Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Reduce solvent loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrophobic coating compositions, articles coated with said compositions, and processes for manufacturing same

InactiveUS7268179B2Low costReduce solvent lossAnalysis material containersSpecial surfacesAlkoxy groupChemistry

Hydrophobic coating compositions are provided as are processes to coat articles with the compositions. Extremely hydrophobic coatings are provided by the compositions. Durable, weatherable and scratch-resistant coatings are provided by compositions comprising a fluorinated component and an adhesion promoter compound. The adhesion promoter compound can include an alkoxy group, a furfuryl-containing ring structure, and a reactive group.

Owner:CYTONIX

Hydrophobic coating compositions and articles coated with said compositions

InactiveUS20050003203A1Surface energy is lowHigh resistance to solvent removalAnalysis material containersSynthetic resin layered productsPolymer chemistryCoating

Hydrophobic coating compositions are provided as are processes to coat articles with the compositions. Extremely hydrophobic coatings are provided by the compositions. Durable, weatherable and scratch-resistant coatings are provided by compositions comprising a trifluoromethyl-containing component and a hardenable material. Weatherable coatings are also provided by compositions comprising a mobile non-volatile fluorinated component and a hardenable material. Processes are also provided for forming hydrophobic coatings on articles.

Owner:CYTONIX

Hydrophobic formulations and vessel surfaces comprising same

InactiveUS20070110907A1Low costReduce solvent lossBioreactor/fermenter combinationsBiochemistry cleaning apparatusAlkoxy groupAdhesion promoters

Hydrophobic coating compositions are provided as are processes to coat articles with the compositions. Extremely hydrophobic coatings are provided by the compositions. Durable, weatherable and scratch-resistant coatings are provided by compositions comprising a fluorinated component and an adhesion promoter compound. The adhesion promoter compound can include an alkoxy group, a furfuryl-containing ring structure, and a reactive group.

Owner:CYTONIX

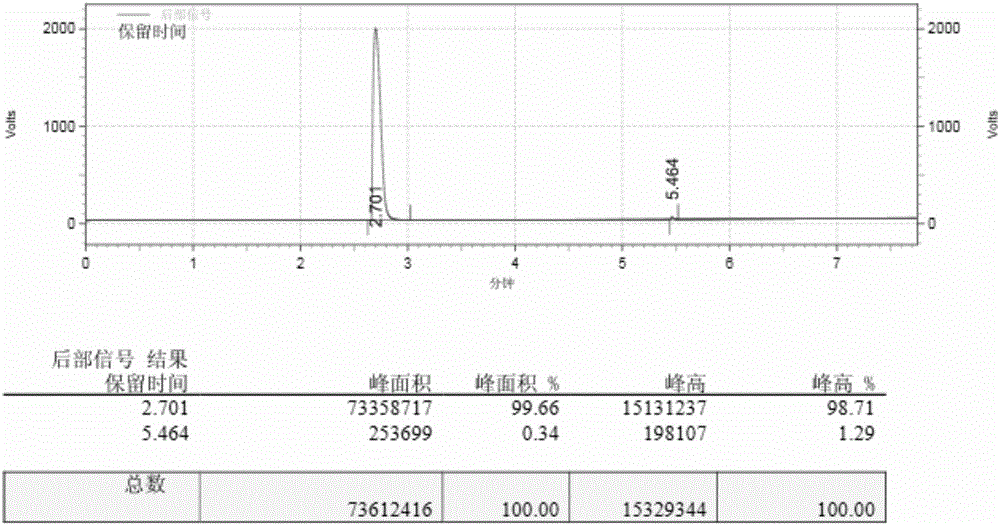

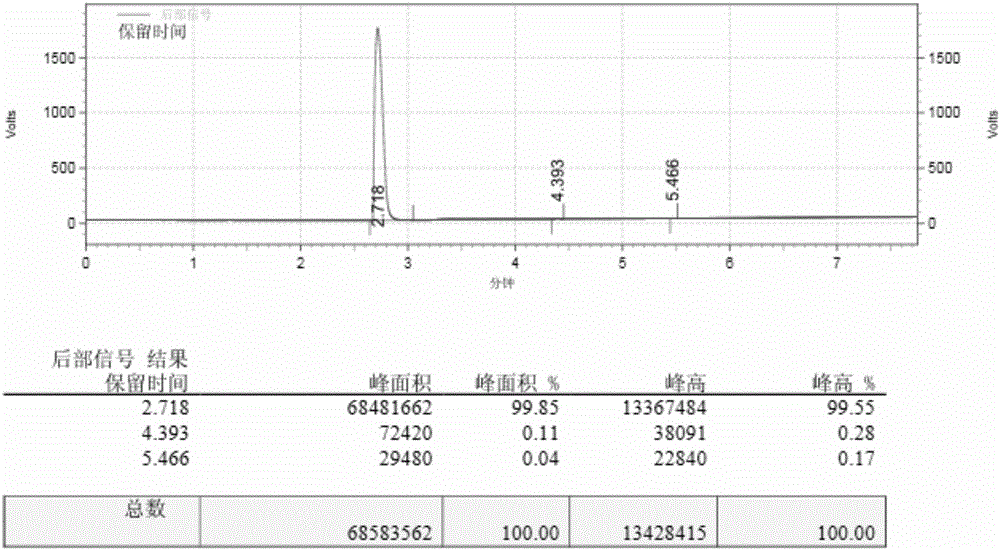

Process for preparing Danshensu

InactiveCN1670008AReduce solvent lossImprove extraction rateCarboxylic compound separation/purificationMacromolecular SubstancesUltrafiltration

The invention relates to a method for preparing danshensu which comprises: getting extract liquid from the water or alcohol with danshensu and danshensu precursors using danshen as the materials, inverting the danshensu precursors of the said extract liquid into danshensu using diluted alkali, super filtering the macromolecular substance of the said extract liquid after conversion using a hyperfiltration membrane, extracting the danshensu from the said extract liquid after hyperfiltration, and separating the said extraction using the normal phase chromatography to get the danshensu.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hydrophobic Coating Compositions and Articles Coated with Said Compositions

InactiveUS20120067908A1Low costReduce solvent lossLarge containersPretreated surfacesPolymer sciencePolymerization

Hydrophobic coating compositions are provided as are processes to coat articles with the compositions. Extremely hydrophobic coatings are provided by the compositions. Compositions that include perfluorohexyl(meth)acrylate and a branched or high Tg monomer are provided as are articles coated with the polymerization product of the composition. Methods are also provided for forming hydrophobic coatings on articles.

Owner:CYTONIX

Hydrophobic Coating Compositions and Articles Coated With Said Compositions

InactiveUS20100256291A1Low costReduce solvent lossAnalysis material containersOrganic chemistryPolymer chemistryMaterials science

Hydrophobic coating compositions are provided as are processes to coat articles with the compositions. Extremely hydrophobic coatings are provided by the compositions. Durable, weatherable and scratch-resistant coatings are provided by compositions comprising a trifluoromethyl-containing component and a hardenable material. Weatherable coatings are also provided by compositions comprising a mobile non-volatile fluorinated component and a hardenable material. Processes are also provided for forming hydrophobic coatings on articles.

Owner:CYTONIX

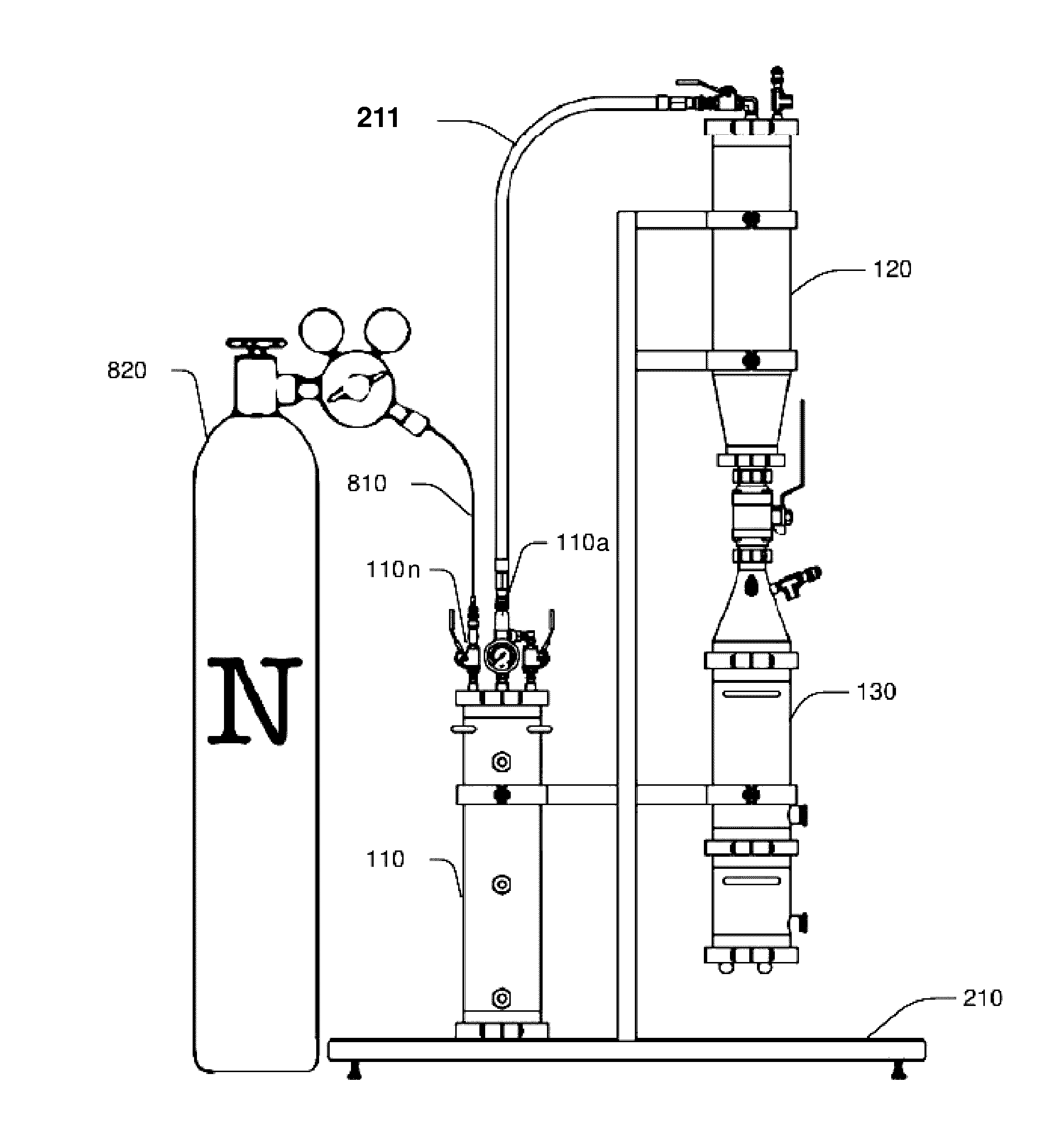

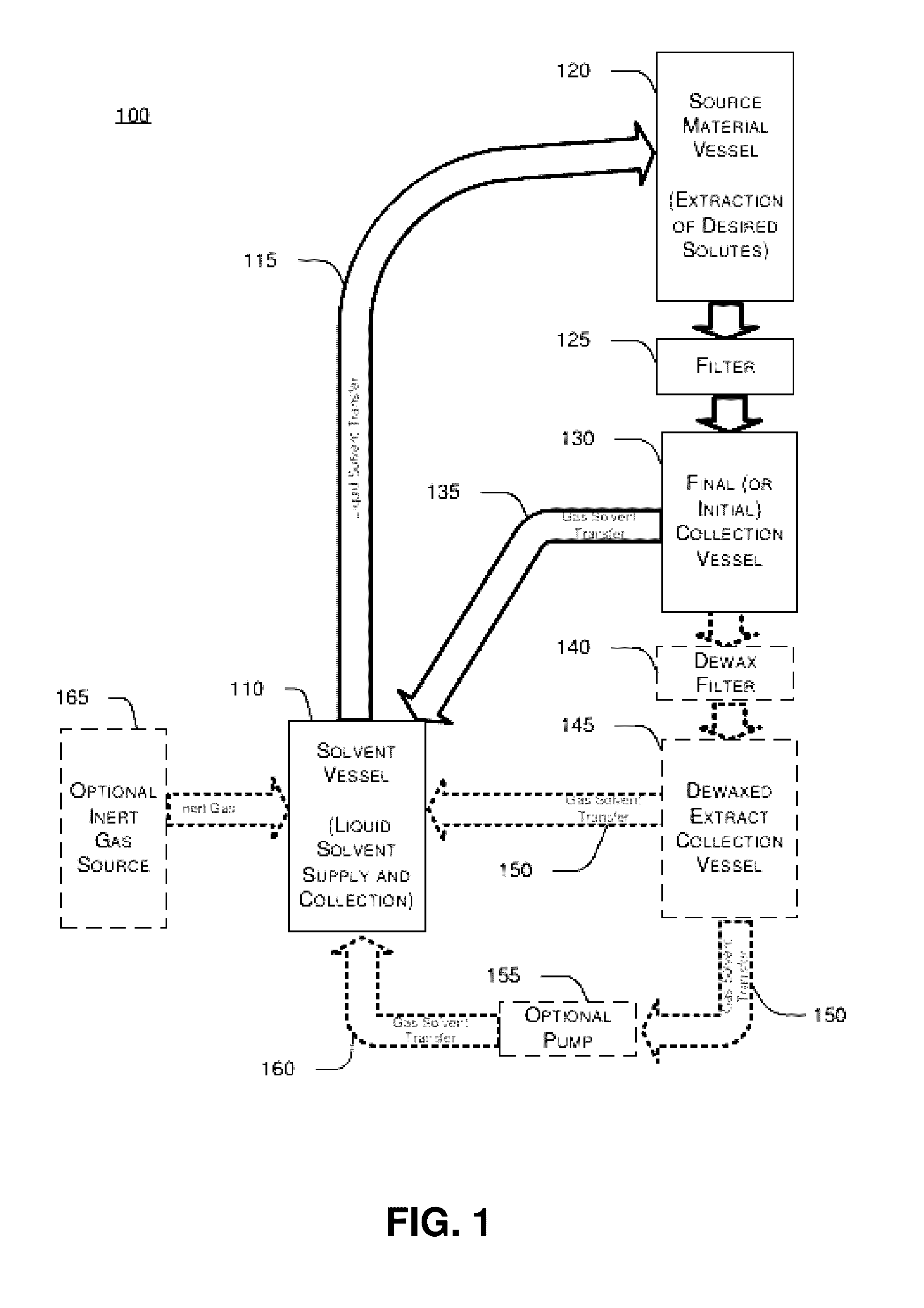

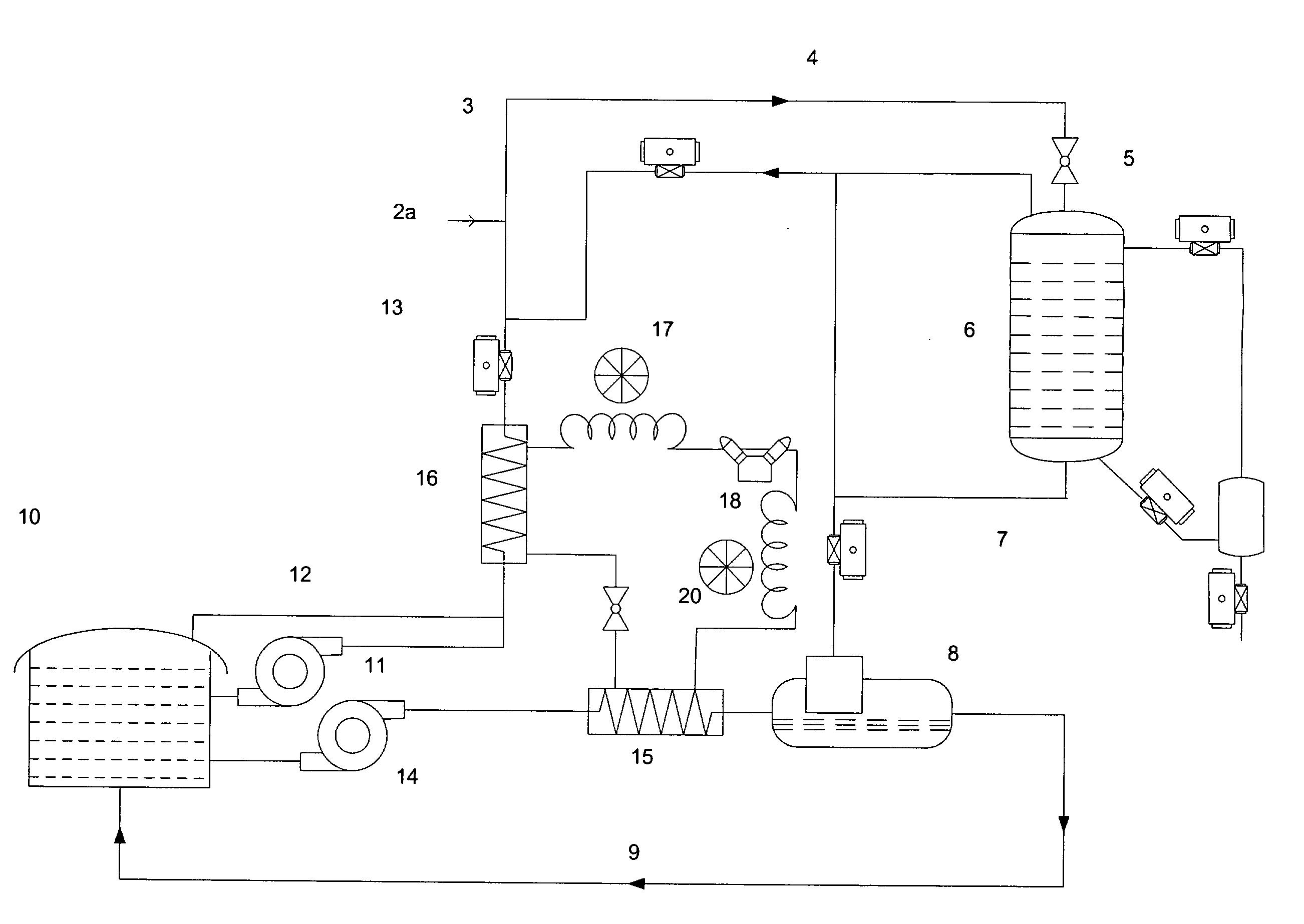

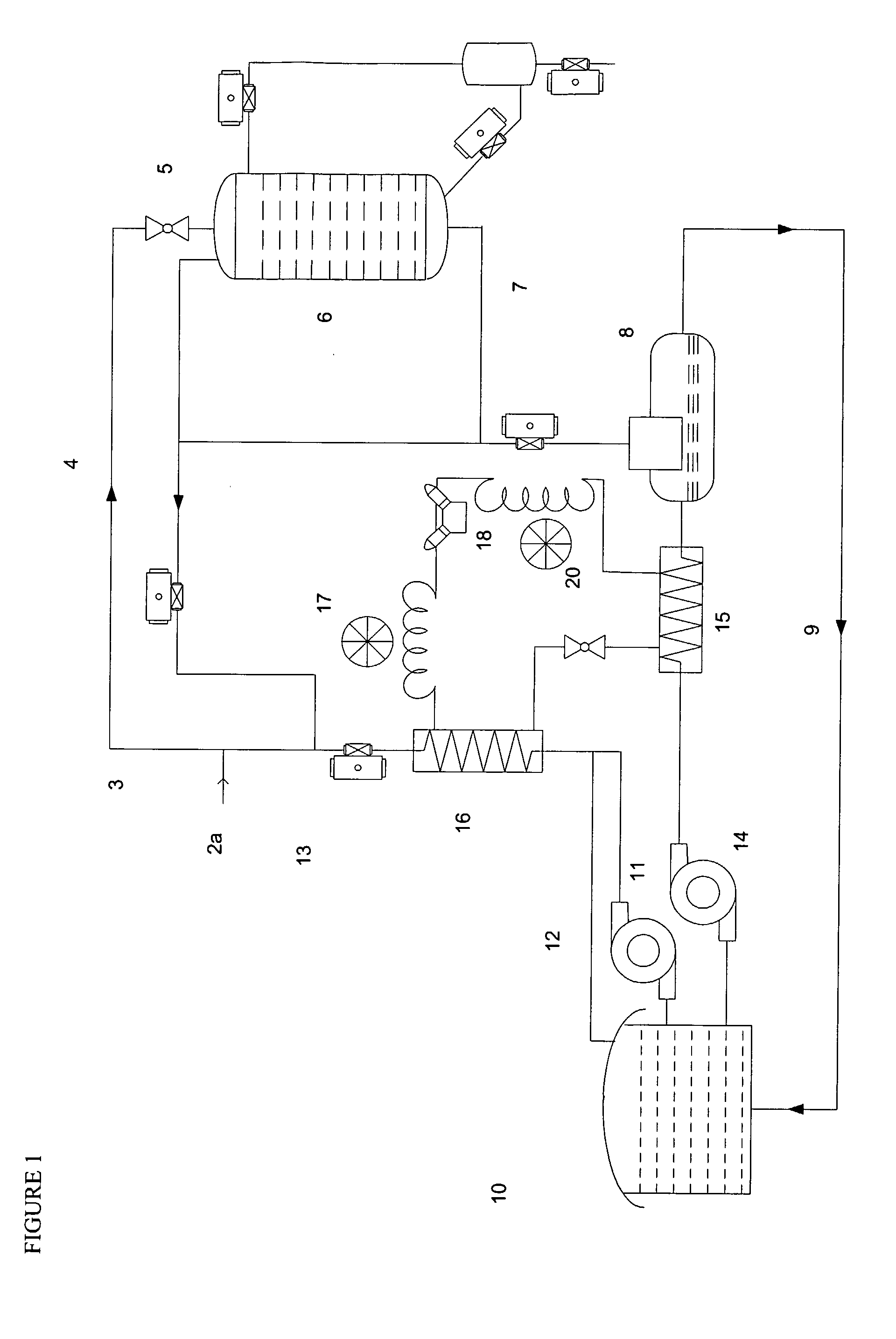

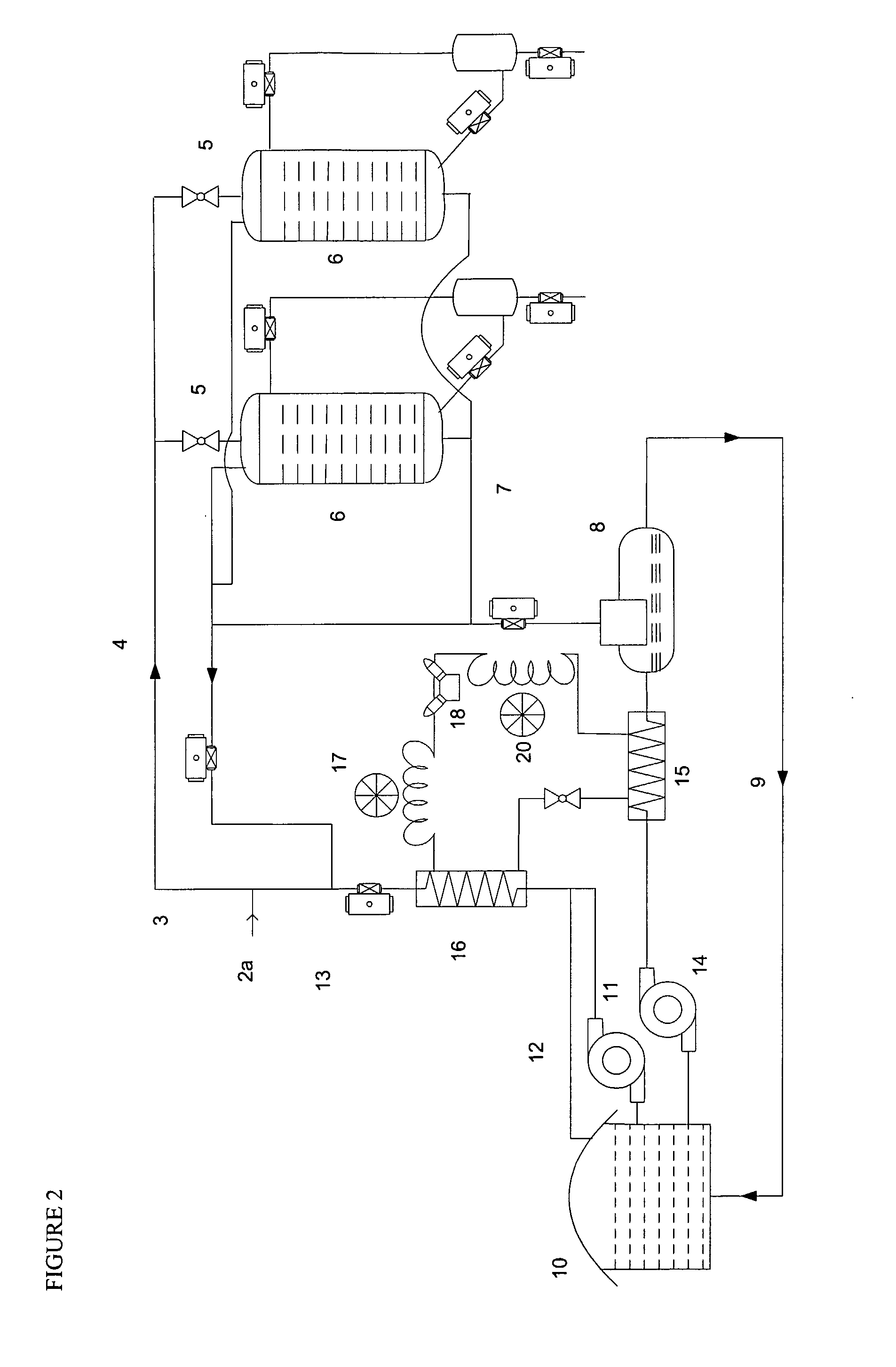

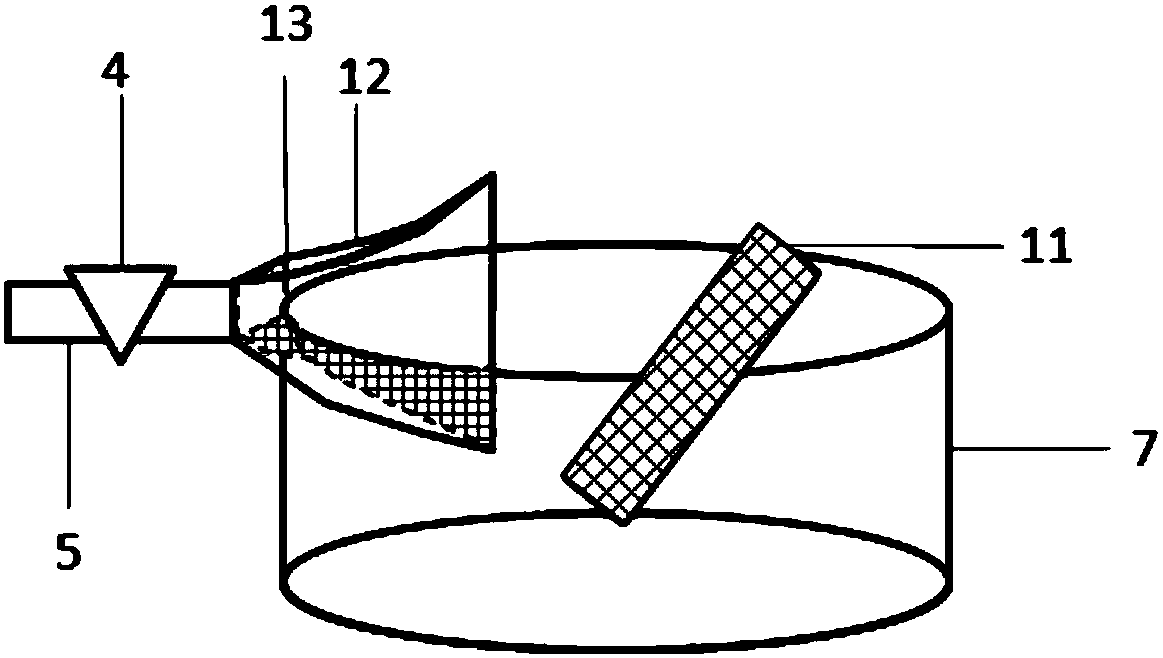

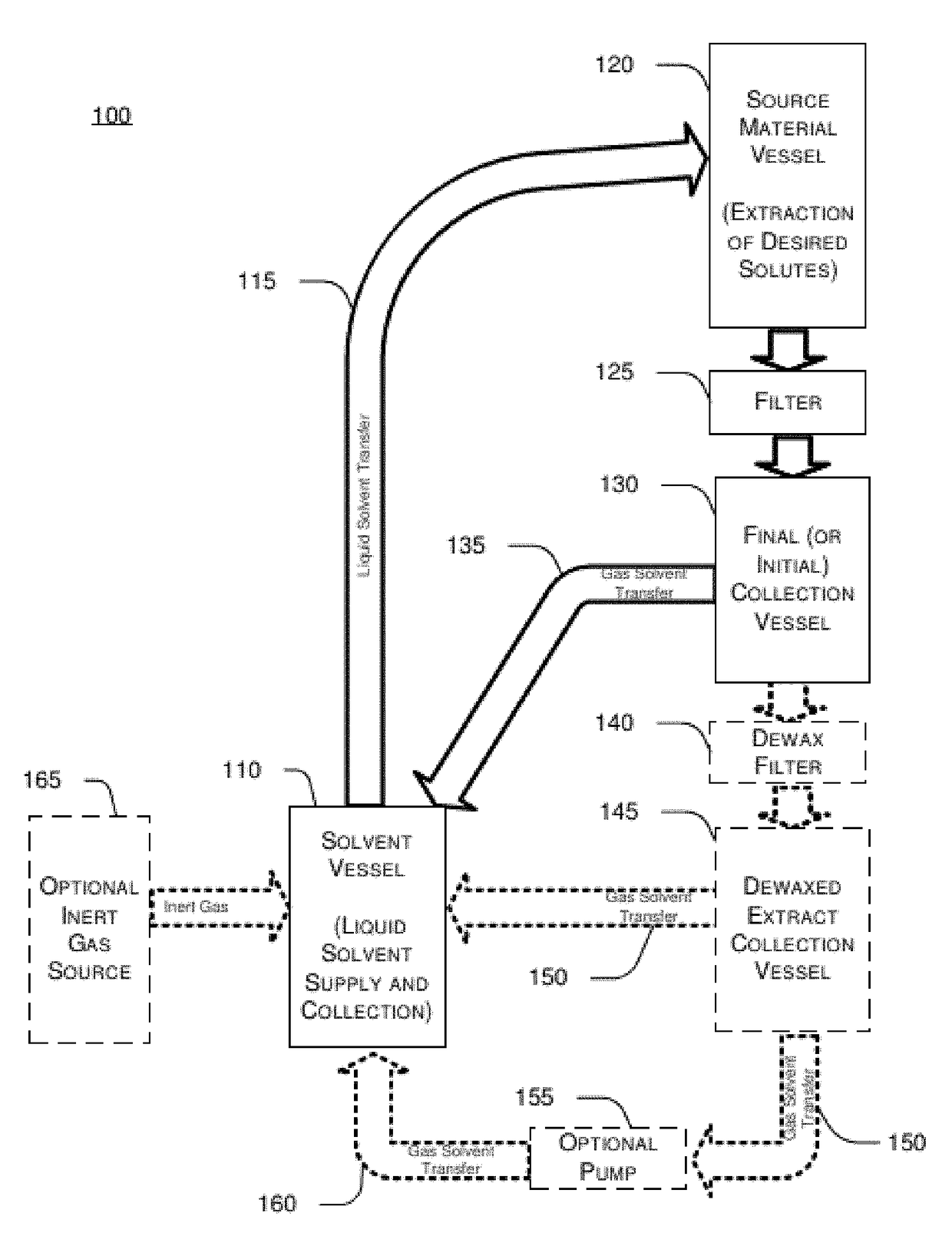

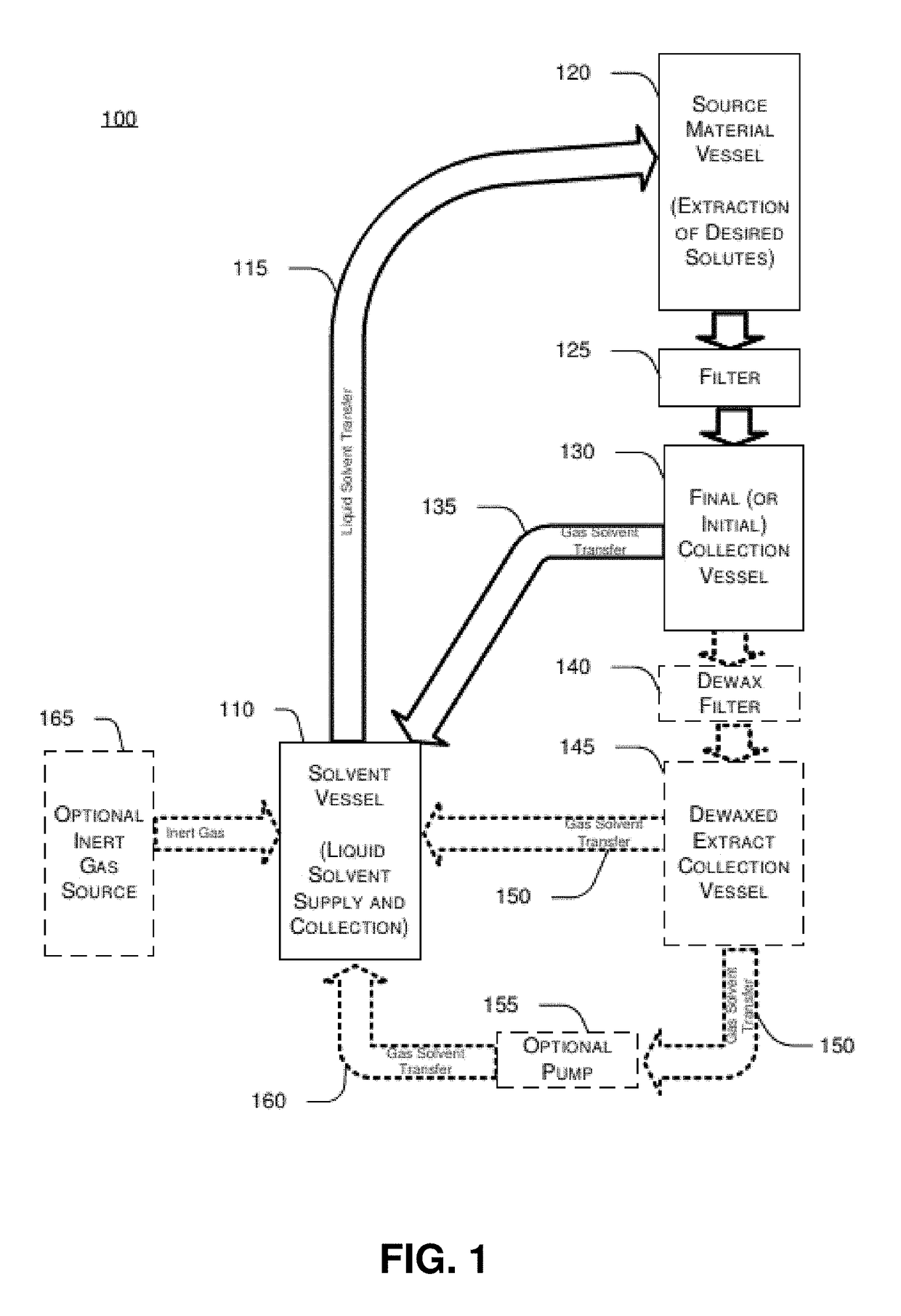

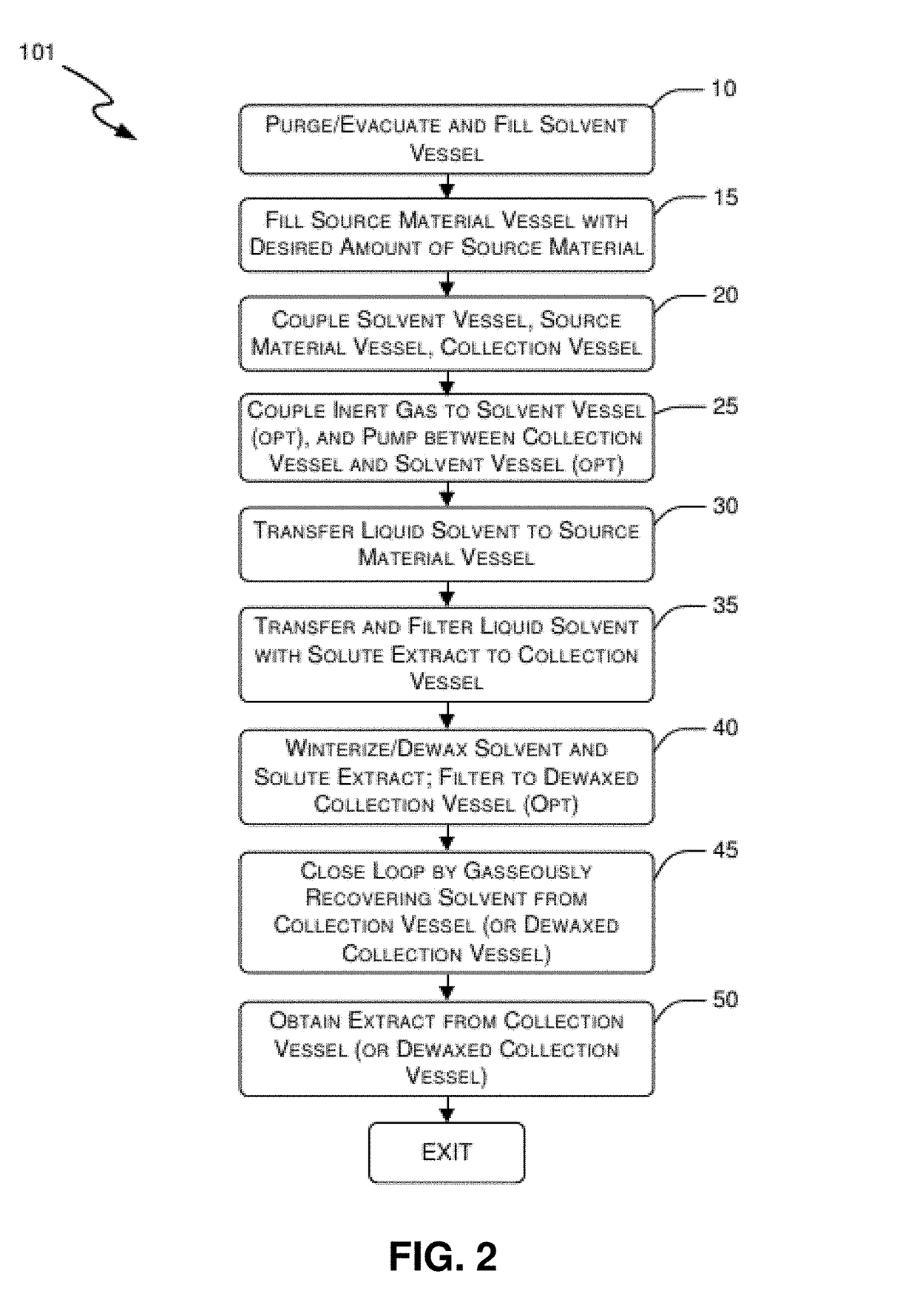

Systems and methods for closed loop solvent extraction and purification

ActiveUS20170002292A1Reduce solvent lossReduce riskFatty-oils/fats refiningFatty-oils/fats separationCannabisWax

Provided herein are systems and methods for the facile extraction and purification of oils from plant material, including cannabis and hemp. The systems and methods herein are versatile, and may utilize a wide range of solvents to extract oils from a variety of plant-based material. Further, the provided systems and methods are closed loop, reducing the loss solvent and decreasing the risk of safety concerns such as human exposure to solvent chemicals or explosion of volatiles. In some embodiments, the systems and methods remove impurities from the extracted oils, for example waxes or other precipitates, and provide a higher purity and higher quality extract.

Owner:MC MACHINERY LLC

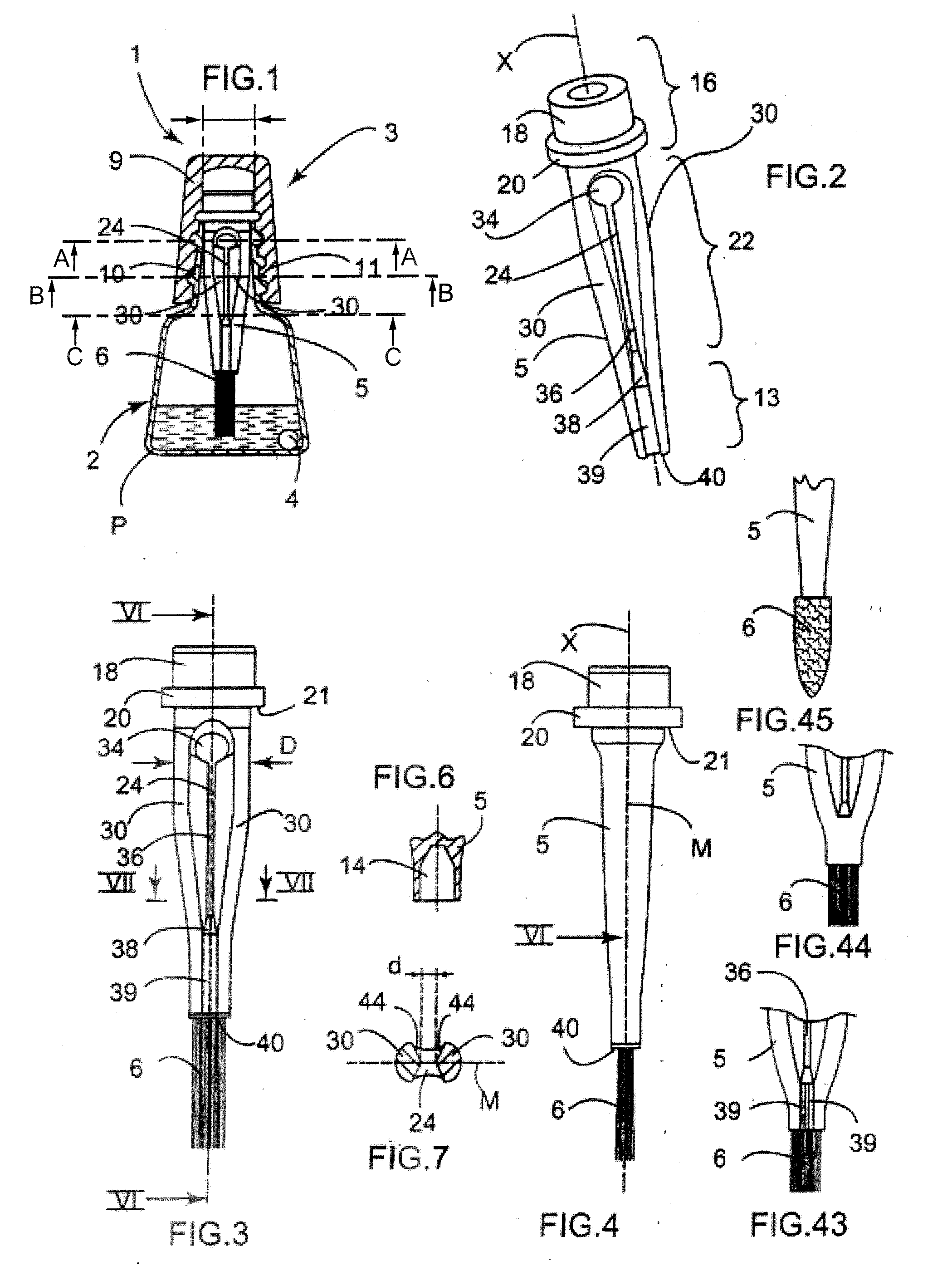

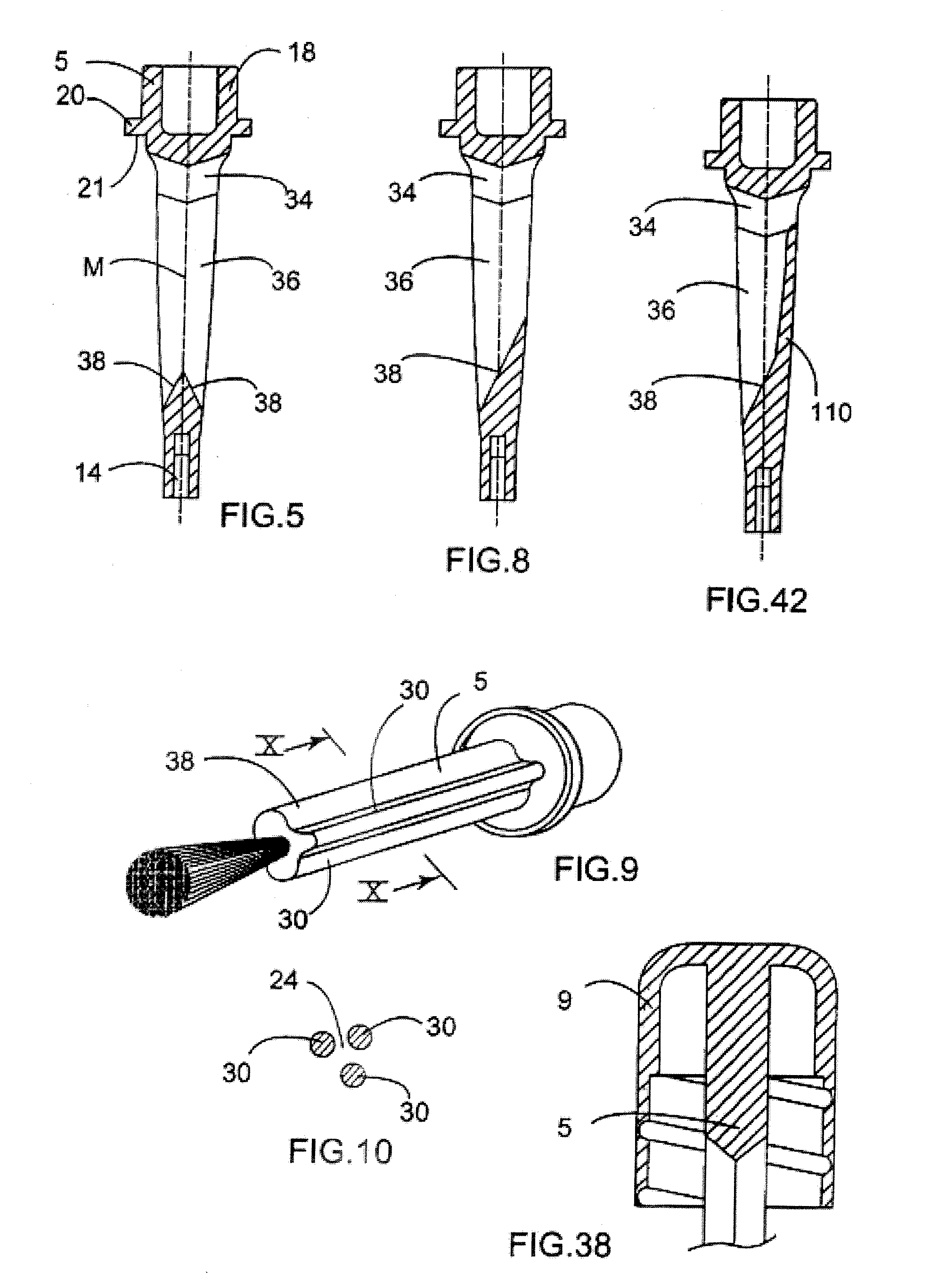

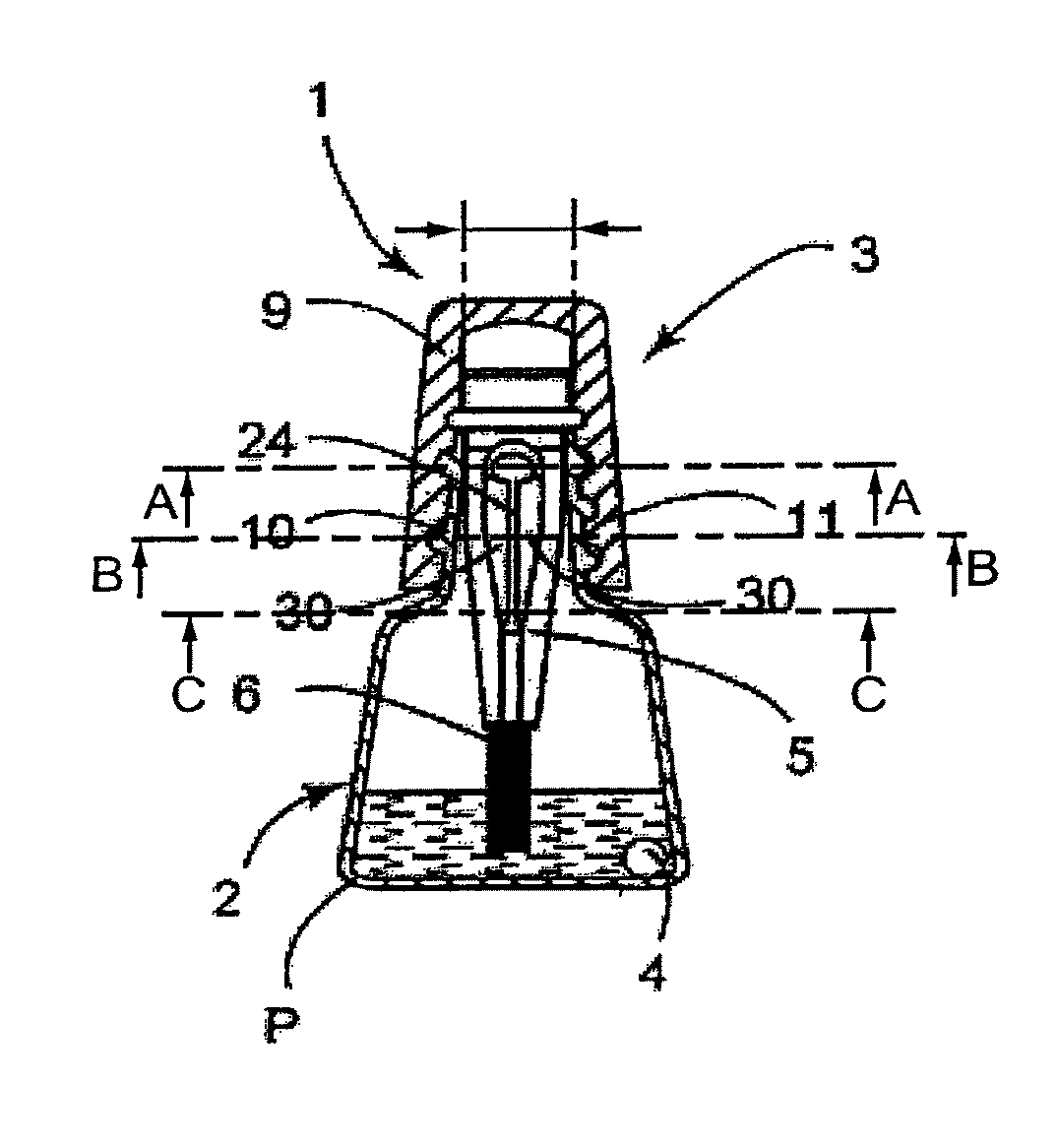

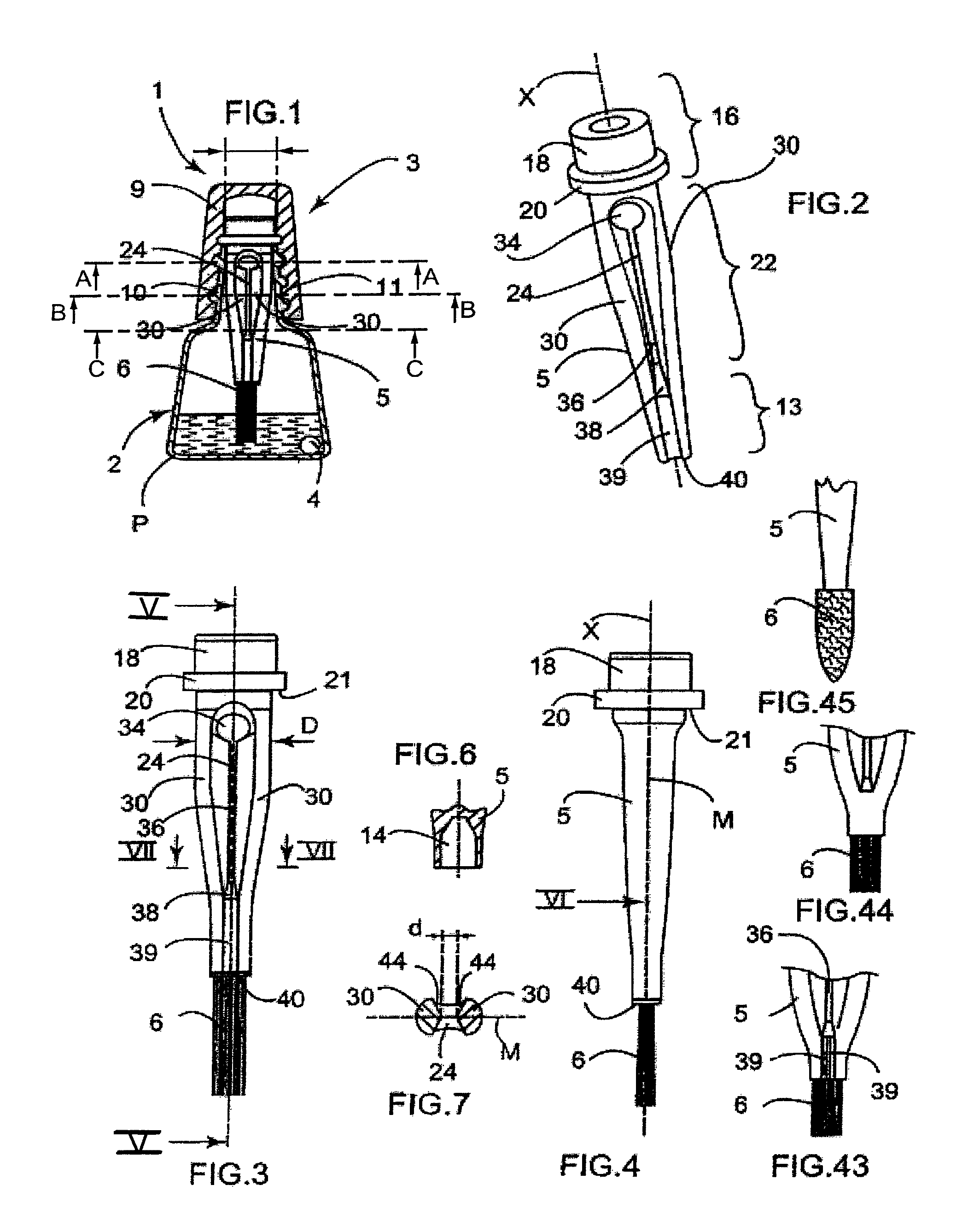

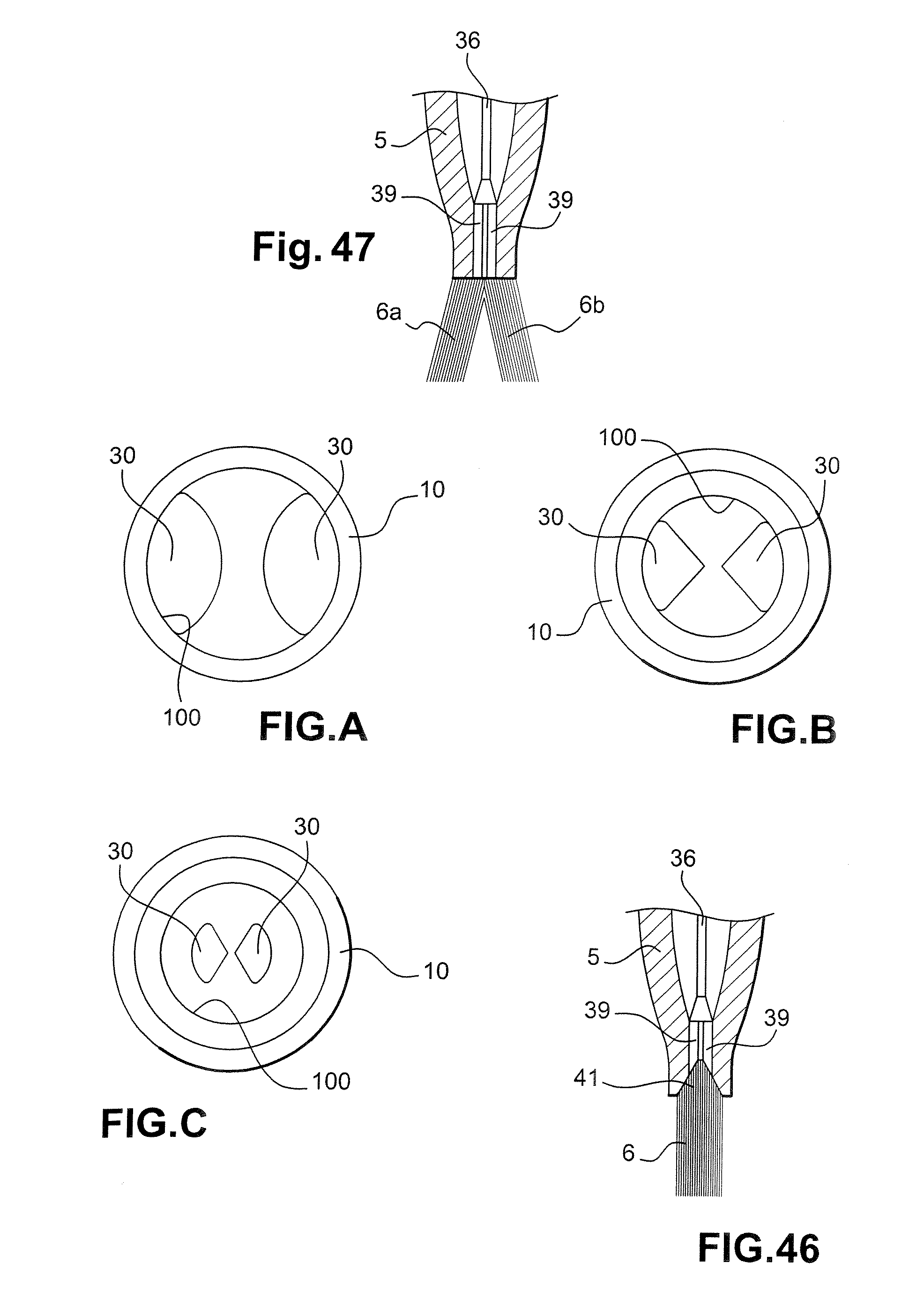

Applicator with product reserve, in particular for nail varnish

InactiveUS20070140773A1Increase volumeSmall sizeBrushesPackaging toiletriesBiomedical engineeringVarnish

Owner:LOREAL SA

Process for extracting insoluble sulfur

ActiveCN101337659AReduce solvent lossEasy to storeSulfur preparation/purificationSolventSulfur product

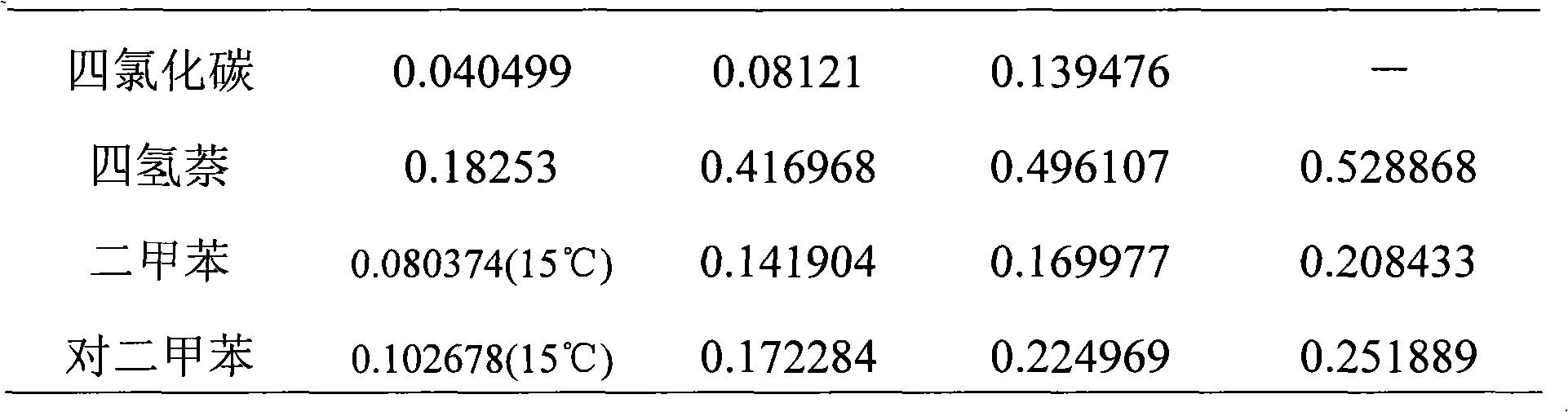

The invention relates to method for extracting insoluble sulfur from a product of IS-90 obtained from a polymerization insoluble sulfur crude product by utilizing tetranap. The method is characterized in that a product of high purity with the content of insoluble sulfur larger than 90m percent is obtained and extracted from a product with the content of insoluble sulfur being 40-80m percent after ordinary sulfur polymerization by using tetranap as an extracting solvent at the temperature of 70-90 DEG C for 10-45 minutes; the mass ratio of the solvent is between 2.3 and 9; the solvent has the characteristics of good effect, low toxicity, no easy volatilization, and good safety, can be used as a novel safe, environmental-friendly and high efficient insoluble sulfur extracting solvent instead of CS2 and tetracarp, and is suitable for the extraction separation of obtaining the insoluble sulfur product of high purity from the product obtained after ordinary sulfur polymerization. The adoption of the technology can greatly reduce investment expense of devices and improve the safety of operation process.

Owner:PETROCHINA CO LTD

Applicator with product reserve, in particular for nail varnish

InactiveUS8070374B2Convenient treatmentReduce solvent lossBrushesPackaging toiletriesEngineeringVarnish

Owner:LOREAL SA

Method for extracting crema from coffee grounds with ultrasonic subcritical fluid extraction technology

InactiveCN107674758AHigh yieldReduce solvent lossFatty-oils/fats refiningFatty-oils/fats productionCoffee groundsChemistry

The invention discloses a method for extracting crema from coffee grounds with an ultrasonic subcritical fluid extraction technology. The method comprises the following steps: dried coffee grounds andan extracting solvent are subjected to ultrasonic subcritical joint extraction according to a material-solvent ratio being 1:1-1:3 kg / L for 30-60 min under the conditions of extracting temperature being 20-60 DEG C, extracting pressure being 0.2-0.6 MPa and ultrasonic frequency being 15-30 KHz; the extracting solvent is pumped out after extraction and subjected to desolvation, the residual solvent is removed by a film evaporator, and the crema is obtained. With adoption of the ultrasonic subcritical joint extraction, active components in the coffee grounds are extracted effectively and completely, and the yield of crema products is increased remarkably; the active components in the coffee grounds cannot be damaged; the solvent can be recycled, solvent loss is reduced, cost is saved, the products have not solvent residues, and the method meets actual demands of large-scale industrial production.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

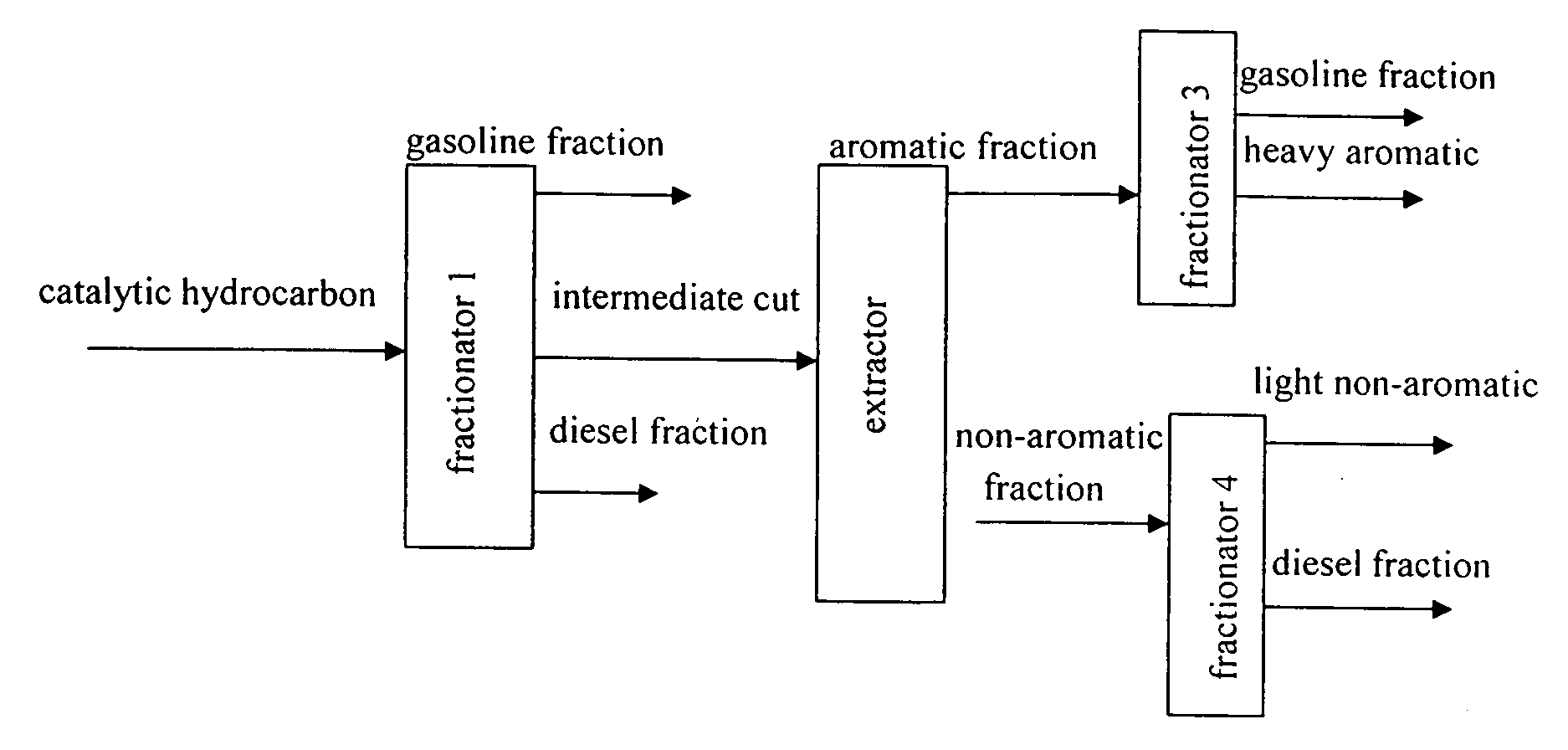

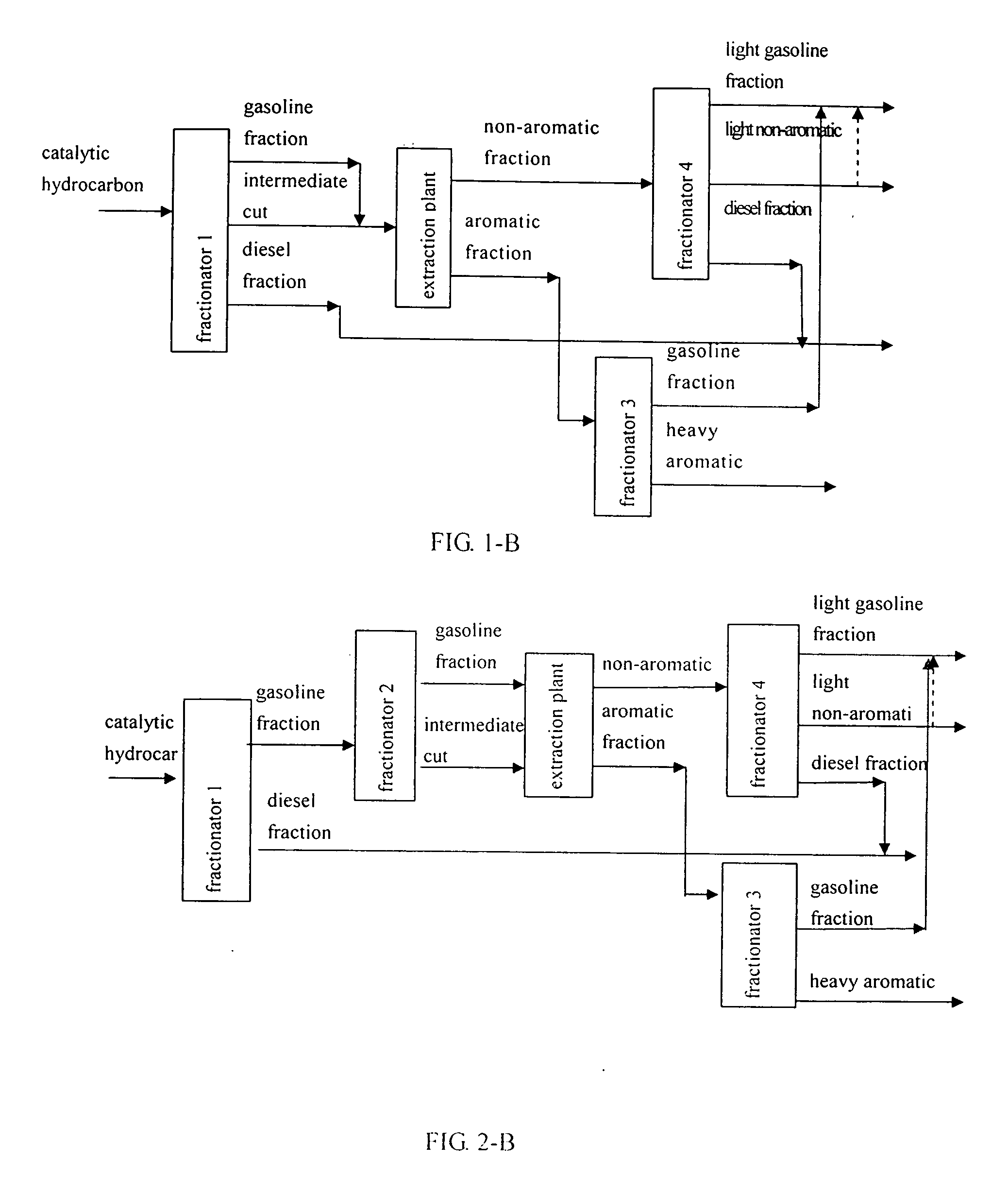

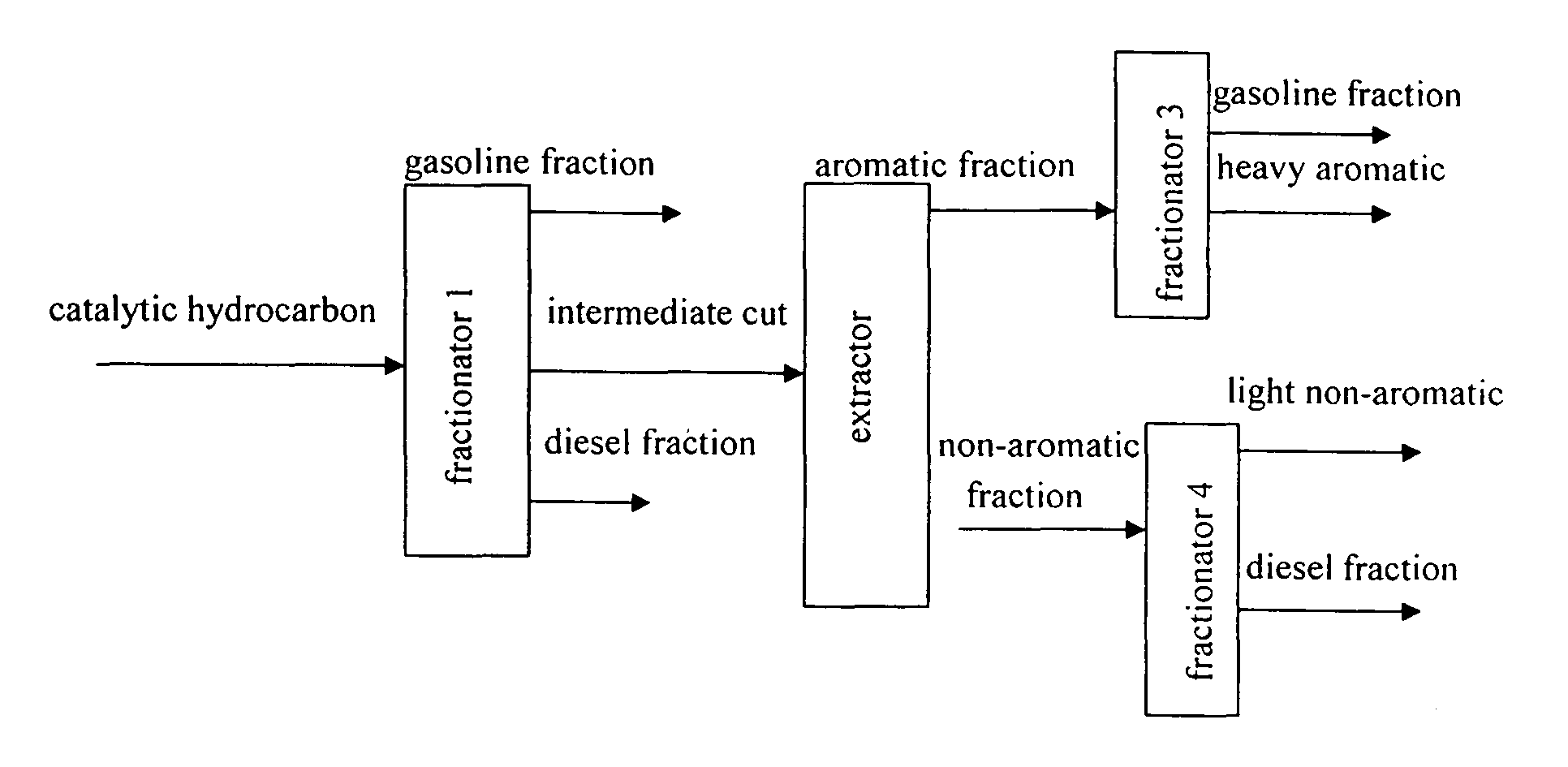

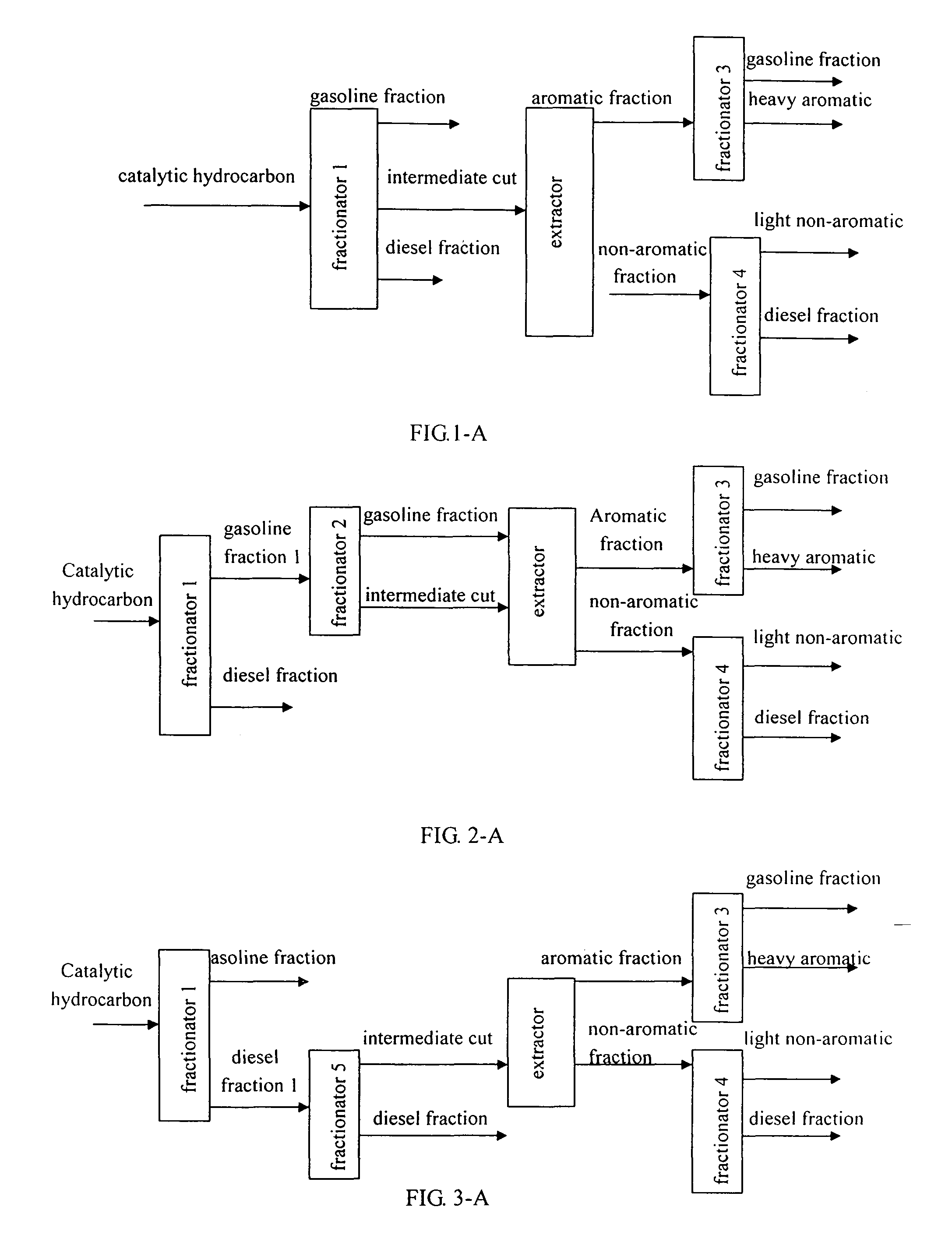

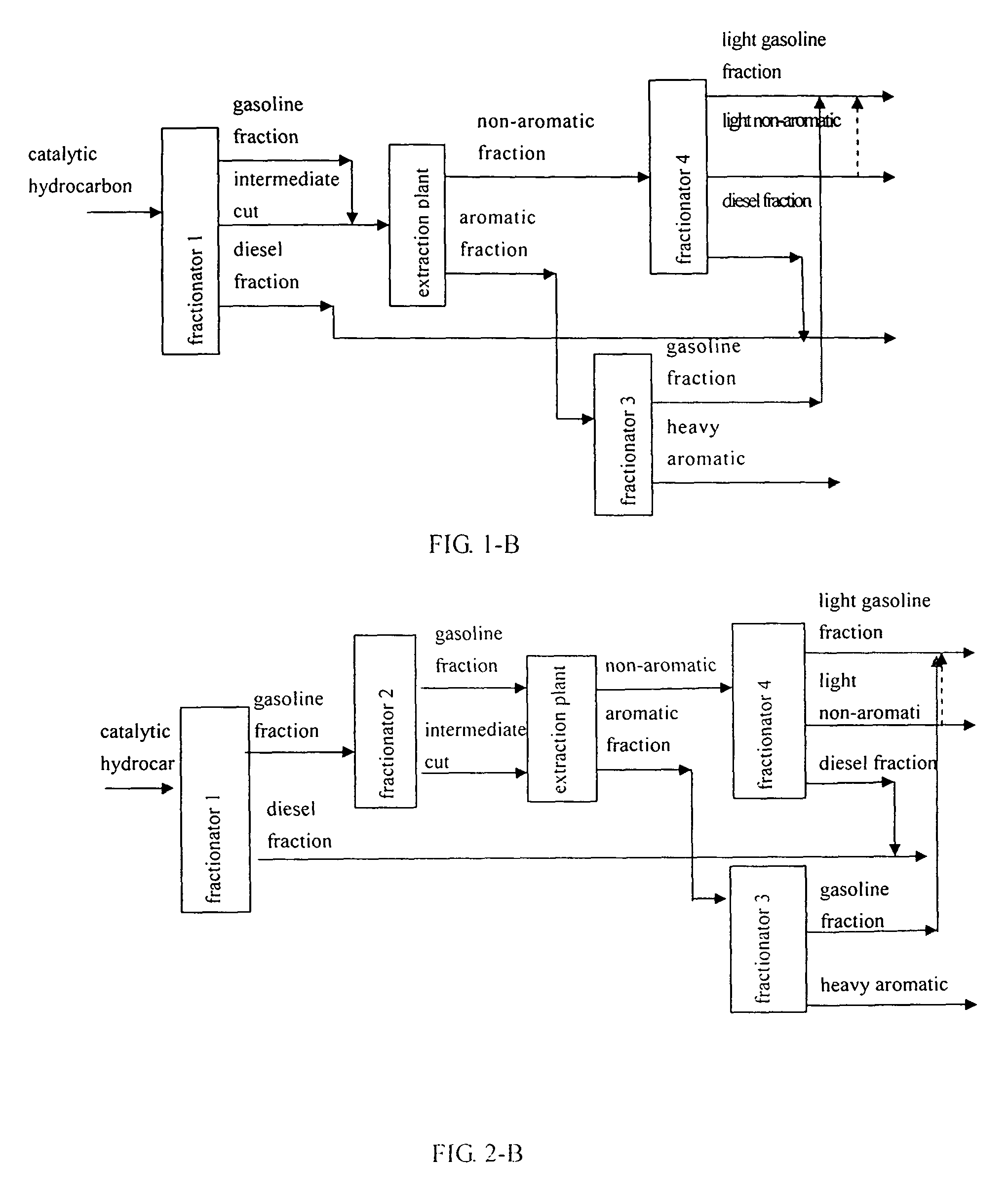

Method for recombining catalytic hydrocarbons

InactiveUS20070175800A1Quality improvementReduce solvent lossHydrocarbon distillationDistillation separationFractionating columnAromatic hydrocarbon

A process for catalytic hydrocarbon recombination is disclosed, in which catalytic hydrocarbons are fractionated at fractionators to fractionate a gasoline fraction and a diesel fuel fraction, an intermediate fraction is drawn; the intermediate fraction or the mixture of the intermediate fraction and the gasoline fraction are treated for aromatic hydrocarbon extraction to get aromatic hydrocarbon fraction and non-aromatic hydrocarbon fraction; the aromatic hydrocarbon fraction are fractionated, and the high octane number gasoline fraction obtained are blended with gasoline fraction to increase the octane number of the gasoline; the non-aromatic hydrocarbon fraction are fractionated, and the diesel fuel fraction obtained are blended with the diesel fuel fraction to increase the diesel fuel output and the cetane number of the diesel fuel. In comparison with the prior art, the recombination process of the present invention has low limitation to the raw material, low capital cost, low operation cost, and increases the types of the products.

Owner:BEIJING GRAND GOLDEN BRIGHT ENG & TECH

Method for recombining catalytic hydrocarbons

InactiveUS7867383B2Quality improvementReduce solvent lossHydrocarbon distillationDistillation separationGasolineAromatic hydrocarbon

Owner:BEIJING GRAND GOLDEN BRIGHT ENG & TECH

Hydrophobic coating compositions and articles coated with said compositions

InactiveUS8653213B2Low costReduce solvent lossPretreated surfacesLarge containersPolymer sciencePolymerization

Hydrophobic coating compositions are provided as are processes to coat articles with the compositions. Extremely hydrophobic coatings are provided by the compositions. Compositions that include perfluorohexyl(meth)acrylate and a branched or high Tg monomer are provided as are articles coated with the polymerization product of the composition. Methods are also provided for forming hydrophobic coatings on articles.

Owner:CYTONIX

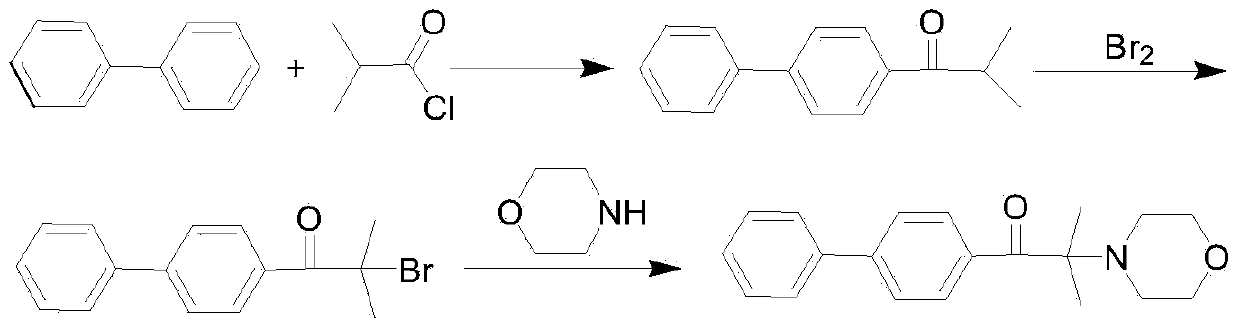

Synthetic method of 1-(biphenyl-4-yl)-2-methyl-2-morpholinopropan-1-one

The invention discloses a synthetic method of 1-(biphenyl-4-yl)-2-methyl-2-morpholinopropan-1-one which is efficient free radical photoinitiator. The synthetic method of the 1-(biphenyl-4-yl)-2-methyl-2-morpholinopropan-1-one specifically comprises the steps that biphenyl serves as a raw material, an acylation reaction and a chlorination reaction are carried out on the biphenyl, and finally the biphenyl reacts with morpholine. According to the three reactions, intermediates do not need to be processed through purification, solvent dose not need to be replaced, continuous reactions can be carried out, the total yield is high, and the technology is friendly to the environment. The synthetic method of the 1-(biphenyl-4-yl)-2-methyl-2-morpholinopropan-1-one is low in cost, friendly to the environment, easy to operate and applicable to industrialization.

Owner:TIANJIN JIURI NEW MATERIALS CO LTD

Impregnation apparatus and method

InactiveUS20090061207A1Increase pressureReduce solvent lossLayered productsPretreated surfacesActive agentBoiling point

Apparel us for impregnating a porous substrate (e.g., wood) with an active agent, including a reservoir for containing a low boiling fluid, a controllable first fluid pathway to permit fluid to flow from the reservoir to a treatment vessel, a fluid junction for introducing the active agent into the first fluid pathway to permit mixing of the active agent with the low boiling fluid to produce an impregnation fluid containing an initial level of active agent and a controllable second fluid pathway to allow fluid to flow from the treatment vessel to the reservoir. The treatment vessel contains the porous substrate while it contacts the impregnation fluid in a liquid state to produce a treated substrate impregnated with the active agent. Also, a method for impregnating a substrate with an active agent, including preparing an impregnation fluid including a low boiling solvent and an active agent, and optionally a co-solvent, contacting the porous substrate with the impregnation fluid in a liquid substrate in an impregnation chamber and removing the impregnation fluid.

Owner:CARTER HOLT HARVEY WOOD PROD AUSTRALIA +1

Automatic solvent replacing apparatus in preparation process of hydrophobic silicon dioxide aerogel

The invention relates to an automatic solvent replacing apparatus in a preparation process of hydrophobic silicon dioxide aerogel. The apparatus comprises a cylindrical reactor, wherein the cylindrical reactor is provided with a condenser (1), the cylindrical reactor is divided into an upper layer and a lower layer, the upper layer is used for the replacement reaction, the lower layer is used forstoring the recycled solvent, and the upper layer, the lower layer and the condenser (1) form a circulating loop by virtue of a reflux pipe (6) and a steam pipe (3). The invention provides the automatic solvent replacing apparatus in the preparation process for the weaknesses in the preparation process of the hydrophobic silicon dioxide aerogel that the solvent is repeatedly replaced, long time isconsumed and the like. By utilizing the apparatus, the solvent can be automatically replaced; and moreover, the solvent can be circularly utilized, materials can be automatically discharged, and timeand labor can be saved.

Owner:WUHAN UNIV OF TECH

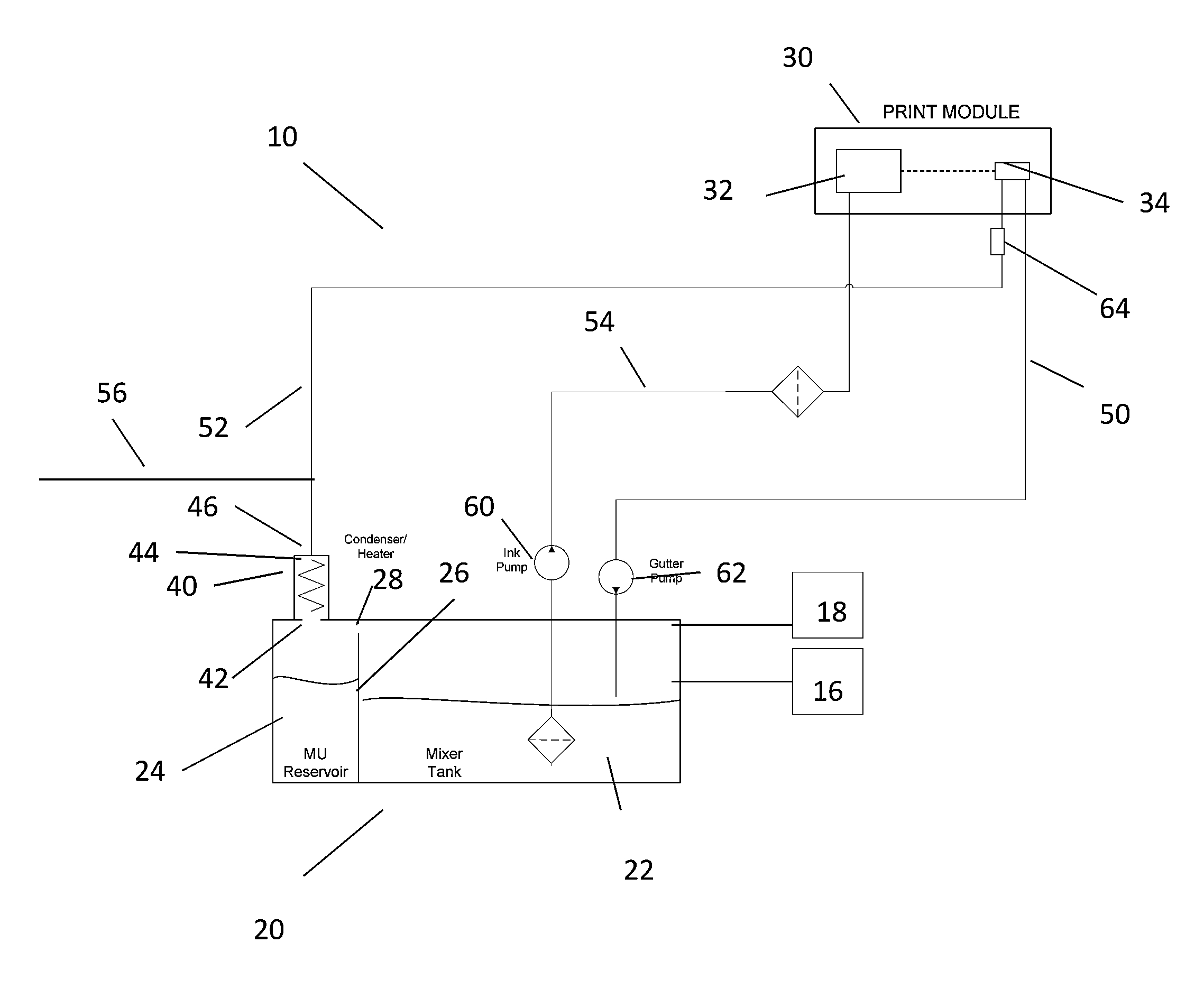

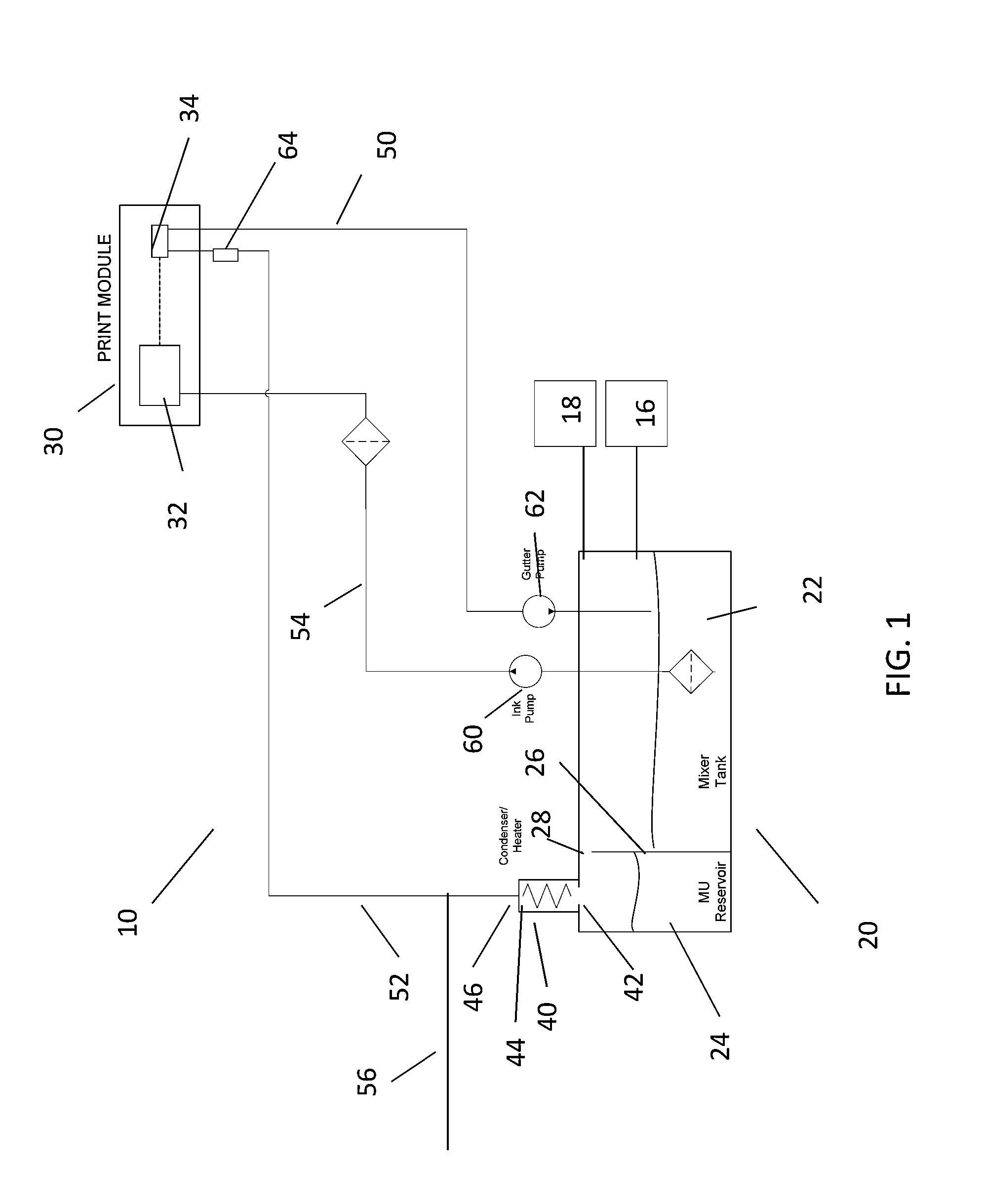

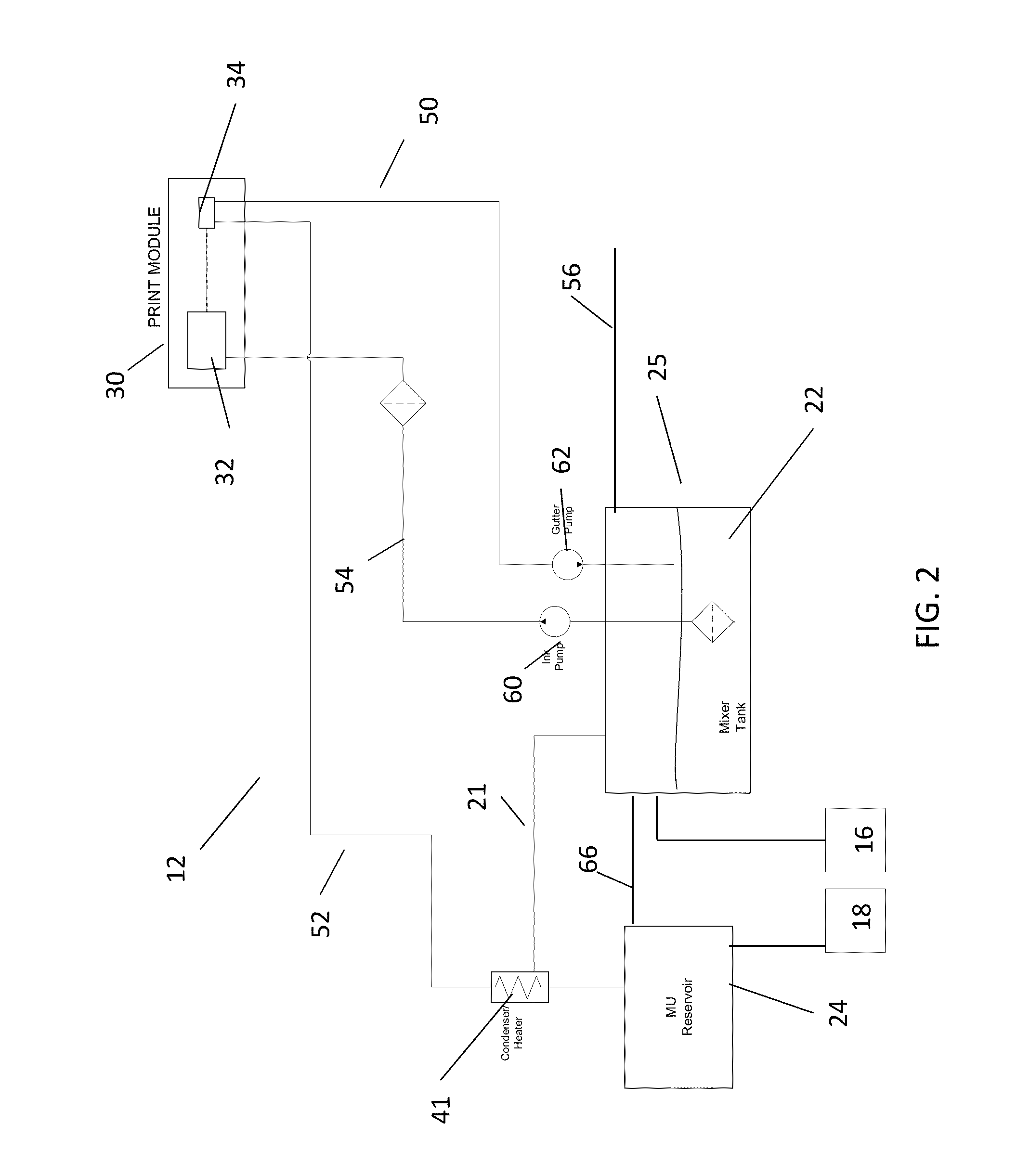

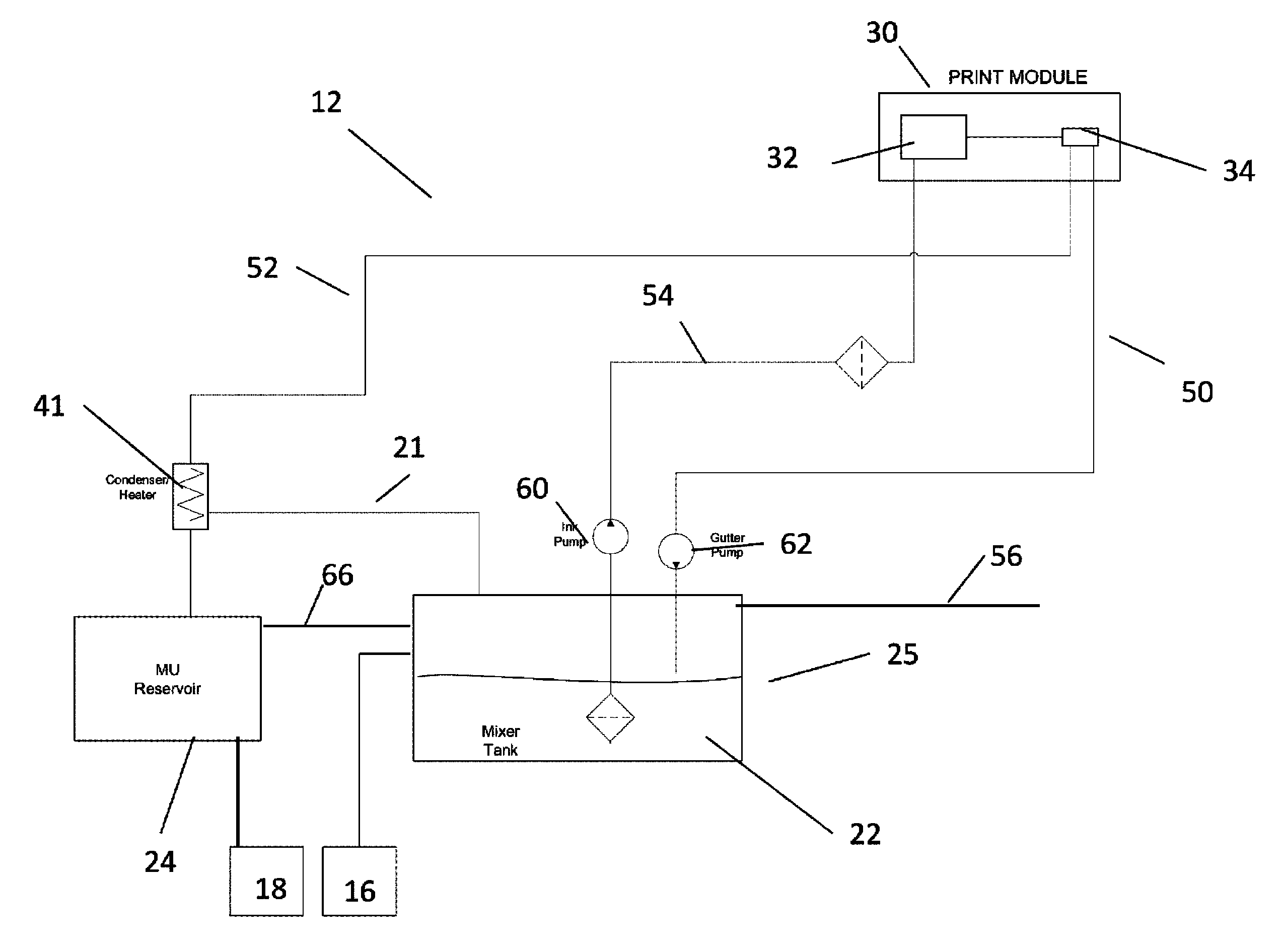

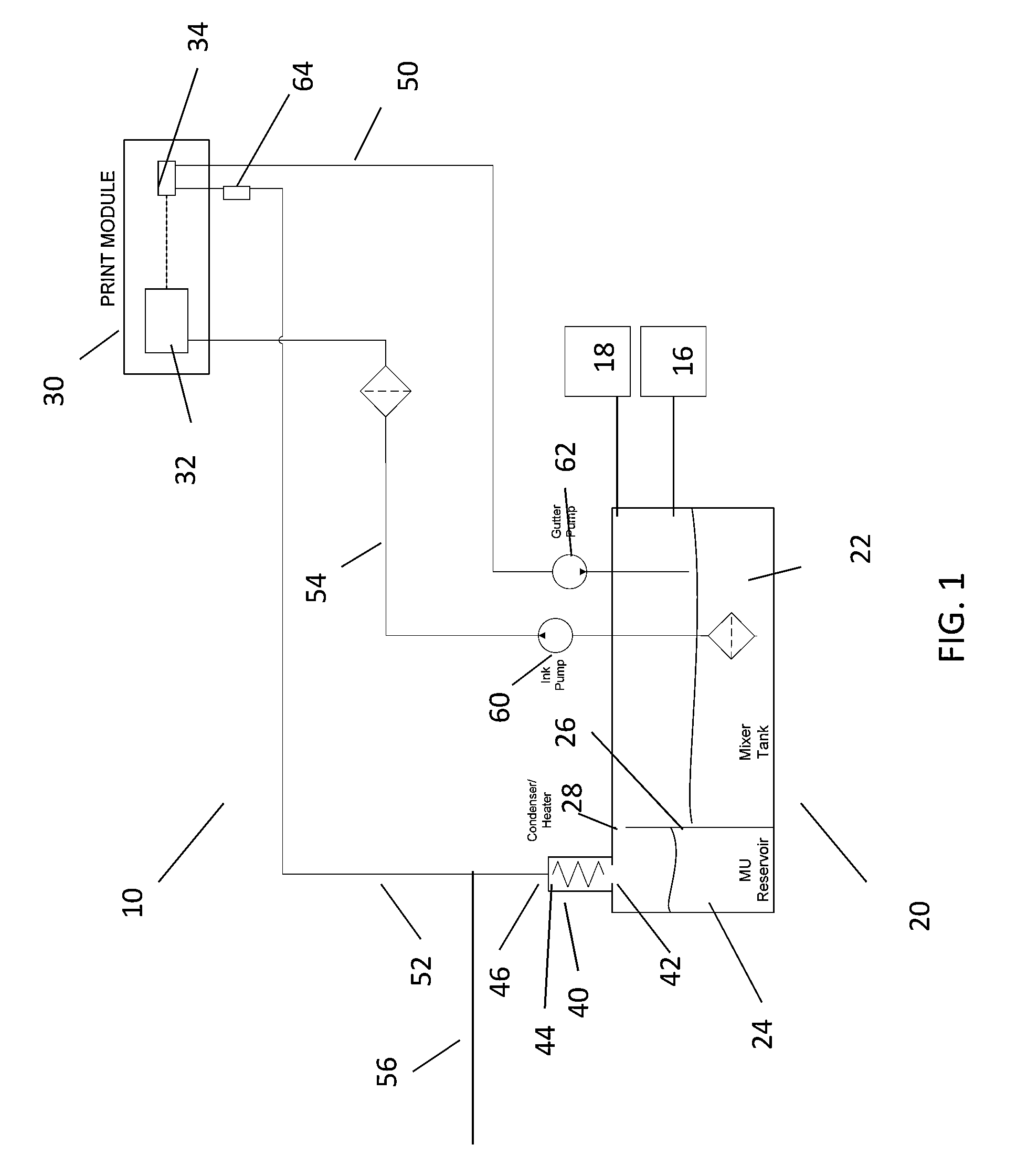

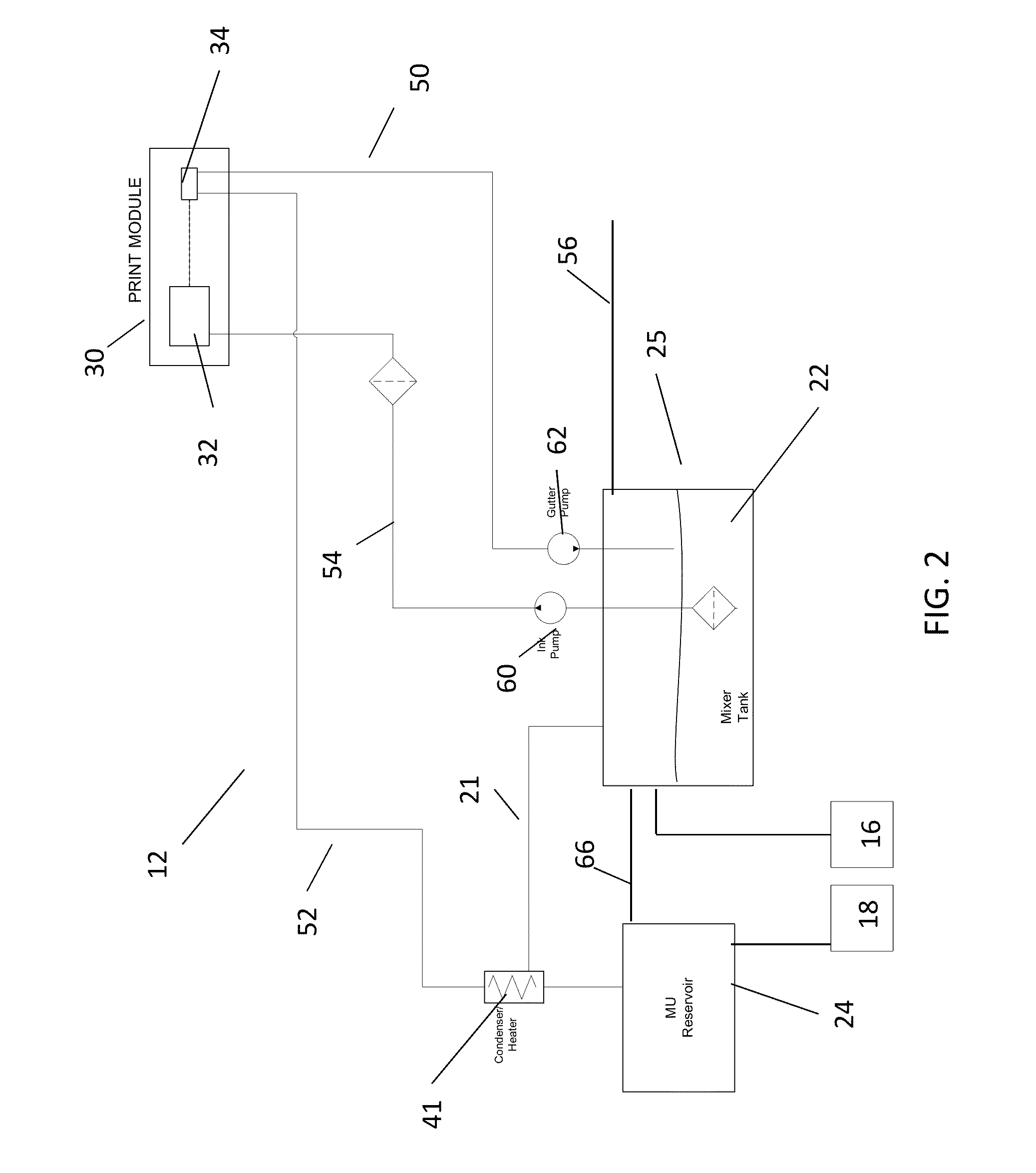

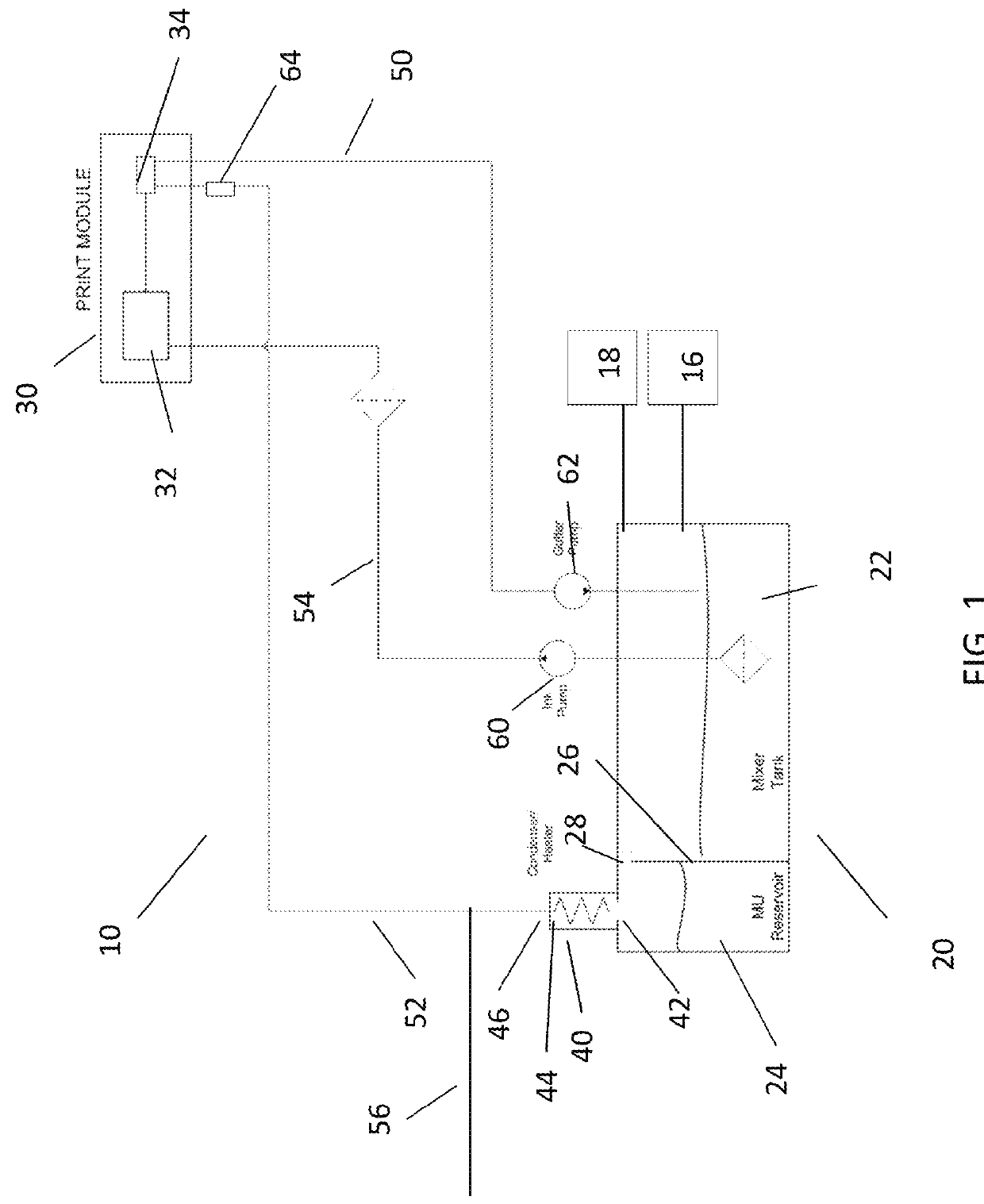

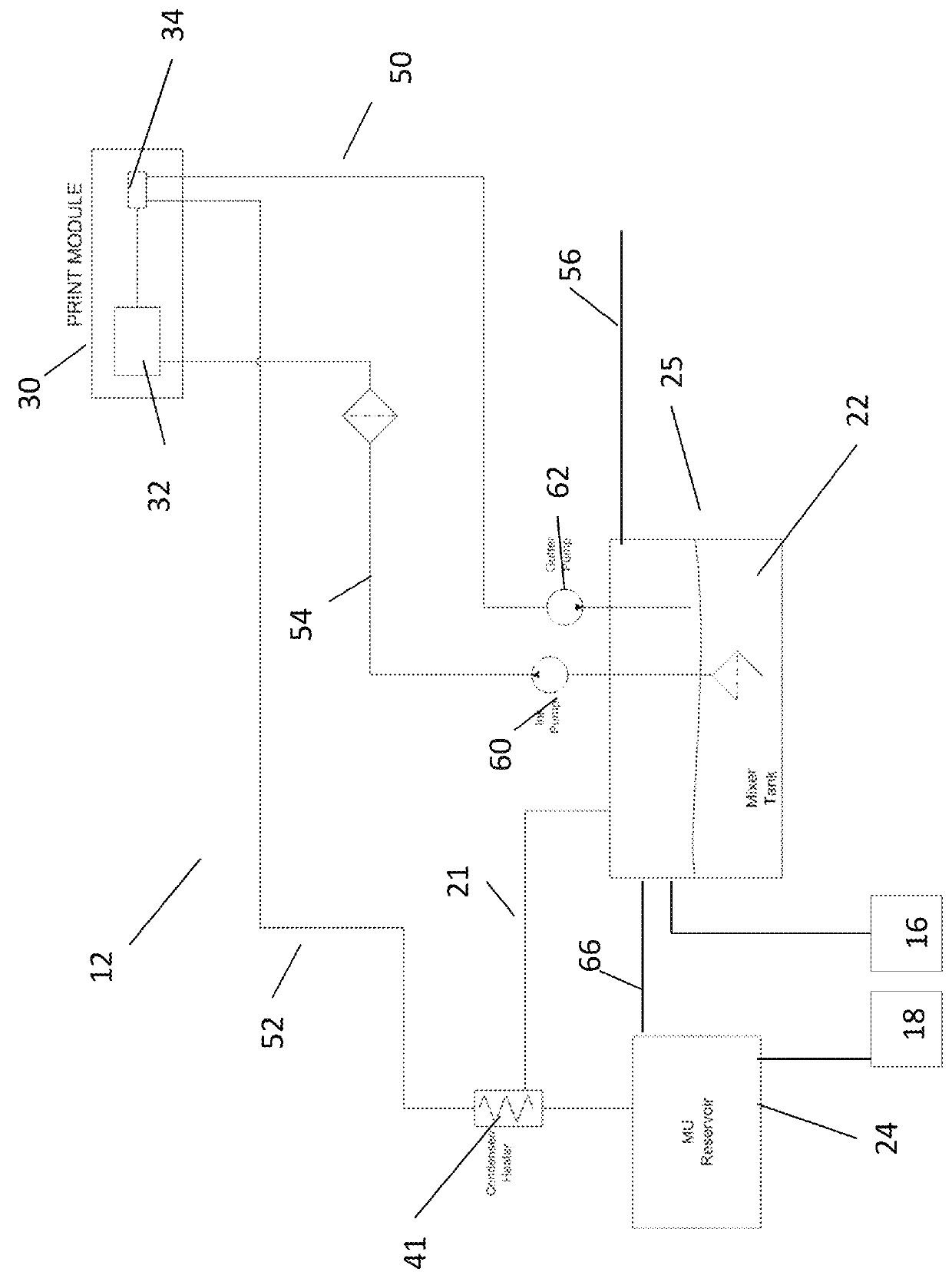

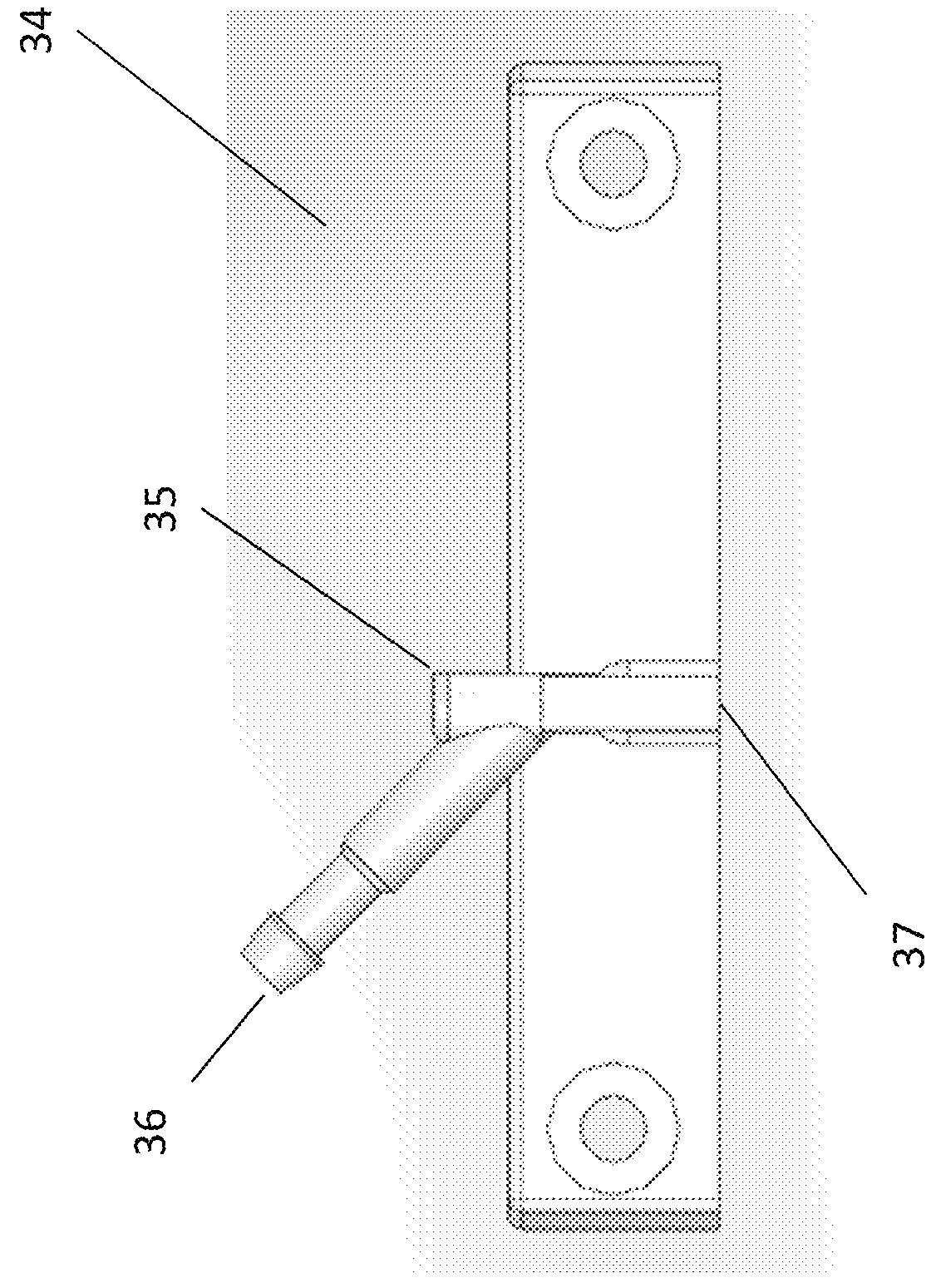

Ink jet printer

ActiveUS20150145928A1Improved management of ink viscosityReduce solvent lossPrintingSpray nozzleWaste management

A continuous ink jet printer including an ink tank for holding ink, an ink nozzle in fluid communication with the ink tank for ejecting ink droplets, and a gutter for receiving, through an ink-receiving inlet thereof, ink droplets which are not used for printing. A gutter flow path starts at the ink-receiving inlet for ink that has entered the gutter through the ink-receiving inlet, and provides fluid communication to the ink tank. A return line is in fluid communication with the gutter for conveying air to enter the gutter flow path. A makeup tank is in vapor communication with the ink tank to allow air to be conveyed from the ink tank to the makeup tank. A condenser is in fluid communication with the makeup reservoir and the return line for condensing solvent.

Owner:VIDEOJET TECH INC

β-Hydroxy-β-methylbutyric (HMB) acid purification method

ActiveUS9598344B2Easy to controlHigh purityOrganic compound preparationCarboxylic compound separation/purificationChemical synthesisPurification methods

Owner:TSI HEALTH SCI

Method for utilizing cycloalkanol in eucalyptol separation water solution and application of cycloalkanol

InactiveCN105820035AGood for recyclingReduce solvent lossOrganic compound preparationHydroxy compound preparationLivestockChemistry

The invention belongs to the technical field of water treatment, and discloses a method for utilizing cycloalkanol in a eucalyptol separation water solution and application of the cycloalkanol. The eucalyptol is used as an extractant to extract cycloalkanol in the water solution at 10-40 DEG C, thereby separating the cycloalkanol under milder conditions. The method is beneficial to maintaining the purity of the cycloalkanol and enhancing the separation efficiency, and is more beneficial to lowering the energy consumption of the separation operation. The extraction equipment is more simplified, thereby being beneficial to enhancing the stability and reliability of the separation technique and lowering the maintenance cost. The eucalyptol is the natural essential oil extract which is friendly to the environment and harmless to humans and livestock, thereby being beneficial to the protection of the ecological environment and enhancing the safety of the treated water body.

Owner:GUANGDONG UNIV OF TECH

Method and apparatus for applying a coating such as a paint or a varnish

InactiveUS6709698B1Reduce in quantityReduce solvent lossSpraying apparatusPretreated surfacesBiomedical engineeringVarnish

Owner:LOREAL SA

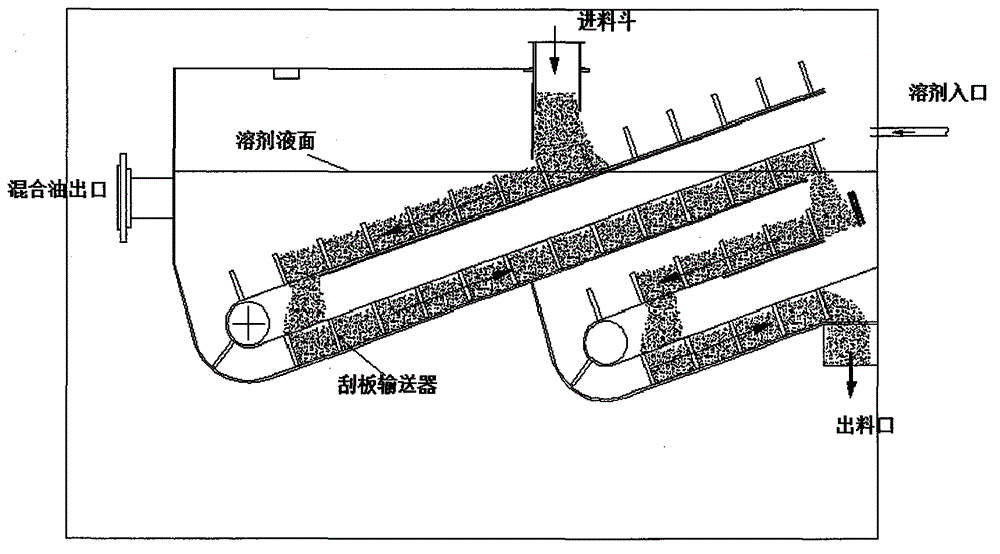

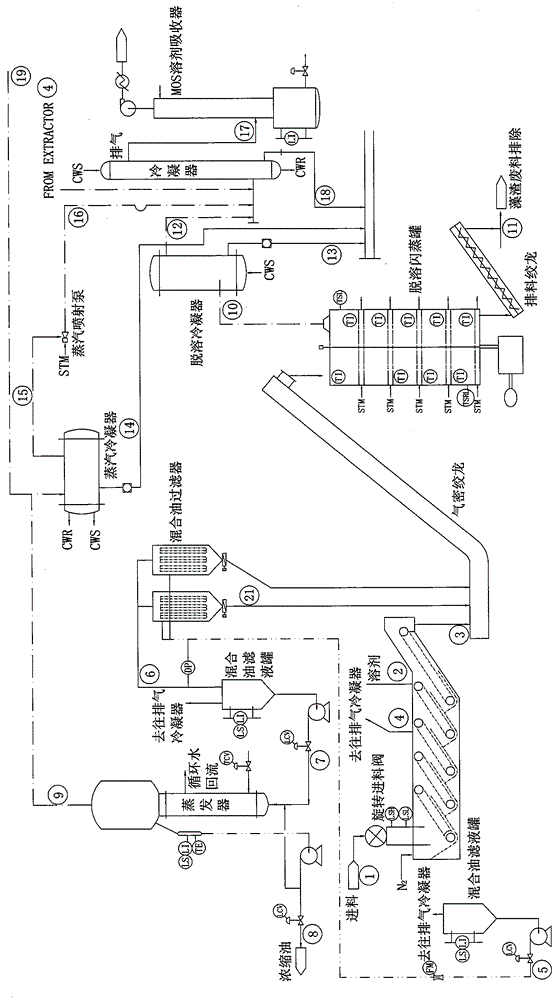

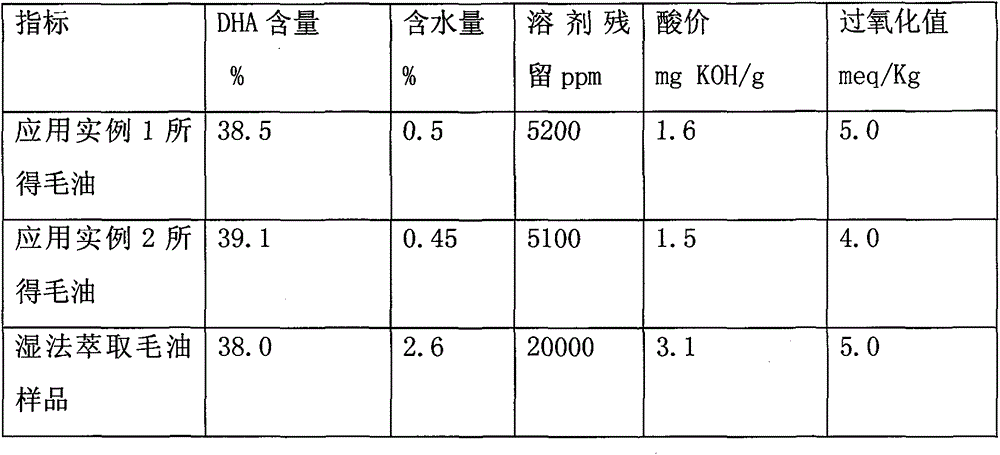

Method for ordinary pressure continuous extraction of grease from schizochytrium limacinum cake and equipment thereof

Owner:青岛海智源生命科技有限公司 +1

Method for preparing high-purity fenofibric acid in phase transfer catalysis method

InactiveCN108383709AReduce usage and consumptionReduce solvent lossPreparation from carboxylic acid saltsOrganic compound preparationFENOFIBRIC ACIDChloroform

The invention discloses a method for preparing high-purity fenofibric acid in a phase transfer catalysis method, which belongs to the field of a fenofibric acid catalytic synthesis process. The methodcomprises the following steps: adopting 4-hydroxyl-4'-chlorobenzophenone, acetone and chloroform as raw materials, adopting a 40 percent sodium hydroxide solution as a catalyst, adopting PEG-400 as aphase transfer catalyst, adopting methylbenzene as a solvent, performing the condensation reaction, filtering, acidifying, separating the solution, heating, washing, filtering, washing, recrystallizing by virtue of absolute ethyl alcohol, and drying, thus obtaining the high-purity fenofibric acid. By adopting the method, the use and consumption of precursor chemical acetone can be greatly reduced, the loss of the solvent is significantly reduced, less waste is produced, and the method is a green method for synthesizing fenofibric acid and is suitable for the industrialized production.

Owner:XUZHOU COLLEGE OF INDAL TECH

Ink jet printer

ActiveUS9044954B1Improved management of ink viscosityReduce solvent lossPrintingLine tubingWaste management

A continuous ink jet printer including an ink tank for holding ink, an ink nozzle in fluid communication with the ink tank for ejecting ink droplets, and a gutter for receiving, through an ink-receiving inlet thereof, ink droplets which are not used for printing. A gutter flow path starts at the ink-receiving inlet for ink that has entered the gutter through the ink-receiving inlet, and provides fluid communication to the ink tank. A return line is in fluid communication with the gutter for conveying air to enter the gutter flow path. A makeup tank is in vapor communication with the ink tank to allow air to be conveyed from the ink tank to the makeup tank. A condenser is in fluid communication with the makeup reservoir and the return line for condensing solvent.

Owner:VIDEOJET TECH INC

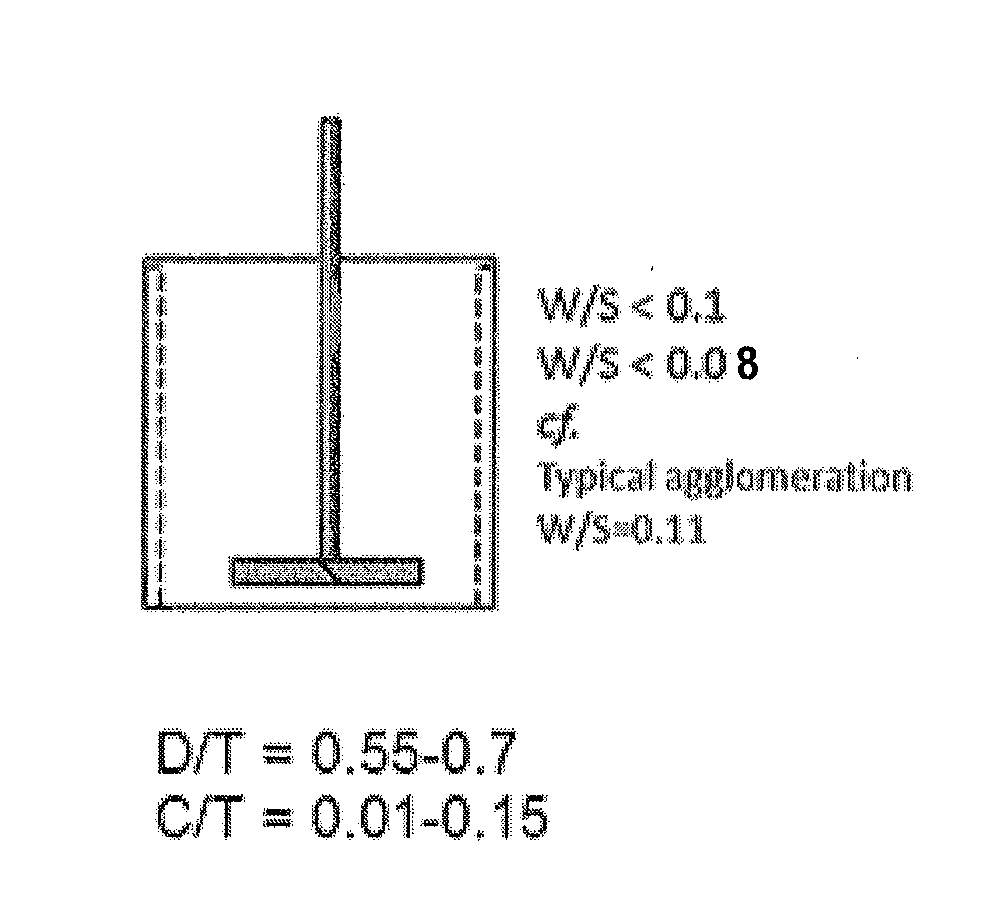

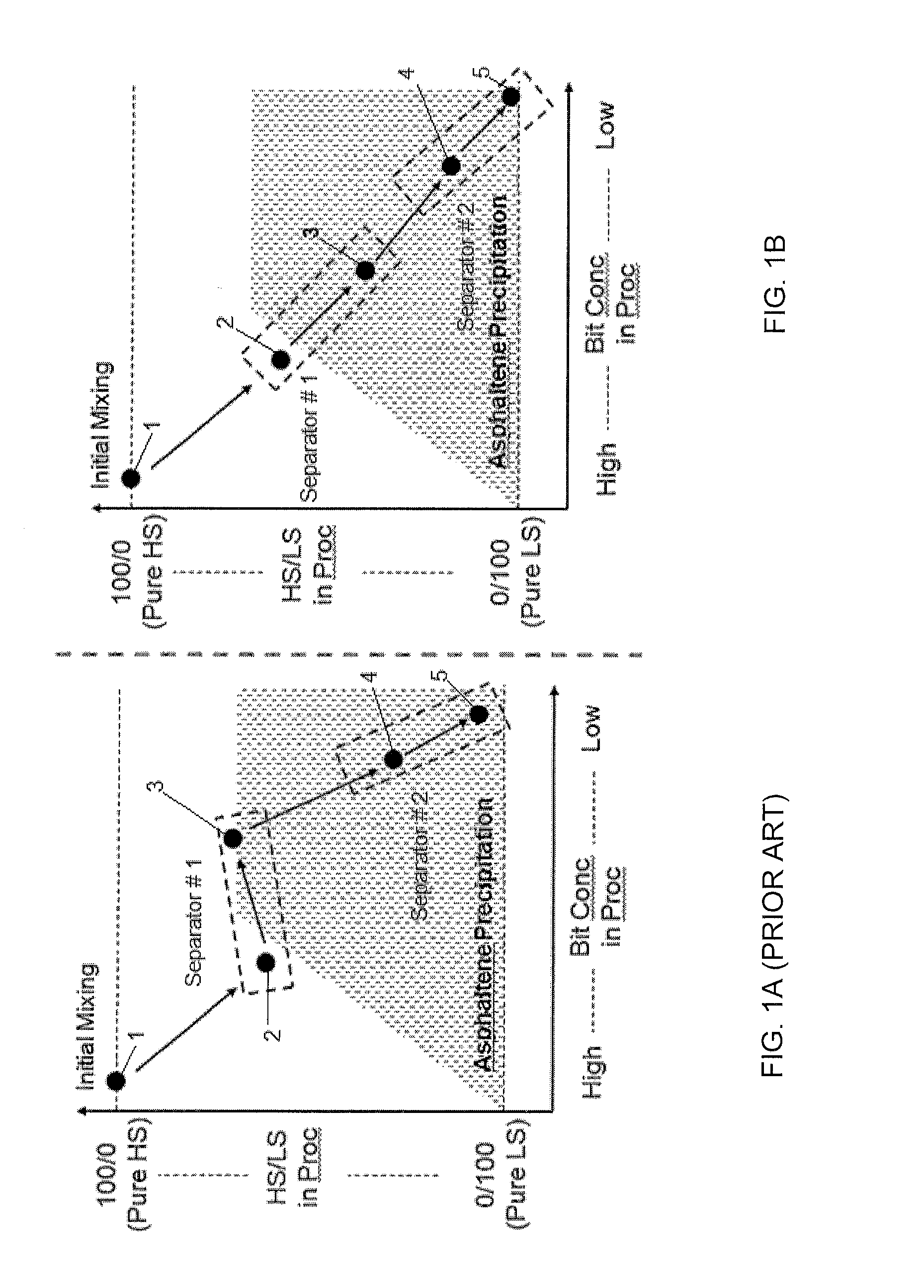

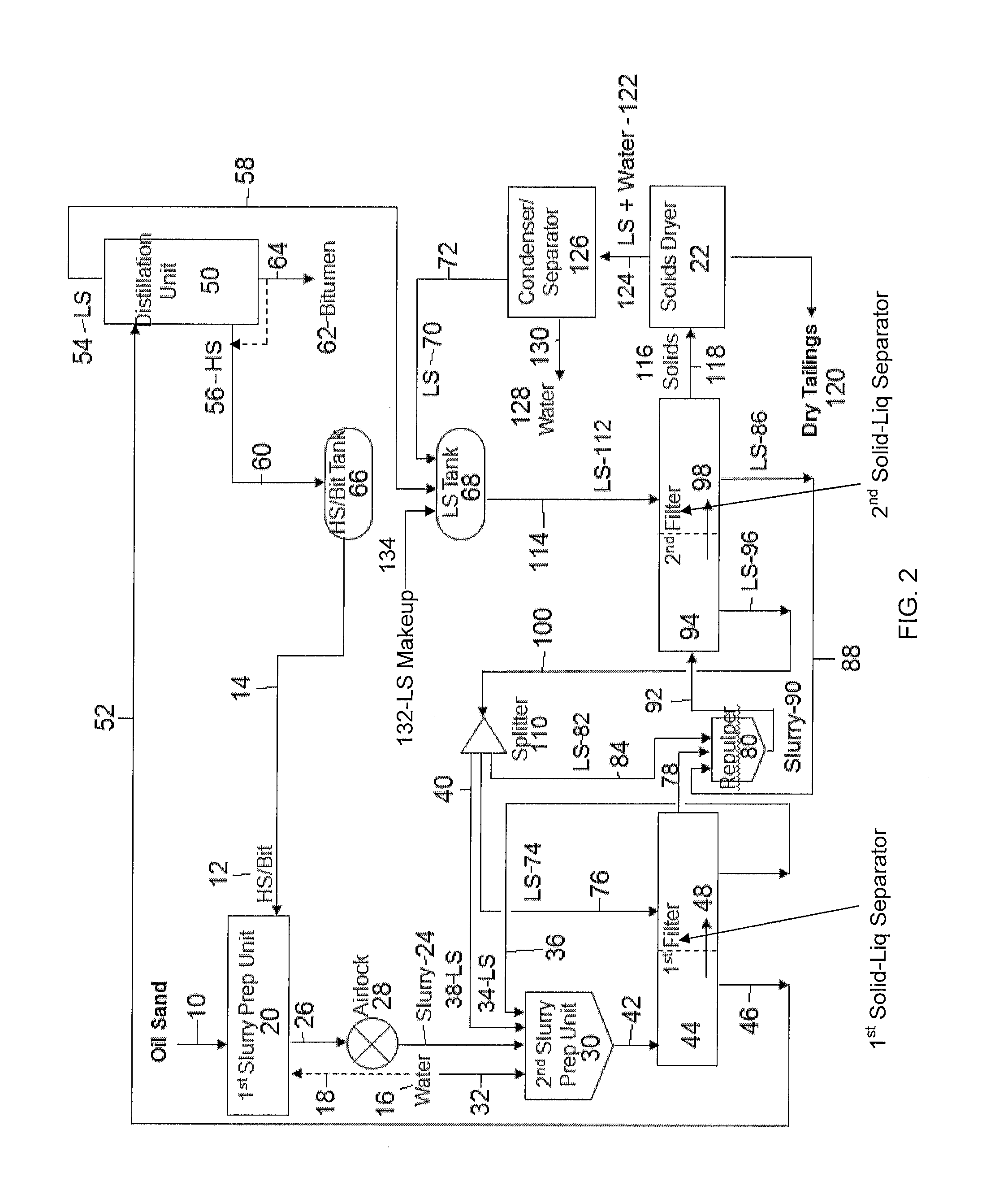

Dual-solvent extraction of oil sand bitumen

InactiveUS20160362608A1Good flexibilityOptimize bitumen recoveryLiquid hydrocarbon mixture productionMass ratioSlurry

A process for extracting bitumen from oil sand is provided, comprising: contacting mined oil sand with a high-flash point heavy solvent (HS) to produce a dense oil sand slurry; mixing the dense slurry with a first light solvent (LS) stream and a second LS stream to give a heavy solvent to light solvent (HS / LS) mass ratio of about 75 / 25 to about 40 / 60; subjecting the HS / LS-diluted oil sand slurry to a first stage solid-liquid separation to produce a first liquids stream containing bitumen and a first solids stream; and washing the first solids stream with a mixed solvent having a HS / LS mass ratio of about 50 / 50 to about 20 / 80 and subjecting the solids and the mixed solvent to a second stage solid-liquid separation to produce a second liquids stream and a second solids stream.

Owner:SYNCRUDE CANADA LTD

Systems and methods for closed loop solvent extraction and purification

ActiveUS9926512B2Reduce solvent lossReduce riskFatty-oils/fats refiningFatty-oils/fats separationWaxCannabis

Provided herein are systems and methods for the facile extraction and purification of oils from plant material, including cannabis and hemp. The systems and methods herein are versatile, and may utilize a wide range of solvents to extract oils from a variety of plant-based material. Further, the provided systems and methods are closed loop, reducing the loss solvent and decreasing the risk of safety concerns such as human exposure to solvent chemicals or explosion of volatiles. In some embodiments, the systems and methods remove impurities from the extracted oils, for example waxes or other precipitates, and provide a higher purity and higher quality extract.

Owner:MC MACHINERY LLC

Method for purifying waste solvent

ActiveUS11465906B2High purityMaximize recoveryOrganic compound preparationDistillation regulation/controlSupercritical dryingDistillation

Provided is a method for purifying a waste solvent by removing carbon dioxide contained in a waste solvent derived from supercritical waste liquid generated after supercritical drying by a decompression process, and removing ammonia by a multi-stage distillation process to obtain a solvent of high purity, which can be reused in producing silica aerogel or a silica aerogel blanket.

Owner:LG CHEM LTD

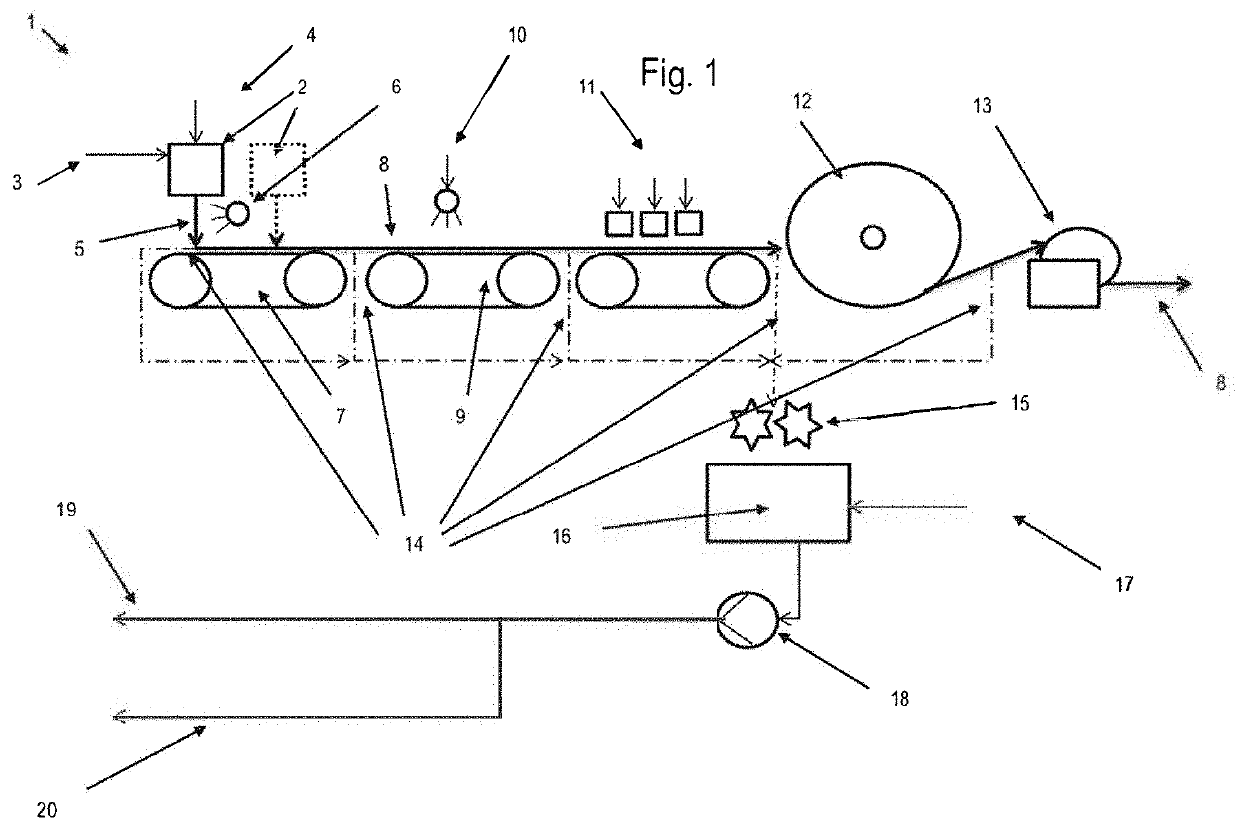

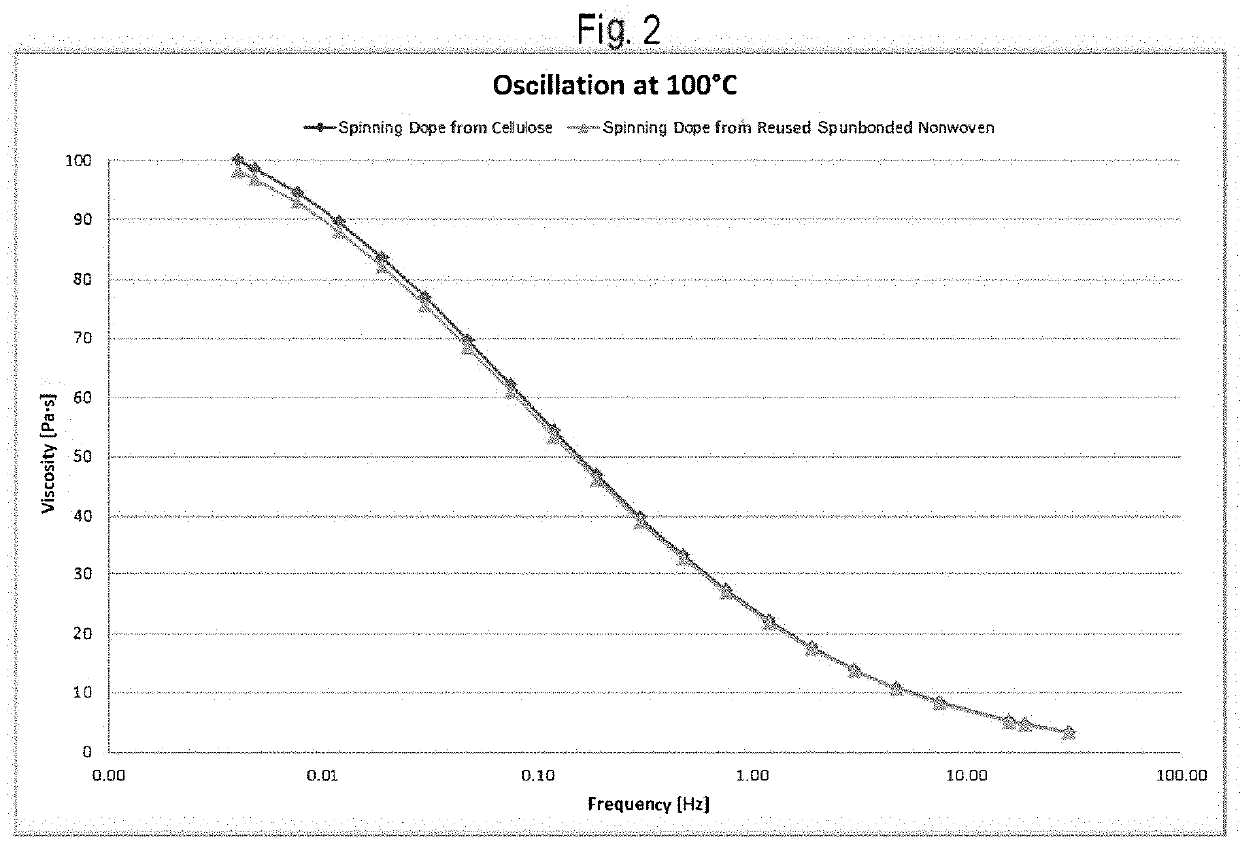

Method for recovering solvent and cellulose in the production of cellulosic spun-bonded nonwoven fabrics

PendingUS20220106719A1Economically and environmentally improvedEasy to operateNon-woven fabricsArtificial thread manufacturing machinesCellulosePolymer science

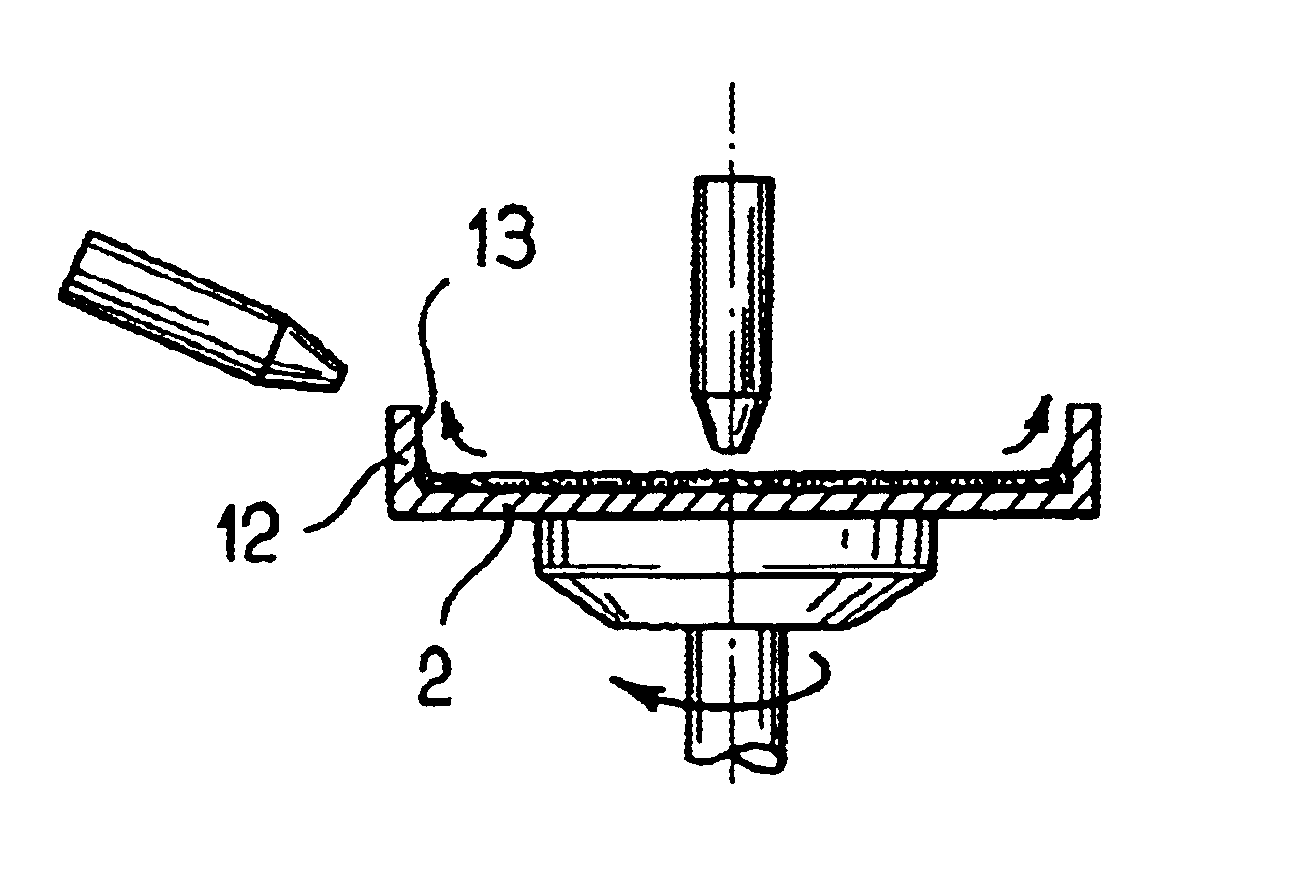

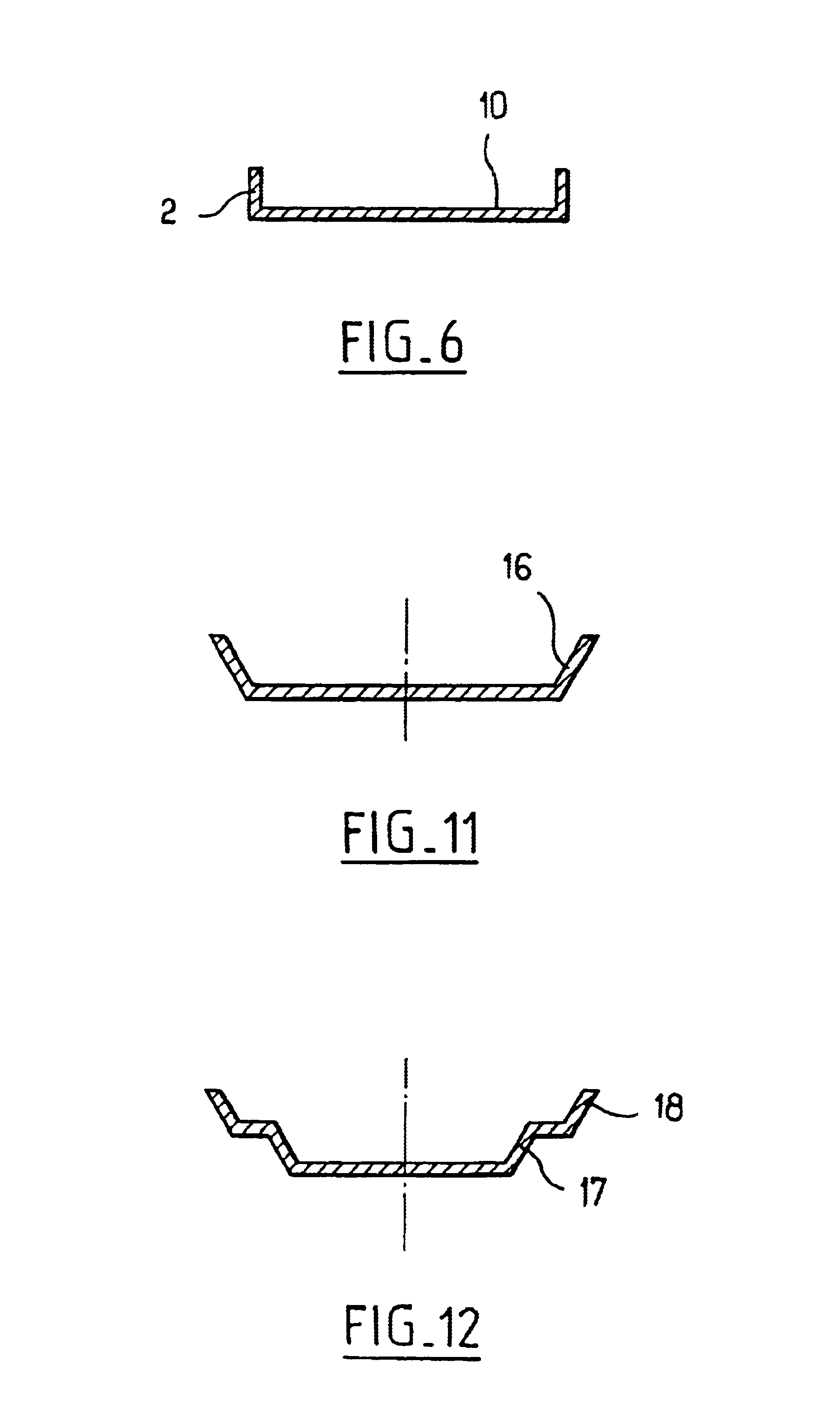

A plant (1) for the production of spunbonded nonwoven (8), comprising a spinning solution production (3), a spinning system (2), a device (6) for the delivery of coagulation liquid, at least one conveying device (7, 9) for depositing the spunbonded nonwoven (8), and a collecting device (13) for the spunbonded nonwoven (8), wherein at least one discharge device (14) is provided between the device (6) for the delivery of coagulation liquid and the collecting device (13) for the spunbonded nonwoven (8).

Owner:LENZING AG

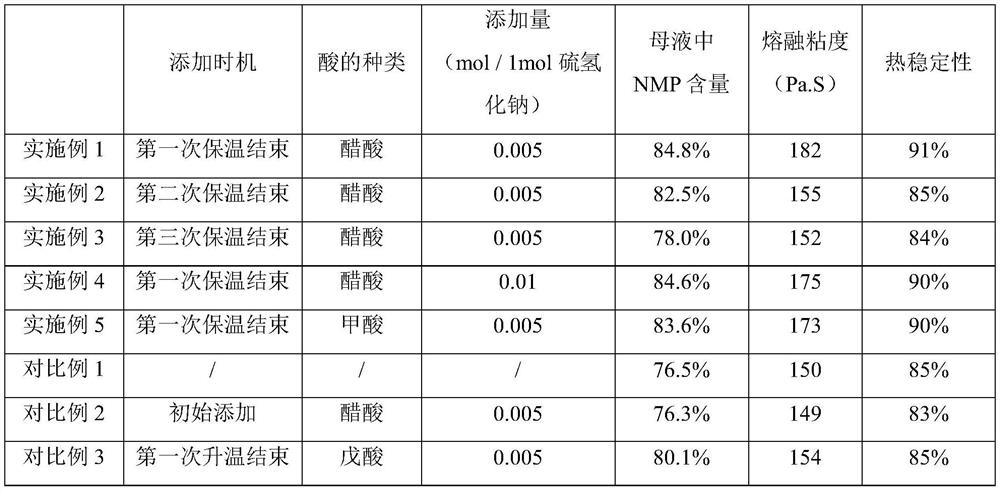

Synthetic method of polyarylene sulfide resin

The invention discloses a synthetic method of polyarylene sulfide resin, which comprises: 1, adding a sulfur source, an alkaline substance and Nmethylpyrrolidone to a reaction kettle, heating to a temperature of 180-210 DEG C, and carrying out a dehydration reaction to obtain an intermediate product; 2, continuously adding a dihalogenated aromatic compound and N-methylpyrrolidone into the reactionkettle, adding organic monobasic acid, carrying out condensation polymerization at 210-280 DEG C to obtain polyarylene sulfide slurry, and carrying out post-treatment to obtain polyarylene sulfide resin, wherein the structural general formula of the organic monobasic acid is R-COOH, and in the formula, R is selected from hydrogen or alkyl with the carbon number of 1-4. According to the synthesismethod provided by the invention, the loss of the solvent NMP is fundamentally reduced, and meanwhile, the alkali metal carboxylate generated in the reaction process can also play a role in promotingpolymerization. The method is simple in process, low in production cost and high in economy.

Owner:ZHEJIANG UNIV +2

Ink jet printer

ActiveUS9227421B2Improved management of ink viscosityReduce solvent lossPrintingSpray nozzleWaste management

A continuous ink jet printer including an ink tank for holding ink, an ink nozzle in fluid communication with the ink tank for ejecting ink droplets, and a gutter for receiving, through an ink-receiving inlet thereof, ink droplets which are not used for printing. A gutter flow path starts at the ink-receiving inlet for ink that has entered the gutter through the ink-receiving inlet, and provides fluid communication to the ink tank. A return line is in fluid communication with the print head for conveying air to enter the gutter flow path. A makeup tank is in vapor communication with the ink tank to allow air to be conveyed from the ink tank to the makeup tank. A condenser is in fluid communication with the makeup tank and the return line for condensing solvent.

Owner:VIDEOJET TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com