Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104results about How to "Reduce view" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

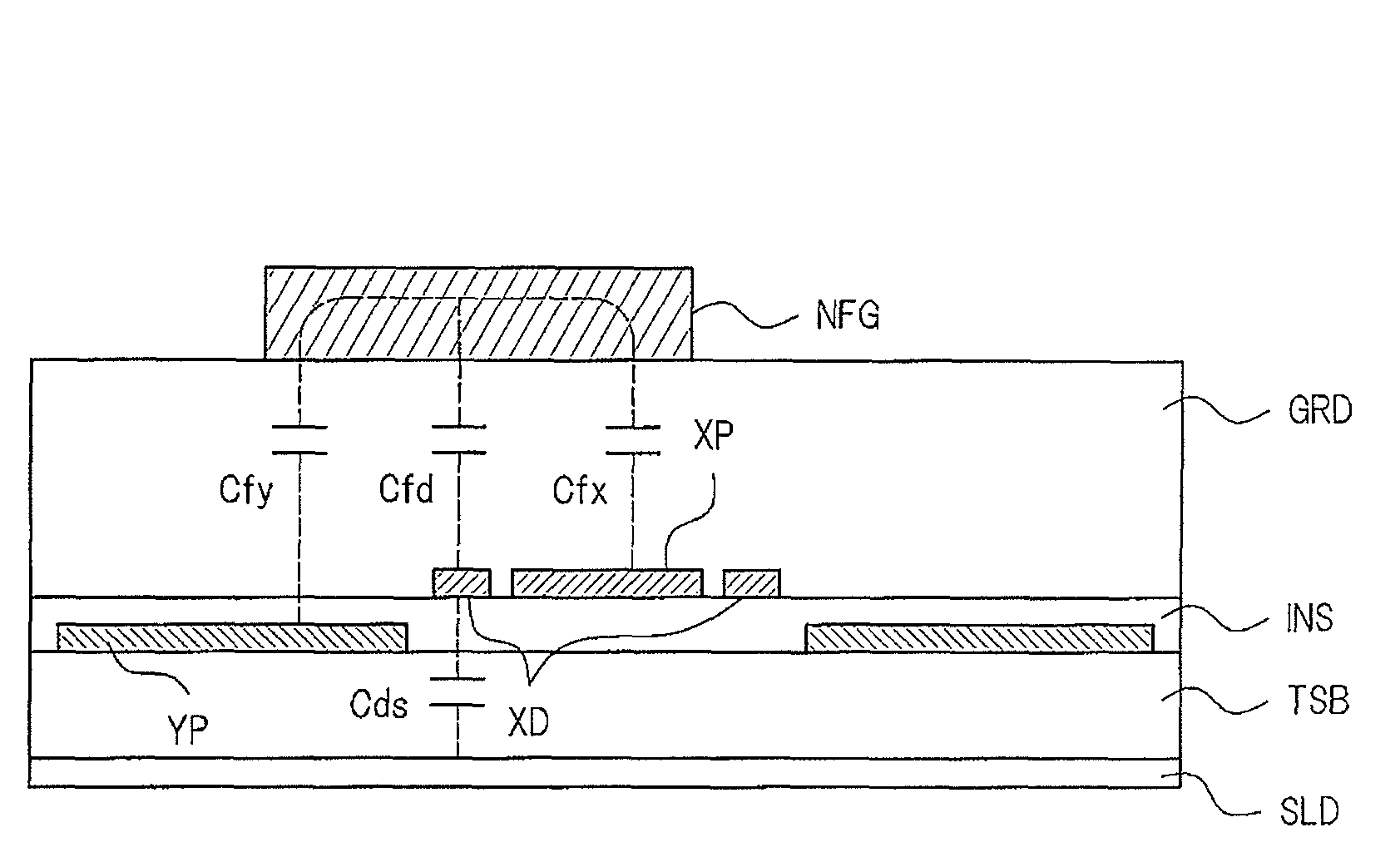

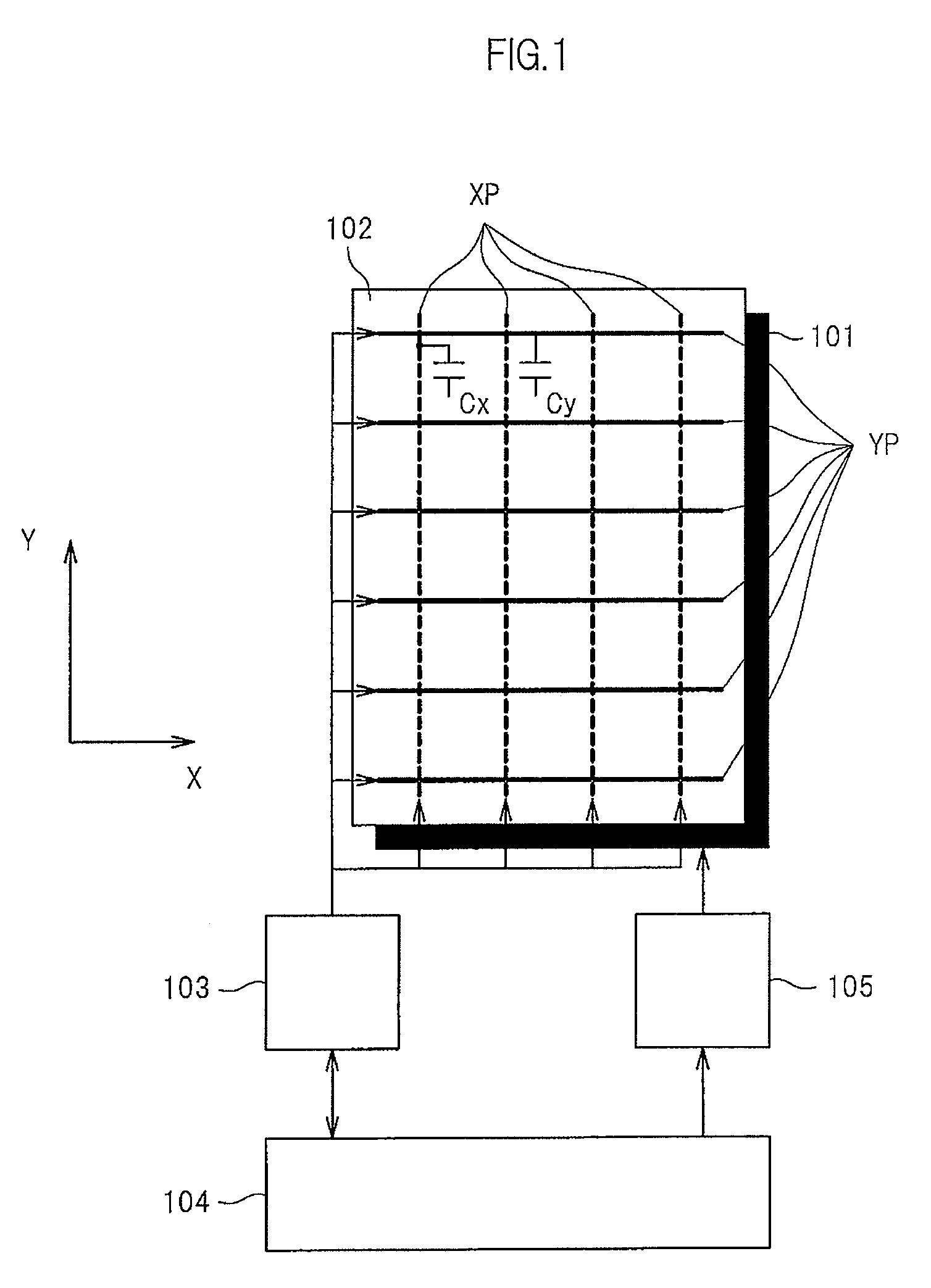

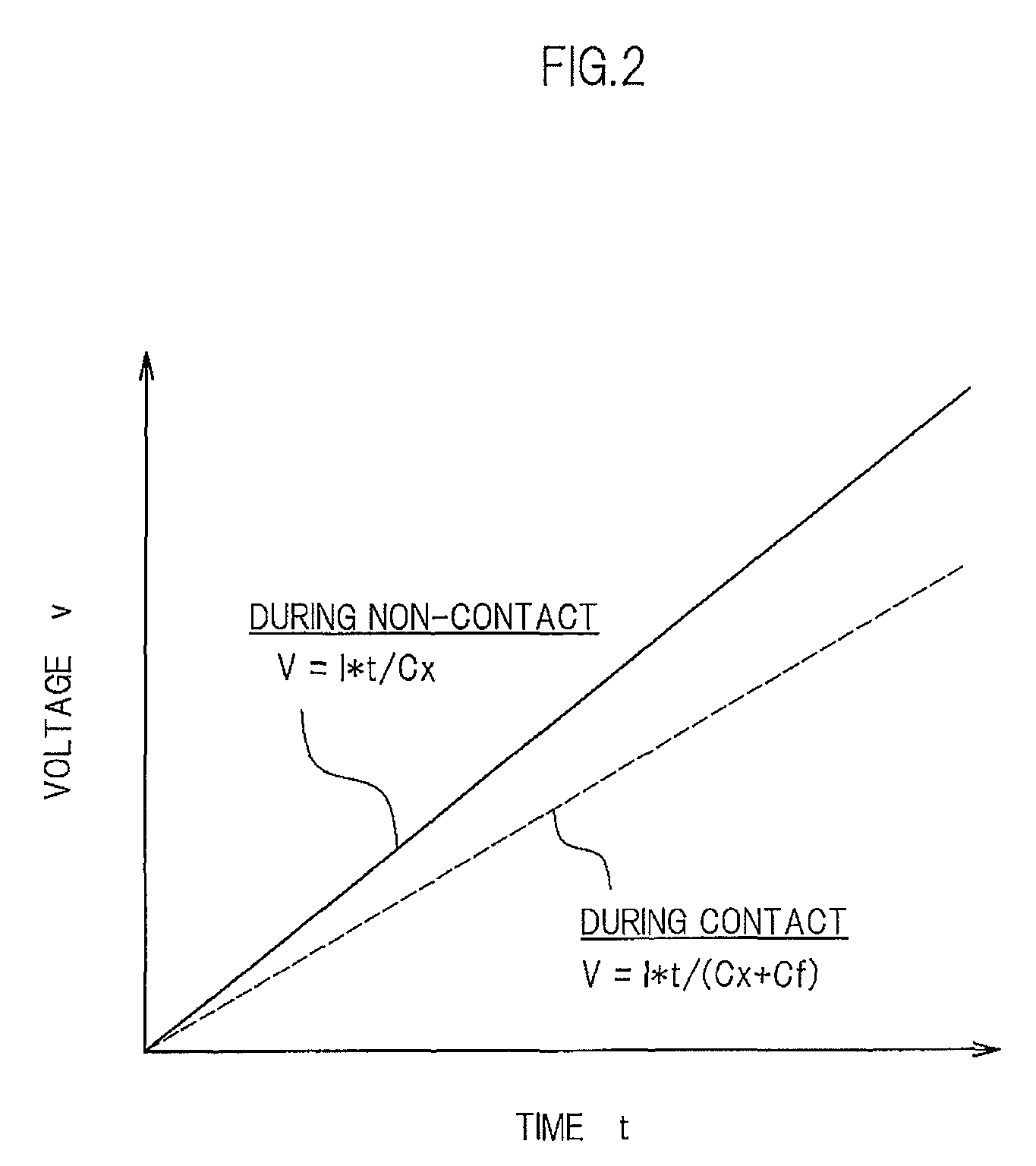

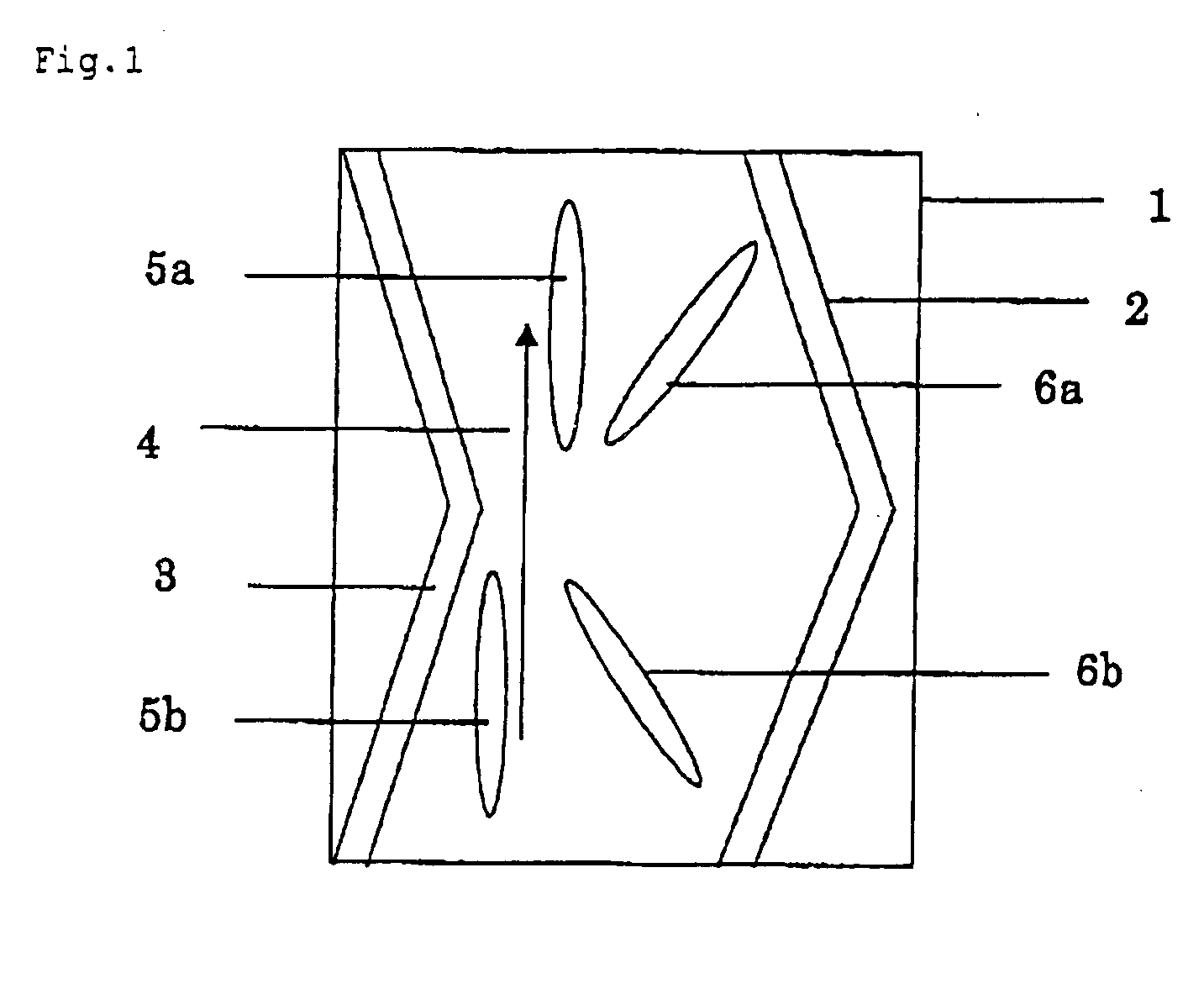

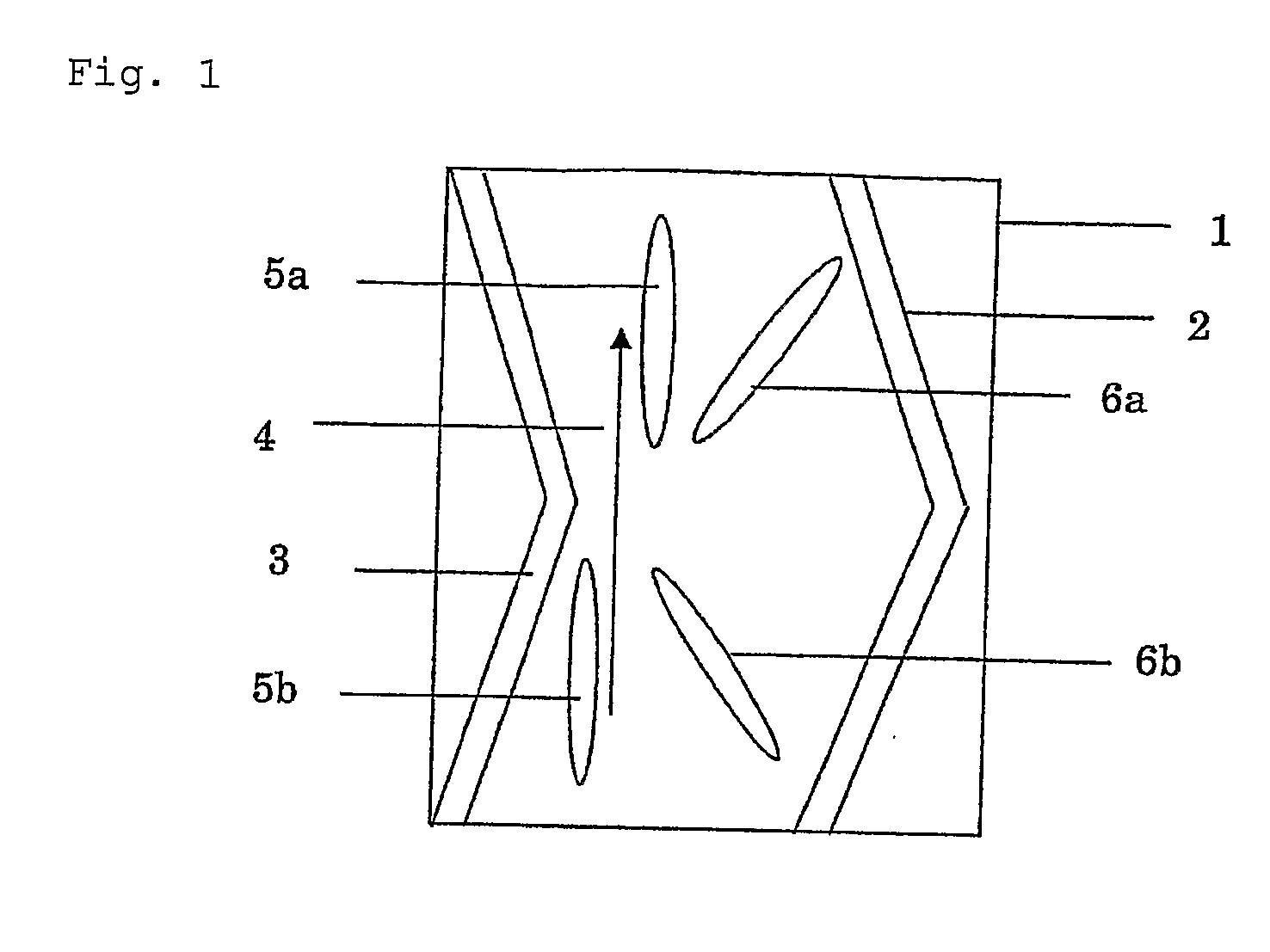

Display Panel

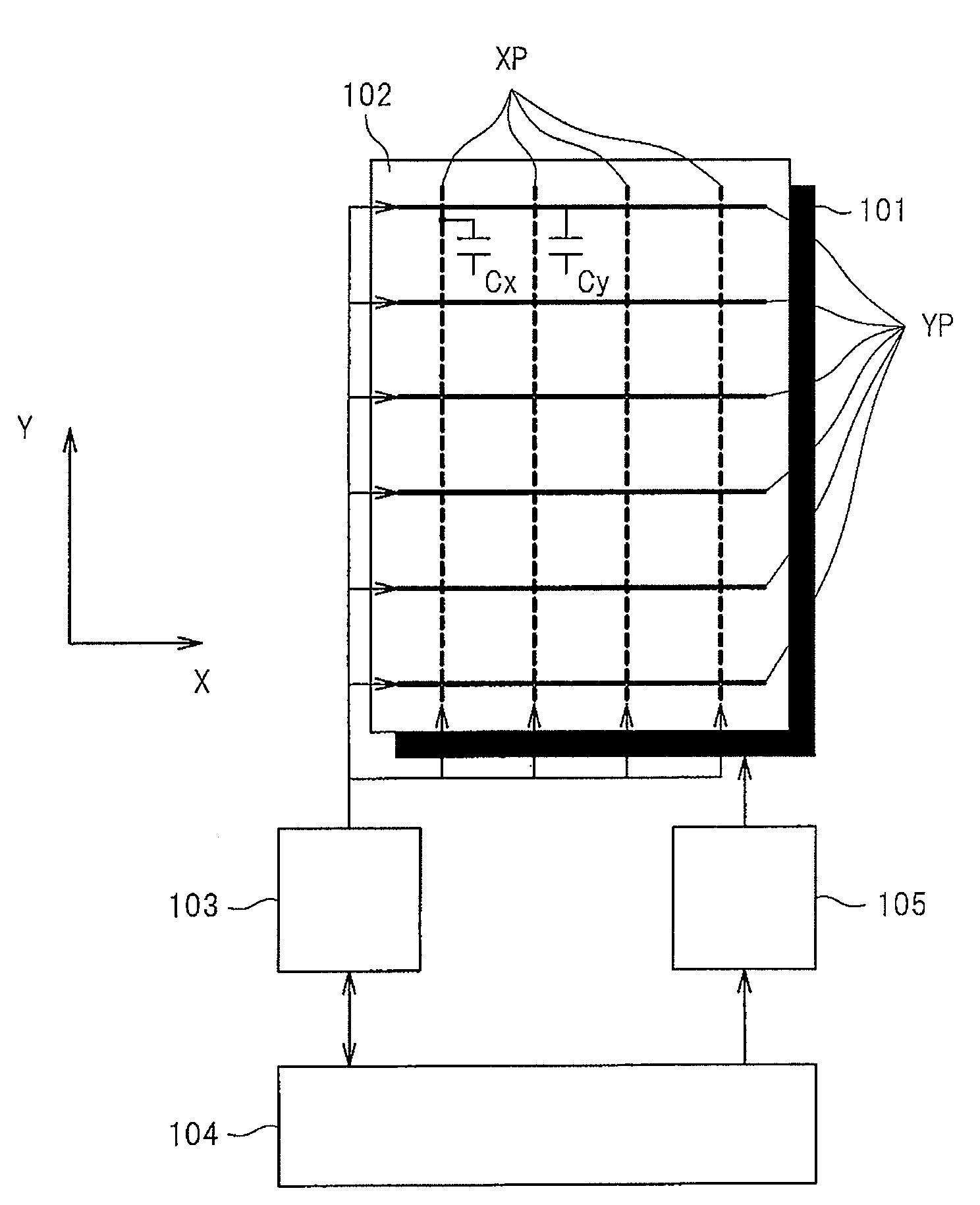

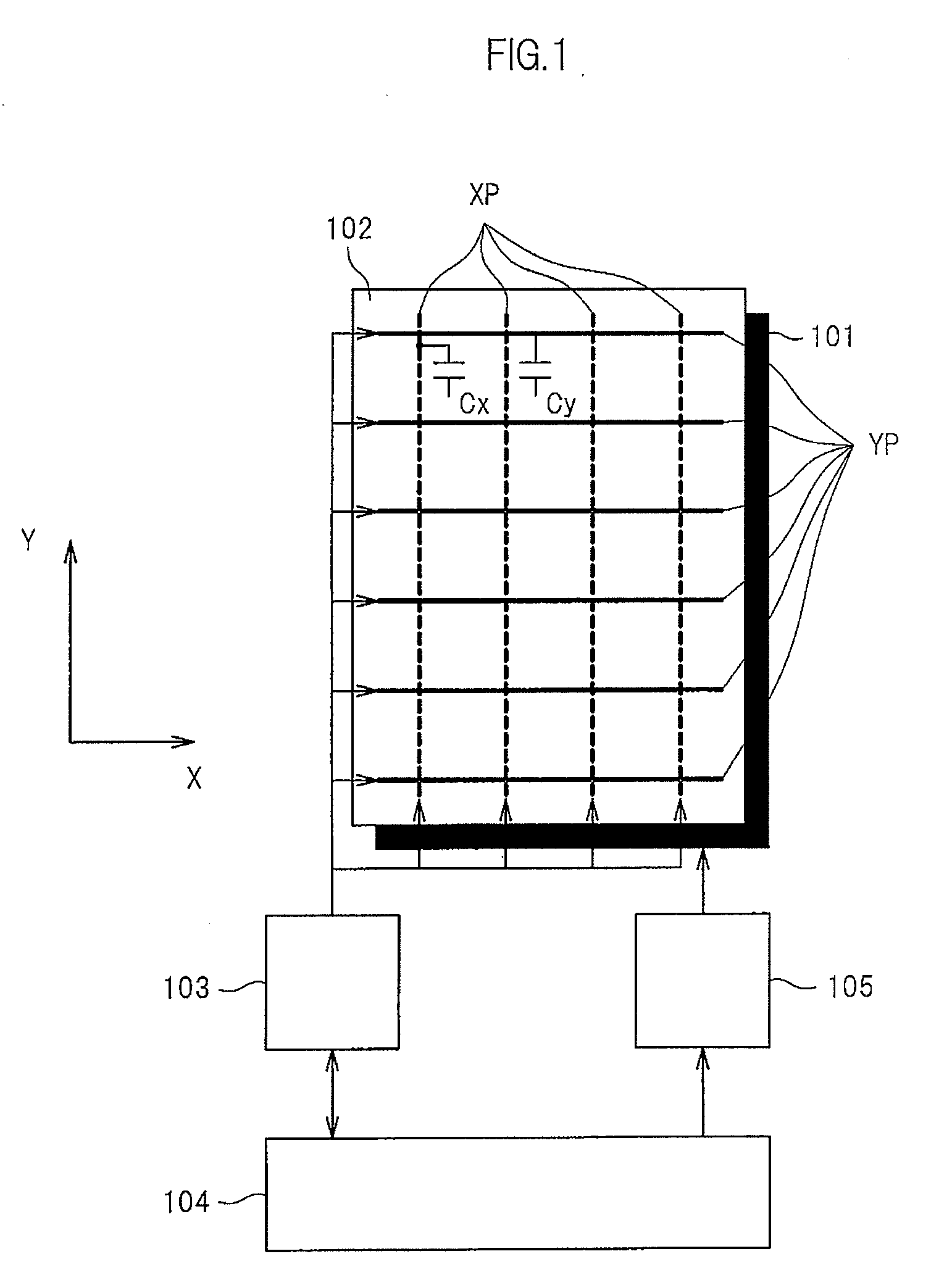

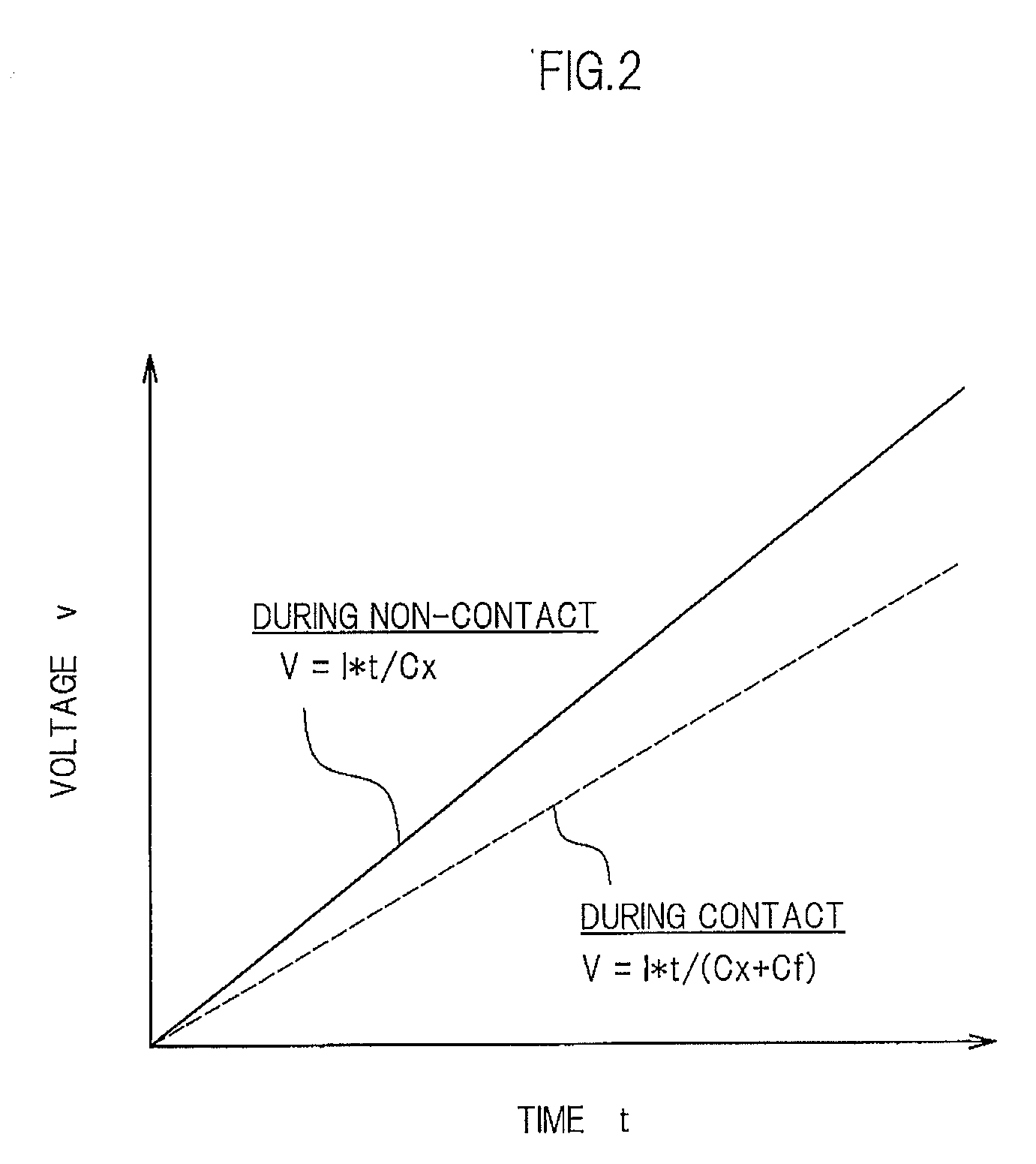

ActiveUS20090213090A1Reduce viewEasy to detectNon-linear opticsInput/output processes for data processingTouch panelElectrical and Electronics engineering

A display panel is provided having a capacitive touch panel over a display region, wherein the capacitive touch panel comprises a plurality of X electrodes and a plurality of Y electrodes formed with an insulating layer there between and in a manner to cross each other, each of the X electrodes and the Y electrodes is formed such that a pad portion and a narrow line portion are alternately placed in a direction of extension, and when viewed from top, the pad portion of the X electrode and the pad portion of the Y electrode are placed to not overlap each other and a dummy electrode which is in a floating relationship with the X electrode and the Y electrode is formed between the pad portion of the X electrode and the pad portion of the Y electrode.

Owner:JAPAN DISPLAY INC +1

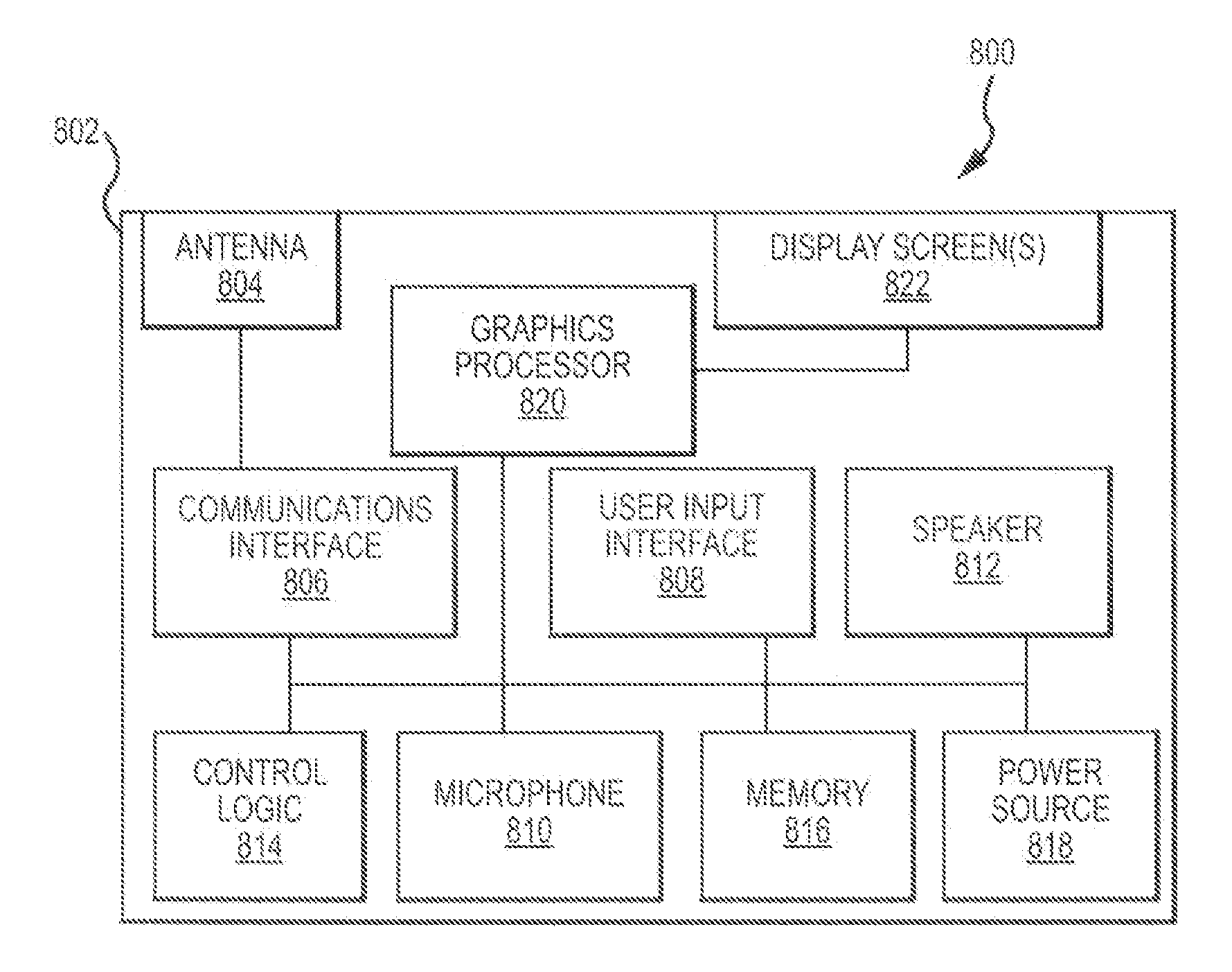

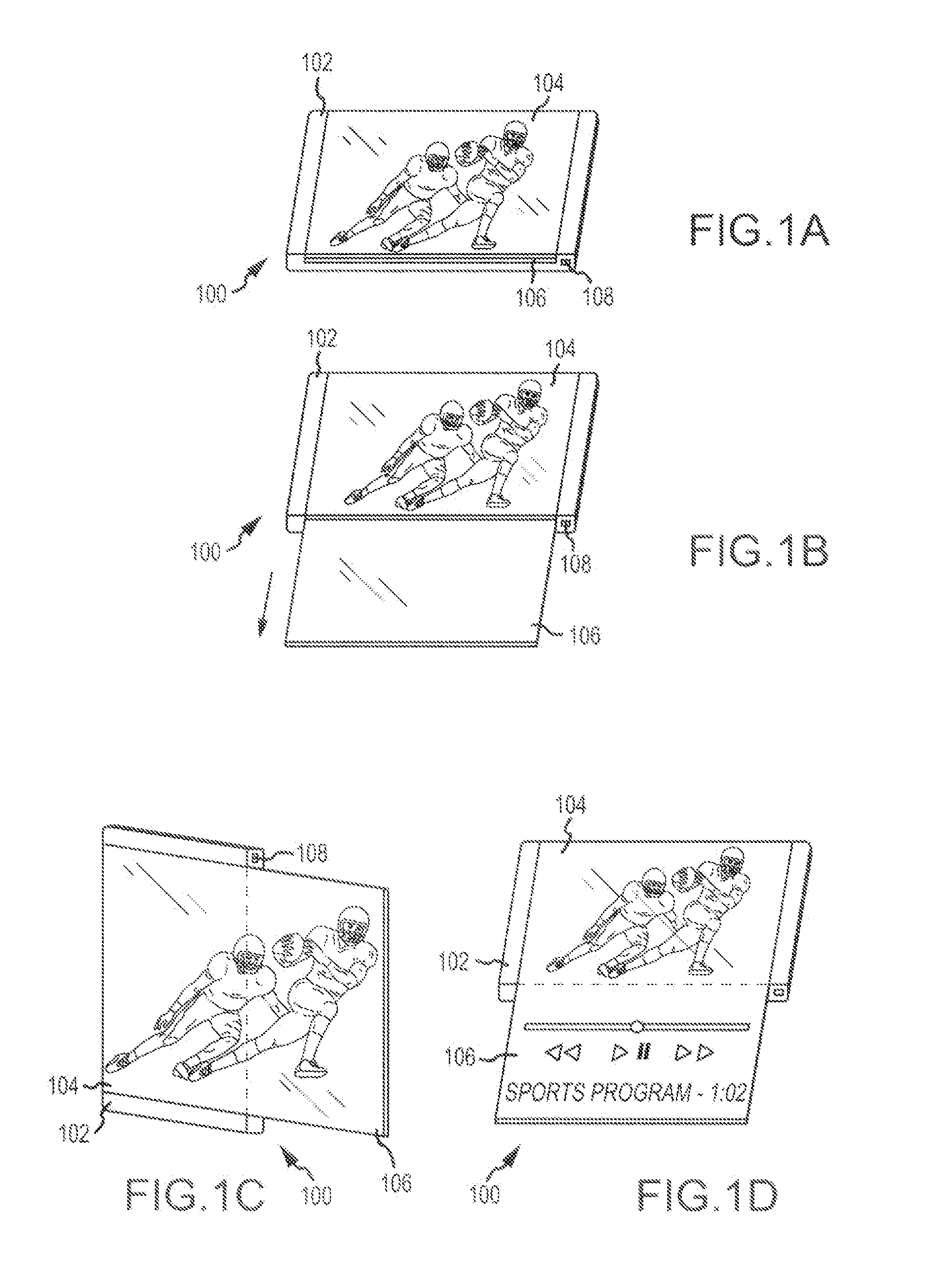

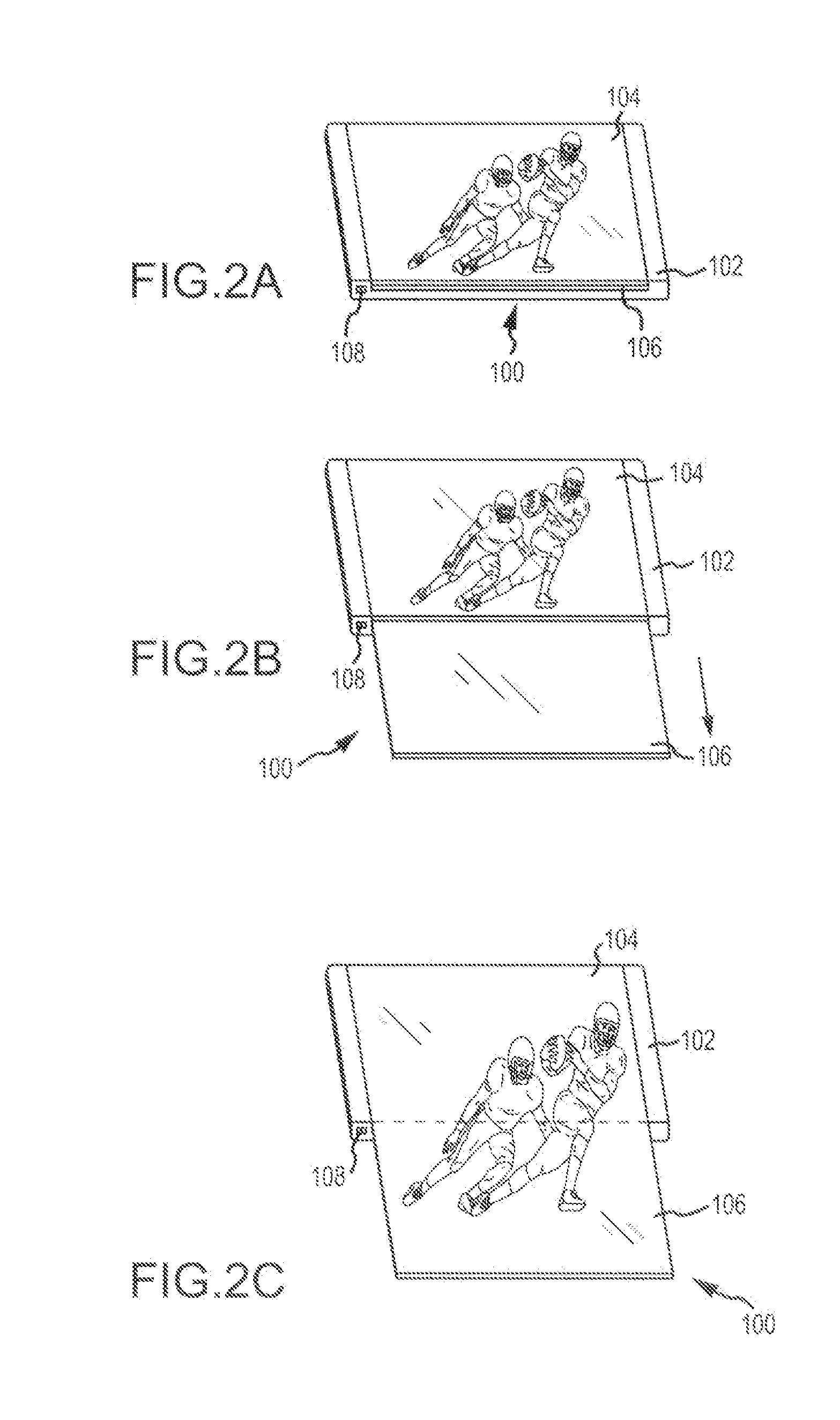

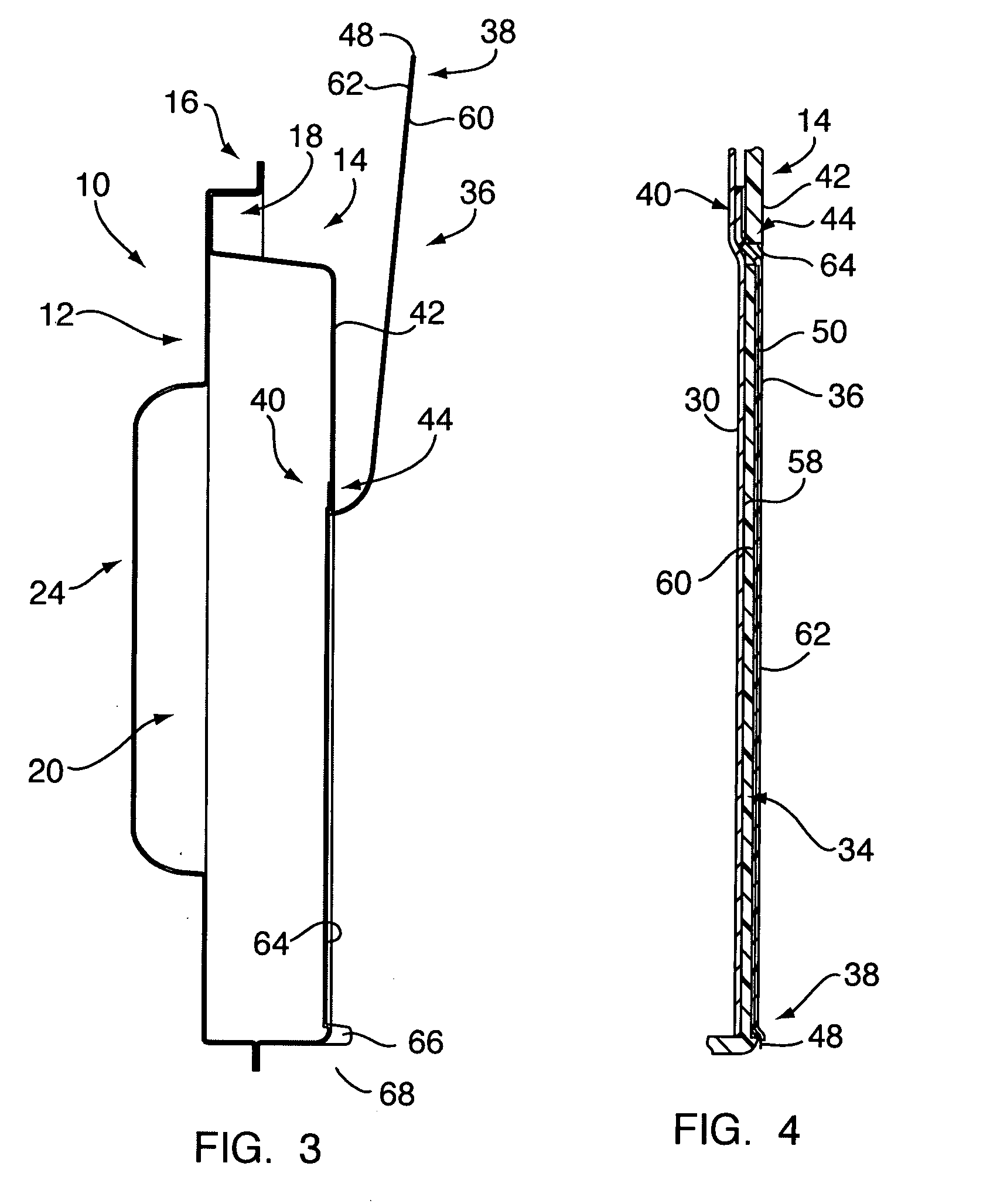

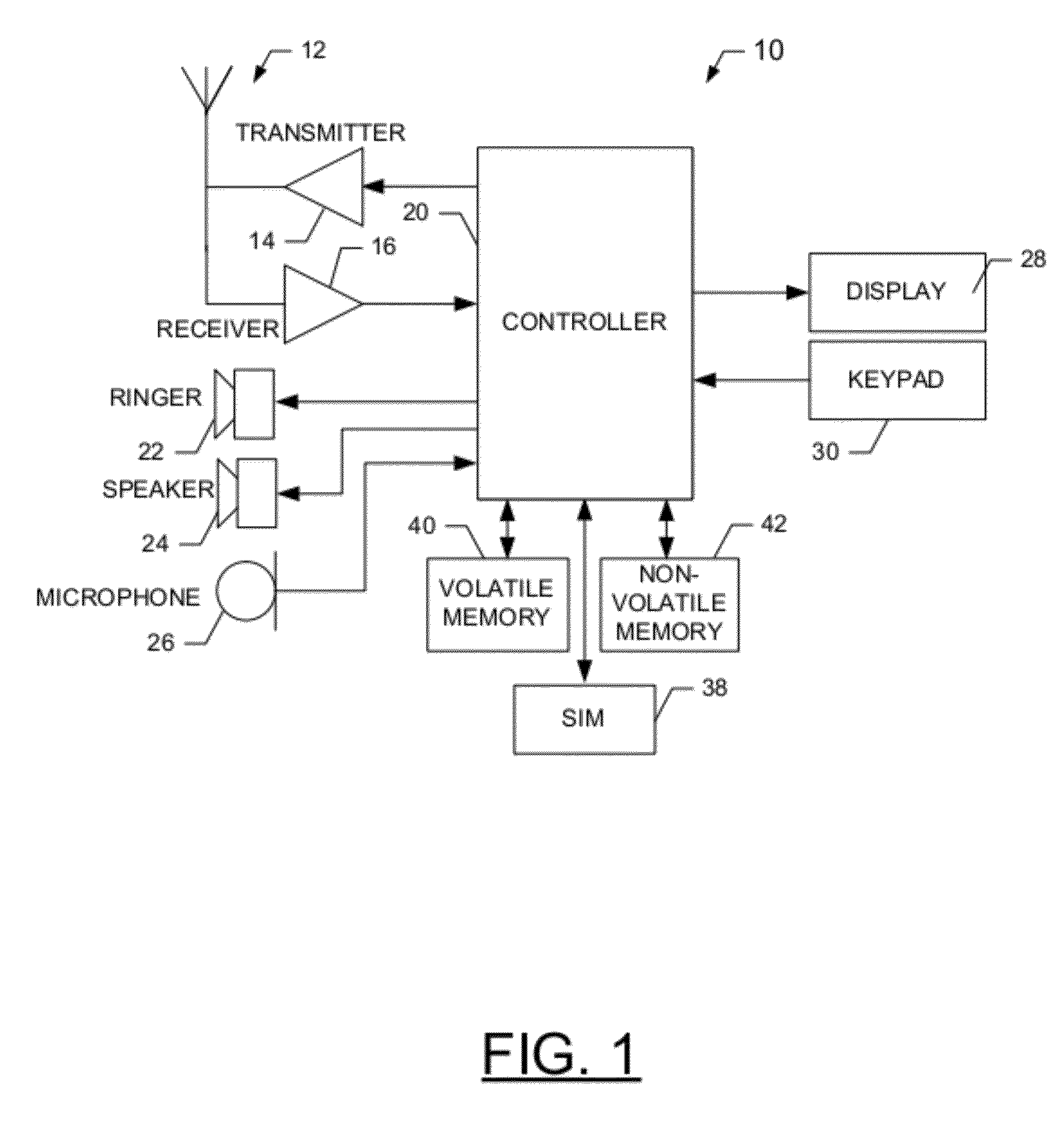

Communications device with extendable screen

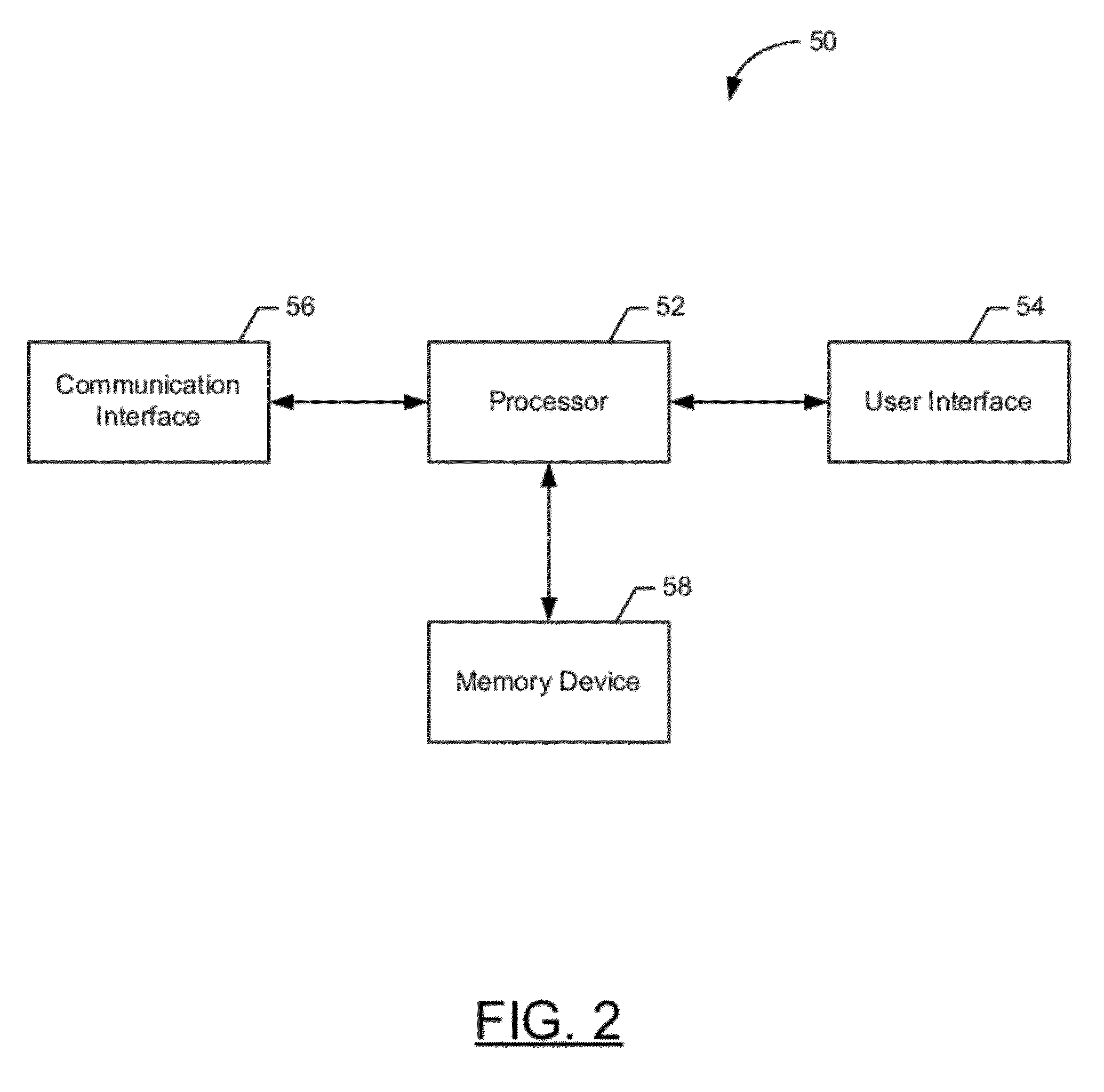

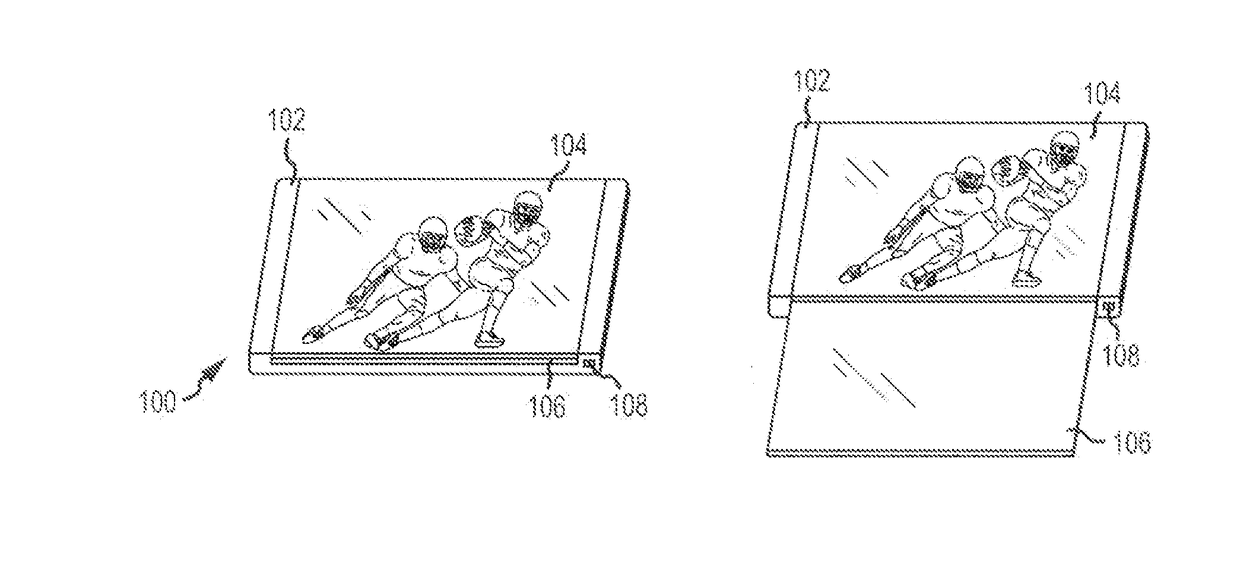

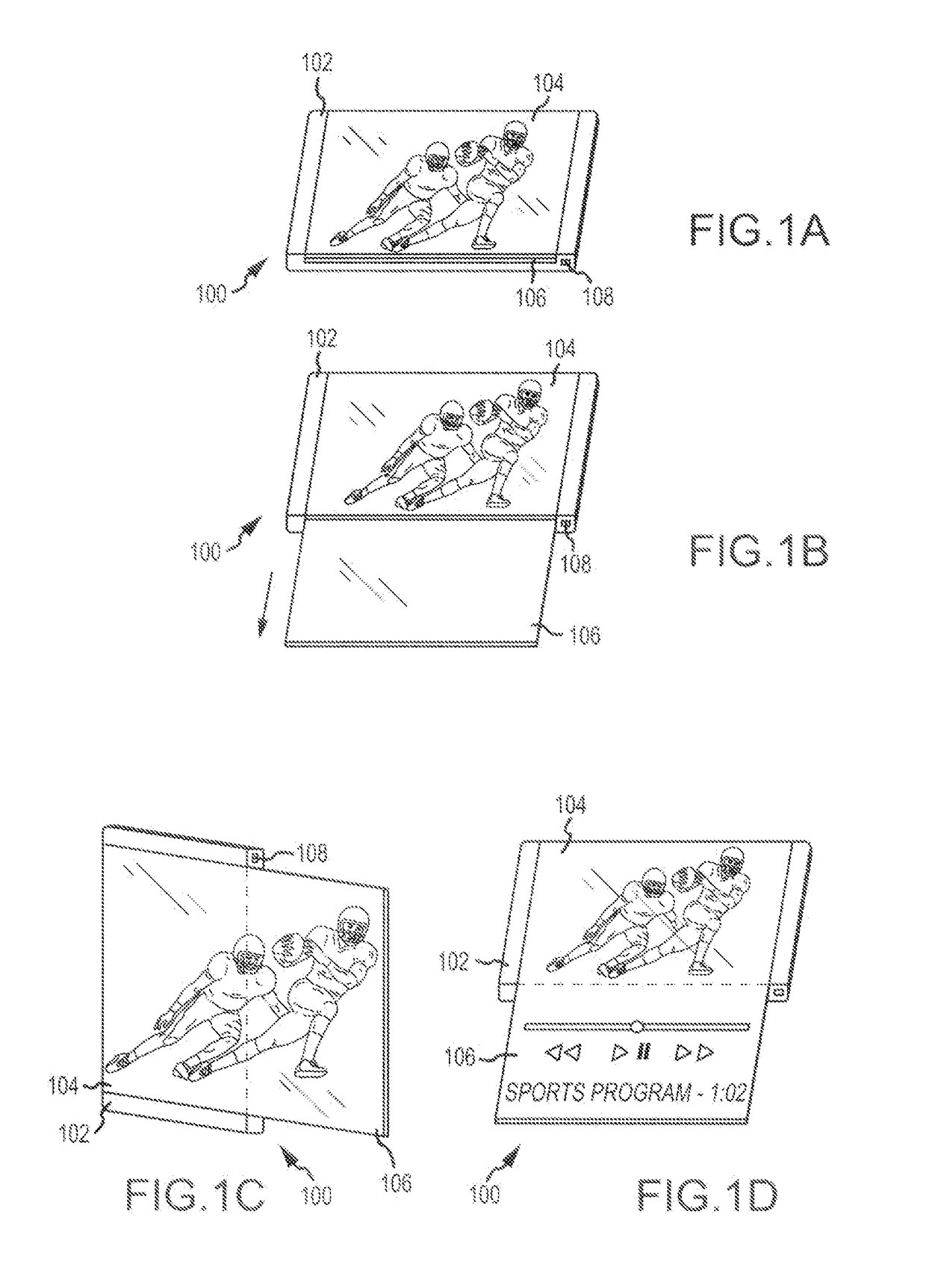

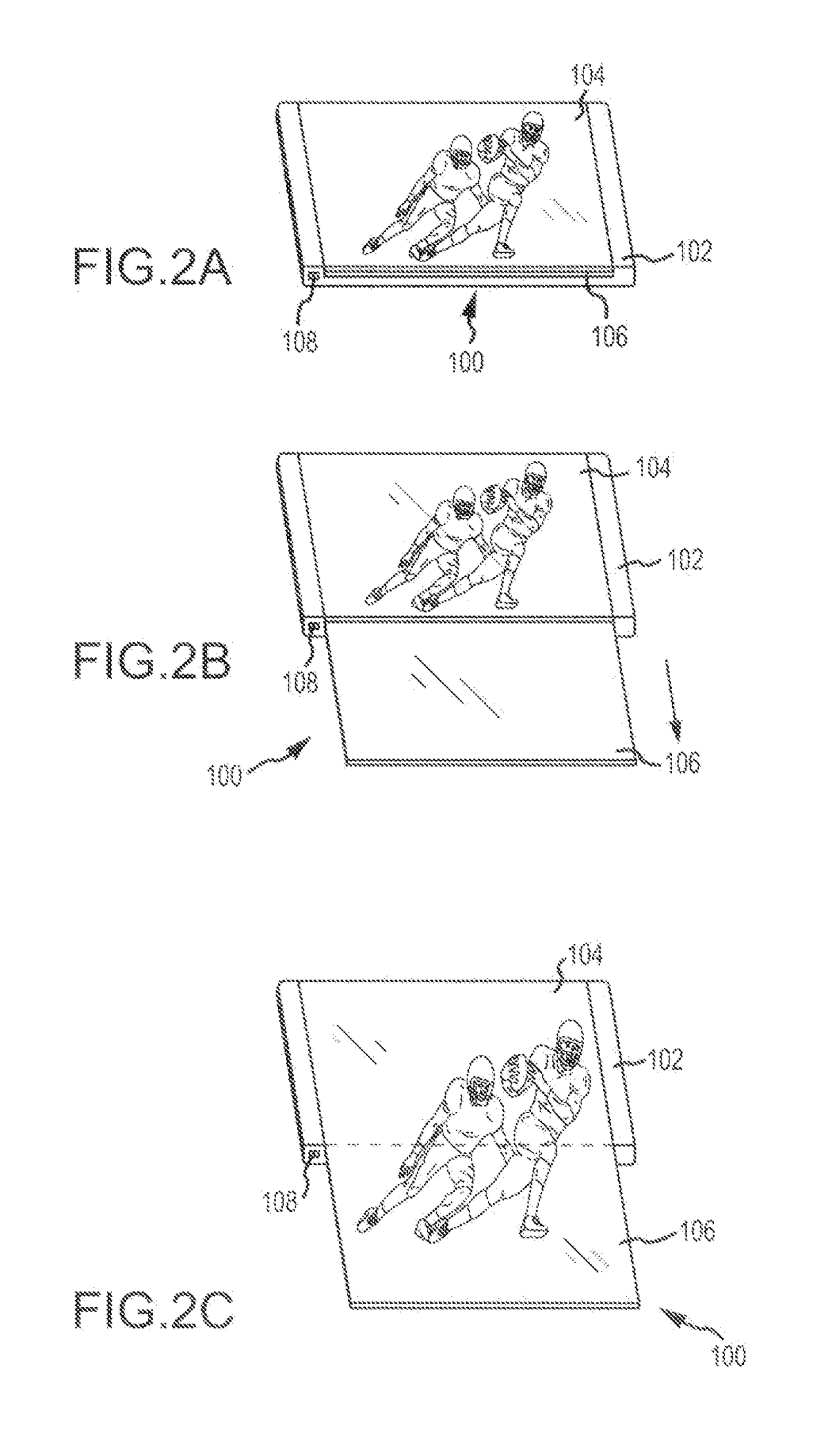

ActiveUS20120280924A1Thinner and lighter displayHigh resolution displayDevices with multiple display unitsStatic indicating devicesGraphical displayImage resolution

Described herein are apparatuses and mechanisms for providing an extendable screen in a portable communications device. A portable communications device may be provided with a multi-part screen, a portion of which may be extended to provide an expanded viewing display surface or may be retracted to provide a reduced viewing mode and increased portability. In a reduced viewing mode, a graphical display may be provided on a first, visible portion of a multi-part display screen, where one or more other screen portions are retracted and / or obscured from view in order to provide a portable mode for the communications device. In an extended viewing mode, the one or more other screen portions may be extended and / or brought into the same plane as a first portion of the multi-part display in order to provide increased display size and resolution.

Owner:DISH TECH L L C

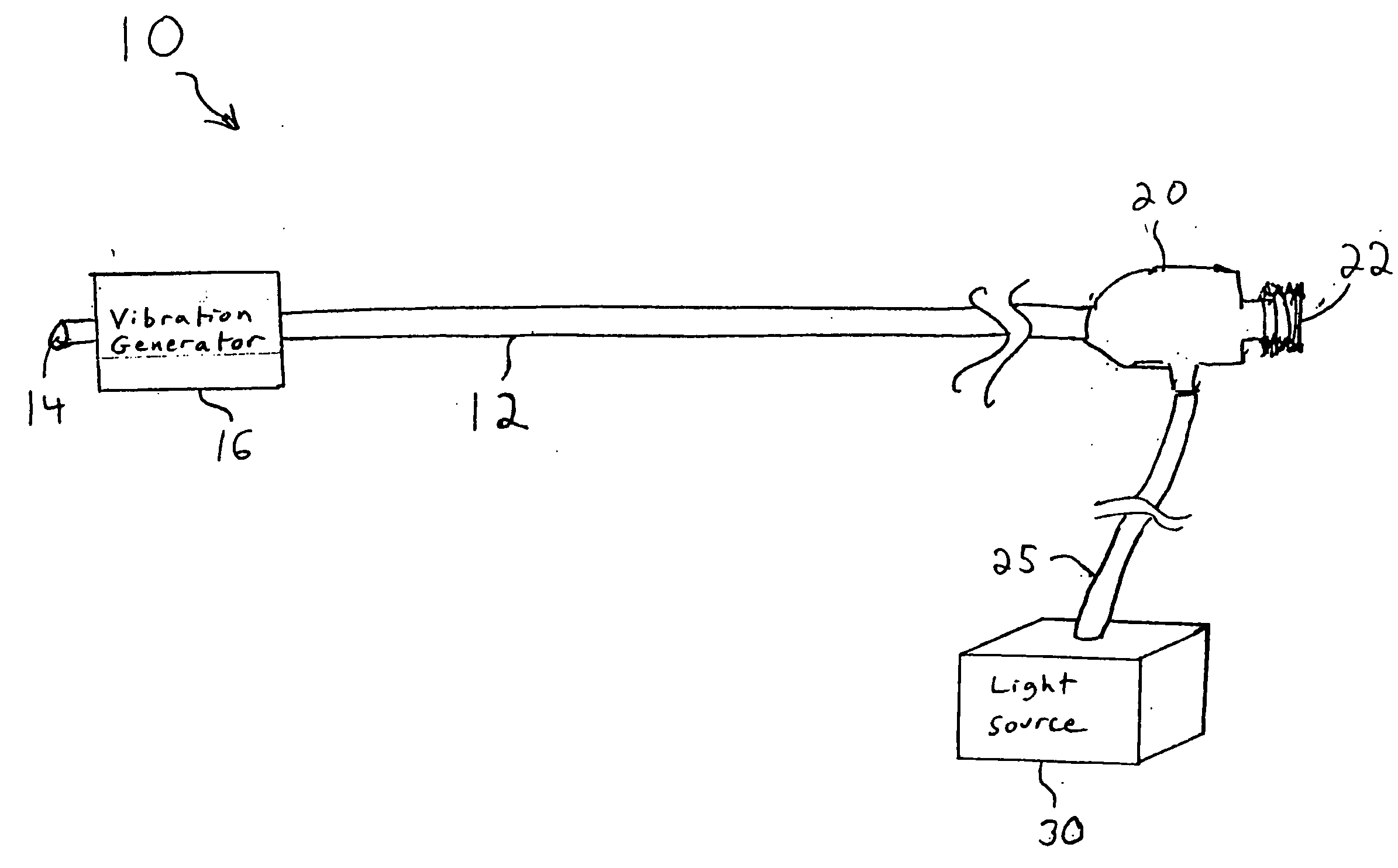

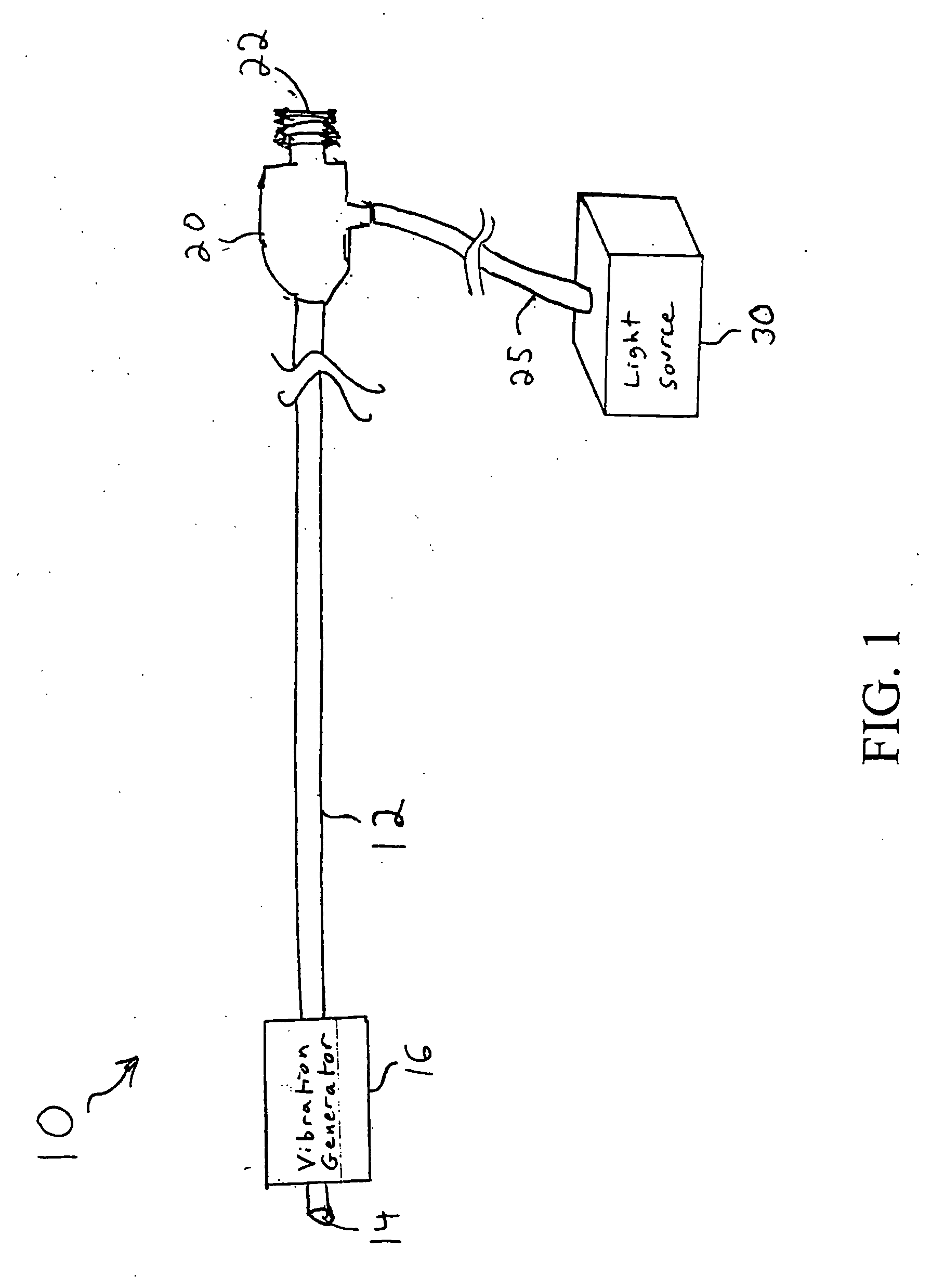

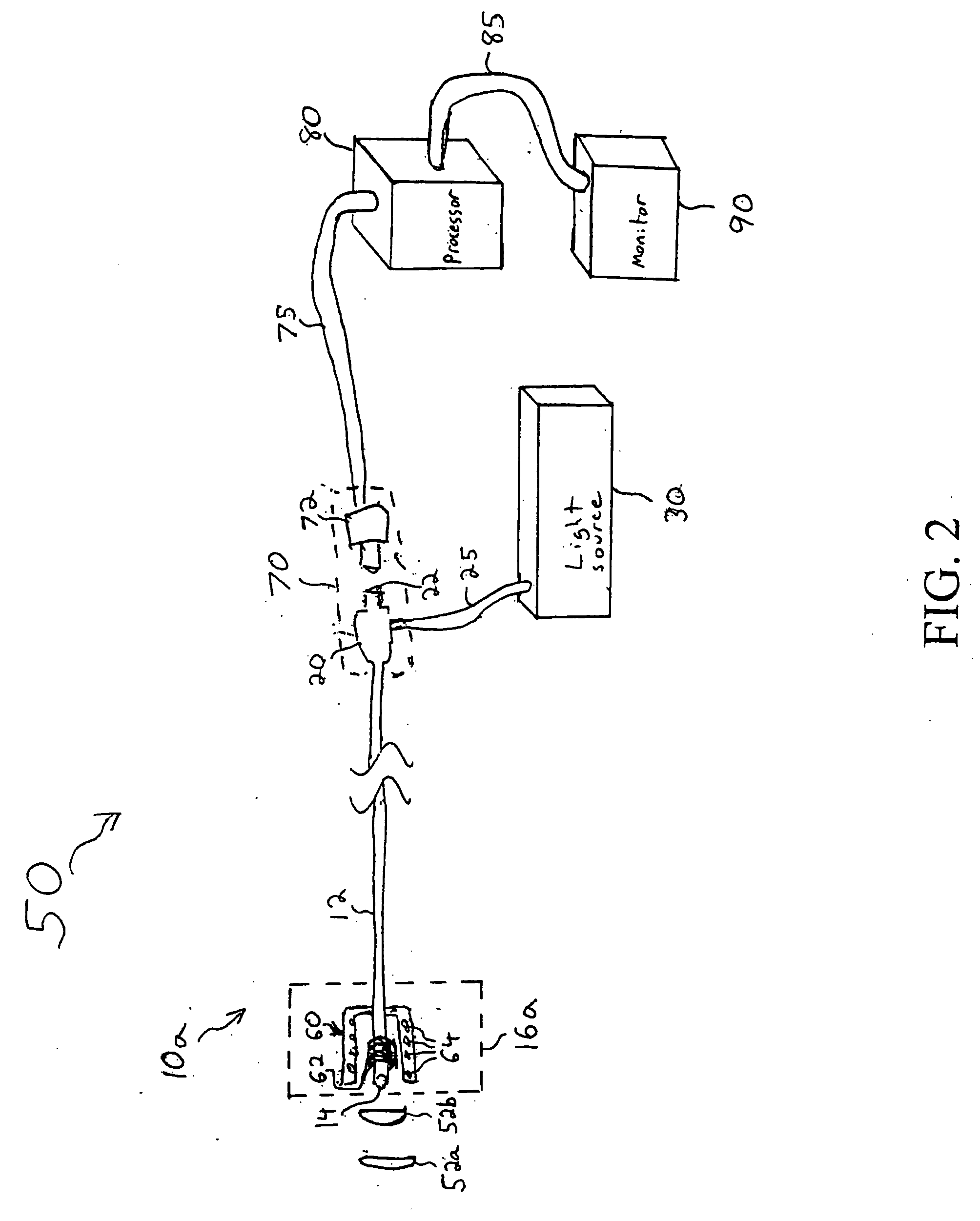

Vision catheter

A catheter with a small optical fiber or bundle of fibers includes a scanning mechanism constructed with the use of any vibration capable component. Magnetic, piezoelectric or other mechanisms are used to vibrate the end of the fiber and thus create a scanning effect which extends the field of view. One or more lenses may be utilized, including a lens attached to the distal tip of the image fiber, or a lens attached to the distal tip of the catheter for creating an image plane which can be scanned by the fiber. In one embodiment, multiple light sources may be connected to the fiber for enabling the use of field sequential color techniques for real-time imaging, as well as real-time fluorescent imaging for disease detection. A photodetector assembly connected to the proximal end may contain both filtered and unfiltered detectors for use with both standard imaging and fluorescent imaging. The resulting vision catheter is relatively inexpensive and disposable.

Owner:SCI MED LIFE SYST

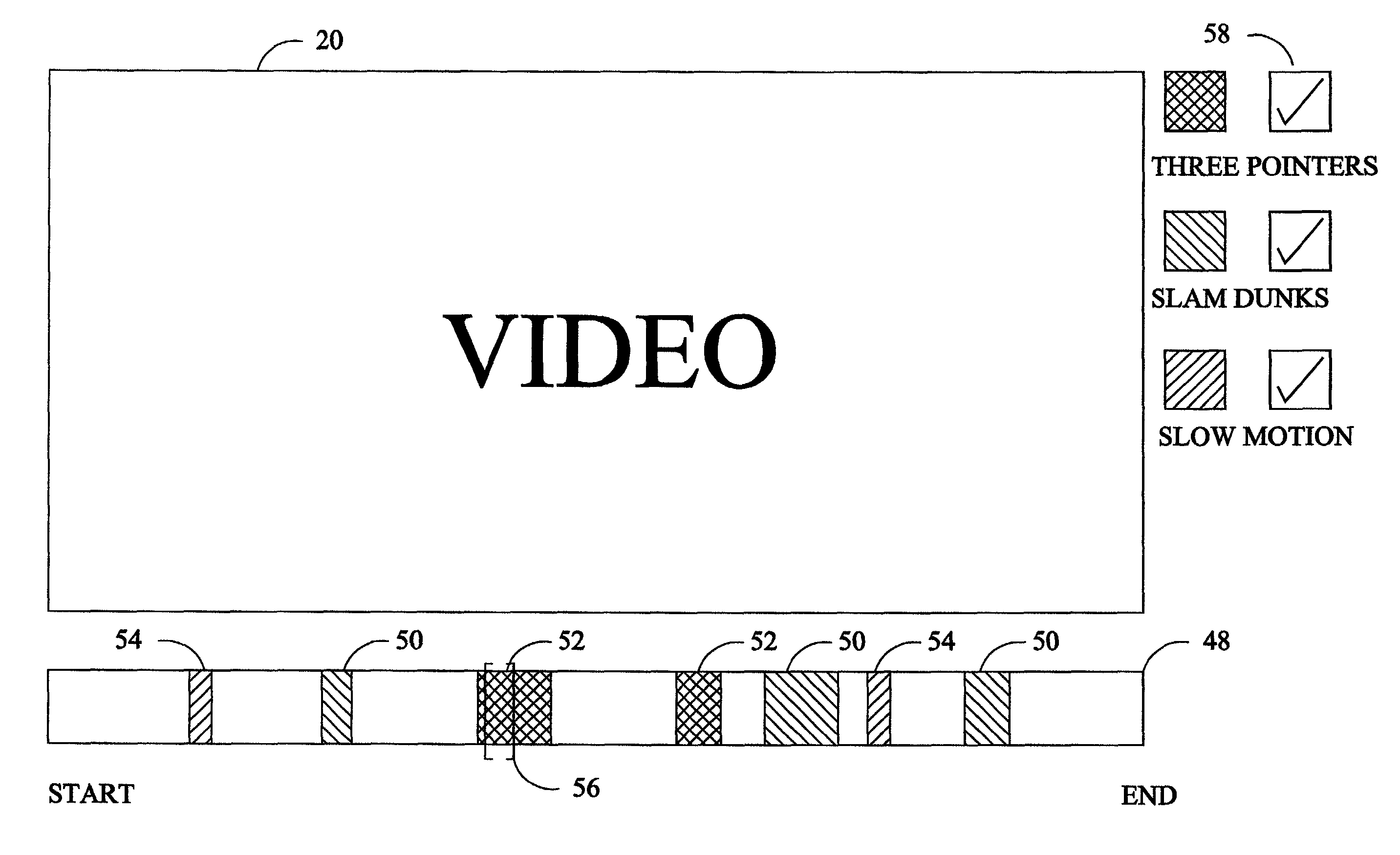

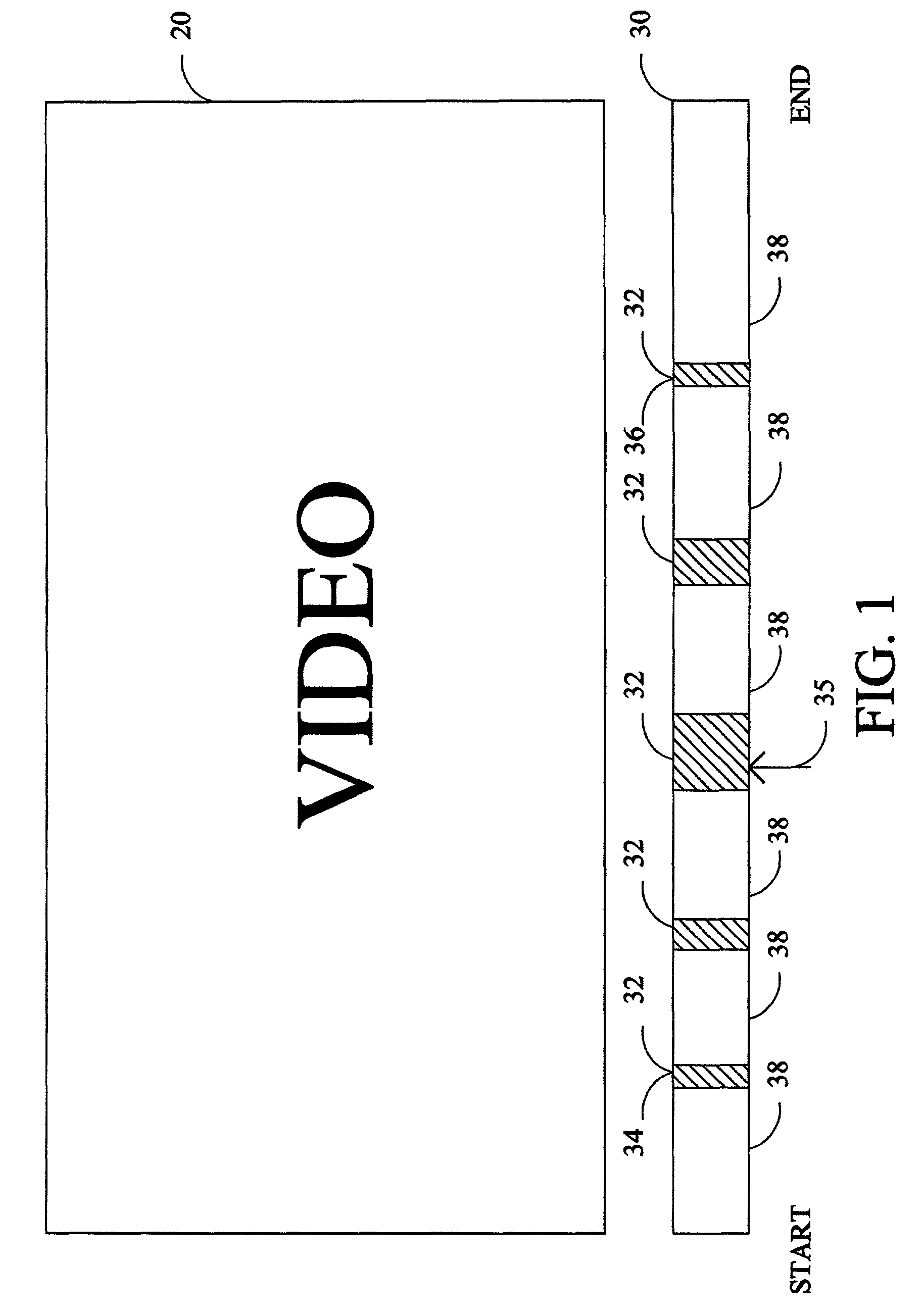

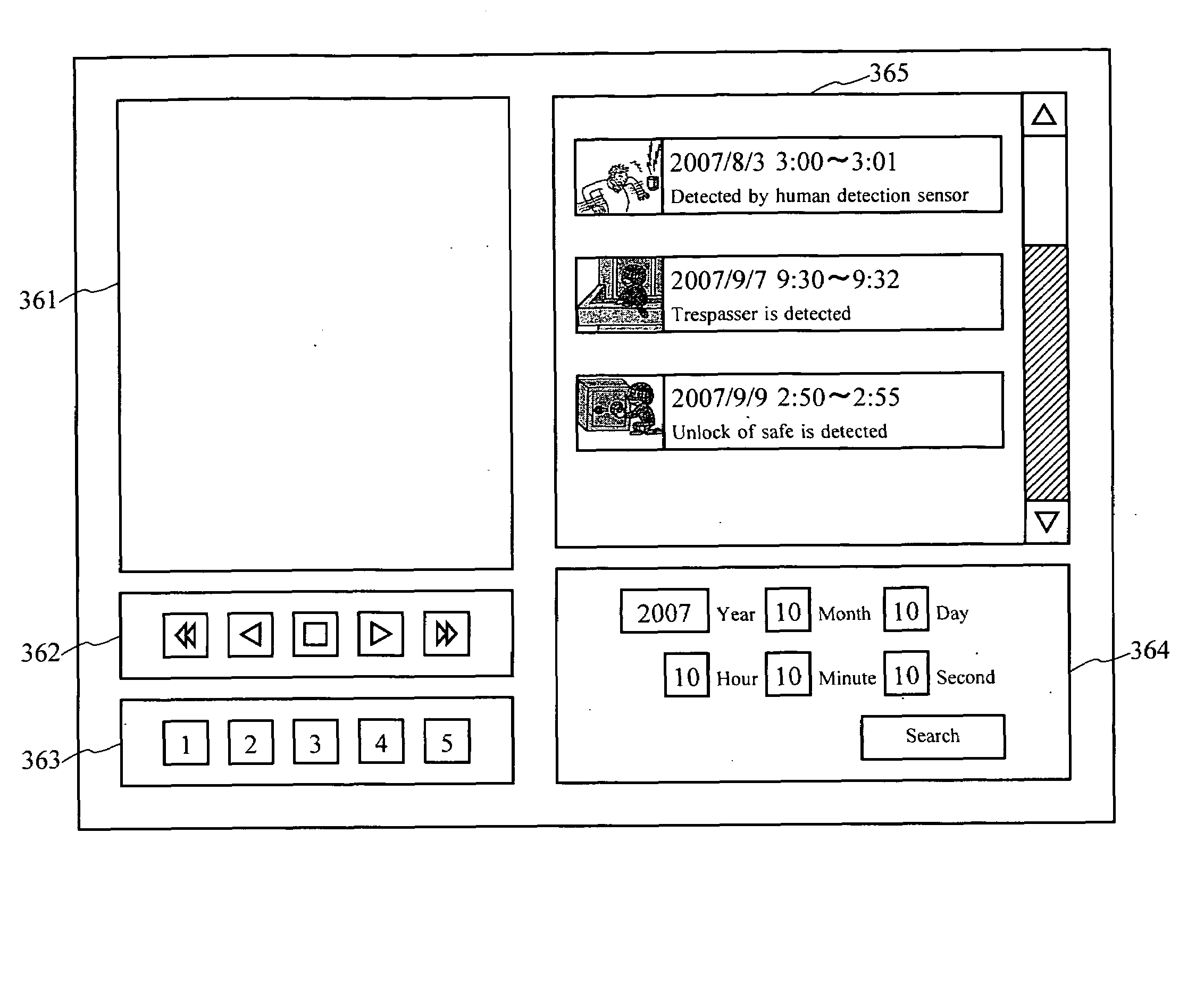

System for presenting audio-video content

InactiveUS7904814B2Easy to operateShorten the timeRecord information storageCathode-ray tube indicatorsGraphicsGraphical user interface

A system for presenting a summarization of audio and / or visual content having a plurality of segments to a user together with a graphical user interface that preferably indicates to the viewer the relative temporal position of video segments viewed in the summary within the content from which the summary was derived.

Owner:SHARP KK

Method for capturing a panoramic image by means of an image sensor rectangular in shape

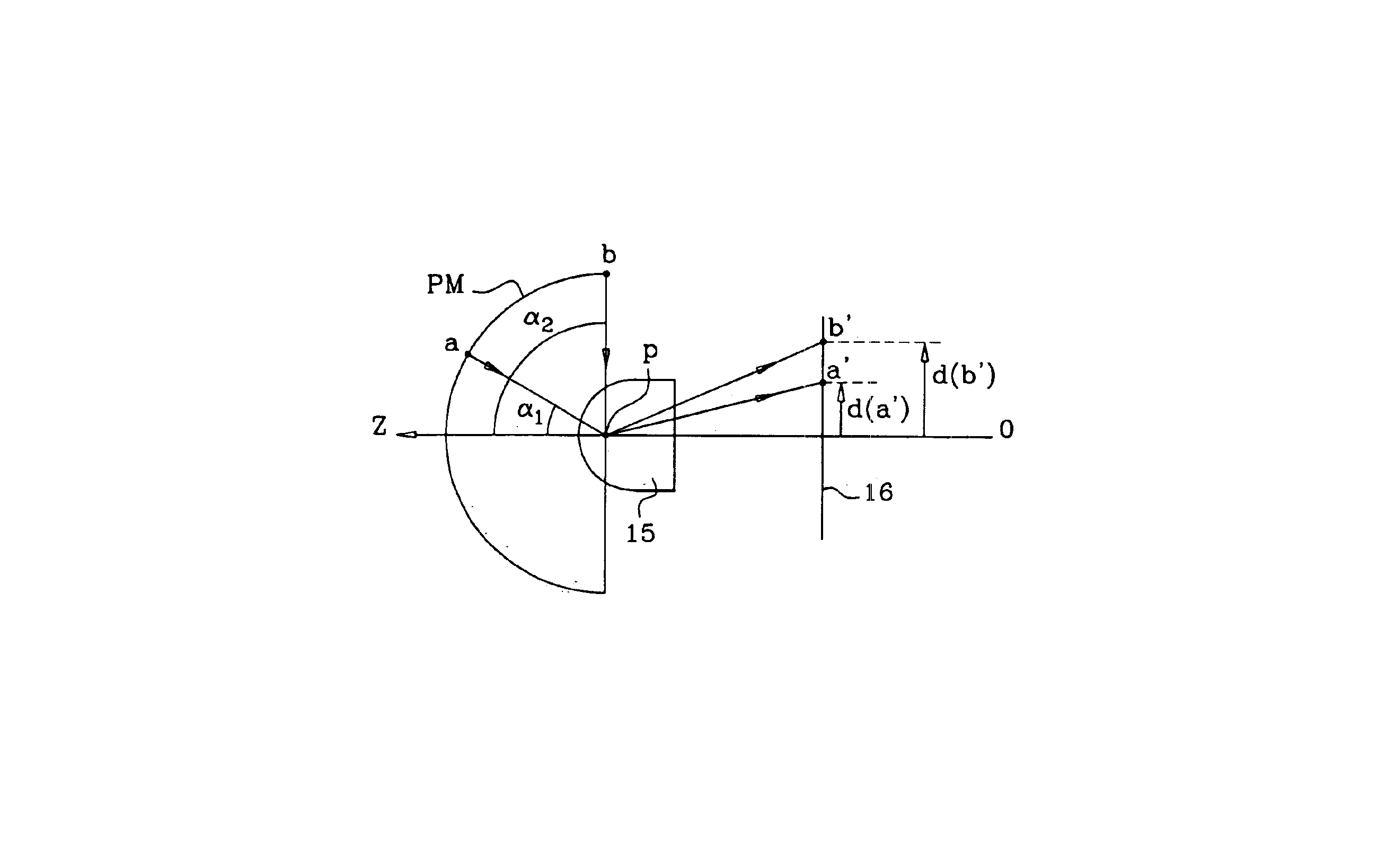

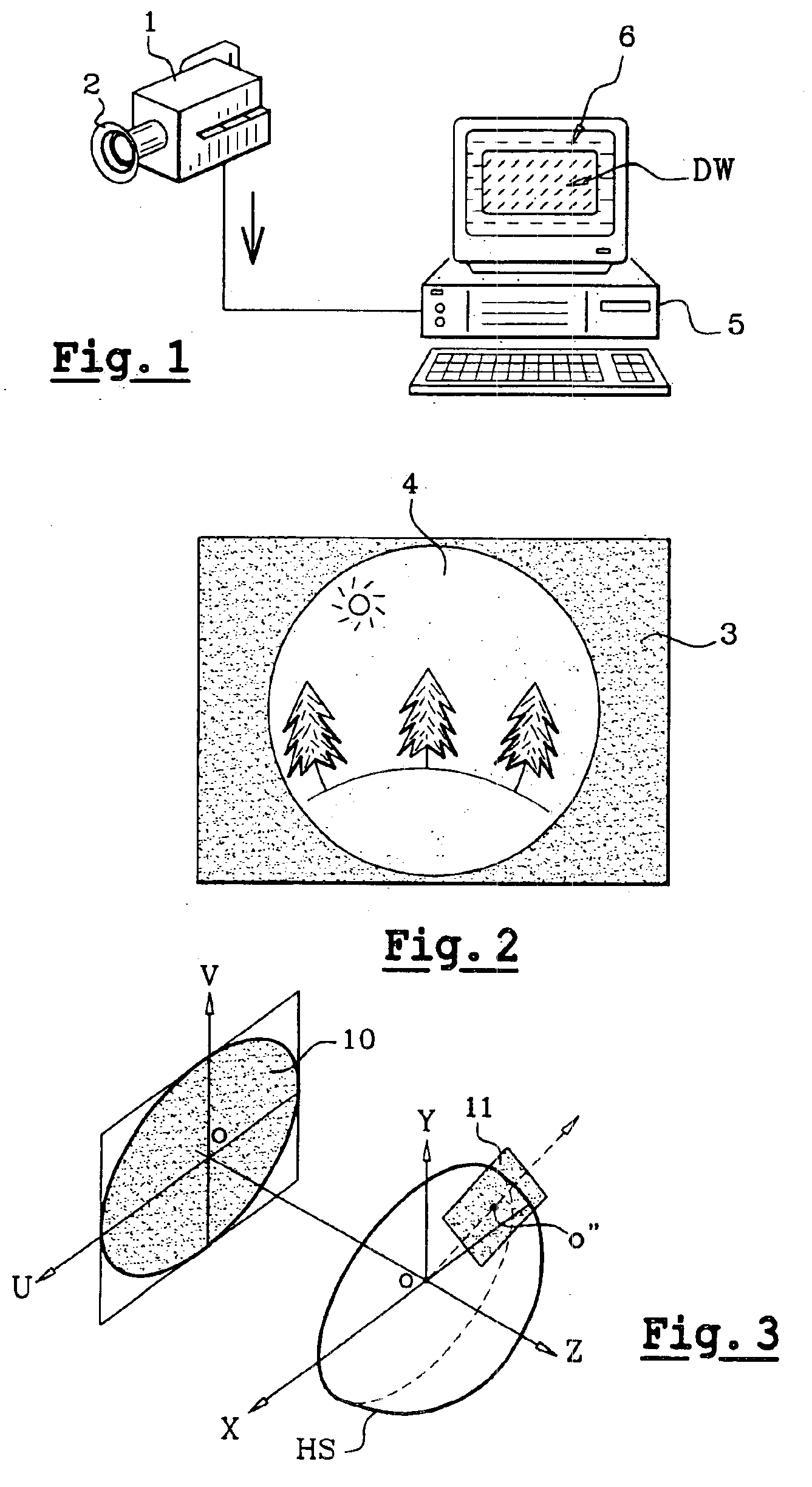

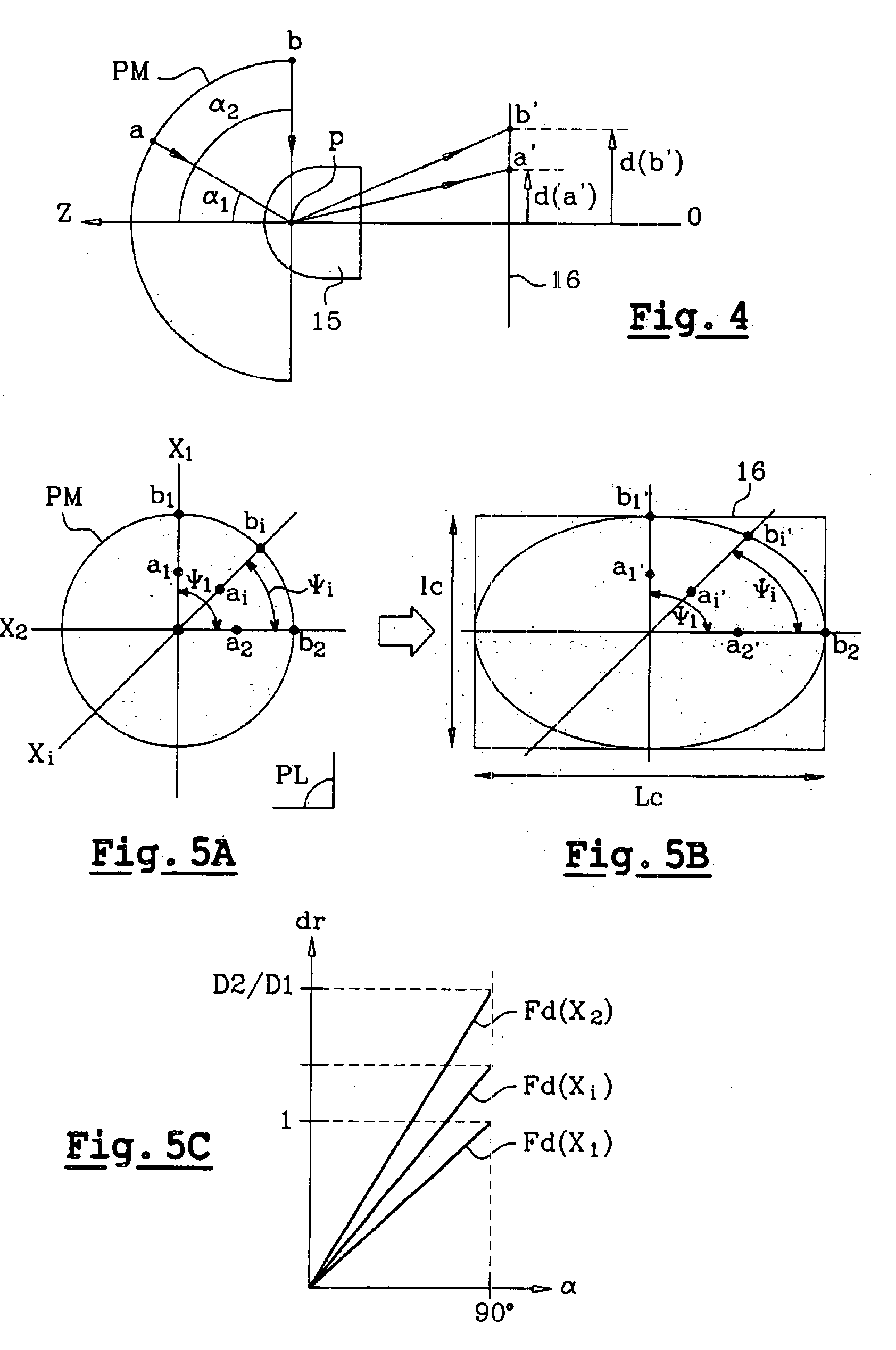

InactiveUS6865028B2Enhancement in definitionIncrease the number of pixelsTelevision system detailsNanoinformaticsConstant fieldOptical axis

A method for capturing a digital panoramic image, includes projecting a panorama onto an image sensor by means of a fish-eye objective lens having a constant field angle relative to its optical axis. The image sensor is rectangular in shape. The fish-eye objective lens is provided to project onto the image sensor, without reducing the field of view, a distorted panoramic image that covers a number of pixels on the image sensor higher than the number of pixels that would be covered by an image disk.

Owner:IMMERVISION INC

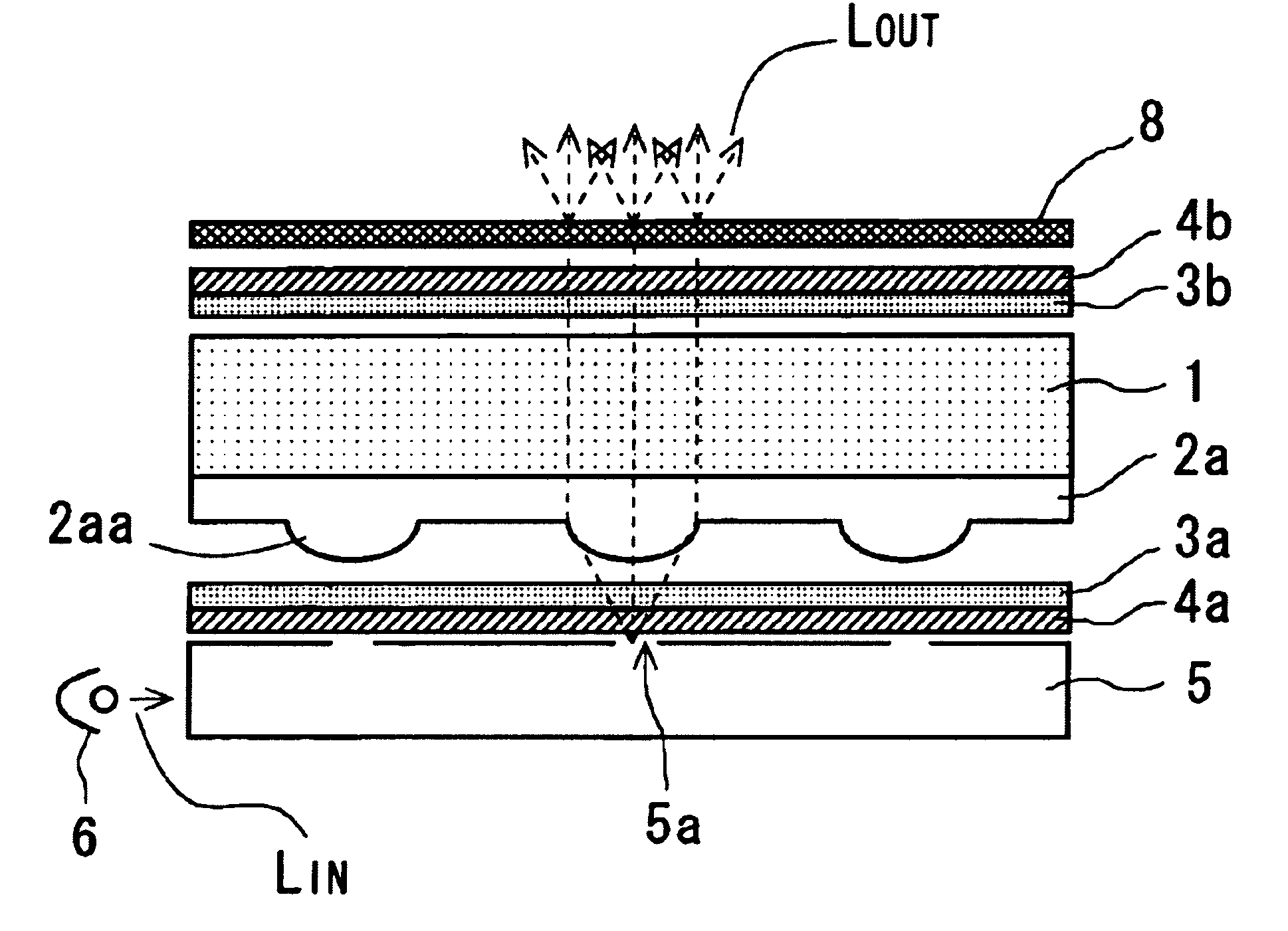

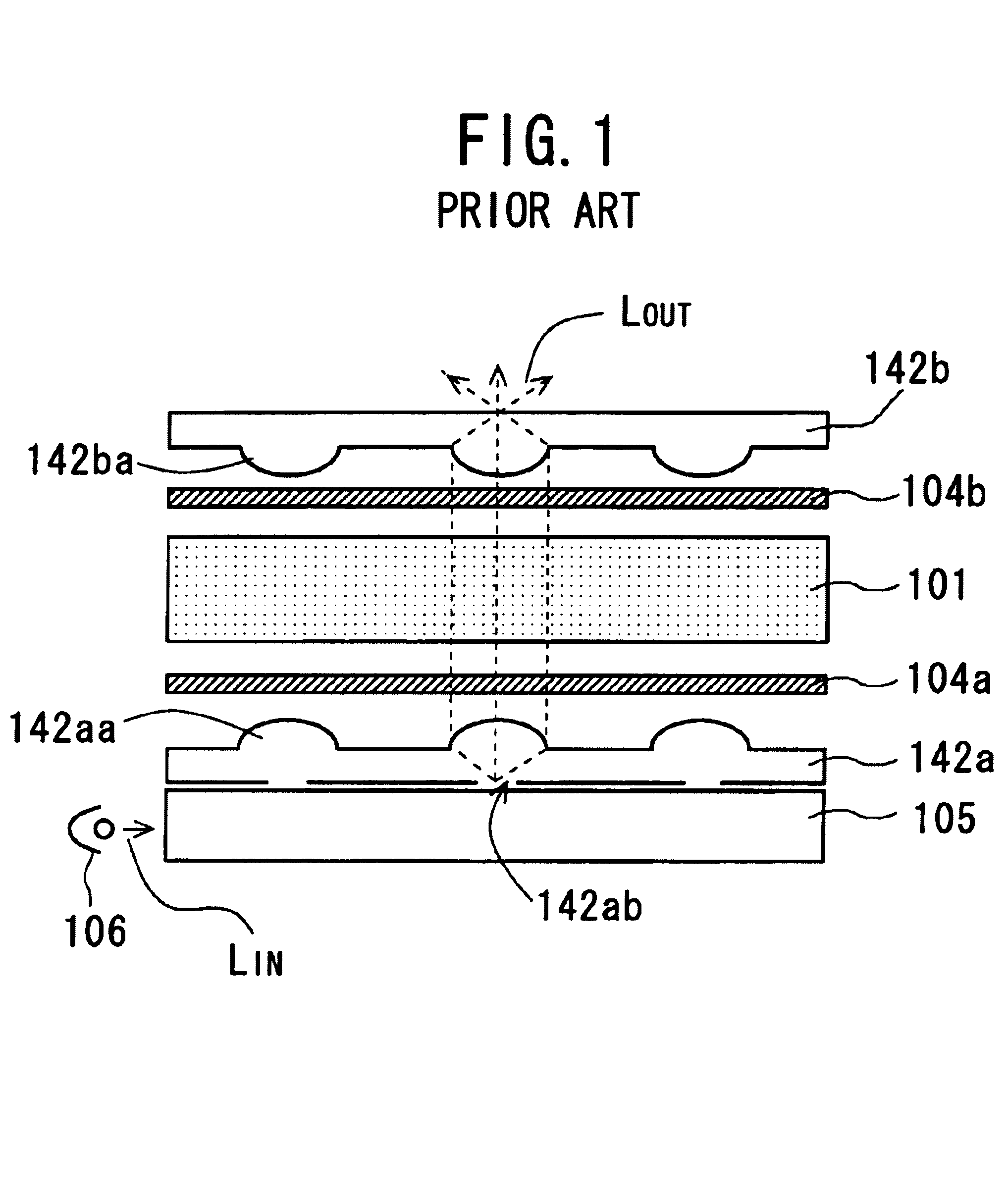

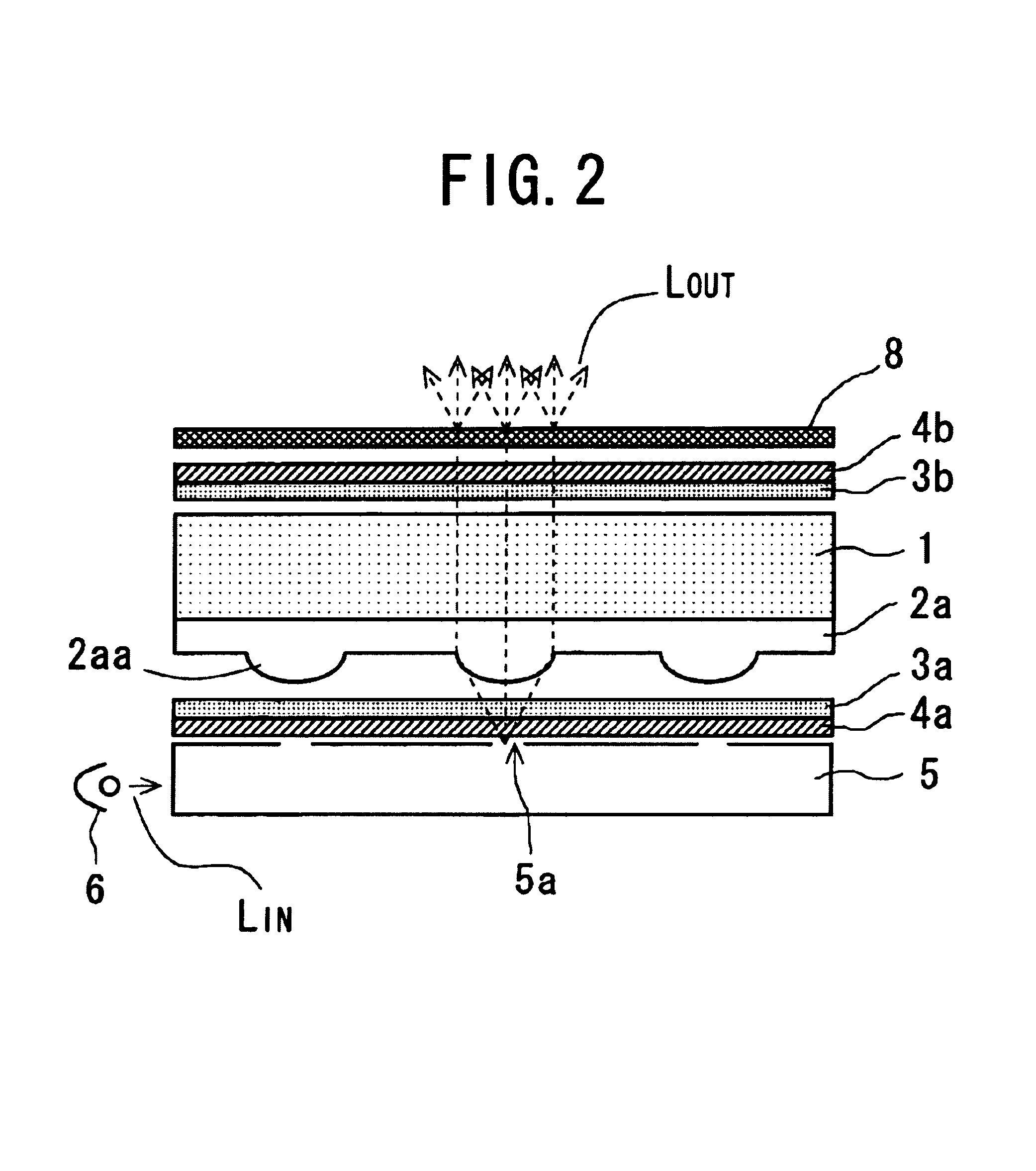

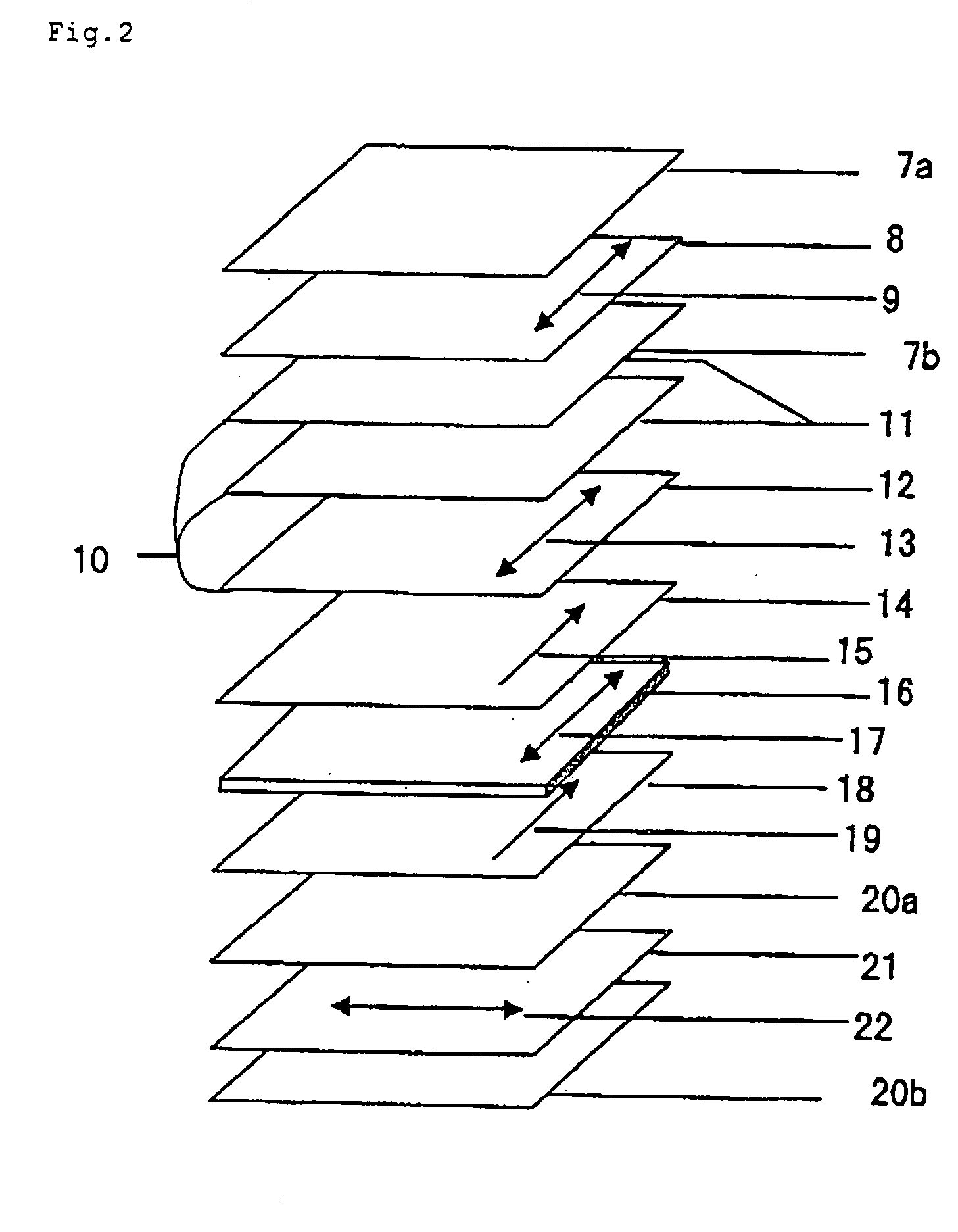

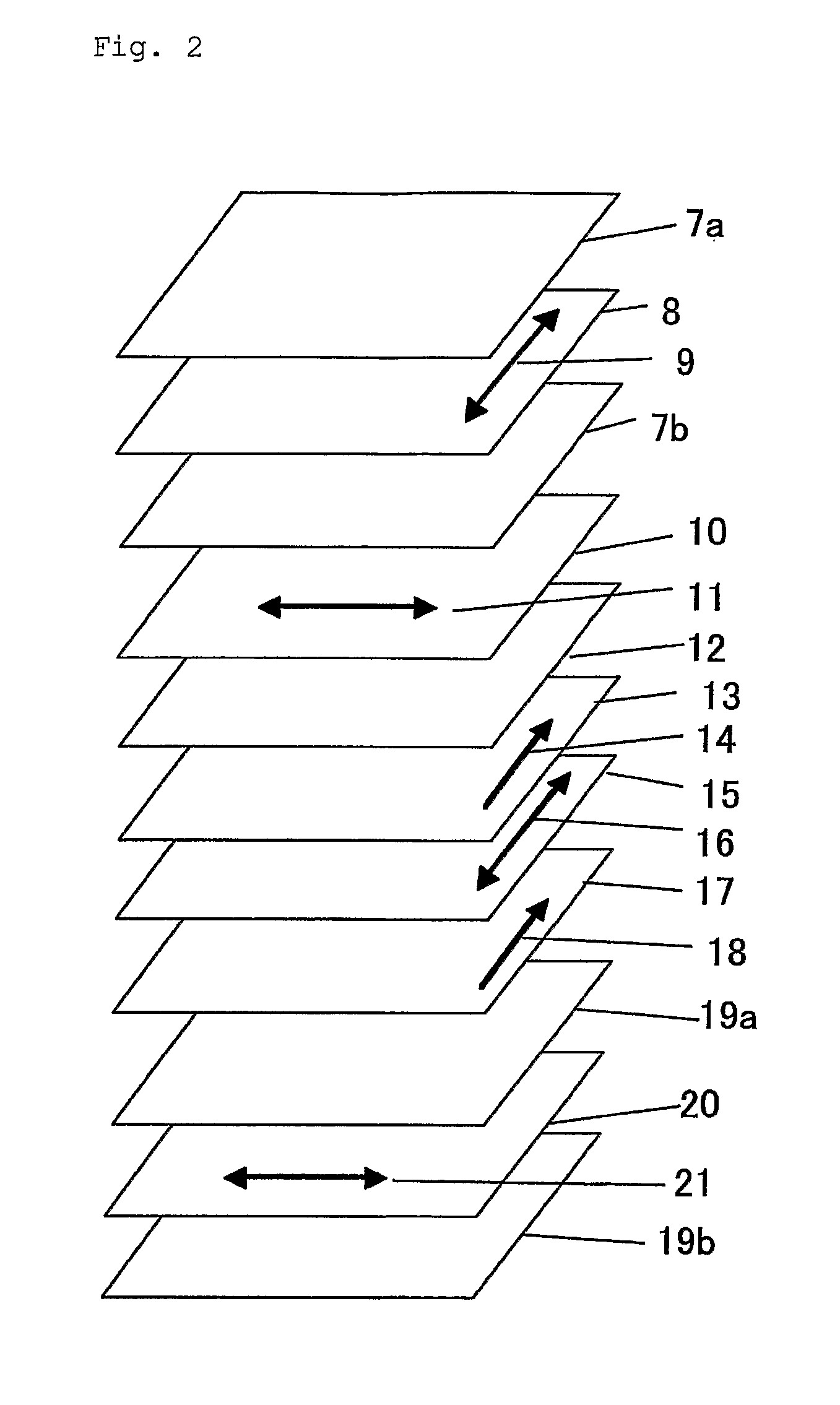

Liquid-crystal display device and method of fabricating the same

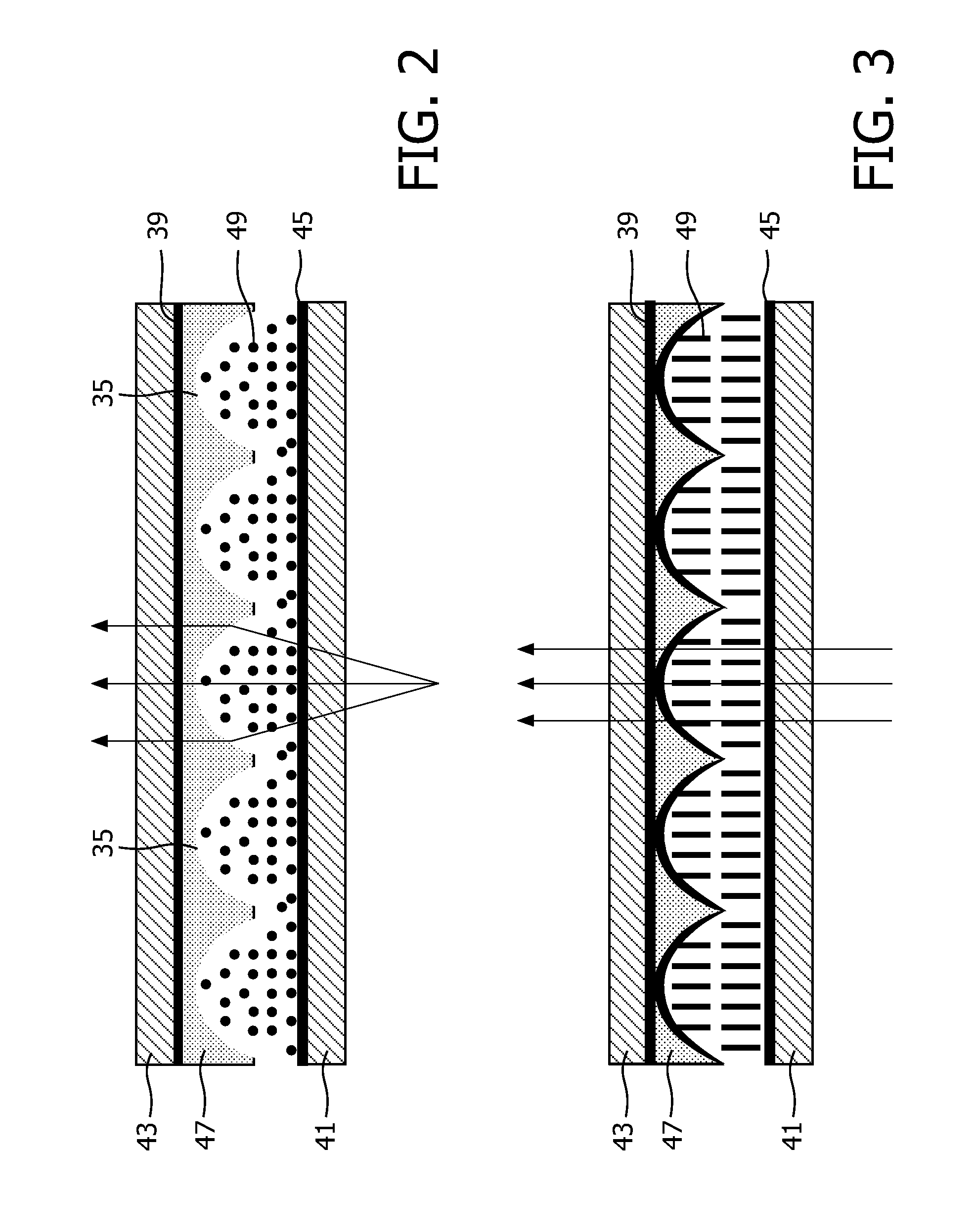

InactiveUS6924856B2Improve quick response characteristicsReduce viewLiquid crystal compositionsDiffusing elementsLiquid-crystal displayPolarizer

A LCD device is provided. On the input side, the collimated-light generator generates collimated light from incident light and then, the first polarizer plate of the first polarized-light controller generates first polarized light from the collimated light. The first quarter wavelength plate of the first polarized-light controller generates second polarized light from the first polarized light. The second polarized light thus generated passes through the liquid crystal layer to reach the output side. On the output side, the second polarized light passes through the second quarter wavelength plate of the second polarized-light controller and the second quarter wavelength plate thereof. Thus, the polarization state of the second polarized light is returned to its original one.

Owner:NEC LCD TECH CORP

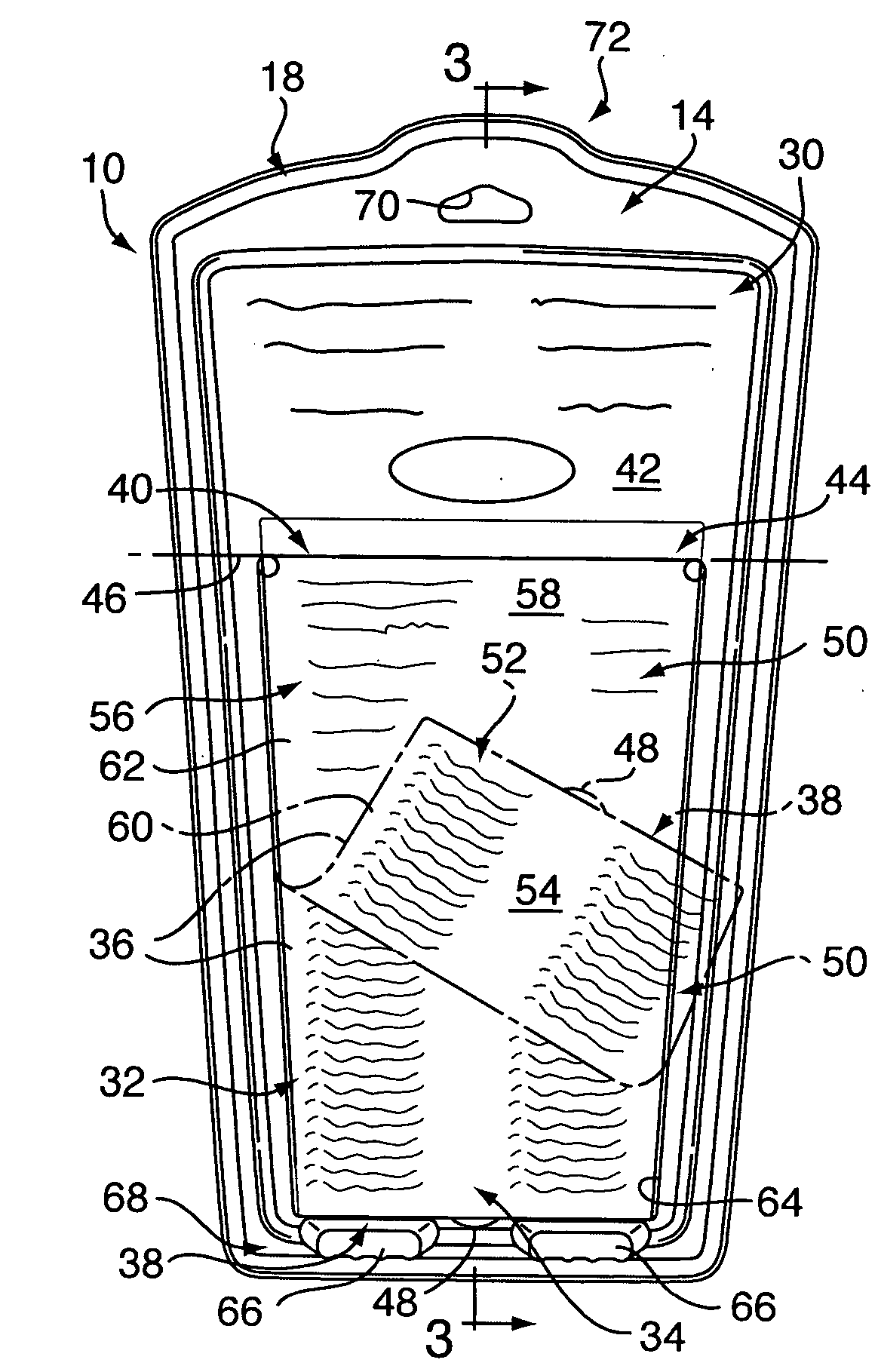

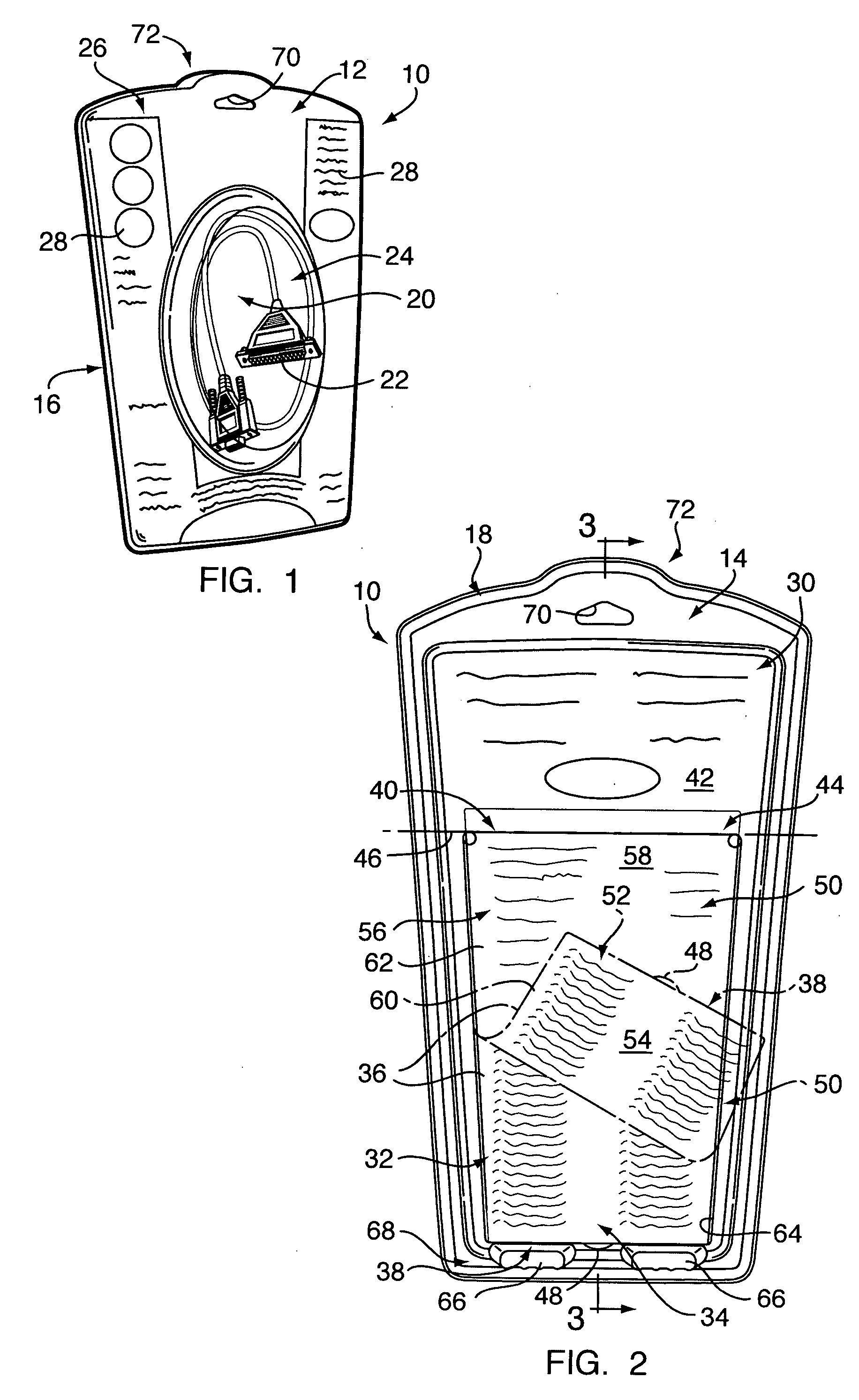

Packaging with increased viewing area

Packaging made of a suitable see-through material is configured and arranged as a sealed enclosure with an interior cavity for holding a desired article for display through a viewing window. A flap body is made of a see-through flexible, somewhat resilient material and overlies at least a portion of the surface of the enclosure obscuring the portion in an unlifted state. The flap body bends or flips-up about a flexible hinge such that in a lifted state the inwardly facing surface of the flap body is available for viewing along with the obscured surface portion of the enclosure. Cardstock or other suitable sheet material upon which indicia may be printed or applied to both sides is carried in a pocket formed in the flap body such that in the unlifted position the indicia is viewable through the flap body outwardly facing surface and in the lifted position the indicia on the opposite side of the cardstock is viewable through the inwardly facing surface of the flap body along with the indicia on the obscured portion of the enclosure surface.

Owner:BLACKSTONE INT

Display panel

ActiveUS8199127B2Reduce viewEasy to detectTransmission systemsNon-linear opticsEngineeringTouch panel

A display panel is provided having a capacitive touch panel over a display region, wherein the capacitive touch panel comprises a plurality of X electrodes and a plurality of Y electrodes formed with an insulating layer there between and in a manner to cross each other, each of the X electrodes and the Y electrodes is formed such that a pad portion and a narrow line portion are alternately placed in a direction of extension, and when viewed from top, the pad portion of the X electrode and the pad portion of the Y electrode are placed to not overlap each other and a dummy electrode which is in a floating relationship with the X electrode and the Y electrode is formed between the pad portion of the X electrode and the pad portion of the Y electrode.

Owner:JAPAN DISPLAY INC +1

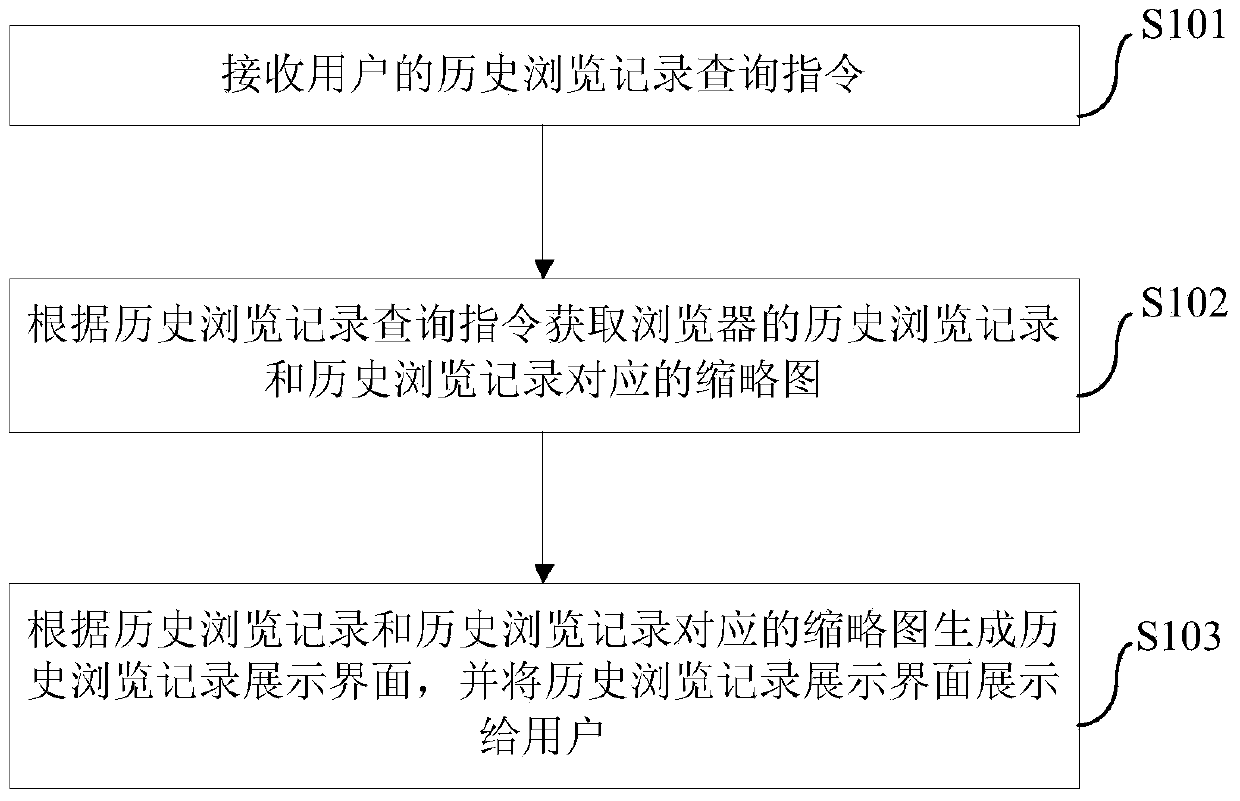

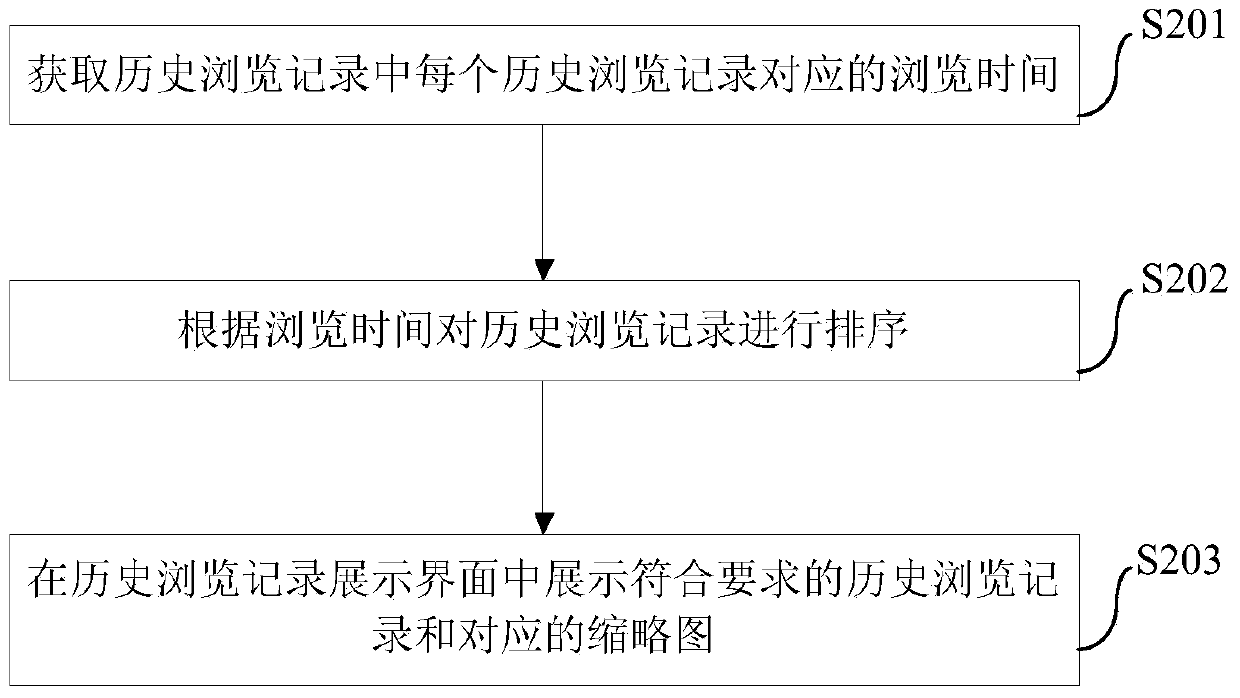

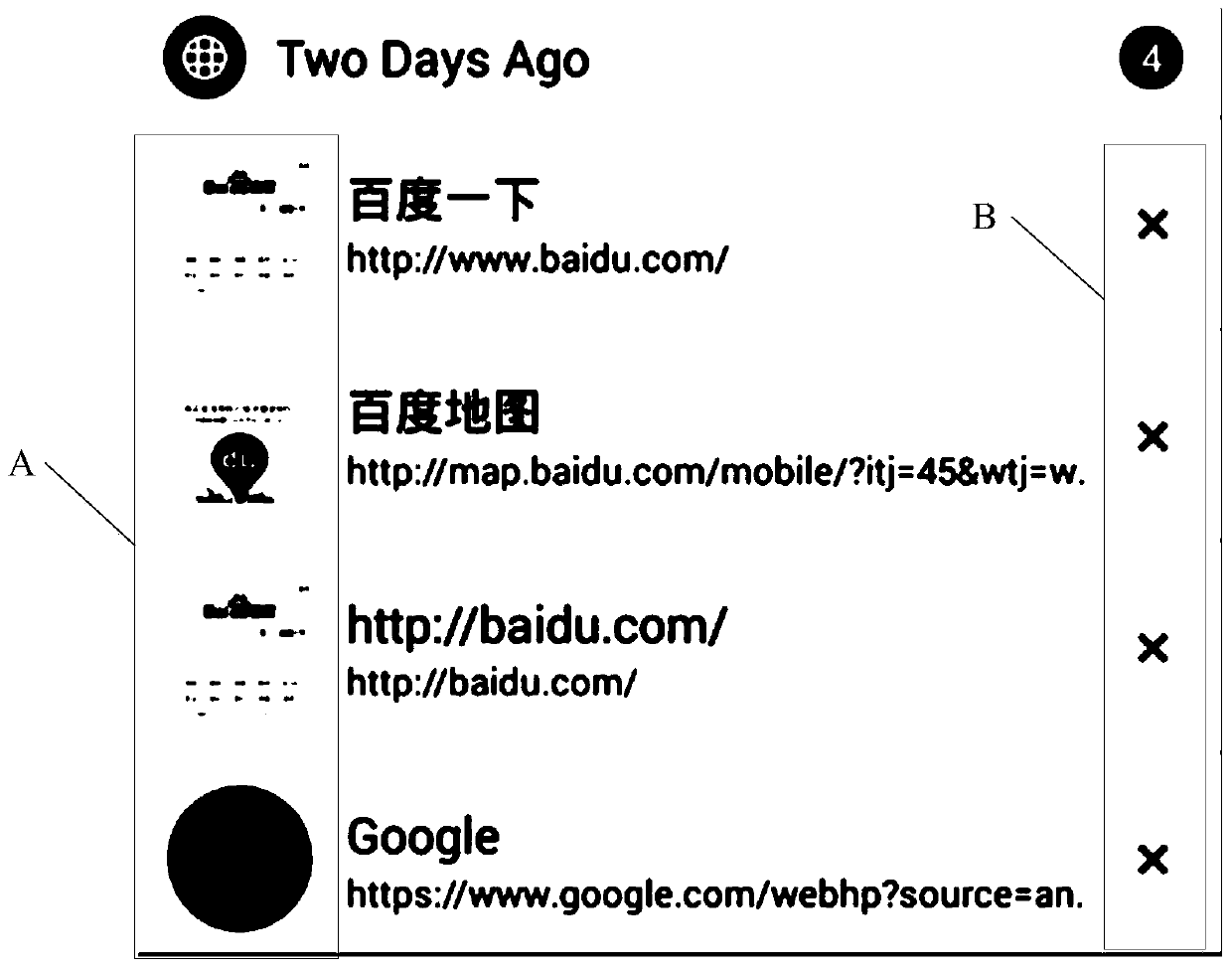

Management method and device for browsing history and mobile terminal

InactiveCN104216967AReduce viewReduce difficultySpecial data processing applicationsThumbnailLibrary science

The invention discloses a management method and device for browsing history and a mobile terminal. The method comprises the following steps: receiving the browsing history inquiry command of a user; acquiring the browsing history of a browser and a thumbnail which corresponds to the browsing history according to the browsing history inquiry command; generating a browsing history display interface according to the browsing history and the thumbnail which corresponds to the browsing history, and showing the browsing history display interface to the user. By adopting the management method for the browsing history in the embodiment of the invention, the user can obtain the detail of the browsing history through the thumbnail which corresponds to the browsing history and can rapidly search for the browsing history from a large amount of browsing history, so that the difficulty in looking up and searching for the browsing history is lowered greatly, the look-up cost of the user is lowered, and the user experience is improved.

Owner:BEIJING KINGSOFT INTERNET SECURITY SOFTWARE CO LTD

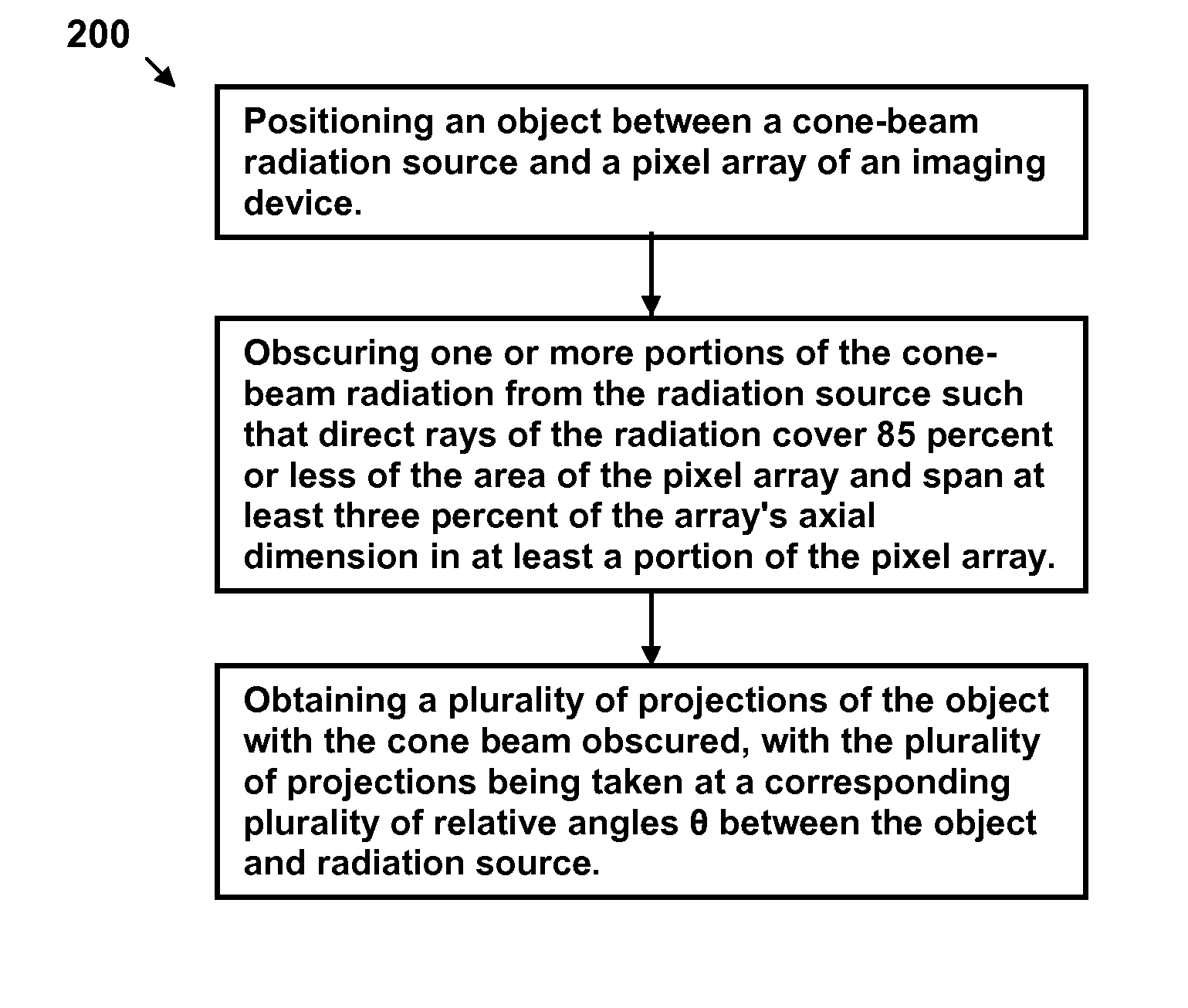

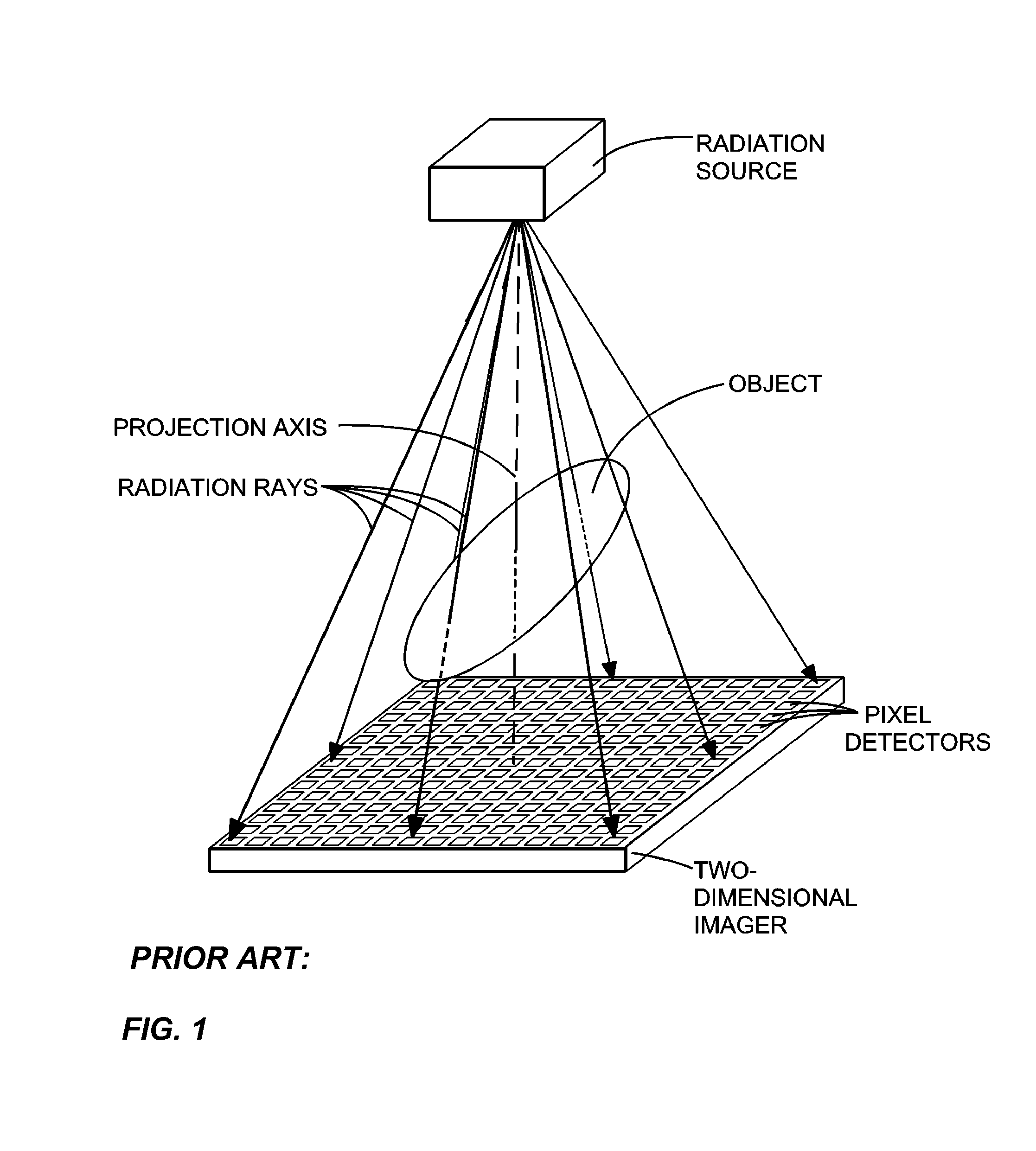

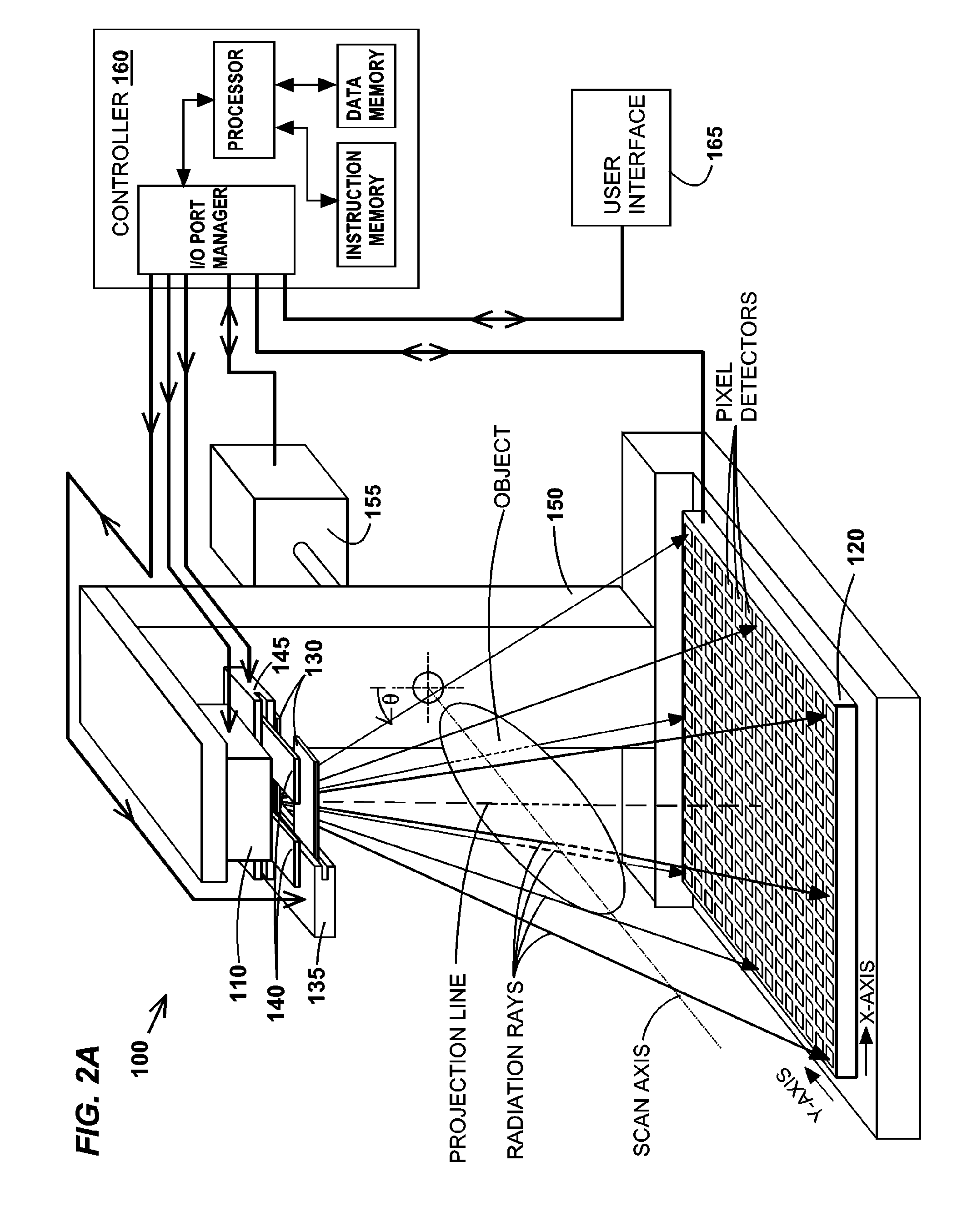

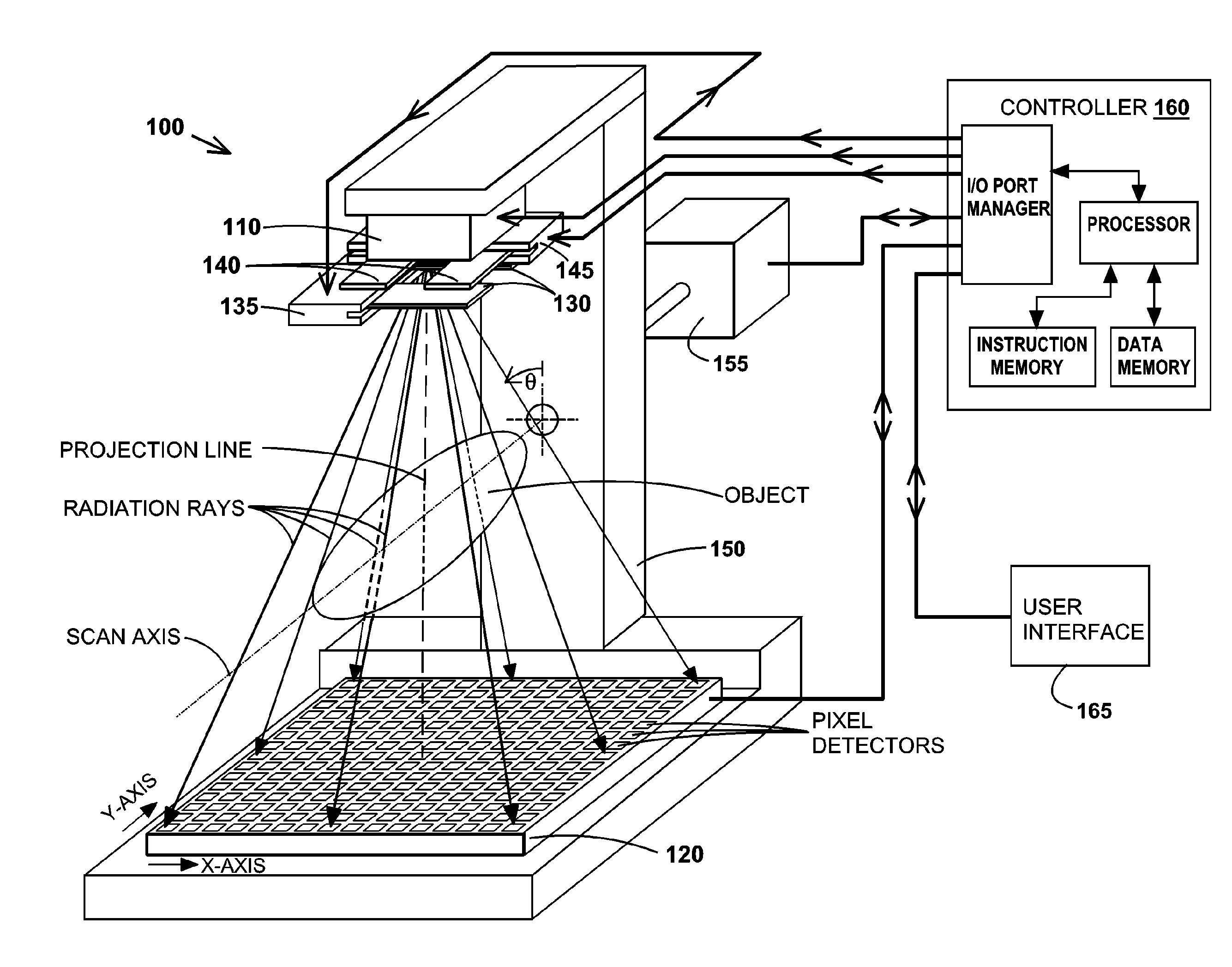

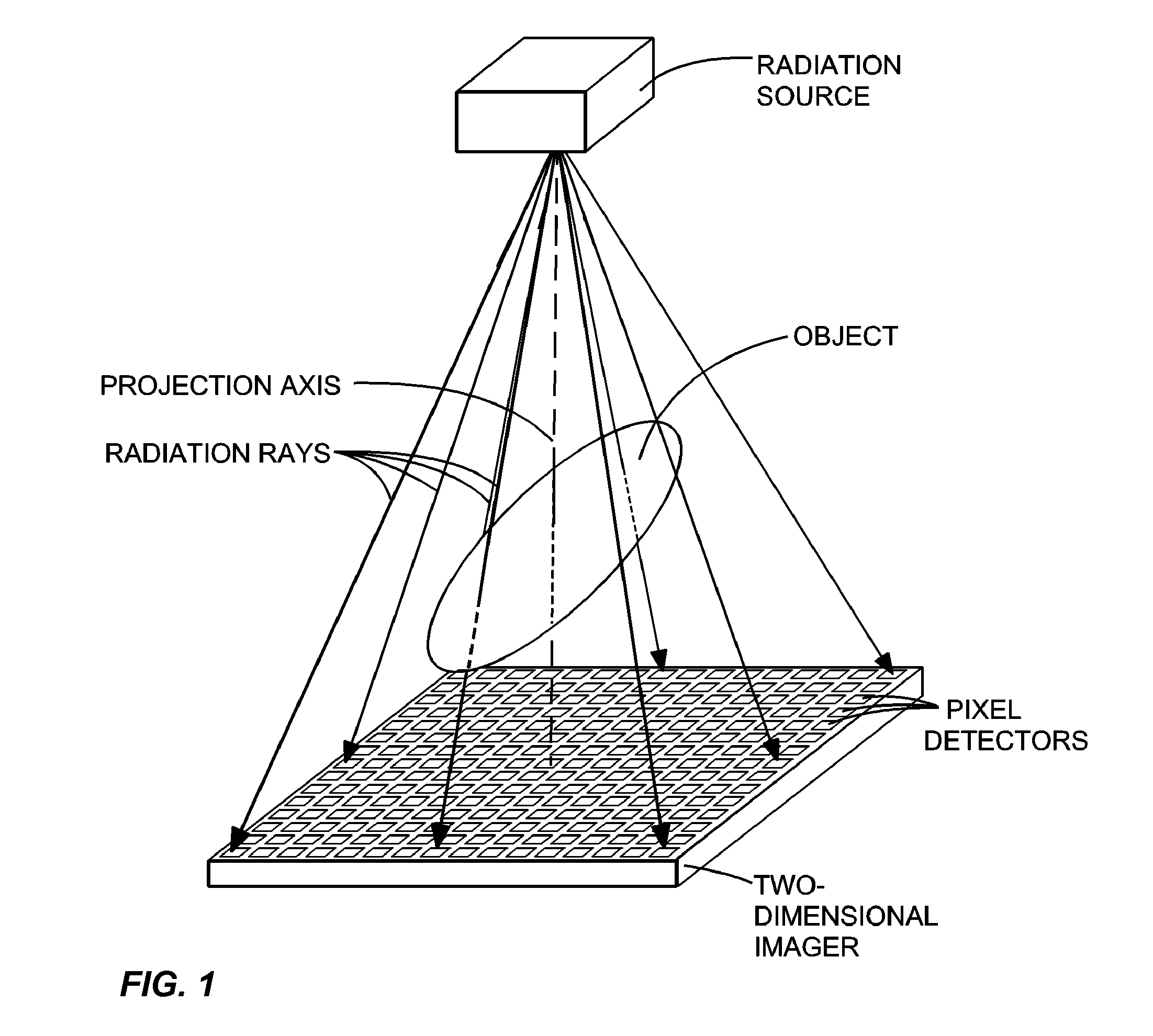

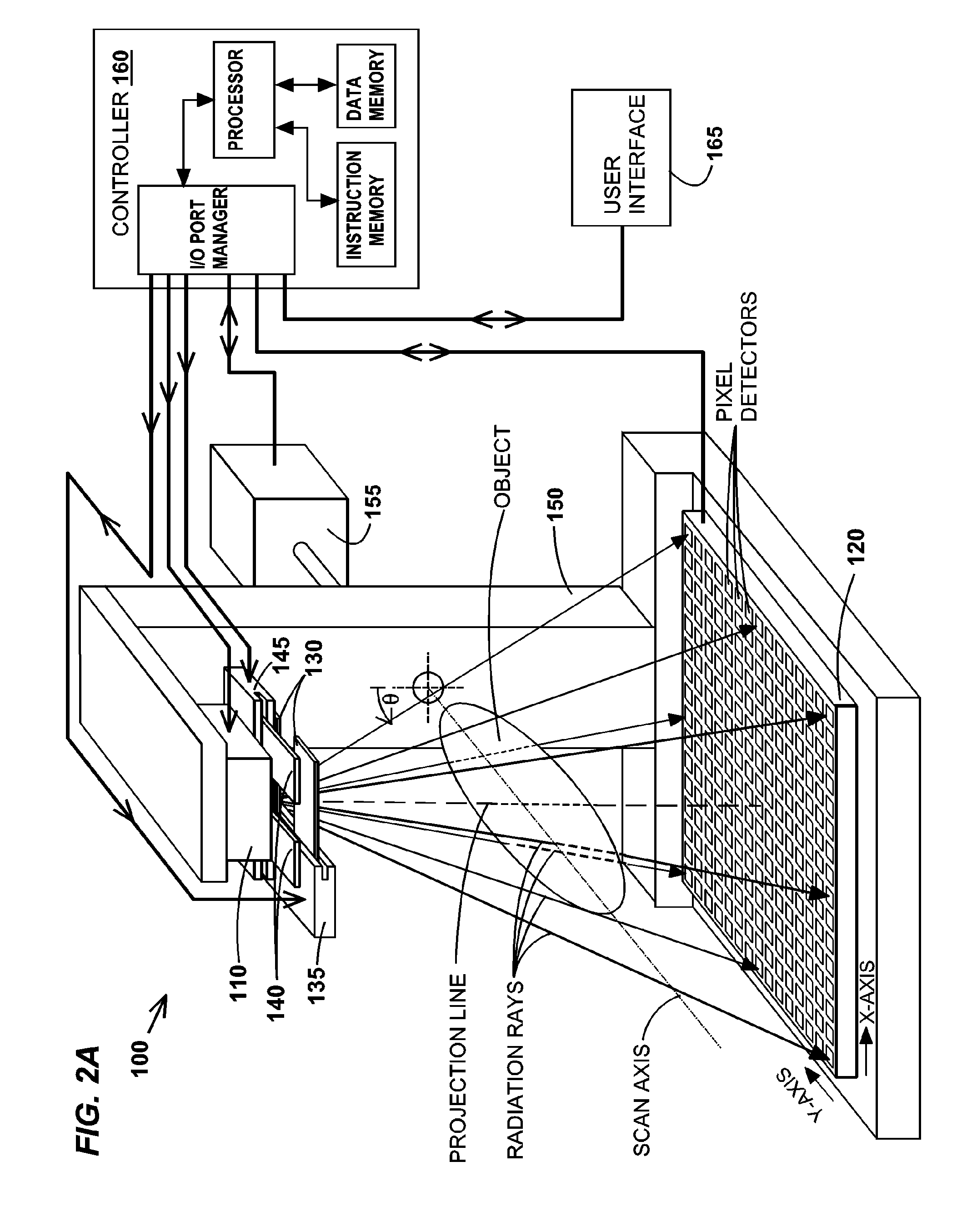

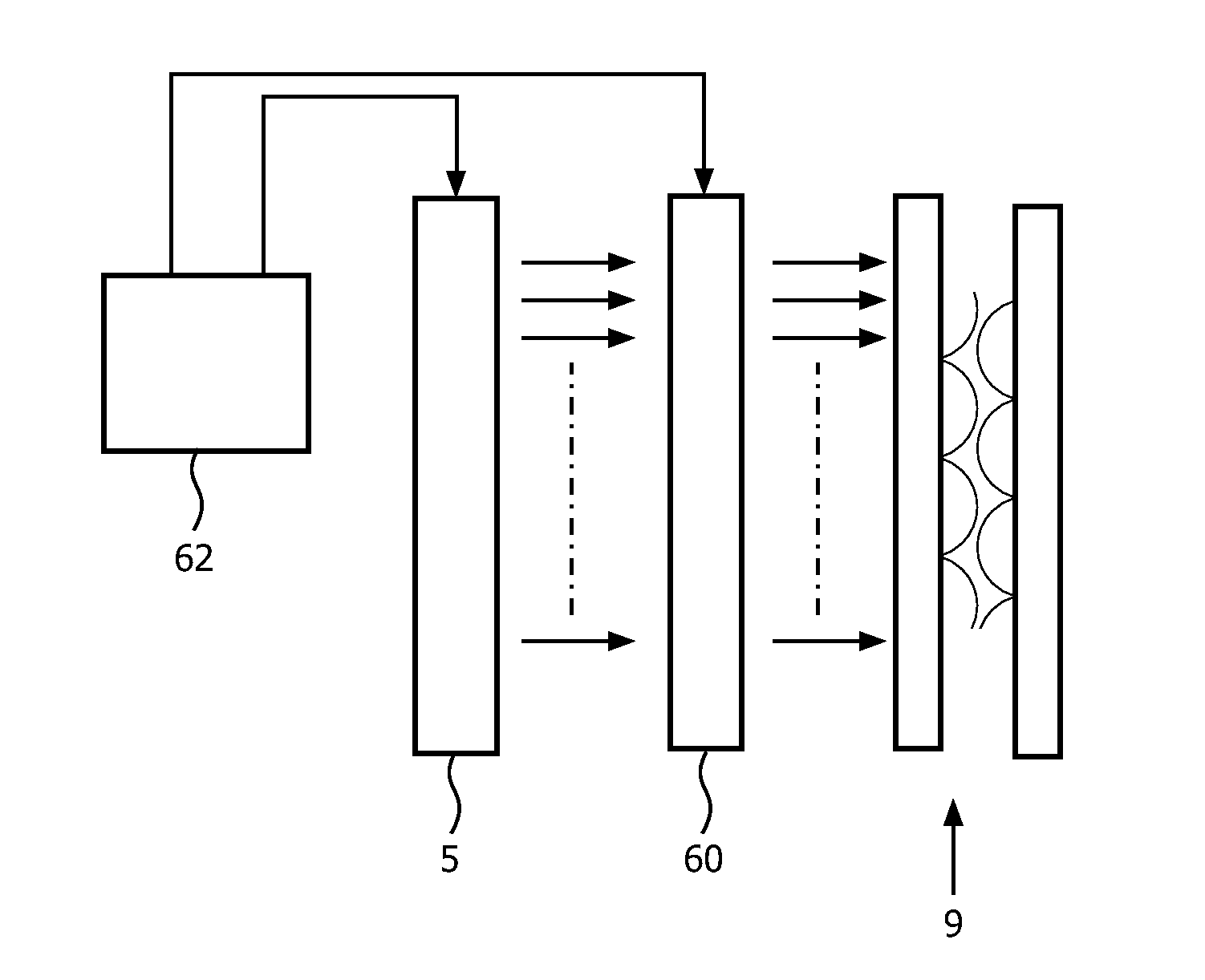

Methods, apparatus, and computer-program products for increasing accuracy in cone-beam computed tomography

ActiveUS8009794B2Reduce errorsImprove accuracyMaterial analysis using wave/particle radiationHandling using diaphragms/collimetersSources of errorTomography

Disclosed are methods, systems, and computer-product programs for increasing accuracy in cone-beam computed tomography (CBCT) by obscuring portions of the radiation source so that the radiation only passes through the specific areas of the patient related to the regions-of-interest to the doctor. The obscuring action causes less radiation scattering to occur in the patient's body, thereby reducing a major source of error in the image accuracy caused by scattered radiation. Scattered radiation received by detector pixels that are obscured by direct-line of sight radiation may be used to estimate the scattered radiation in the un-obscured portion, which can be used to further increase the accuracy of the image.

Owner:VARIAN MEDICAL SYSTEMS

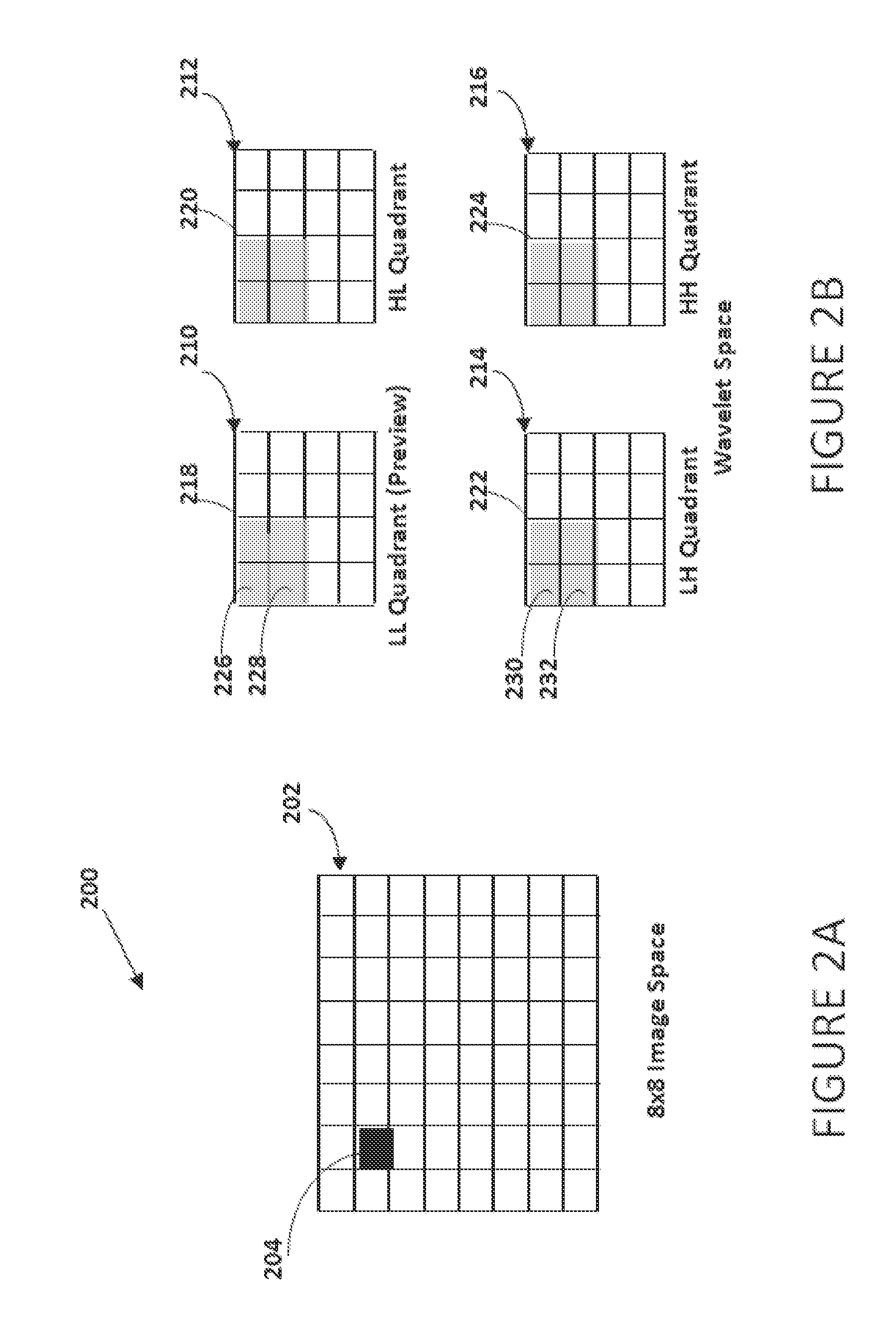

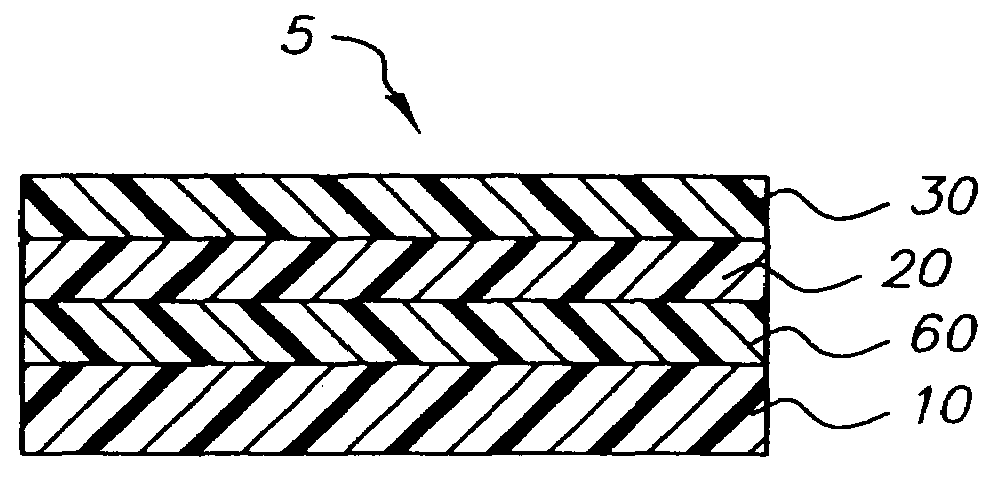

Systems and methods for wavelet and channel-based high definition video encoding

InactiveUS20120183073A1High HD quality-preserving compressionEasy to compressColor television with pulse code modulationColor television with bandwidth reductionData streamCompressibility

A wavelet transform (WT) is applied to a data stream of high definition video frames, each comprising one or more data channels digitally representing the same image. A WT is applied to each channel. Visual-quality preserving data filters and data substitution techniques are selectively applied that typically lead to at least 90-to-1 compression of the final encoded video frame. Image edge data is extracted and preserved and image noise is reduced to enhance compressibility. After the first WT, primarily low frequency (LL) image data is retained. With each later WT, more non-LL data is retained. Temporal sequences of LL images that result from the final iteration of the wavelet transform are compressed by means of a chain of invertible differenced images. Any color space can be used. Cross-channel conditional substitution is applicable. Complete multiresolution scalability is incorporated into the encoded product. Extra-high definition video encoding is also achievable.

Owner:EXAIMAGE CORP

Optical film and liquid crystal display using the same

InactiveUS7208205B2Minimizes problemImprove waterproof performanceLiquid crystal compositionsSynthetic resin layered productsCelluloseLiquid-crystal display

A film for a liquid crystal display comprising a fatty acid cellulose ester film having an acetyl group and a propionyl group is disclosed. Sum of degree of acetyl substitution (DSac) and degree of propionyl substitution (DSpr) of the fatty acid cellulose ester film of the film is 2.8 or less, and a retardation value (Rt value) in the thickness direction define by Formula 1 is 60 to 300 nm.

Owner:KONICA CORP

Methods, Apparatus, and Computer-Program Products for Increasing Accuracy in Cone-Beam Computed Tomography

ActiveUS20090190714A1Reduce errorsImproving Imaging AccuracyMaterial analysis using wave/particle radiationHandling using diaphragms/collimetersComputer scienceCone beam computed tomography

Disclosed are methods, systems, and computer-product programs for increasing accuracy in cone-beam computed tomography.

Owner:VARIAN MEDICAL SYSTEMS

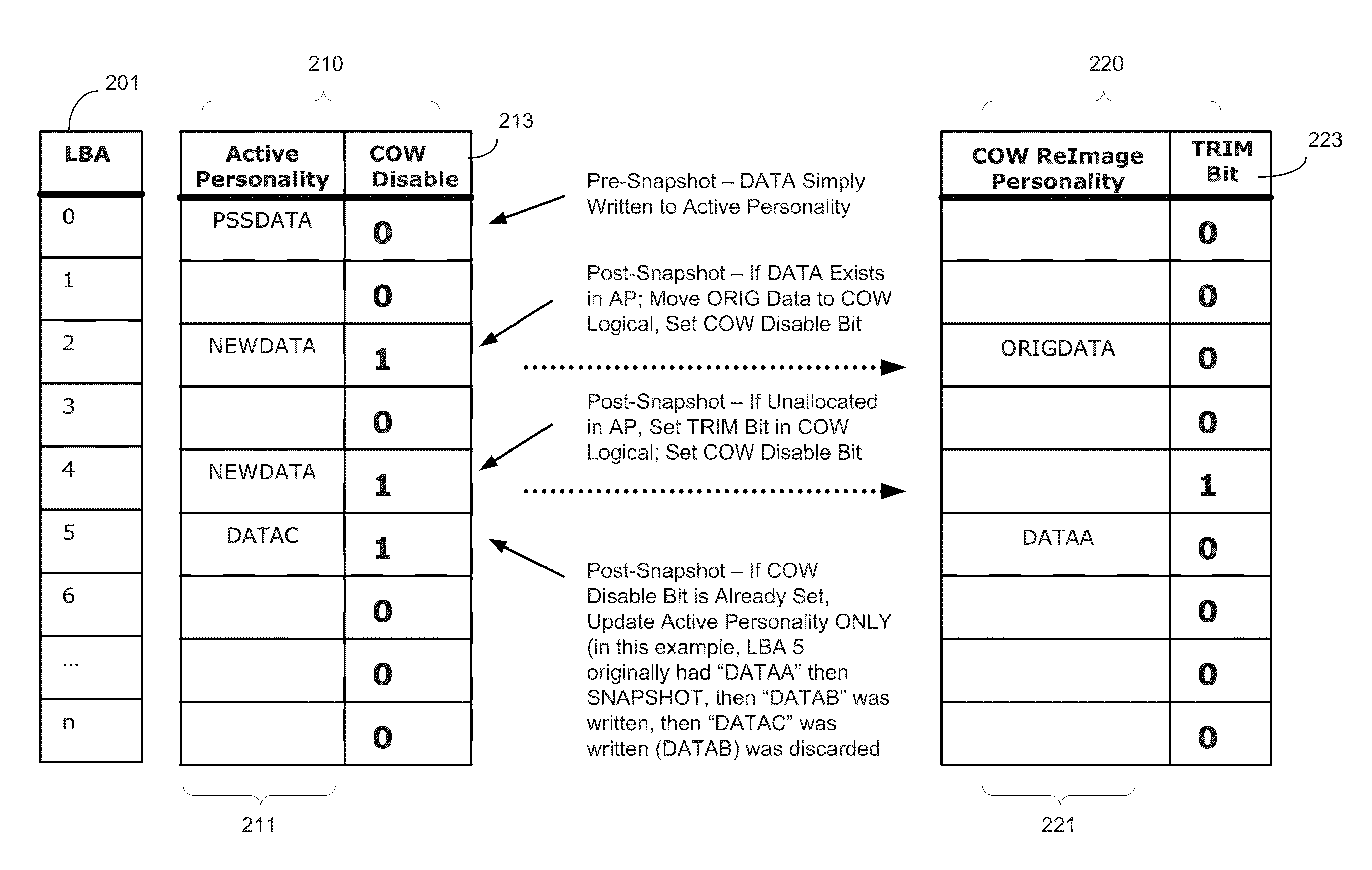

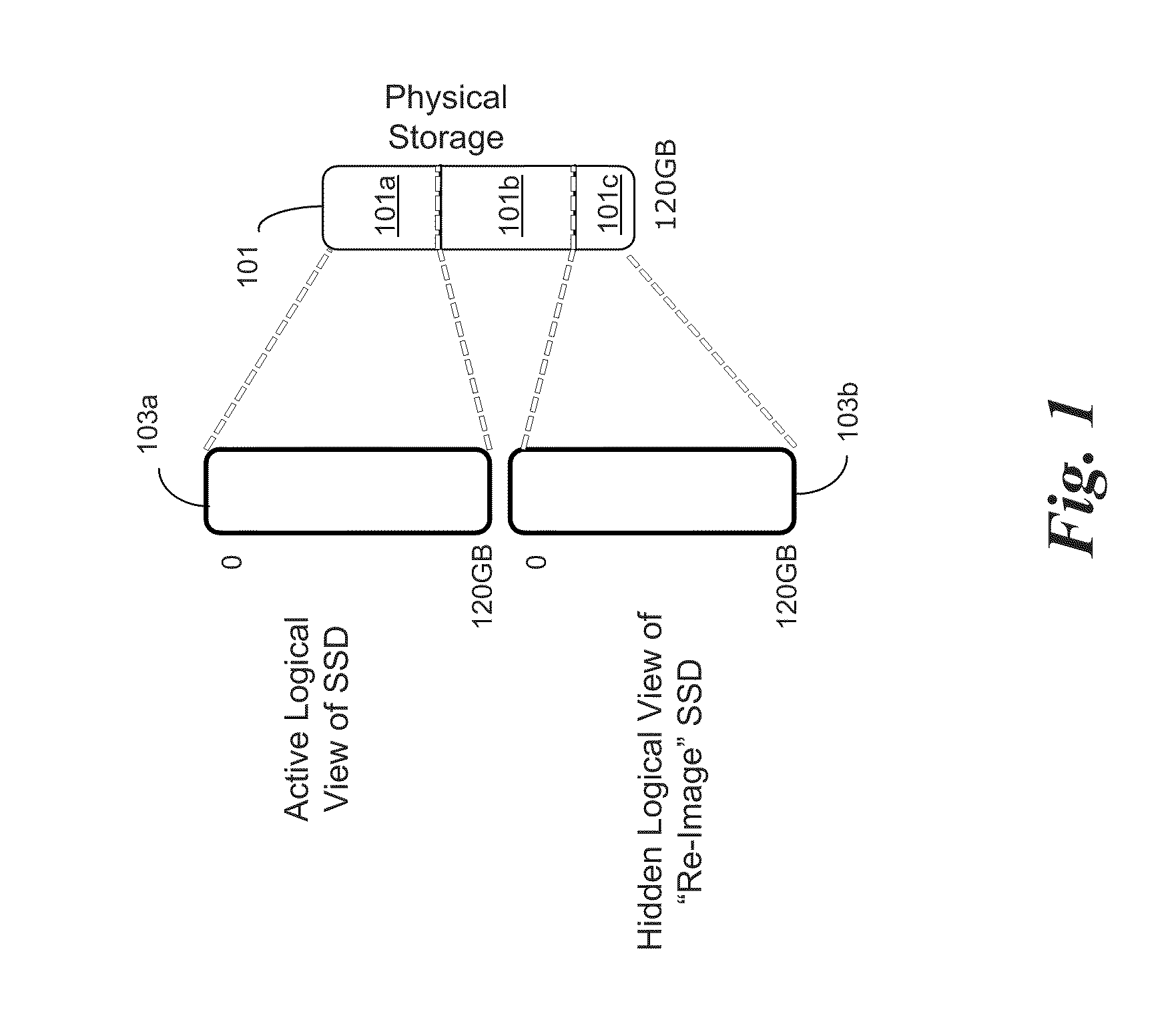

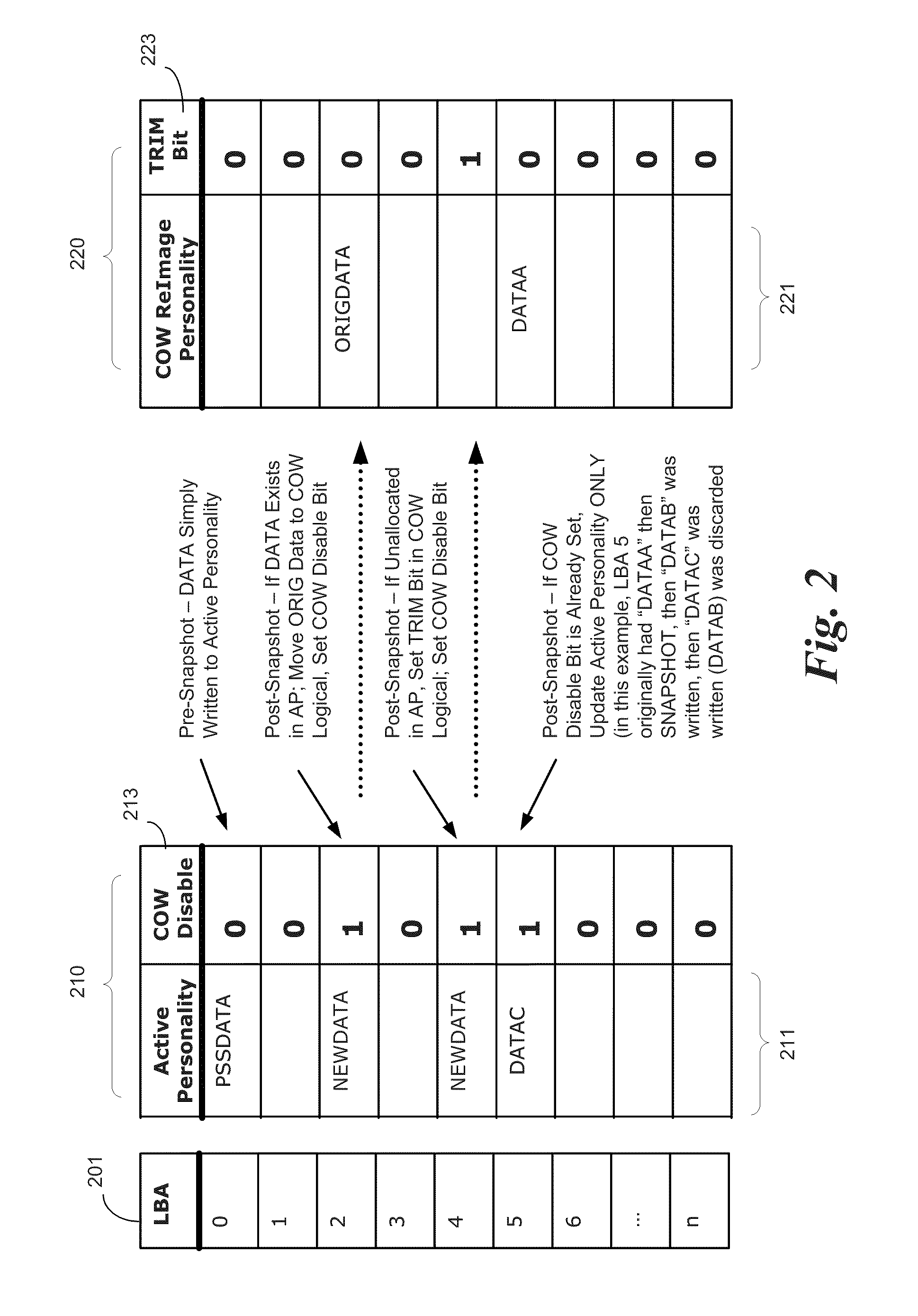

System and method for opportunistic re-imaging using cannibalistic storage techniques on sparse storage devices

InactiveUS20110161298A1Increase spacingReduce viewMemory loss protectionDigital data processing detailsCopy-on-writeSolid-state storage

In some embodiments, the invention involves a system and method for instant re-imaging of a computing device using a sparse storage partition of dynamically variable size to hold re-imaging data. An embodiment uses a solid state storage device to hold the binary image, or re-imaging personality. An embodiment uses copy on write methodology to maintain the re-imaging personality. An embodiment allows the primary, or active, personality to cannibalize storage used for a re-imaging personality when additional storage is required. The state of a computing device may be switched to allow or prohibit re-imaging, or to prohibit cannibalization of storage. Other embodiments are described and claimed.

Owner:INTEL CORP

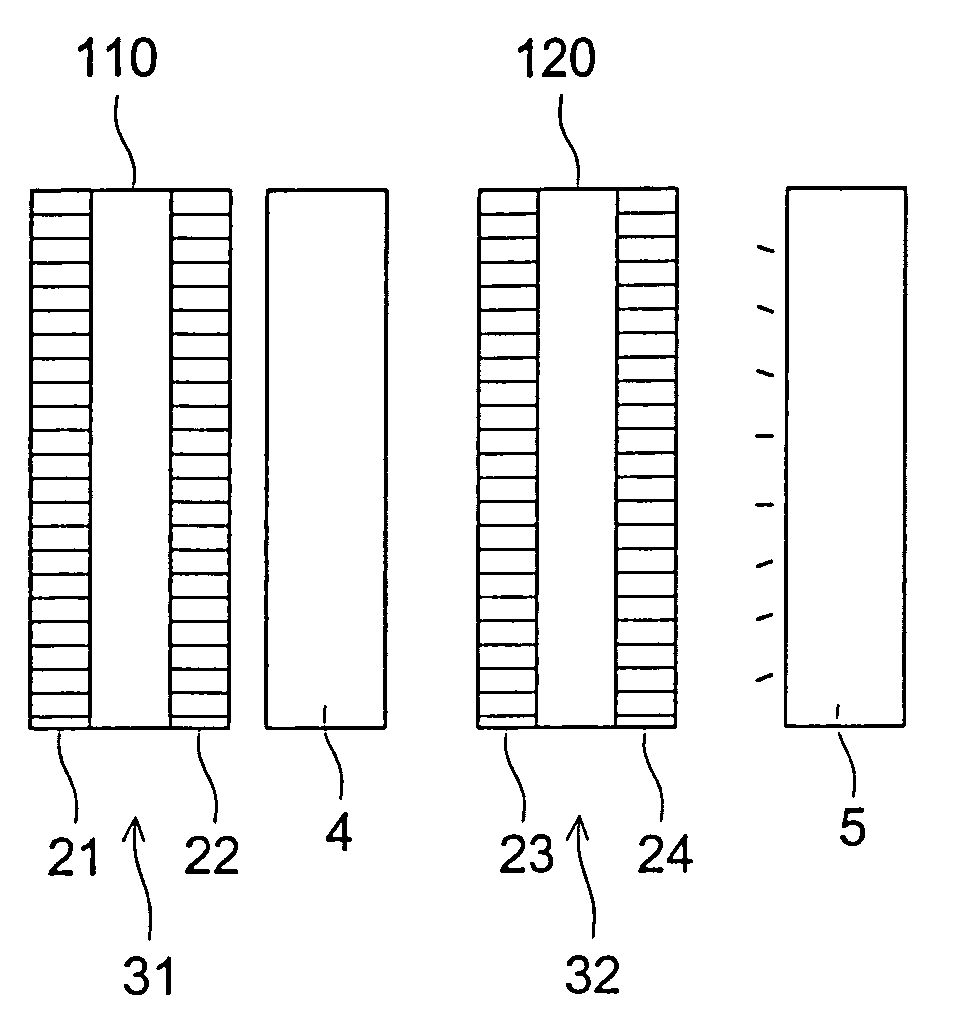

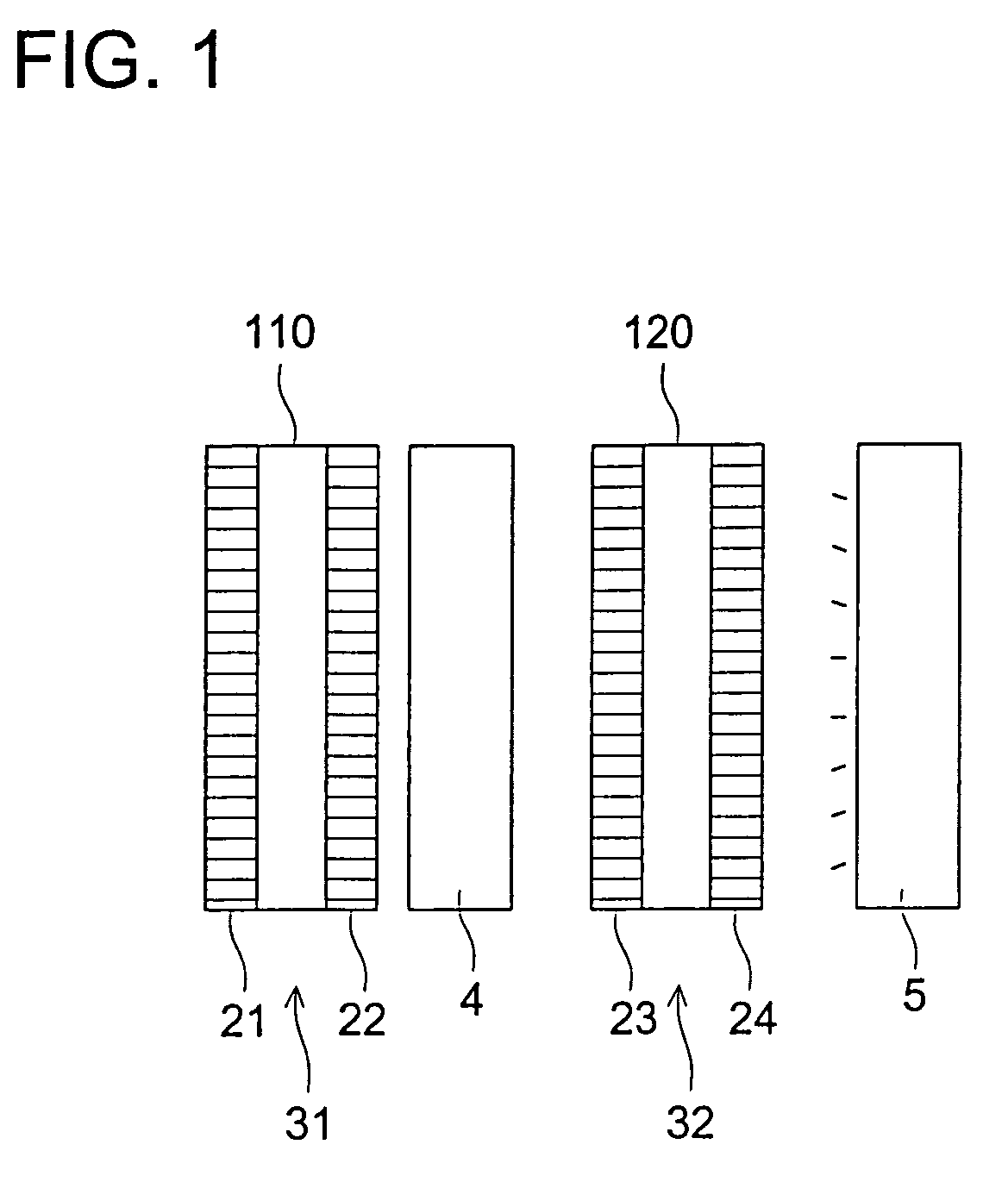

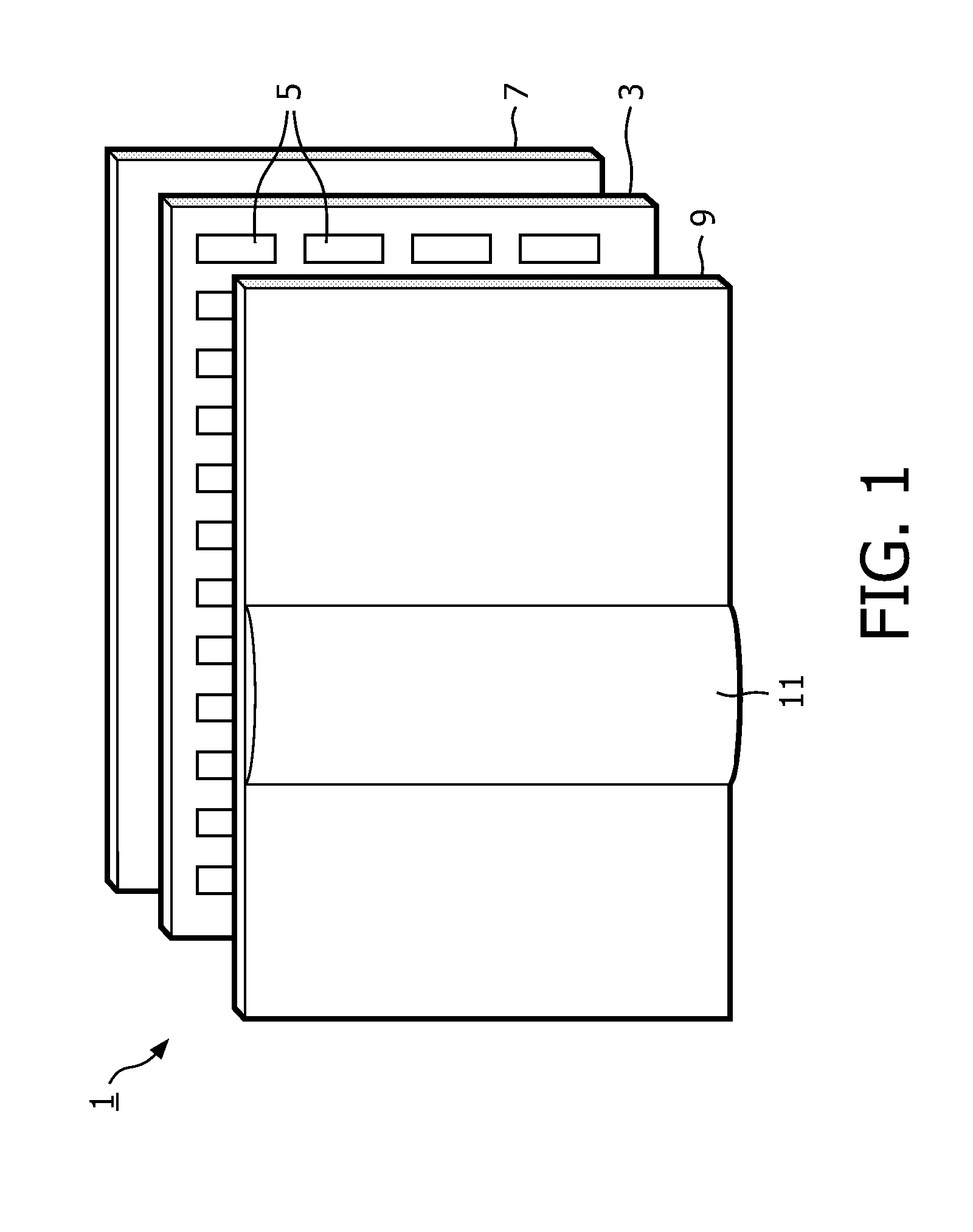

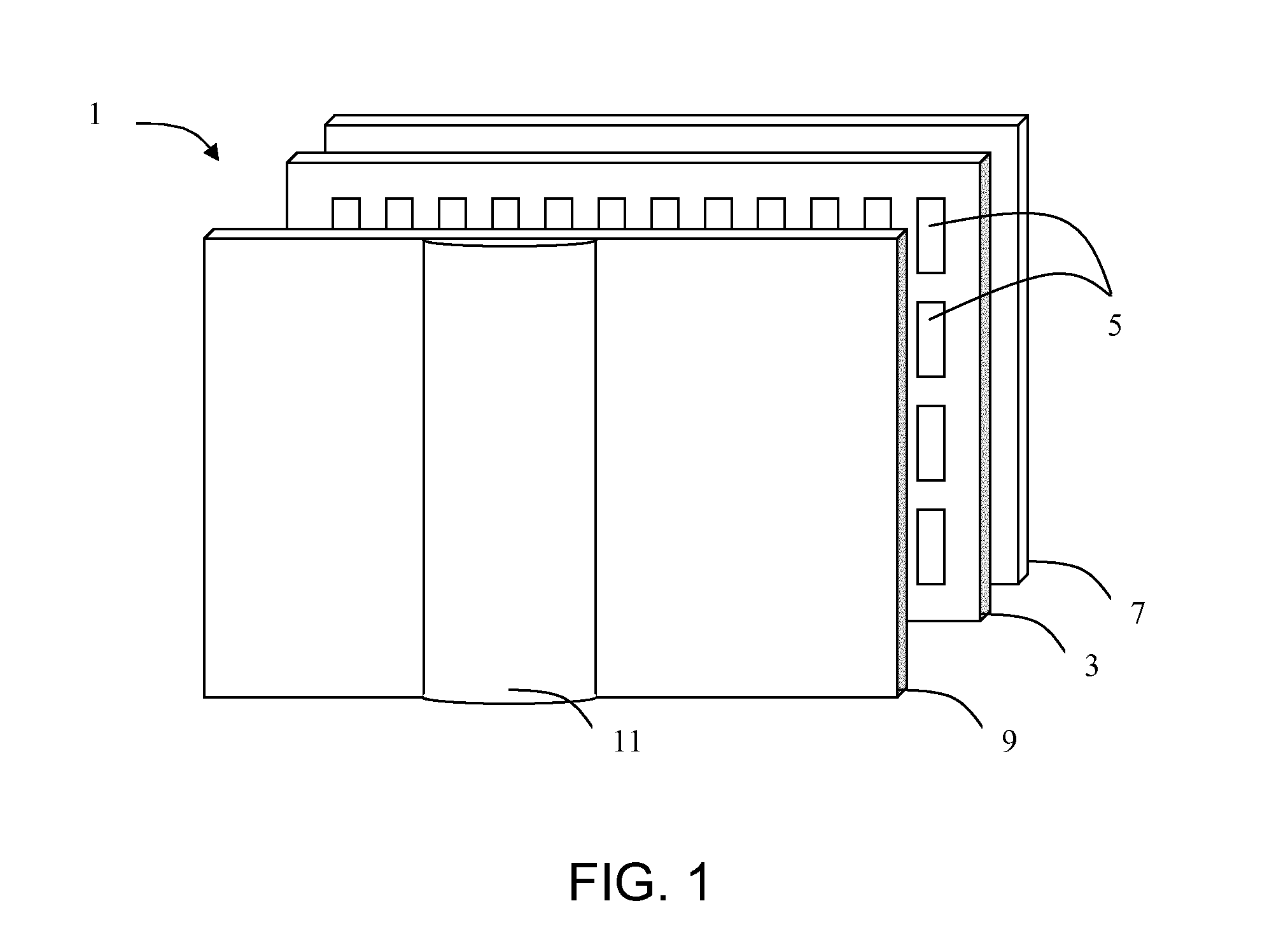

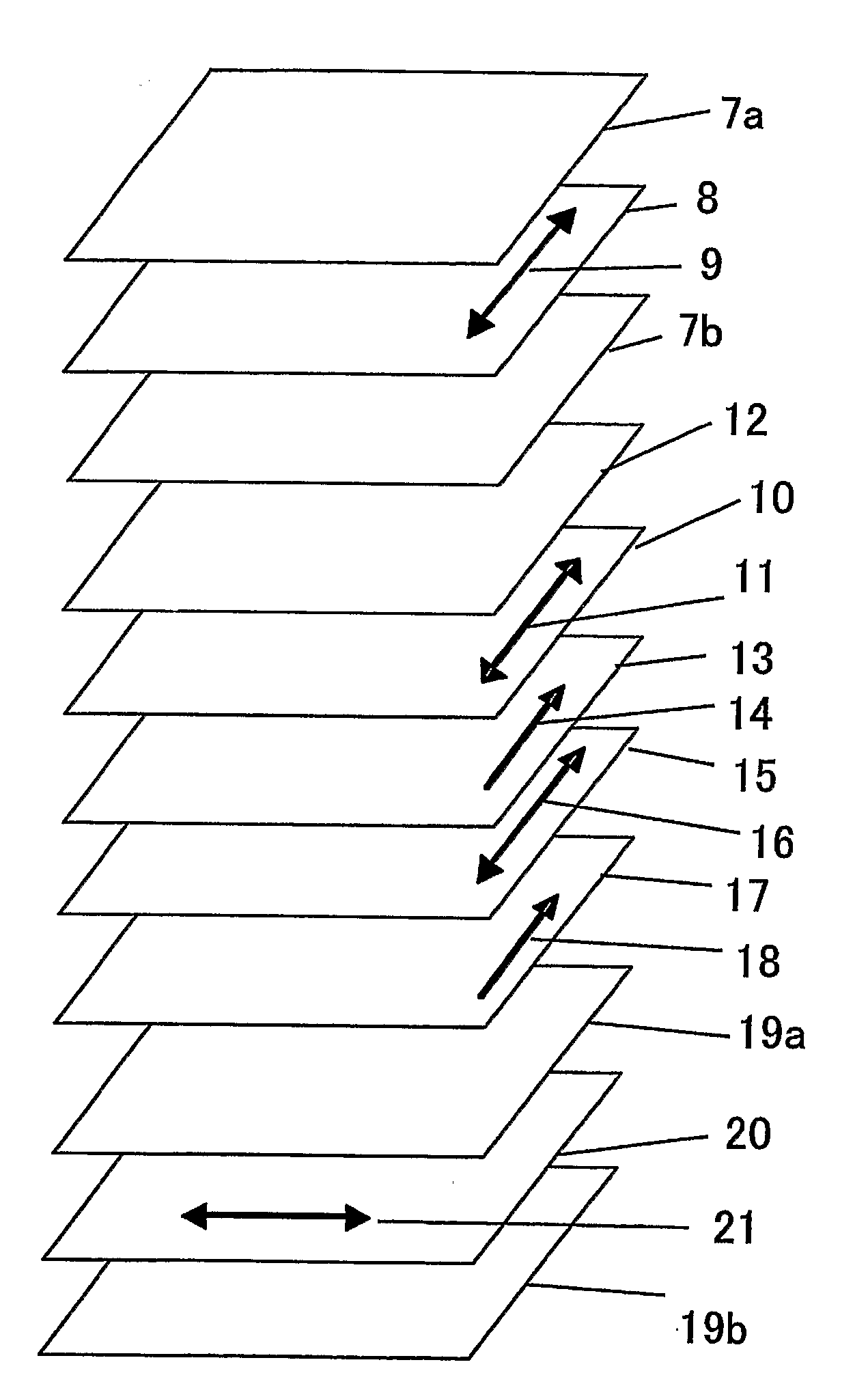

Multi-view autostereoscopic display device

InactiveUS20120092339A1Increase output resolutionReduce bandingSteroscopic systems3D-image renderingImage resolutionComputer graphics (images)

An autostereoscopic display device comprises a display panel (3) having an array of display pixel elements (5) for producing a display, the display pixel elements being arranged in rows and columns. An imaging arrangement (9) directs the output from different pixel elements to different spatial positions to enable a stereoscopic image to be viewed. The imaging arrangement comprises first and second polarization-sensitive lenticular arrays (50,52), wherein the light incident on the imaging arrangement is controllable to have one of two possible polarizations, and wherein each of the two possible polarizations gives a different 3D mode. These multiple modes can be used to increase the resolution, or increasing the number of views, or provide additional functionality to the display device.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

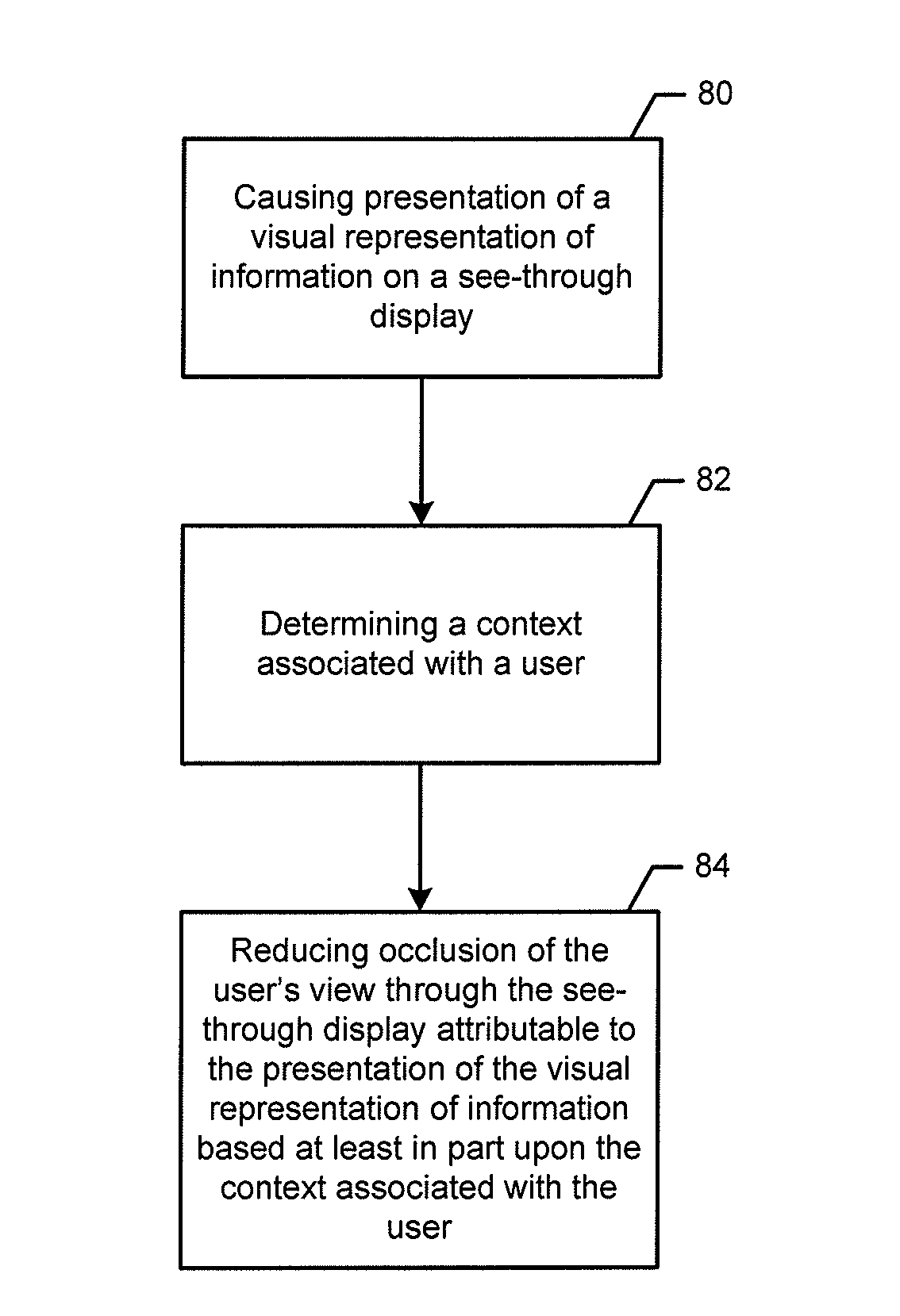

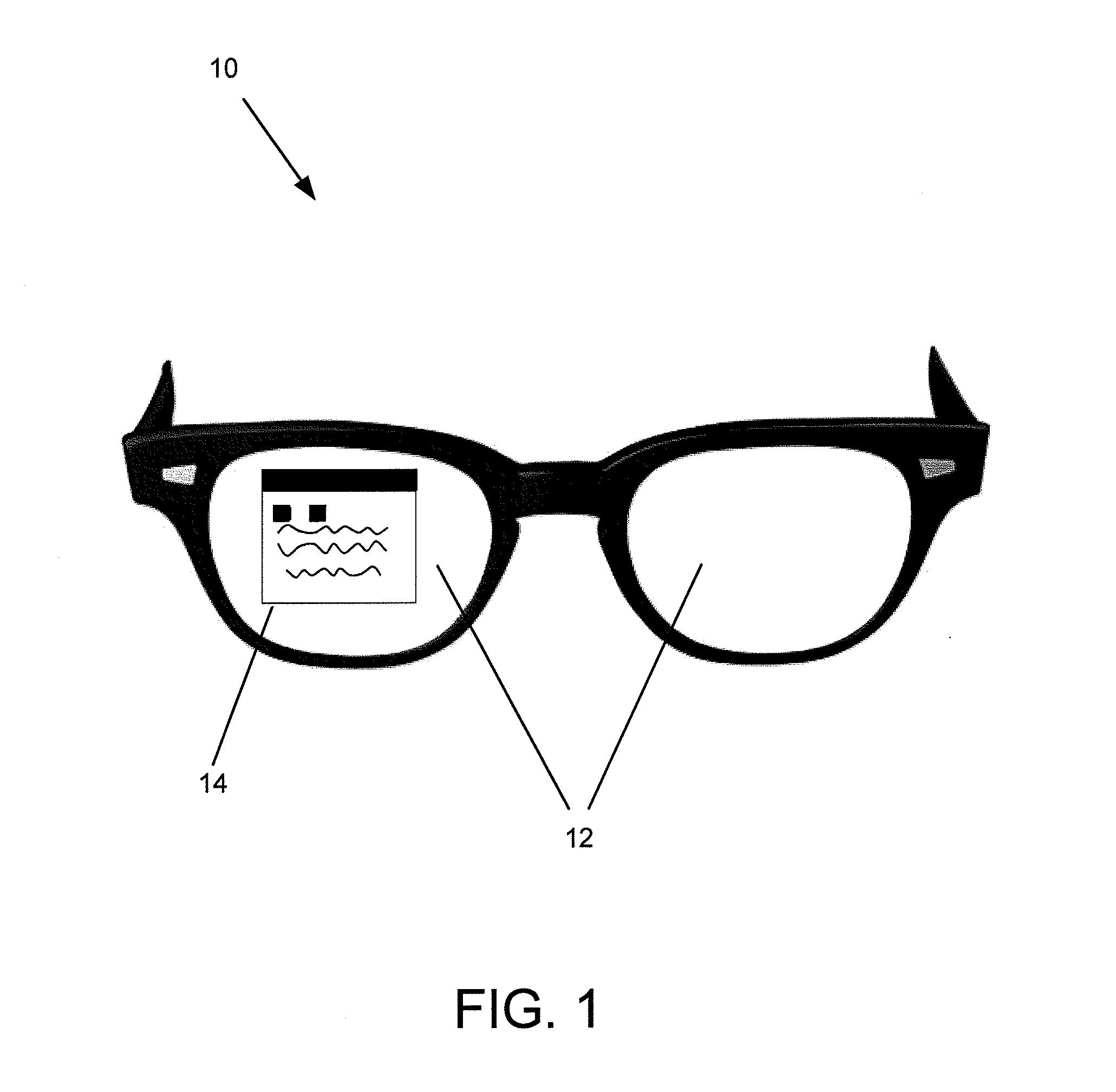

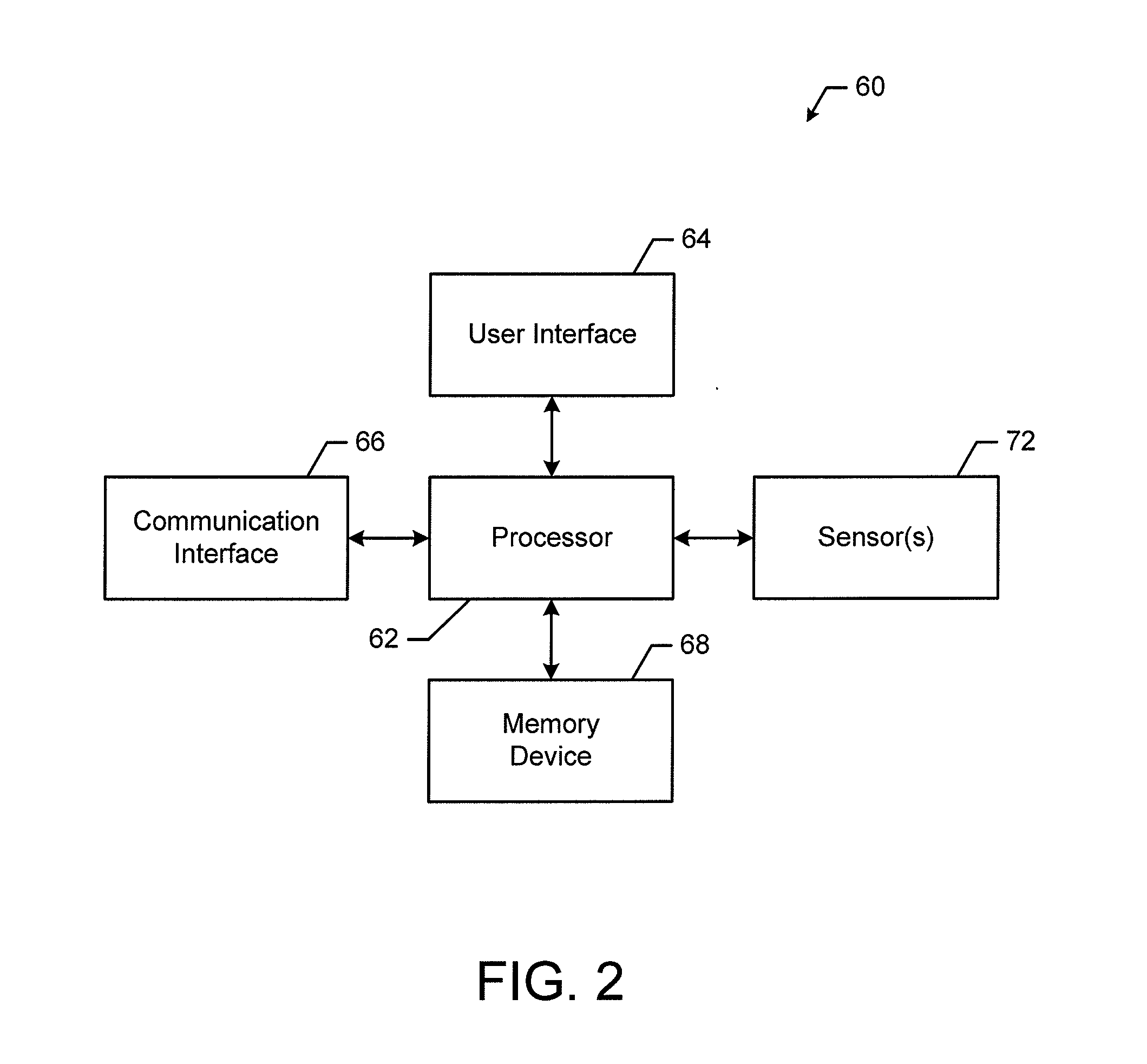

Method and apparatus for controlling the visual representation of information upon a see-through display

InactiveUS20130088507A1Reduce occlusionReduce opacityCathode-ray tube indicatorsOptical elementsDisplay deviceSee-through display

A method, apparatus and computer program product are provided for controlling the presentation of a visual representation of information upon a see-through display. In the context of a method, a visual representation of information is initially caused to be presented on a see-through display. At least a portion of the information at least partially occludes a user's view through the see-through display. The method also determines a context associated with the user. For example, the method may determine the context associated with the user by receiving data based upon an activity of the user and determining the activity performed by the user based upon the data. Regardless of the manner in which the context is determined, the method reduces occlusion of the user's view through the see-through display attributable to the visual representation of the information based at least in part on the context associated with the user.

Owner:NOKIA TECHNOLOGLES OY

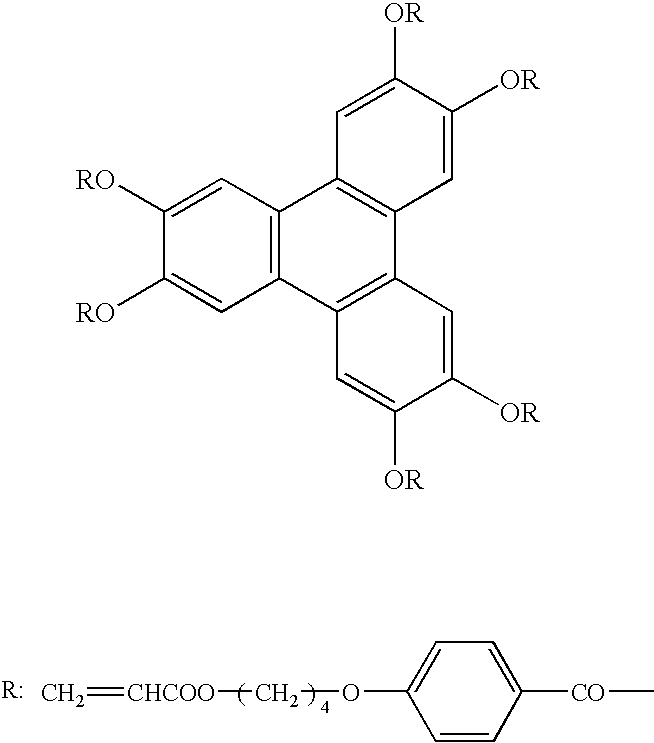

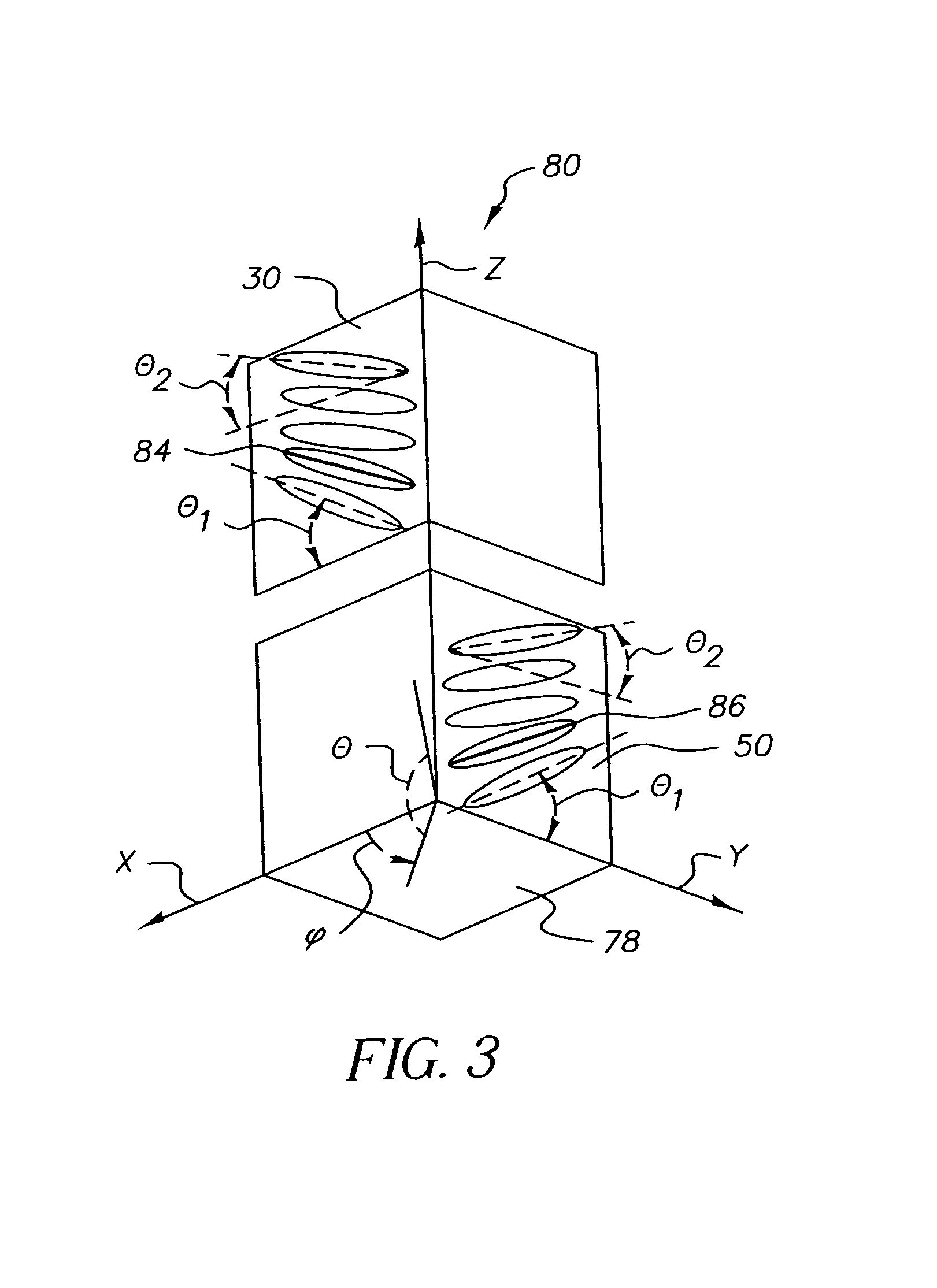

Composition, optical compensatory film and liquid crystal display

ActiveUS20050179004A1Reduce viewWiden perspectiveLiquid crystal compositionsPolarising elementsLiquid-crystal displayOnium

A composition comprising at least one compound having a fluoro-aliphatic group and at least one hydrophilic group selected from the group consisting of a carboxyl group (—COOH), a sulfo group (—SO3H), a sulfato group (—OSO3H), a phosphonoxy group {—OP(═O)(OH)2} and salts thereof; at least one onium salt; and at least one liquid-crystal compound is disclosed.

Owner:FUJIFILM CORP

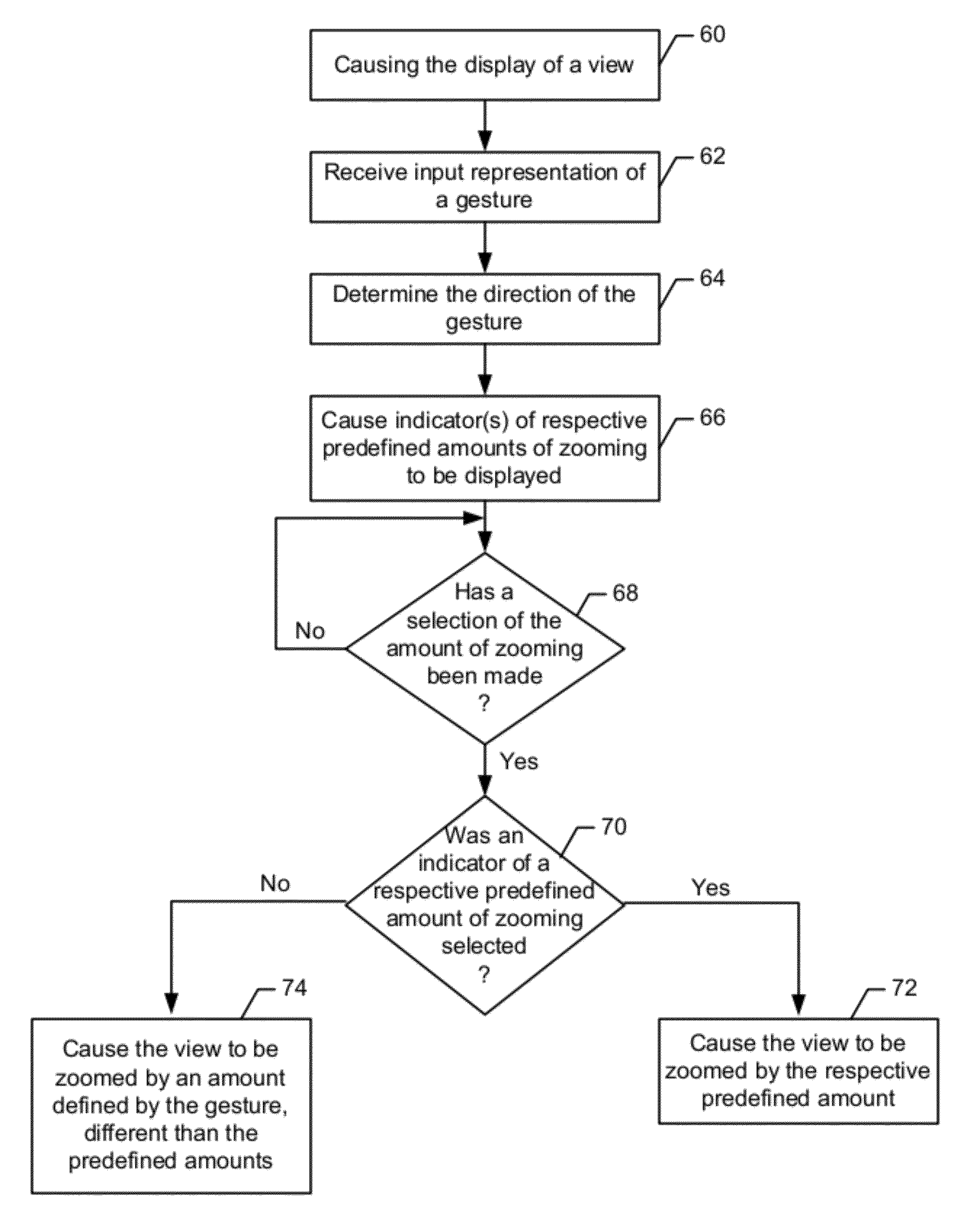

Method and apparatus for causing predefined amounts of zooming in response to a gesture

InactiveUS20120327126A1Reduce artifactsReduce viewCathode-ray tube indicatorsInput/output processes for data processingComputer scienceComputer program

A method, apparatus and computer program product are provided to permit a user to utilize a gesture, such as a pinching gesture, to select from among one or more predefined amounts of zooming. In the context of a method, the method may include receiving input representative of a gesture associated with zooming of a view and then causing one or more indicators of respective predefined amounts of zooming to be displayed in response to receiving the input. In response to selection of a respective indicator, the method may also cause the view to be zoomed in accordance with the predefined amount of zooming associated with the respective indicator.

Owner:NOKIA CORP

Communications device with extendable screen

ActiveUS9927839B2Reduce viewImprove portabilityDevices with multiple display unitsStatic indicating devicesGraphicsImage resolution

Owner:DISH TECH L L C

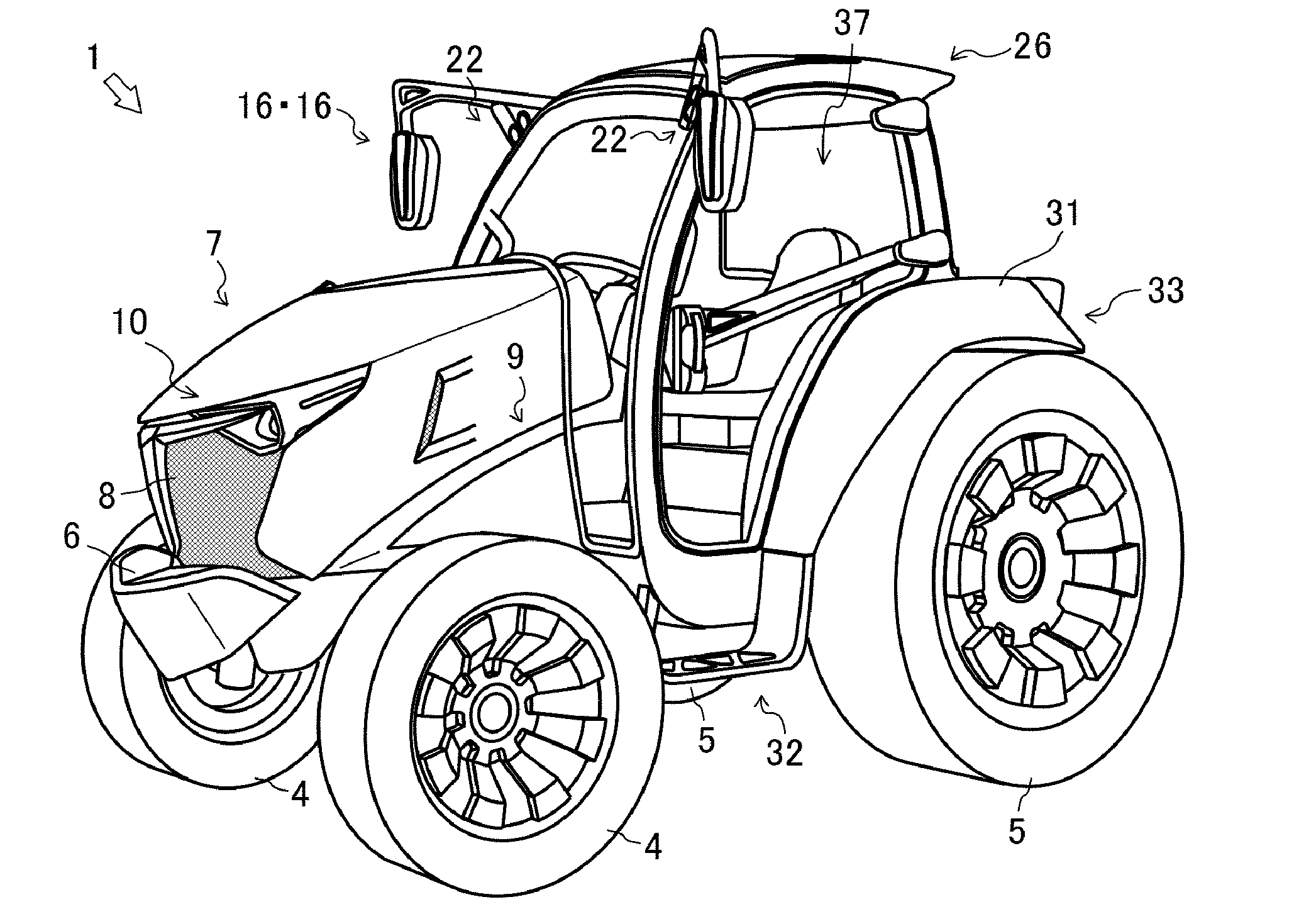

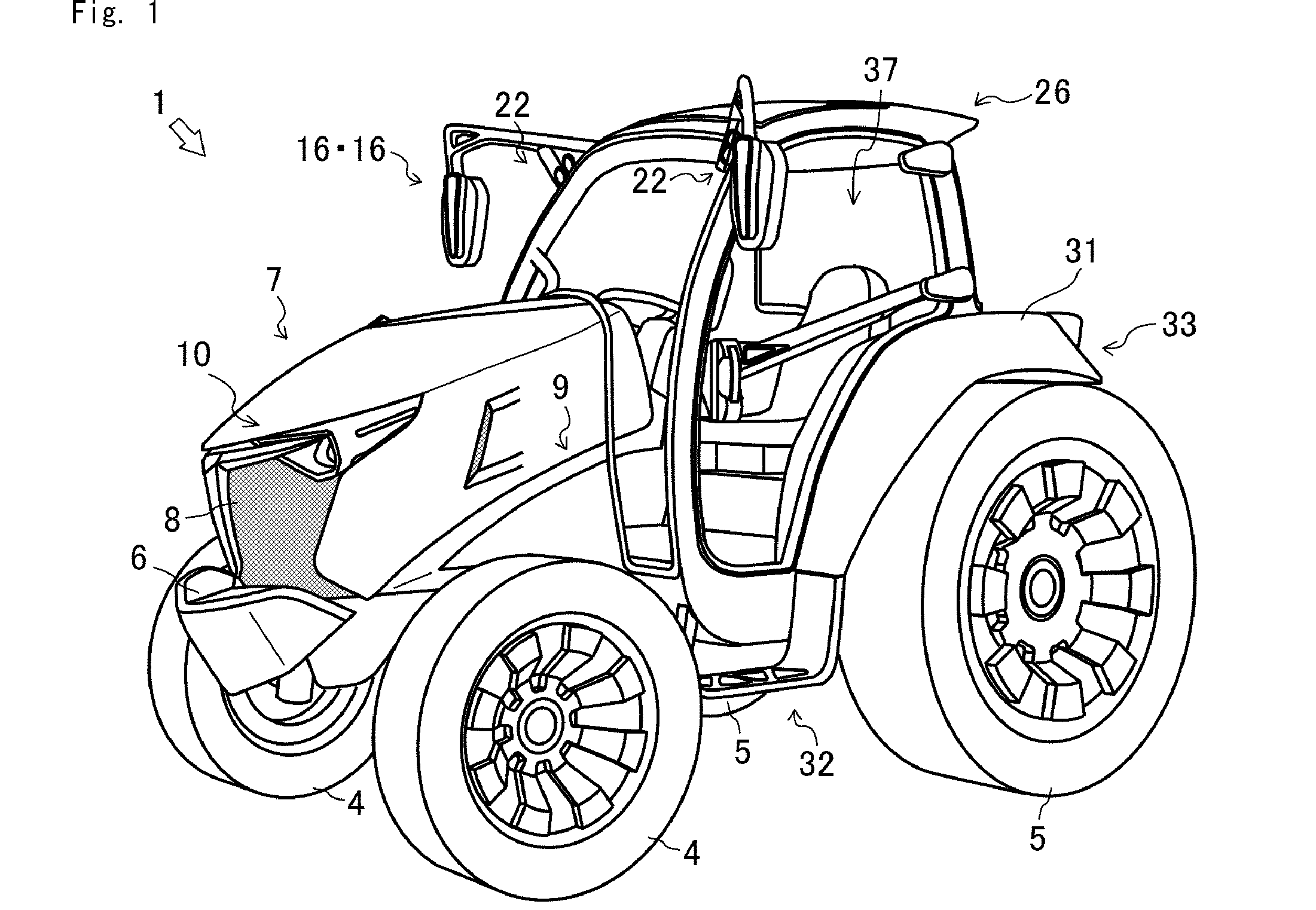

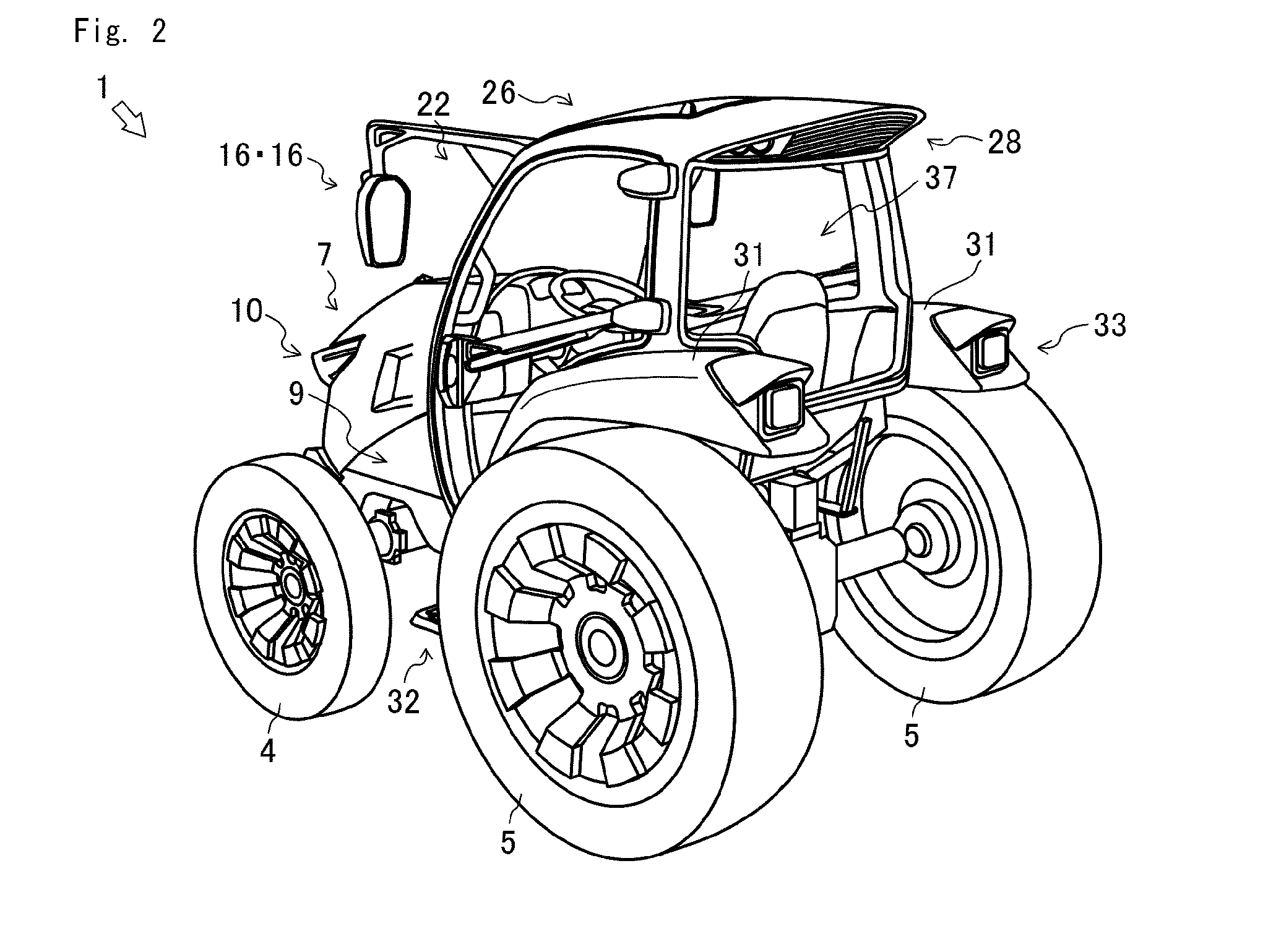

Work vehicle

It is an object to provide a work vehicle being capable of arranging side view mirrors at arbitrary positions while reducing the vibration of the side view mirrors. Regarding a tractor, which is a work vehicle in which a mirror portion of a side view mirror is provided on the other end of a support arm whose one end is fixed on a cabin for covering a drive operating unit, the support arm is bent in a midway portion, and a beam is integrally formed with the support arm in such a manner as to sandwich a bending portion, and a cross-sectional area of a cross section vertical to the axial direction of the support arm is configured to be reduced as the support arm advances from the one end to the other end thereof.

Owner:YANMAR POWER TECHNOLOGY CO LTD

Autostereoscopic display device and drive method

ActiveUS9479767B2Improve imaging clarityInhibition transitionSteroscopic systemsOptical elementsComputer graphics (images)Display device

The invention provides an autostereoscopic display device in which a viewer tracking system determines a position of a viewer with respect to the display panel. The display panel is controlled to display a number of different views which is dependent on at least the distance of the viewer from the display panel. This enables the number of views to optimized with respect to the position and / or speed of movement of the viewer.

Owner:DIMENCO HLDG BV

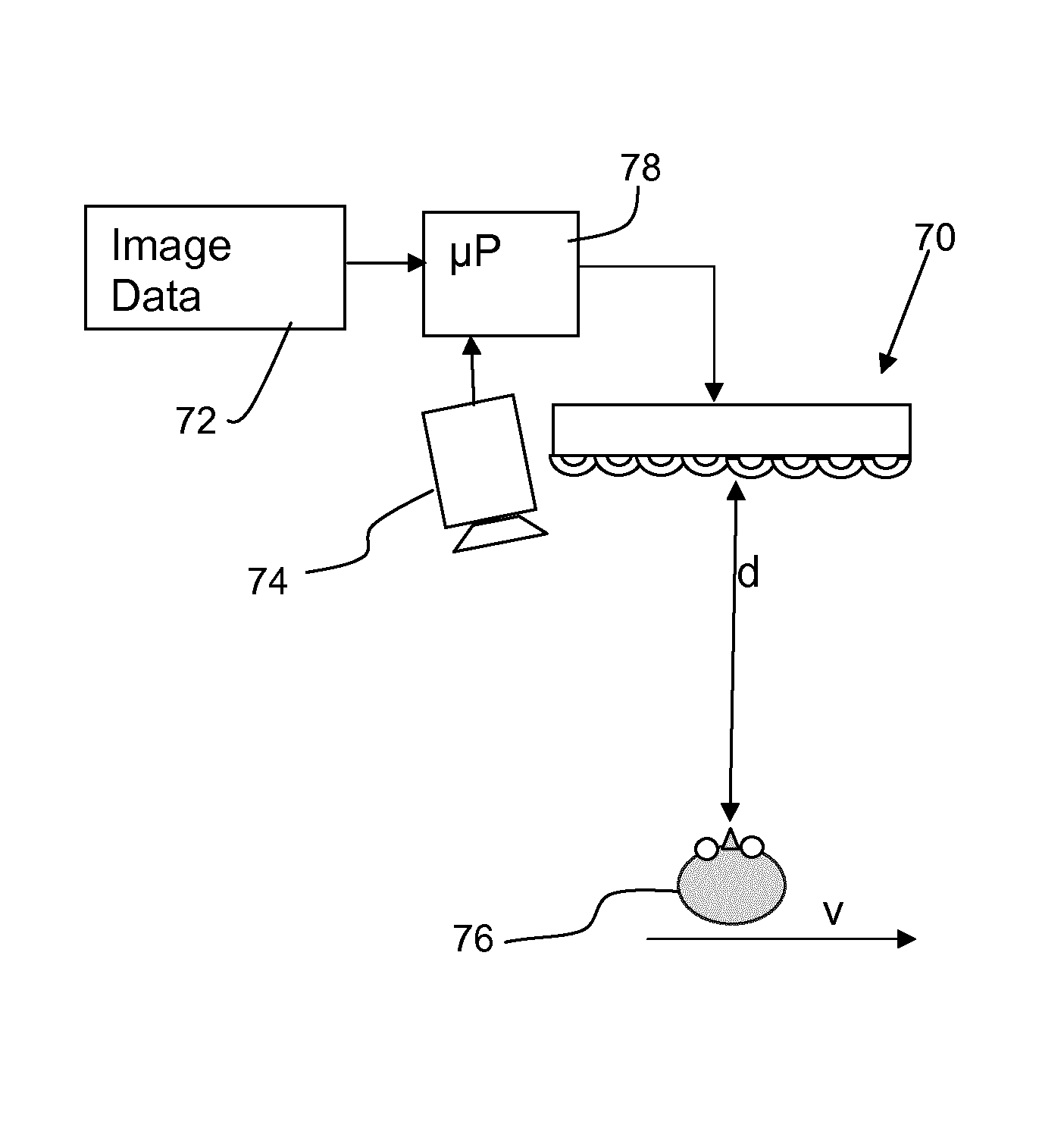

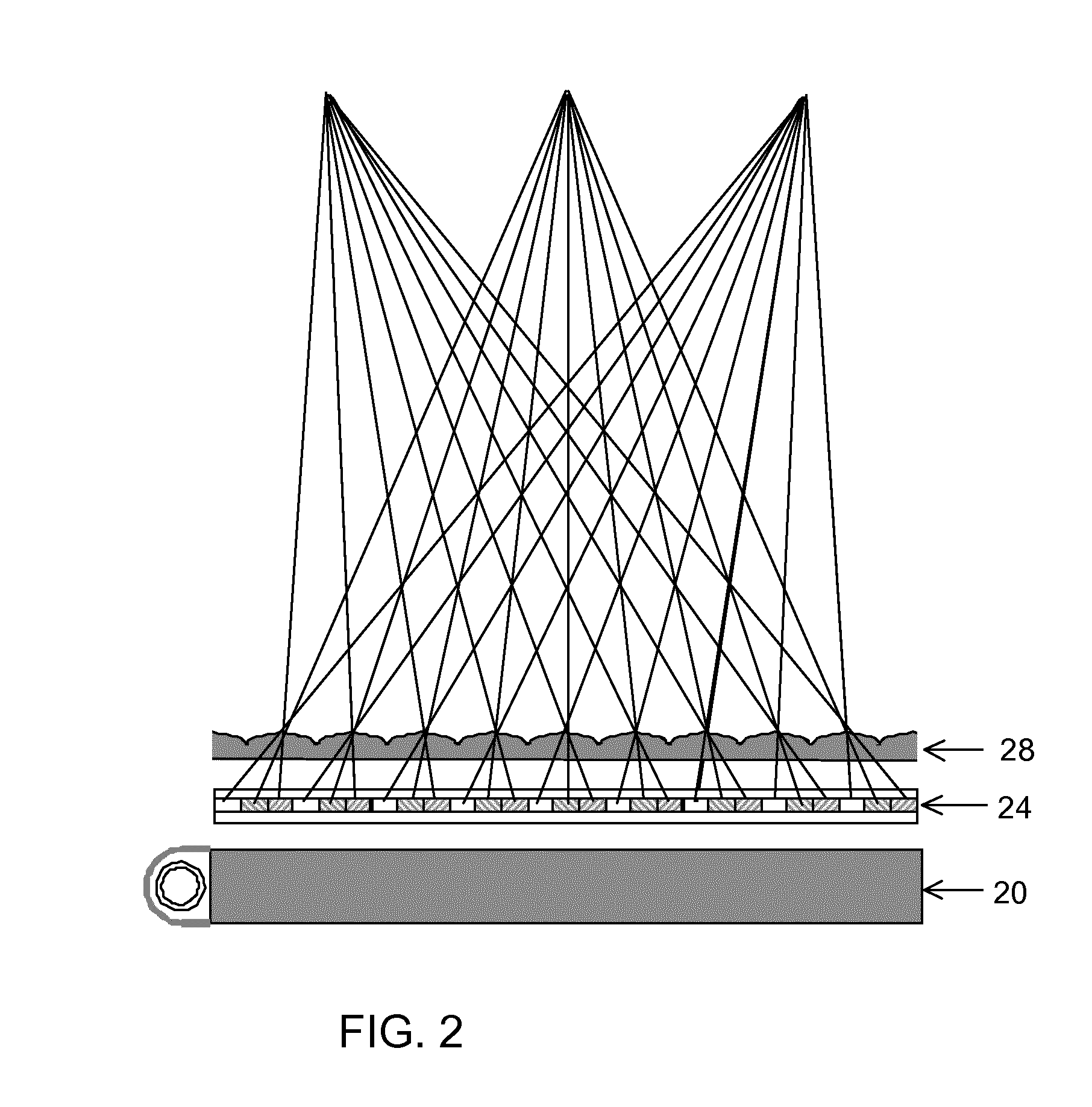

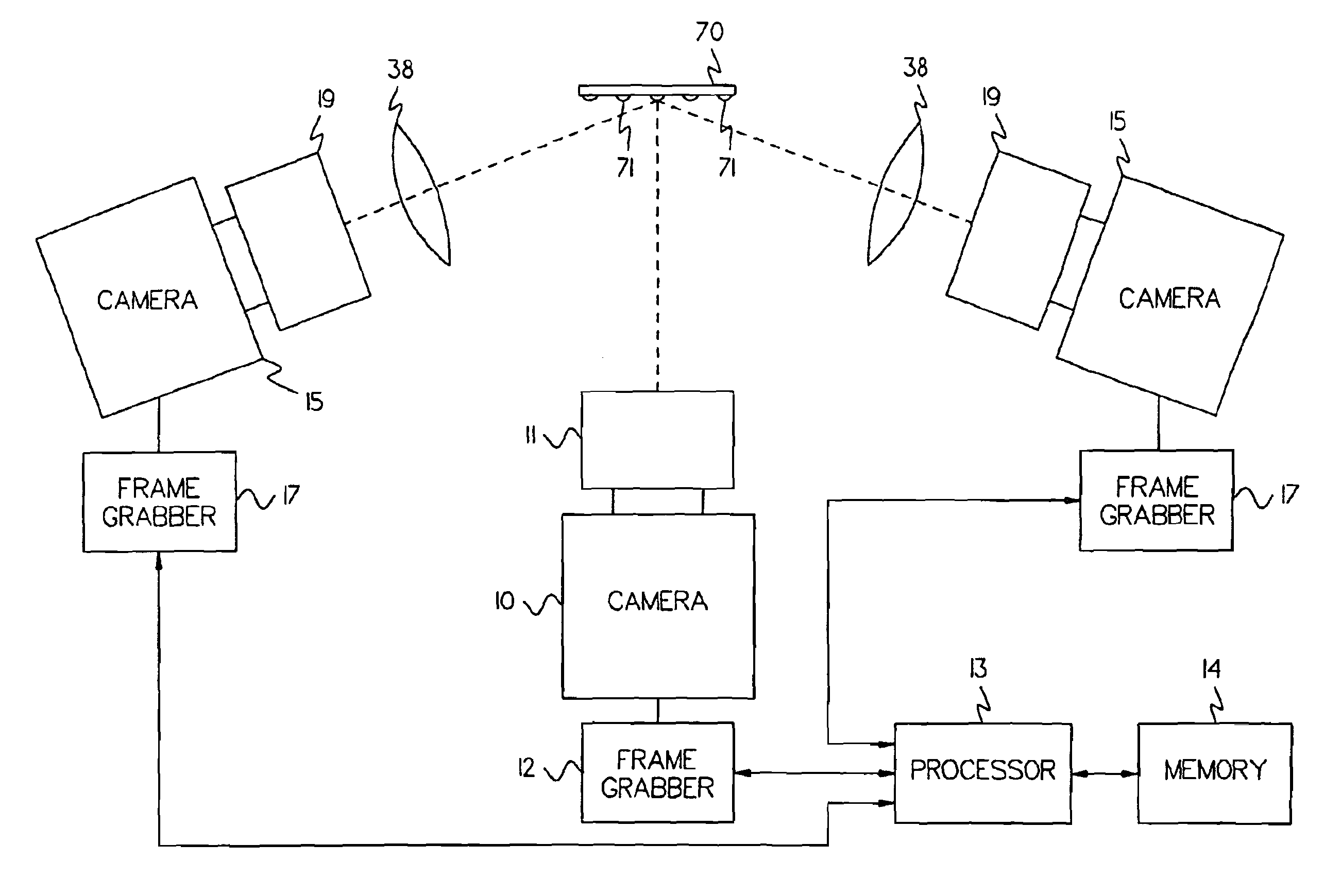

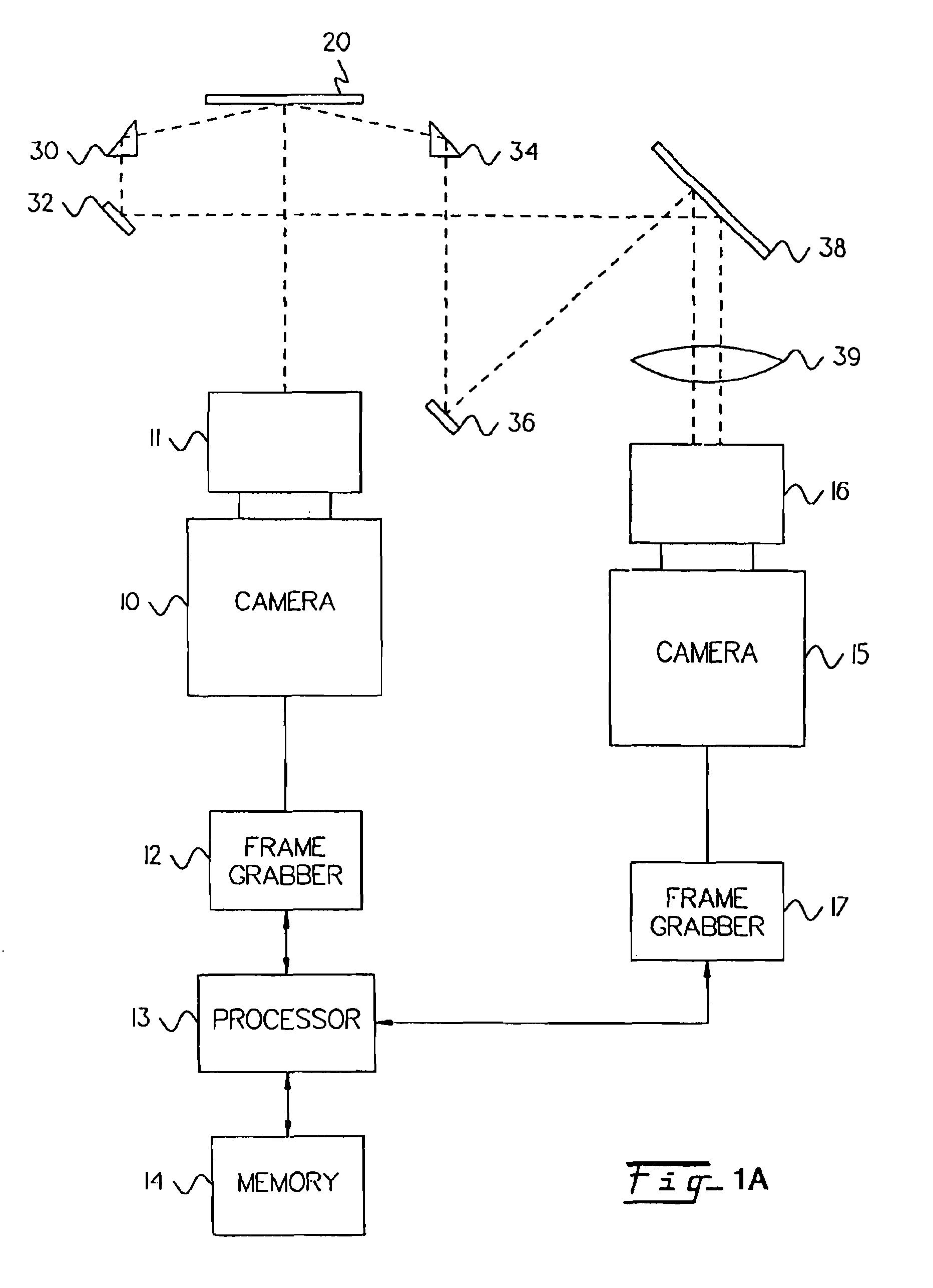

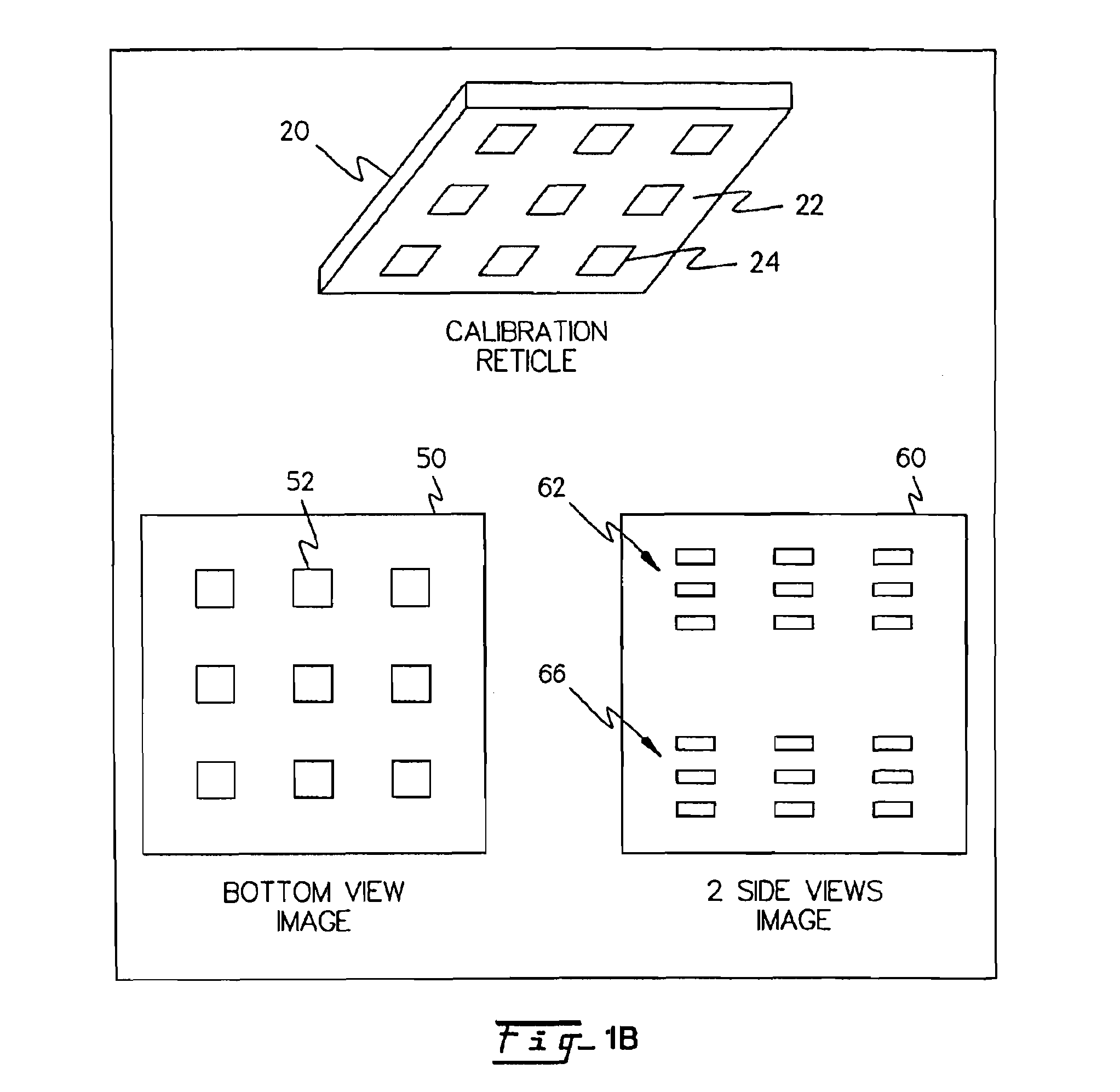

Method of Manufacturing Ball Array Devices Using an Inspection Apparatus having Two or More Cameras and Ball Array Devices Produced According to the Method

InactiveUS20070183646A1Increase apparent spaceIncrease apparent spacingImage enhancementImage analysisPrismOptoelectronics

A calibration and part inspection method for the inspection of ball grid array, BGA, devices. Two cameras image a precision pattern mask with dot patterns deposited on a transparent reticle. The precision pattern mask is used for calibration of the system. A light source and overhead light reflective diffuser provide illumination. A first camera images the reticle precision pattern mask from directly below. An additional mirror or prism located below the bottom plane of the reticle reflects the reticle pattern mask from a side view, through prisms or reflective surfaces, into a second camera and a second additional mirror or prism located below the bottom plane of the reticle reflects the opposite side view of the reticle pattern mask through prisms or mirrors into a second camera. By imaging more than one dot pattern the missing state values of the system can be resolved using a trigonometric solution. The reticle with the pattern mask is removed after calibration and the BGA to be inspected is placed with the balls facing downward, in such a manner as to be imaged by the two cameras. The scene of the part can thus be triangulated and the dimensions of the BGA are determined.

Owner:SCANNER TECH CORP

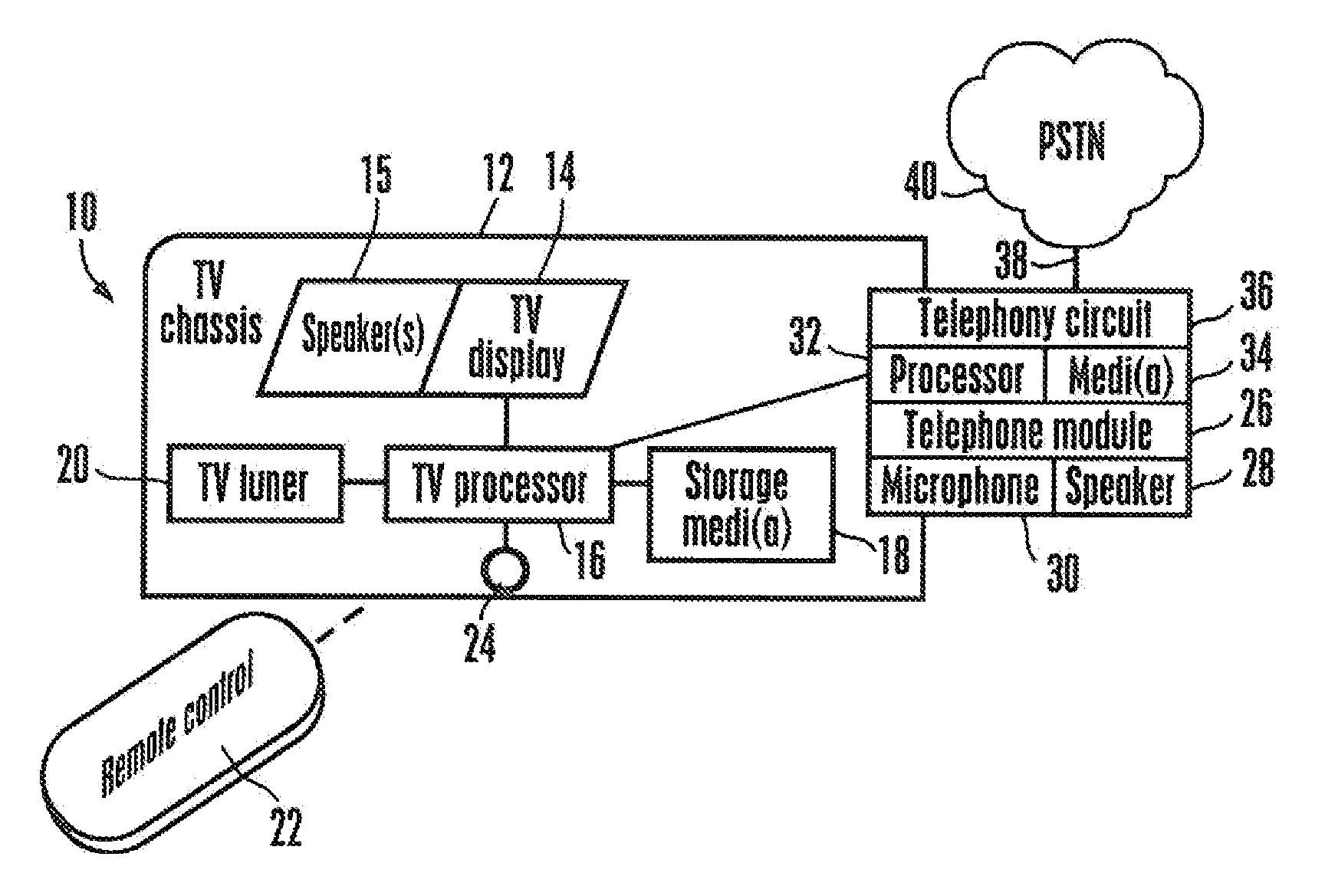

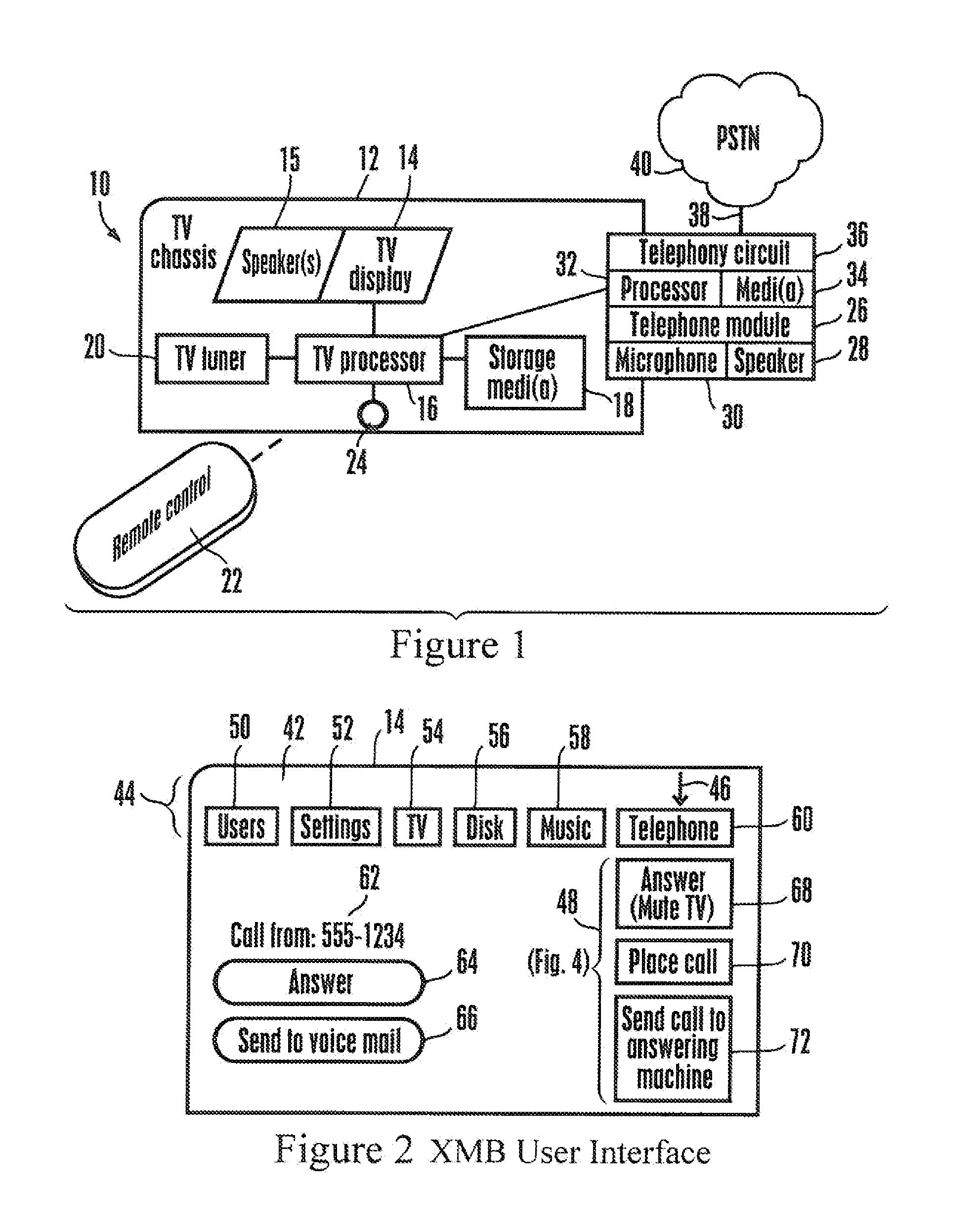

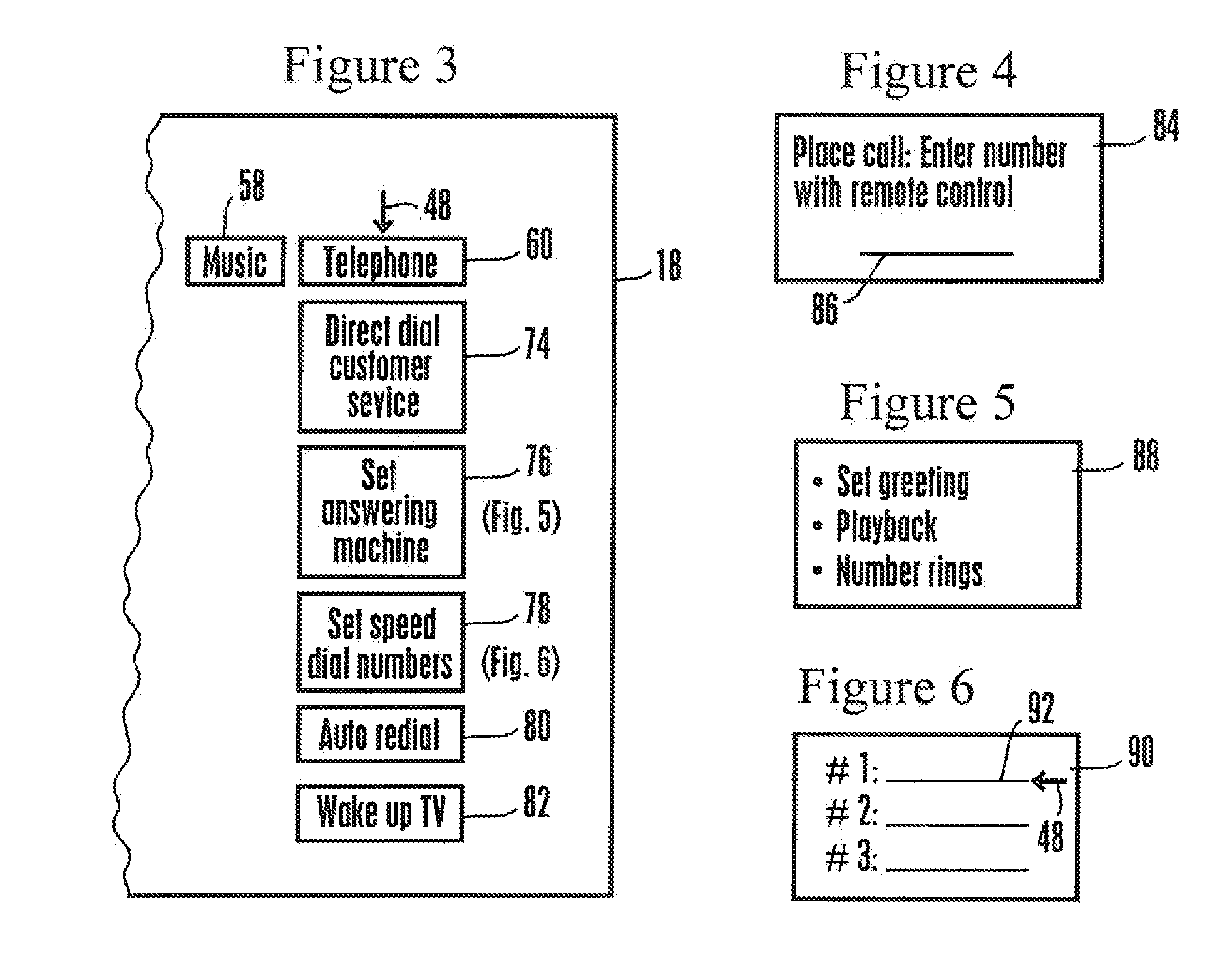

TV with landline integrated into tv's user interface

InactiveUS20120030710A1Reduce usageReduce in quantityTelevision system detailsCalling susbscriber number recording/indicationRemote controlUser interface

A landline telephone circuit is provided within a TV chassis or in a set-back box connectable to the TV processor to enable a user to place and receive calls through the TV. The telephone feature is integrated with the UI of the TV so that telephone features appear alongside other TV features. The telephone feature is controlled by the TV remote control, and has a microphone and computer storage for audio and database information.

Owner:SONY CORP

Liquid Crystal Display Device

ActiveUS20080218672A1Increase contrastReduce color variationPolarising elementsNon-linear opticsEngineeringLiquid crystal cell

A novel liquid crystal display device is disclosed. The liquid crystal display device comprises a first polarizing film, a first retardation area with an Re of 70 to 330 nm and a value of Nz of not less than 0 to less than 0.5 and a slow axis perpendicular to a transmission axis of the first polarizing film; a second retardation region with an Re of not greater than 50 nm and an Rth of 10 to 140 nm; and a liquid crystal cell comprising a liquid crystal layer with a slow axis in a black state parallel to the transmission axis of the first polarizing film; and a second polarizing film in this order.

Owner:FUJIFILM CORP

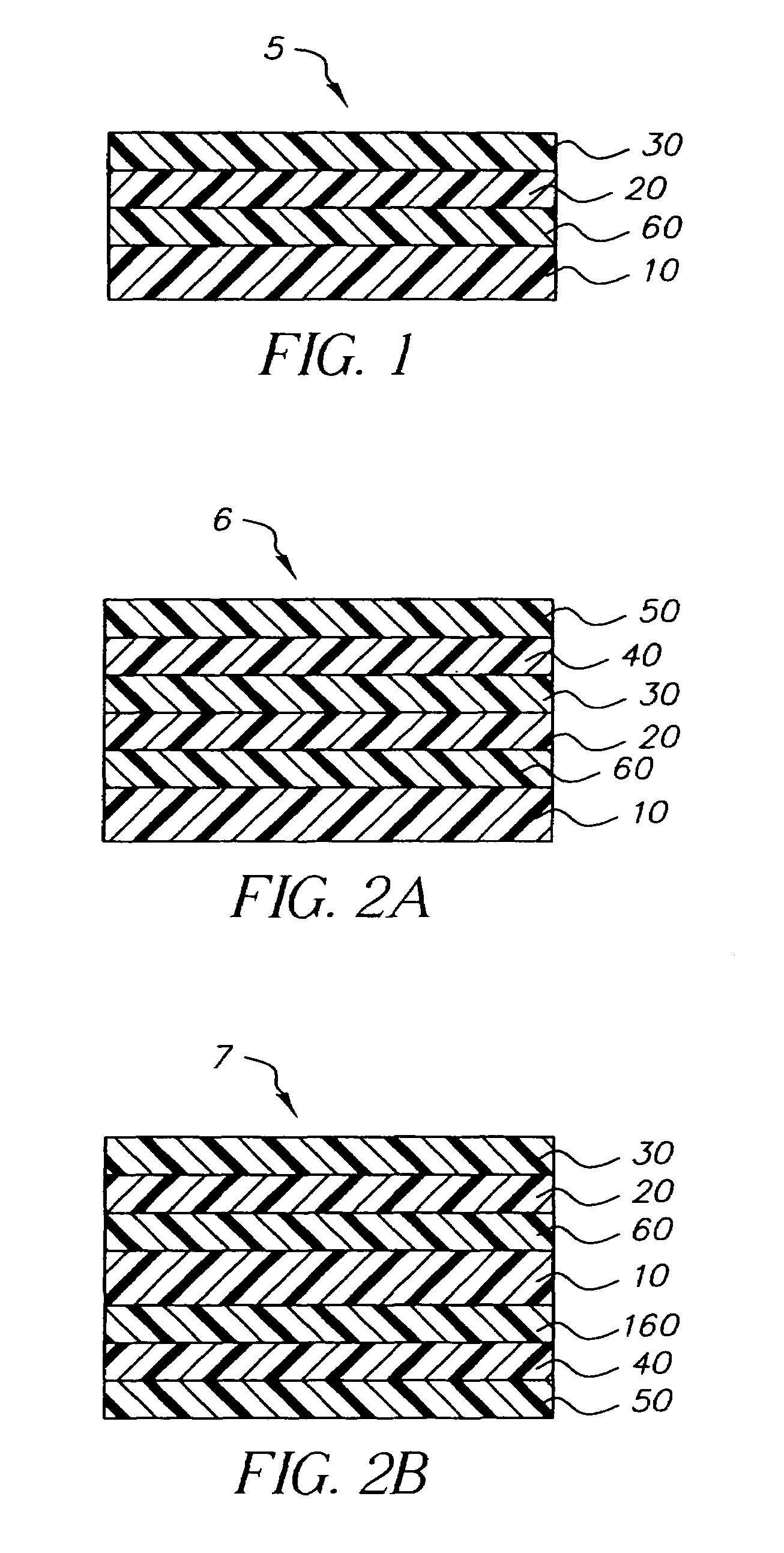

Compensator having particular sequence of films and crosslinked barrier layer

InactiveUS7084945B2Reduce viewPolarising elementsNon-linear opticsLiquid-crystal displayOptical property

Disclosed is an optical compensator for a liquid crystal display comprising a transparent polymeric support, an orientation layer, and an optically anisotropic layer, in order, and located between the support and the orientation layer, a barrier layer comprising a crosslinked polymer impermeable to the components of the support. Embodiments exhibit improved optical properties.

Owner:NITTO DENKO CORP

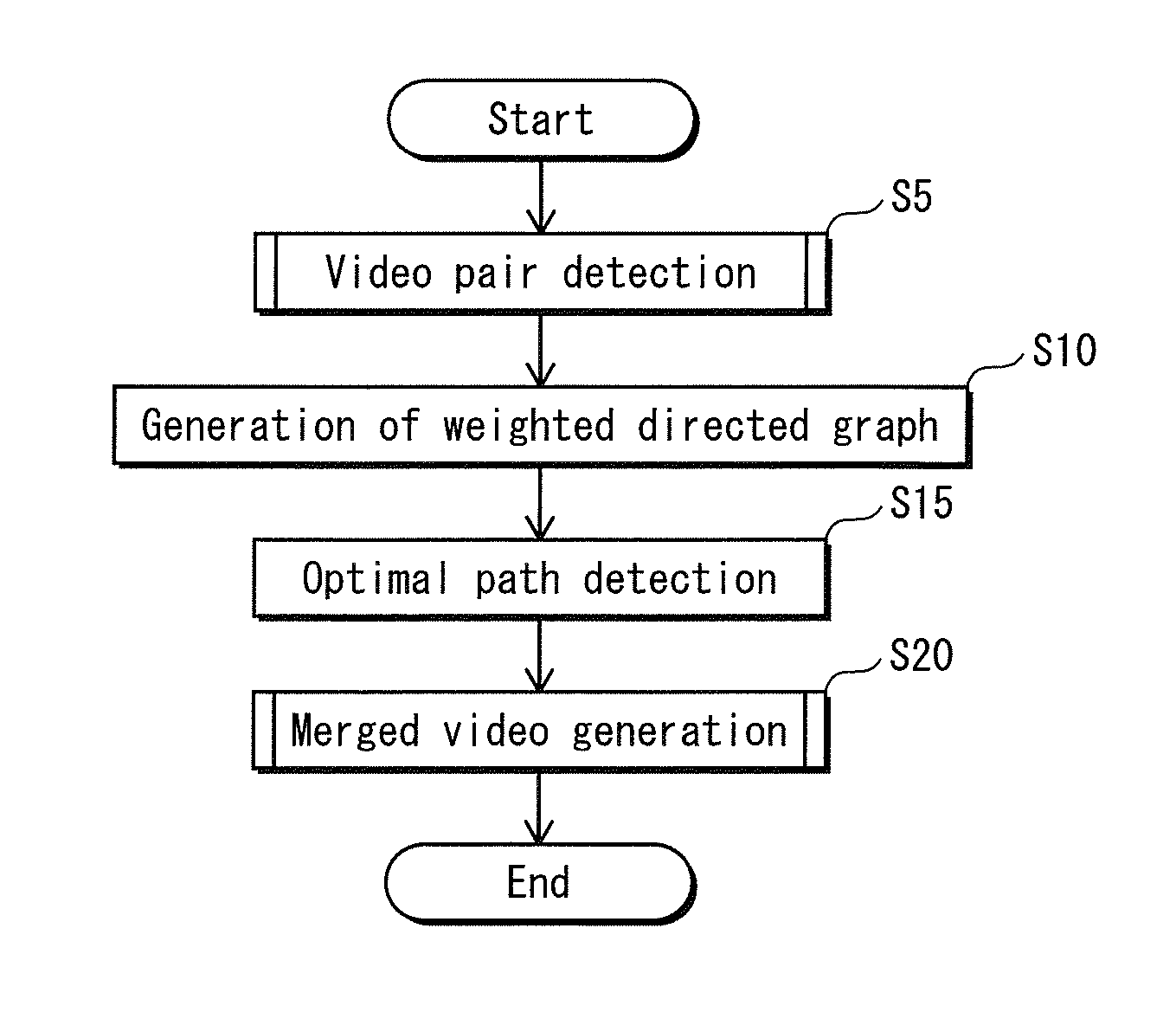

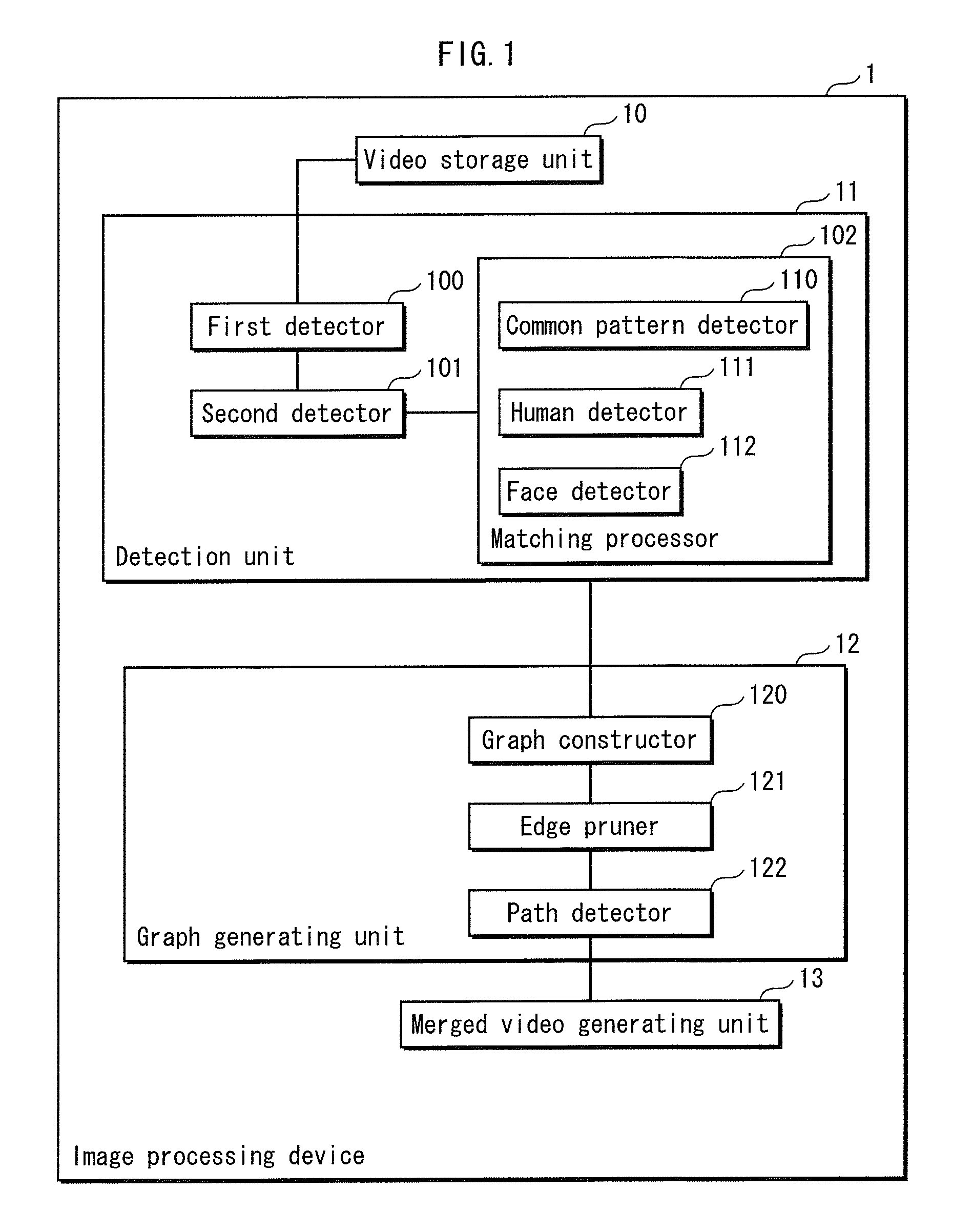

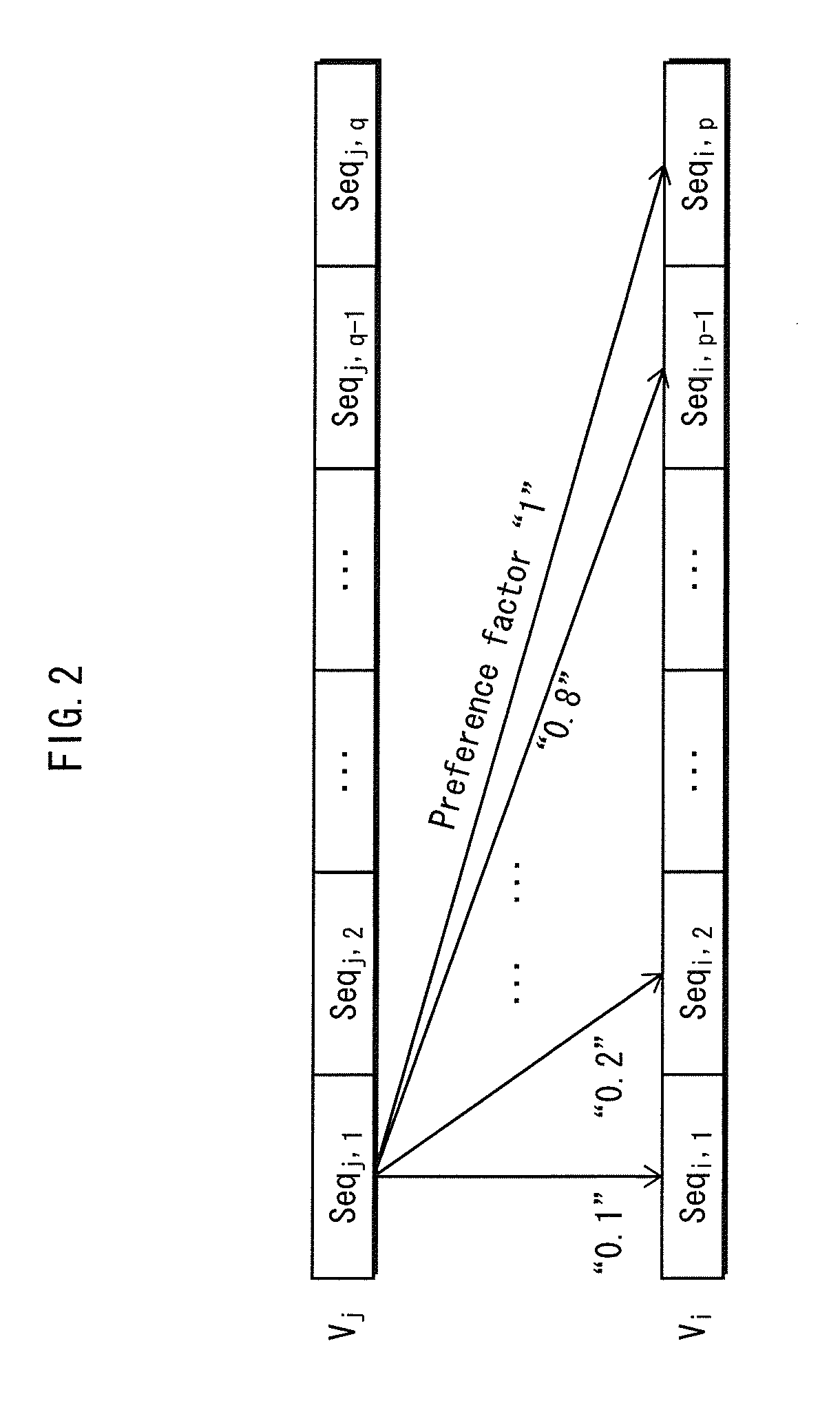

Image processing device, image processing method, image processing program, and integrated circuit

ActiveUS8958646B2Reduce viewTelevision system detailsElectronic editing digitised analogue information signalsPattern recognitionImaging processing

An image processing device combines a plurality of contents (e.g. videos) with a story line retained as much as possible, while reducing view's discomfort. The image processing device compares one of the contents, which contains a first partial content and a second partial content subsequent to the first partial content, with another one of the contents, which contains a plurality of consecutive partial contents; detects, as a third partial content, a partial content with the highest similarity value from among the plurality of partial contents; and generates relational information by using the highest similarity value obtained by the first processing unit. The relational information is then used for merging the first partial content, the second partial content and the third partial content.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

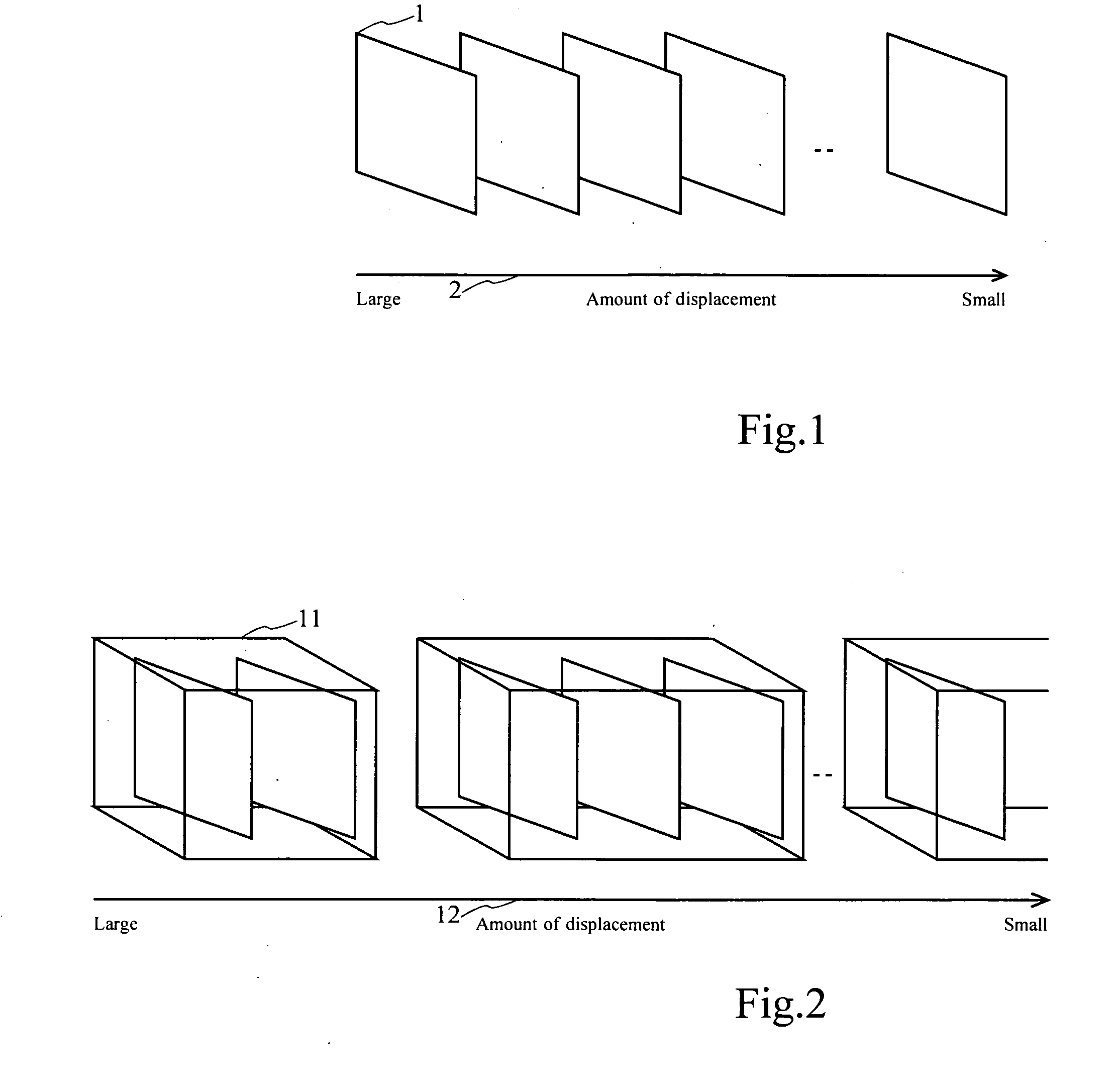

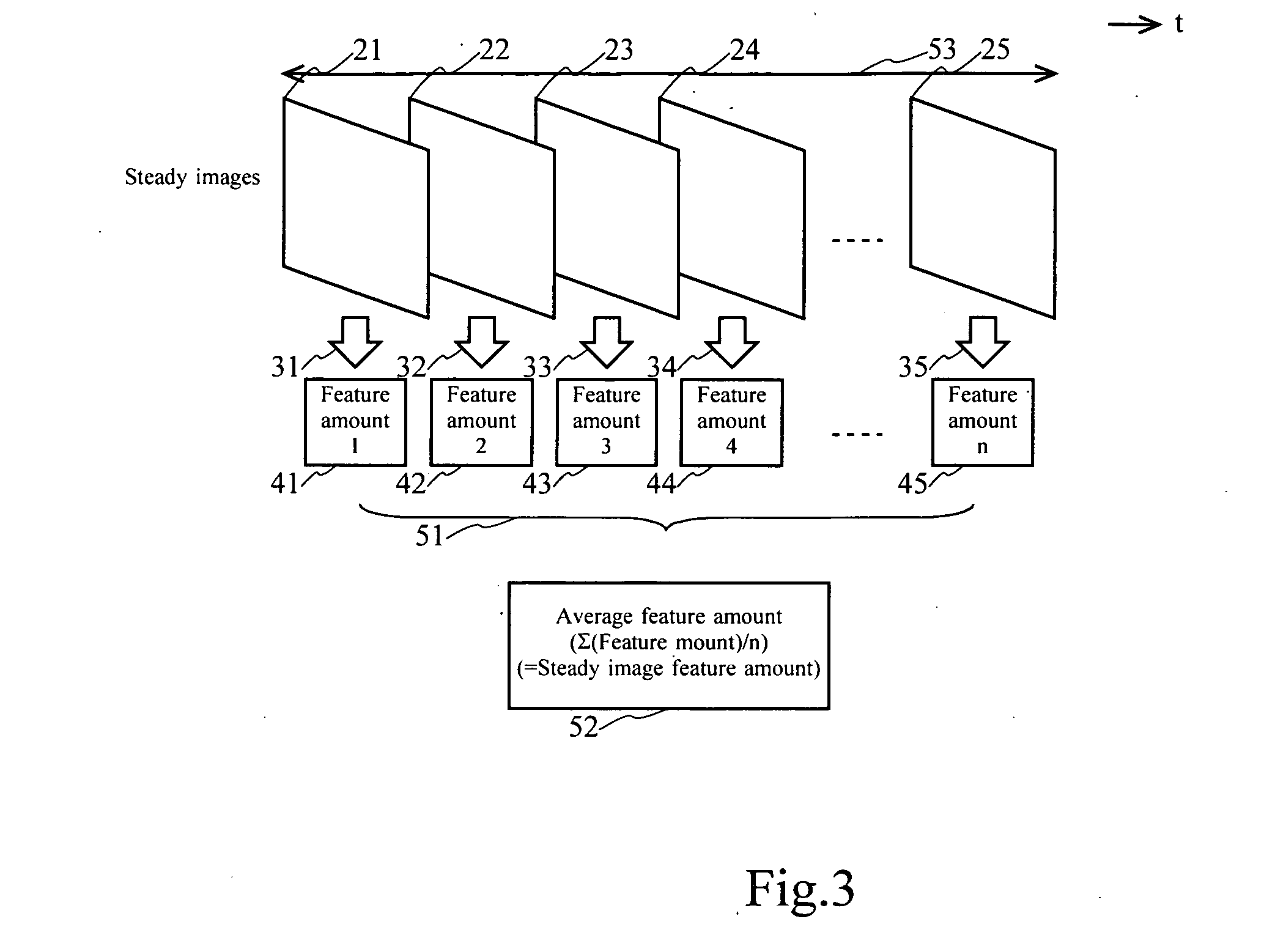

Video processing method

InactiveUS20090015718A1Reduce loadReduce viewTelevision system detailsRecording carrier detailsStable stateVideo processing

A video processing apparatus obtains information describing the amount of displacement of images in multiple predetermined units (such as video durations) imaged by an imaging apparatus from an image at steady state, which is a reference, and displays the images in the multiple predetermined units in decreasing order of amounts of displacement based on the obtained information describing the amounts of displacement.

Owner:KOKUSA ELECTRIC CO LTD

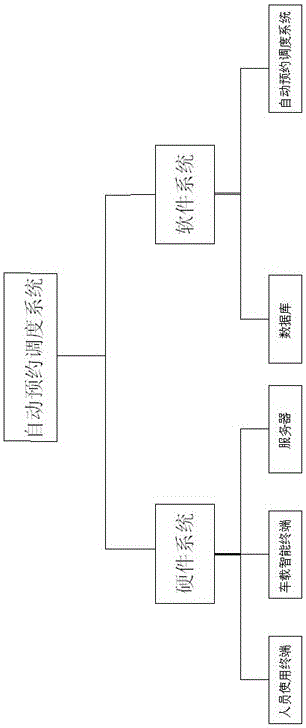

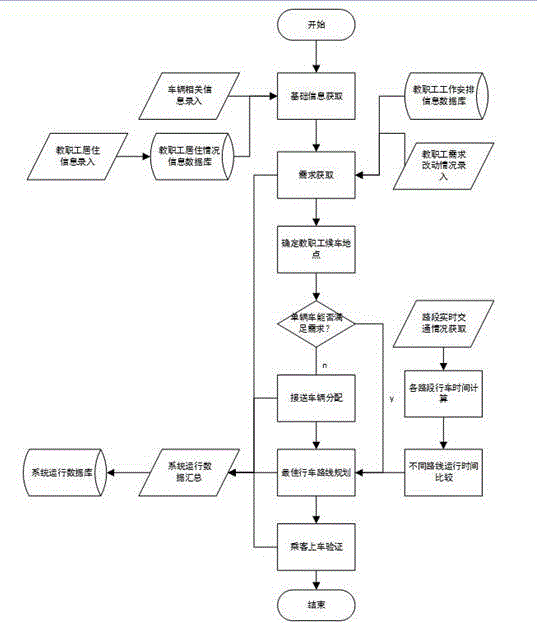

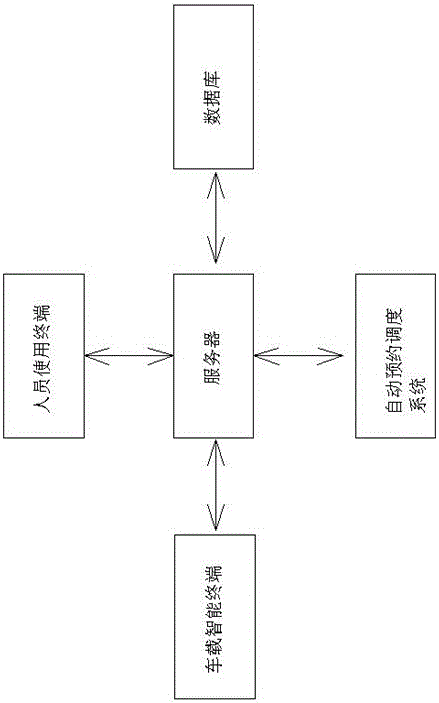

System and method for automatic reservation and scheduling of college faculty member transportation vehicles

InactiveCN106652537AImprove convenienceReduce waiting timeRoad vehicles traffic controlTransmissionInformation transmissionSystem maintenance

The present invention provides a system and method for automatic reservation and scheduling of college faculty member transportation vehicles. A staff usage terminal and a vehicle intelligent terminal are connected with a server through a wireless network, and a database is configured in the server; the staff usage terminal is held by users' hands, and the staff usage terminal comprises an information transmission module and an identity verification module; vehicle intelligent terminal is installed on a vehicle and comprises a GPS location module, an operation speed obtaining module and a passenger identity authentication module; the server comprises an information storage module, an information transmit-receive module and a scheduling module; and the server obtains and receives the corresponding information and requirements of the staff usage terminal and the vehicle intelligent terminal to perform reasonable scheduling of the staff and the vehicles and send the scheduling results and other corresponding information to the staff usage terminal and the vehicle intelligent terminal. The system and method for automatic reservation and scheduling of college faculty member transportation vehicles realize that the faculty members can wait for vehicles at many vehicle waiting stations so as to reduce the no-load condition of vehicles and the detouring phenomenon, reduce the waiting time, improve the system operation stability, reduce the investment of human cost and facilitate system maintenance.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

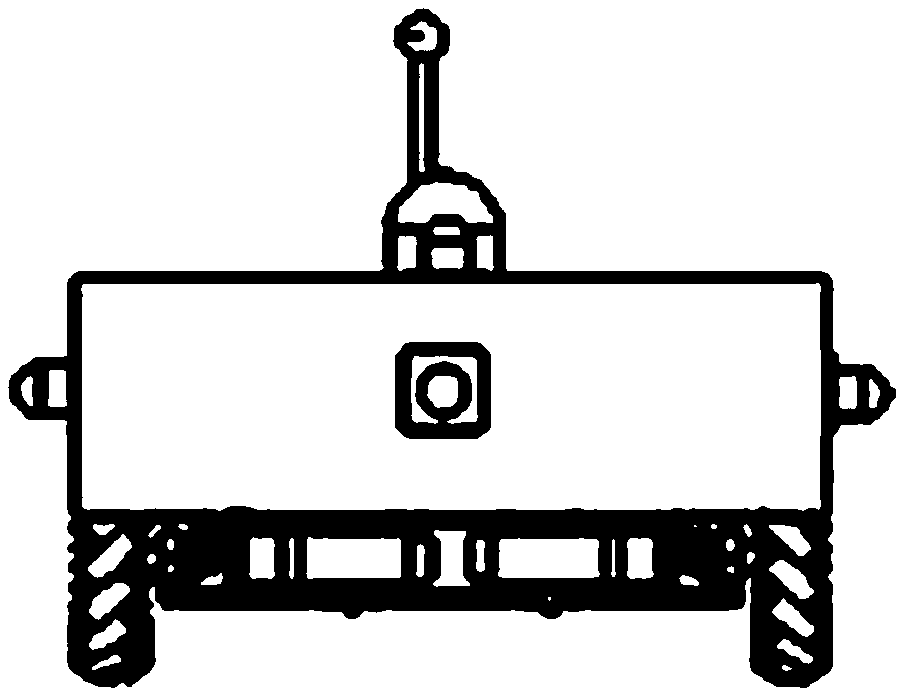

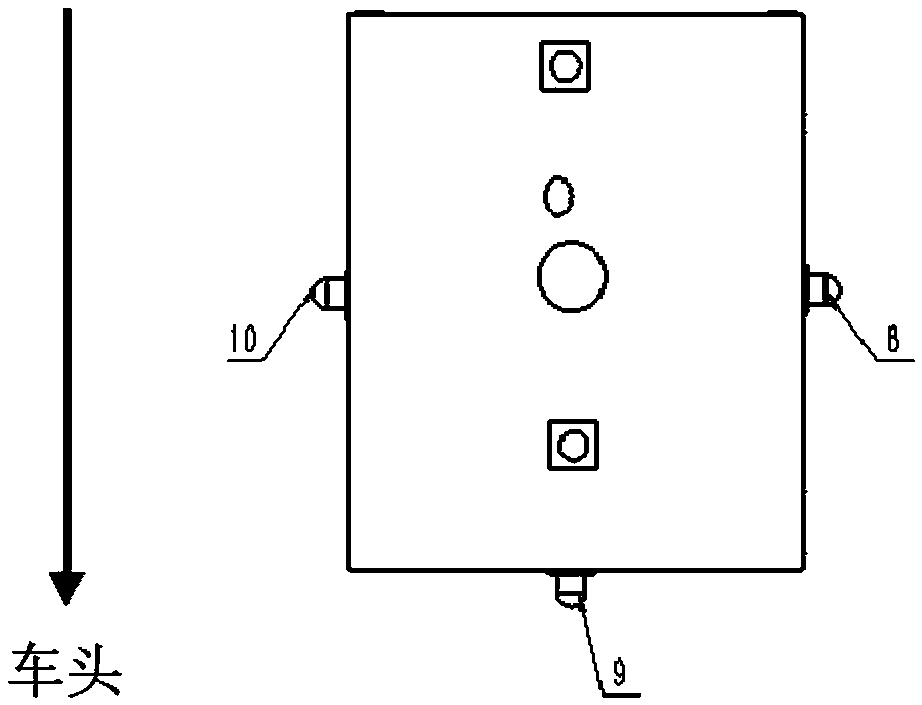

Omnidirectional movement unmanned driving platform method based on highway tunnel crack detection

ActiveCN107589744AImprove accuracyIncrease flexibilityMeasurement devicesPosition/course control in two dimensionsElectric machineryMecanum wheel

The invention provides an omnidirectional movement unmanned driving platform method based on highway tunnel crack detection. The platform comprises a vehicle body and Mecanum wheels arranged at the bottom of the vehicle body. The Mecanum wheels are arranged at the bottom of the vehicle body through pressure springs. The pressure springs at the left side and the right side are configured in a reversed-V-shaped manner in which the pressure springs gradually incline outwards from top to bottom. The Mecanum wheels are connected with a motor in the vehicle body. The motor is connected with a motordriver. The motor driver is connected with a master control single-chip microcomputer. The master control single-chip microcomputer is connected with a computer, an ultrasonic module, a GPS and a nine-axis sensor module. The computer is connected with a laser radar (3) and a camera. The omnidirectional movement unmanned driving platform method has advantages of well settling problems of high speed, high efficiency and high automation in tunnel detection, realizing high significance, reducing wastage of a large amount of manpower and physical resource in highway tunnel crack detection, and greatly improving crack detection accuracy.

Owner:SHENYANG POLYTECHNIC UNIV

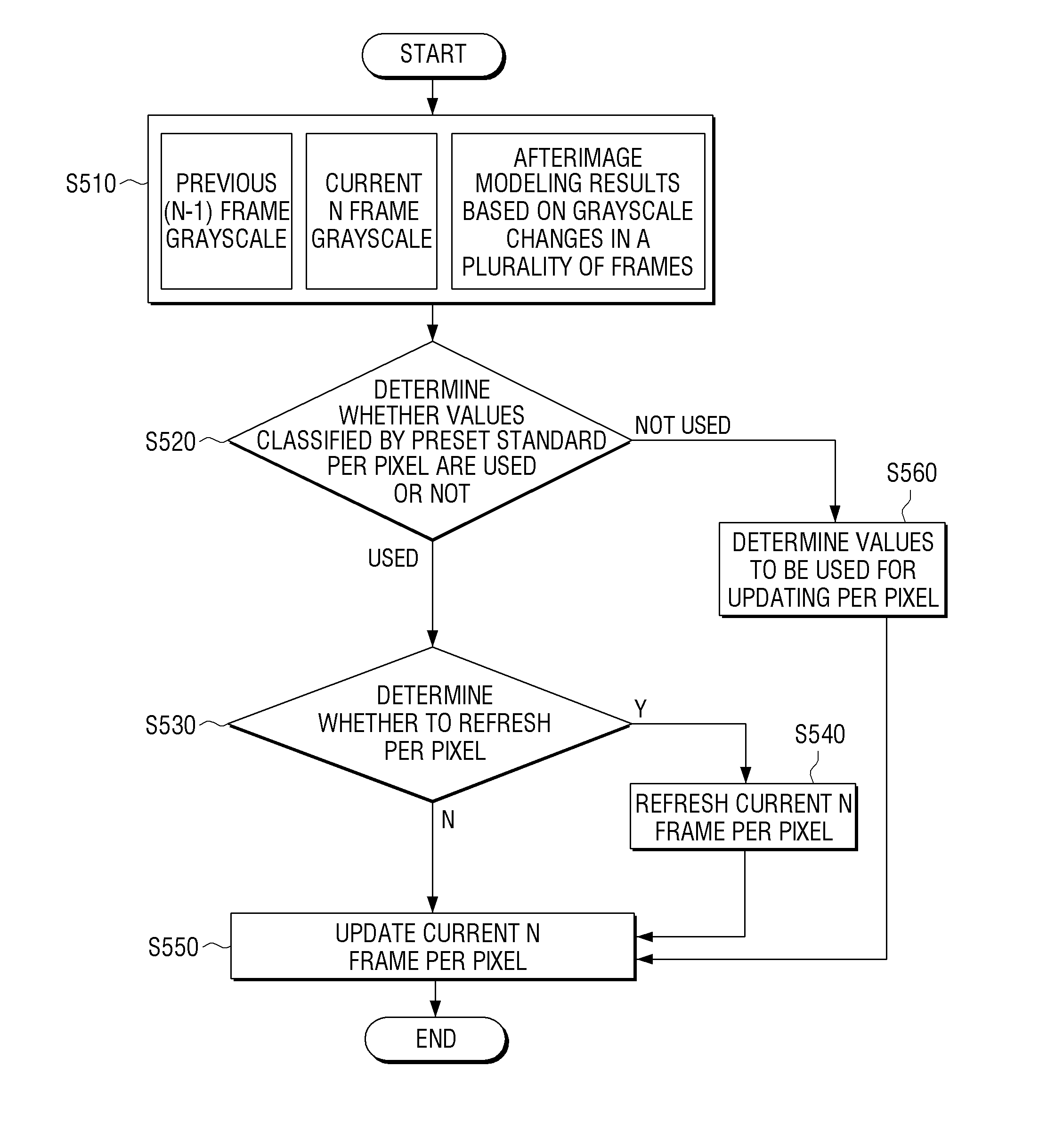

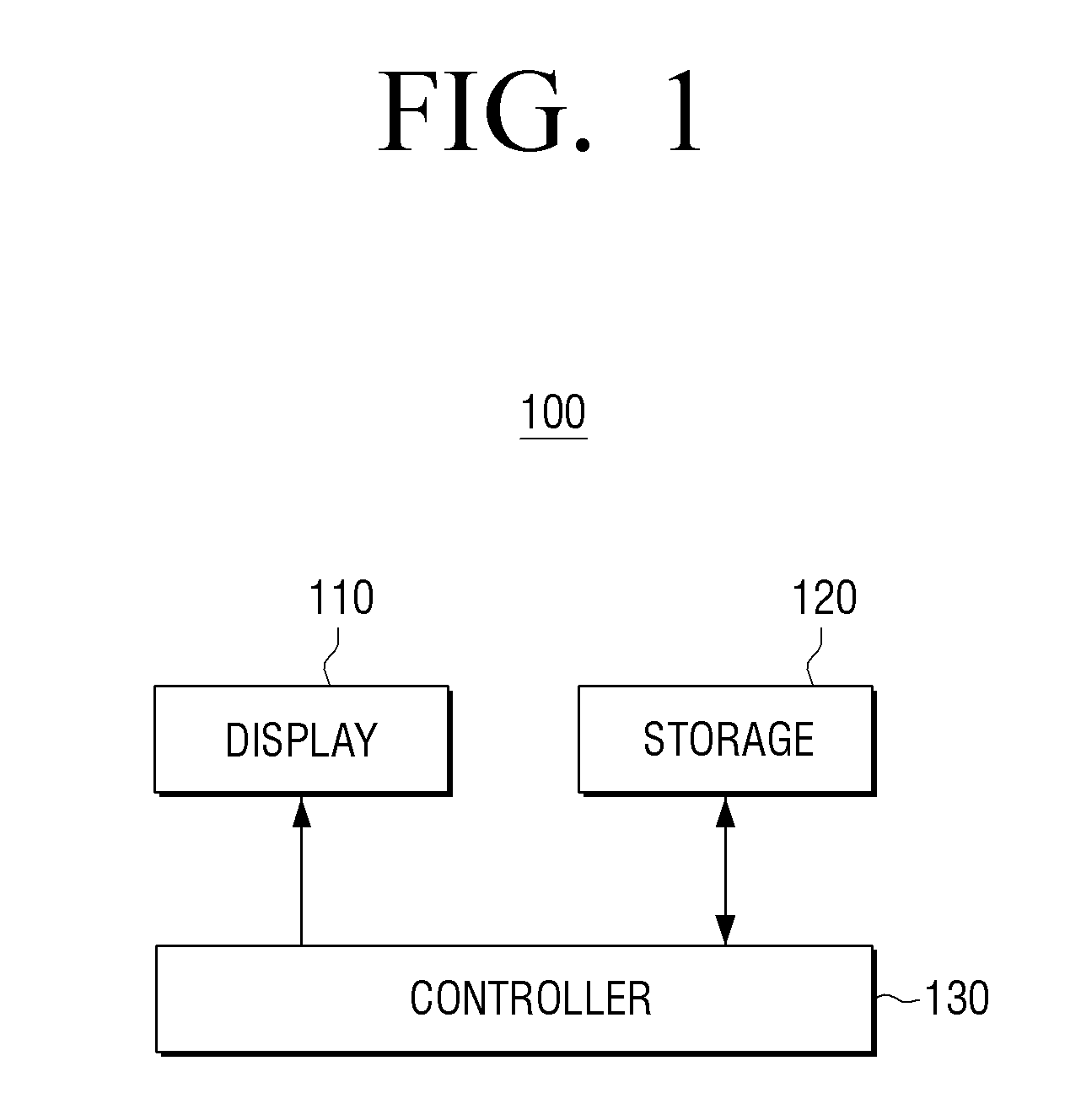

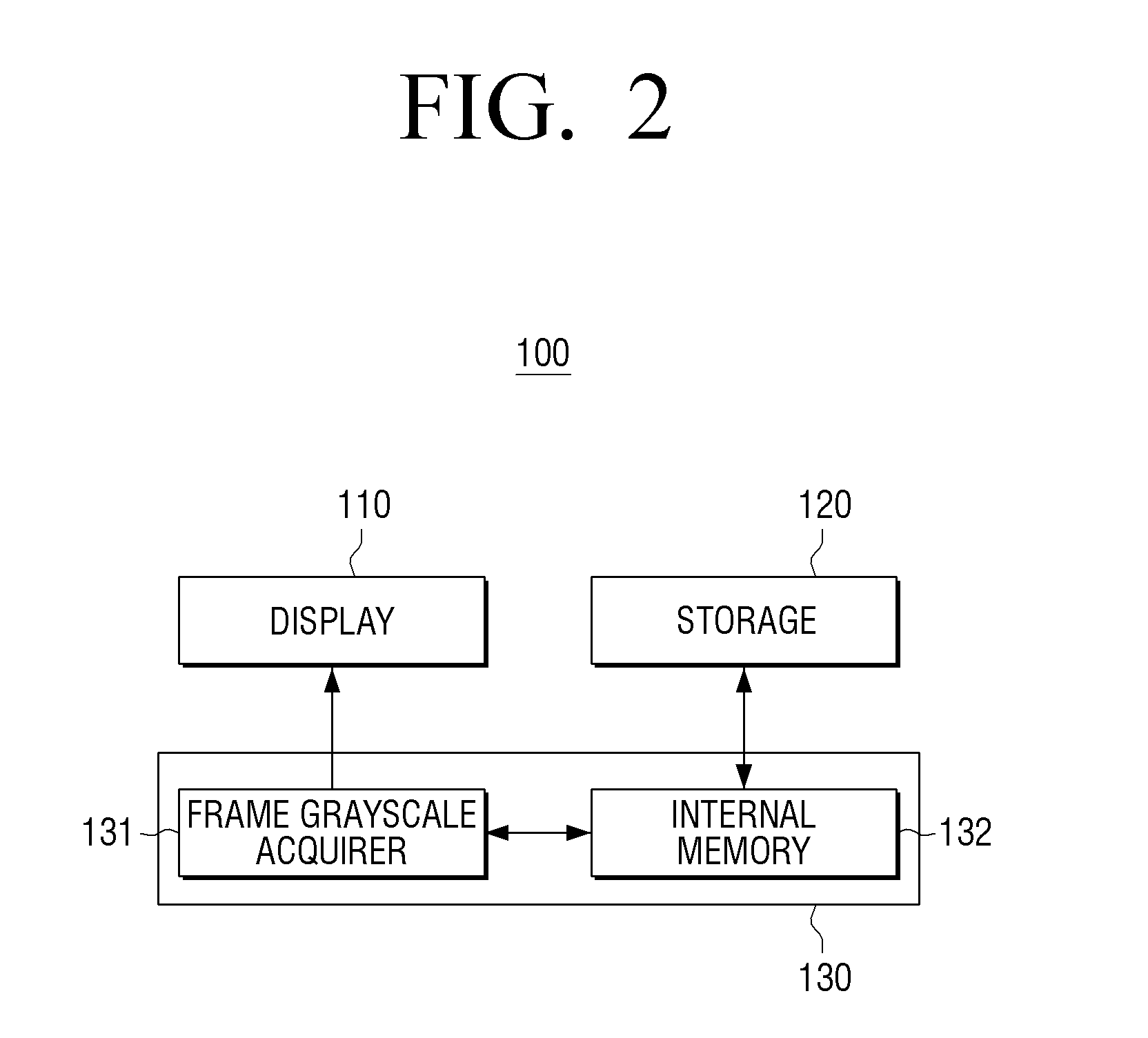

Display apparatus and controlling method thereof

ActiveUS20160125813A1Flickering of a screen may be reducedReduce viewCathode-ray tube indicatorsInput/output processes for data processingComputer graphics (images)Display device

A display apparatus and method are provided. The display apparatus includes a display, a storage which stores afterimage modeling information the includes afterimage information based on grayscale changes in a plurality of image frames, and a controller which controls the display to consecutively display the plurality of image frames and pixel-wise refresh pixels for afterimage removal in each image frame based on the afterimage modeling information. Therefore, flickering of a display screen can be reduced and the viewing fatigue of a user can decrease when the screen is converted.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com