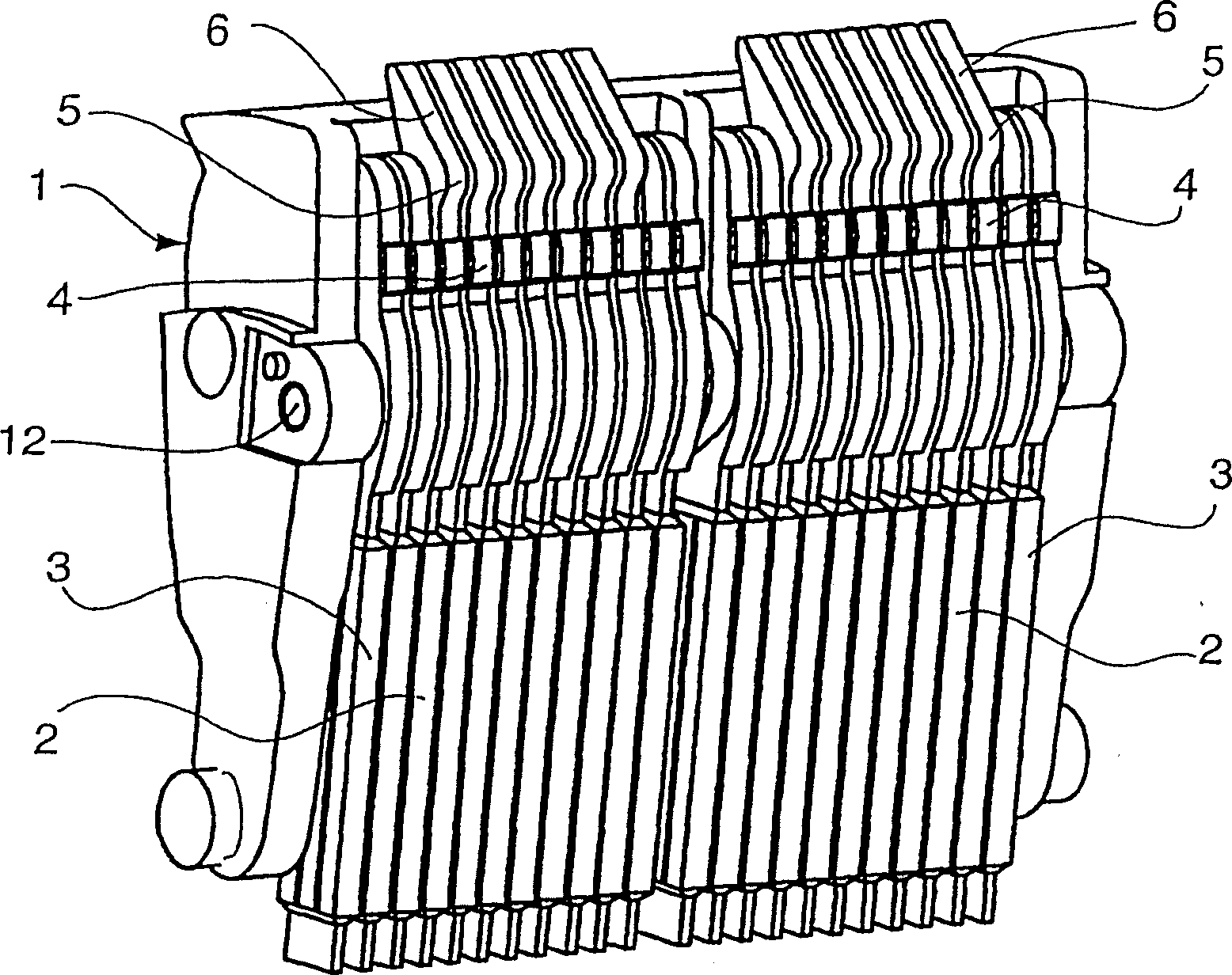

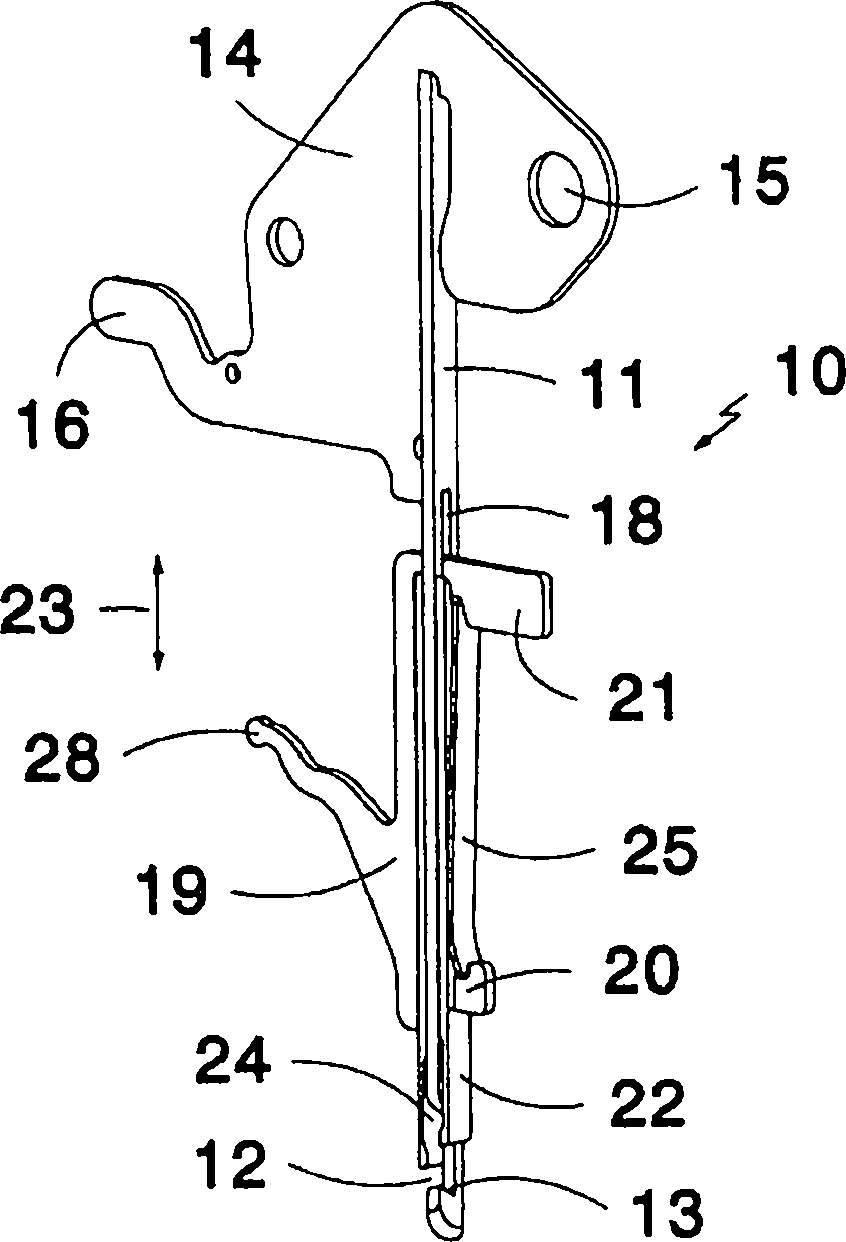

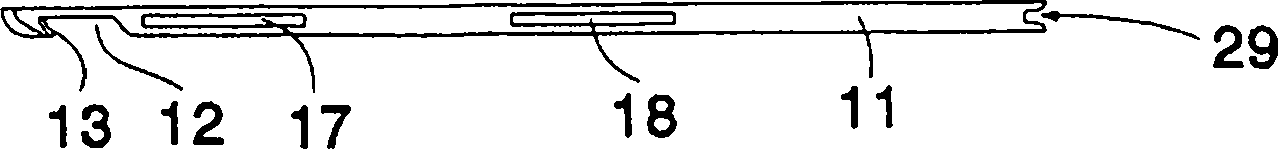

Thread guiding device for a thread changing device

The invention relates to a thread guiding device(10) for a thread changing device, comprising a long finger body (11), one end of the finger body is fixed on a pivoted rod (14), the other end of the finger body is provided with a yarn receiving zone (12) provided with knitting yarns, and the thread guiding device comprises a guide element (19) movable along the finger body (11), a blade (22) and a clamping element (24) prestressed via a spring force can move along the finger body (11) via the guiding element, the finger body (11) is provided with at least one longitudinal seam (17, 18), the guiding element (19) can be movably supported in the longitudinal seam. The invention also relates to a thread changing device provided with the thread guiding device and a knitting machine provided with the thread changing device.

Owner:SIPRA PATENTENTWICKLUNGS & BETEILIGUNGSGMBH

Escalator or moving walkway

Owner:THYSSENKRUPP ELEVATOR AG (DE)

Multi-aperture imaging device, imaging system and method for capturing an object area

ActiveUS10771668B2Reduce in quantityReduced structure widthTelevision system detailsColor television detailsRadiologyComputer science

A multi-aperture imaging device includes at least one image sensor and an array of juxtaposed optical channels. Each optical channel includes optics for imaging of projecting at least one partial area of an object area on an image sensor area of the image sensor. A first optics of a first optical channel is configured to project a first partial area of the object area on a first image sensor area and to project a second partial area of the object area on a second image sensor area. A second optics of a second optical channel is configured to project at least a third partial area of the object area on a third image sensor area. The first partial area and the second partial area are disjoint in the object area. The third partial area overlaps incompletely with the first partial area.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

A terminal block

ActiveCN105826733BQuick assemblyFull deformation spaceCoupling contact membersClamped/spring connectionsEngineeringBinding post

Owner:NINGBO SUPU ELECTRONICS

Electronic unit for a sensor, vehicle and method of manufacturing an electronic unit

InactiveCN109219284AOptimize layoutReduced structure widthCasings with connectors and PCBCasings/cabinets/drawers detailsEngineeringPrinted circuit board

The invention relates to an electronics unit (1) for a sensor (2), in particular a foot switch, for a vehicle (3), having a first connection region (31) for connecting the electronics unit (1) to thevehicle (3), a second connection region (32) for connecting the electronics unit (1) to the sensor (2), a housing (10) and a printed circuit board (20), wherein the printed circuit board (20) in a cavity (11) of the housing (10) is arranged. Furthermore, the invention relates to a vehicle (3) having an electronics unit (1) and a manufacturing method (100) for producing an electronics unit (1).

Owner:HUF HULSBECK & FURST GMBH & CO KG

Personalized Air Purifier with Stand

ActiveCN109611962BReduced structure widthSmall sizeMechanical apparatusDispersed particle filtrationAir cleaningEnvironmental engineering

Personalized air purification device (1) with housing (42) having at least one air intake area (5) for drawing air into the housing (42) and at least one area for drawing purified air into the housing (42) Air blowing area (44) from which air is blown out from the housing (42), wherein the purified blown air flow (17) is directed towards the body and in particular towards the user's face, wherein the air cleaning device (1) is configured as The desktop device is detachably fixed with a stand (26) at the casing (42).

Owner:IQAIR AG

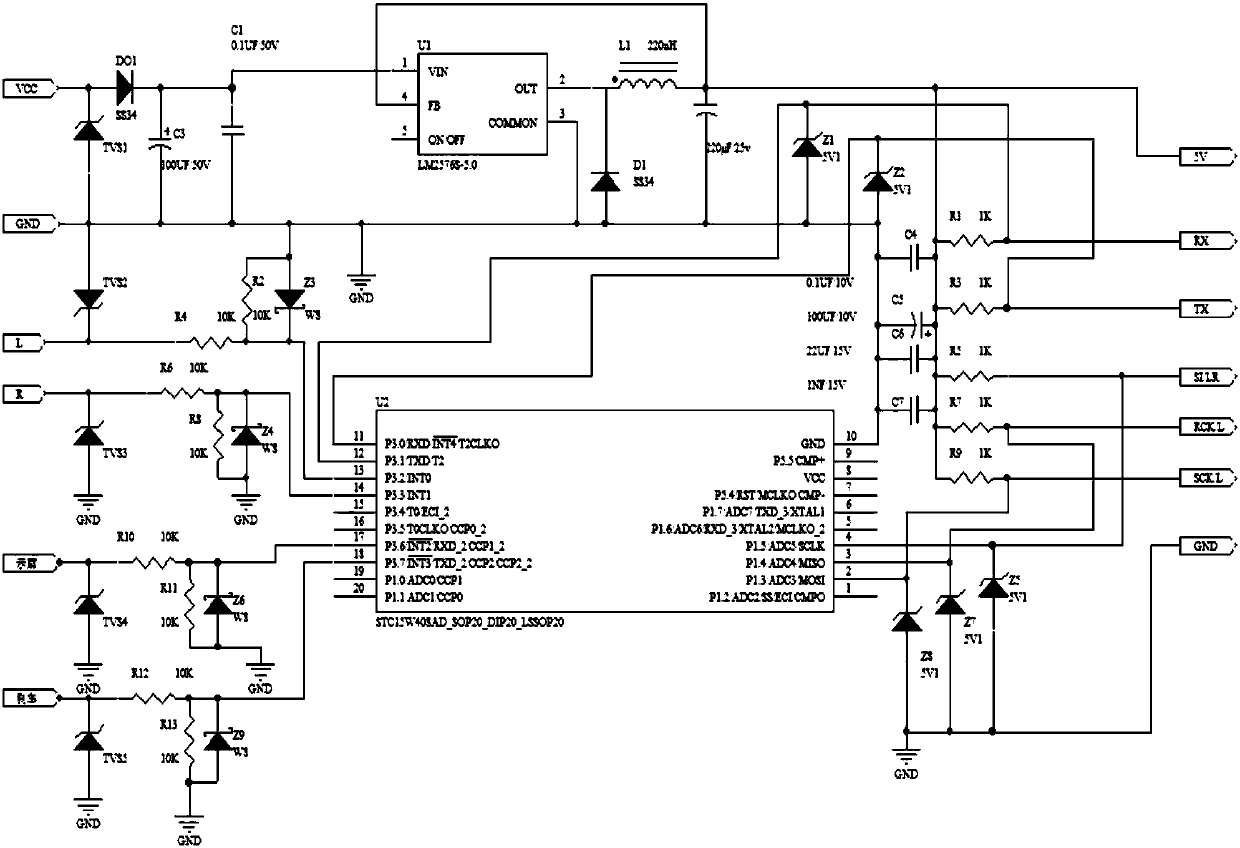

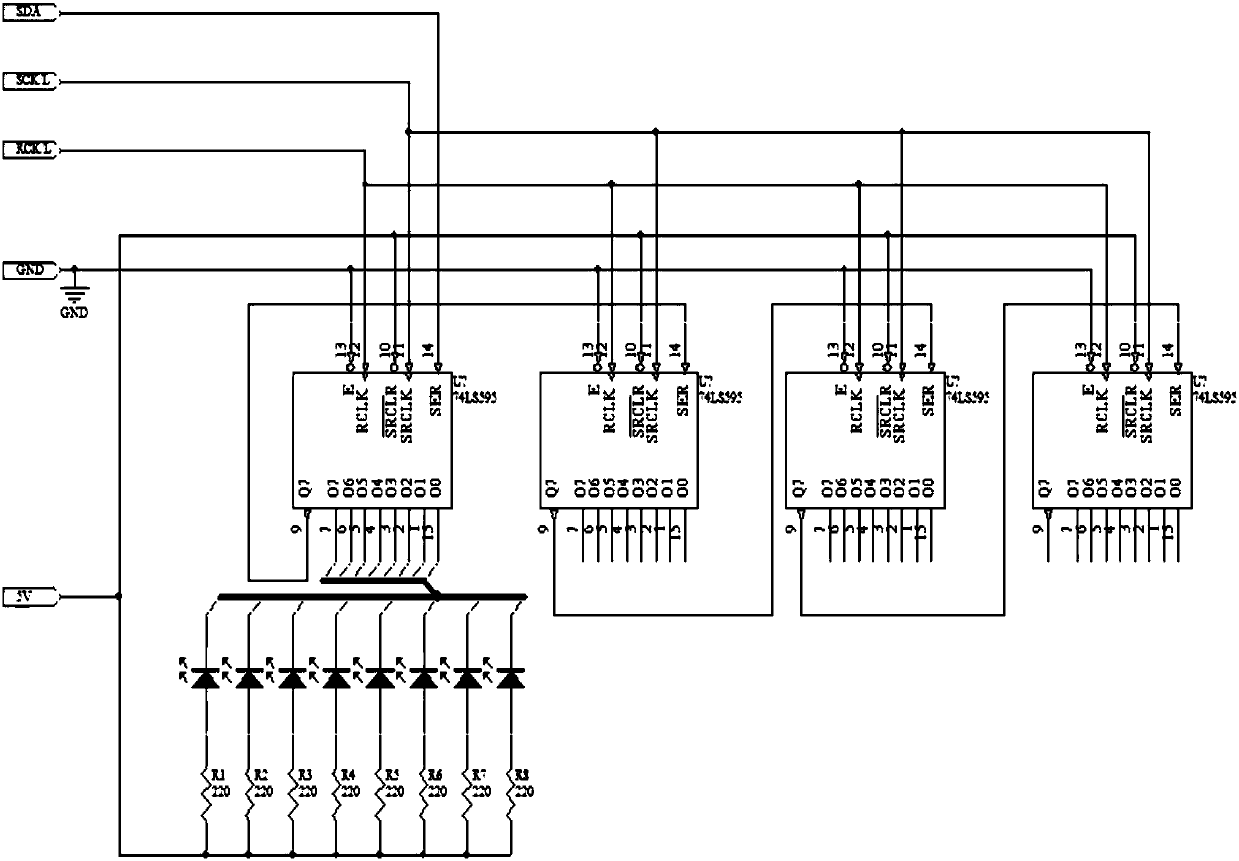

Streamer tail light control circuit

PendingCN107820349ARealize continuous streamer flashing functionBeautiful and elegant formElectrical apparatusElectroluminescent light sourcesMicrocomputer controlControl circuit

The invention discloses a streamer tail light control circuit. The streamer tail light control circuit comprises a front end input instruction end, a single chip microcomputer control end connected with the front end input instruction end, and a lamp bead driving end positioned on a lamp plate; the single chip microcomputer control end adopts an STC15W408AD single chip microcomputer; and front end input instruction end comprises a left steering instruction end connected with a P3.2INT0 port of the STC15W408AD single chip microcomputer, a right steering instruction end connected with a P3.3INT1 port of the STC15W408AD single chip microcomputer, and a clearance lamp instruction end connected with a P3.6INT2 port of the STC15W408AD single chip microcomputer. By virtue of the sectional type control structure, higher stability and reliability, relatively low loss rate, relatively low power consumption, and saving of a part of energy can be realized; and in addition, in installation, the lamp beads are mounted a PCB with width of less than 8.5mm, so that the overall structural width is relatively small, and the thickness is relatively thin, thereby realizing installation very conveniently.

Owner:江苏润深智能科技有限公司

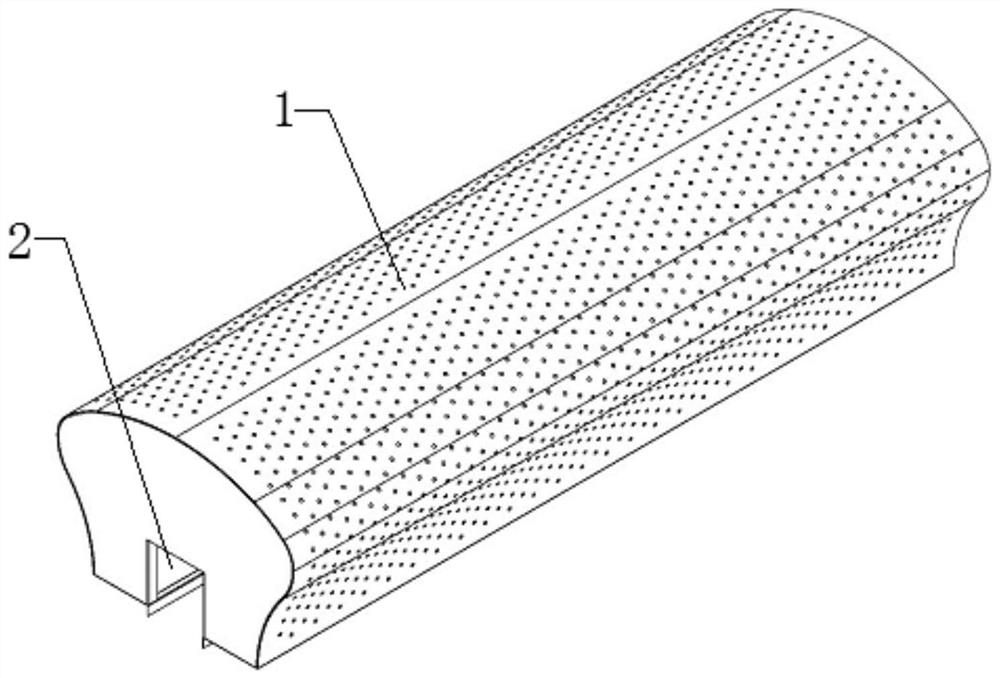

Noise reduction structure at top end of sound barrier based on diffuser coupling micro-perforated plate

PendingCN113089516AReduced structure widthMeet engineering application requirementsNoise reduction constructionMicro perforated plateSound barrier

The invention discloses a noise reduction structure at the top end of a sound barrier based on a diffuser coupling micro-perforated plate, which comprises an outer protection panel and a diffuser structure, the outer protection panel and the diffuser structure are coupled to form an integral structure and are connected with an upper screen body, and the upper screen body is connected with an I-shaped steel beam structure in an inserting manner. The optimized acoustic diffuser structure is coupled with the micro-perforated plate structure, the structure width is reduced, the engineering application requirement is met, meanwhile, the streamlined outer panel is utilized, the modeling is simple and attractive, the sound diffusion and absorption effects of the structure are adopted, additional sound absorption materials are not needed, and the problem that the noise reduction performance is reduced due to the fact that a porous sound absorption material loses efficacy along with time in a common sound barrier is solved. The structure is small in size width, simple in structure, convenient to install, long in service life and stable and effective in noise reduction effect for a long time.

Owner:CHINA SHIPPING ENVIRONMENT SCI & TECH SHANGHAI CO LTD

Roll changing device with wedge adjusting device

InactiveCN101534970BReduce adjustment forceNo shift biasMetal rolling stand detailsMetal rolling arrangementsMechanical engineering

Owner:PRIMETALS TECH AUSTRIA GMBH

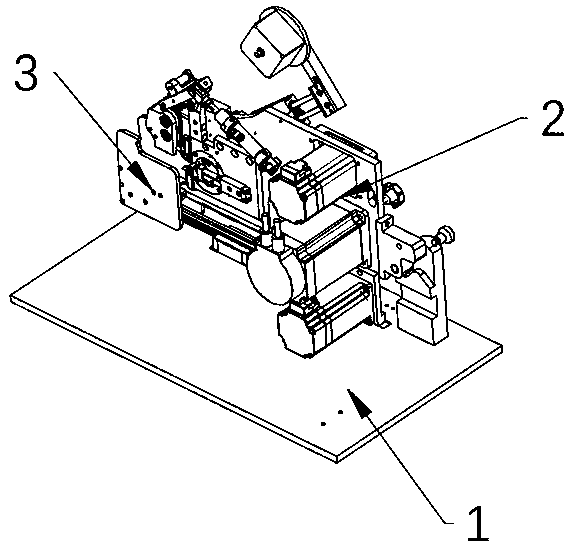

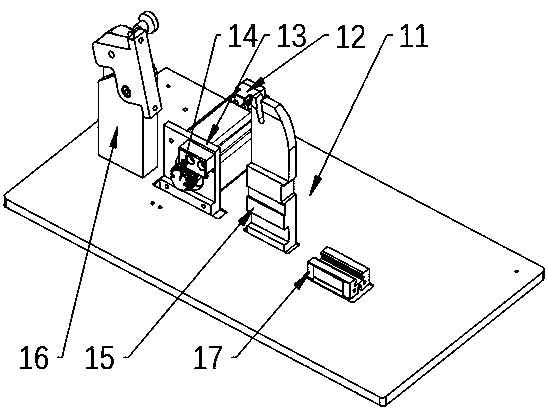

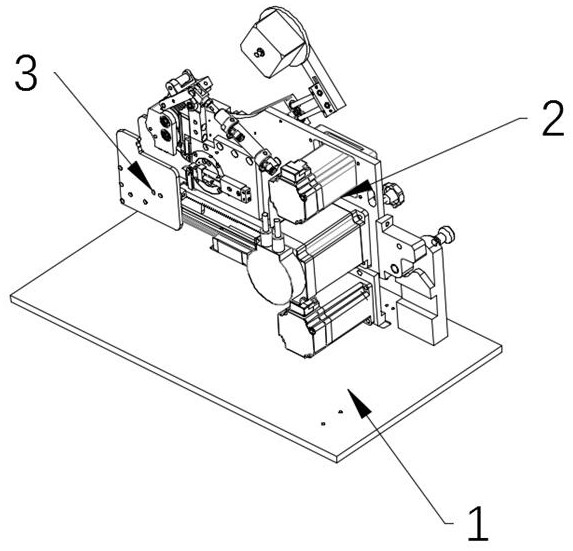

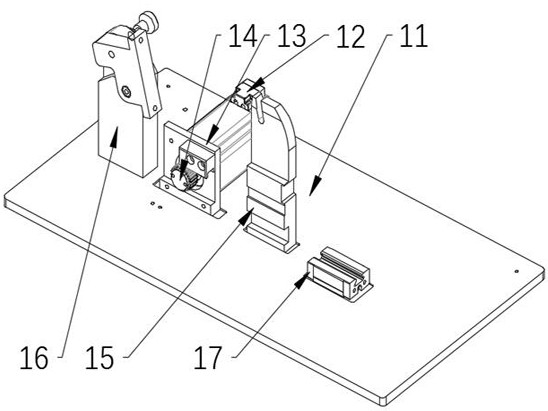

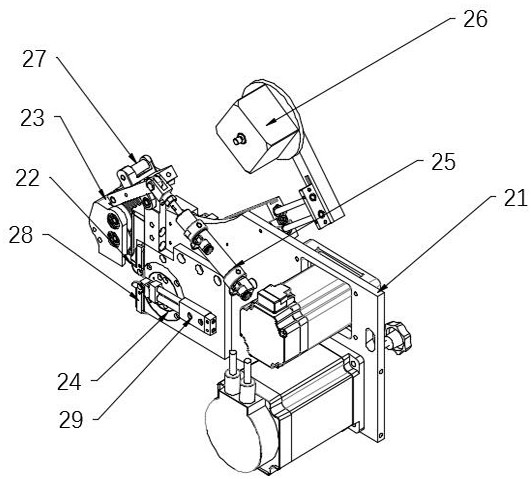

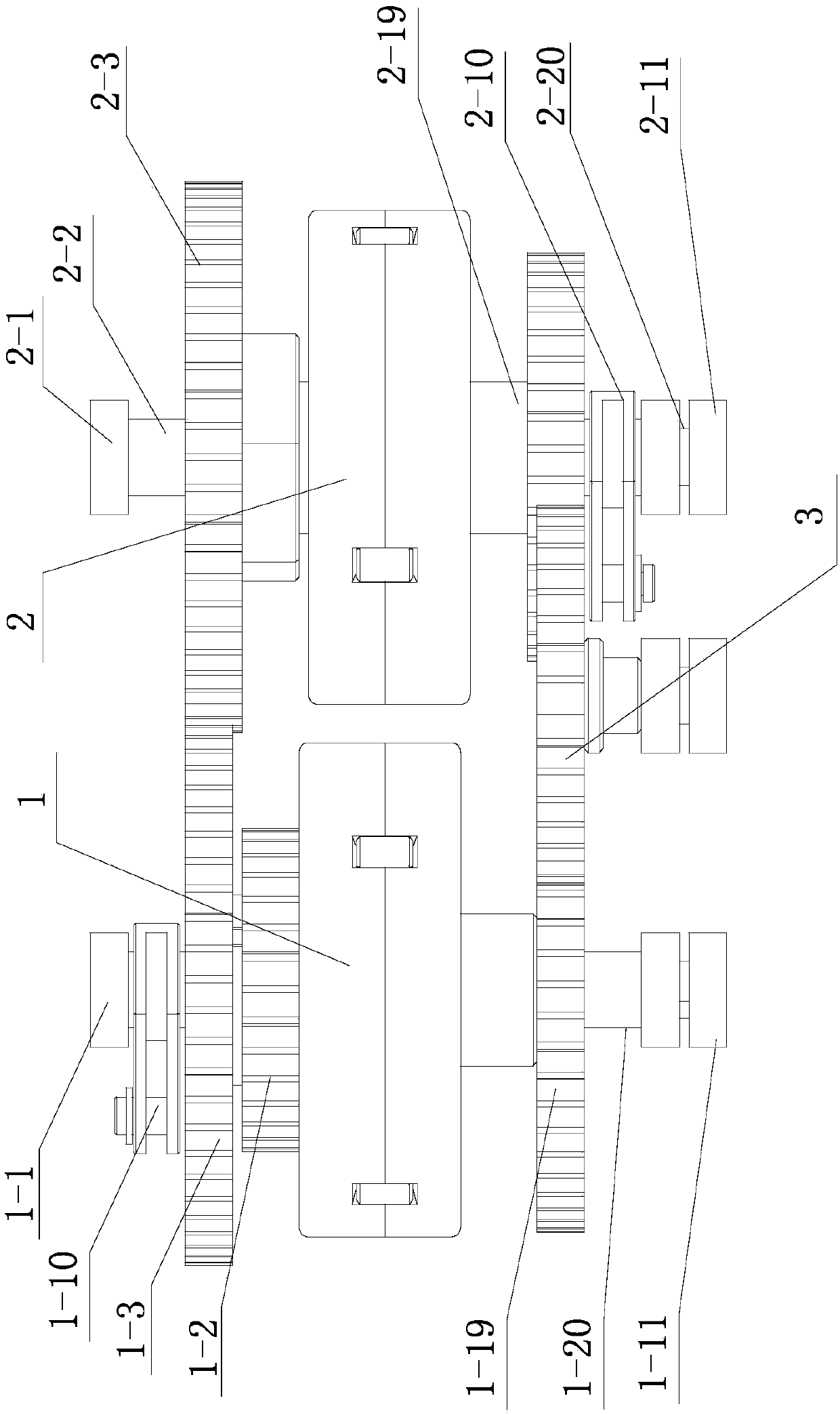

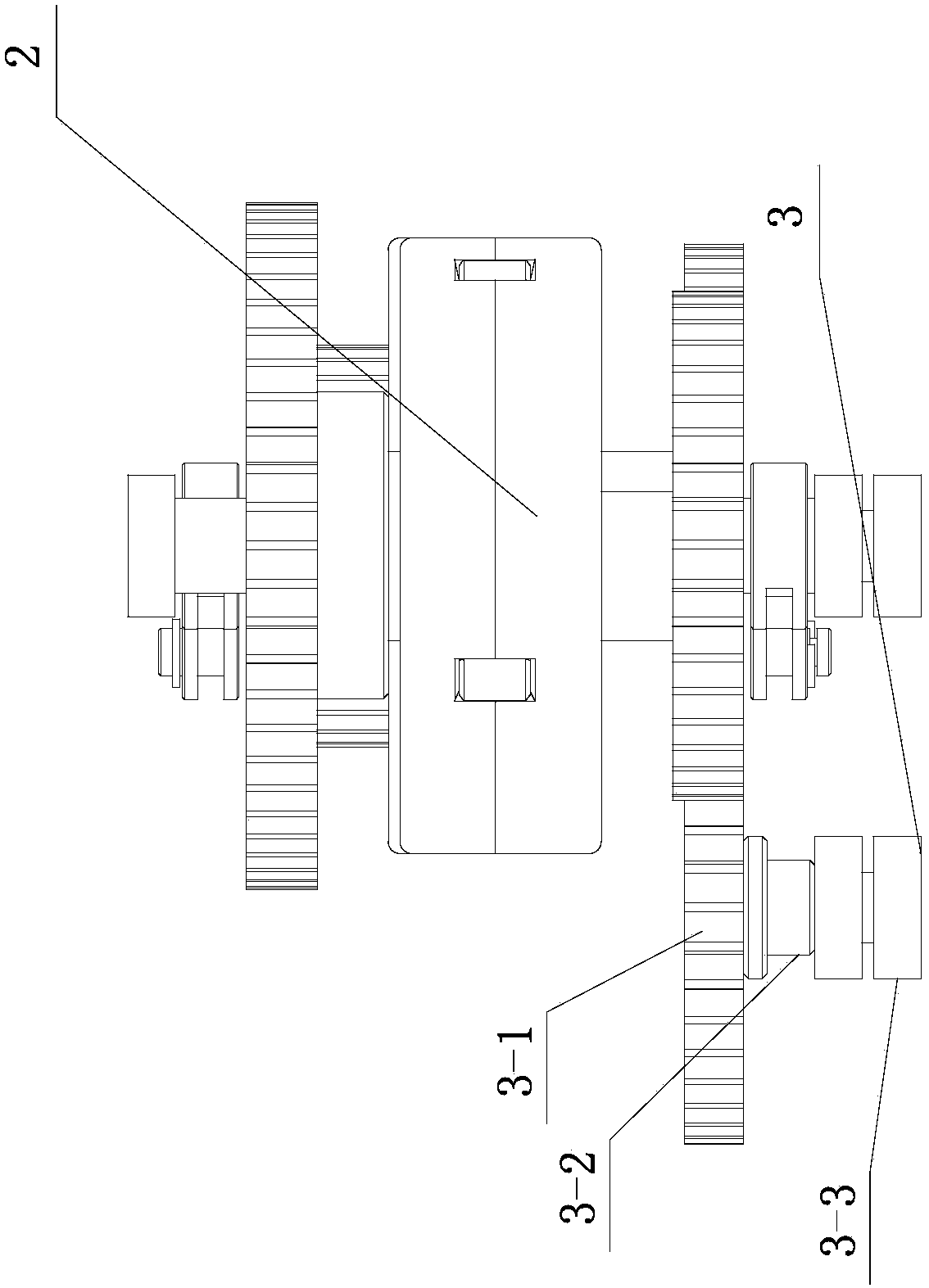

Novel narrow-tape positioning winding machine

ActiveCN110775733AReduced structure widthRealize glue deliveryFilament handlingArticle deliveryWinding machineControl theory

The invention discloses a novel narrow-tape positioning winding machine. The machine comprises a base mechanism, a machine head mechanism and a wire clamping mechanism, wherein the machine head mechanism is mounted on the right side of the top of the base mechanism, the wire clamping mechanism is mounted on the left side of the top of the base mechanism, the machine head mechanism is connected with the wire clamping mechanism, the base mechanism comprises a bottom plate, a wire feeding motor, a wire feeding motor frame, a wire feeding motor gear, a positioning base, a lifting assembly and a linear sliding block, wherein the linear sliding block is mounted on the right side of the top of the bottom plate, the wire feeding motor is mounted on the rear side of the wire feeding motor frame, and the wire feeding motor gear is mounted on an output shaft on the front side of the wire feeding motor. According to the machine, through mutual cooperation among the base mechanism, the machine headmechanism and the wire clamping mechanism, the novel narrow-tape positioning winding machine is realized, a wire clamping part is designed separated, the structure width is reduced, tape feeding andwinding of narrow tape are realized, and an air cylinder linearly drives a tape ring to pre-feed the tape, so that pre-feeding is precise and adjustable.

Owner:徐州领君自动化设备有限公司

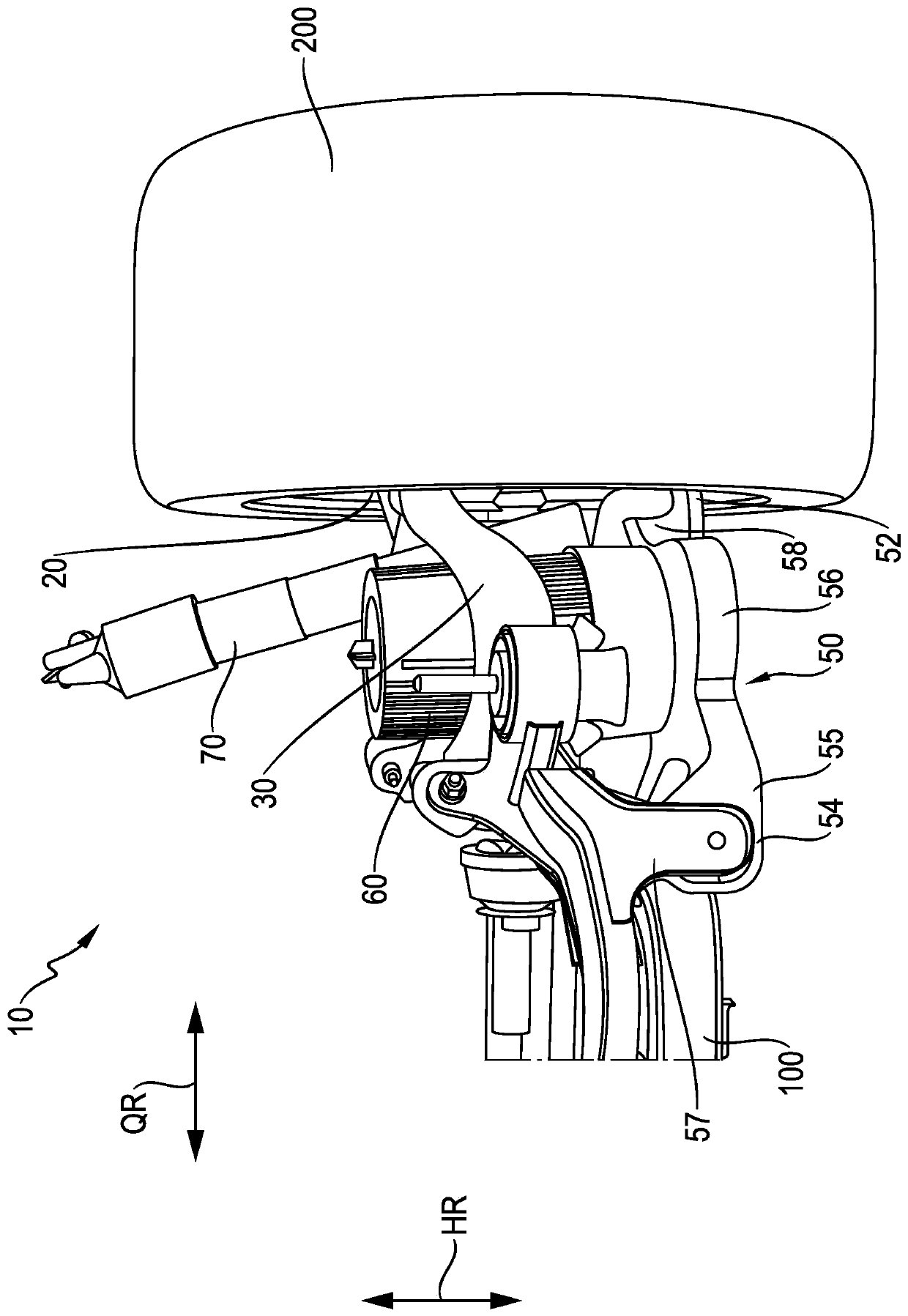

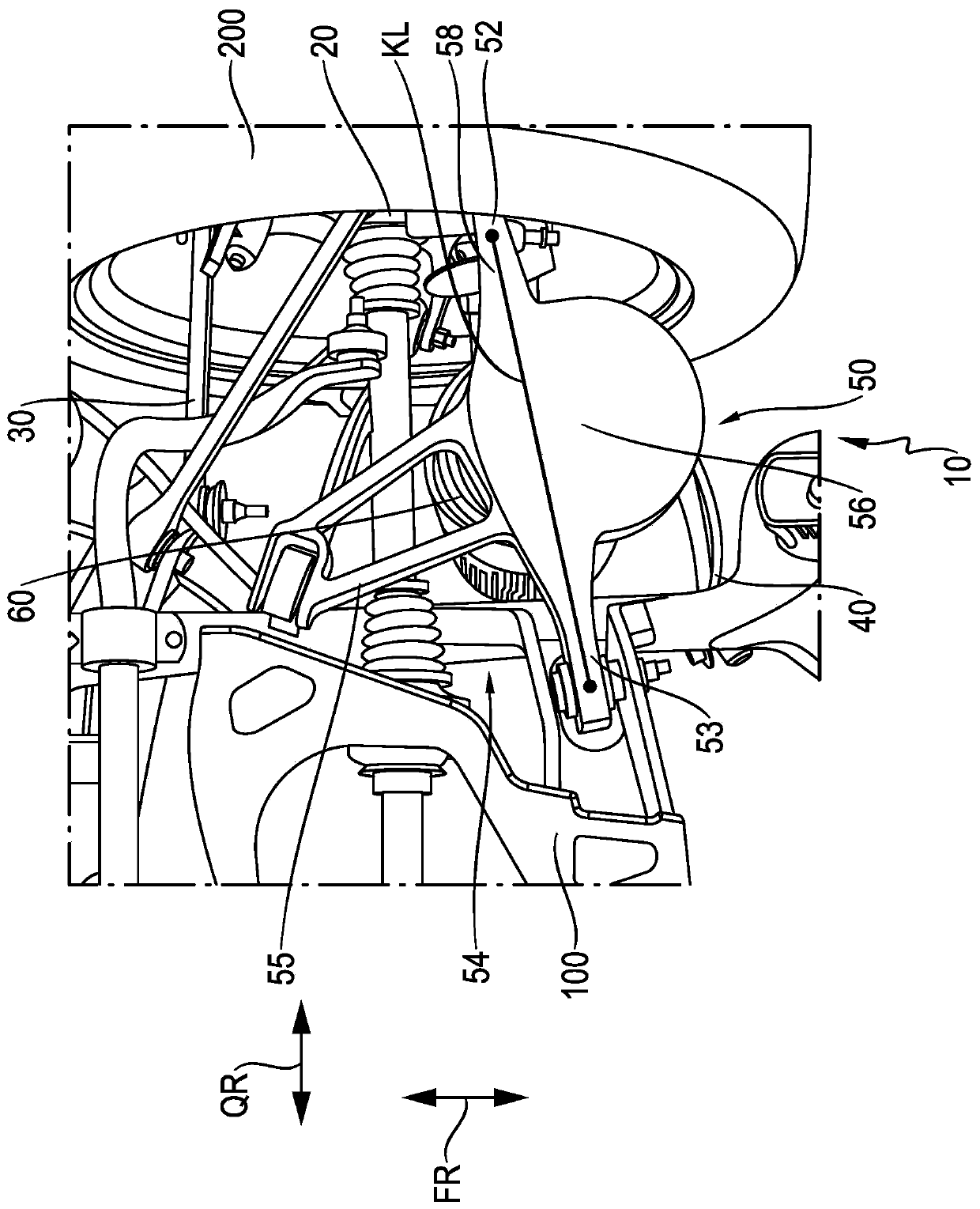

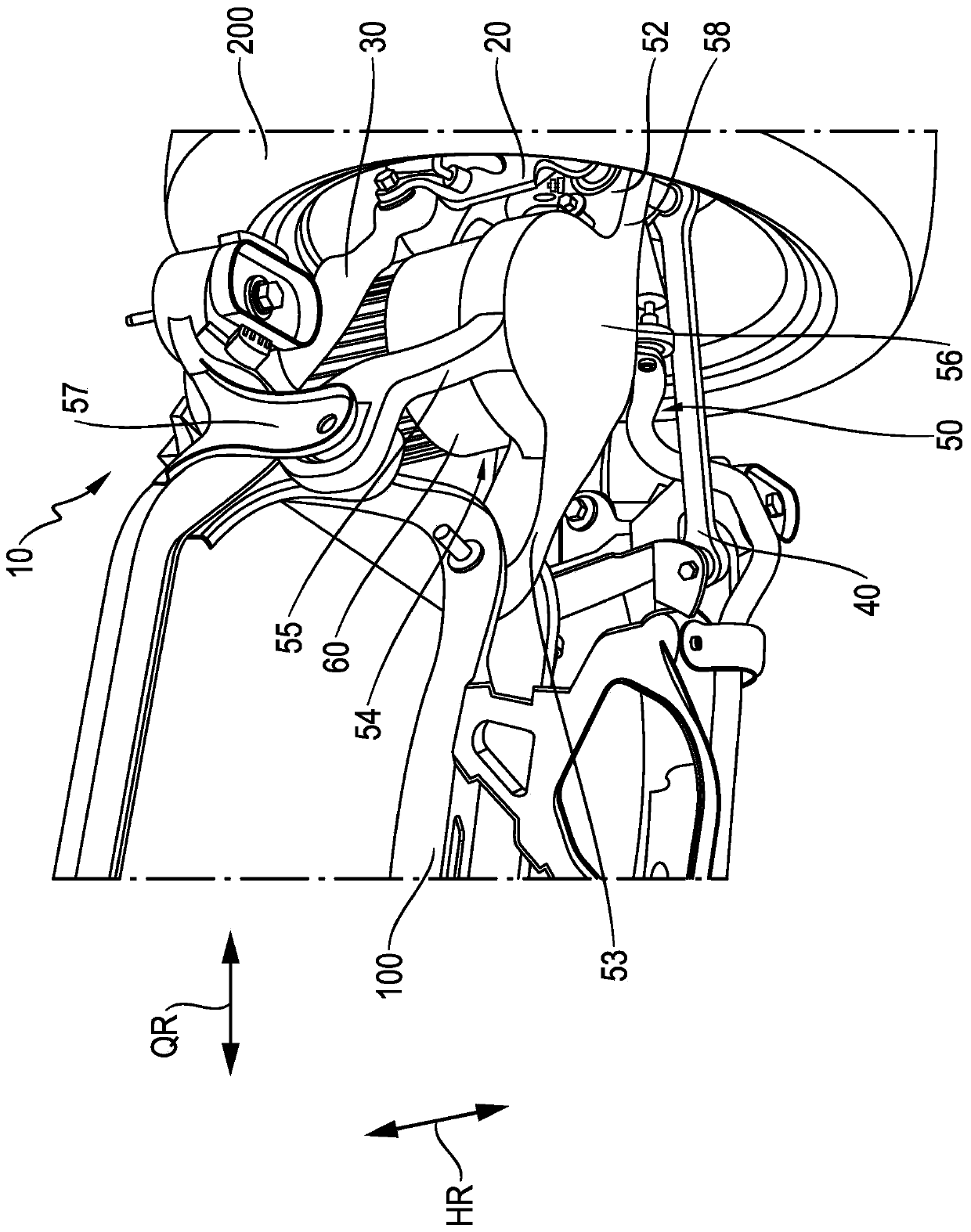

Axle device for connection of wheel to body of vehicle

ActiveCN110065353AReduced structure widthSmall space requirementResilient suspensionsPivoted suspension armsMechanical engineering

An axle device for the connection of a wheel to the body of a vehicle, having a wheel carrier for the fastening of the wheel, a first link and a second link for force-transmitting connection to the body, which links are both connected to the wheel carrier, furthermore having a supporting link with a carrier portion, which is connected to the wheel carrier, and with a body portion for force-transmitting connection to the body. The supporting link has a spring portion or supporting a spring unit and a damper portion for supporting a damper unit, which spring portion and damper portion are spacedapart from each other in the direction of travel of the body. The body portion has a torsion support portion with fastening freedom in the direction of travel and in the transverse direction of the body and with fastening stiffness in the vertical direction of the body.

Owner:DR ING H C F PORSCHE AG

Escalator or moving walkway

Owner:THYSSENKRUPP ELEVATOR AG (DE)

Roll changing device with wedge adjusting device

InactiveCN101534970AReduce adjustment forceNo shift biasMetal rolling stand detailsMetal rolling arrangementsEngineeringMechanical engineering

Owner:PRIMETALS TECH AUSTRIA GMBH

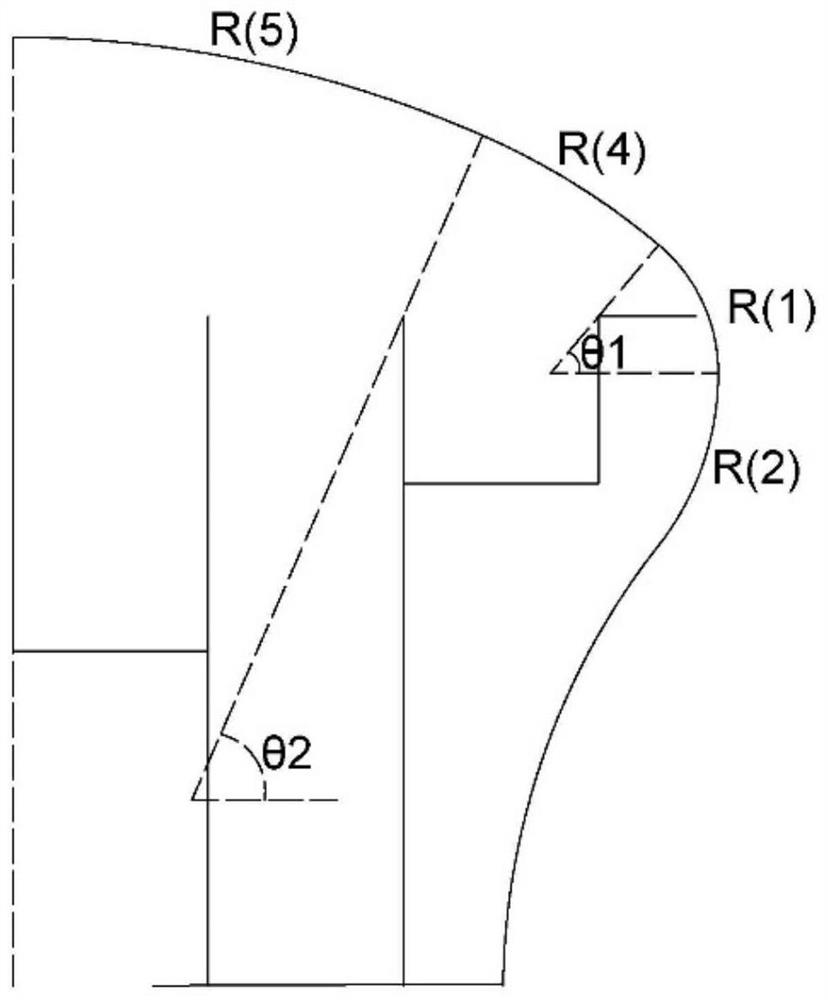

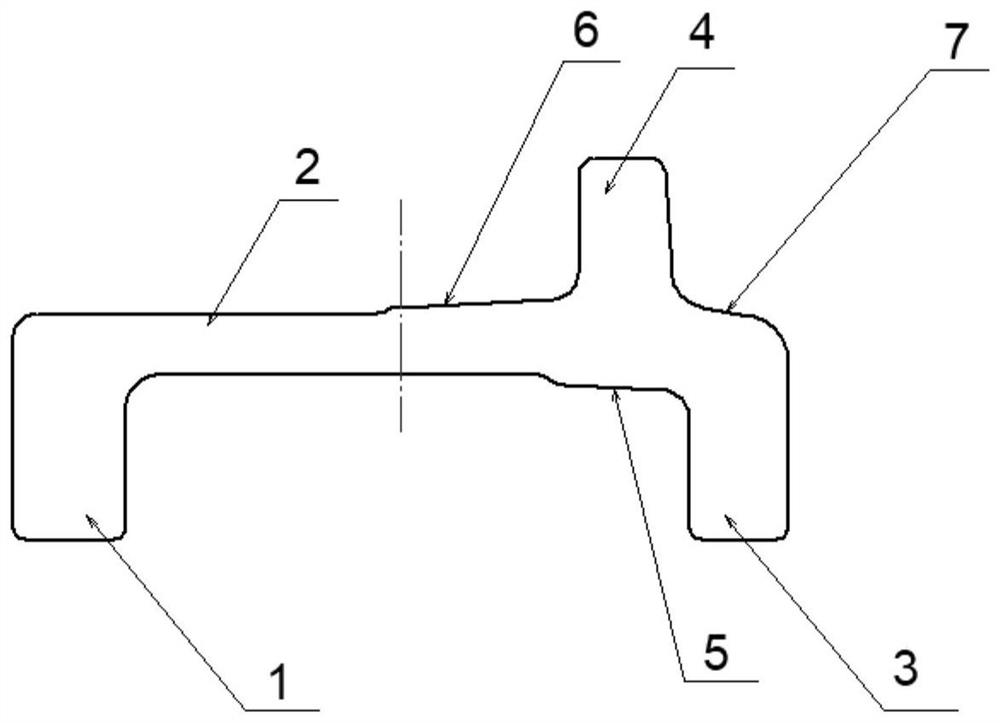

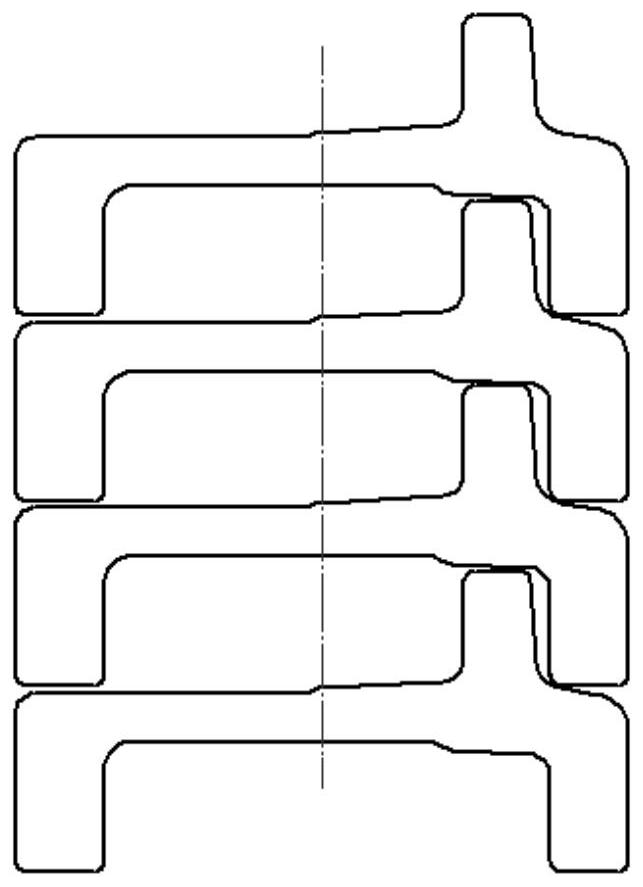

Hot-rolled J-shaped steel for forklift portal

PendingCN112794243AReduced structure widthExpand the operating horizonLifting devicesManufacturing engineeringMaterials processing

The invention relates to the technical field of machinery and material processing, and particularly relates to hot-rolled J-shaped steel for a forklift portal. The hot-rolled J-shaped steel for the forklift portal comprises a web, a first wing plate, a second wing plate and a third wing plate, and further comprises a first boss, a second boss and a wedge-shaped table, wherein the first wing plate and the second wing plate are positioned at the two ends of the lower surface of the web, and form a C-shaped structure with the web; the third wing plate is positioned at the position, far away from one end of the first wing plate, of the upper surface of the web; the first boss is positioned at the joint of the lower surface of the web and the left side surface of the second wing plate; the second boss is positioned at the joint of the upper surface of the web and the left side surface of the third wing plate; and the wedge-shaped table is positioned at the joint of the upper end surface of the second wing plate and the right side surface of the third wing plate. The hot-rolled J-shaped steel is wide in operation view, is high in rigidity, saves materials, and is low in hot-rolling difficulty and production cost.

Owner:SHANDONG IRON & STEEL CO LTD +1

A narrow tape positioning winding machine

ActiveCN110775733BRealize glue deliveryReduced structure widthFilament handlingArticle deliveryWinding machineElectric machine

The invention discloses a narrow adhesive tape positioning winding machine, which comprises a base mechanism, a machine head mechanism and a clamping mechanism. The left side, and the head mechanism is connected with the clamping mechanism; the base mechanism includes a bottom plate, a wire feeding motor, a wire feeding motor frame, a wire feeding motor gear, a positioning seat, a lifting component and a linear slider. The linear slide block is installed on the right side of the bottom plate top, the wire feeding motor is installed on the rear side of the wire feeding motor frame, and the wire feeding motor gear is installed on the output shaft on the front side of the wire feeding motor. Through the mutual cooperation of the base mechanism, the head mechanism and the clamping mechanism, the invention realizes a narrow tape positioning winding machine, the clamping part is designed separately, which reduces the structure width, and realizes the glue feeding and wrapping of the narrow tape , The cylinder linearly drives the tape ring to pre-feed the tape to achieve accurate and adjustable pre-feeding.

Owner:徐州领君自动化设备有限公司

Double-input and multiple-output synergy device based on differential planetary gear

ActiveCN105840763BSmall size of use spaceTransmission ratio is smallTransmission elementsDifferential gearingsEngineeringArtificial hand

The invention discloses a double-input and multi-output collaborative device based on differential planetary gears and relates to a collaborative device. The double-input and multi-output collaborative device based on the differential planetary gears aims at solving the problems that an existing collaborative artificial hand driving mechanism is huge and cannot be integrated on a palm, only movement collaboration of four finger metacarpophalangeal joints can be achieved, and movement between all joints of all fingers needs to be independently subjected to collaborative or coupling driving. The double-input and multi-output collaborative device based on the differential planetary gears comprises a first differential planetary gear mechanism, a second differential planetary gear mechanism and a differential planetary gear transmission gear assembly; a first input shaft gear of the first differential planetary gear mechanism and a second gear holder gear of the second differential planetary gear mechanism are both in tooth engagement with the differential planetary gear transmission gear assembly. The double-input and multi-output collaborative device based on the differential planetary gears is used for the mechanical field.

Owner:HARBIN INST OF TECH

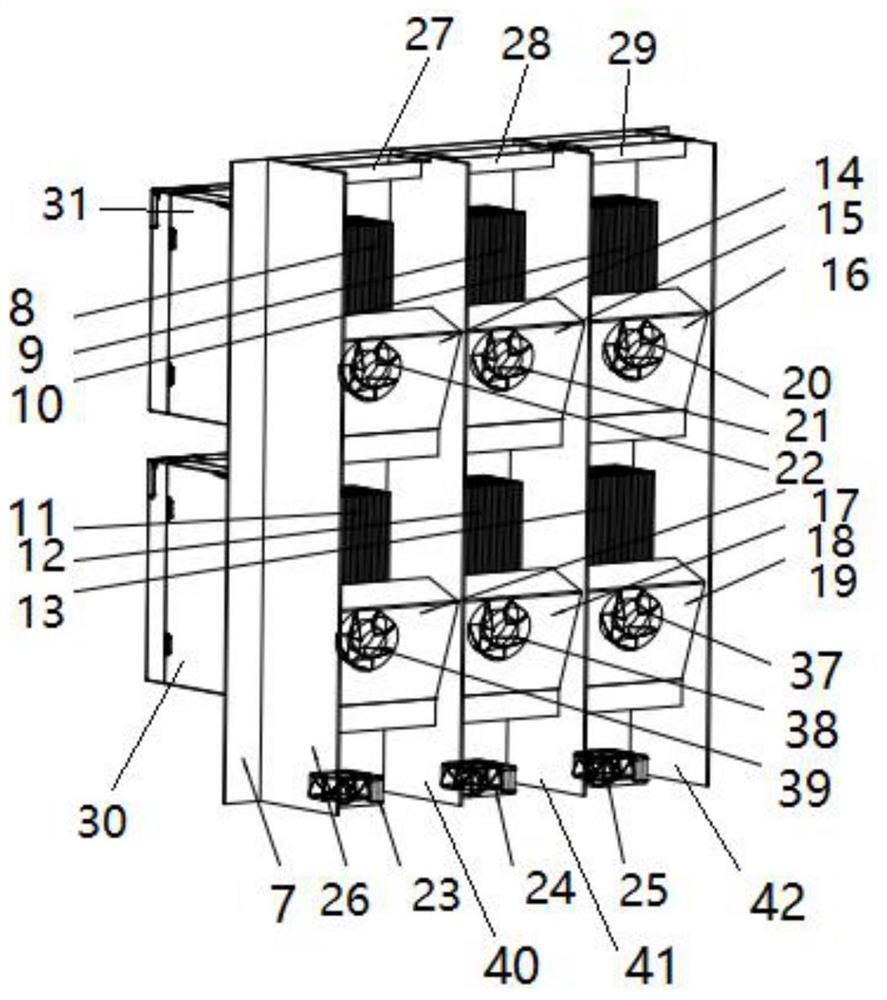

A heat dissipation structure of a servo drive and a control cabinet including the same

ActiveCN110545645BSolve the problem that accumulation cannot dissipate heat quicklyImprove cooling efficiencyCooling/ventilation/heating modificationsFluid phaseMechanical engineering

The invention relates to a heat dissipation structure of a servo drive and a control cabinet including the same. A heat dissipation air duct and a heat pipe are arranged in the cabinet of the servo drive. The evaporation section of the heat pipe contacts each heating component of the servo drive. There is a working medium inside the heat pipe, and the working medium can absorb the heat transmitted to the evaporation section and undergo a liquid-gas phase change, then flow to the condensation section and undergo a gas-liquid phase change in the condensation section, and cooperate with the air duct to discharge the heat, The setting of the heat pipe and its internal working medium can quickly take away the heat of the servo drive, and solve the heat accumulation problem of the traditional servo drive heat dissipation structure. In this way, there is no need to set fans and cooling holes inside the servo drive, which greatly reduces the size, volume and weight are effectively reduced, and is suitable for control cabinets of various power types.

Owner:GREE ELECTRIC APPLIANCES INC

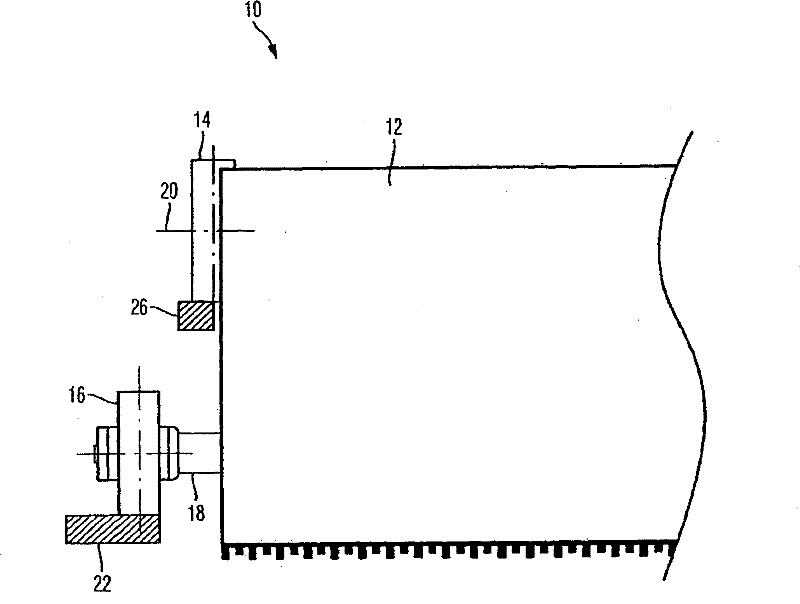

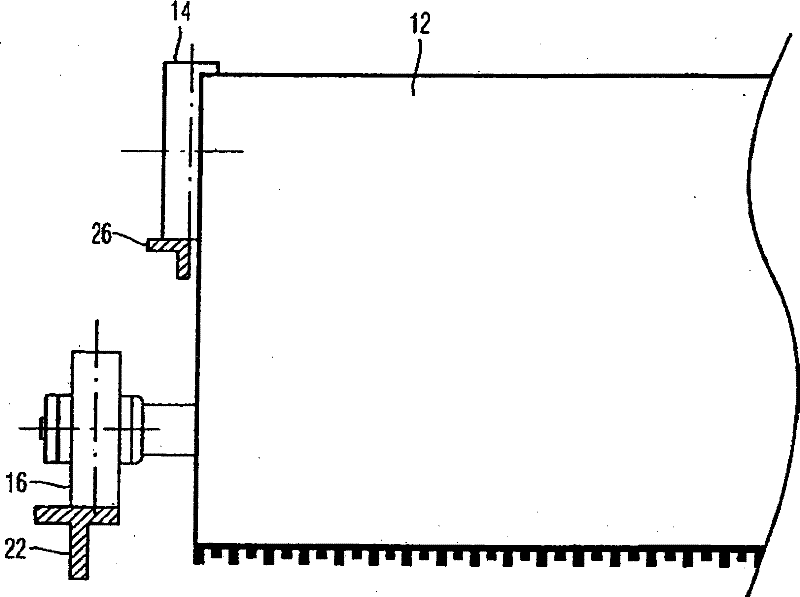

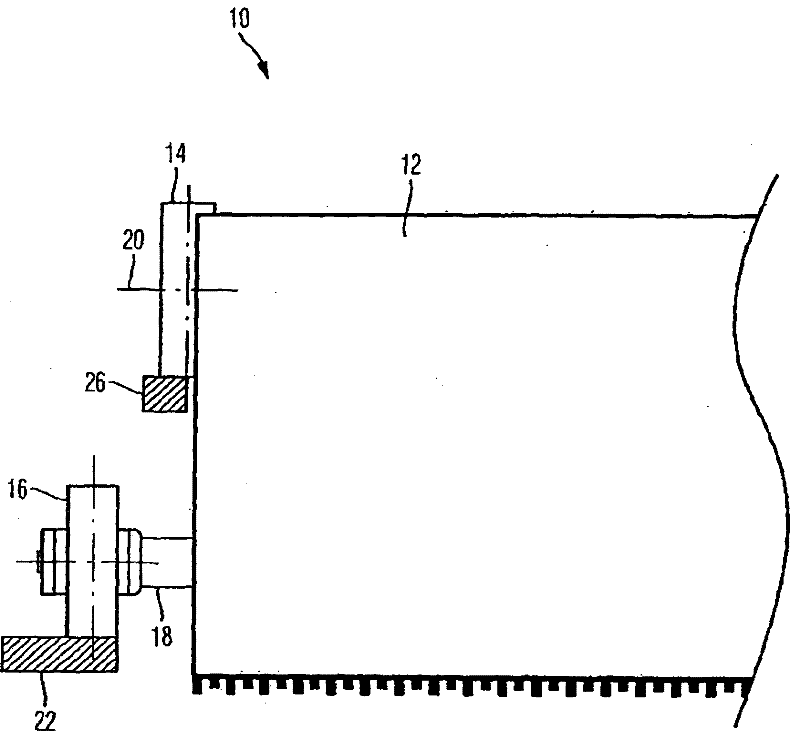

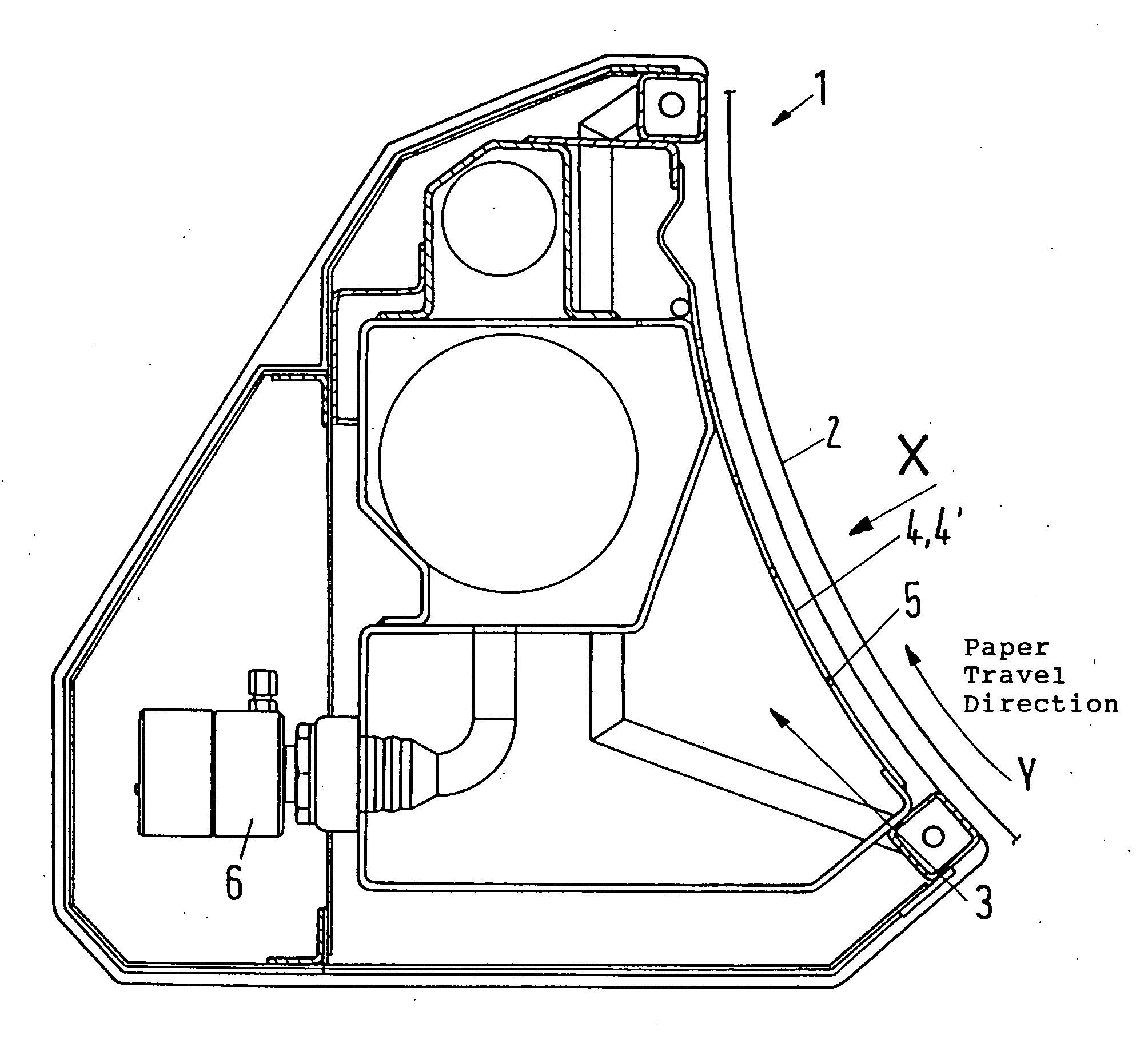

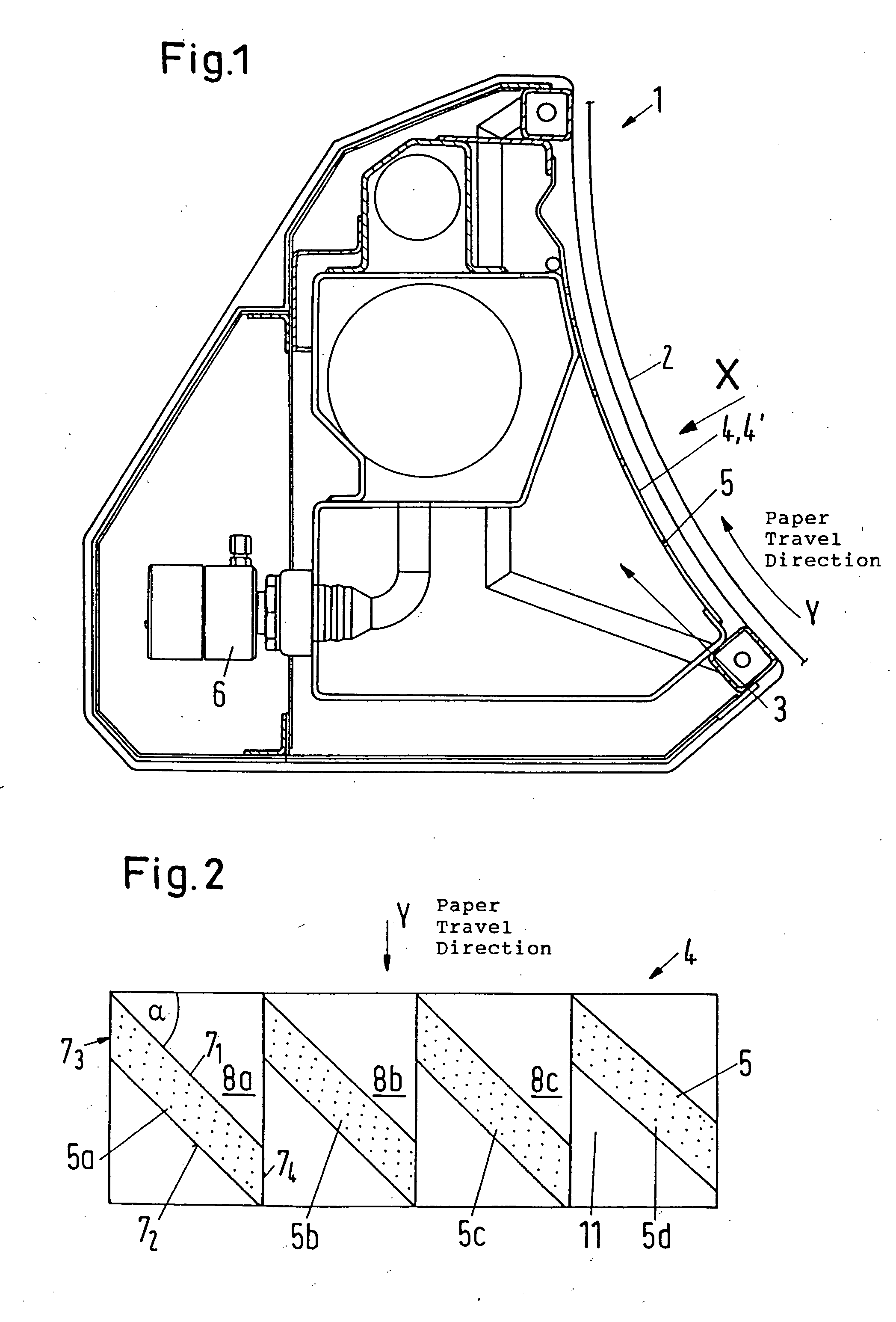

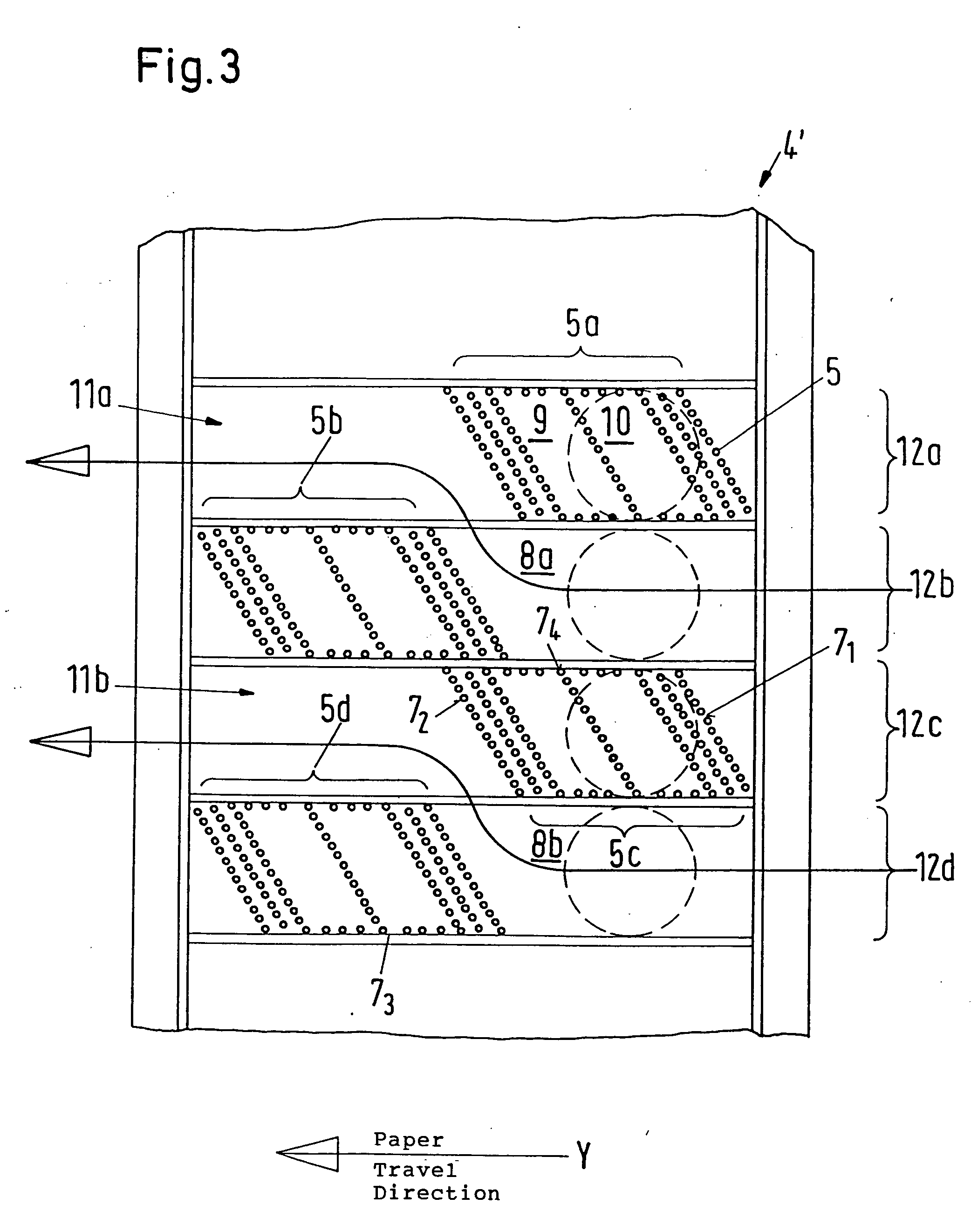

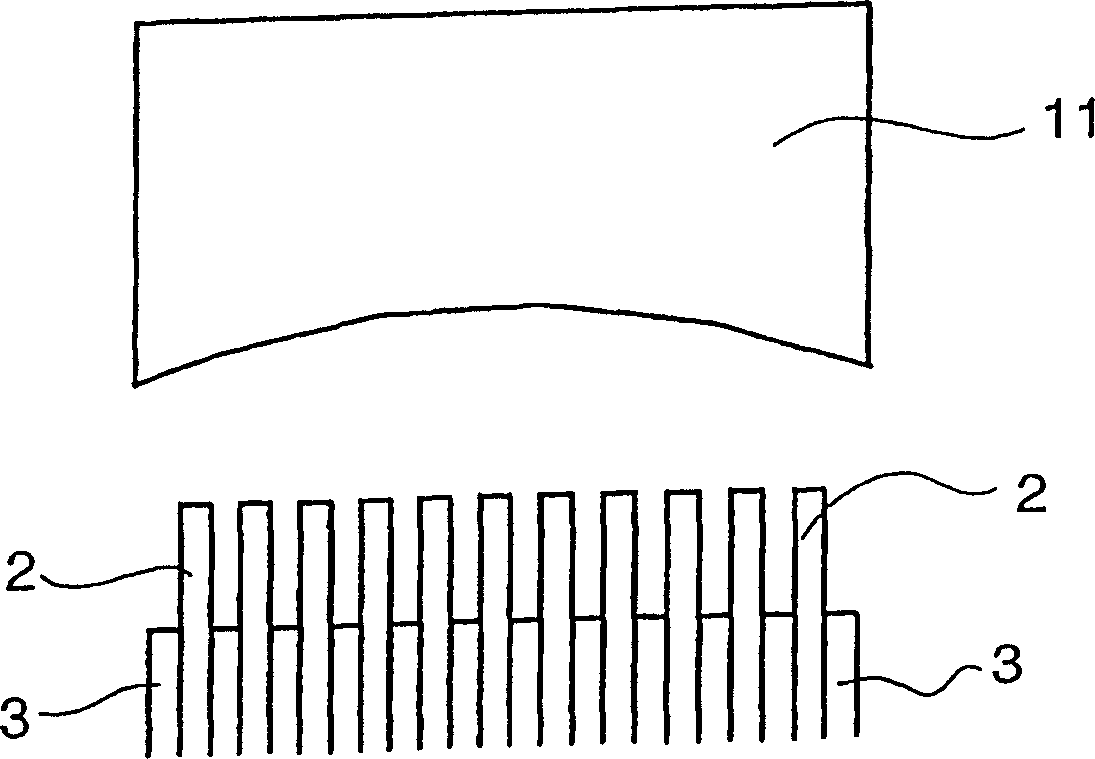

Steam blower box

InactiveUS20050108894A1Reduced structure widthAvoid turbulenceDrying machines with progressive movementsDrying machines with non-progressive movementsEngineeringMechanical engineering

Owner:V I B SYST

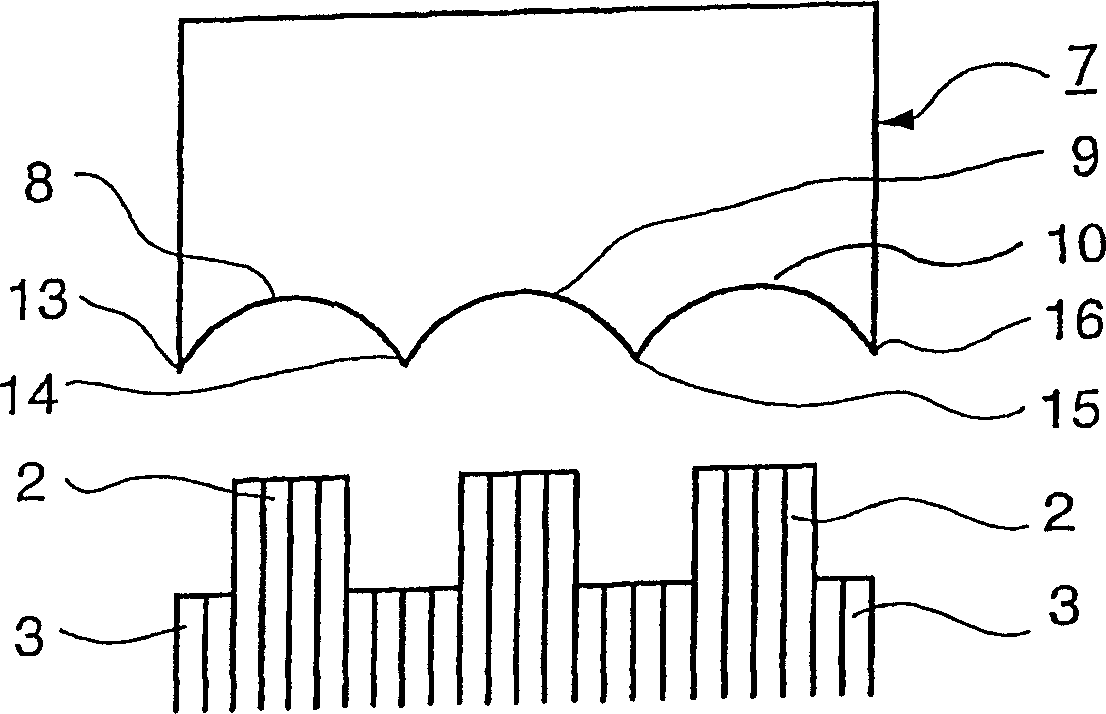

Switching arrangement for low-voltage circuit breakers

InactiveCN1230845CEvenly distributedReduced structure widthHigh-tension/heavy-dress switchesAir-break switchesLow voltage circuitsElectrical and Electronics engineering

A switching arrangement for low-voltage circuit breakers with a high nominal current, comprising moveable switching contacts (2,3) arranged essentially on a moveable contact carrier (1), fixed switching contacts and a device for cooling, de-ionizing and extinguishing an electric switching arc (7, 11). The fixed contact is provided with a pre-contact function over the entire contact width thereof. Moveable contact levers (2,3) are arranged according to a set pattern in a distributed manner over the entire width of the contact carriers and are provided with or without a pre-contact (5). A contact lever (2) with a pre-contact (5) and a contact lever (3) without a pre-contact can be provided successively. Similarly, two or more contact levers (2) with a pre-contact (5) and two or more contact levers (3) without a pre-contact can be successively and alternatingly provided in packet-form.

Owner:SIEMENS AG

Laminated rail connection station for urban rail transit

PendingCN113561997ASmall scaleAvoid problems such as difficulty in evacuation and large amount of demolitionRailway componentsRailway stationTelecommunicationsMechanical engineering

The invention relates to an urban rail transit laminated rail connection station which comprises a main left line, a main right line, an access left line, an access right line, a left line platform and a right line platform, the main left line and the access left line are arranged on the two sides of the left line platform respectively, and the main left line is connected with the access left line through a left line single crossover; the main right line and the access right line are arranged on the two sides of the right line platform respectively, and the main right line is connected with the access right line through the right line single crossover; the main left line and the main right line are arranged in a station range in an up-and-down parallel and overlapped mode, the access left line and the access right line are arranged in a station range in an up-and-down parallel and overlapped mode, and the access left line and the access right line are respectively connected with a vehicle base. The laminated rail connection station is small in relative width and small in occupied area, compared with an existing rail connection station, the laminated rail connection station has the advantages that the engineering scale is reduced, the engineering cost is saved, and the problems that surrounding traffic is difficult to relieve, and the demolition amount is large are solved.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

A tapered array broadband absorber and its preparation method

Owner:SHENZHEN INLIGHT TECH CO LTD

Hot-rolled C-shaped steel for forklift gantry

PendingCN112777528AReduced structure widthReduce stiffnessLifting devicesStructural engineeringMaterials processing

The invention relates to the technical field of machinery and material machining, in particular to hot-rolled C-shaped steel for a forklift gantry. The hot-rolled C-shaped steel for the forklift gantry comprises a web plate, a first wing plate and a second wing plate and further comprises a boss, the first wing plate and the second wing plate are located at the two ends of the lower surface of the web and form a C-shaped structure with the web, and the boss is located at the joint of the lower surface of the web plate and the left side surface of the second wing plate. The steel has the advantages of wide operation field, light weight, good rigidity, low hot rolling difficulty and low production cost.

Owner:SHANDONG IRON & STEEL CO LTD +1

Thread guiding device for a thread changing device

Owner:SIPRA PATENTENTWICKLUNGS & BET GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com