Switching arrangement for low-voltage circuit breakers

A technology of low-voltage circuit breaker and switchgear, which is applied in the direction of high-voltage air circuit breaker, high-voltage/high-current switch, electric switch, etc., and can solve the problems of large bending stress of supporting pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

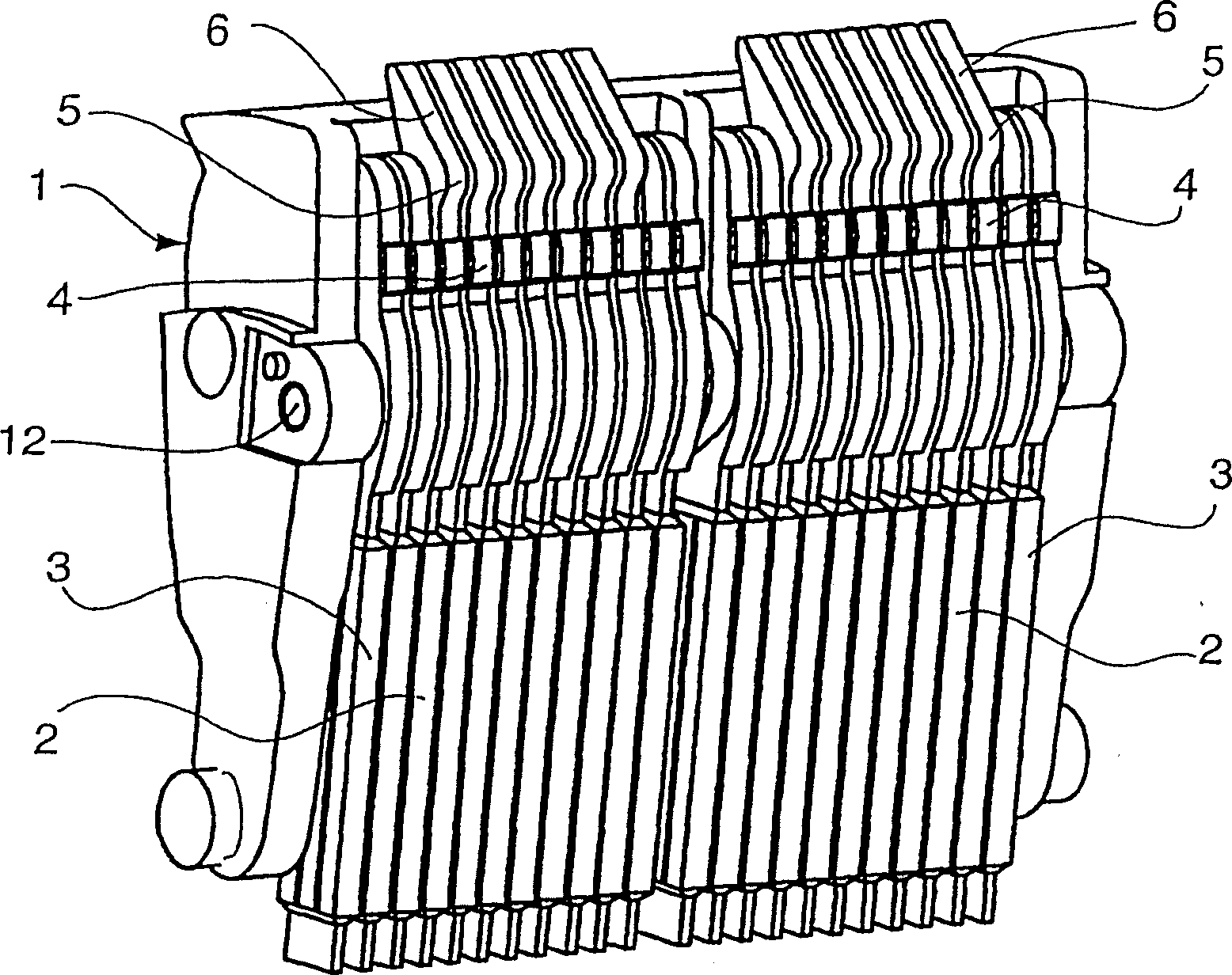

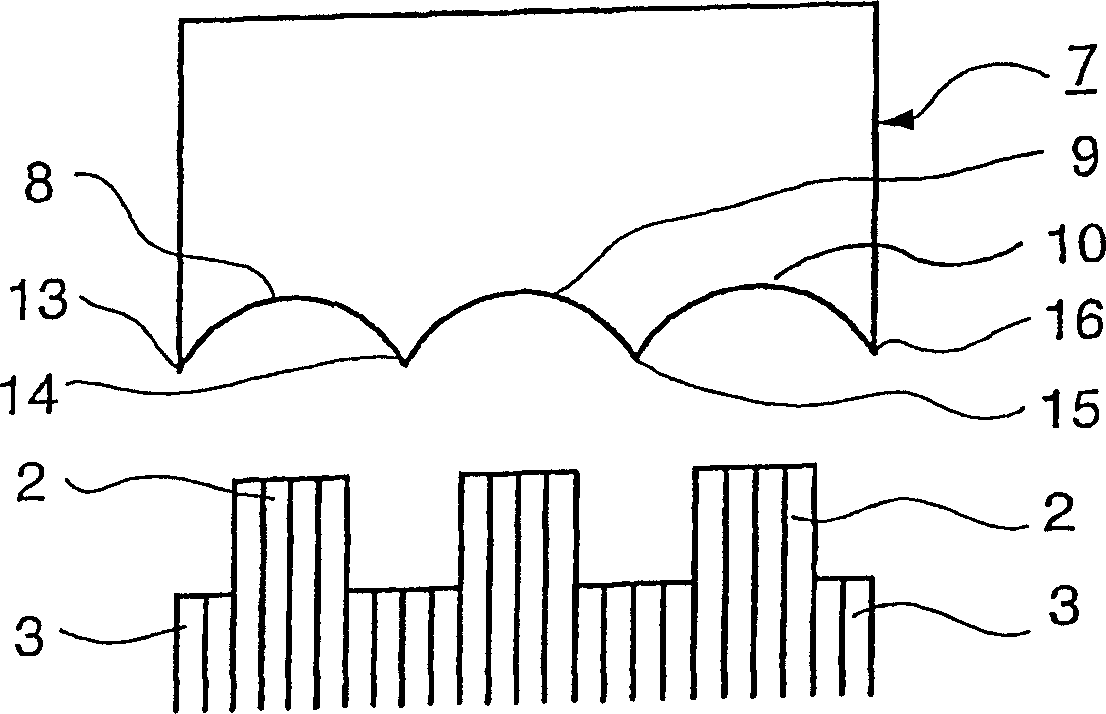

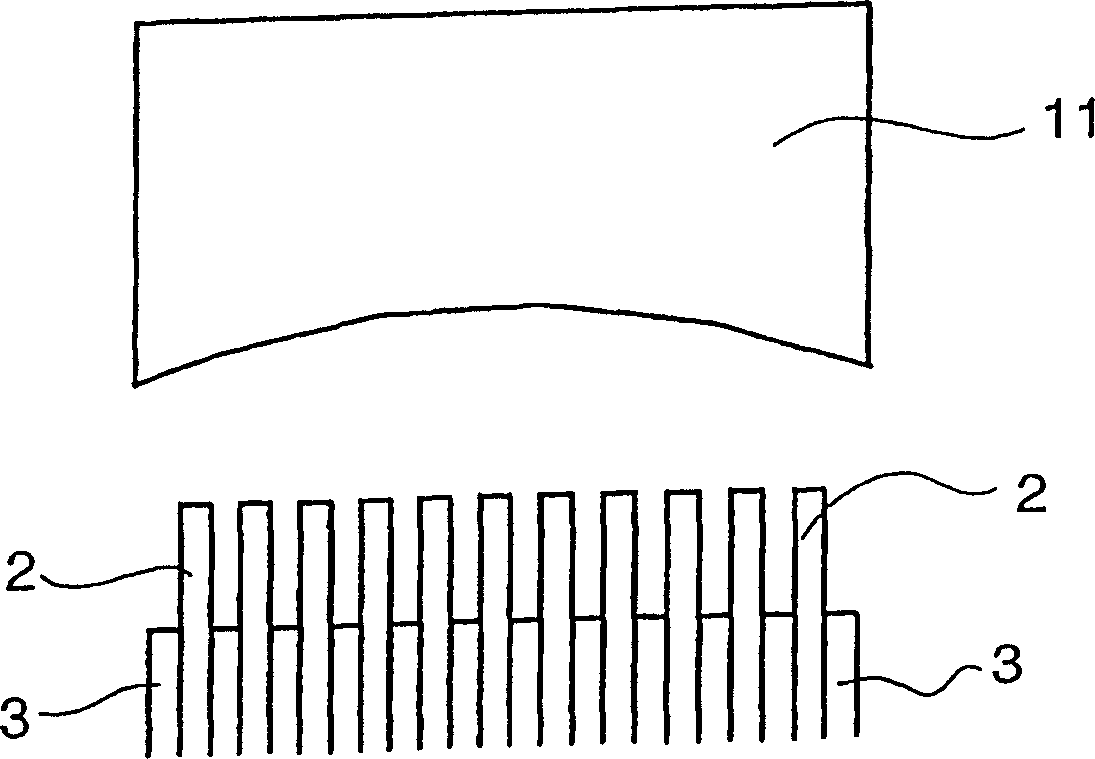

[0016] figure 1 A movable contact carrier 1 with multiple contacts for a low-voltage circuit breaker with a high rated current is shown, which has a plurality of movable contact rods 2 , 3 which are arranged parallel to one another at a small relative distance. In this case, a part of the contact rod 2 has, in addition to the main contact 4 , a preliminary contact 5 which is arranged between the end of the contact rod 2 designed as an arc 6 and the main contact 4 . These movable precontact contacts 5 , like the movable main contacts 4 , cooperate in a known manner with non-illustrated fixed precontact contacts and main contacts. According to the invention, the contact rods 3 which are not provided with pre-contact contacts 5 are arranged in a defined sequence which differs from the conventional arrangement which is limited to the outer area, here they are arranged in sections or in groups. The arrangement sequence is not limited to the one shown in the present embodiment, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com