Hot-rolled C-shaped steel for forklift gantry

A forklift mast and C-shaped steel technology, applied in the direction of lifting devices, etc., can solve the problems of increased manufacturing costs, reduced operational convenience and safety, and increased work blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

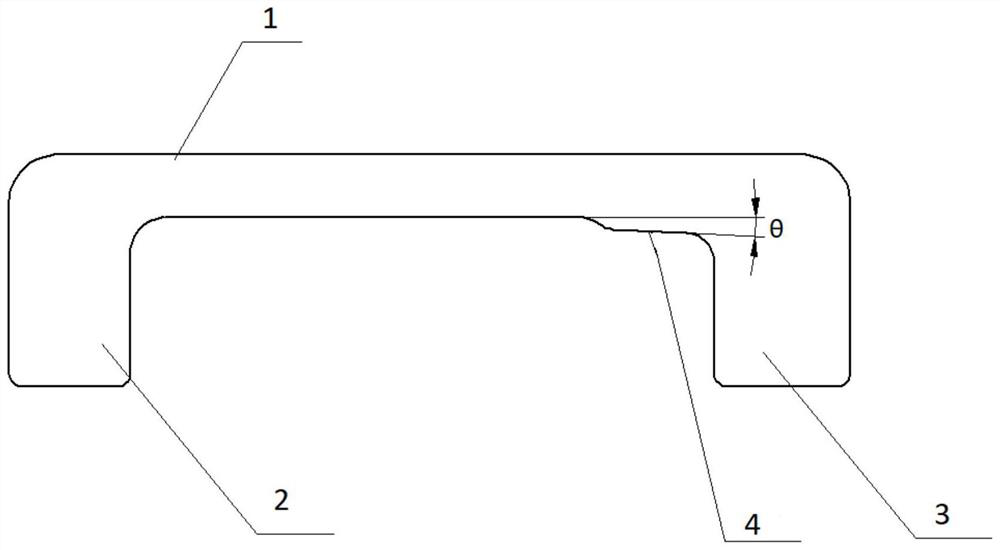

[0018] The invention provides a hot-rolled C-shaped steel for a forklift mast. The hot-rolled C-shaped steel for a forklift mast includes a web 1, a first wing 2 and a second wing 3. The forklift inner mast also includes : boss 4; the first wing 2 and the second wing 3 are located at both ends of the lower surface of the web 1, and then form a C-shaped structure with the web 1; the boss 4 is located at the lower surface of the web 1 and the second wing 3 Connections on the left side.

[0019] The web 1 has a thickness of 10mm and a width of 170mm; the first wing plate 2 has a thickness of 23mm and a width of 33mm; the second wing plate 3 has a thickness of 25mm and a width of 33mm; the boss 4 has a width of 20mm and a height of 3mm.

[0020] The joints of the above-mentioned parts are arc transitions, and the radius of the arc is 3mm.

[0021] The angle θ between the boss 4 and the lower surface of the web 1 is 2°.

Embodiment 2

[0023] The present invention also provides a hot-rolled C-shaped steel for a forklift mast. The hot-rolled C-shaped steel for a forklift mast includes: a web 1, a first wing 2 and a second wing 3, and the inner mast of a forklift is also Including: the boss 4; the first wing 2 and the second wing 3 are located at both ends of the lower surface of the web 1, and then form a C-shaped structure with the web 1; the boss 4 is located at the lower surface of the web 1 and the second wing The junction on the left side of board 3.

[0024] The web 1 has a thickness of 11 mm and a width of 173 mm; the first wing plate 2 has a thickness of 25 mm and a width of 35 mm; the second wing plate 3 has a thickness of 27 mm and a width of 35 mm; the boss 4 has a width of 25 mm and a height of 4 mm.

[0025] The joints of the above-mentioned parts are arc transitions, and the radius of the arc is 8mm.

[0026] The angle θ between the boss 4 and the lower surface of the web 1 is 4°.

Embodiment 3

[0028] The present invention also provides a hot-rolled C-shaped steel for a forklift mast. The hot-rolled C-shaped steel for a forklift mast includes: a web 1, a first wing 2 and a second wing 3, and the inner mast of a forklift is also Including: the boss (4); the first wing plate 2 and the second wing plate 3 are located at both ends of the lower surface of the web 1, and then form a C-shaped structure with the web 1; the boss 4 is located at the lower surface of the web 1 and the second The junction of two wing plates 3 left sides.

[0029] The web 1 has a thickness of 13mm and a width of 176mm; the first wing 2 has a thickness of 27mm and a width of 37mm; the second wing 3 has a thickness of 30mm and a width of 37mm; the boss 4 has a width of 30mm and a height of 5mm.

[0030] The joints of the above-mentioned parts are arc transitions, and the radius of the arc is 12mm.

[0031] The angle θ between the boss 4 and the lower surface of the web 1 is 5°.

[0032] The prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com