Hot-rolled J-shaped steel for forklift portal

A technology for a forklift gantry and section steel, which is applied in the direction of a hoisting device and the like, can solve the problems of decreased operation convenience and safety, decreased rigidity and safety of the gantry, and increased manufacturing cost, so as to make up for the decreased rigidity of the gantry and reduce heat. Rolling difficulty, production cost, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

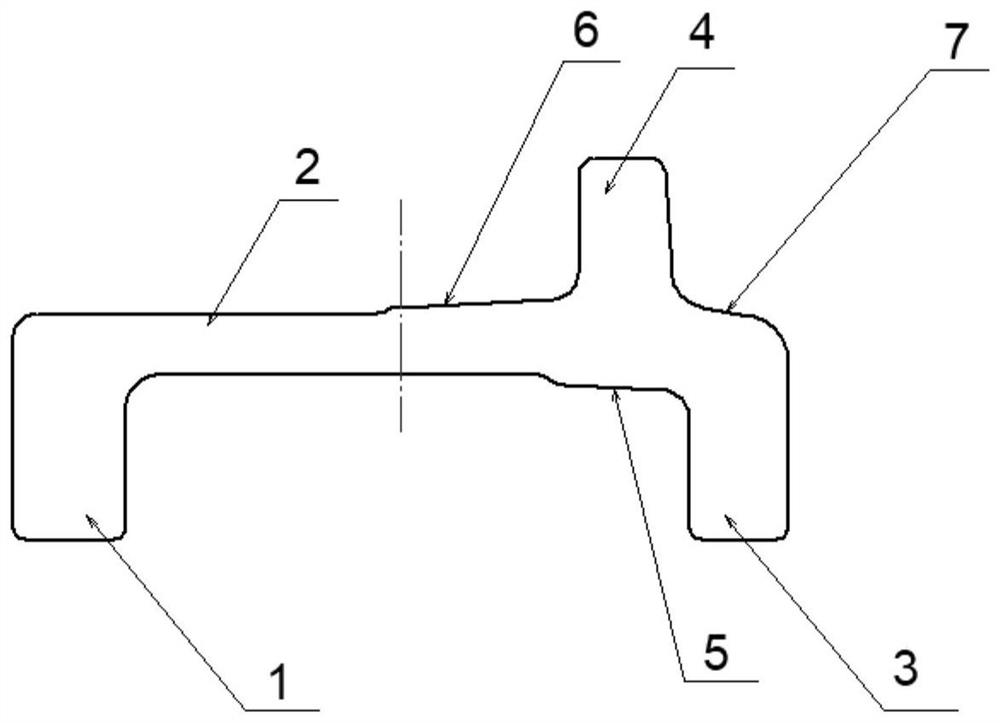

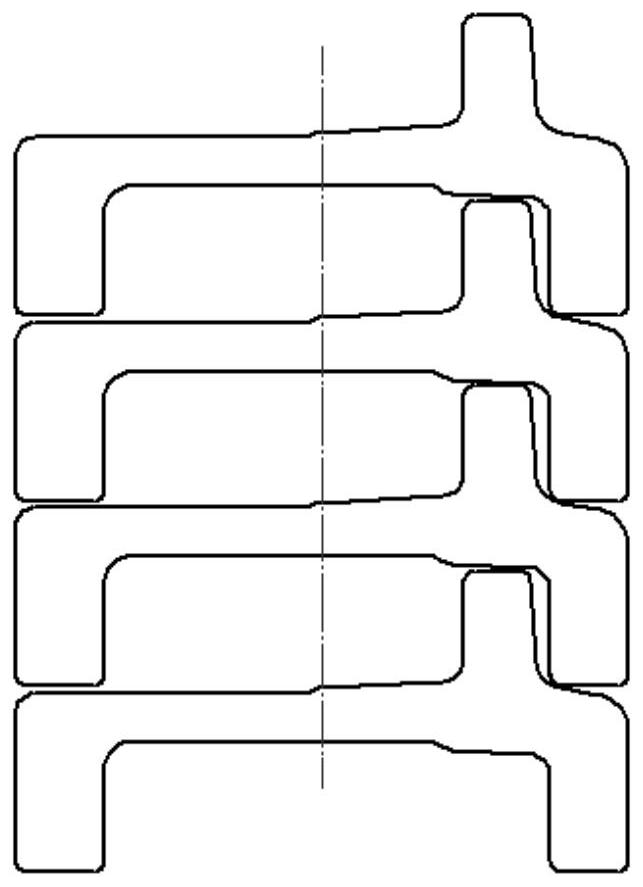

[0022] Such as figure 1 As shown, the present invention provides a hot-rolled J-shaped steel for a forklift mast. The hot-rolled J-shaped steel for a forklift mast includes: a web 1, a first wing 2, a second wing 3 and a third wing 4 , the forklift inner mast also includes: a first boss 5, a second boss 6 and a wedge-shaped platform 7; the first wing plate 2 and the second wing plate 3 are located at the two ends of the lower surface of the web 1, and then connected The plate 1 forms a C-shaped structure; the third wing plate 4 is located on the upper surface of the web 1 away from the end of the first wing plate 2, the third wing plate 4 gradually becomes thicker from the end to the root, and the right side of the third wing plate 4 The side surface corresponds approximately up and down to the left side of the second wing plate 3; the first boss 5 is located at the joint between the lower surface of the web 1 and the left side of the second wing plate 3; the second boss 6 is ...

Embodiment 2

[0027] The present invention also provides a hot-rolled J-shaped steel for a forklift mast. The hot-rolled J-shaped steel for a forklift mast includes: a web 1, a first wing 2, a second wing 3, and a third wing 4. The inner mast of the forklift also includes: the first boss 5, the second boss 6 and the wedge-shaped platform 7; Form a C-shaped structure; the third wing plate 4 is located on the upper surface of the web 1 away from the end of the first wing plate 2, the third wing plate 4 gradually becomes thicker from the end to the root, and the right side of the third wing plate 4 Corresponds approximately up and down to the left side of the second wing plate 3; the first boss 5 is located at the connection between the lower surface of the web 1 and the left side of the second wing plate 3; the second boss 6 is located at the upper surface of the web 1 and At the junction of the left side of the third wing 4, the left side of the second boss 6 is close to the vertical bisecto...

Embodiment 3

[0032] The present invention also provides a hot-rolled J-shaped steel for a forklift mast. The hot-rolled J-shaped steel for a forklift mast includes: a web 1, a first wing 2, a second wing 3, and a third wing 4. The inner mast of the forklift also includes: the first boss 5, the second boss 6 and the wedge-shaped platform 7; Form a C-shaped structure; the third wing plate 4 is located on the upper surface of the web 1 away from the end of the first wing plate 2, the third wing plate 4 gradually becomes thicker from the end to the root, and the right side of the third wing plate 4 Corresponding up and down to the left side of the second wing plate 3; the first boss 5 is located at the connection between the lower surface of the web 1 and the left side of the second wing plate 3; the second boss 6 is located at the upper surface of the web 1 and the second At the junction of the left side of the three-wing plate 4, the left side of the second boss 6 is close to the vertical bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com