Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Reduce the number of segments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

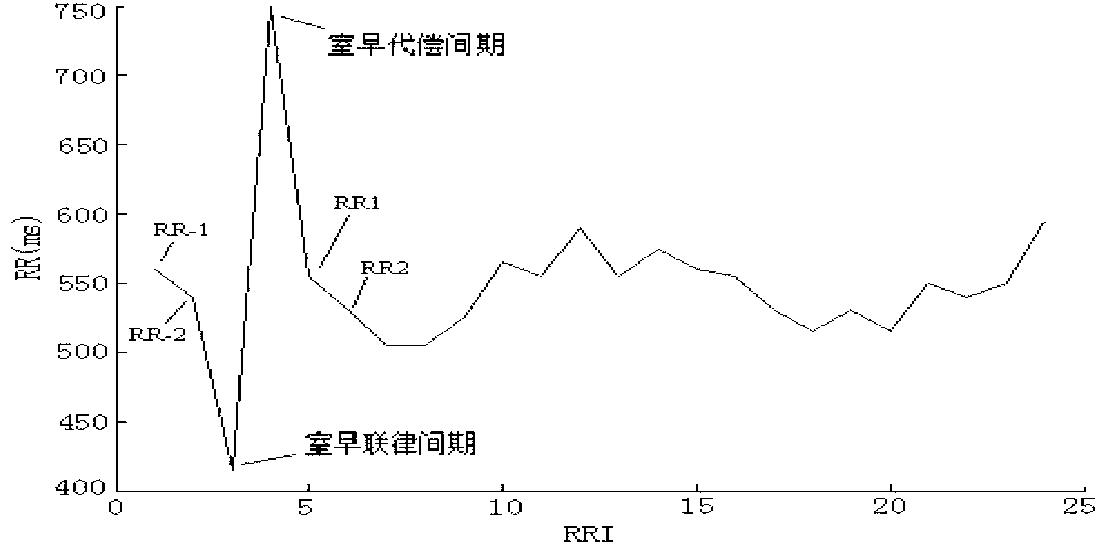

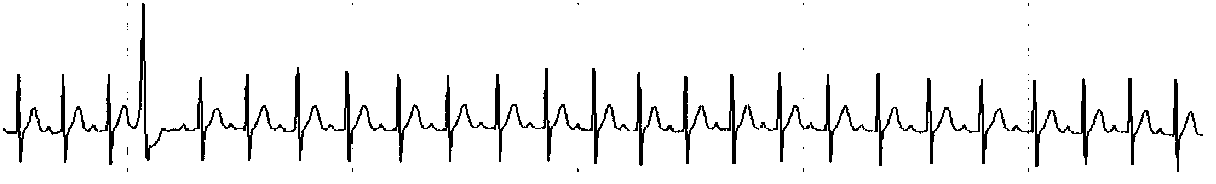

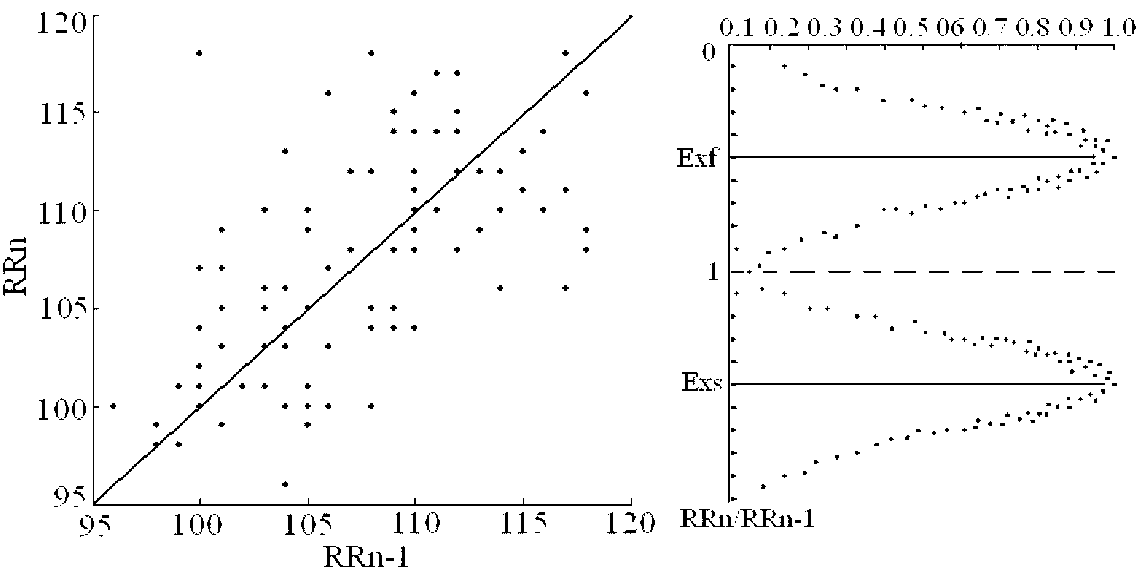

Heart rate turbulence tendency extraction method based on cloud model and scatter diagram

InactiveCN103271737ASimple methodRealize real-time detectionDiagnostic recording/measuringSensorsRR intervalCoupling

The invention discloses a heart rate turbulence tendency extraction method based on a cloud model and a scatter diagram. The heart rate turbulence tendency extraction method based on the cloud model and the scatter diagram comprises the specific steps of (1) collecting HRT samples, (2) drawing the Poincare scatter diagram of RR intervals, dividing coupling points into two types of coupling points, matching the two types of the coupling points with a decelerating cloud and an accelerating cloud, and determining two ortho-state cloud curvilinear equations through a reverse-cloud generator, (3) finding critical points of two types of the coupling points, calculating linear regression slopes section by section, and storing slope vectors, (4) calculating tj_mean when changes of types continuously happen on adjacent k coupling points, and substituting the tj_mean into the two ortho-state cloud curvilinear equations to calculate the degree of membership, (5) comparing a sign yun with a subsection slope before k coupling points, comparing the sign yun and a subsection slope after the k coupling points, and classifying the k coupling points into a front subsection or a later subsection, (6) updating subsection points, calculating the linear regression slopes section by section, and updating the slope vectors, (7) mixing adjacent subsections together when the adjacent subsections are the same in sign of slopes, and repeatedly carrying out the step (6) until adjacent subsections needing to be mixed together do not exist.

Owner:SHANDONG NORMAL UNIV

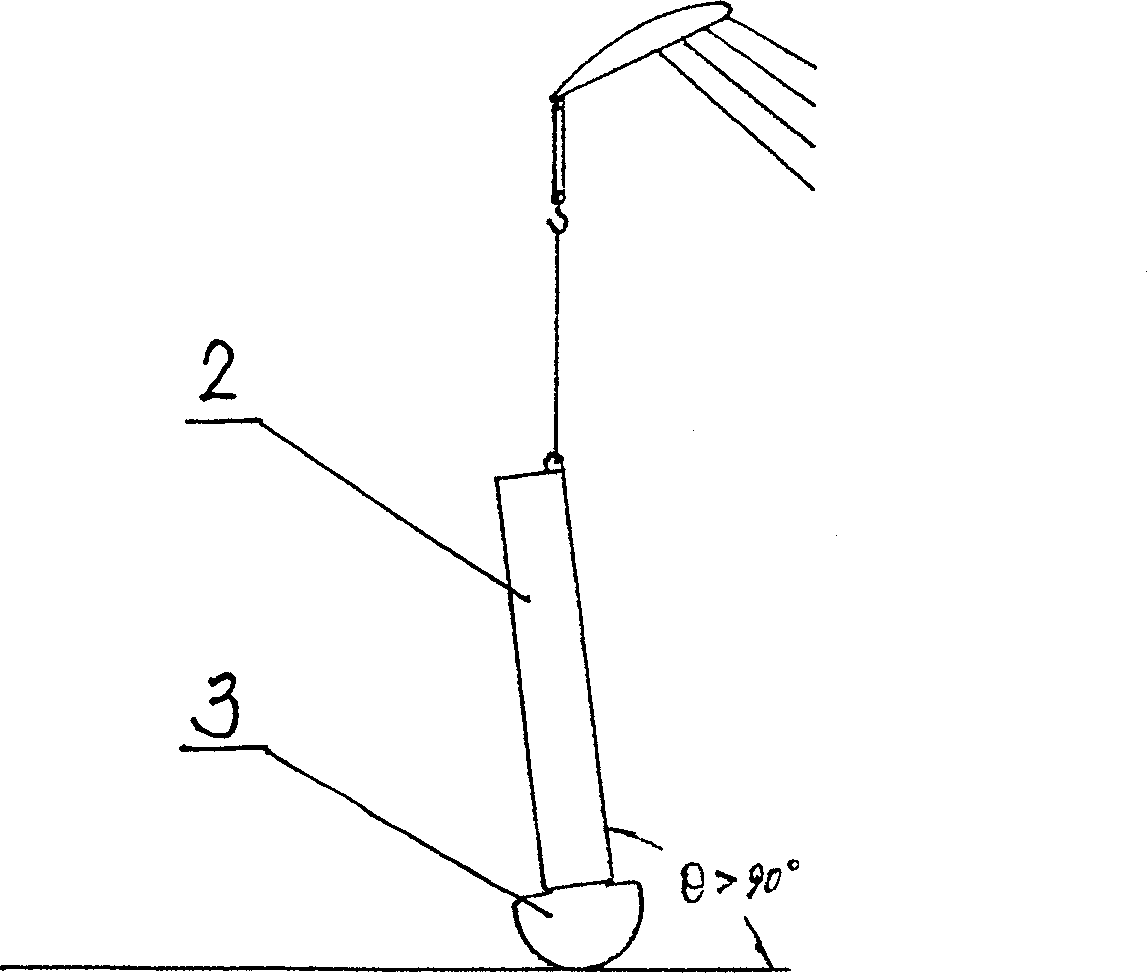

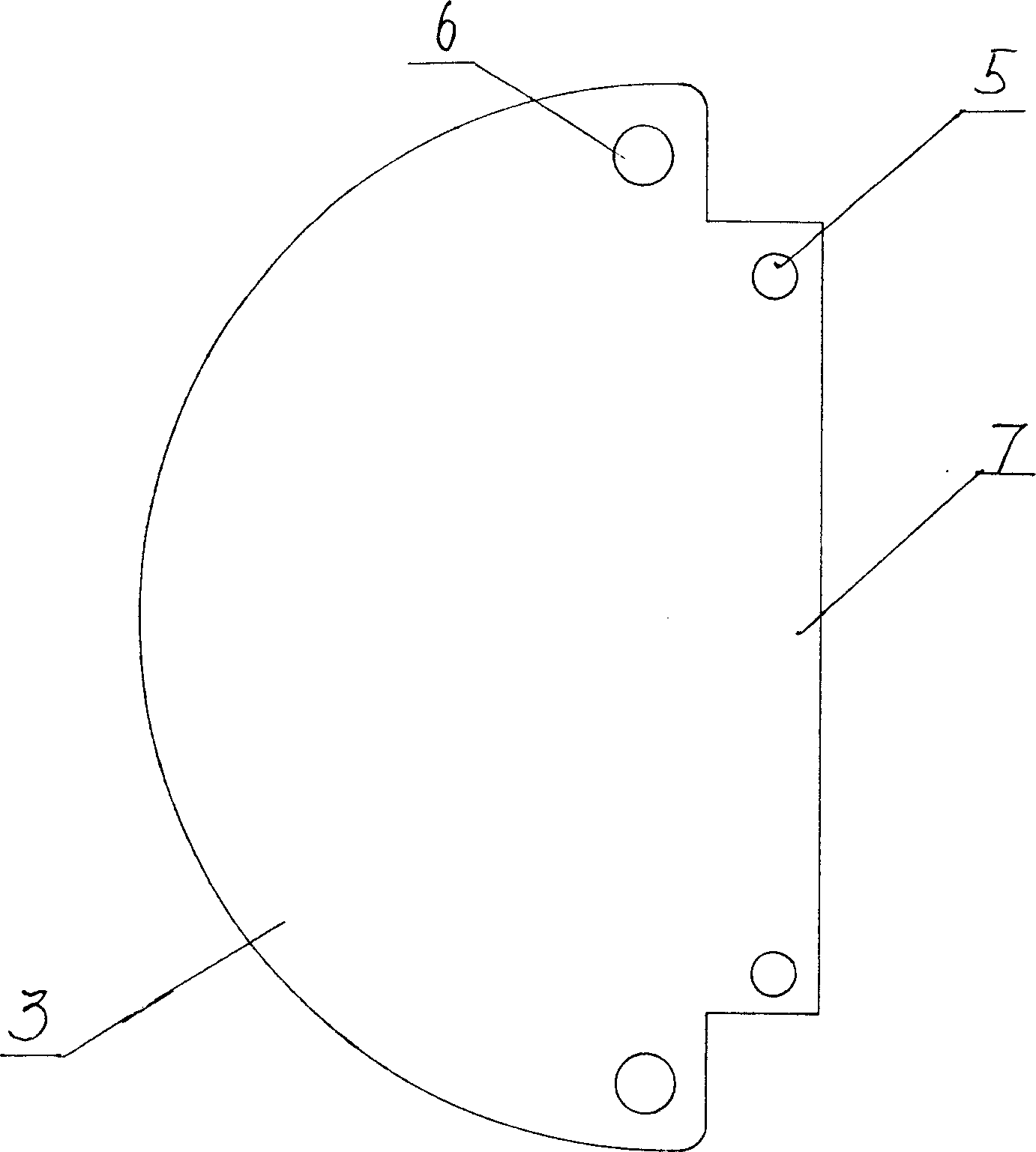

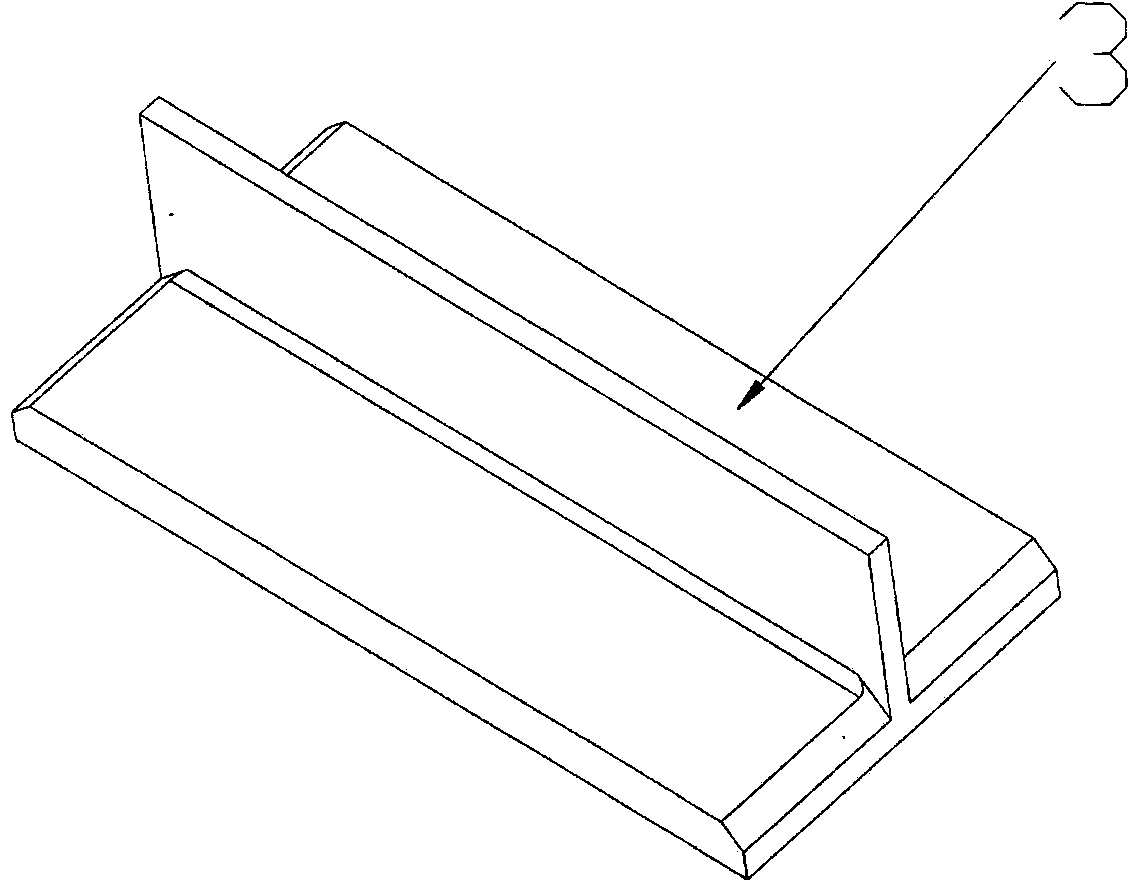

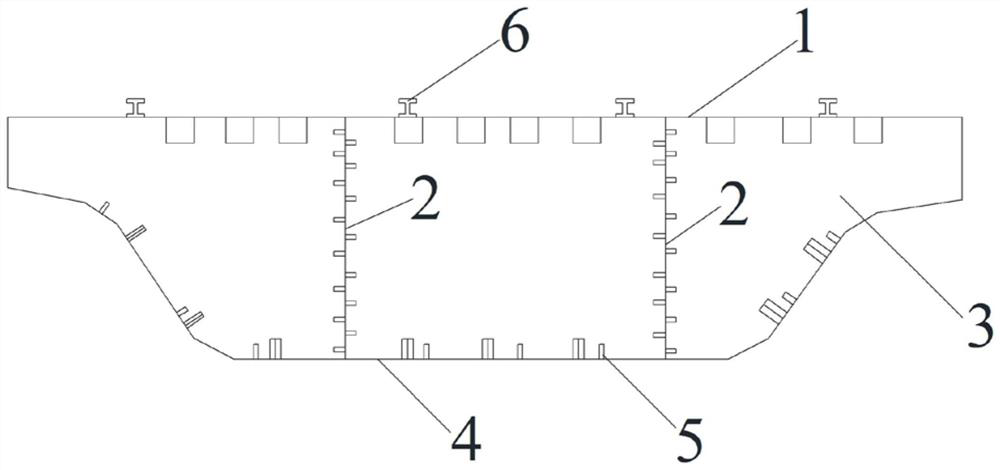

Ship hull sectional turn-over method and special-purpose rolling rack

InactiveCN1769133AGive full play to the lifting capacityReduce the number of segmentsVessel partsStructural engineeringMechanical engineering

The invention discloses a method for sectional turning the ship and special rolling bracket, comprising: (1) each side edge of one end of section has one arc rolling bracket while its axis is parallel to the sectional turning surface; (2) the invention uses the crane to hang the another end of section to turn the section for 180 degrees along the arc surface of rolling bracket to complete the sectional turning. The inventive special rolling bracket has a round arc surface and a connection plate arranged on the chord of round arc and connected to the section via connection hole. Compared to present technique, the invention can fully utilize the lifting ability of crane while the section weight can be two times of the section weight turned by two crane; since the section is large, the number of sections is fewer, the closing quality of ship is confirmed, and the period of building ship can be shorted; since the section is turned by the support of rolling bracket, it has better support condition, reliable safety, simple operation, and fast turning speed.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

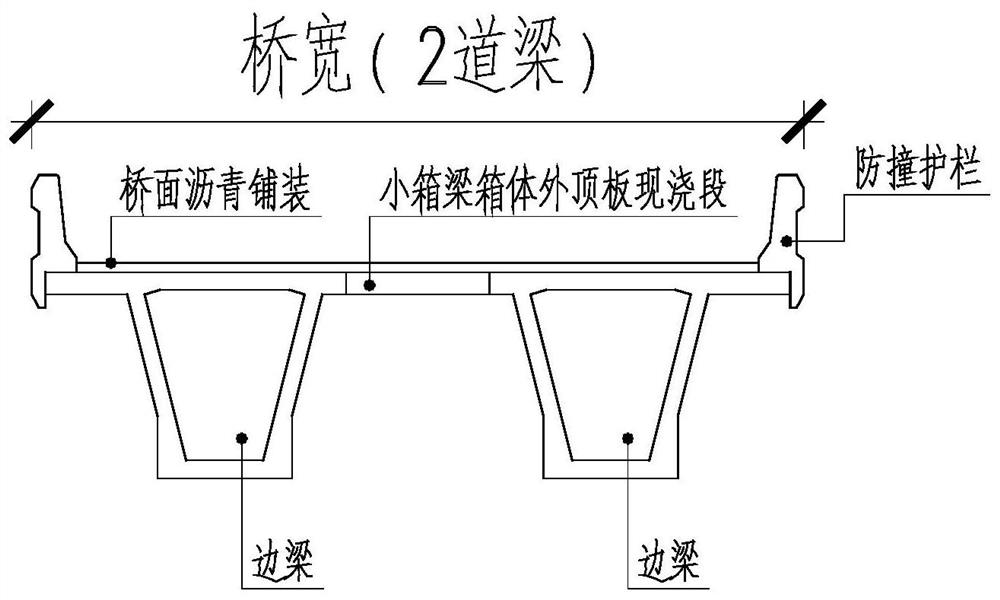

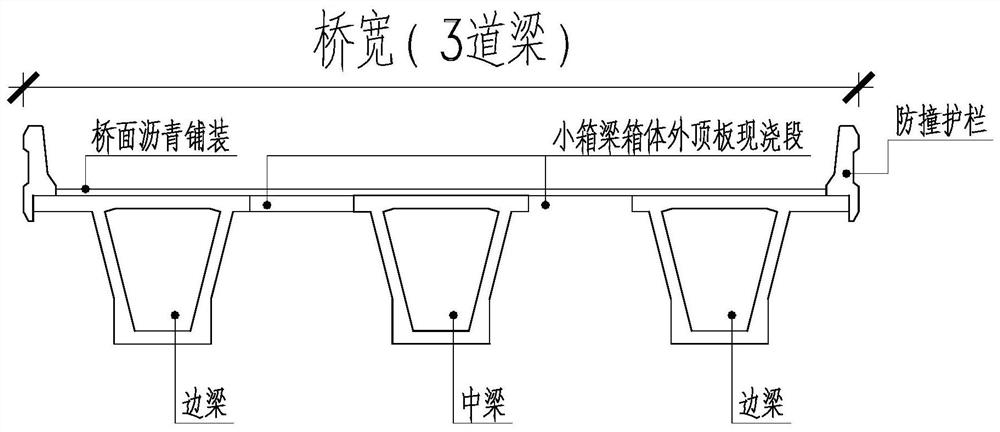

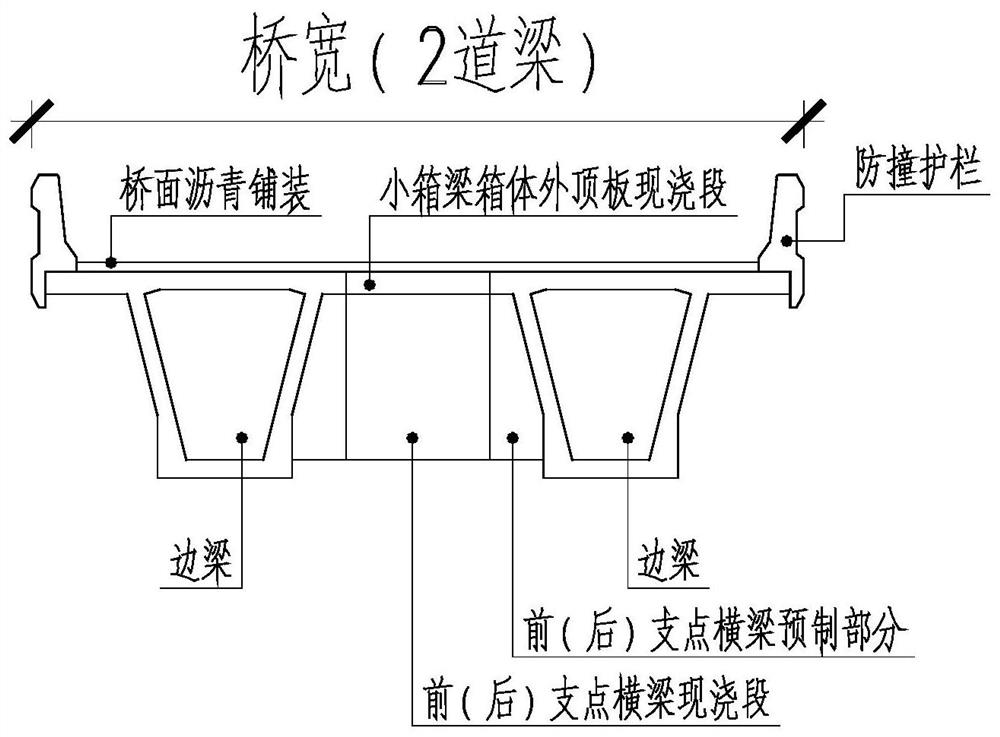

Bridge of longitudinal segmental prefabricated small box girder, and construction method thereof

PendingCN111778864AReduce the number of segmentsEasy constructionCeramic shaping apparatusBridge erection/assemblyArchitectural engineeringSupport point

The invention discloses a bridge of a longitudinal segmental prefabricated small box girder, and a construction method thereof. The bridge comprises two or more girders extending in the length direction of the bridge, wherein the side girders are located on the two sides of the bridge, and the middle girder is located between the side girders on the two sides of the bridge; each girder comprises aplurality of small prefabricated box girders and is formed by adopting a segment method; every two adjacent girders are connected through a small box girder transverse cast-in-place segment between the corresponding prefabricated small box girders; and the plurality of prefabricated small box girders comprise a front supporting point segment prefabricated small box girder, a front span inner cross girder segment prefabricated small box girder, a mid-span segment prefabricated small box girder, a rear span inner cross girder segment prefabricated small box girder and a rear supporting point segment prefabricated small box girder. During construction, firstly, segments of the prefabricated small box girder are manufactured; then all the prefabricated small box girders are conveyed to a construction site to be spliced into the girder; and finally, transverse connection of the girder is conducted. Compared with a method using a traditional prefabricated segmental girder, the method of theinvention greatly reduces the number of segments and simplifies construction.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

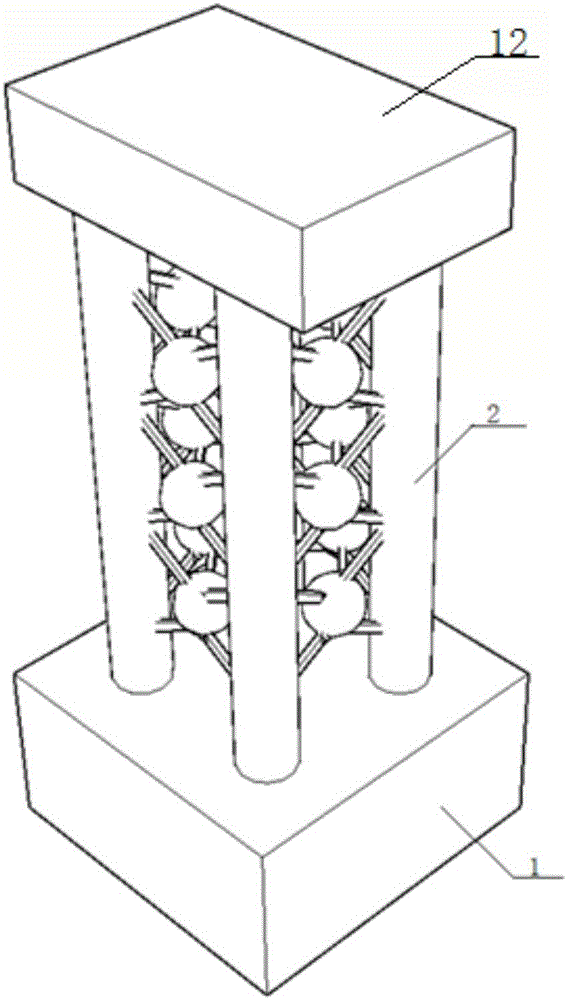

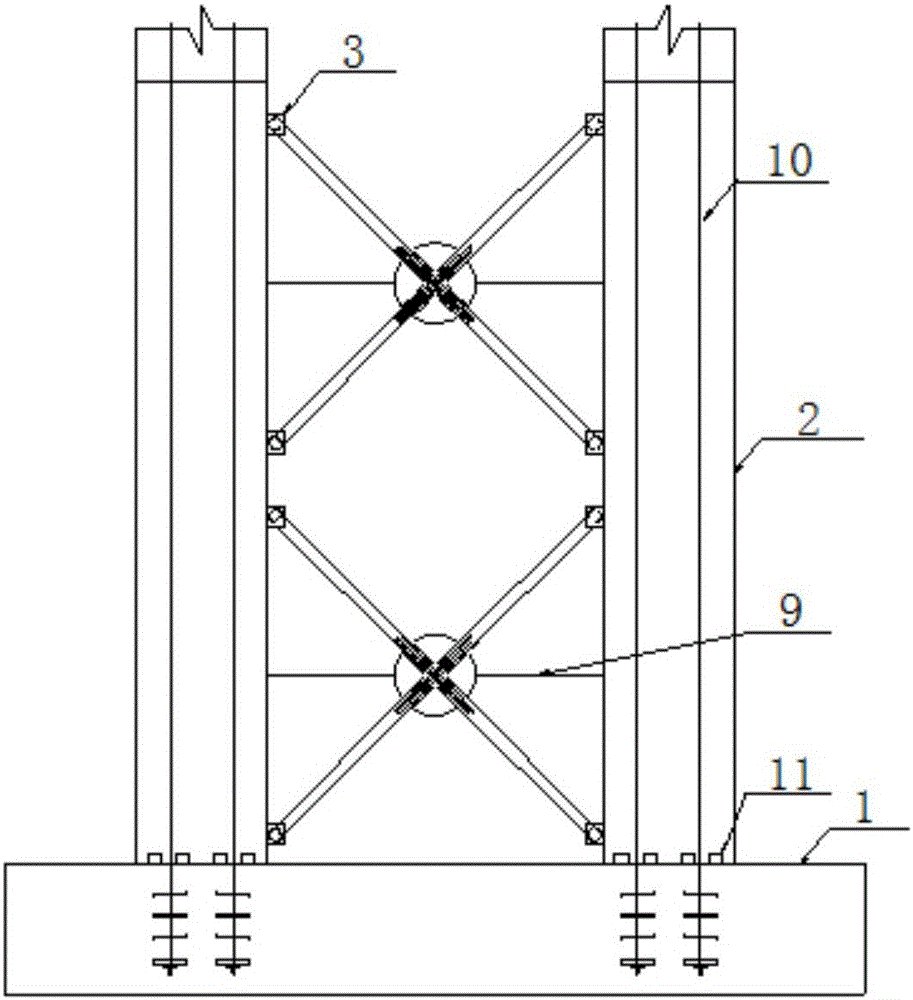

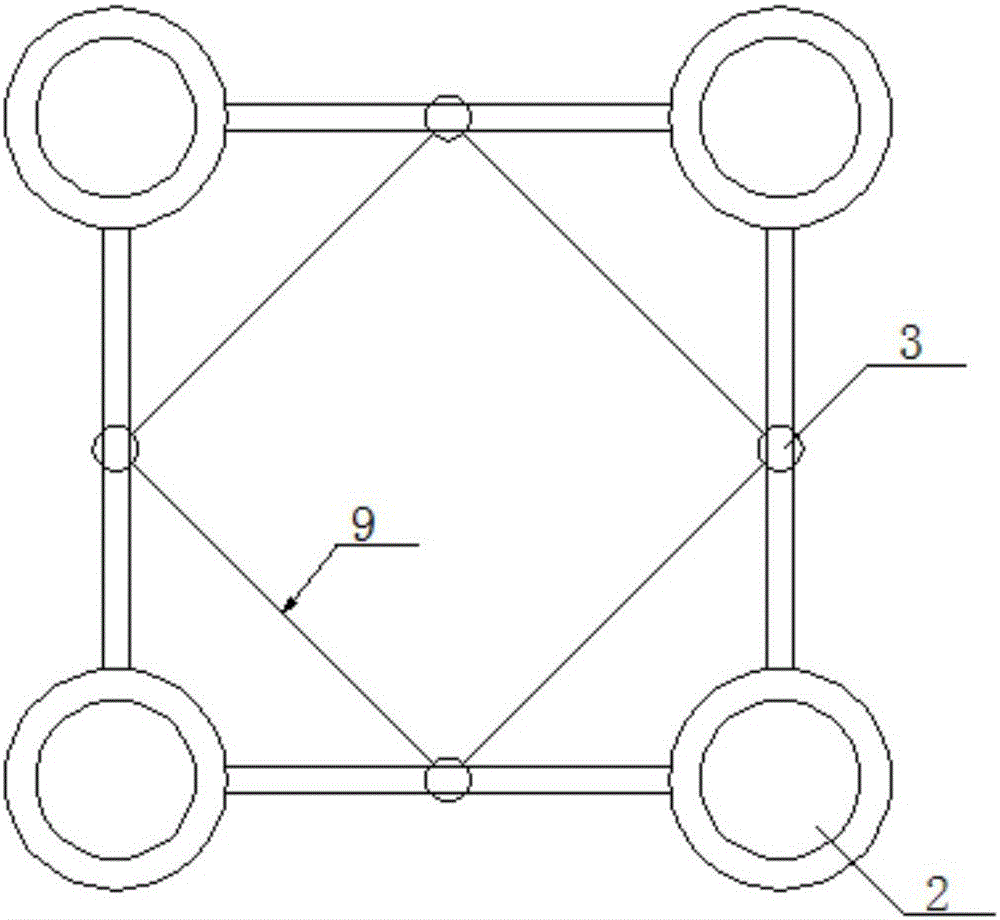

Energy-consuming prefabricated pier structure and construction method thereof

ActiveCN106012813AImprove product qualityShorten the construction periodBridge structural detailsBridge erection/assemblyPre stressArchitectural engineering

The invention discloses an energy-consuming prefabricated pier structure and a construction method thereof. Multiple prefabricated assembled piers are vertically arranged on the upper surface of a bearing platform, every four prefabricated assembled piers form a group, multiple dampers are arranged among the prefabricated assembled piers in one group, and a cover beam is arranged on the upper surface of the prefabricated assembled piers; and a pre-stressed tendon penetrates through the prefabricated assembled piers to be respectively connected with the bearing platform and the cover beam. The energy-consuming prefabricated pier structure has the advantages that one pier is divided into four-leg frame piers respectively composed of four pier columns, so that the sectional area of each segment can be effectively reduced, the height of each segment can be increased, the quantity of the segments of a single pier body is reduced, and the construction efficiency and mechanical properties of the prefabricated segment assembled piers are improved; and energy consumption of the dampers in operation is provided in two aspects of soft steel deformation and friction energy dissipation of a mandrel and a lantern ring, and energy produced by plane deformation and spatial deformation can be absorbed, so that different vibration modes which can be produced by the piers under strong shock can be adaptive.

Owner:NANJING UNIV OF TECH

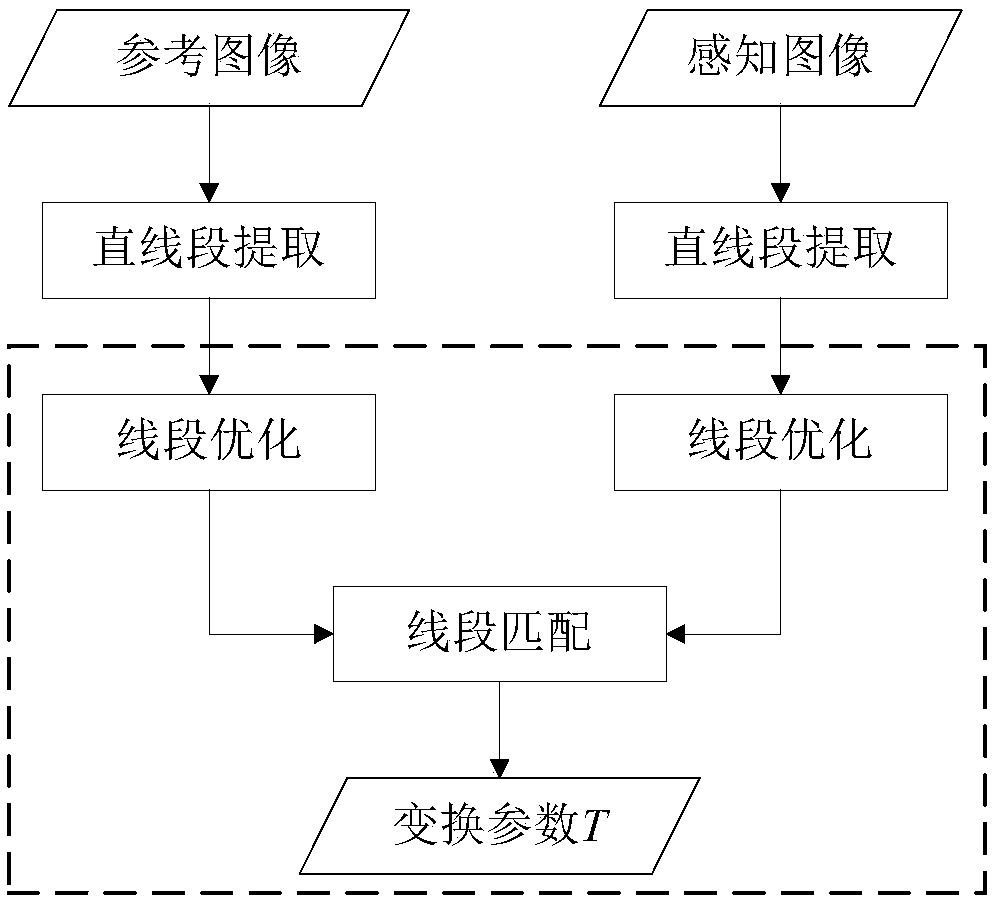

Straight line-based different-source image coupling method

ActiveCN108305277AIncreased complexityImprove search efficiencyImage enhancementImage analysisAs elementAviation

The invention relates to the technical field of image processing and provides a straight line-based different-source image coupling method. The method includes the steps of extracting line characteristics of a reference image and line characteristics of a sensing image, and taking the line characteristics as elements of different-source image coupling; constructing a neighborhood relation betweenline end points and end points and a neighborhood relation between end points and lines, connecting the end points with the lines with the neighborhood relations, obtaining straight lines with betterstability, and constructing line sets accurately representing scene structures; constructing line pairs between the line sets of the reference image and the line sets of the sensing image, and calculating possible transformation parameters; and selecting transformation parameters that enable the sensing image and the reference image to have the highest similarity, and thus realizing coupling of the sensing image and the reference image. A phenomenon of double sides can be effectively prevented when road lines are extracted from an aviation image, the number of lines for coupling is greatly reduced, and the geometrical structure of a scene can be represented by as few lines as possible. The method is easy to realize, is fast in calculating speed and can realize quantitative analysis.

Owner:中国航天电子技术研究院

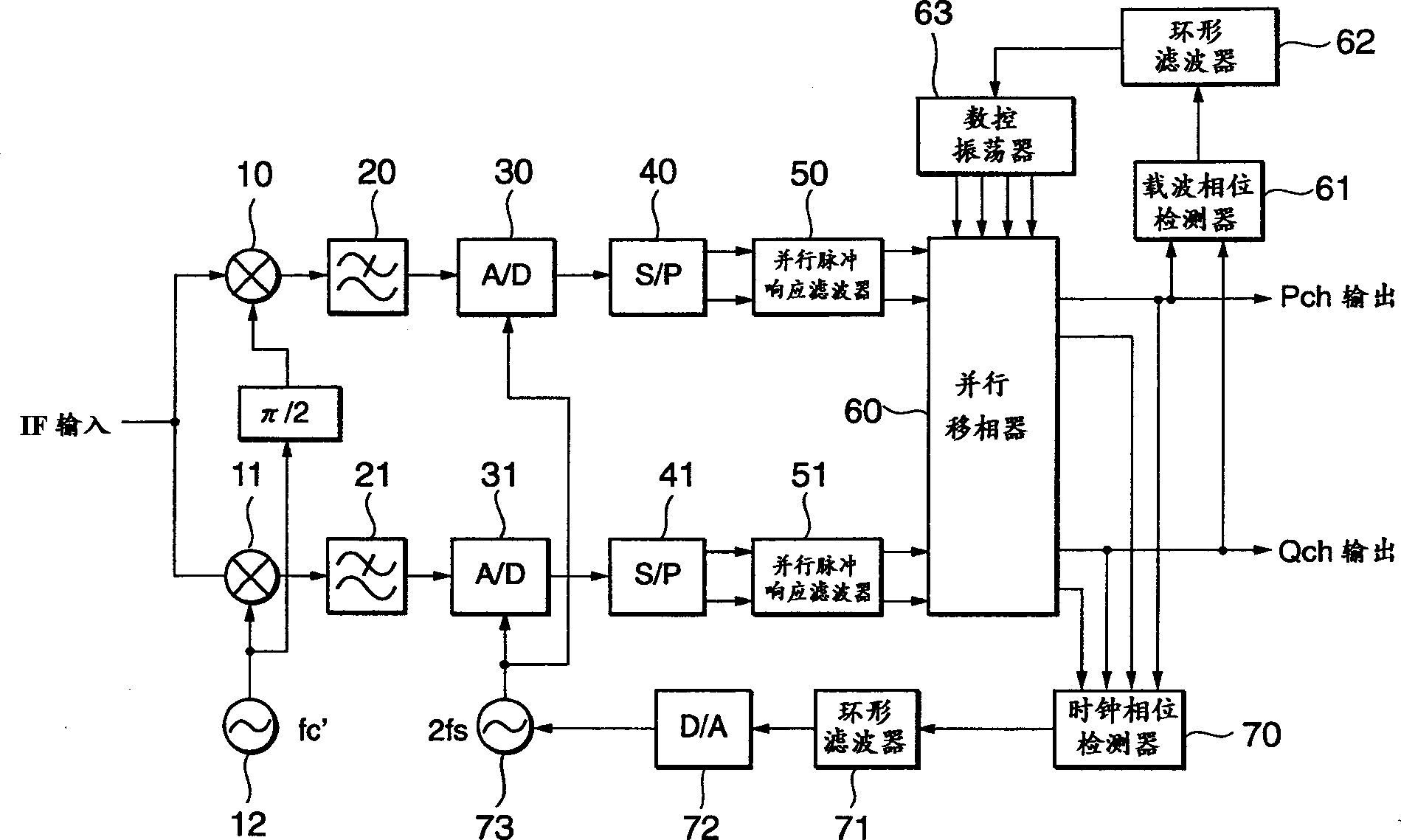

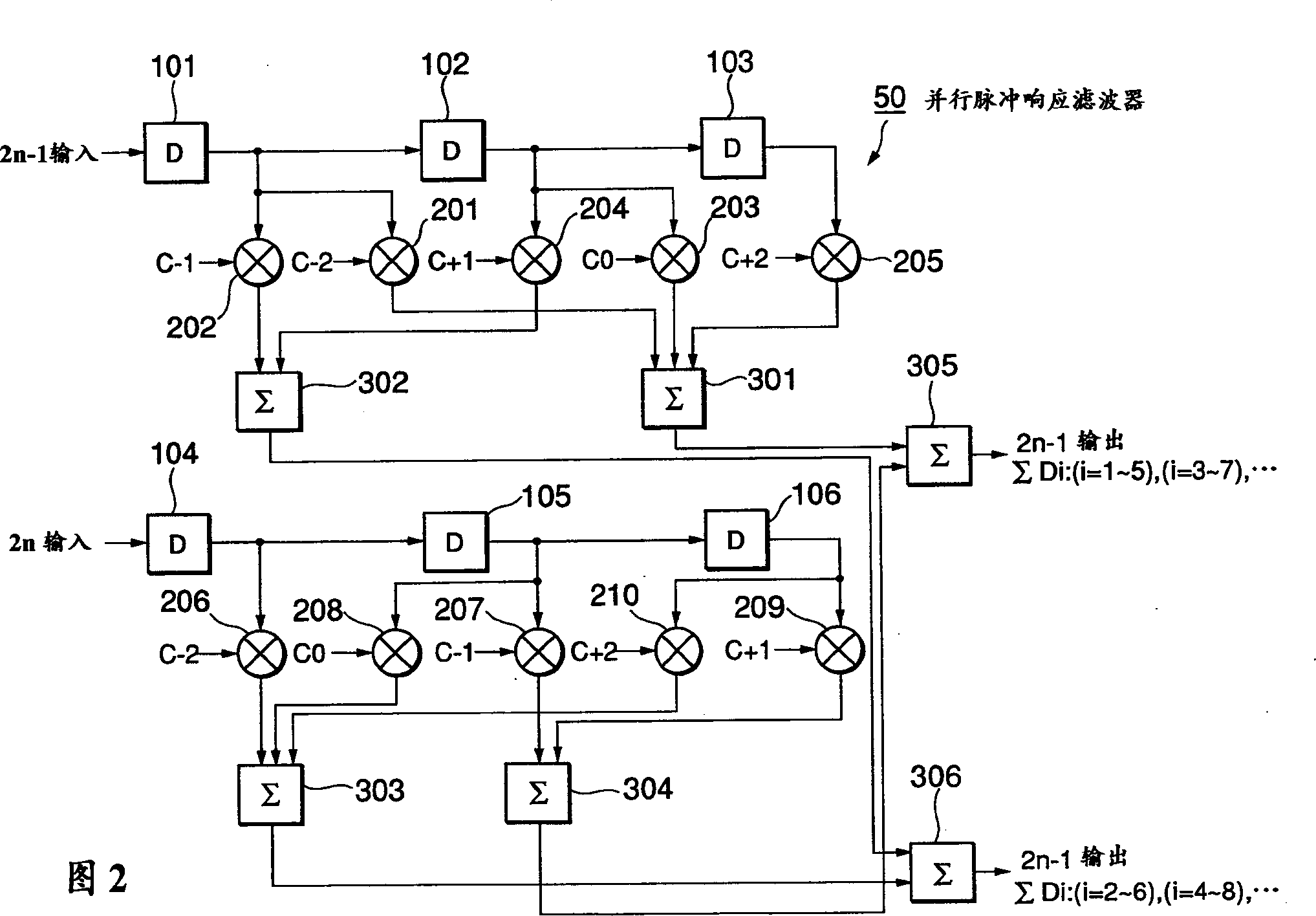

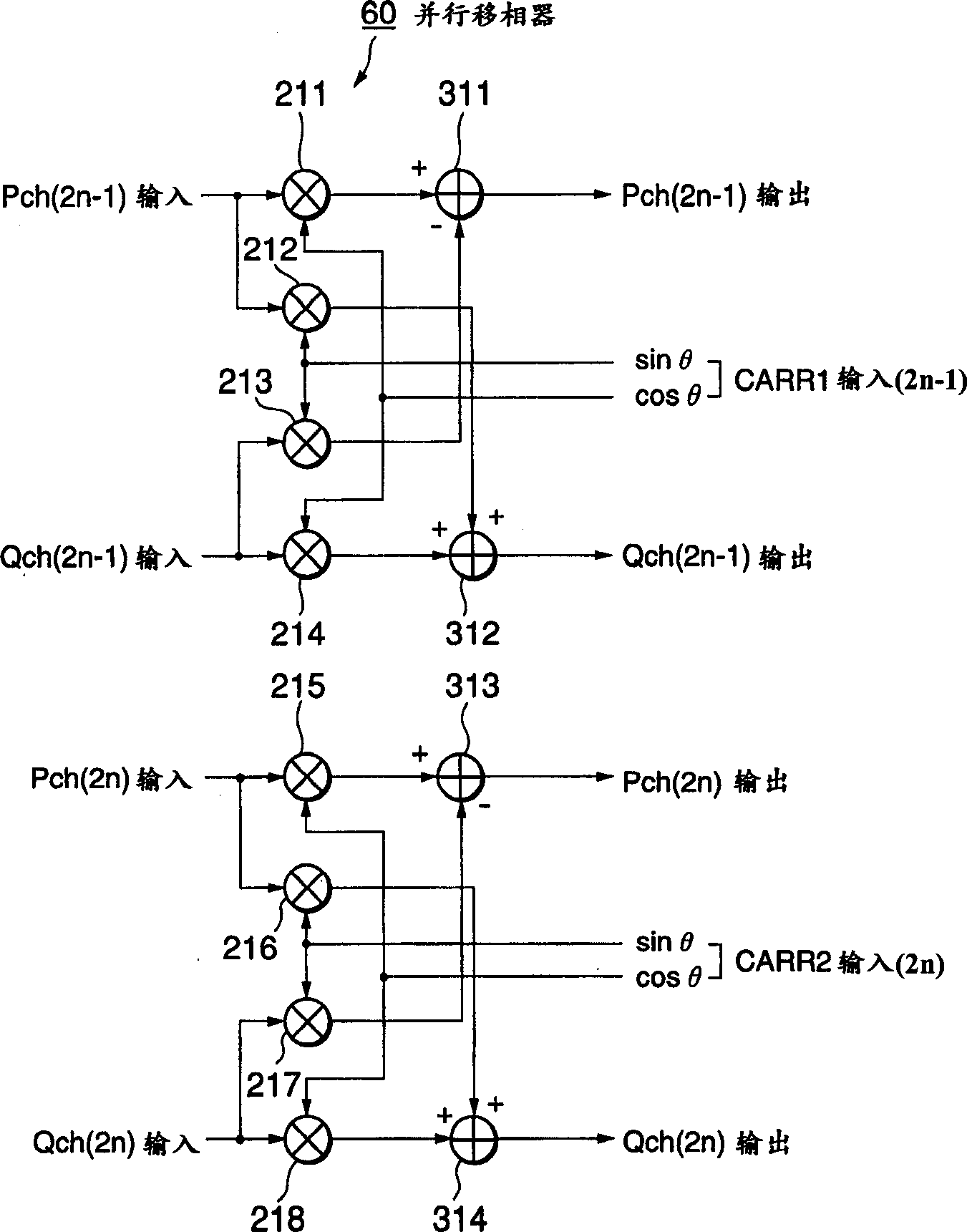

Demodulator for processing digital signal

InactiveCN1339216AReduce circuit sizeReduce the number of segmentsDigital technique networkPhase-modulated carrier systemsDigital signal processingCommunications system

The serial data signal obtained by carrying out an A / D conversion at two times the modulation speed is S / P-converted, at a data ratio of 1:2, into a pair of parallel data signals of the modulation speed. The demodulation process is carried out by parallelly processing the pair of parallel data signals, resulting in that the demodulation speed is equal to the modulation speed. The serial data obtained by carrying out the A / D conversion at four times the modulation speed is S / P-converted at a data ratio of 1:4, and is then similarly subjected to demodulation at the demodulation speed equal to the modulation speed. With this arrangement, the demodulator carrying out the digital signal processing can be applied to communication systems having a high modulation speed.

Owner:NEC CORP

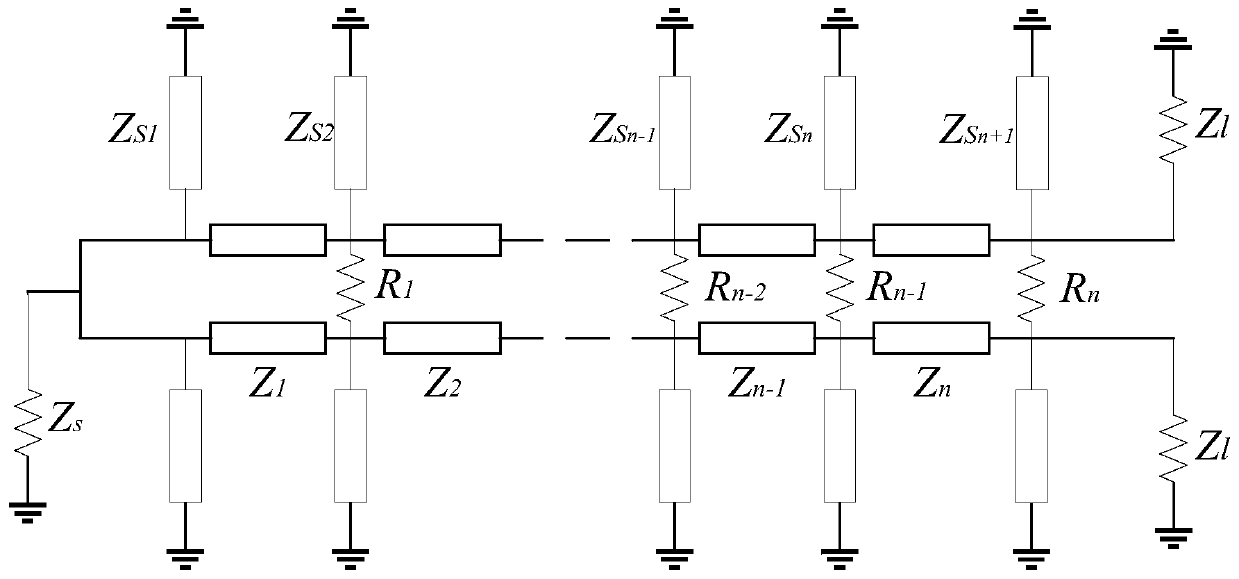

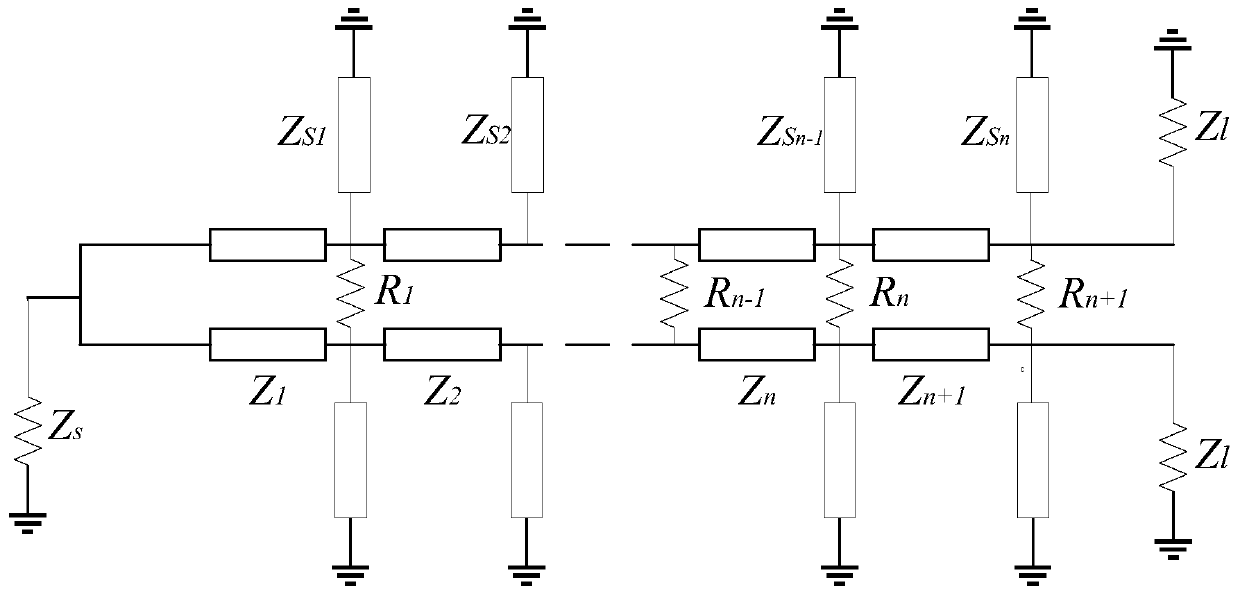

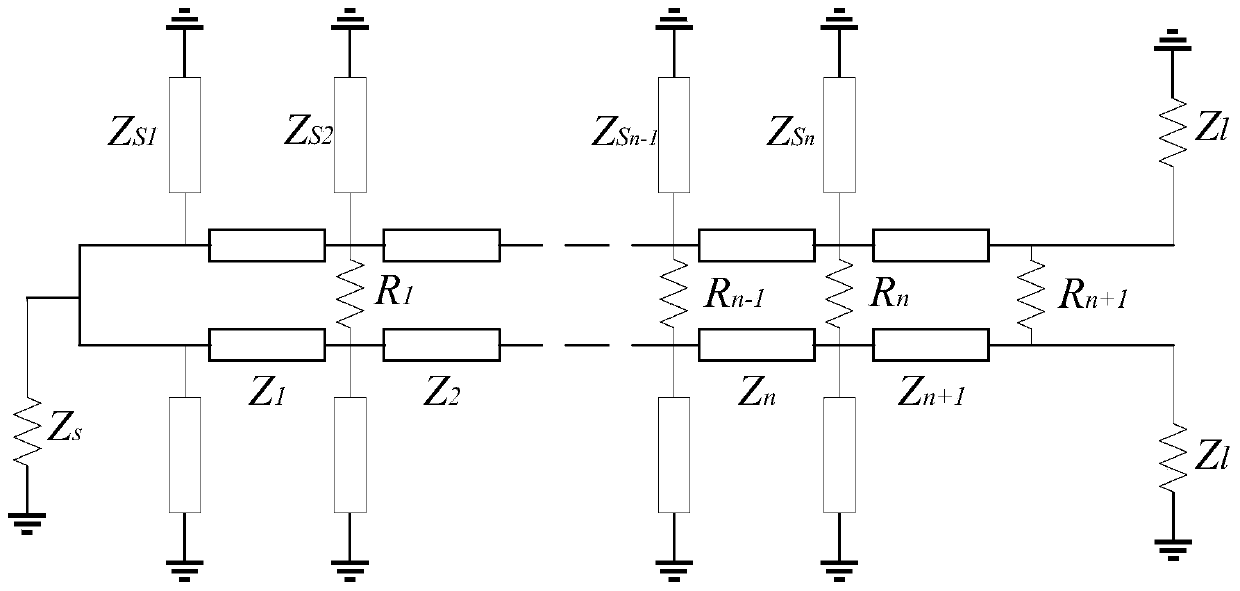

Wilkinson power divider with isolation frequency point aligned Chebyshev filtering characteristics and a preparation method thereof

InactiveCN109766657AReduce the number of segmentsReduce the impact of bandwidthSpecial data processing applicationsCoupling devicesElectrical resistance and conductanceWilkinson power divider

The invention discloses a Wilkinson power divider with isolation frequency point aligned Chebyshev filtering characteristics, which comprises an input end and two output ends, and also comprises two transmission branches connected in parallel between the input end and the two output ends; Each transmission branch is formed by connecting n sections of first transmission lines and one section of second transmission line in series; Wherein the second transmission line is selectively connected to the starting end or the tail end of the transmission shunt; The plurality of resistors are respectively connected between every two corresponding sections of transmission lines on the two transmission branches; The two groups of short-circuit wires are symmetrically connected to the two transmission branches; Each group of short-circuit lines comprises m short-circuit lines, and m is greater than or equal to 2 and less than or equal to n; When m is an even number, the short-circuit lines are connected to symmetrical positions on the two sides of the center of the n sections of first transmission lines; And when m is an odd number, the short circuit lines are connected to the central positionsof the n sections of first transmission lines and the symmetrical positions on the two sides of the central positions. The invention also provides a preparation method of the power divider.

Owner:JILIN UNIV

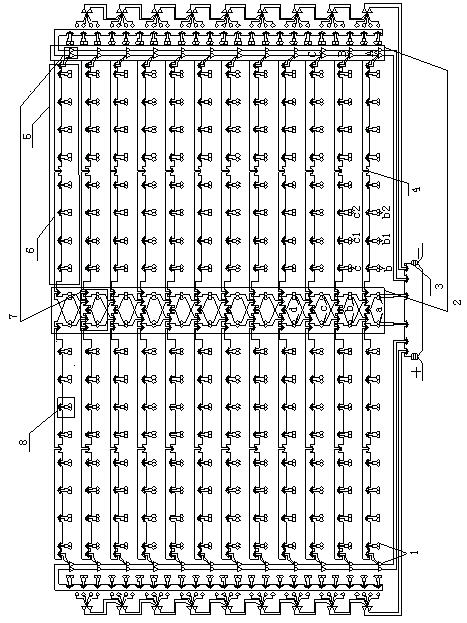

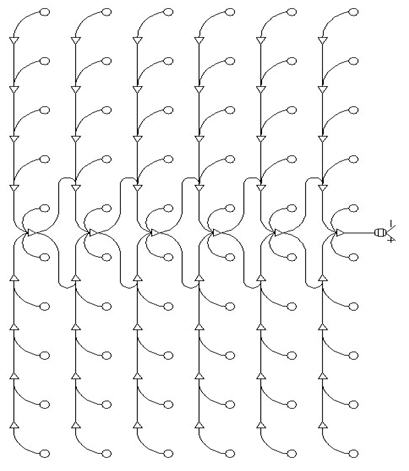

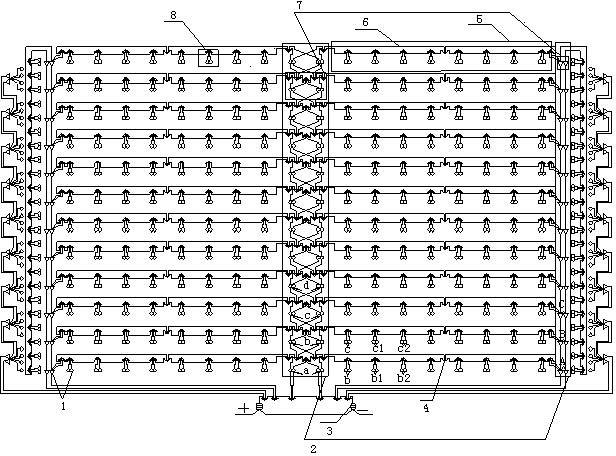

Inner screen continuous type coil adopting fractional turn integer winding method and winding method thereof

PendingCN107785165AImprove fill rateLow costInductances/transformers/magnets manufactureCapacitanceFilling rate

The invention relates to an inner screen continuous type coil adopting a fractional turn integer winding method and a winding method thereof. The coil comprises operating wires and a shielding wire. The operating wires are two wires wound in parallel, the shielding wire is arranged between the interturn and wire space of the operating wires; at the wire segment changing position of the operating wires, one of the two operating wires wound in parallel winds one more circle and then moves upward to the next segment, and the other of the two operating wires wound in parallel directly moves upwardto the next segment, and accordingly an integer plus half turn structure is formed. The coil adopts two wires for winding, the number of turns of each segment is no longer limited to an integer turn,but to an integer plus half turn; filling rate of the coil is effectively improved, coil costs are reduced, longitudinal capacitance of the coil is effectively increased, turn insulation thickness ofthe shielding wire can be correspondingly smaller, and anti-short circuit capacity of the coil is enhanced while the filling rate is improved.

Owner:TBEA SHENYANG TRANSFORMER GRP CO LTD

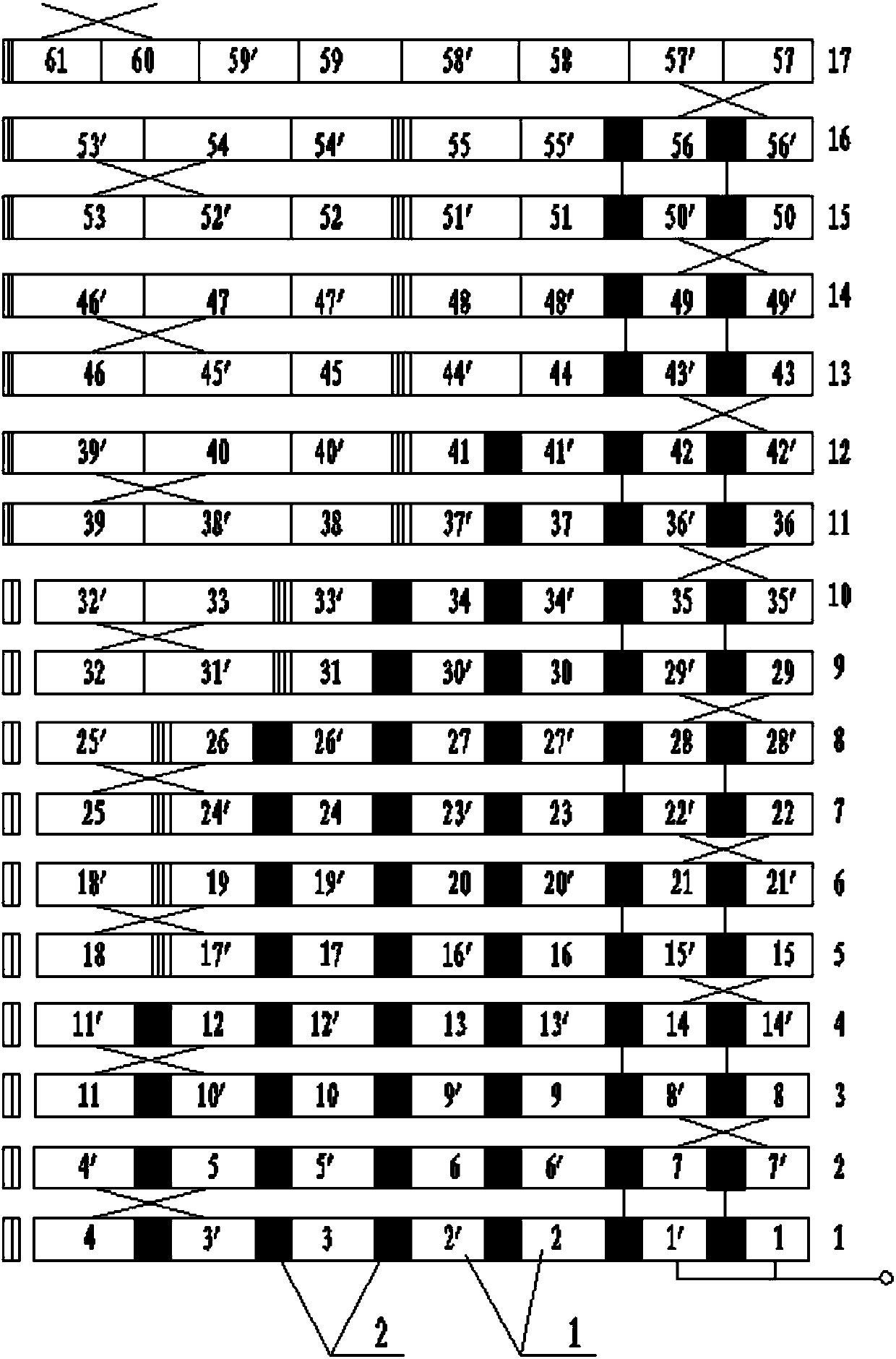

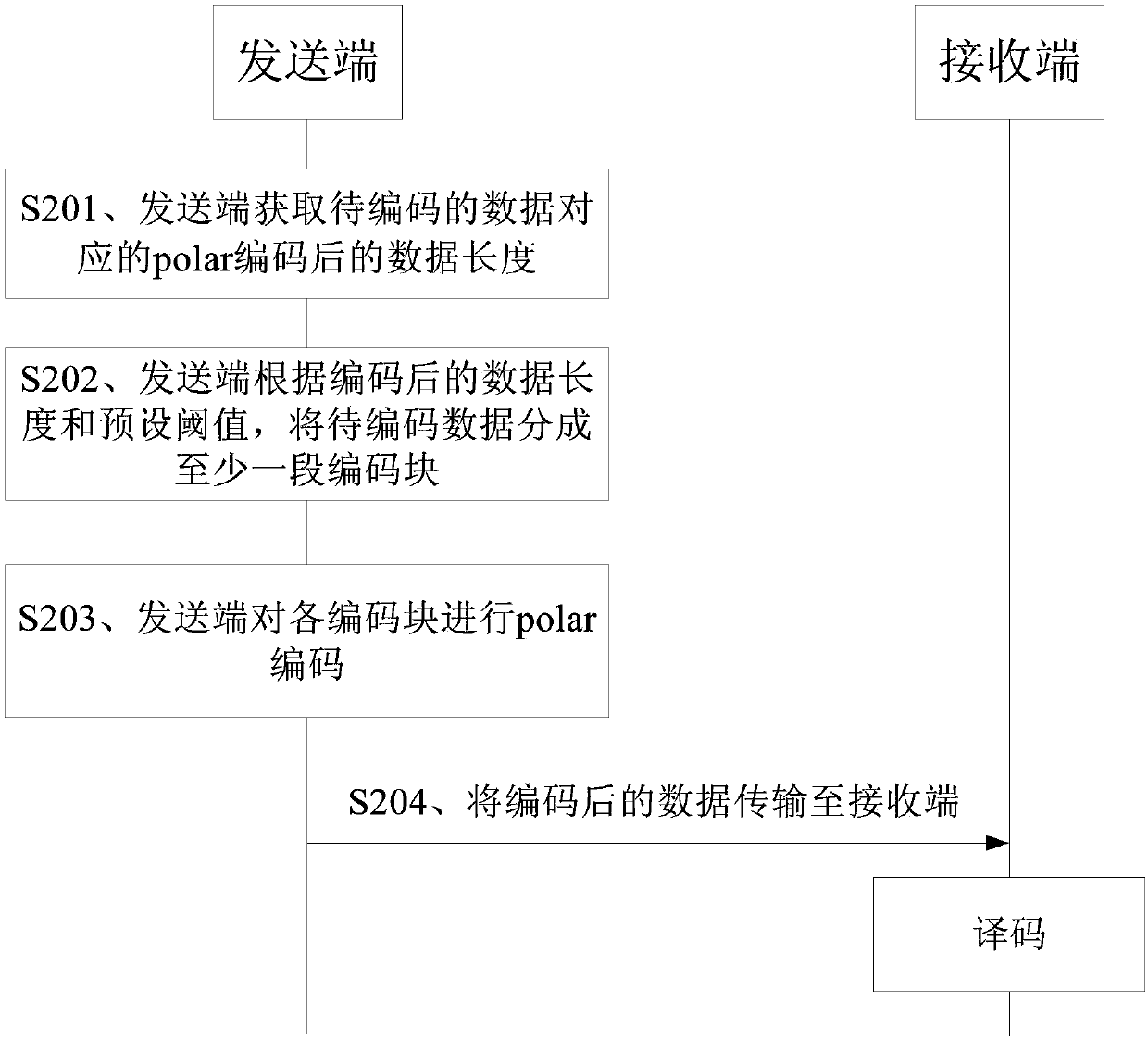

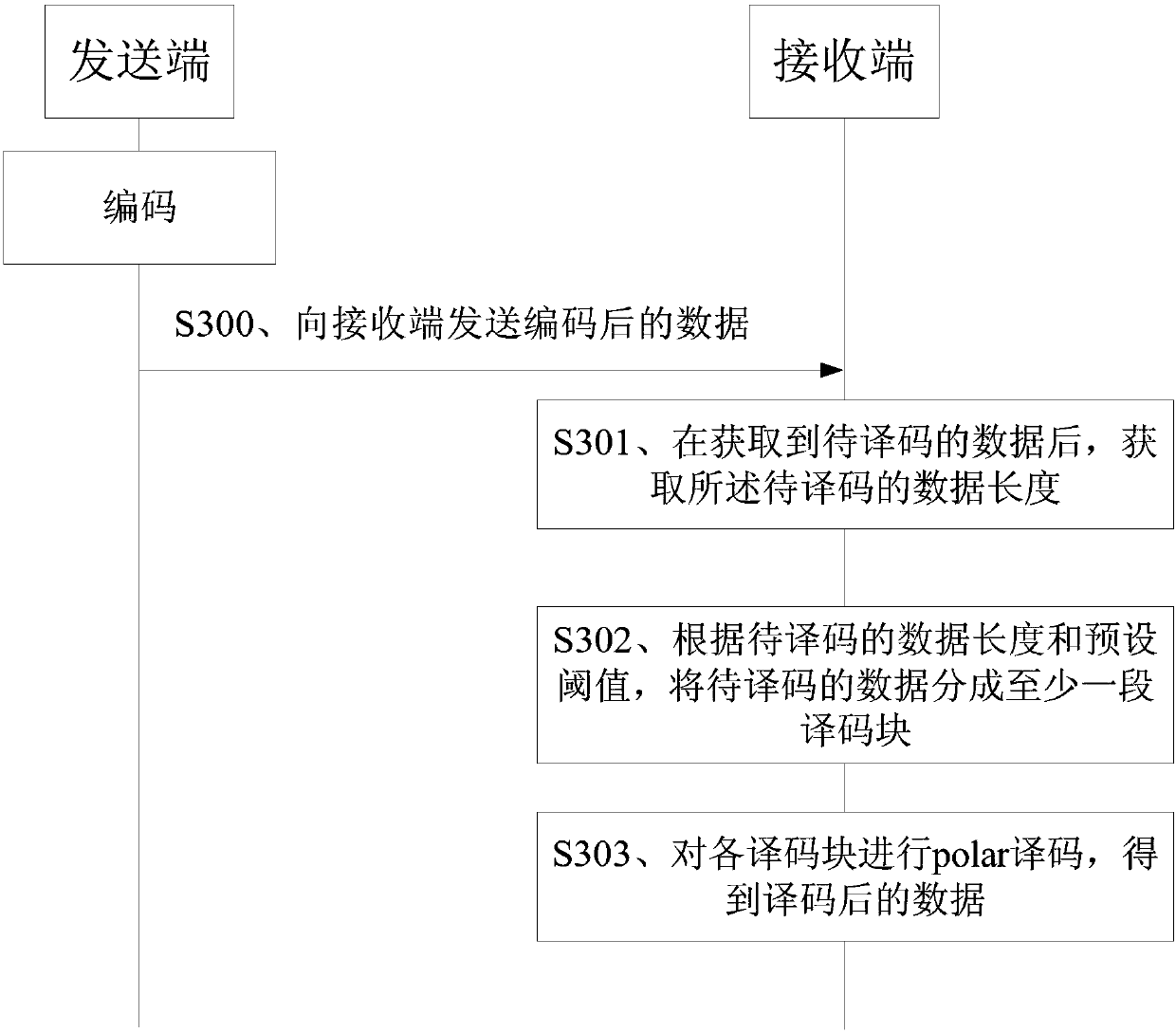

Coding and decoding methods and equipment

PendingCN107342773AAvoid lostReduce the number of segmentsError preventionCode conversionCoding blockData transmission

The embodiment of the invention provides a coding method, a decoding method, coding equipment and decoding equipment. The coding method comprises the steps as follows: a sending terminal acquires the length of data after polar coding corresponding to the data to be coded; the sending end divides the data to be coded into at least one segment of coded blocks according to the length of the coded data and a preset threshold; and the sending end performs polar coding on each coded block, and transmits the coded data to the a receiving end. According to the methods and the equipment provided by the embodiment of the invention, the problem that loss of data transmission performance caused by too much segmenting is avoided.

Owner:HUAWEI TECH CO LTD

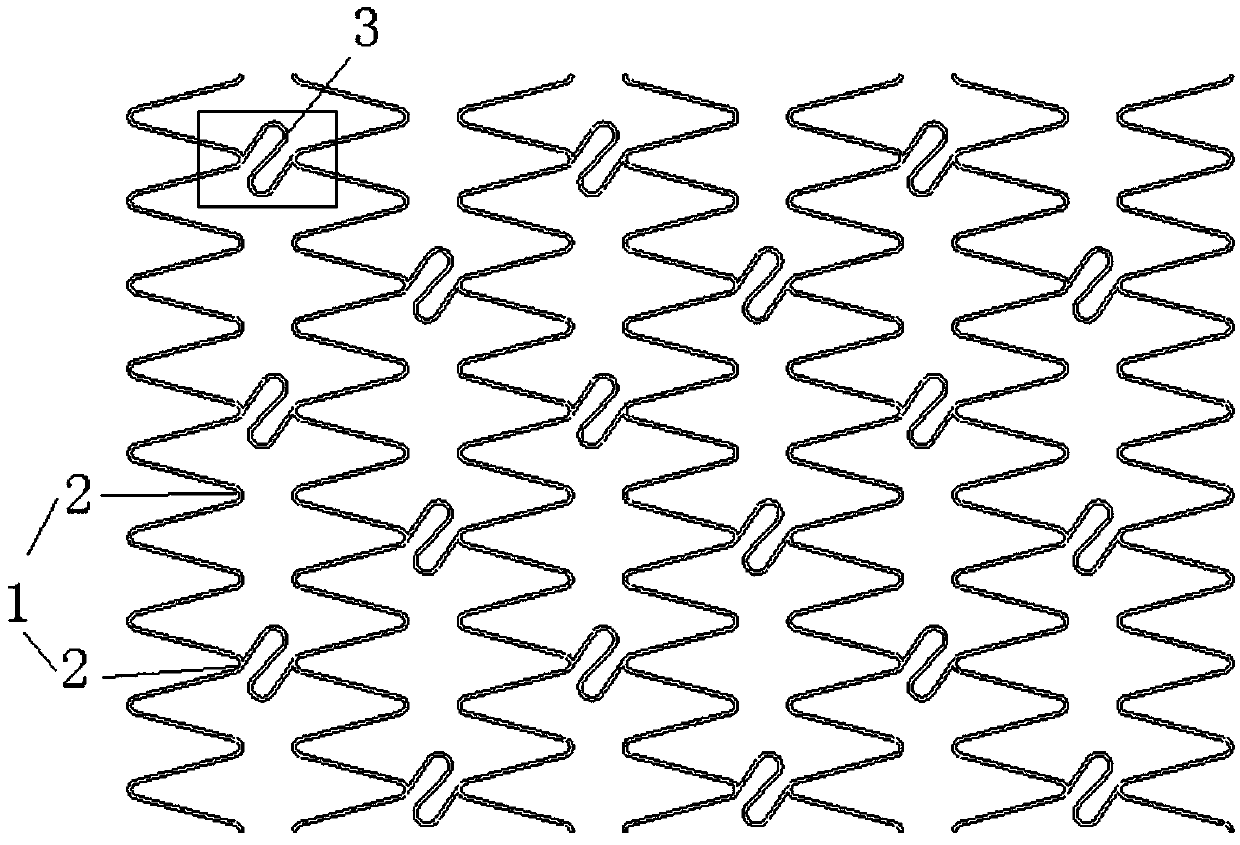

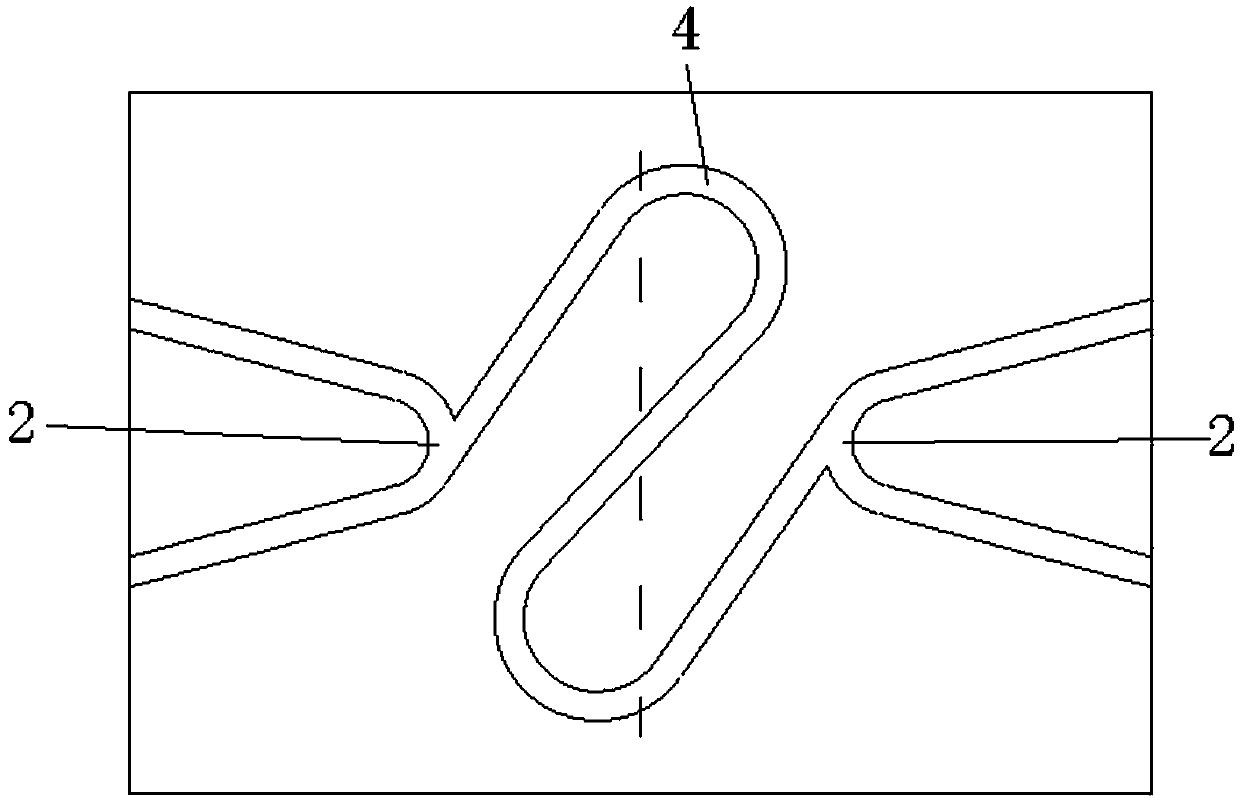

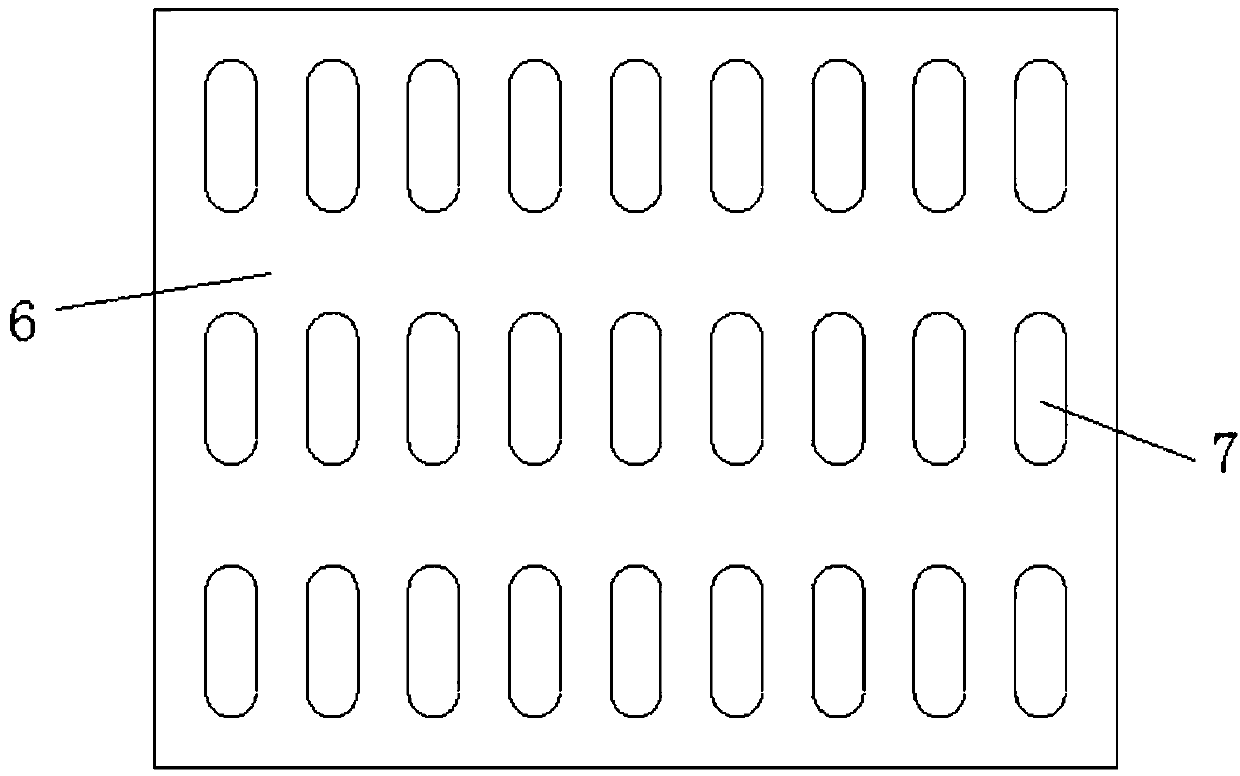

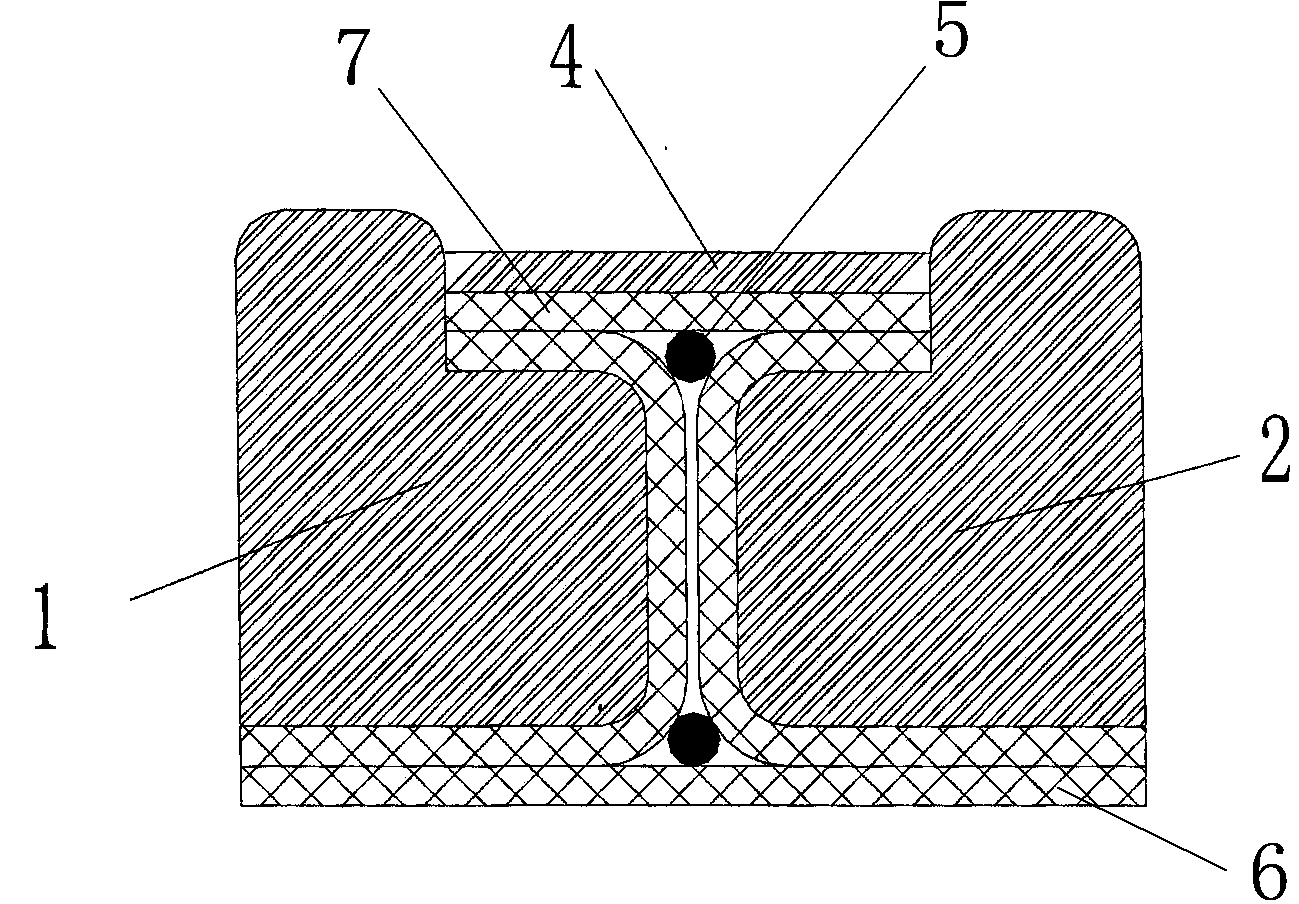

Vascular stent

PendingCN109646148AReduce the number of segmentsImprove flexibilityStentsBlood vesselsProximal pointInsertion stent

The invention relates to a vascular stent. The vascular stent comprises multiple supporting rings and multiple connecting rods, and the supporting rings are arranged at the near end and the far end ofthe vascular stent and in the middle of the vascular stent, and are composed of multiple unit waves; every two adjacent supporting rings are connected through a connecting rod; the connecting rod between every two adjacent supporting rings is connected to the wave tops of the two corresponding adjacent unit waves through a top-to-top mode; each connecting rod is composed of one or more first connecting parts, and the first connecting parts are one or a combination of S-shaped connecting parts, N-shaped connecting parts and Z-shaped connecting parts. The vascular stent has the advantages thatby improving the structure, the number of segments of the vascular stent si decreased, the distance between the segments is increased, accordingly, the coverage rate of metal of the stent is decreased, and the flexibility and wall attachment of the vascular stent are improved; multiple holes are formed in a film covering unit, so that the permeability of the film covering unit is improved; statindrugs are loaded onto the film covering unit to accelerate endothelialization of blood vessels.

Owner:SHANGHAI SIXTH PEOPLES HOSPITAL

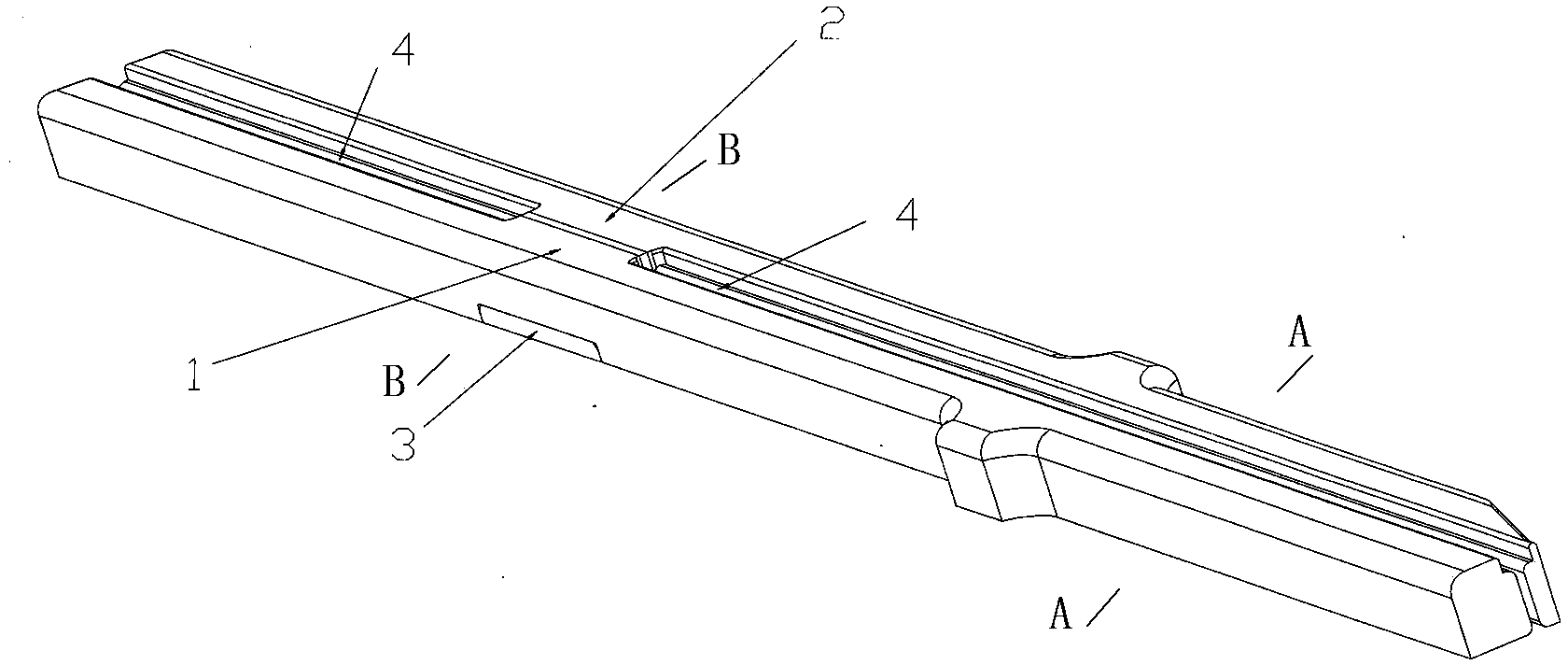

Forming tool and method for I-shaped stringers with openings

The invention relates to a forming tool and method for I-shaped stringers with openings. The structure of the forming tool is characterized in that a left forming die and a right forming die are arranged adjacently; opening strip grooves are symmetrically formed in the upper surface and communicated; the opening strip grooves are in discontinuous structures in axis directions of the left forming die and the right forming die; the discontinuous parts correspond to openings of the I-shaped stringers; grooves are formed in the lower parts of the discontinuous parts of the left forming die and the right forming die; transverse planes of T-shaped stop blocks are formed in the grooves; the vertical edges of the T-shaped stop blocks are formed in gaps between the left forming die and the right forming die; upper edge strip cover plates are arranged in the opening strip grooves. The method is capable of effectively guaranteeing the surface quality of the openings and avoiding the order difference in the horizontal edges of the stringers; moreover, the left forming die and the right forming die for the stringers are accurately positioned, the thickness sizes of vertical edges of the openings of the stringers can be guaranteed, the forming linearity of the stringers can be guaranteed and the defects of the length directions of the stringers caused by the forming tooling can be avoided.

Owner:SHENYANG AIRCRAFT CORP

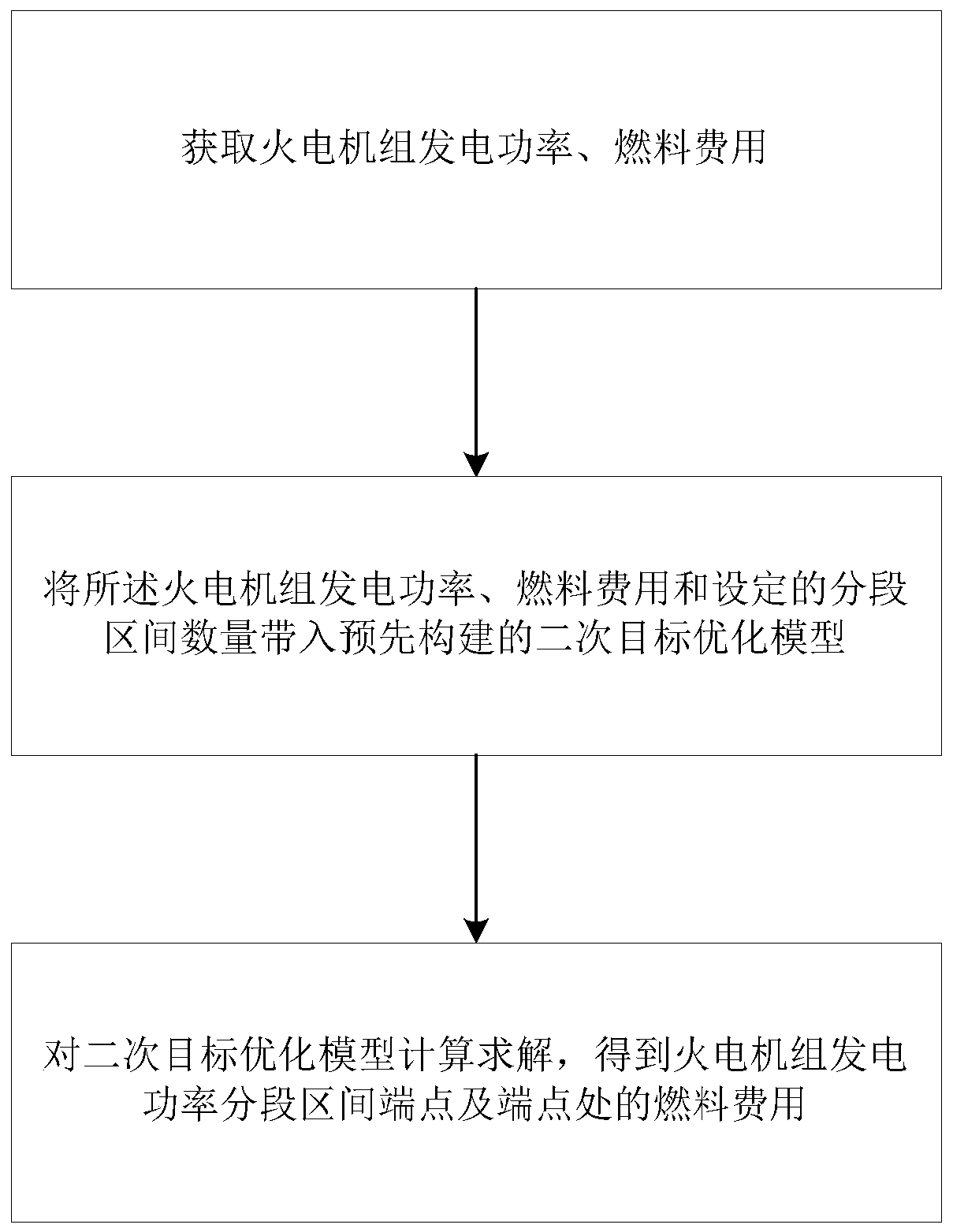

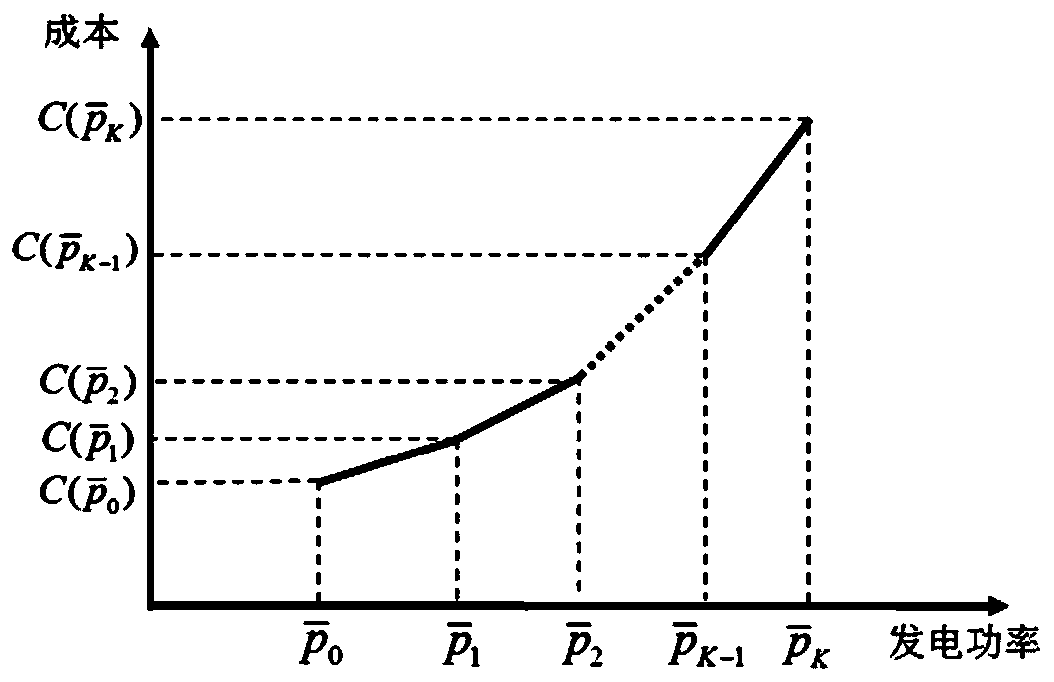

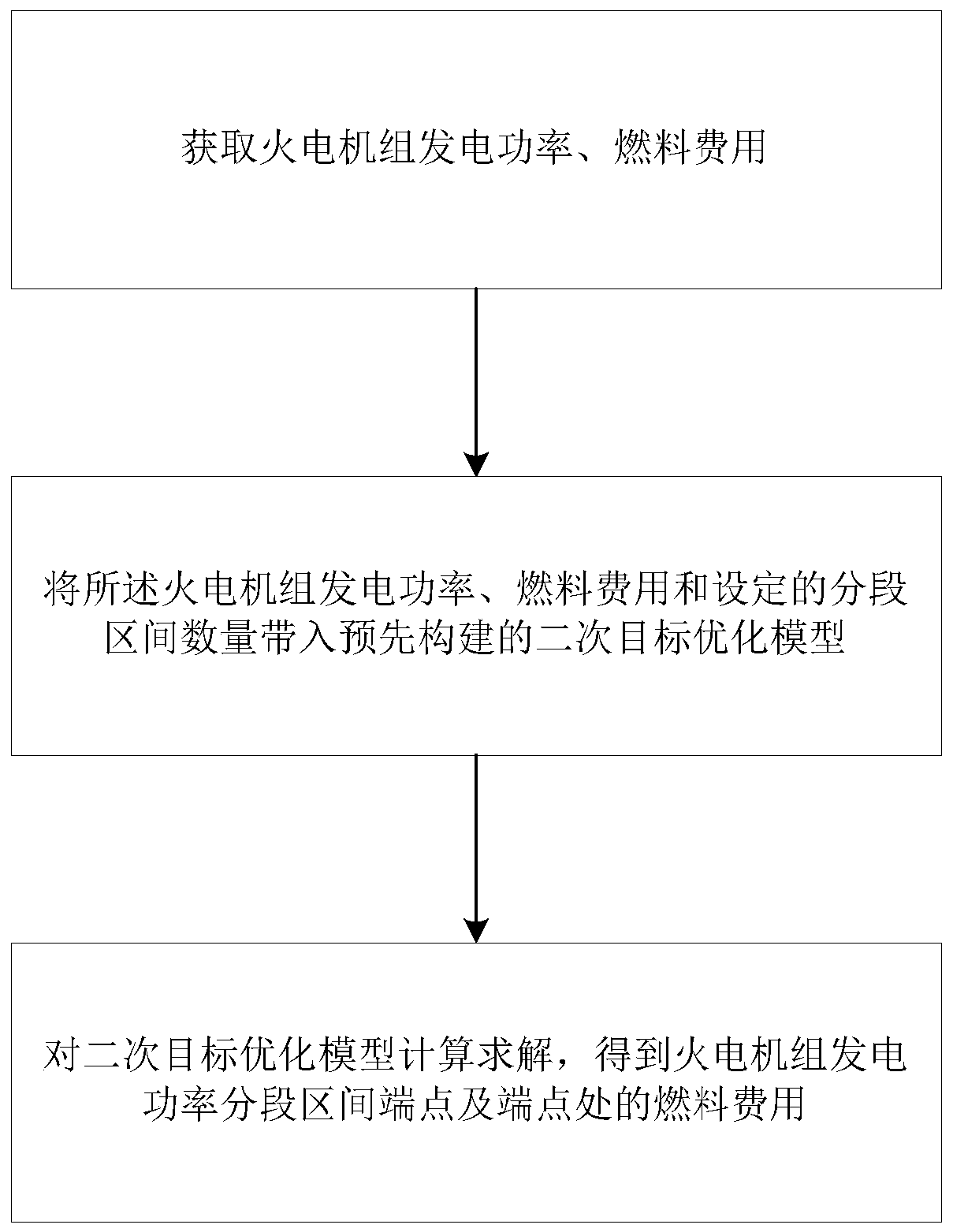

A fitting method and system for power generation fuel cost of a thermal power generating unit

ActiveCN109840367AReduce complexityReduce the difficulty of solvingData processing applicationsSystems intergating technologiesControl engineeringIndustrial engineering

The invention relates to a fitting method and system for power generation fuel cost of a thermal power generating unit. The method comprises the following steps: acquiring data of the thermal power generating unit and the number of subsection intervals for fitting the fuel cost; Abstracting a pre-established piecewise linear optimal fitting optimization model into a mathematical form based on theacquired data and the number of piecewise intervals fitted by the fuel cost; And optimizing the abstracted mathematical form by adopting a reliability domain algorithm to obtain the endpoint of the power generation power subsection interval of the thermal power generating unit and the fuel cost at the endpoint. The invention discloses a fitting method and system for power generation fuel cost of athermal power generating unit. The method comprises the following steps: acquiring data of the thermal power generating unit and the number of subsection intervals fitted with the fuel cost; And optimizing the abstracted mathematical form by adopting a reliability domain algorithm to obtain a thermal power generating unit generating power subsection interval end point and the fuel cost at the endpoint, thereby greatly reducing the error of subsection linear fitting, and reducing the number of subsections required by a fuel cost function, thereby reducing the complexity and solving difficultyof a time sequence simulation optimization model.

Owner:CHINA ELECTRIC POWER RES INST +1

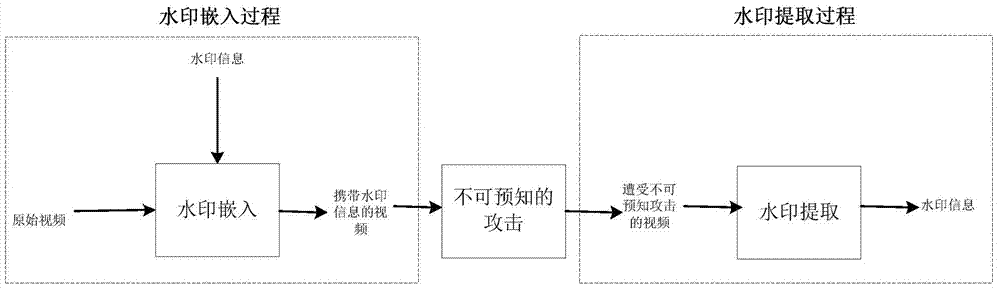

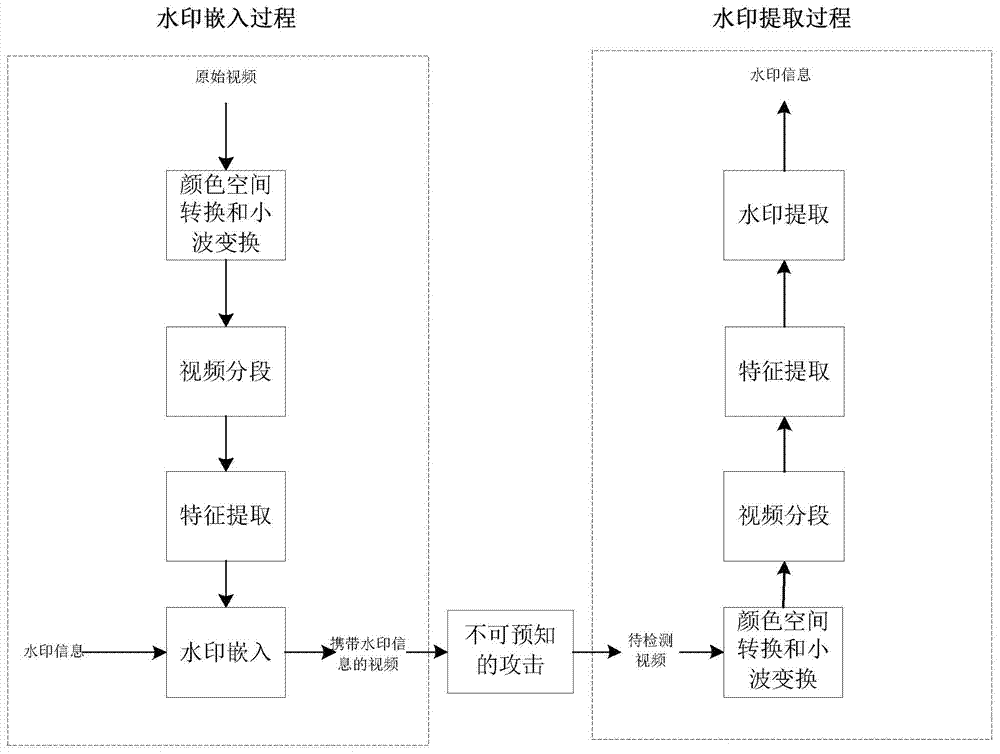

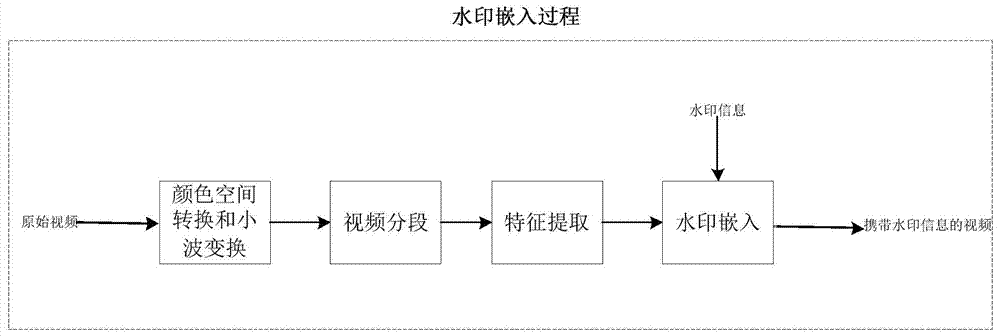

SIFT (Scale-Invariant Feature Transform)-based geometric-attack-resistant robust video watermarking method

InactiveCN103491456AResistance to geometric attacksSmall distortionImage data processing detailsSelective content distributionScale-invariant feature transformYcbcr color space

The invention relates to an SIFT (Scale-Invariant Feature Transform)-based geometric-attack-resistant robust video watermarking method. A watermark embedding process comprises the following steps: (1) representing video frame images by Ycbcr, carrying out one-layer two-dimensional DWT (Discrete Wavelet Transform) on Y components of the images, and selecting harr wavelets as wavelet bases, thus obtaining low-frequency components after DWT; (2) taking n frames as a group, carrying out SIFT feature point extraction on the low-frequency components obtained in the step (1) of a first frame of each group, and recording the positions of obtained feature points; (3) adding a variable decided by watermark information to a pixel value of each feature point; (4) carrying out inverse DWT so as to obtain watermark embedded Y components, and transforming to an RGB (Red / Green / Blue) space from the Ycbcr, thereby completing watermark embedding. A watermark extracting process comprises the steps of carrying out steps (1) and (2) which are the same as the steps (1) and (2) of the embedding process, then, predicting pixel values of feature points according to surrounding pixels so as to obtain predicted difference values, and comparing the predicted difference values with a set threshold value, thereby obtaining embedded watermark information. The SIFT-based geometric-attack-resistant robust video watermarking method has the advantages that the robustness of video watermarking methods to geometric attacks is improved, the distortion is little, and the processing is simple.

Owner:深圳市千方航实科技有限公司

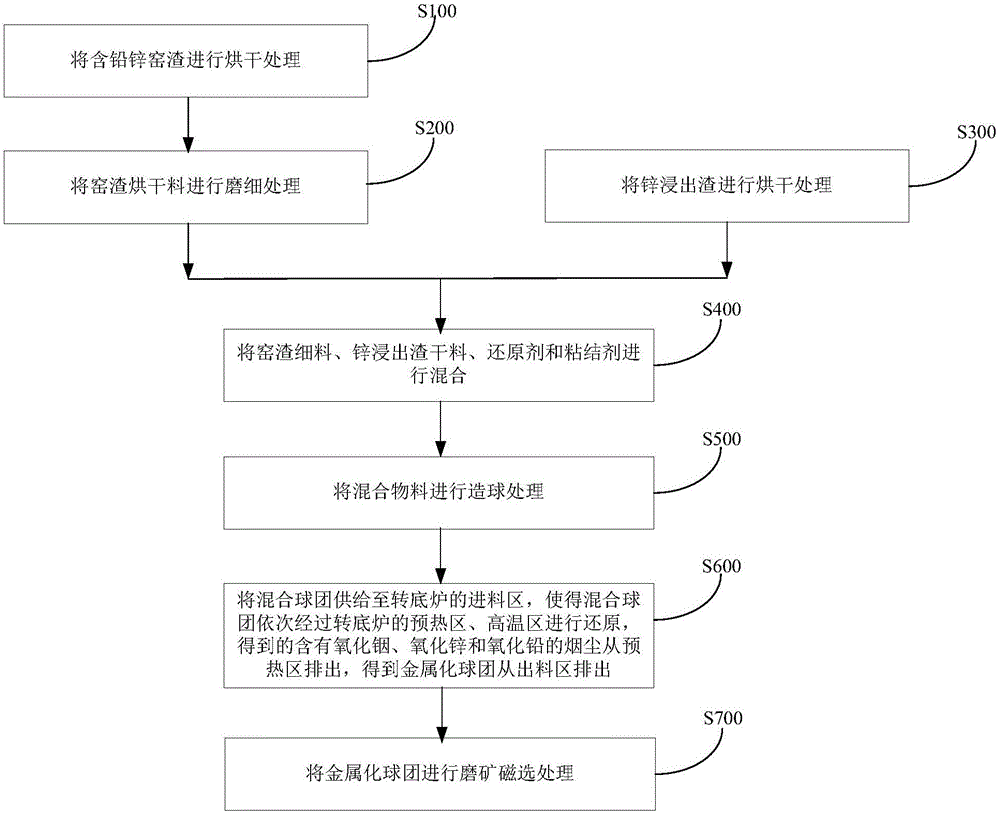

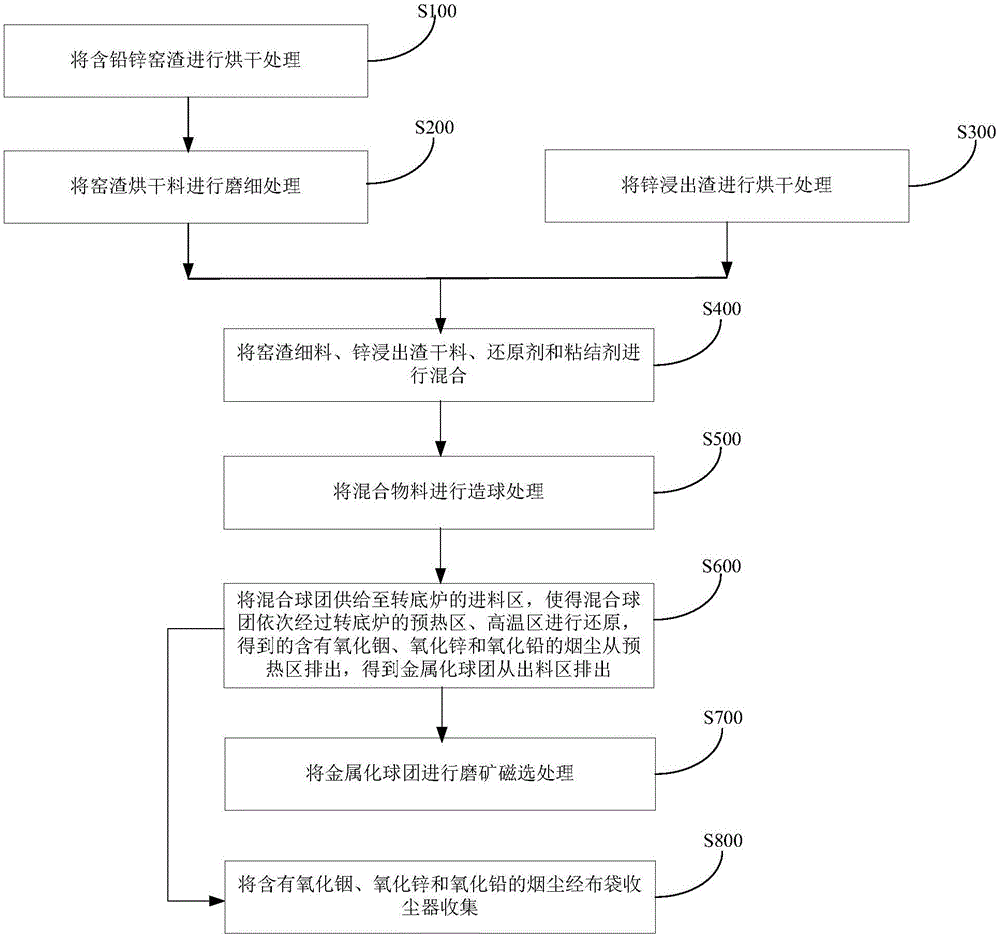

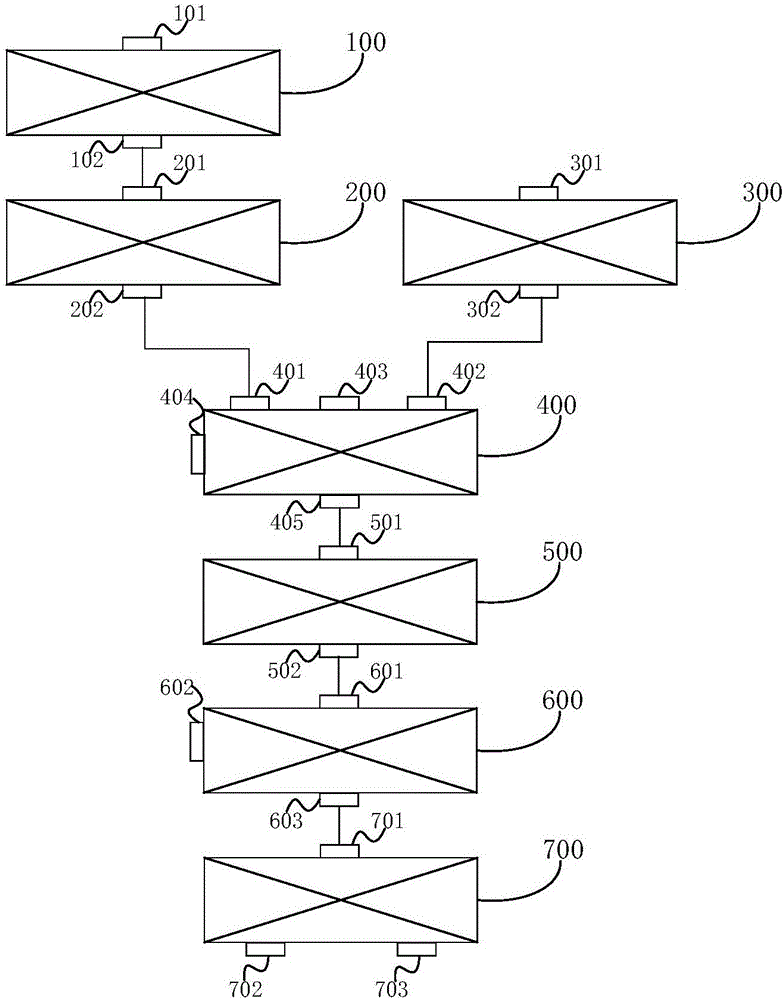

Method and system for treating lead and zinc waste materials

InactiveCN106086400ASolve environmental problemsReduce outsourcingProcess efficiency improvementIndiumIron powder

The invention discloses a method and a system for treating lead and zinc waste materials. The method comprises the steps of (1) drying lead and zinc containing kiln slags; (2) grinding dried kiln slags; (3) drying zinc leaching slags; (4) mixing fine kiln slags, dry zinc leaching slags, reducing agents and binders; (5) pelletizing a mixture, so as to obtain mixed pellets; (6) supplying the mixed pellets to a feed area of a rotary hearth furnace, so that the mixed pellets pass through a preheating area and a high-temperature area of the rotary hearth furnace in sequence for reduction, obtained smoke which contains indium oxide, zinc oxide and lead oxide is discharged from the preheating area, and obtained metallized pellets are discharged from a discharging area; (7) performing ore grinding and magnetic separation on the metallized pellets, so as to obtain metal iron powder and tailings. According to the method, the comprehensive recovery and utilization of carbon, iron, lead, zinc and indium in the zinc leaching slags and the lead and zinc containing kiln slags can be realized, the volatilization rate of lead, zinc and indium can reach more than 98%, and the recovery rate of iron can reach more than 90%.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

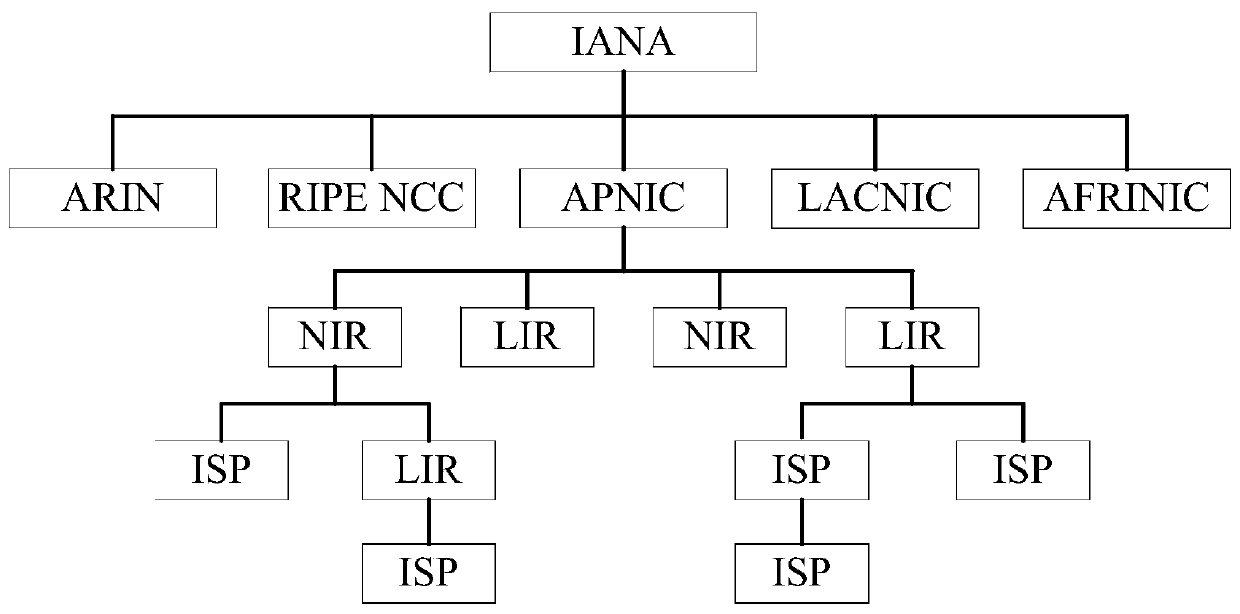

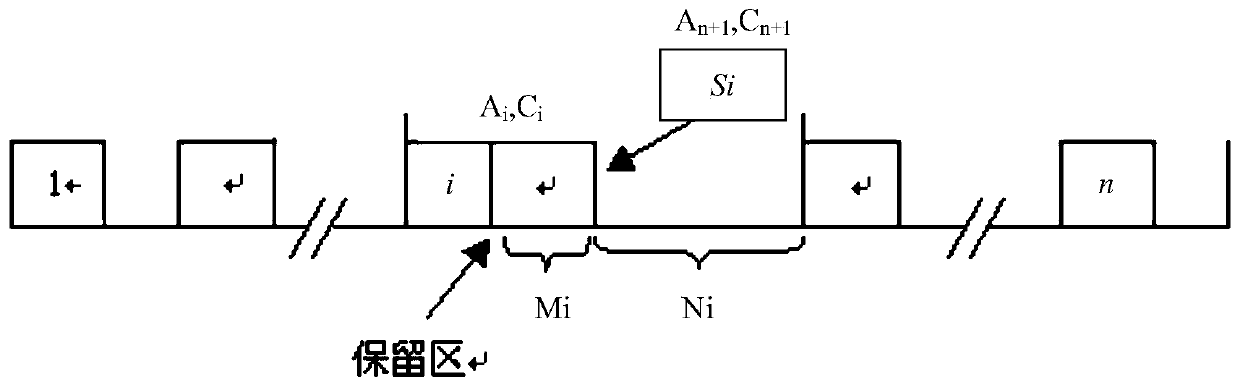

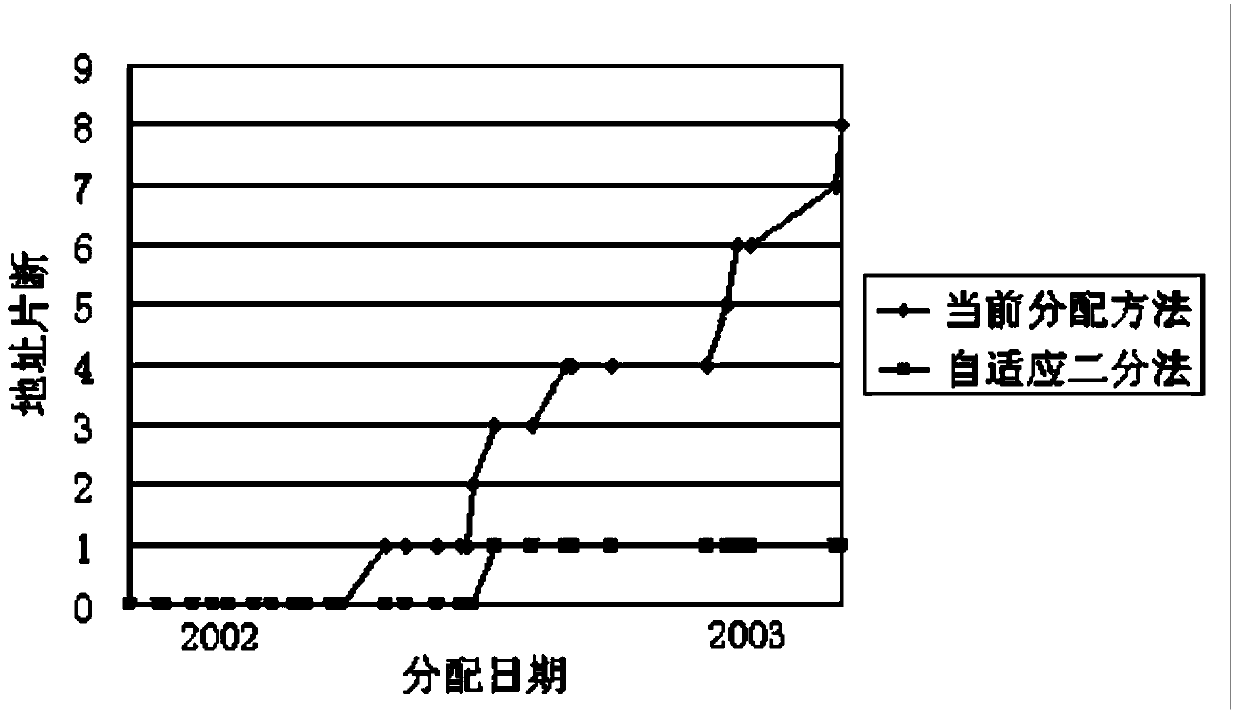

Self-adaptive IPv6 address allocation method for industrial Internet identifier analysis

The invention discloses a self-adaptive IPv6 address allocation method for industrial Internet identifier analysis. The method comprises the following steps: 1) dividing an industrial Internet IP address into a plurality of layers, and each layer corresponding to a section of address space; 2) for each layer of L, when the total amount of the address space applied to be allocated exceeds the capacity of each idle address field in the L address space of the layer, and when the available address space of the layer L is greater than the total amount of the address space allocated by the current application and the HD ratio of the address space of the layer L does not reach the set threshold, decomposing the address application of the user, and allocating an idle address to each decomposed address field. According to the method, excessive address fragments can be avoided, and the overall allocation effect is improved.

Owner:COMP NETWORK INFORMATION CENT CHINESE ACADEMY OF SCI

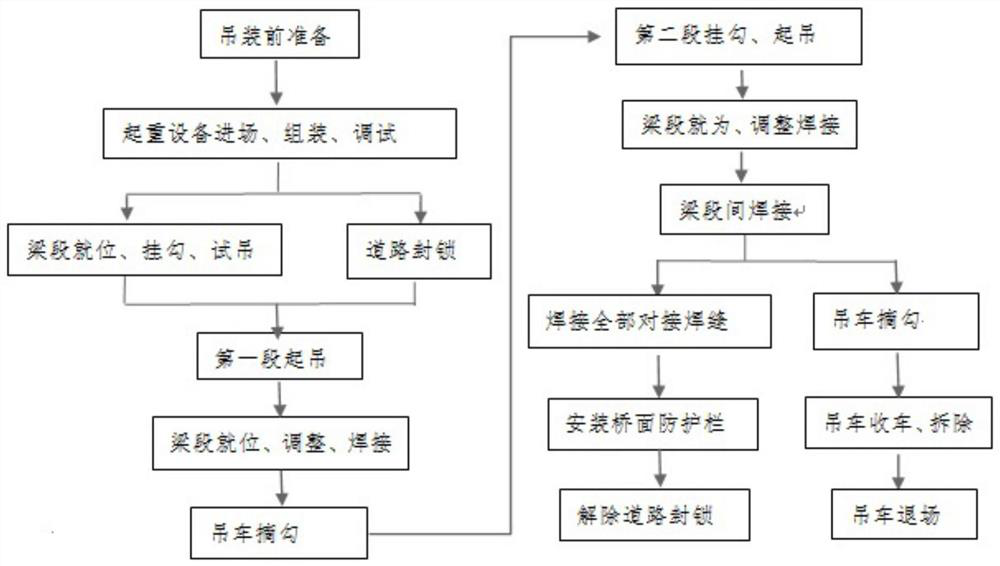

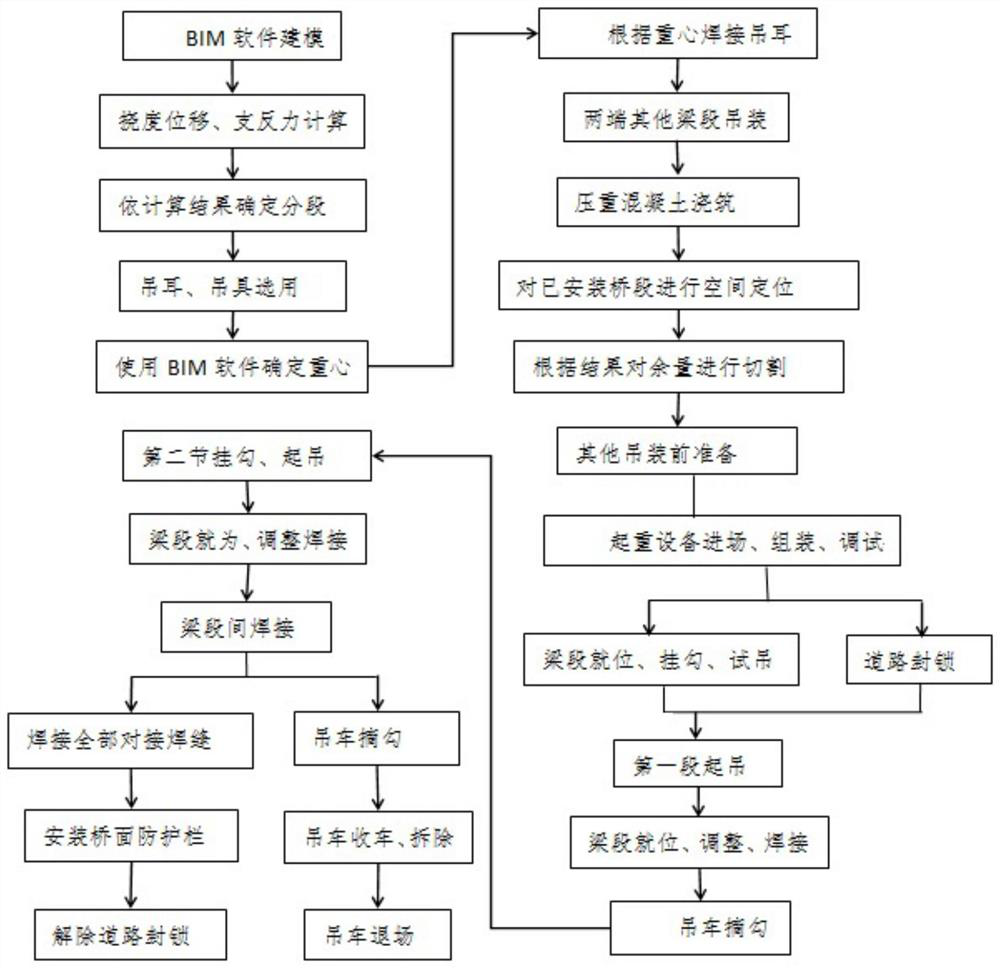

Unsupported large-span hyperbolic cross-city viaduct steel box girder sectional construction method

The invention provides an unsupported large-span hyperbolic cross-city viaduct steel box girder sectional construction method. The method comprises the steps that S1, other girder sections except a first arc girder section and a second arc girder section in a cross-bridge section are installed in advance; S2, the first arc girder section is hoisted firstly, and the two ends of the first arc girdersection are connected with two fractures of the cross-bridge section correspondingly; S3, the second arc girder section is hoisted, the two ends of the second arc girder section are connected with the two fractures of the cross-bridge section correspondingly, and the arc joint of the second arc girder section and the arc joint of the first arc girder section are connected; and S4, hoisting is completed, and a crane evacuates from the site. According to the method, a support-free hoisting is adopted, a temporary buttress does not need to be erected on an existing bridge during construction, the influence on traffic on the bridge during buttress erection is avoided, the number of cross-bridge sections is smaller than that of cross-bridge sections adopting a conventional hoisting method, thehoisting progress is accelerated, meanwhile, the number of welded junctions and the length of weld joints are reduced, the construction time of the cross-bridge sections is shortened, and the influence on the ground traffic for a long time is also avoided.

Owner:NO 4 ENG CO LTD OF CHINA RAILWAY NO 9 GRP

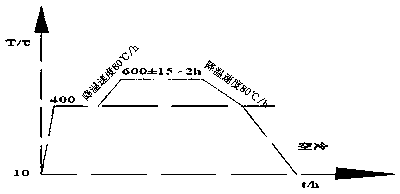

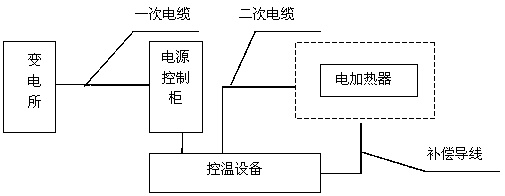

Non-strengthening heat treatment construction technology for over-sized device aerial strength weld

InactiveCN107043849AGuarantee the quality of heat treatmentGuaranteed feasibilityFurnace typesHeat treatment process controlTemperature stressPetrochemical

The invention relates to a non-strengthening heat treatment construction technology for an over-sized device aerial strength weld. Along with the fast development of maximization, modularization and automation of a petrochemical device, compared with an overall lifting technology, an over-sized device aerial assembling technology can relieve the pressure of field plane arrangement and can also reduce the parameter grade of a crane; however, high-temperature stress will be certainly generated at the weld position to cause cylinder deformation when the aerial weld is affected by the factors such as the heating temperature, the constant-temperature time, the weld upper portion device weight and the wind load during heat treatment. By means of the non-strengthening heat treatment construction technology for the over-sized device aerial strength weld, targeted safety technological measures are implemented through data mastered through a material high-temperature test under the premise that the device aerial heat treatment weld is not strengthened, the heat treatment quality of the weld is ensured, feasibility of the technology is forcefully verified, and the non-strengthening heat treatment construction technology is worthy of being applied and popularized in the same industry.

Owner:陕西化建工程有限责任公司

Controllable blasting network

The invention discloses a controllable blasting network. The controllable-blasting network comprises nonel detonators, a nonel exciting pen and detonation assemblies, wherein the detonation assemblies are formed by the nonel detonators which are connected in series or in parallel; the plurality of detonation assemblies are connected in series to form a blasting network line; the blasting network is connected on a blasting control loop in parallel to form the controllable blasting network; and the blasting control loop consists of at least one detonation unit connected in series; and the nonel exciting pen is connected with the start end of the blasting control loop. The controllable-blasting network provided by the invention has the advantages that the detonators are saved, the firing rate is high, the operability is strong, and the problems of high misfired rate and low safety under the backward condition of blasting equipment and blasting elements in China are solved.

Owner:刘国祥

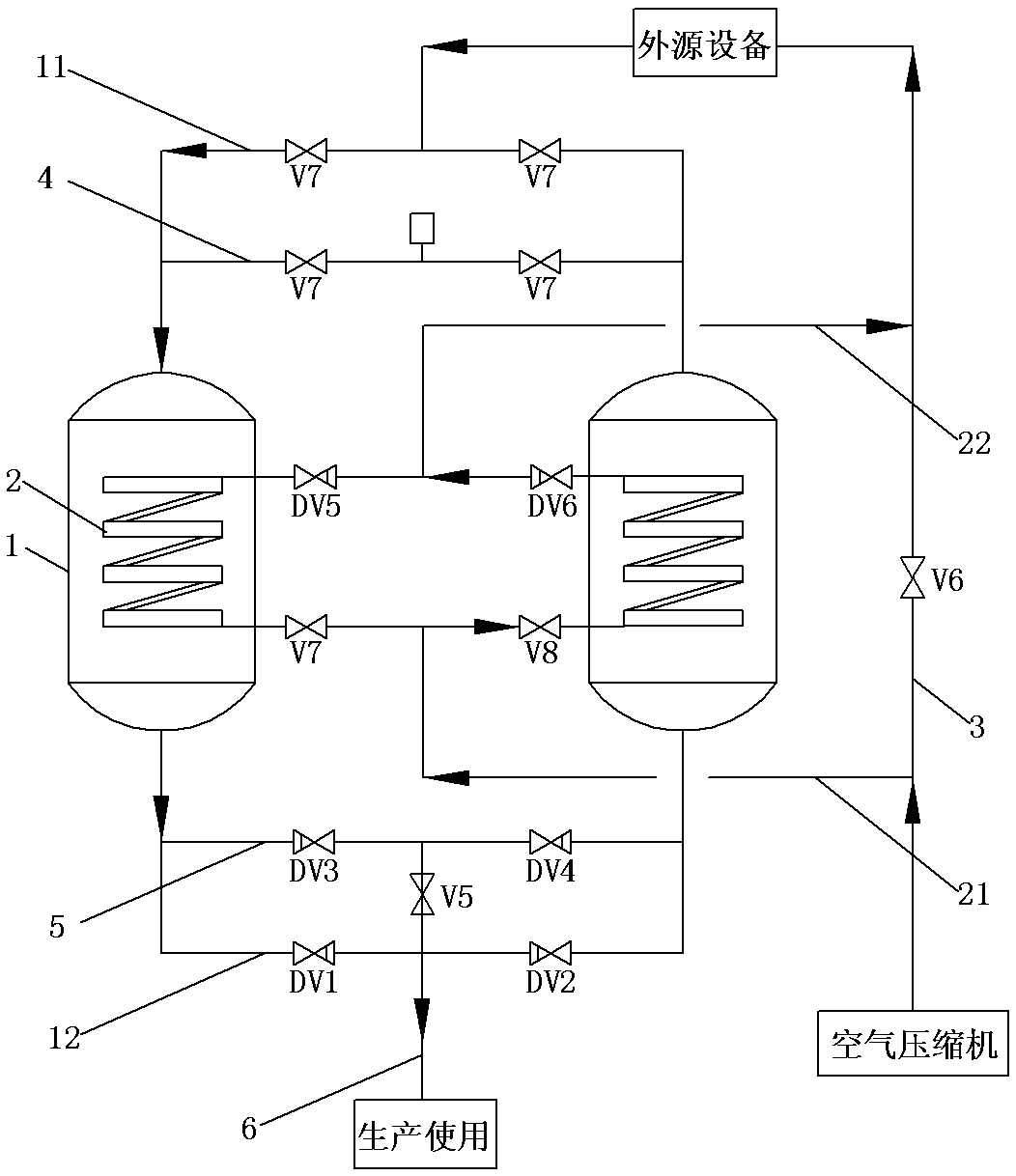

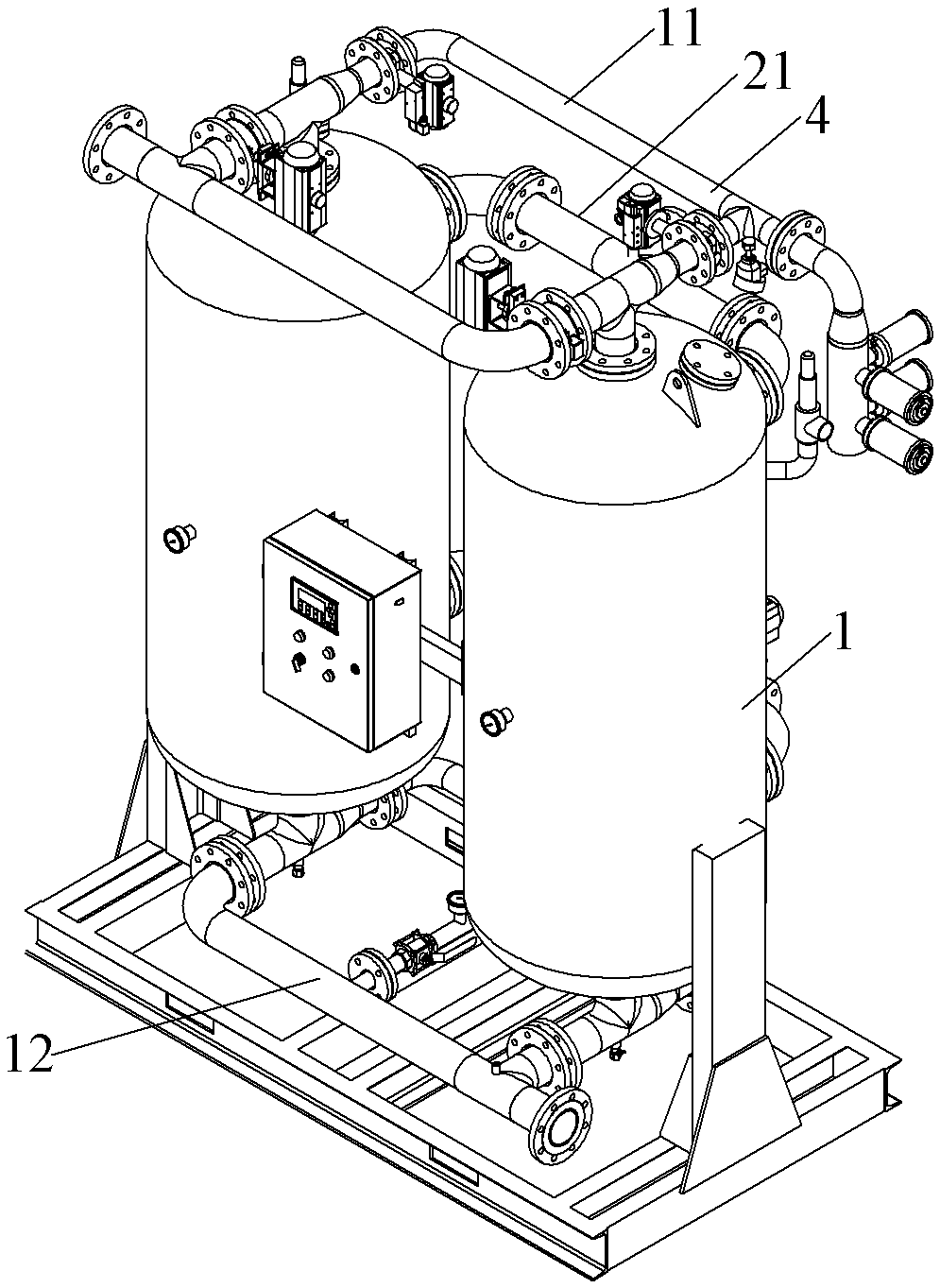

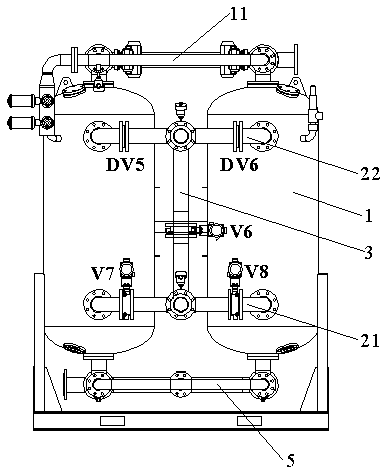

Water-containing gas dryer

PendingCN109718642AMoisture removal completelyAchieve zero gas consumptionDispersed particle separationGas pipelineProcess engineering

The invention discloses a water-containing gas dryer. The dryer comprises two tower bodies, every tower body is filled with an adsorbent, the upper end of every tower body is provided with a water-containing gas inlet, the lower end of every tower body is provided with a dry gas outlet, every water-containing gas inlet is connected with a water-containing gas feeding pipeline, every dry gas outletis connected with a dry gas discharging pipeline, a drying tube is arranged in every tower body, one end of every drying tube is a heat source gas inlet, the other end of every drying tube is a heatsource gas outlet, a heat source gas feeding pipeline connected with the heat source gas inlets in the two tower bodies and a heat source gas discharging pipeline respectively connected with the heatsource gas outlets in the two tower bodies are arranged outside the two tower bodies, the heat source gas feeding pipeline and the heat source gas discharging pipeline are connected with a water-containing high temperature gas pipeline, the heat source gas feeding pipeline is arranged in front of the heat source gas discharging pipeline along the flowing direction of a gas in the water-containinghigh temperature gas pipeline, and a valve is arranged at a position, between the heat source gas feeding pipeline and the heat source gas discharging pipeline, of the heat source gas feeding pipeline.

Owner:杜松林

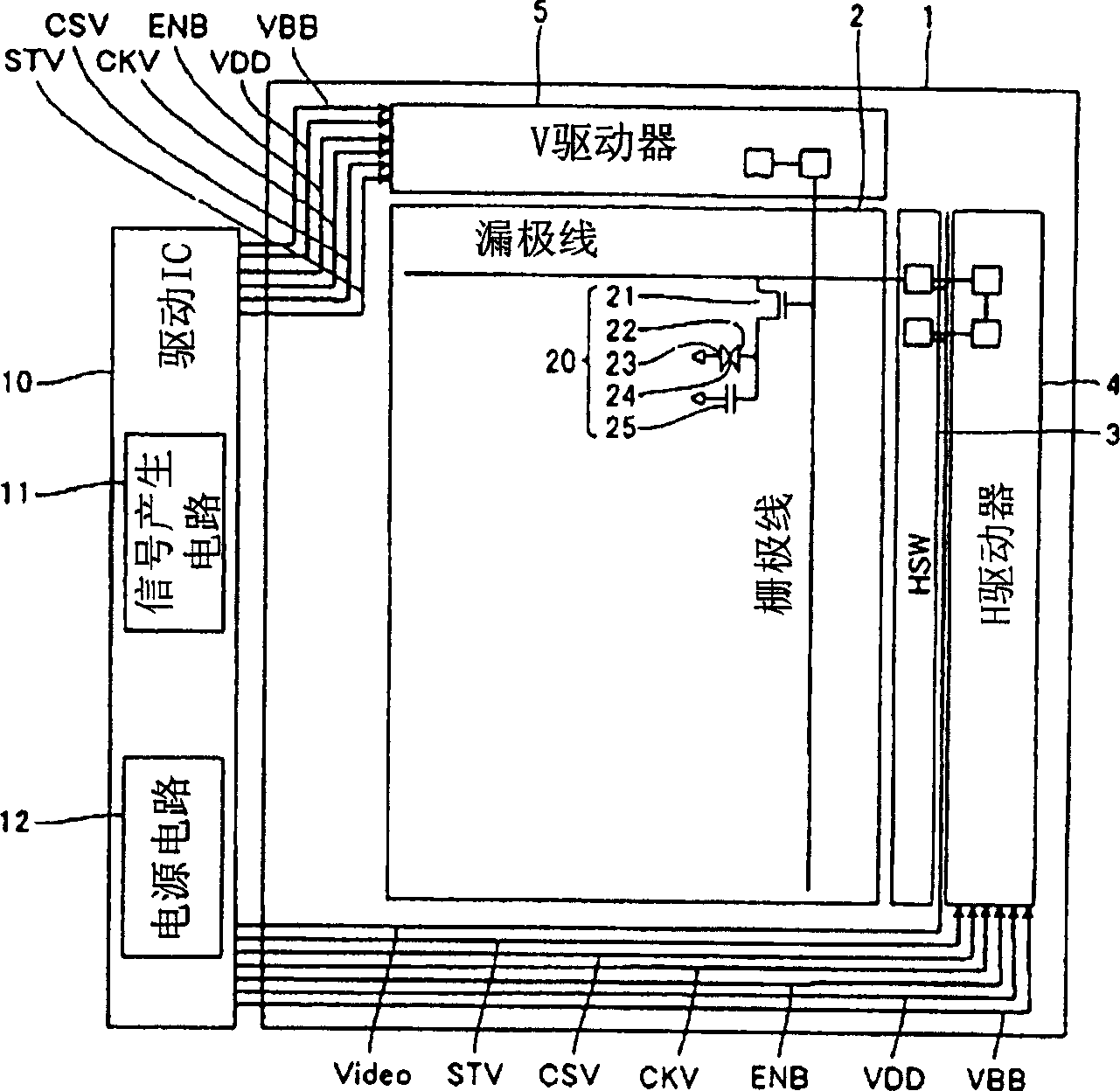

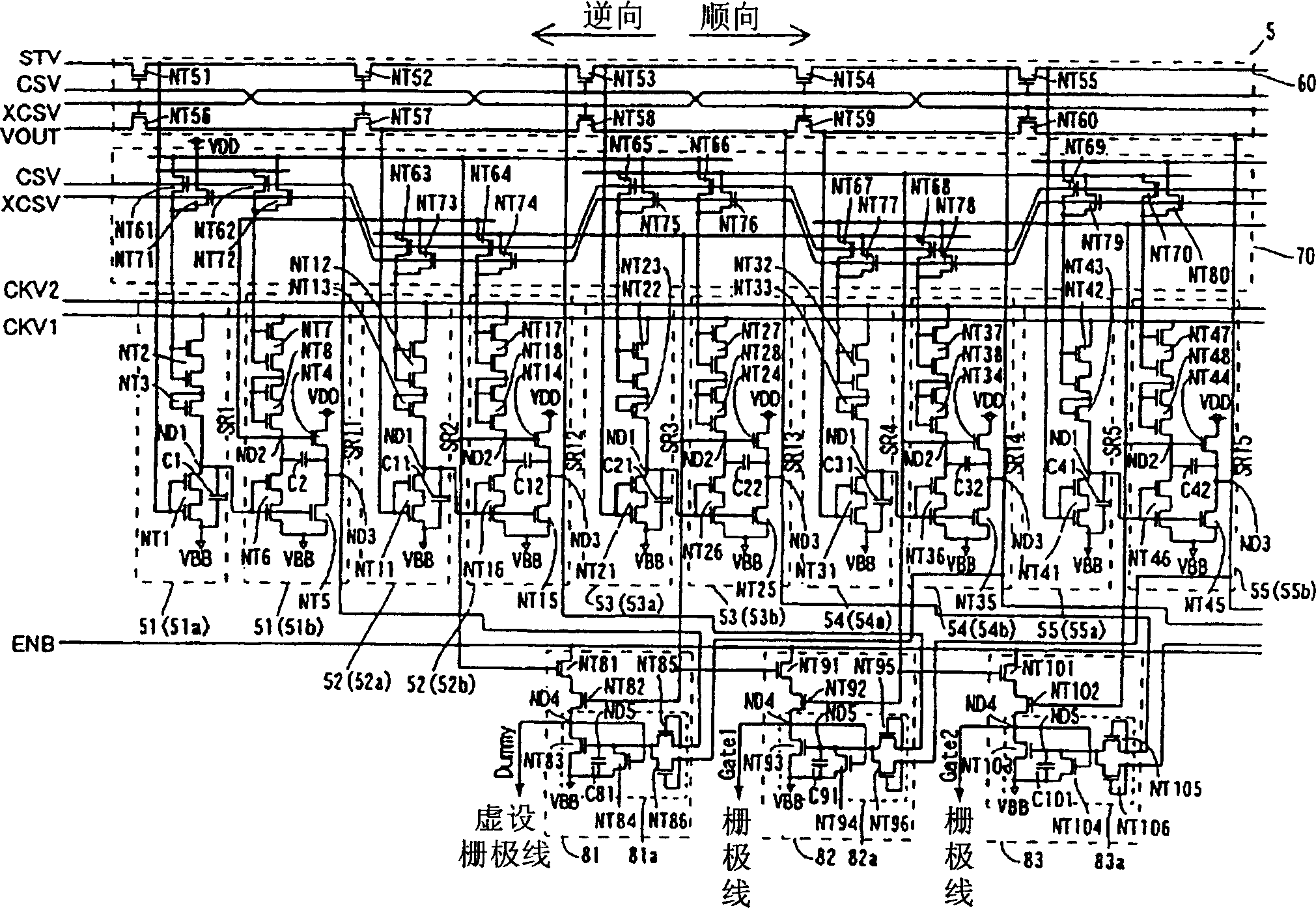

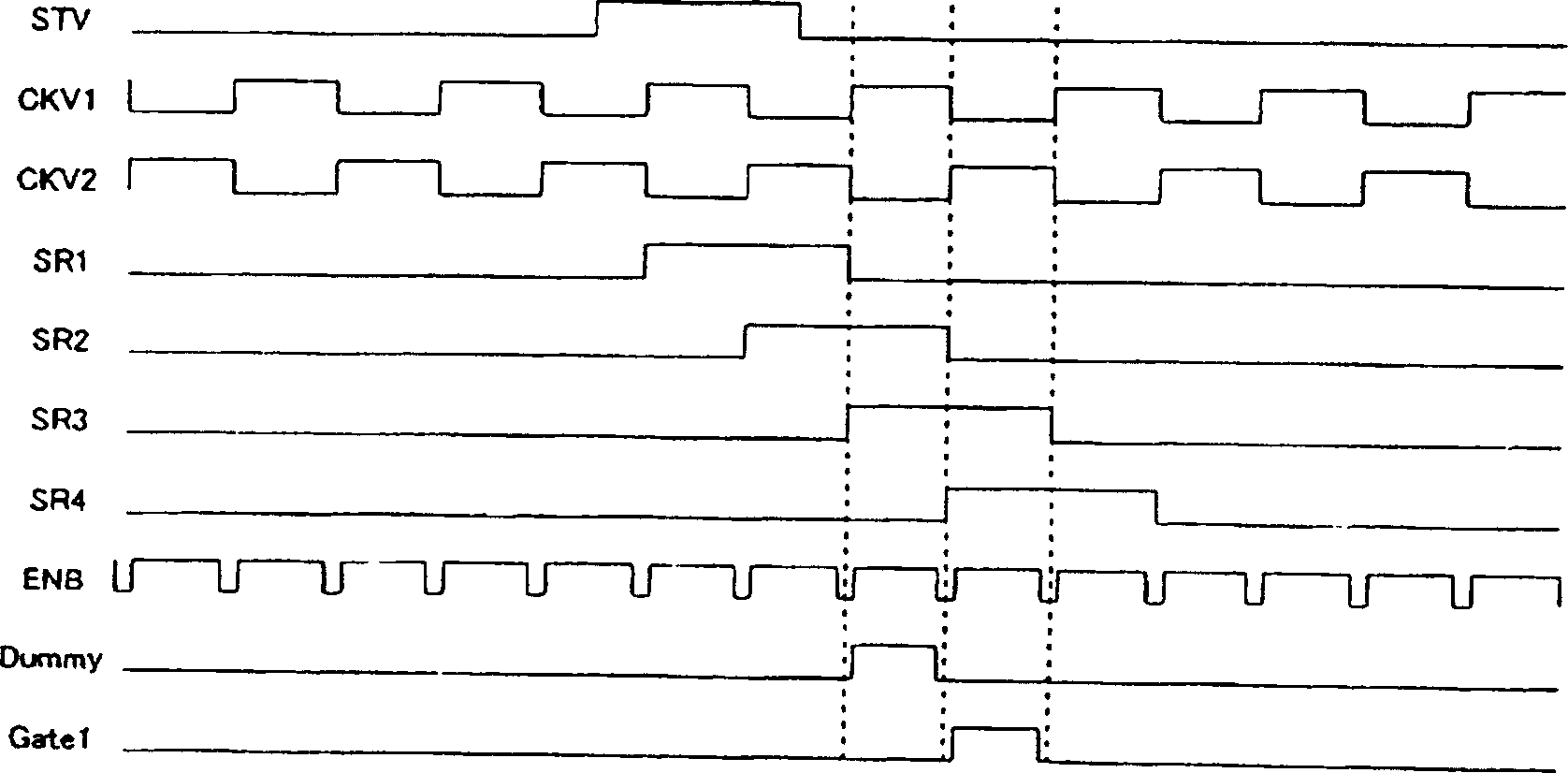

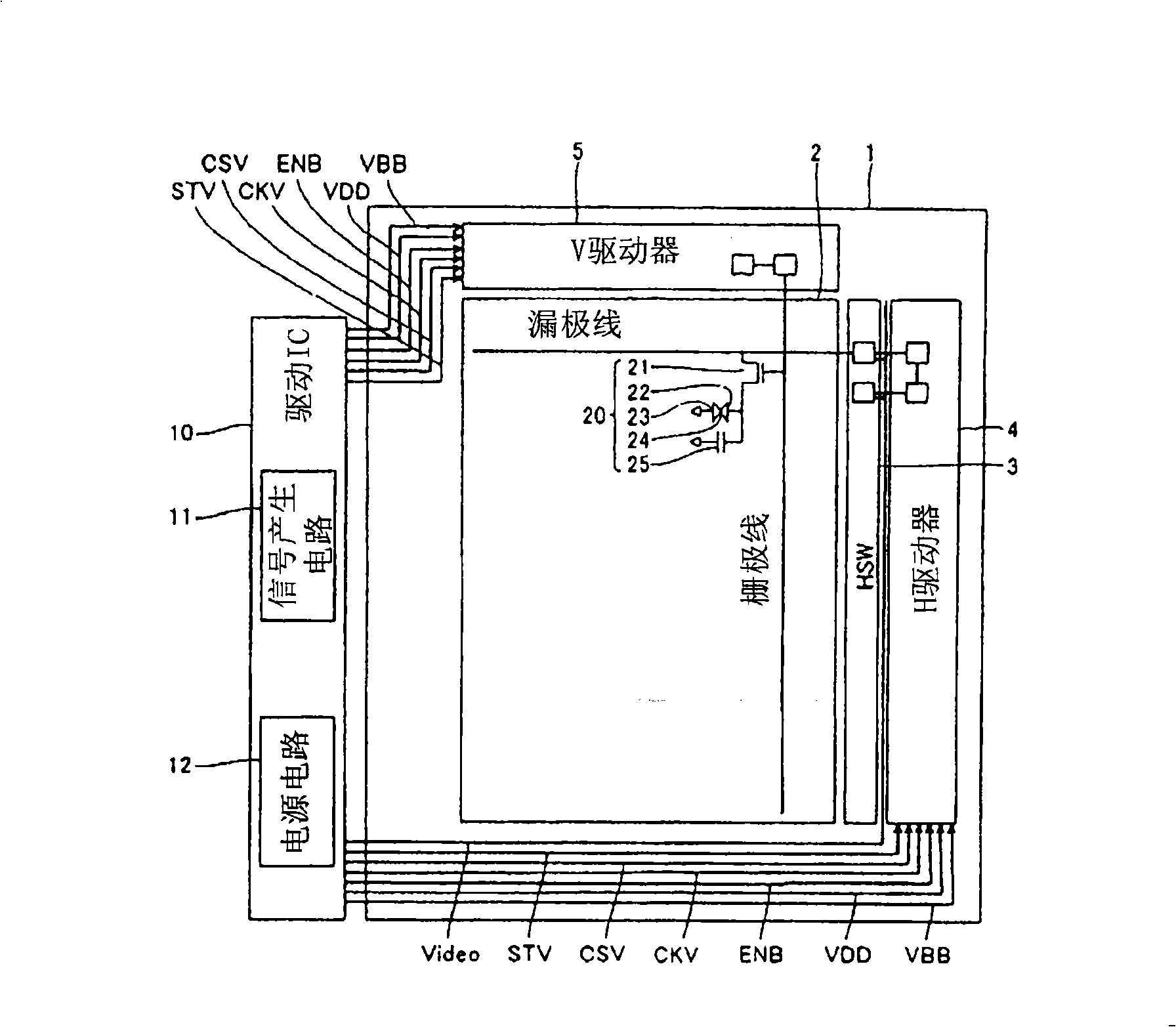

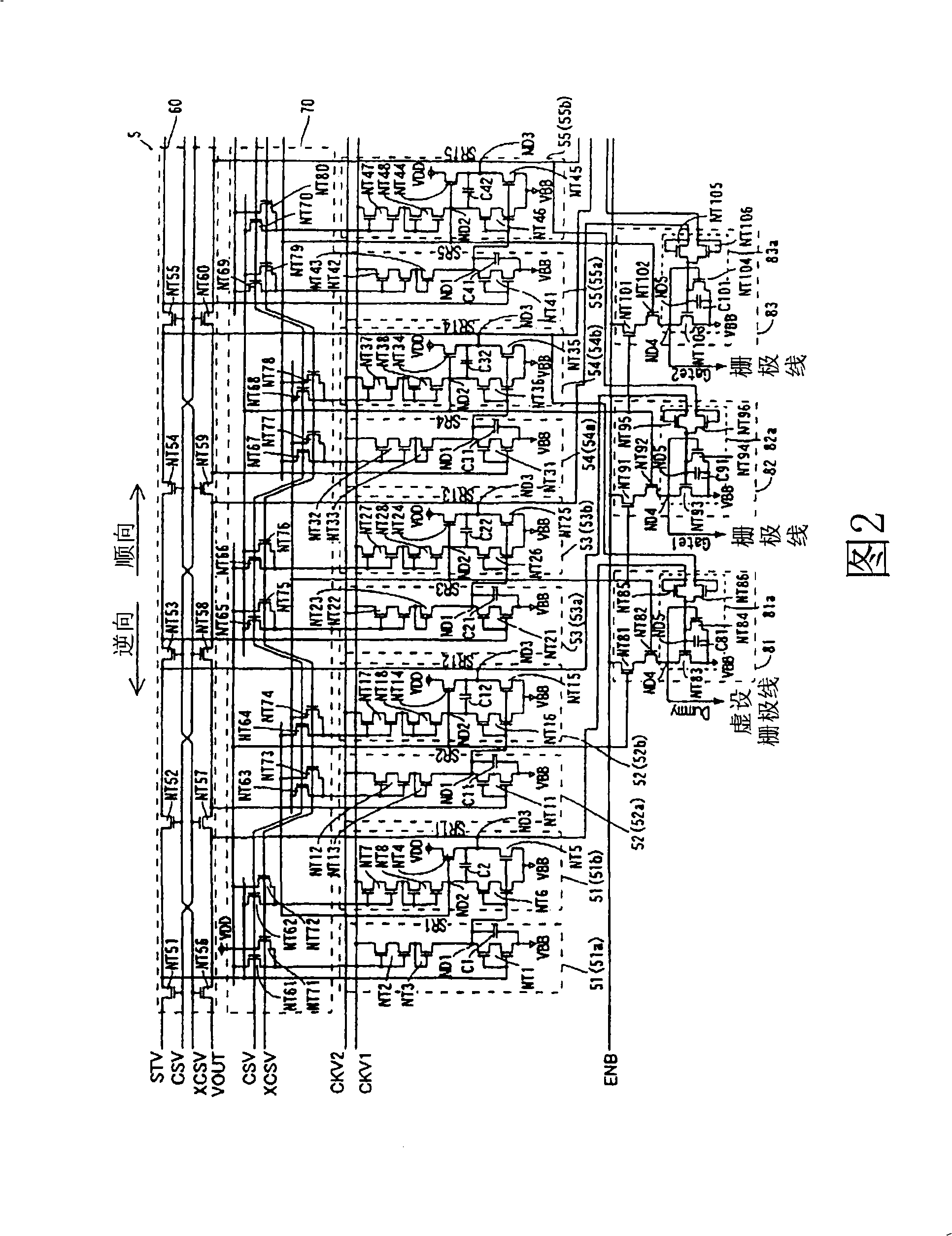

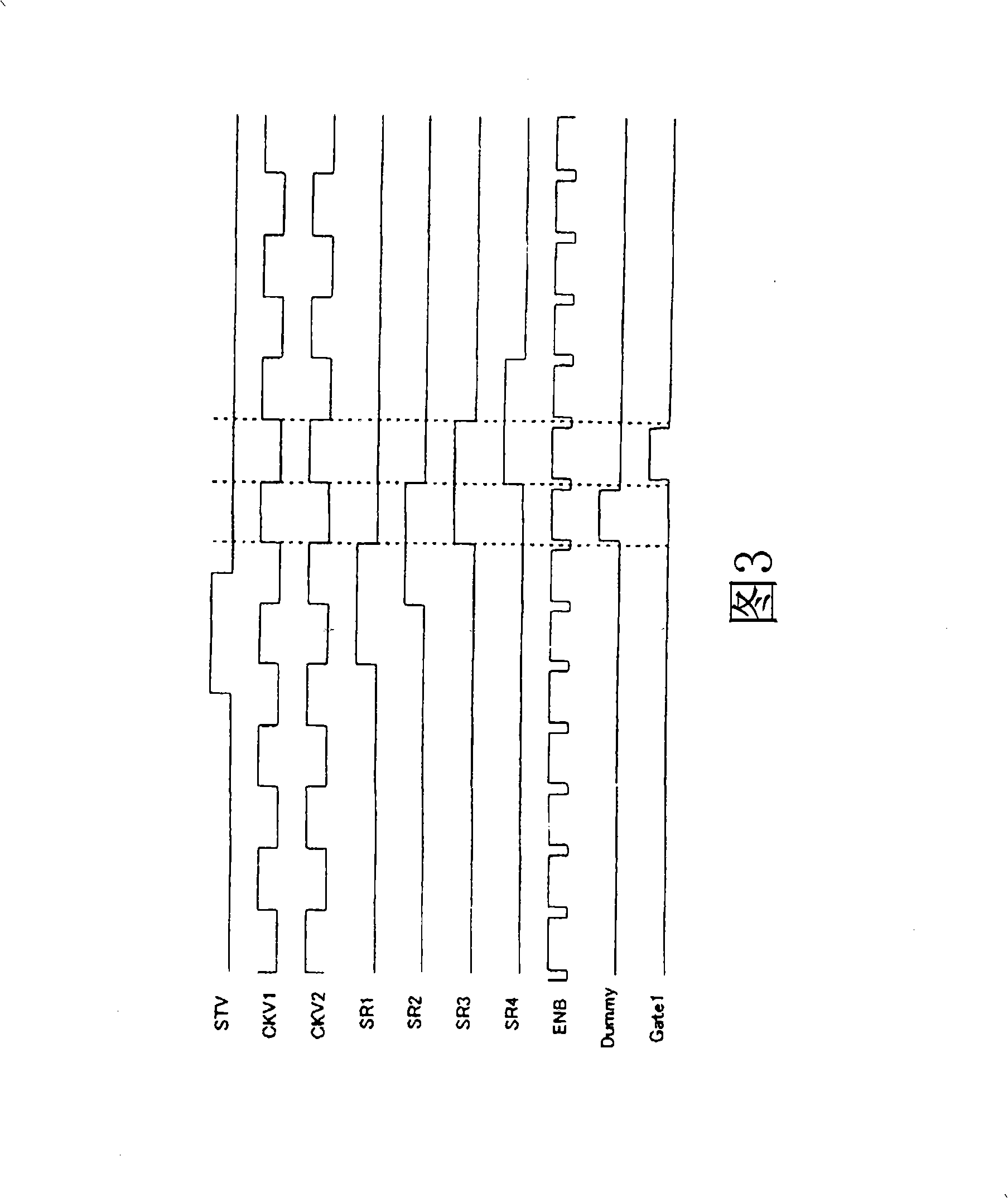

Display

ActiveCN1783174ASimple compositionReduce the number of segmentsStatic indicating devicesDigital storageShift registerDisplay device

The present invention provides a display device including a shift register circuit capable of suppressing an increase in power consumption. This display device is provided with a shift register circuit, and the shift register circuit includes: a shift register circuit part, including a first circuit part and a second circuit part, and the first circuit part has a first circuit part that is turned on in response to a first signal. 2 transistors; the second circuit section has a sixth transistor that is turned on in response to a second signal that can obtain a period of an on-state that does not overlap with a period of the on-state of the second transistor; and an input The signal switching circuit part switches the first and second signals respectively supplied to the second and sixth transistors.

Owner:SANYO ELECTRIC CO LTD

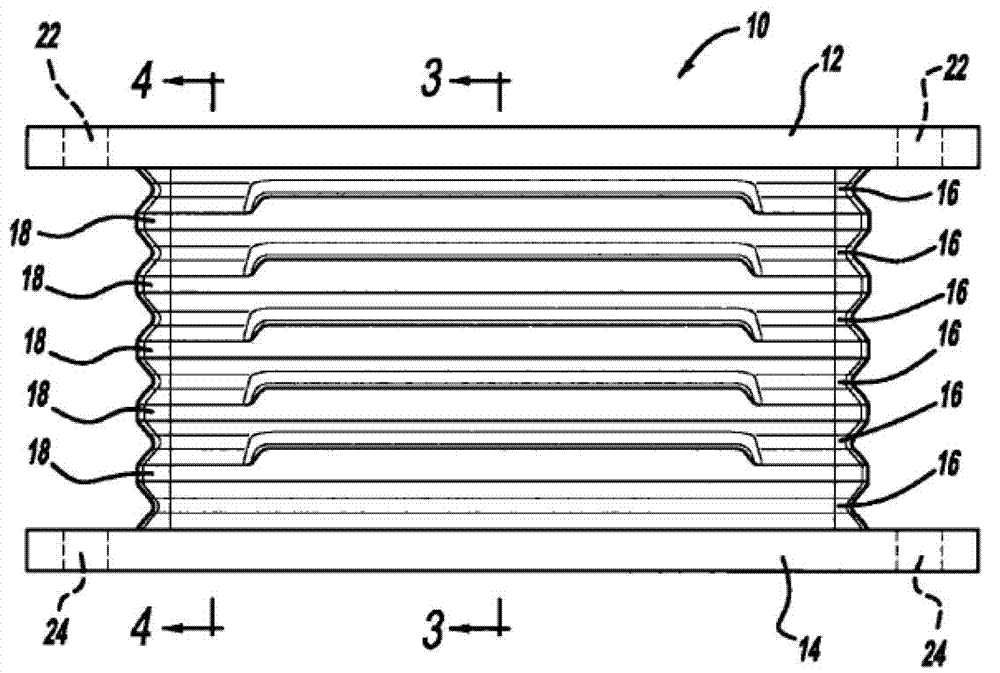

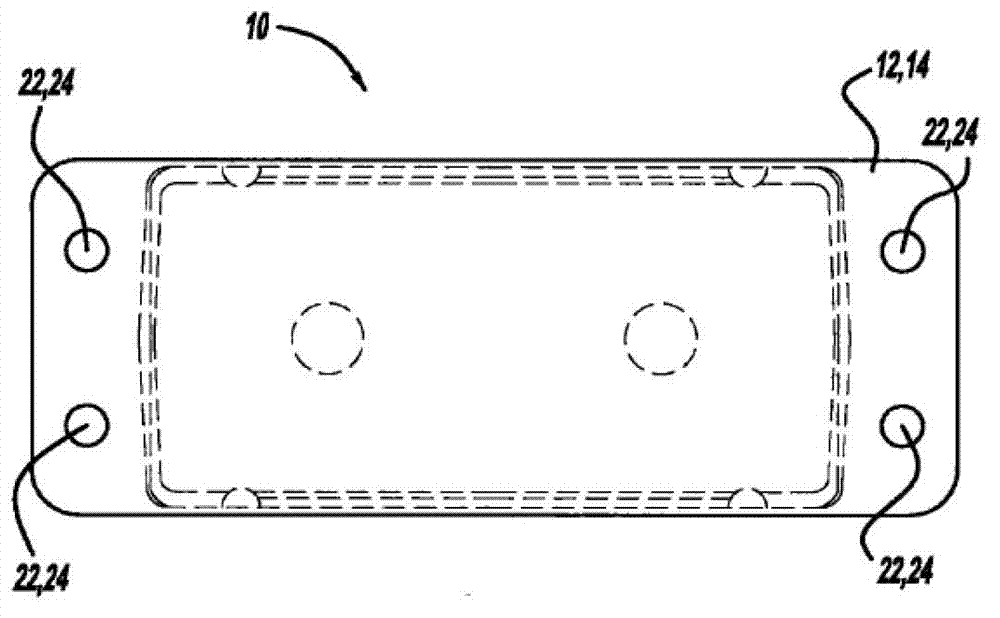

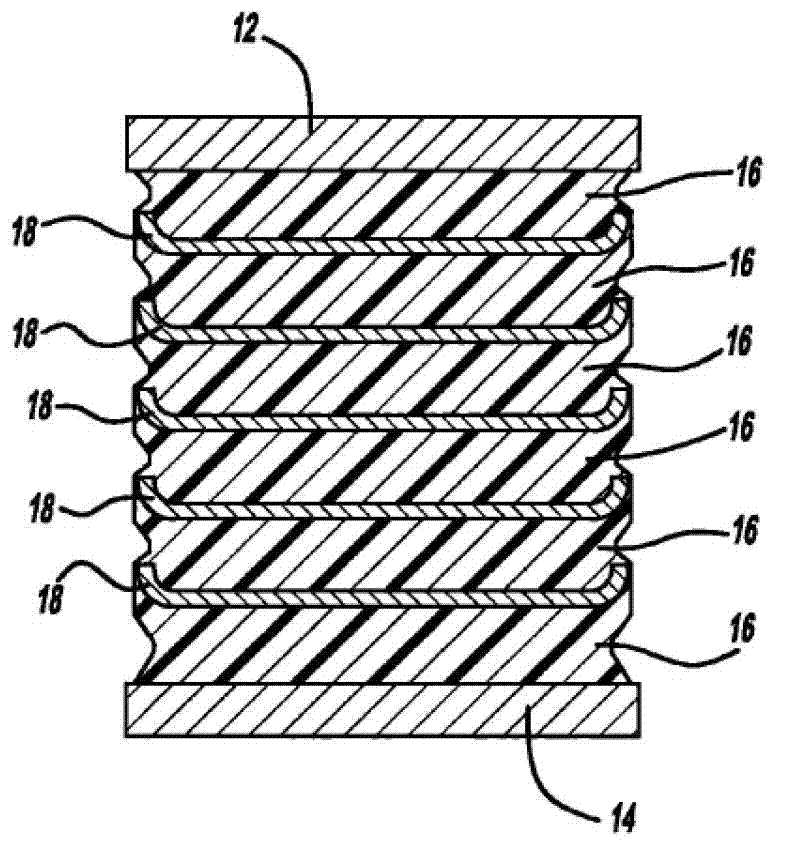

Segmented elastomeric vibration mount with edge control

InactiveCN102959273AReduce stressIncreased durabilitySpringsNon-rotating vibration suppressionEngineeringFlange

A mount assembly has a plurality of elastomeric members having a separator plate disposed between adjacent elastomeric members. The separator plate defines a flange which extends toward an adjacent separator plate to confine the elastomeric layer. A mounting plate is located at both ends of the mount assembly and can be used to attach the mount assembly to two components.

Owner:PULLMAN INC

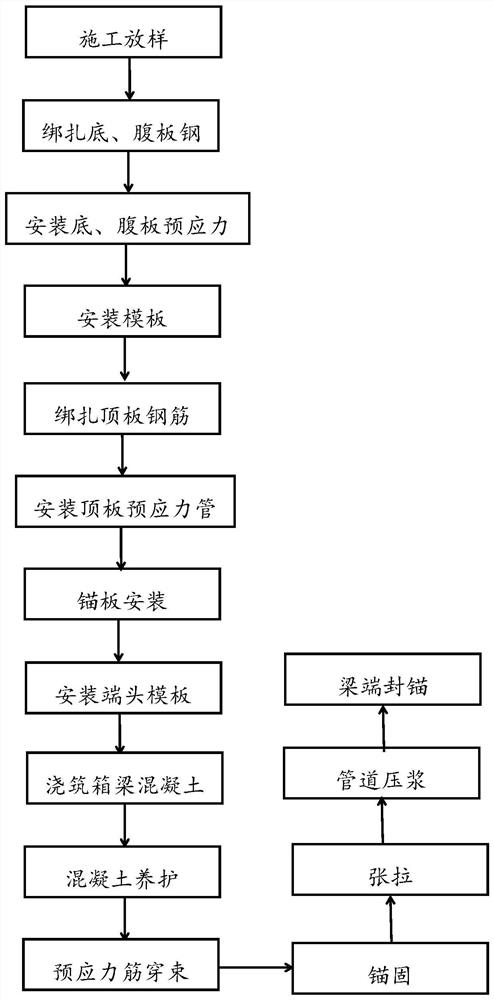

Prefabricated small box girder prestress engineering construction method for intelligent expressway

PendingCN112695633AReduce the number of segmentsEasy constructionBridge erection/assemblyBridge materialsPre stressArchitectural engineering

The invention discloses a prefabricated small box girder prestress engineering construction method for an intelligent expressway. The prefabricated small box girder prestress engineering construction method specifically comprises the following steps that S1, construction lofting is conducted; s2, bottom and web steel bars are bound; s3, bottom and web prestressed pipelines are installed; the pipeline installation is synchronously carried out along with the prefabricated small box girder steel bar binding; s4, a formwork is installed; s5, top plate reinforcing steel bars are bound; s6, a top plate prestress pipeline is installed; s7, mounting an anchor plate; after the pipeline is installed and before the beam end formwork is sealed, an anchor plate is installed, and the anchor plate and the prestressed pipeline are perpendicularly installed; s8, an end formwork is installed; compared with a traditional prefabricated segmental beam, the number of segments is greatly reduced, and construction is simplified; an internal prestress mode is adopted, the structural durability can be guaranteed by controlling the grouting quality, the structural maintenance cost is reduced, and the method has the advantages of being safe and convenient to construct, good in feasibility and high in reliability.

Owner:中能建建筑集团有限公司

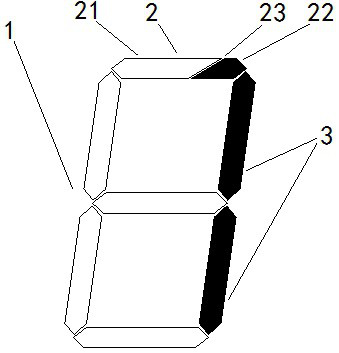

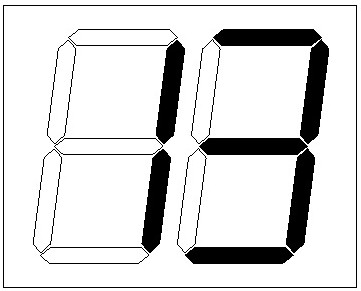

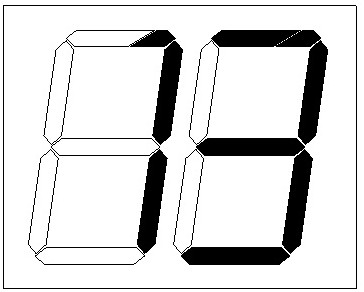

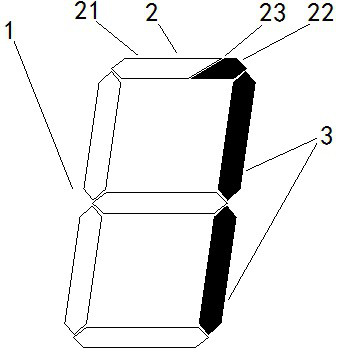

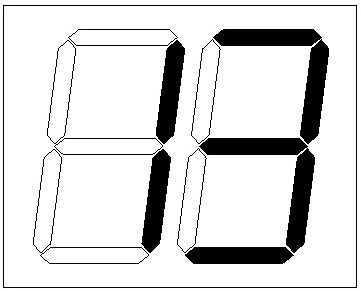

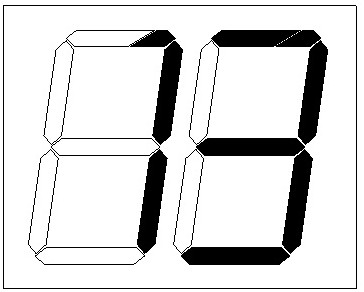

Stroke segment type liquid crystal screen for small measuring instrument

PendingCN112216226AImprove discriminationEfficient use ofIdentification meansPhysical medicine and rehabilitationChinese characters

The invention aims to solve the problem of how to reduce misreading caused by connection with a right number when a Chinese character ri-shaped stroke segment type liquid crystal screen displays the figure 1. A stroke segment type liquid crystal screen for a small measuring instrument is a Chinese character ri-shaped stroke segment type liquid crystal screen and is characterized in that the upperedge of the Chinese character 'ri' is transversely divided into a left segment and a right segment, namely an upper left segment and an upper right segment for short, each segment at least comprises apixel, and only the upper right segment and the right side of the Chinese character 'ri' are vertically lightened when displaying a figure 1. The upper right segment enables the distinction degree ofthe number 1 and other numbers to be higher, and misreading caused by connection of the figure 1 and the right figure is avoided; besides, the upper right segment enables the figure 1 to visually shift leftwards integrally, so that the left space is effectively utilized, and the unattractive appearance of the figure 1 which is too close to the side is relieved to a certain extent; and meanwhile,the displayed figure 1 is similar to a common thick number, a small hook is arranged on the figure 1, and the figure 1 is thickened when the stroke segment type liquid crystal screen is used for displaying, and the thickened figure 1 is very attractive.

Owner:HUNAN UNIV OF SCI & TECH

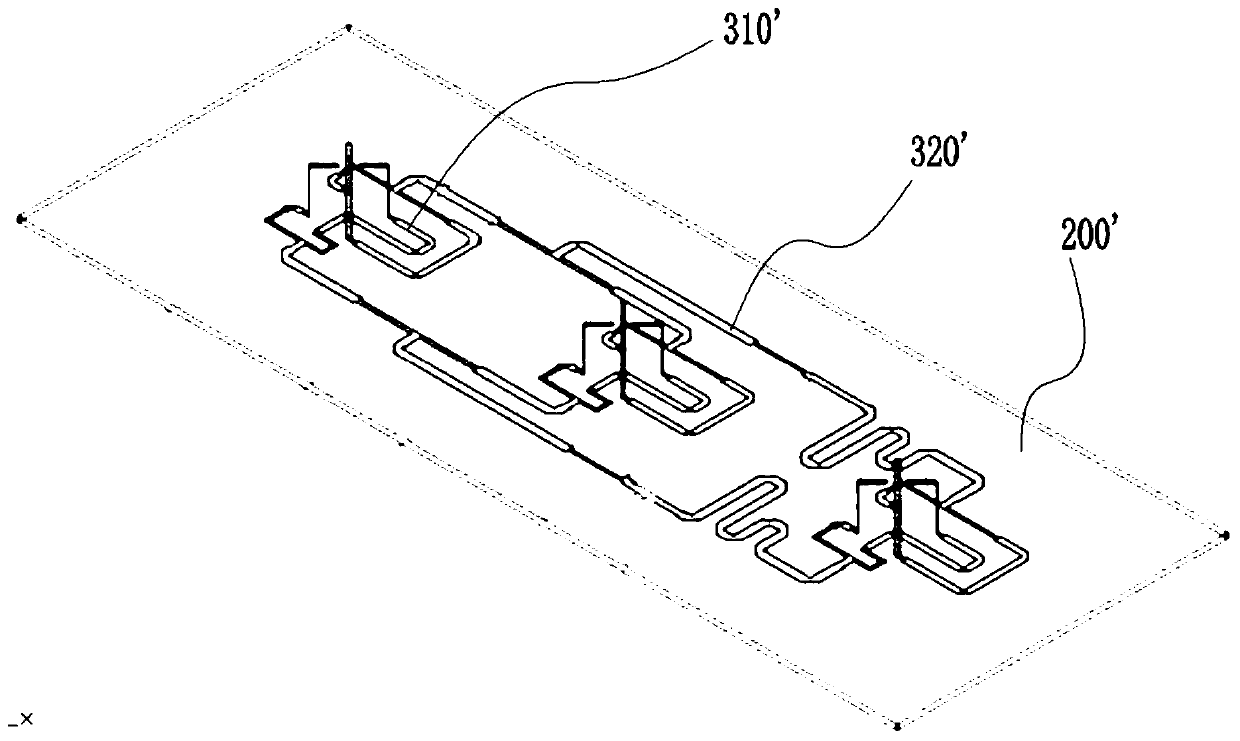

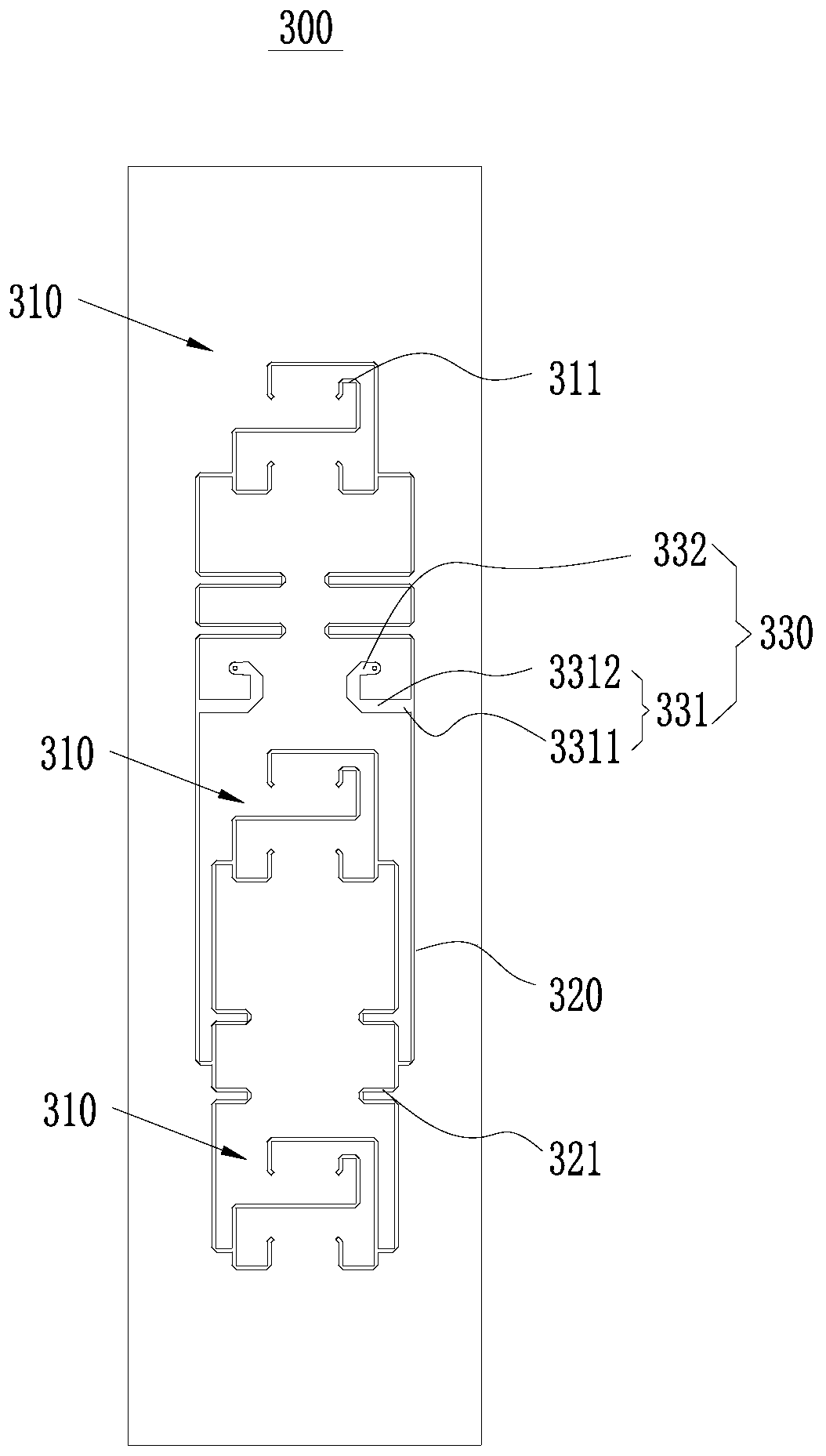

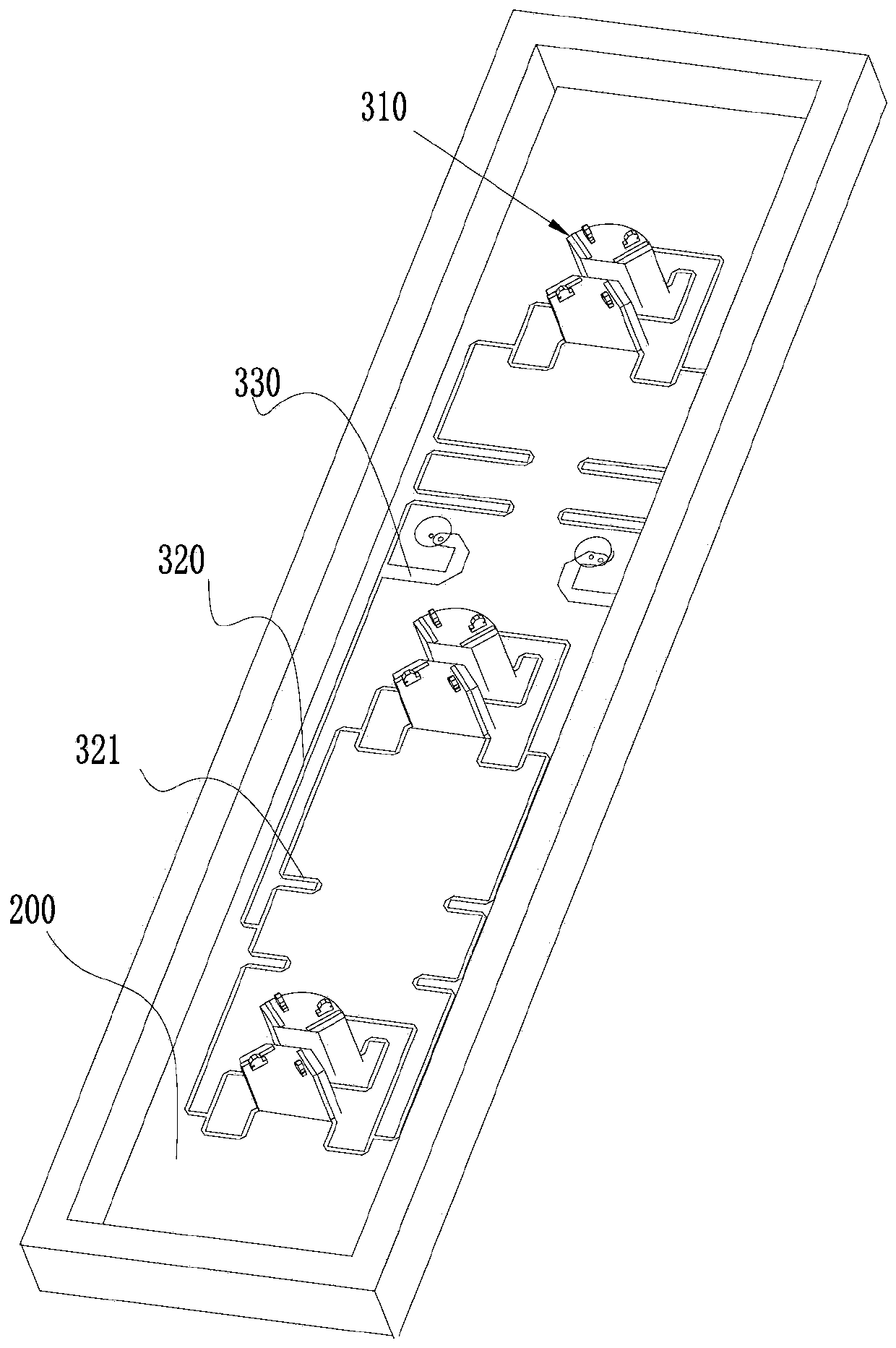

Feed network and antenna feed system

PendingCN111478020ASimple designReduce the number of segmentsAntenna supports/mountingsRadiating elements structural formsFeeder lineInput impedance

The invention provides a feed network and an antenna feed system. The antenna feed system comprises a feed plate, arrays and a feed network, wherein the feed network comprises array matching lines, sub-array matching lines and debugging lines, the line width of the array matching line is equal to the line width of the sub-array matching line, the line width of the debugging line can be unequal tothe line width of the array matching line and the line width of the sub-array matching line, the array matching line is used for being connected with the array, the adjacent arrays are connected through the sub-array matching line, the debugging lines are arranged on the sub-array matching lines, and the input impedance of a feeder line is adjusted and matched through the length and the width of the debugging line. According to the design method that the line width of the array matching line and the line width of the sub-array matching line are equal, the design of a matching circuit is greatly simplified, the number of sections and the number of bends of the matching lines are reduced, and losses are reduced; and high consistency and reliability can be achieved when an electroplating process is adopted for machining while the whole circuit diagram is attractive and simple.

Owner:ANHUI TATFOOK TECH CO LTD

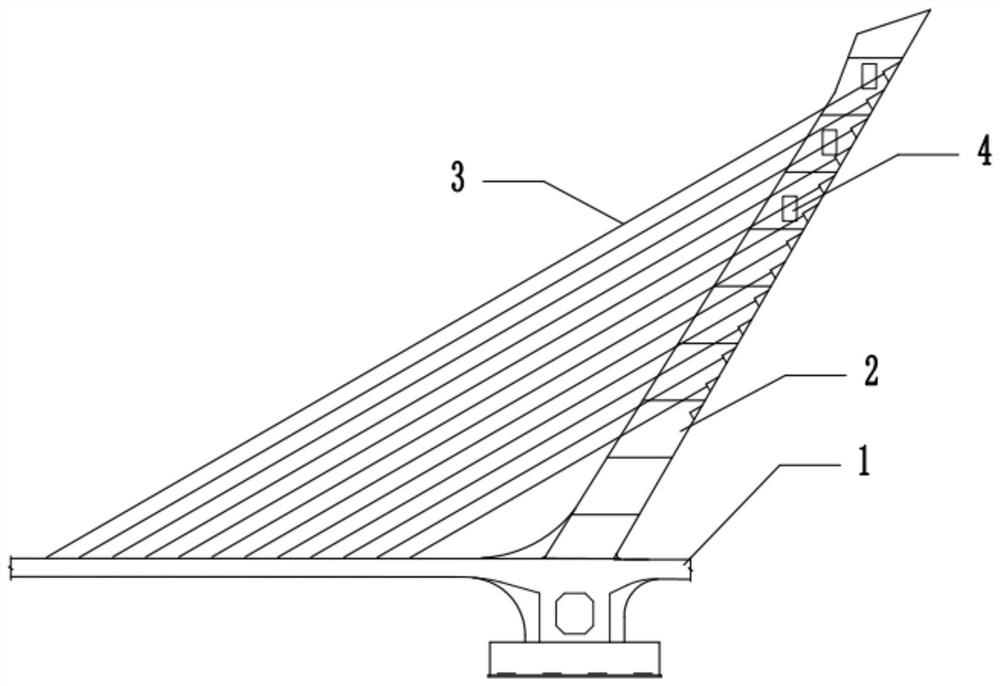

Construction method of cable-stayed bridge without back cables

ActiveCN110792028BReduce distortionAvoid cumbersome proceduresCable-stayed bridgeBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses a construction method of a cable-stayed bridge without back cables. The cable-stayed bridge includes a pier, a main bridge deck, two tower columns and stay cables, and the stay cables connect the top of the tower columns and the main bridge deck. , the main bridge deck spans the piers, two tower columns are located on both sides of the main bridge deck, and each tower column is inclined along the bridge direction, and the tops of the tower columns are connected together by three parallel connecting beams . The entire bridge body adopts the tower girder pier structure. The steps are as follows: pour the bridge pier first, and then construct the main bridge deck. During the construction of the main bridge deck, reserve holes for the tower column construction; then, the two tower columns are constructed at the same time. ; Finally, dismantle the construction support frame of the tower column; improve the bridge deck and other auxiliary facilities. The deformation of the support frame is effectively reduced to ensure the construction quality; the construction period is shortened, the working hours are saved, and the construction cost is reduced.

Owner:HEBEI ROAD & BRIDGE GROUP

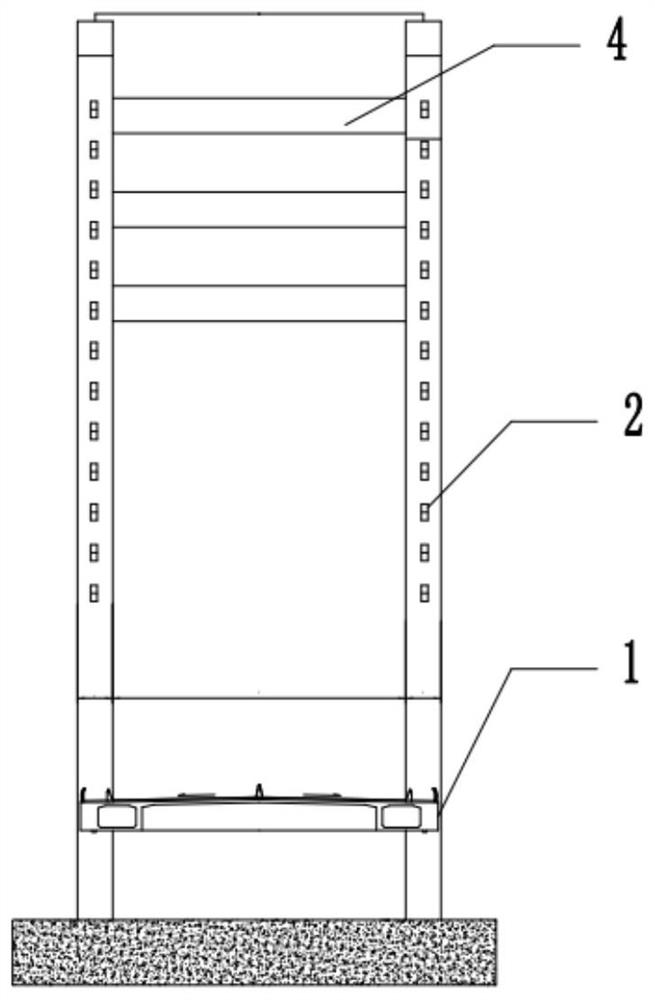

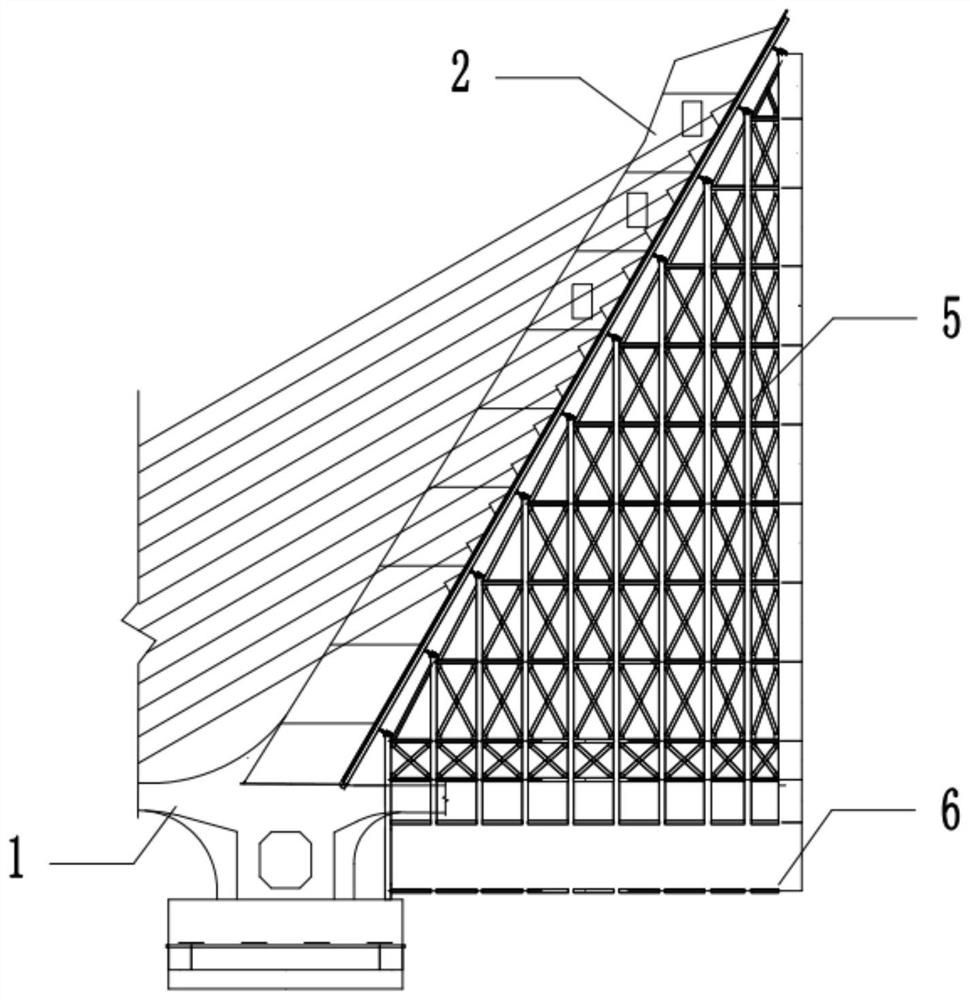

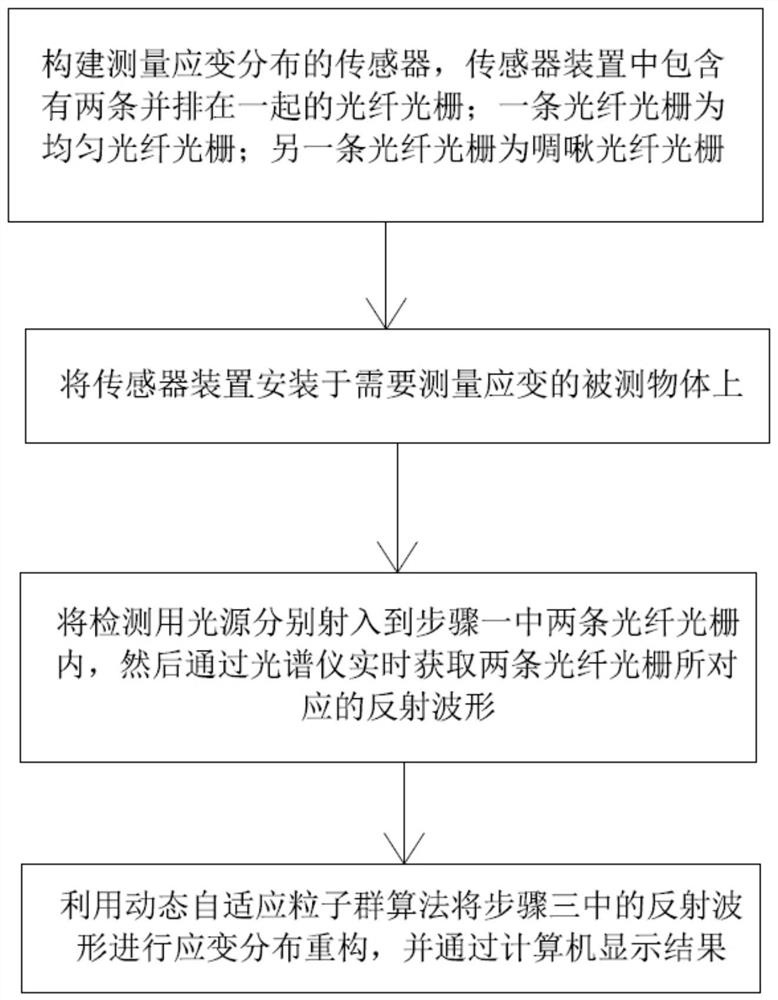

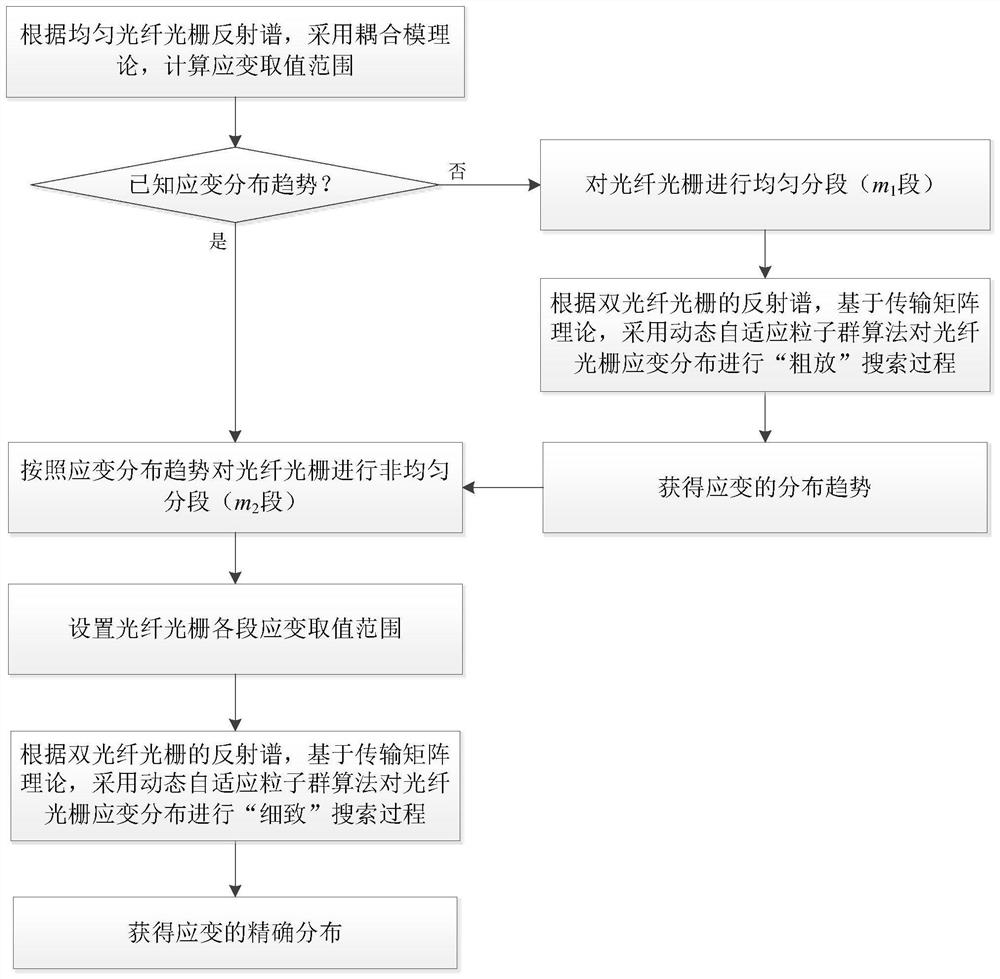

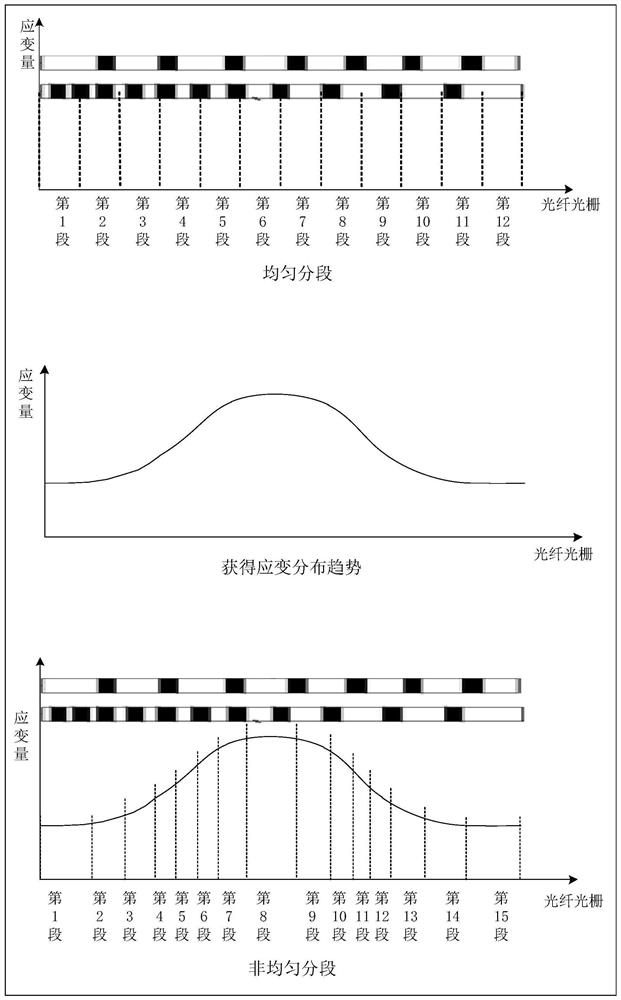

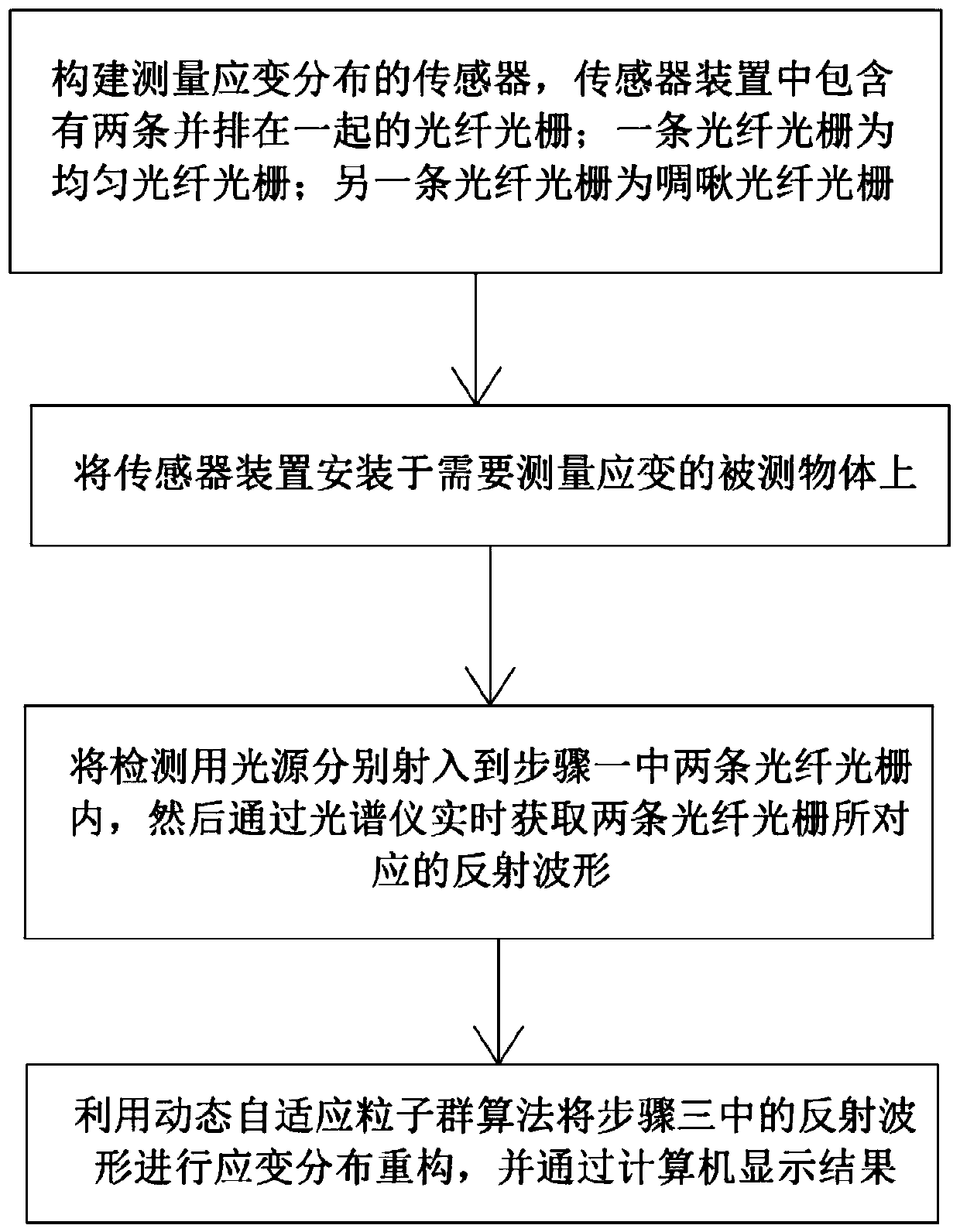

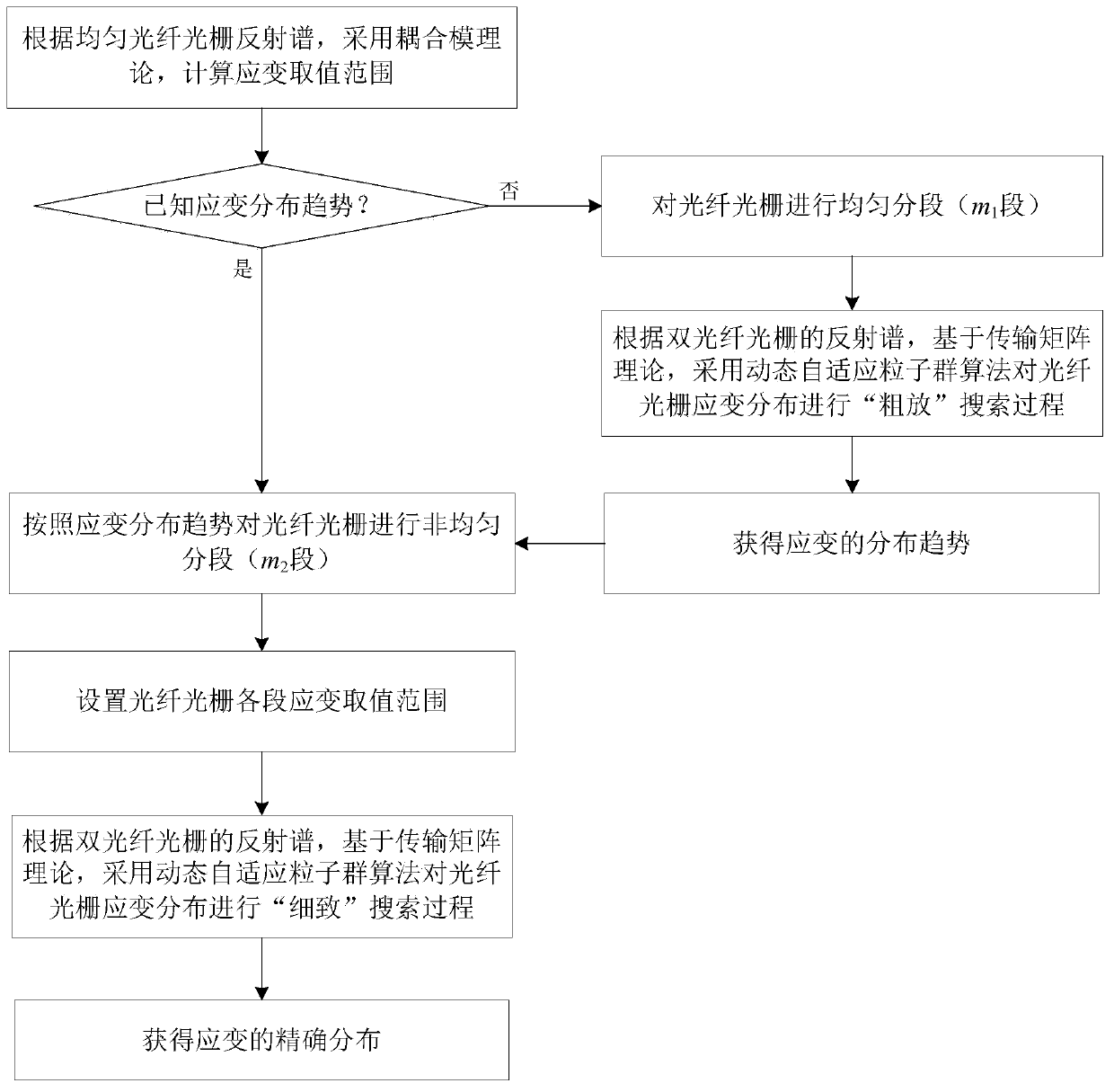

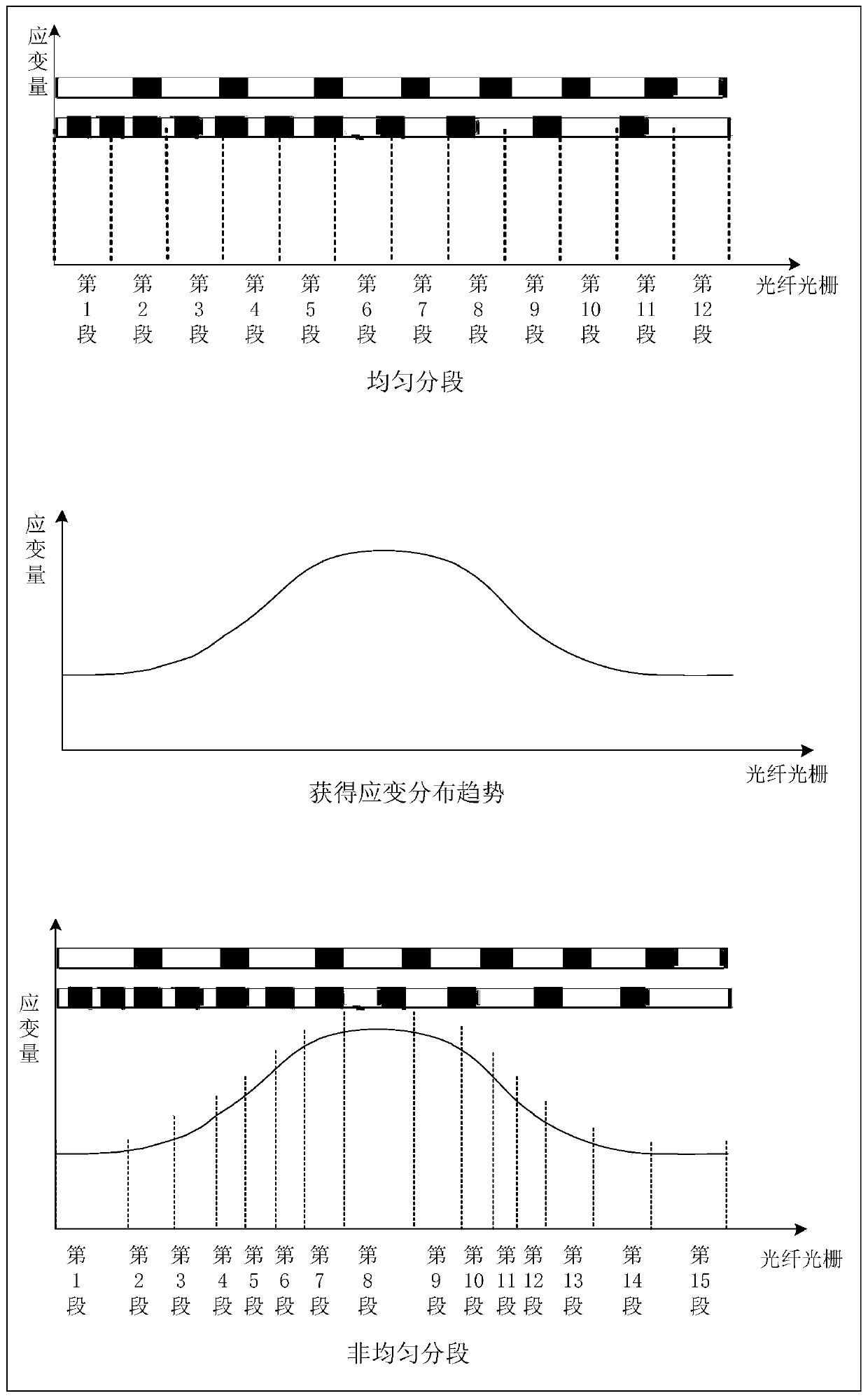

Fiber Bragg Grating Strain Distribution Reconstruction Method Based on Dynamic Adaptive Particle Swarm Optimization

ActiveCN110864642BReduce the number of segmentsIncrease diversityUsing optical meansConverting sensor output opticallyFiberOptical spectrometer

The present invention provides a fiber grating strain distribution reconstruction method based on a dynamic adaptive particle swarm algorithm that can more accurately reconstruct non-uniform strains. It includes the following steps: the first step is to construct a sensor device for measuring strain distribution, using To collect the original signal of the strain distribution; the sensor device includes two fiber gratings arranged side by side; one of the fiber gratings is a uniform fiber grating; the other fiber grating is a chirped fiber grating; in the second step, the sensor The device is installed on the measured object that needs to measure the strain; in the third step, the light source for detection is respectively injected into the two fiber gratings in the first step, and then the reflection spectrum corresponding to the two fiber gratings is obtained in real time through the spectrometer; The fourth step is to reconstruct the strain distribution of the reflectance spectrum in the third step by using the dynamic adaptive particle swarm algorithm, and display the results by computer.

Owner:NAT UNIV OF DEFENSE TECH

Digital display LED nixie tube

PendingCN112216221AImprove discriminationEfficient use ofIdentification meansChinese charactersEngineering

The invention aims to solve the problem of how to reduce misreading caused by connection when an LED nixie tube shaped like a Chinese character 'ri' displays a figure 1, and meanwhile, the displayed figure 1 is attractive. A digital display LED nixie tube is an LED nixie tube shaped like a Chinese character 'ri' and is characterized in that the upper edge of the Chinese character 'ri' is transversely divided into a left segment and a right segment which are respectively called as an upper left segment and an upper right segment for short, and only the upper right segment and the right side ofthe Chinese character 'ri' are vertically lightened when the digital display LED nixie tube displays the figure 1. The beneficial effects are that the upper right segment enables the distinction degree of the figure 1 and other figures to be higher, and misreading caused by connection of the figure 1 and the right figure is avoided; besides, the upper right segment enables the figure 1 to visuallyshift leftwards integrally, so that the left space is effectively utilized, and the unattractive appearance of the figure 1 which is too close to the side is relieved to a certain extent; meanwhile,' / ' enables the displayed figure 1 to be similar to a common thick figure, a small hook is arranged on the figure 1, the figure 1 is thickened when the LED nixie tube is used for displaying, and the thickened figure1 is very attractive.

Owner:HUNAN UNIV OF SCI & TECH

Fiber bragg grating strain distribution reconstruction method based on dynamic adaptive particle swarm algorithm

ActiveCN110864642AReduce the number of segmentsIncrease diversityUsing optical meansConverting sensor output opticallyFiberAlgorithm

The invention provides a fiber bragg grating strain distribution reconstruction method based on a dynamic self-adaptive particle swarm algorithm, and non-uniform strain can be more accurately reconstructed. The method comprises the following steps of 1, constructing a sensor device for measuring strain distribution and for acquiring an original signal of the strain distribution, wherein the sensordevice comprises two fiber bragg gratings which are arranged side by side, one fiber bragg grating is a uniform fiber bragg grating, and the other fiber bragg grating is a chirped fiber bragg grating; 2, installing the sensor device on a measured object with the need of strain measurement, 3, respectively emitting light sources for detection into the two optical fiber gratings in the step 1 and then acquiring reflection spectra corresponding to the two optical fiber gratings in real time through a spectrograph; and 4, performing strain distribution reconstruction on the reflection spectrum inthe step 3 by using the dynamic adaptive particle swarm algorithm and displaying a result through a computer.

Owner:NAT UNIV OF DEFENSE TECH

Display device

ActiveCN101334960ASimple compositionReduce the number of segmentsStatic indicating devicesLogic circuits coupling/interface using field-effect transistorsShift registerDisplay device

The invention provides a display having a shift register circuit capable of suppressing increase of power consumption is provided. This display comprises a shift register circuit including a shift register circuit portion including a first circuit portion having a second transistor turned on in response to a first signal and a second circuit portion having a sixth transistor turned on in response to a second signal providing an ON-state period not overlapping with an ON-state period of the second transistor and an input signal switching circuit portion for switching the first and second signals supplied to the second and sixth transistors respectively.

Owner:SANYO ELECTRIC CO LTD

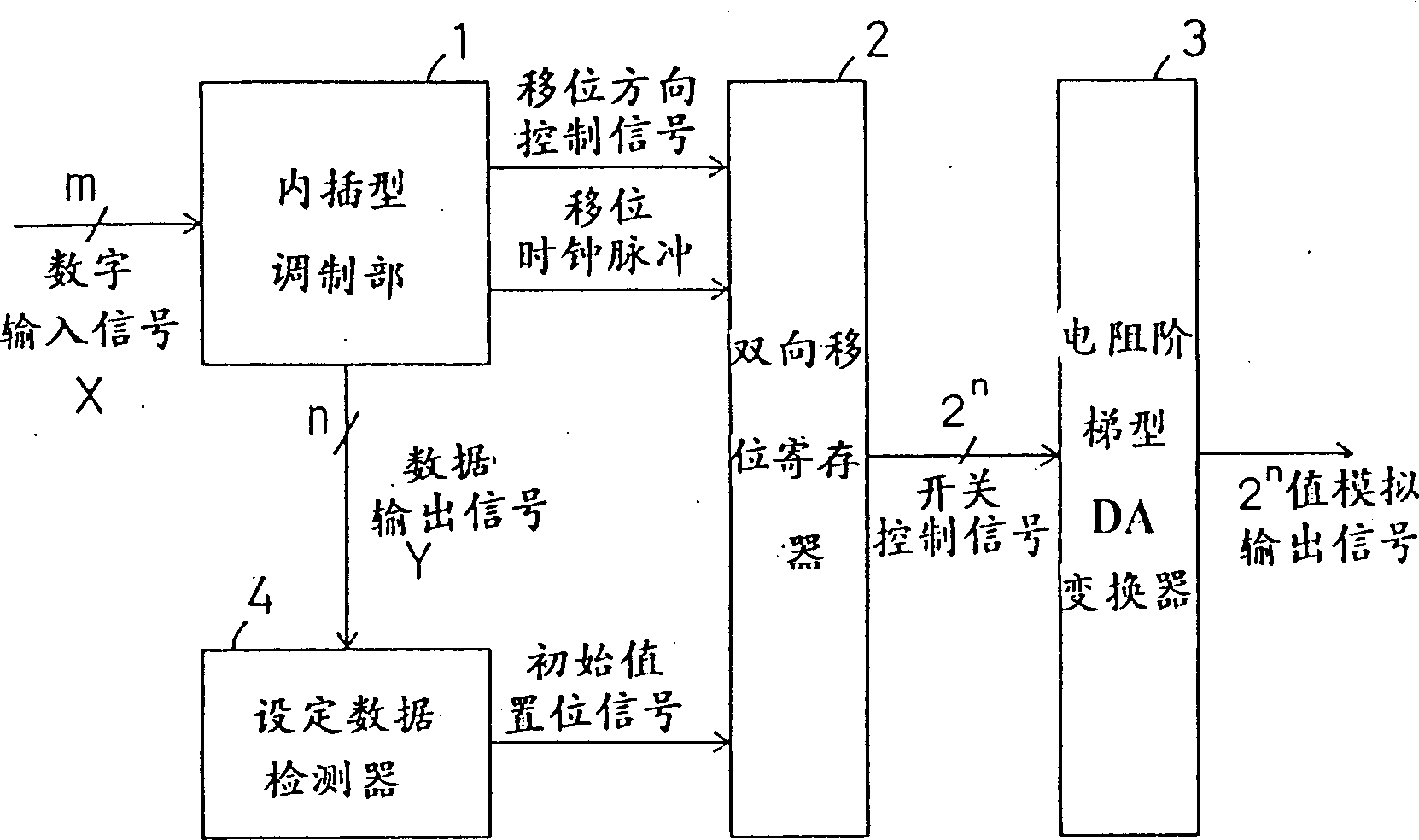

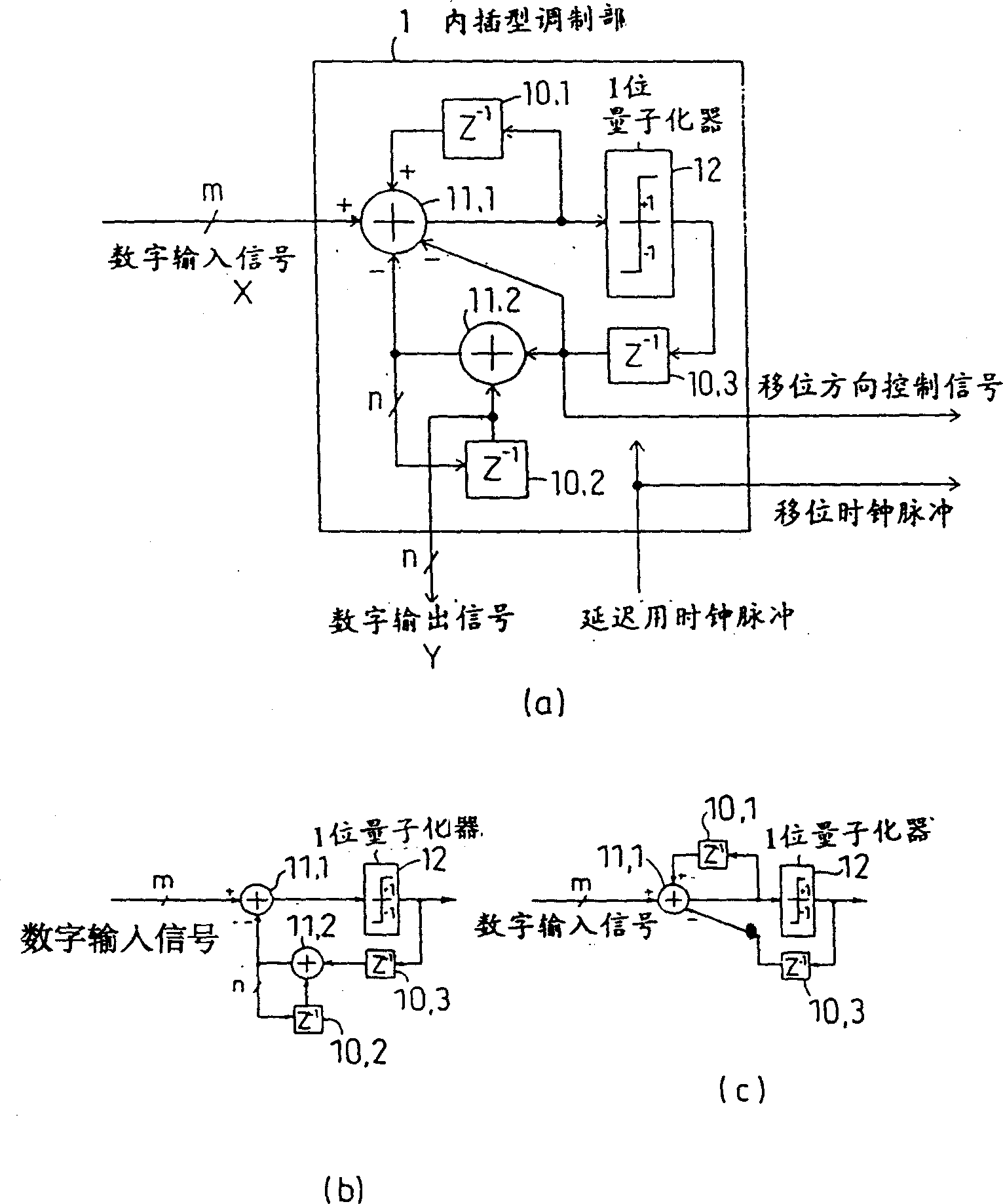

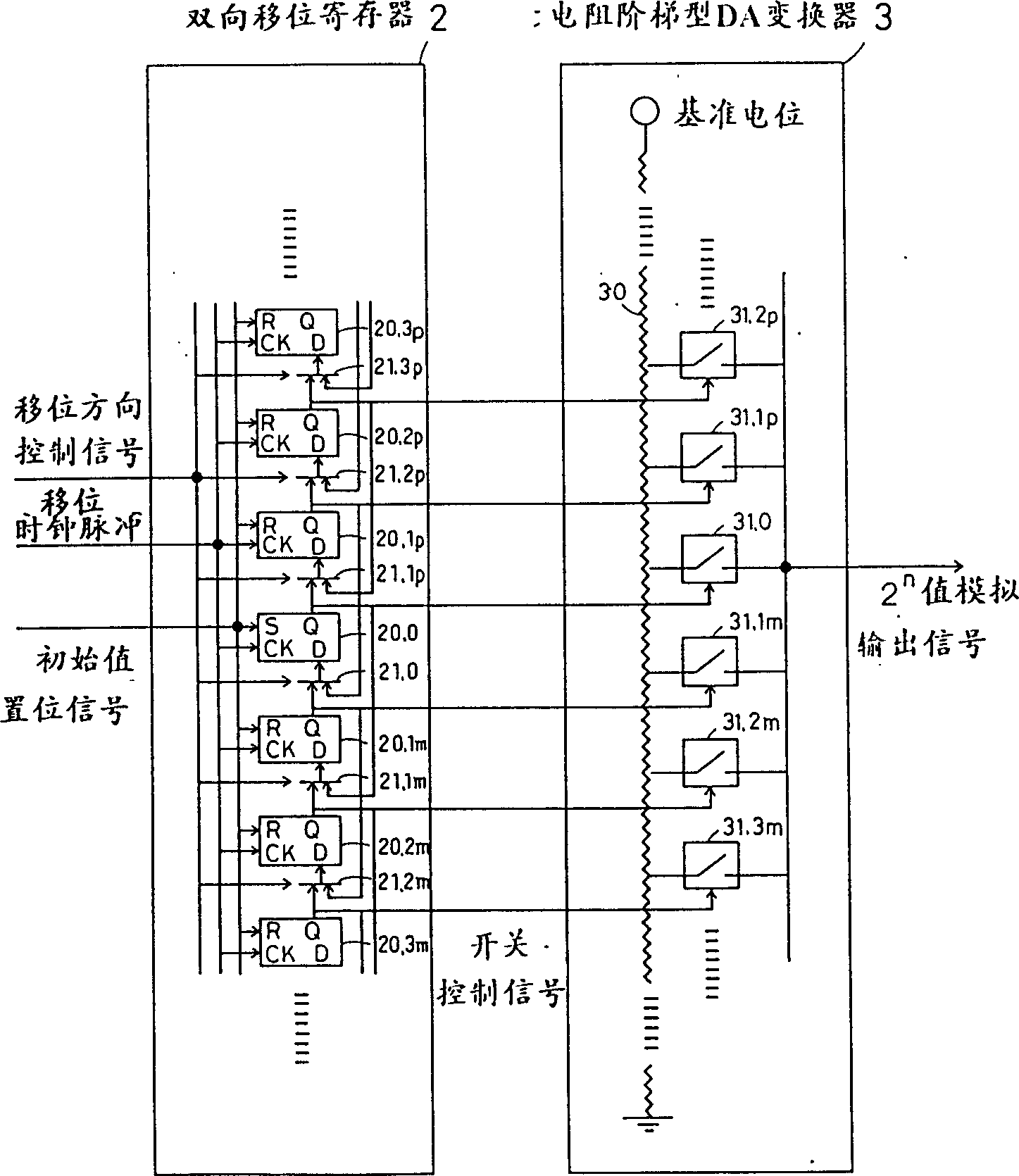

Oversampling DA converter

InactiveCN1128502CGood precisionImprove yieldDifferential modulationDigital-analogue convertorsShift registerControl signal

In an interpolative modulator, a signal which varies by only + / -1 with one clock from a 1-bit quantizer is used as a shift-direction control signal. The shift-direction control signal is given to a bidirectional shift register. The bidirectional shift register shifts data based on the value of the shift-direction control signal that has been received. The output from the bidirectional shift register is given as a control signal to a resistive-ladder-type D / A converter. The resistive-ladder-type D / A converter outputs an analog potential corresponding to a switch selected by the above control signal. Therefore, if a delay difference occurs between any two bits, two adjacent switches are simply selected simultaneously, so that the output from the resistive-ladder-type D / A converter varies continuously. Consequently, there can be provided an oversampling D / A converter of resistive-ladder type with high accuracy and an increased yield, which is free from glitch (transiently generated noise).

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com