Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Reduce negative friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

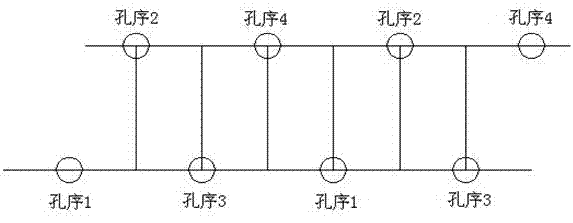

Method for reinforcing existing pile foundation in collapsed loess area by slip casting

InactiveCN102162255AReduce negative frictionImprove carrying capacityFoundation repairBulkheads/pilesCheck valveUltimate tensile strength

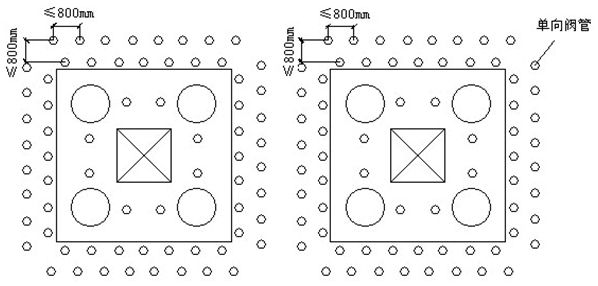

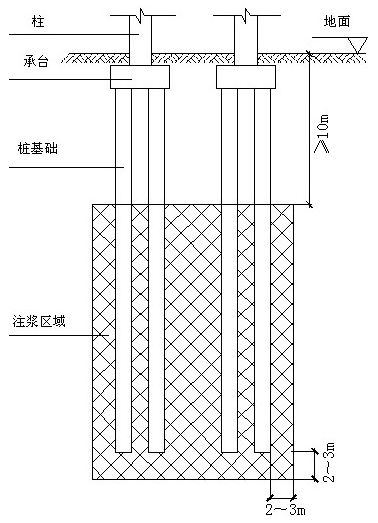

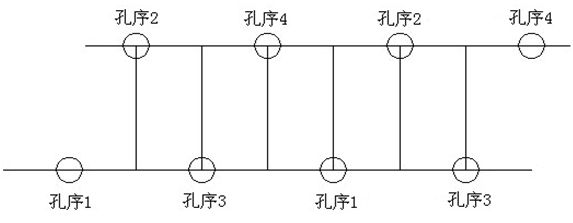

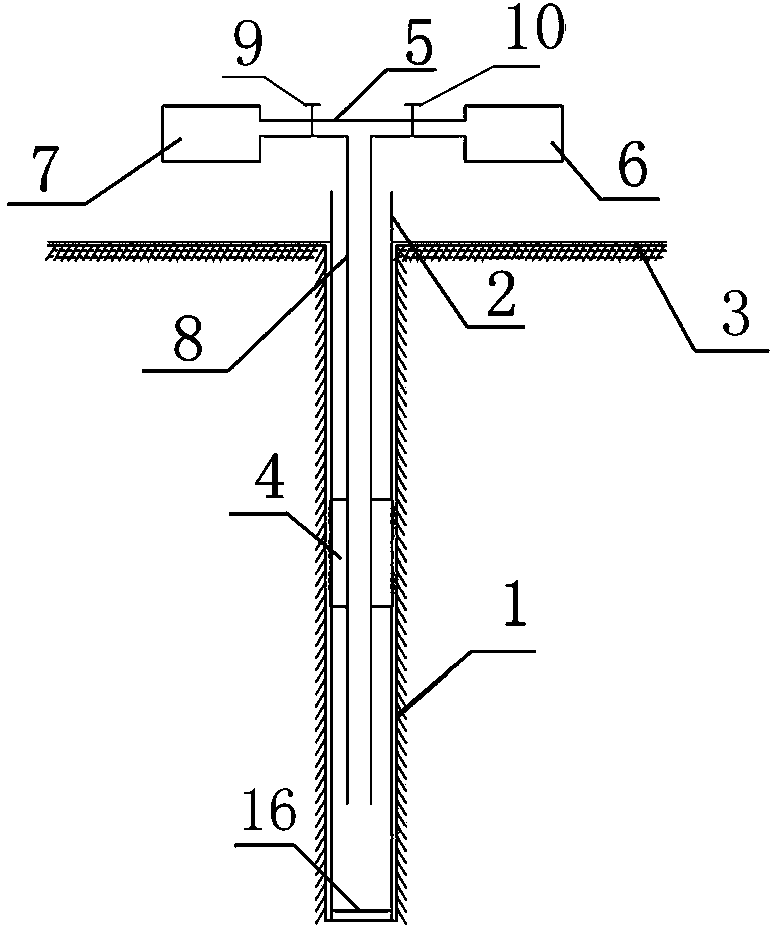

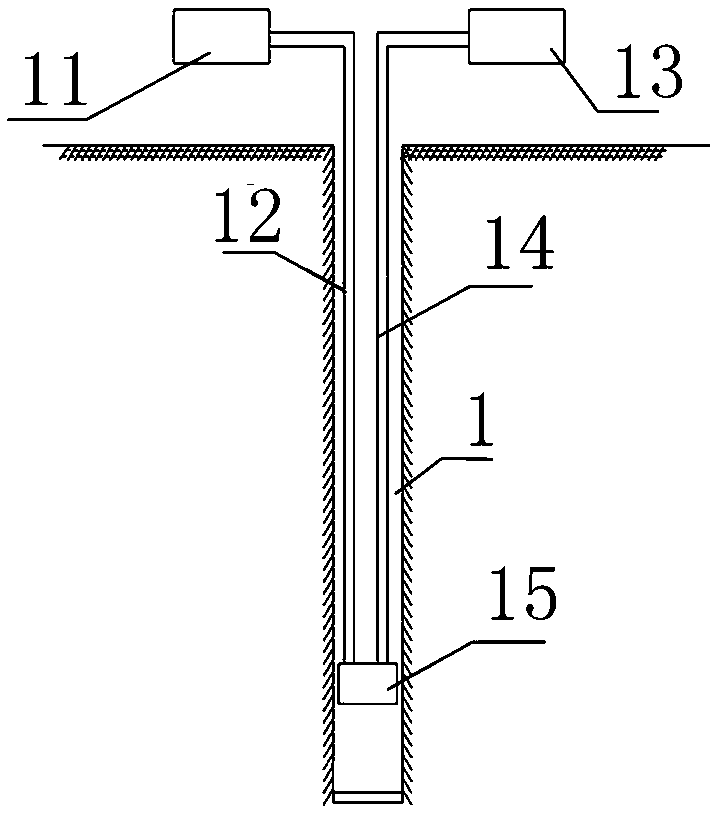

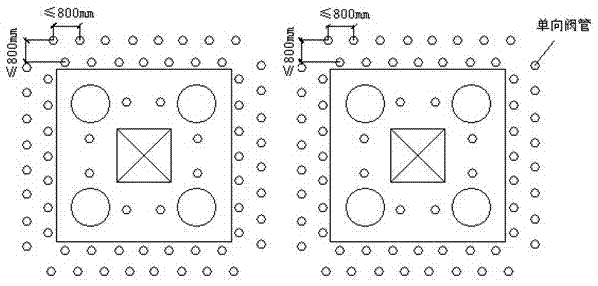

The invention discloses a method for reinforcing an existing pile foundation in a collapsed loess area by slip casting. The method is a method required for reinforcement of a checking valve pipe of the existing pipe foundation adjacent to an underground project during construction. In the method, checking valve pipe slip casting is adopted as a main reinforcing technical measure; and the method comprises the following steps of: distributing slip casting hole positions on a pile foundation bearing table and at the periphery of the pile foundation bearing table within a certain range; after a driller finishes drilling, installing a checking valve pipe; filling a prepared shell material into an annular space between the checking valve pipe and the wall of the drilled hole; when the shell material reaches certain strength, reinforcing the soil at the periphery of the pile foundation by slip casting; after slip casting, covering a slip casting protective cover; and performing slip casting at any time as required. By the reinforcing method, a pile body negative friction force of the soil body at the periphery of the pile foundation in the collapsed loess area due to collapsibility can be reduced, the bearing capacity of the pile foundation is enhanced, the settlement of the pile foundation due to the underground project construction is decreased, and an aim of reinforcing by slip casting is fulfilled.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

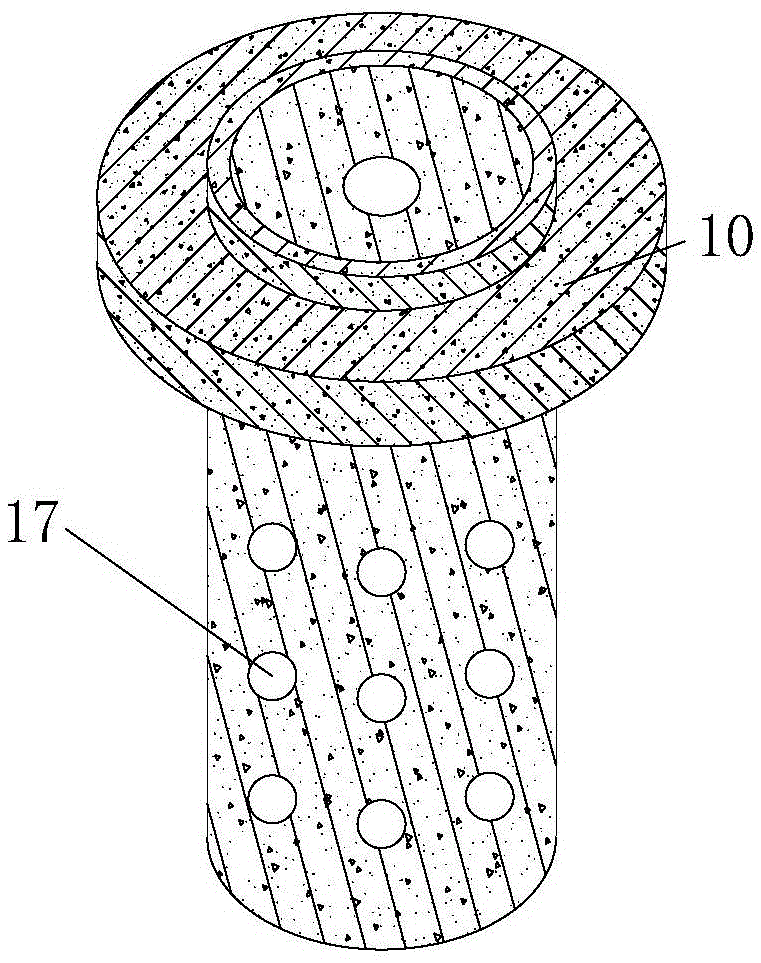

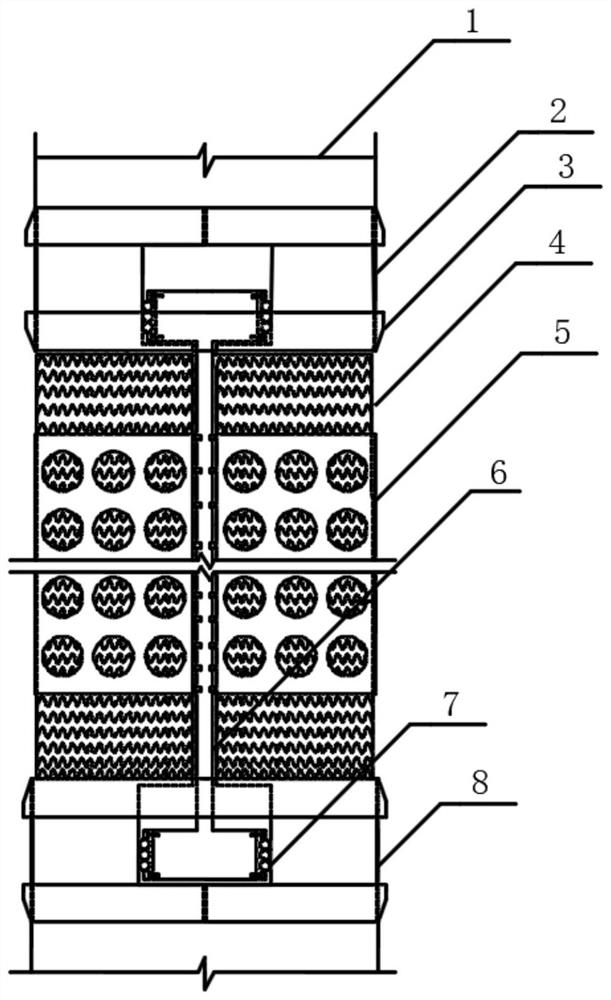

Top-reinforced cast-in-place concrete thin-wall pipe pile and construction method

ActiveCN103510511AImprove carrying capacityReduce disturbanceBulkheads/pilesEconomic benefitsEarth surface

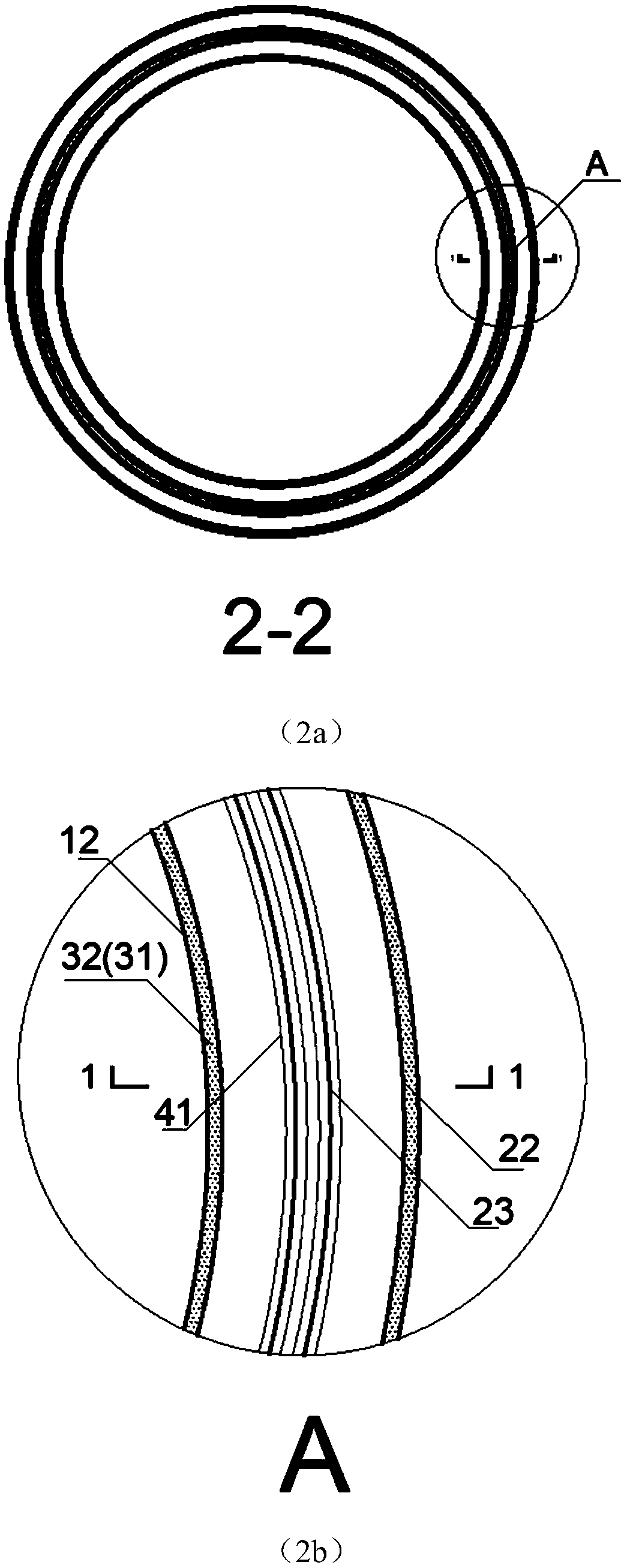

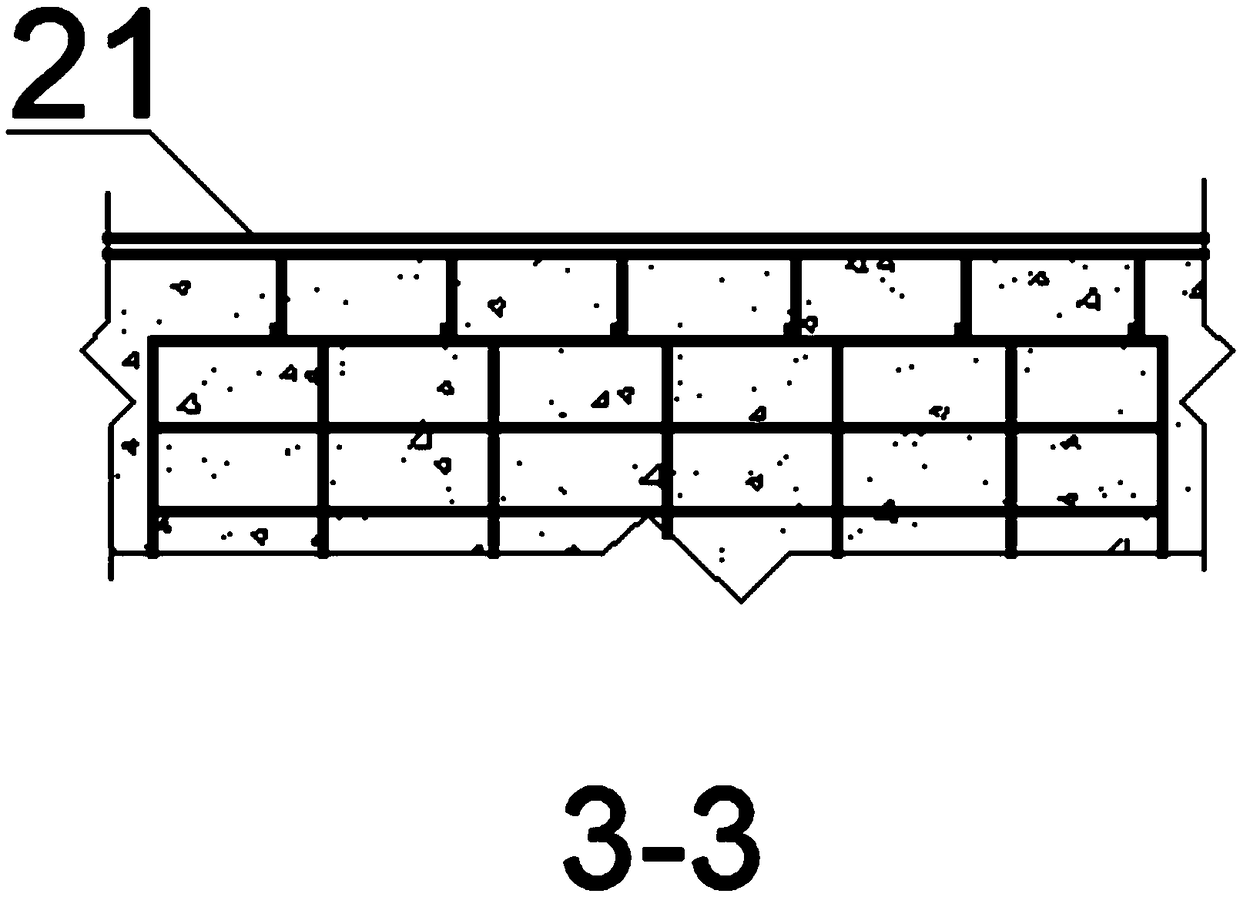

The invention relates to a top-reinforced cast-in-place concrete thin-wall pipe pile, and further discloses a construction method of the top-reinforced cast-in-place concrete thin-wall pipe pile. The top-reinforced cast-in-place concrete thin-wall pipe pile is characterized in that the pile body of a thin-wall pipe pile body is formed by cast-in-place of double-layer steel immersed pipes. The pile diameter of the upper portion of the pile body is enlarged, and a plastic casing pipe and a vertical drainage body are sequentially arranged on the outer side of a concrete pile body of the pile-diameter-enlarged section from inside to outside; the pile-diameter-enlarged section is connected with an upper precast pile tip, and the bottom of the pile body is connected with a lower precast pile tip; the soil body, on the upper portion of the thin-wall pipe pile, around the pile is solidified to be a solidified soil layer; connection ribs are arranged between the top of the thin-wall pipe pile and a pile core closed section and a pile top cover plate; a drainage channel communicated with the vertical drainage body is formed in the pile top cover plate. The top-reinforced cast-in-place concrete thin-wall pipe pile improves pile body casting quality, can improve the mechanical property of the upper-portion pile body and the mechanical property of the soil body around the pile and prevent the pile body from deforming when mud cakes are taken out of the earth surface and has good technical and economic benefits.

Owner:HONGSHA CONSTR

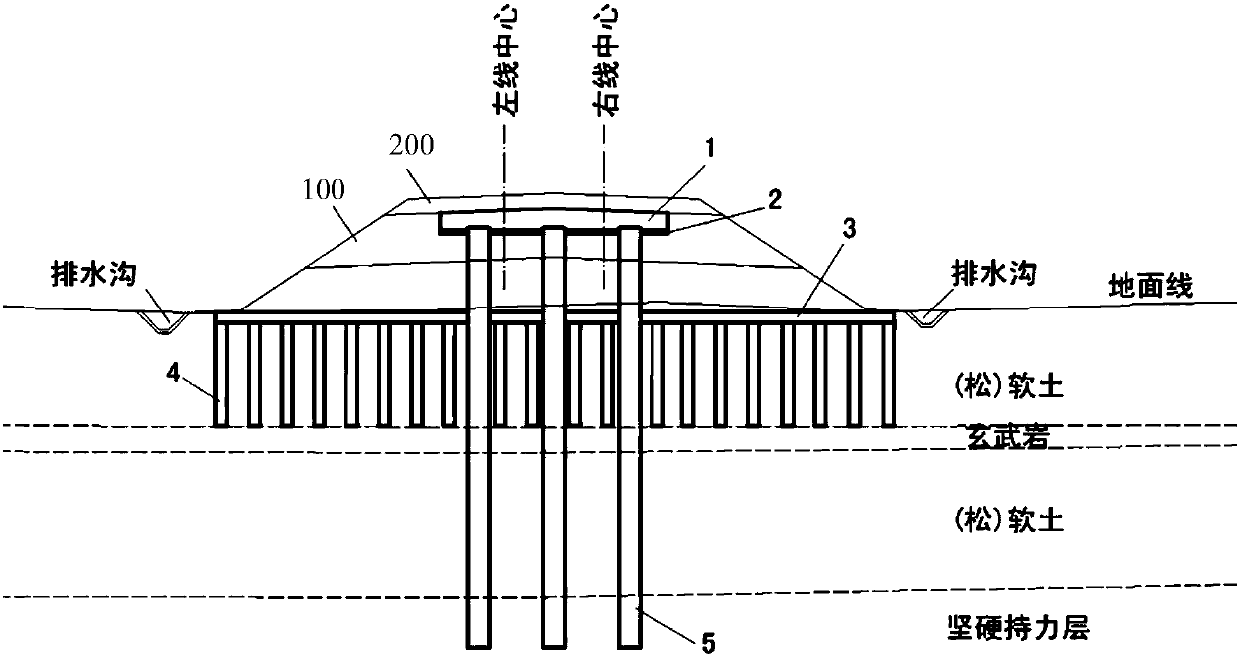

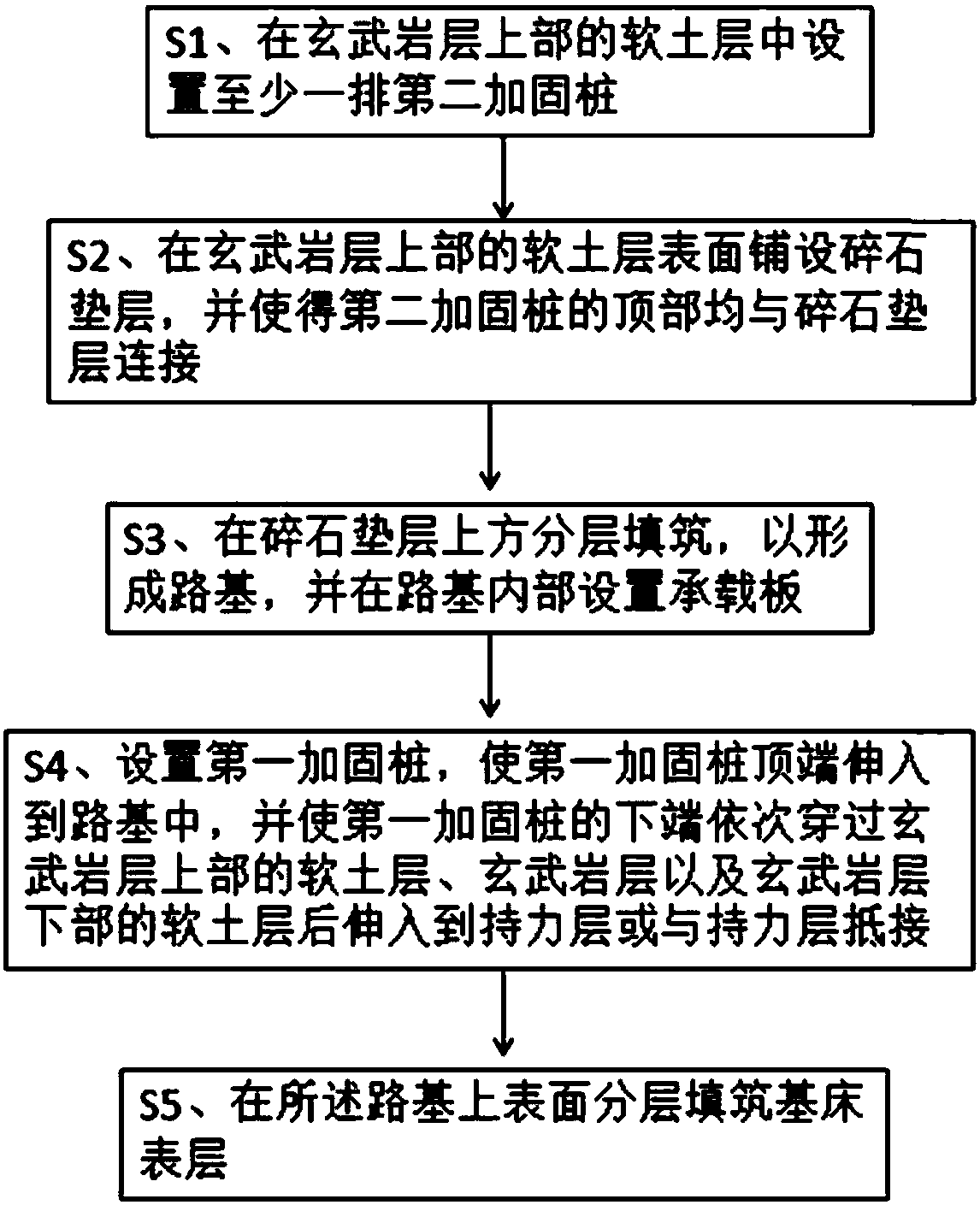

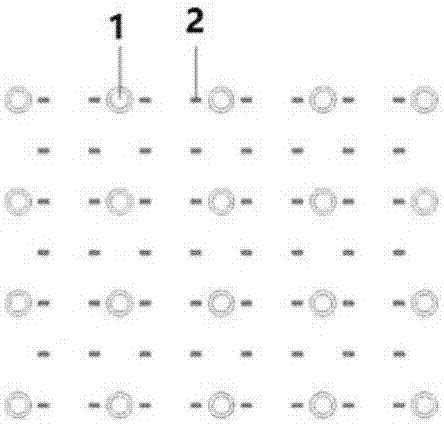

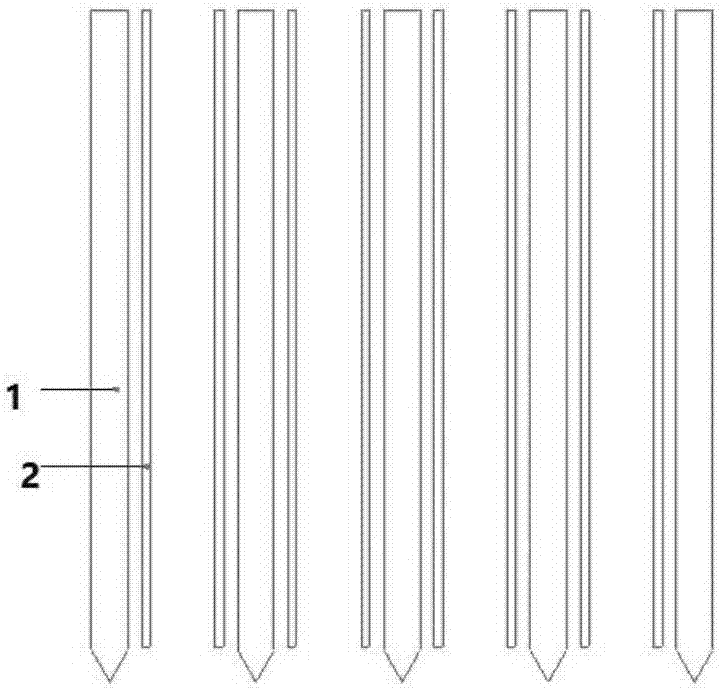

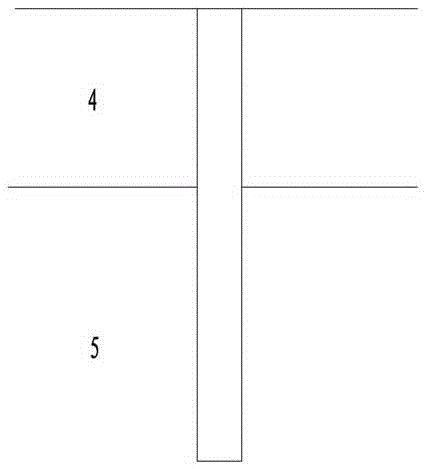

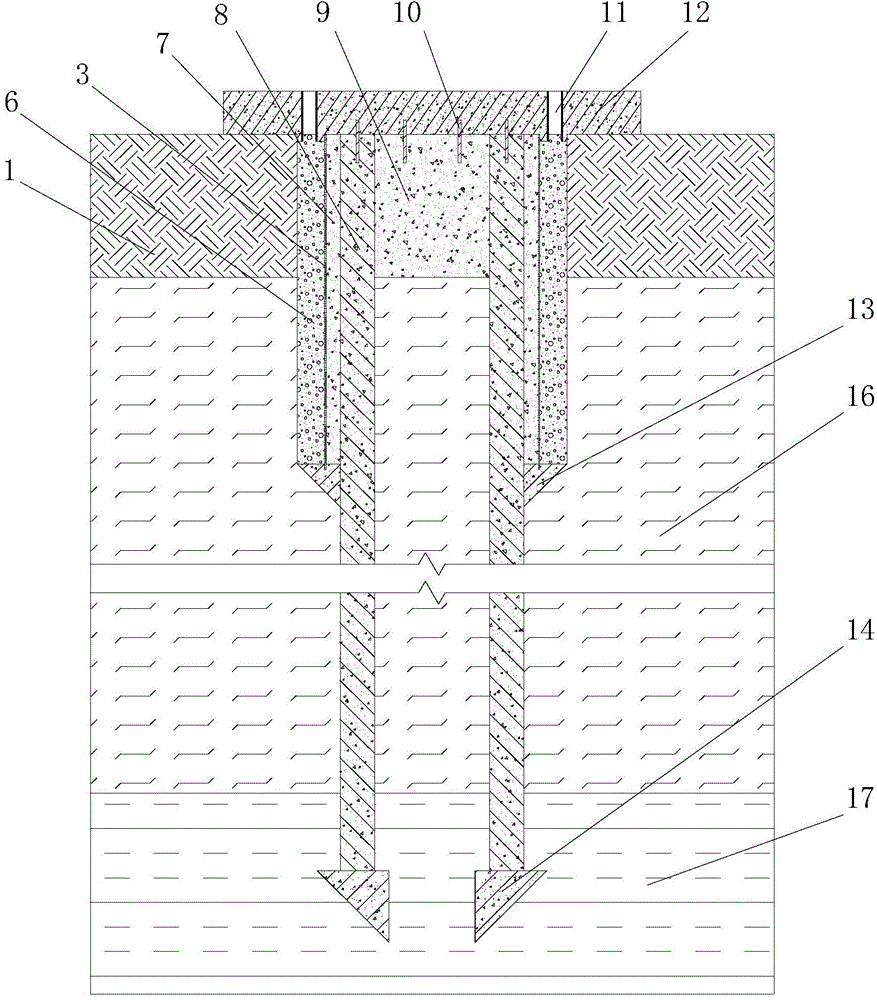

Reinforcing structure and method of roadbed foundation of structure with basaltic layer sandwiched between soft soil layers

PendingCN107938455AImprove stabilityReduce negative frictionRoadwaysSoil preservationReinforced concreteGeotechnical engineering

The invention discloses a reinforcing structure of a roadbed foundation of a structure with a basaltic layer sandwiched between soft soil layers. The reinforcing structure comprises at least two rowsof first reinforcing piles and at least one row of second reinforcing piles, the top end of each first reinforcing pile extends into the foundation, and the lower end of each first reinforcing pile sequentially penetrates through the soft soil layer on the upper portion of the basaltic layer, the basaltic layer and the soft soil layer on the lower portion of the basaltic layer of the roadbed foundation; and each second reinforcing pile is arranged in the soft soil layer on the upper portion of the basaltic layer. The reinforcing structure and method of the foundation composed of long reinforced concrete bored piles + bearing plates + short cement mortar mixing piles + a gravel cushion layer are adopted and are used for high-speed railway settlement deformation control. The mode that long pile treatment and short pile treatment are combined, and rigid piles and flexible piles cooperate to act is adopted, so that the technology is economical and reasonable and high in adaptability, and technical and economic benefits are obvious.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

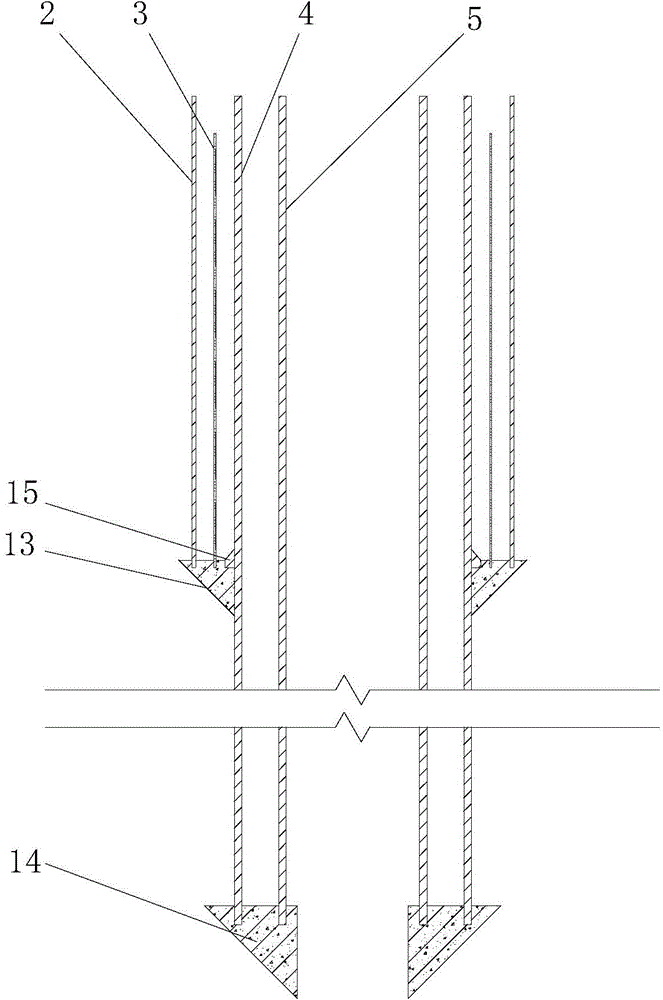

Method for improving pile foundation performance of soil-compaction piles by lateral soil-compaction, drainage and consolidation

InactiveCN107268581AIncrease the horizontal bearing capacityImprove lateral resistanceSoil preservationHigh water contentSilt

The invention relates to a method for improving pile foundation performance, in particular to a method for improving the pile foundation performance of soil-compaction piles by lateral soil-compaction, drainage and consolidation. The method is especially suitable for the soil-compaction piles in a slit soft-soil foundation with a high water content, and comprises the steps of before soil-compaction pile construction, inserting one or more vertical drainage bodies in the foundation between the soil-compaction piles; then, conducting the soil-compaction pile construction; utilizing the soil-compaction effect of the piles to make soil around the piles subjected to the lateral compaction, so that water is drained and the soil is consolidated. According to the method, the construction is simple, the cost is low, and the effect of improving the pile foundation performance is excellent.

Owner:广东省水利电力勘测设计研究院有限公司

Composite foundation pile with lower portion enlarged diameter section and construction method of composite foundation pile

InactiveCN105297717AImprove pile foundation bearing capacityImprove performanceBulkheads/pilesEngineeringSoil horizon

The invention discloses a composite foundation pile with a lower portion enlarged diameter section and a construction method of the composite foundation pile. The composite foundation pile comprises a precast concrete pile body, and a cast-in-place pile is arranged on the outer side of the lower portion of the precast concrete pile body. The construction method comprises the following steps that (1) a hole is formed by a drilling machine or manually; (2) mechanical or manual chambering is conducted on a soil layer below a soft soil layer; (3) cured materials are poured into the hole; and (4) the precast concrete pile body is implanted into the hole. Compared with a pile body of a single diameter and the same length, the bearing capacity of the composite foundation pile with the lower portion enlarged diameter section is greatly improved, the pile is shorter on the premise of meeting the requirement of designed bearing capacity, and the playing capacity of side resistance and tip resistance of a pile foundation is improved.

Owner:周同和

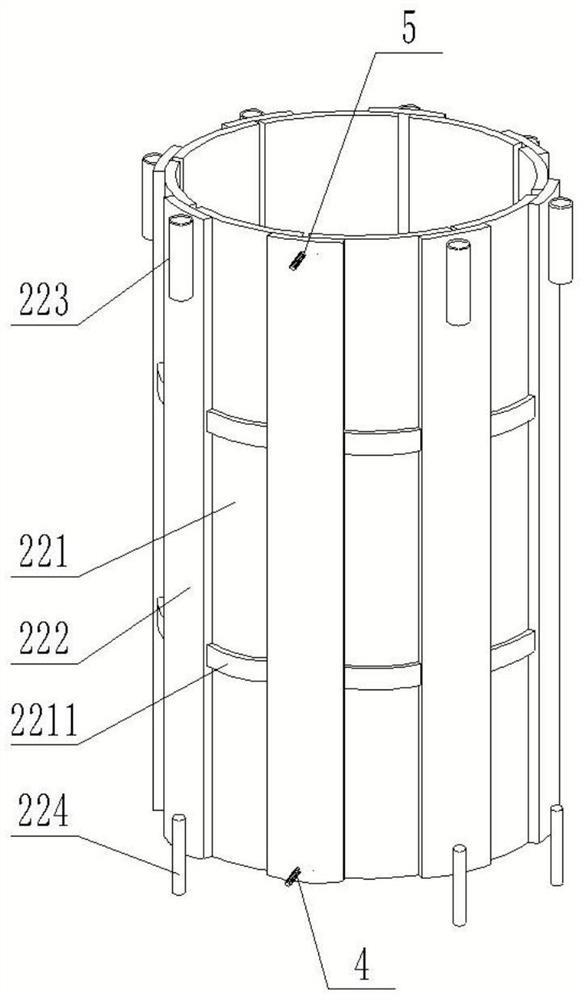

Device for reducing negative friction resistance of pile foundation in soft soil area and construction method

InactiveCN110158585AReduce the impactNegative friction avoidanceBulkheads/pilesEconomic benefitsHearing perception

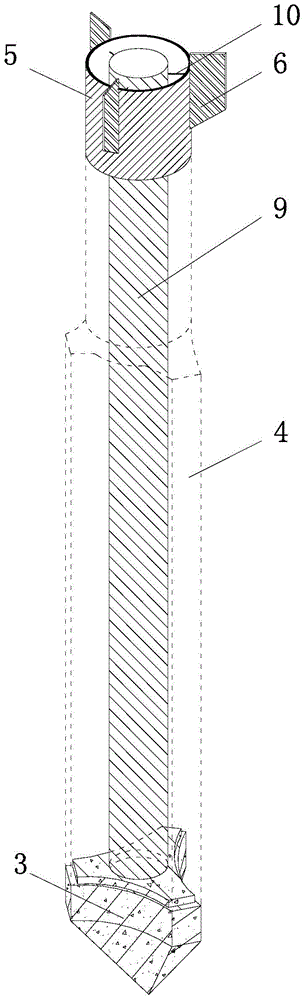

The invention discloses a device for reducing negative friction resistance of a pile foundation in a soft soil area and a construction method. The device for reducing negative friction resistance of the pile foundation in the soft soil area comprises an inner sleeve, a negative friction pipe and an outer sleeve; the negative friction pipe is connected with the inner sleeve through a rubber sealingring at the bottom and peripheral cushion blocks at a certain interval; the negative friction pipe is in an inverted cone shape; and a gap between the negative friction pipe and the inner sleeve is filled with pebbles and fine sands. According to the construction method, the vertical bearing capacity of the vertical load-hearing pile foundation can be improved by utilizing the inverted cone-shaped negative friction pipe, the pile diameter of the negative friction pipe is larger than the diameter of the pile foundation, and the horizontal bearing resistance of the pile foundation can also be increased; meanwhile, the combination device of the negative friction pipe and the inner sleeve is utilized, so that the pile foundation and the negative friction pipe slide relatively, the negative friction resistance caused by settlement of oversize soils around a pile is reduced, additional load and additional settlement of the pile foundation can be effectively reduced, and problem of the uneven settlement of the pile foundation in the soft soil area is solved. The construction method is wide in application range, and has the advantages of saving resources, improving social and economic benefits, being beneficial to traffic operation safety and building safety, and the like.

Owner:SOUTHEAST UNIV

Carbon fiber cloth bag cast-in-situ anti-arch curved surface combined irregular-shaped pile and construction method thereof

InactiveCN103741682AReduce pile side squeeze effectAccelerate soil consolidationBulkheads/pilesGeotechnical engineeringStructural engineering

The invention relates to a carbon fiber cloth bag cast-in-situ anti-arch curved surface combined irregular-shaped pile, which is characterized in that the upper part of the combined irregular-shaped pile is a round pile body while the lower part thereof is an anti-arch curved surface pile body, and the pile bottom is provided with an irregular-shaped prefabricated pile tip. A carbon fiber cloth bag wraps the outside of the pile body; a steel sleeve with a reinforcing plate is arranged on the top part of the combined irregular-shaped pile; a vertical drain body is filled in the cavity at the outer side of the round pile body; a vertical drain pipe communicated with the vertical drain body is preset in a cast-in-situ cover plate on the top part of the pile. The carbon fiber cloth bag arranged on the outer side of the pile body can reinforce the pile body, improve the stress performance of the pile body and enhance the integrity of the pile body; the section of the pile body on the lower part is an anti-arch curved surface which can prevent influence from excessive fullness of concrete of the pile body to the lateral friction of the pile; the section of the pile body on the upper part is round and can reduce the influence from the lateral negative friction of the pile to the performance of the pile body. The invention also discloses a construction method of the combined irregular-shaped pile.

Owner:JIANGSU ZHONGRUI ROAD & BRIDGE CONSTR

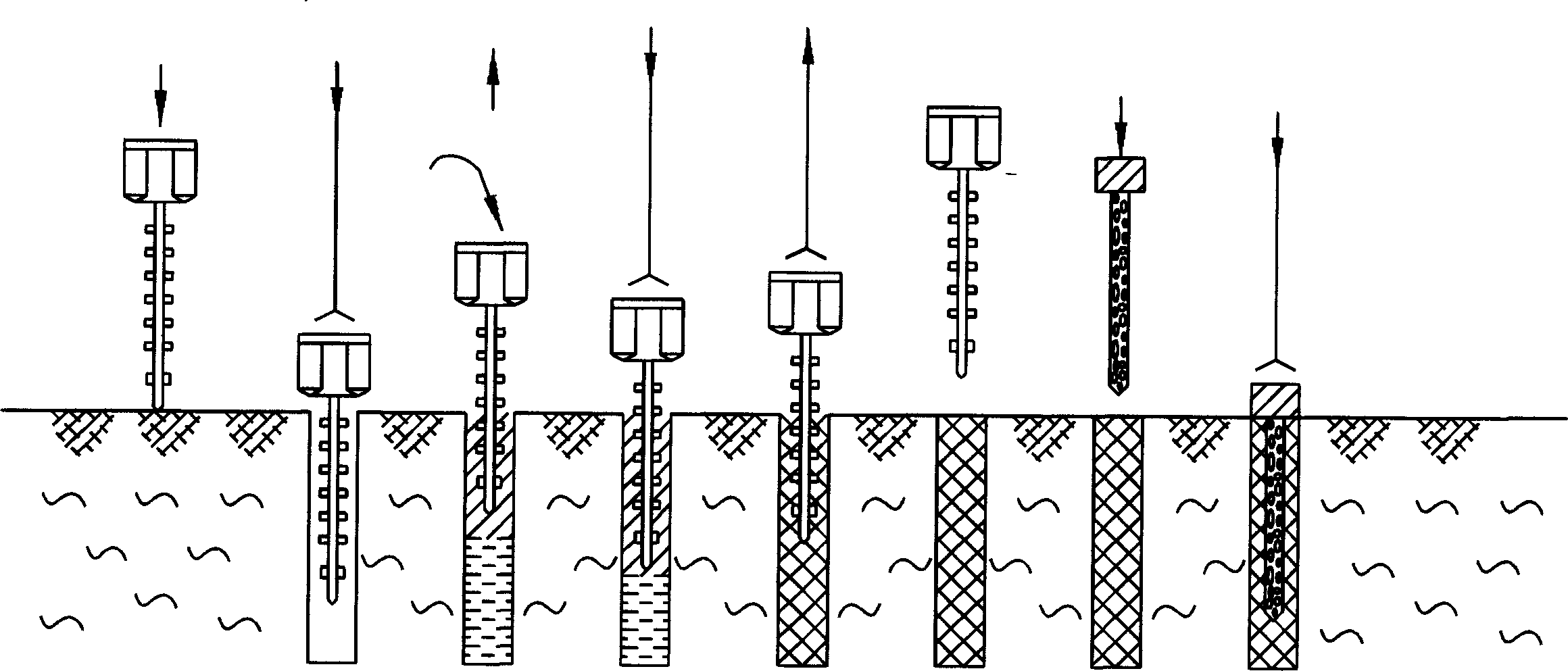

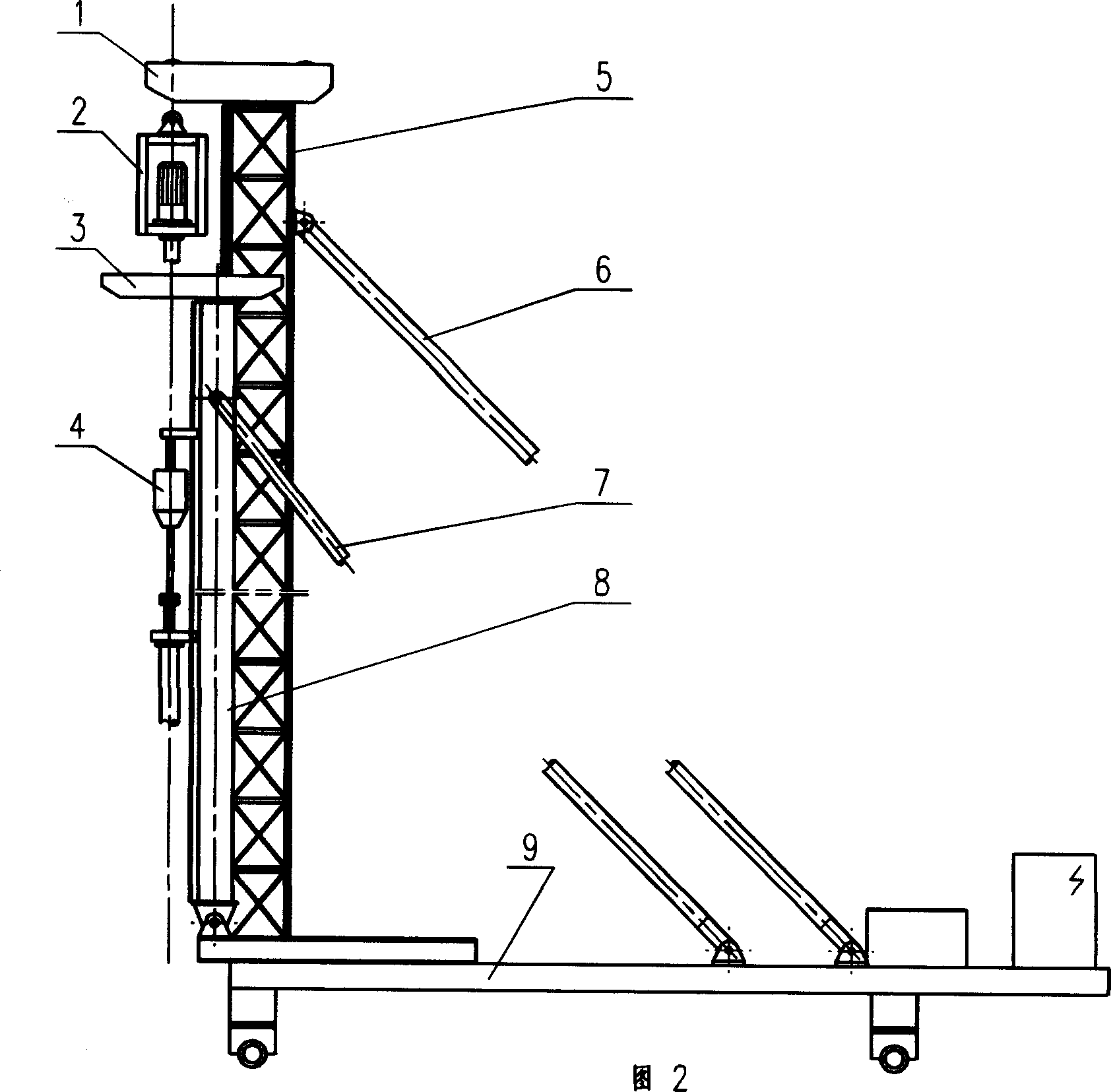

Original soil strengthen pile sinking method and its construction apparatus

The invention discloses a method of crude soil solidifying pile sinking used in building operation and its construction device. The method of pile sinking is that cut moving is stirred into stirred cut crude soil as pre-selected at pre-calculated position of the ground base; prepared curing agent is pressed into the stirred cut crude soil and stirred uniformly into solidified soil; the prefabricated pile is sunk into the solidified soil, the ground base is formed into crude soil solidified pile base. The construction device includes bottom head, stirring machine upright equipped on the bottom head, deep lift stirring machine equipped on the stirring machine upright, pile driver upright equipped on the bottom head, pile driver equipped on the pile diver upright. The advantage of the ground base formed by this method is high intension, strong bearing capacity, and low cost.

Owner:江苏东达集团股份公司

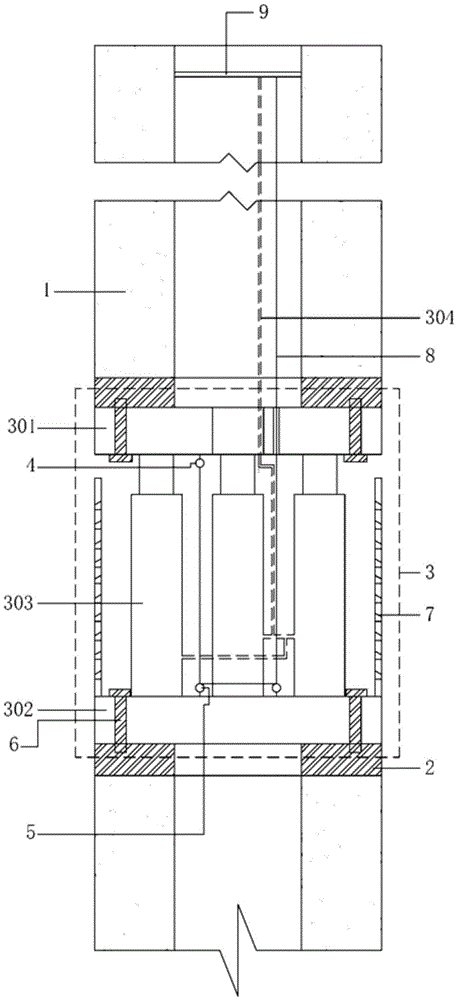

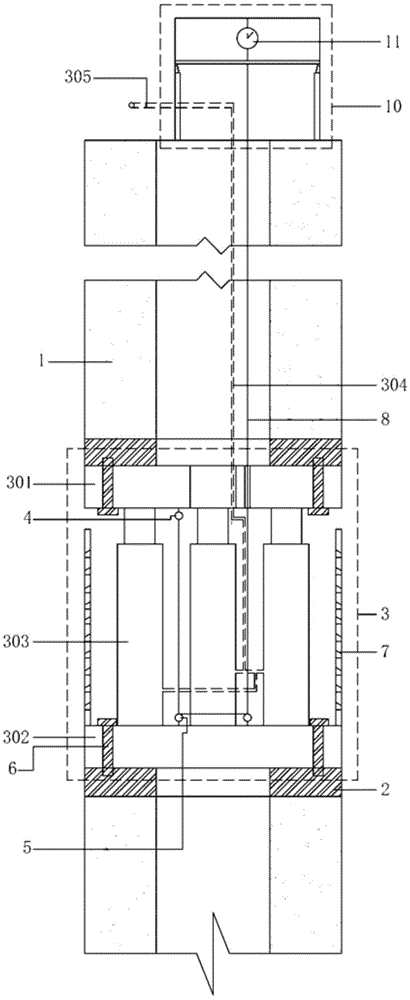

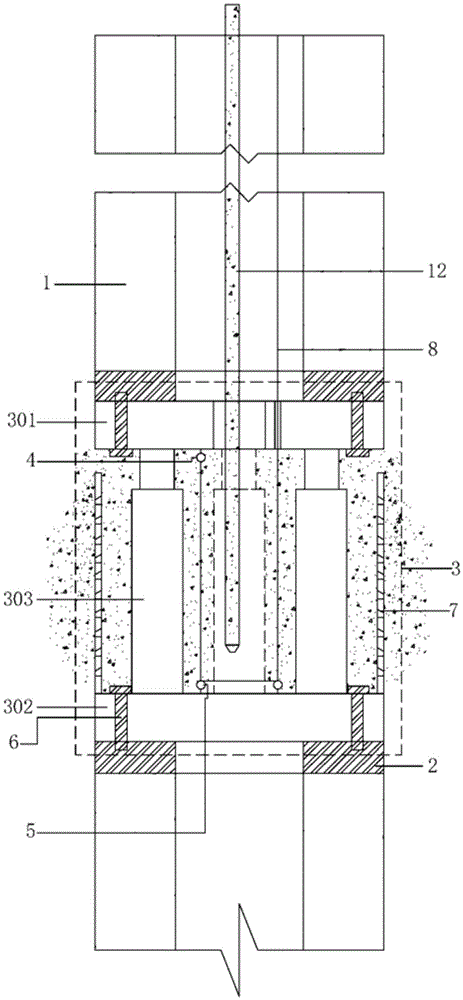

Device for regulating and controlling contact and interaction between pile and earth

InactiveCN104631452AEngineering safety and controllabilityReduce negative frictionBulkheads/pilesJoint workingStructural engineering

The invention discloses a device for regulating and controlling contact and interaction between a pile and earth. The device comprises a negative pressure pump, a grouting pump and a pile body embedded in a selected region. The device is structurally characterized in that a main negative pressure pipeline and a main grouting pipeline are arranged in the pile body or on the surface of the pile body, wherein the main negative pressure pipeline is connected with the negative pressure pump, and the main grouting pipeline is connected with the grouting pump; the device is further provided with a plurality of branch negative pressure pipelines distributed at intervals and a plurality of branch grouting pipelines distributed at intervals, wherein the branch negative pressure pipelines are communicated with the main negative pressure pipeline, and the branch grouting pipelines are communicated with the main grouting pipeline; a valve can be arranged in each branch grouting pipeline, and a plug can be arranged in the main grouting pipeline; deformation sensors and stress sensors can be further arranged in the pile body, wherein the deformation sensors and the stress sensors are connected with a monitoring station. The device has the advantages that opening and closing of the contact surface between the pile and the earth can be flexibly controlled, the stress condition of the end of the pile can be effectively controlled, stress and deformation of the pile body can be flexibly adjusted, and the device can effectively cooperate with the pile and the earth to work together.

Owner:刘林松

Drainage cast-in-situ concrete thin-wall pipe pile construction method

ActiveCN105484279AImprove carrying capacityReduce disturbanceFoundation engineeringReinforced concreteEconomic benefits

The invention relates to a drainage cast-in-situ concrete thin-wall pipe pile construction method. The method comprises the following steps: preparing before construction, paving solidified soil, driving a sinking steel pipeline and a pile casing, mounting a precast reinforced concrete sleeve, pouring concrete in a pile body, vibrating and drawing the pipeline, filling the pile top, pre-burying connecting screw rods and a water drainage pipe, and mounting a pile top precast cover plate. According to the method, mechanical properties of the upper part of the pile body and a soil body around the pile body are improved, the effect that pile groups compact soil is relieved, the consolidation settlement amount caused by the change of underground water level in foundation soil and other reasons is reduced, and better technical and economic benefits are realized.

Owner:JINAN CHANGXING CONSTR GRP

Construction method of bituminous coating pile in sandy foundation

InactiveCN104695433AImprove construction qualityReduce negative frictionBulkheads/pilesEngineeringSoil horizon

The invention discloses a construction method of a bituminous coating pile in a sandy foundation. The construction method is characterized in that the bituminous coating pile is hammered and driven under the protection action of a steel sleeve. The construction method specially comprises the construction steps that the steel sleeve penetrates through a backfill sandy soil layer and is driven into a soft soil layer laid at the bottom of the sandy soil layer; the bituminous coating pile in the steel sleeve is driven into a bearing stratum, and the steel sleeve is clamped, pulled and taken out through a vibratory hammer. Compared with the prior art, the construction method has the advantages that a bituminous coating is completely protected, the effect that negative friction is reduced through the bituminous coating is fully achieved, operation is easy, the project quality is reliable, the adaptability is high, the construction method is particularly applicable to a pile foundation project with the soft soil layer at the bottom and a thick backfill sandy foundation on the top in a covering mode, the problem of the negative friction can be effectively solved, and the construction quality of the pile foundation project is improved.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

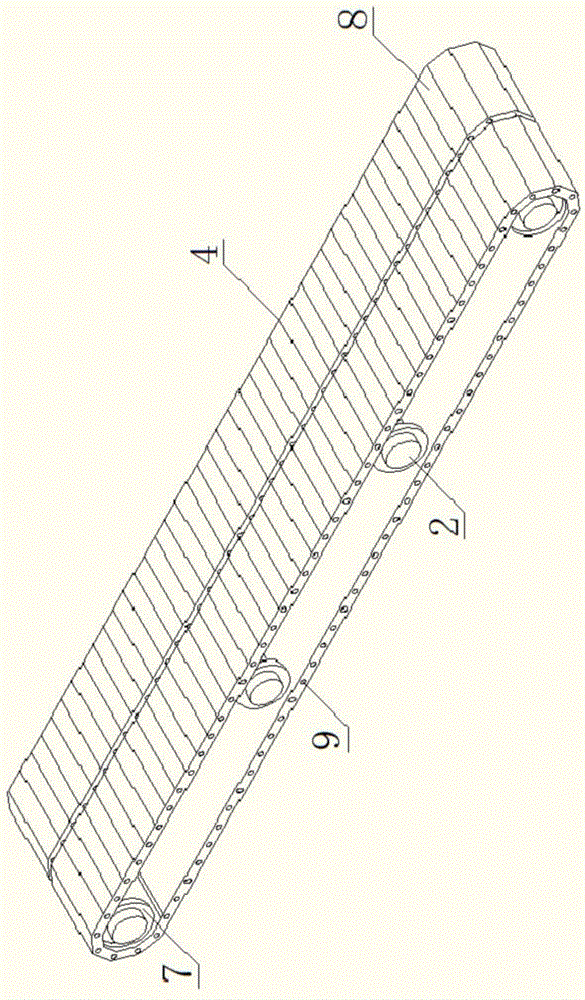

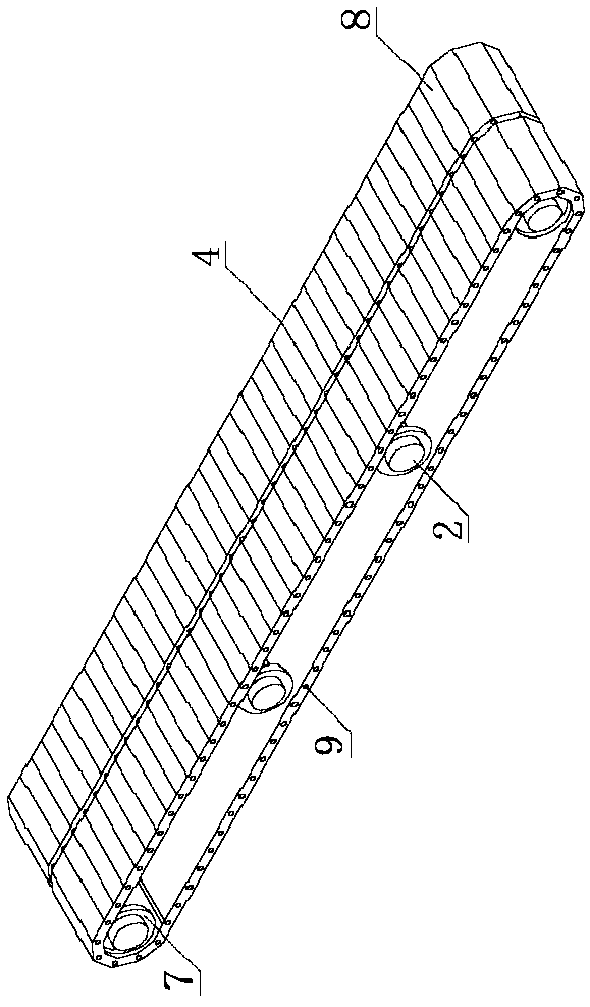

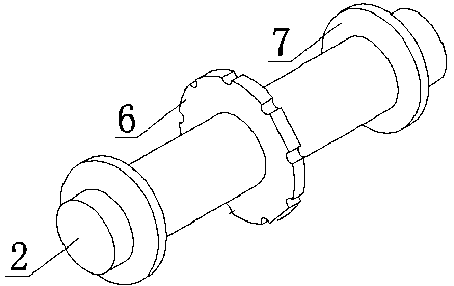

Track steel-pipe pile capable of reducing negative friction force and construction method

ActiveCN106836260AIncrease positive frictionReduce negative frictionBulkheads/pilesEngineeringFoundation engineering

The invention discloses a track steel-pipe pile capable of reducing negative friction force and a construction method, and belongs to the technical field of building foundation engineering. The track steel-pipe pile comprises a pile body, gear shafts, T-shaped steel beams and a rigid track. Concrete is poured into a round steel pipe to form the pile body. The middle of each gear shaft is provided with a one-way rotating gear, and the two ends of each gear shaft are provided with one-way rotating pulleys. Webs of the T-shaped steel beams are annularly welded to the outer side of the pile body at equal intervals. The gear shafts are symmetrically welded to the two sides of the webs of the T-shaped steel beams and are arranged at equal intervals in the longitudinal direction of the webs. The rigid track is composed of track shoes and track pins. The two ends of each track shoe are provided with holes, and the track shoes are connected through the corresponding track pins to form the rigid track. The rigid track is engaged with the one-way rotating gears on the gear shafts and further attached to the one-way rotating pulleys at the two ends of the gear shafts, and the rigid track can be closed through the track pins so that the track steel-pipe pile can be formed. According to the track steel-pipe pile capable of reducing negative friction force and the construction method, through one-way rotation of the rigid track, pile-soil positive friction force can be increased while the pile-soil negative friction force is reduced, insufficient bearing capacity of the pile body is prevented, and safety and stability of an upper structure are guaranteed.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

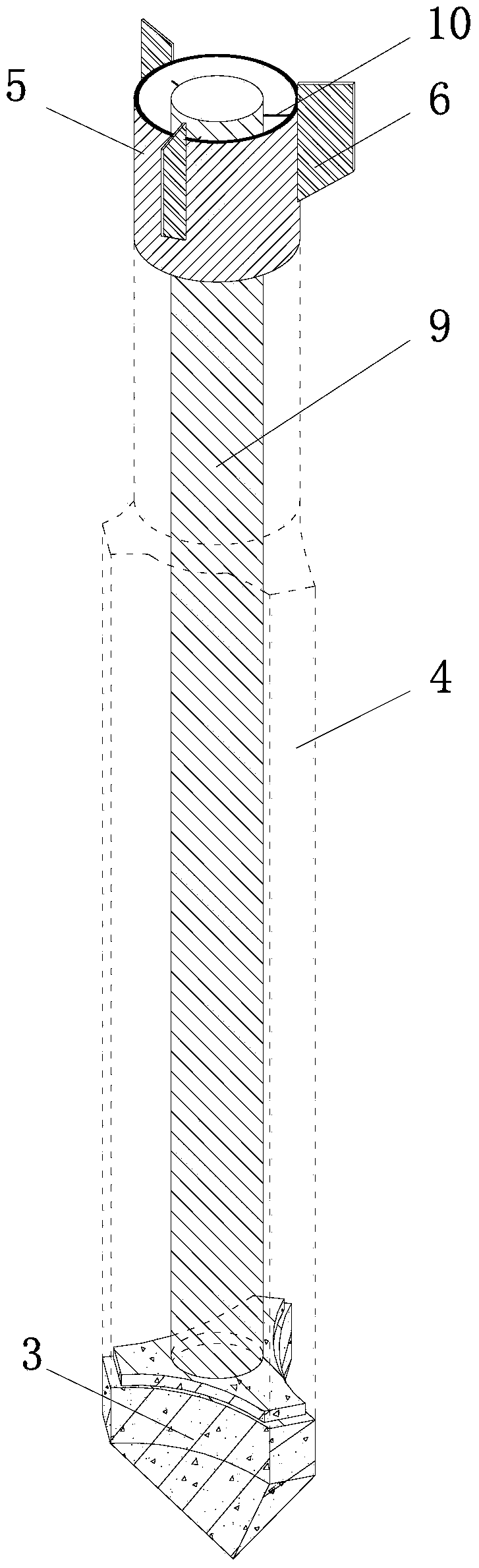

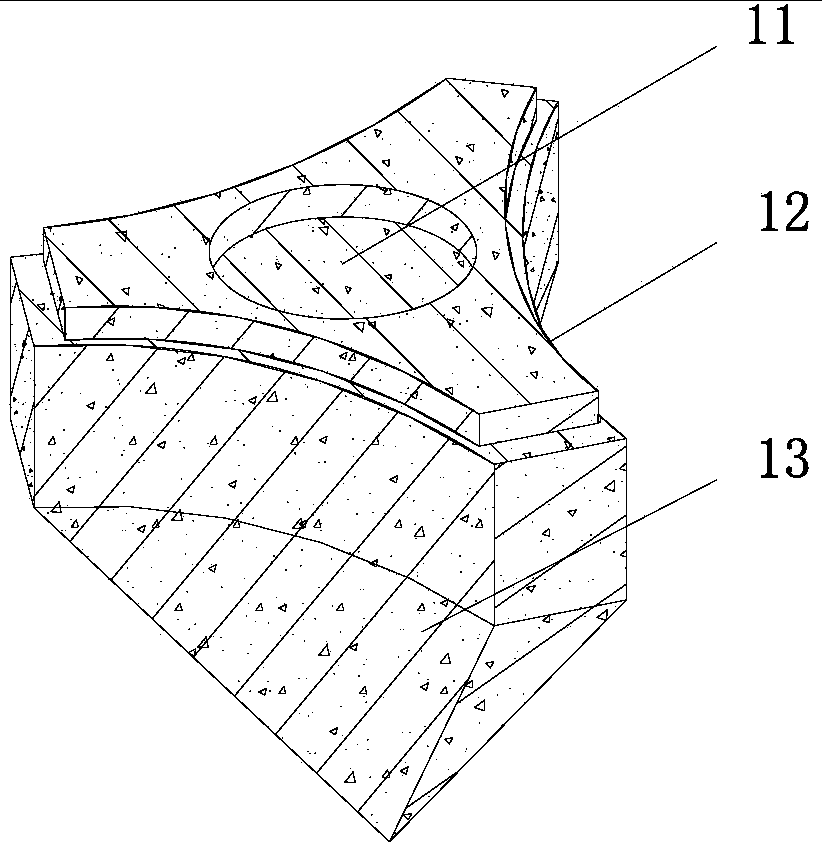

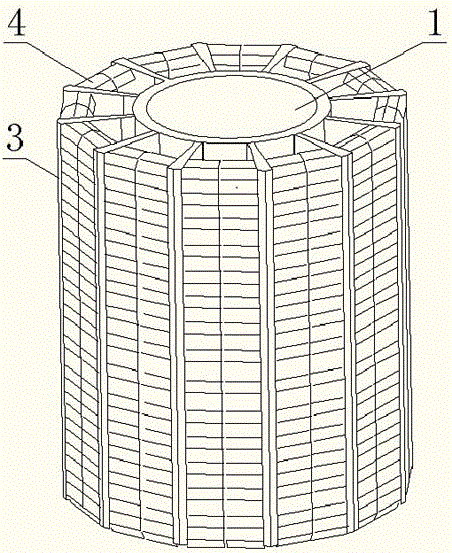

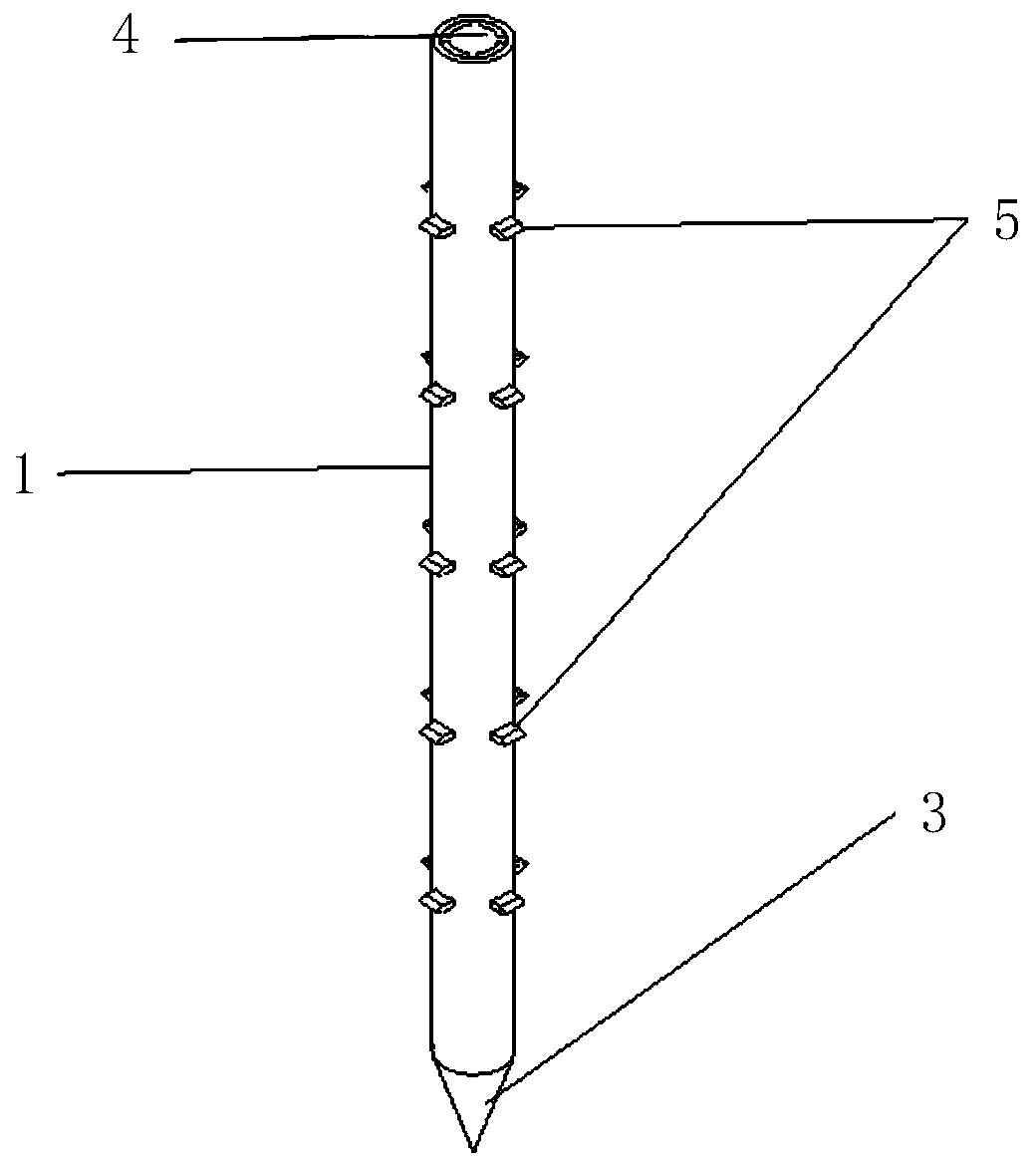

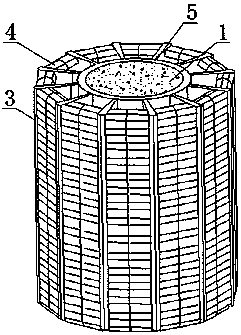

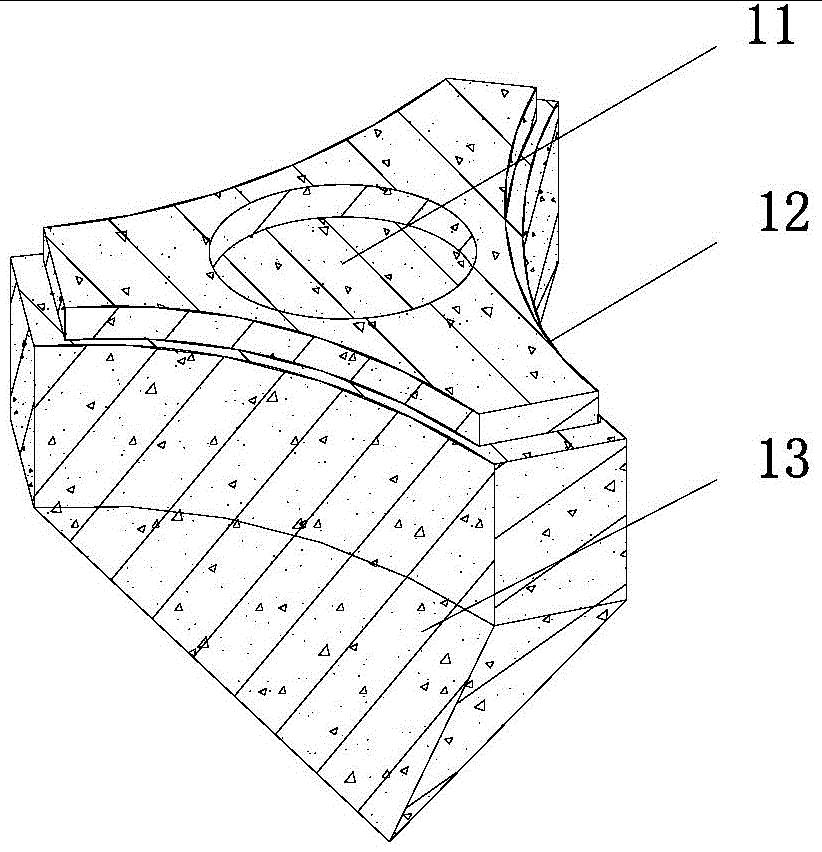

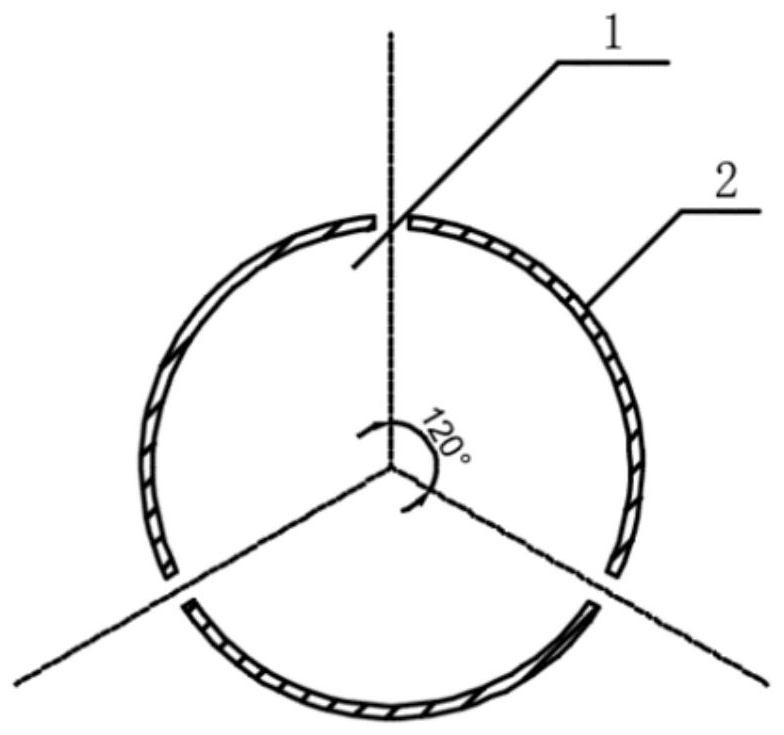

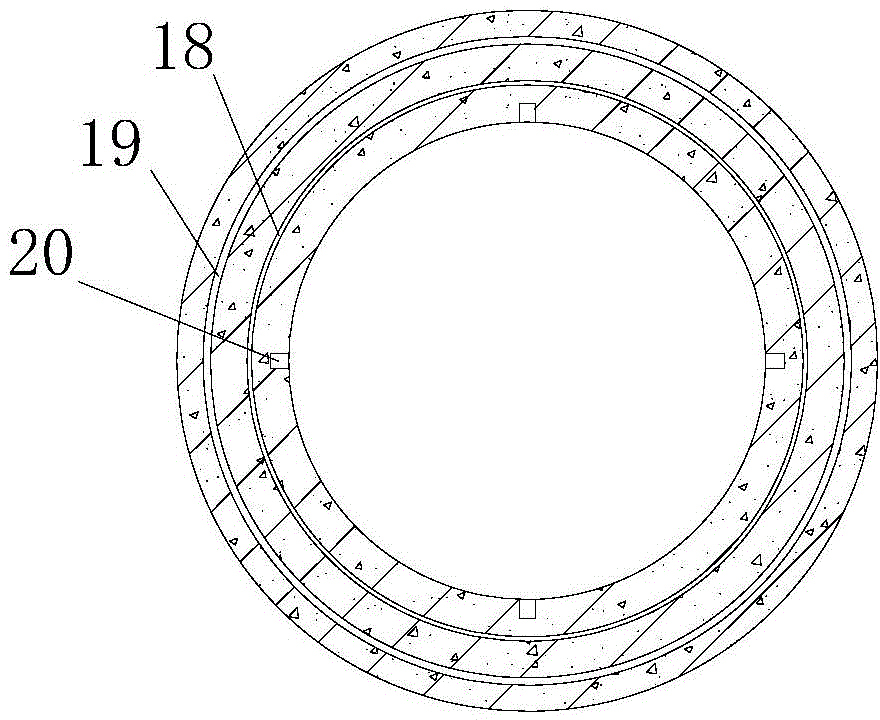

Steel pipe composite pile for collapsible loess

PendingCN110629746AReduce negative frictionImprove carrying capacityBulkheads/pilesHollow coreSteel tube

The invention provides a steel pipe composite pile for collapsible loess, and belongs to the technical field of a building pipe pile. The steel pipe composite pile for collapsible loess comprises a steel pipe sleeve, steel insertion plates, a pile point and a concrete pile core, wherein each steel insertion plate comprises a horizontal hollow insertion plate and a vertical arc-shaped insertion plate; a plurality of horizontal hollow insertion plates are uniformly arranged on the outer walls of the vertical arc-shaped insertion plates; a plurality of steel insertion plates are uniformly arranged inside the steel pipe sleeve; a plurality of clamping grooves corresponding to the horizontal hollow insertion plates are uniformly arranged in the peripheral direction of the steel pipe sleeve andare used for being clamped with the horizontal hollow insertion plates; the pile point is arranged at the end part of the steel pipe sleeve; and the concrete pile core is arranged inside the steel pipe sleeve. The steel pipe composite pile for collapsible loess can prevent the water collapsibility of a loess body in the horizontal direction; water in the loess can be adsorbed so as to reduce the loess sedimentation; the pile side negative frictional resistance is further eliminated or reduced; and the bearing capability of the pile foundation is improved.

Owner:LIAONING TECHNICAL UNIVERSITY

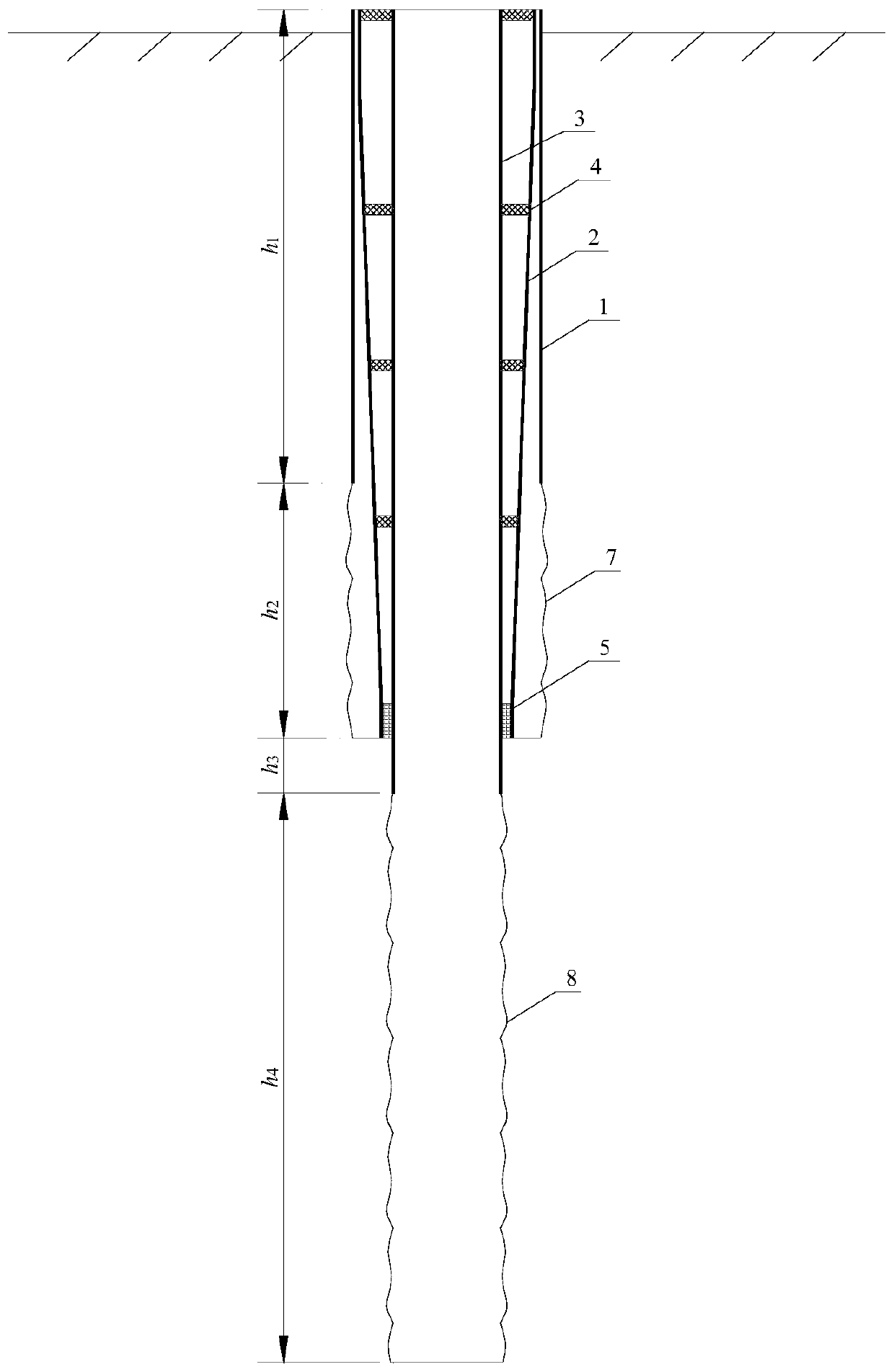

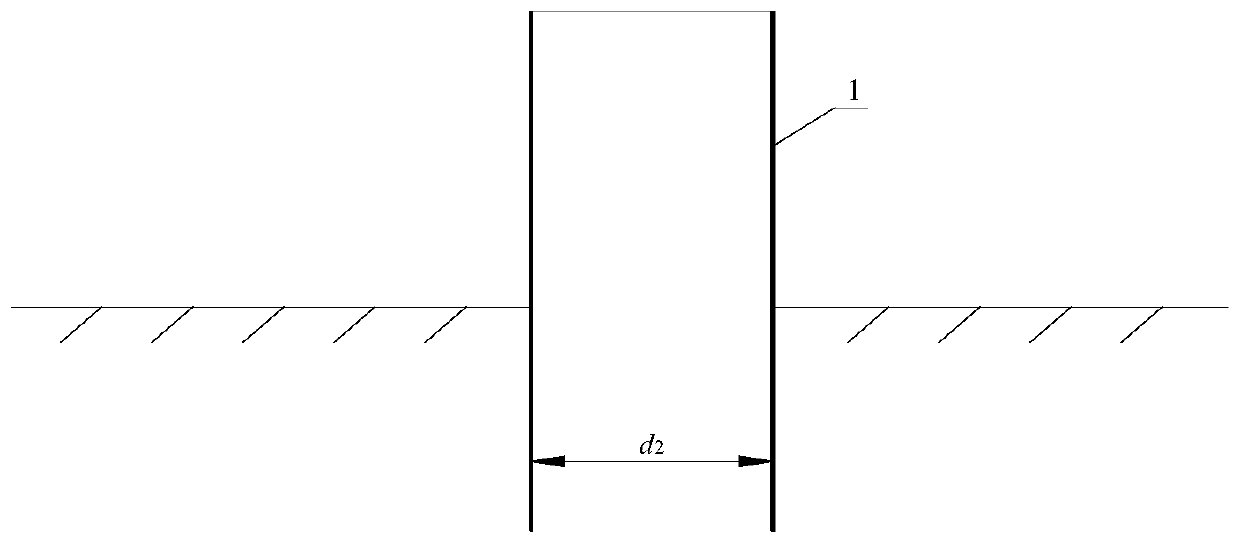

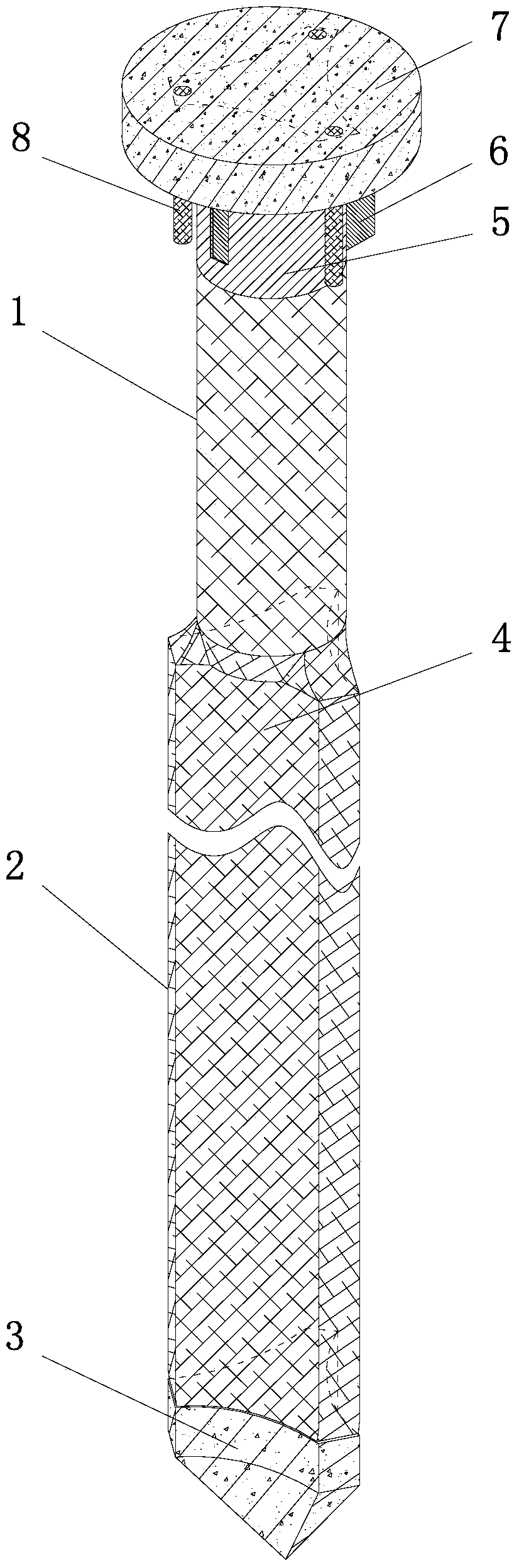

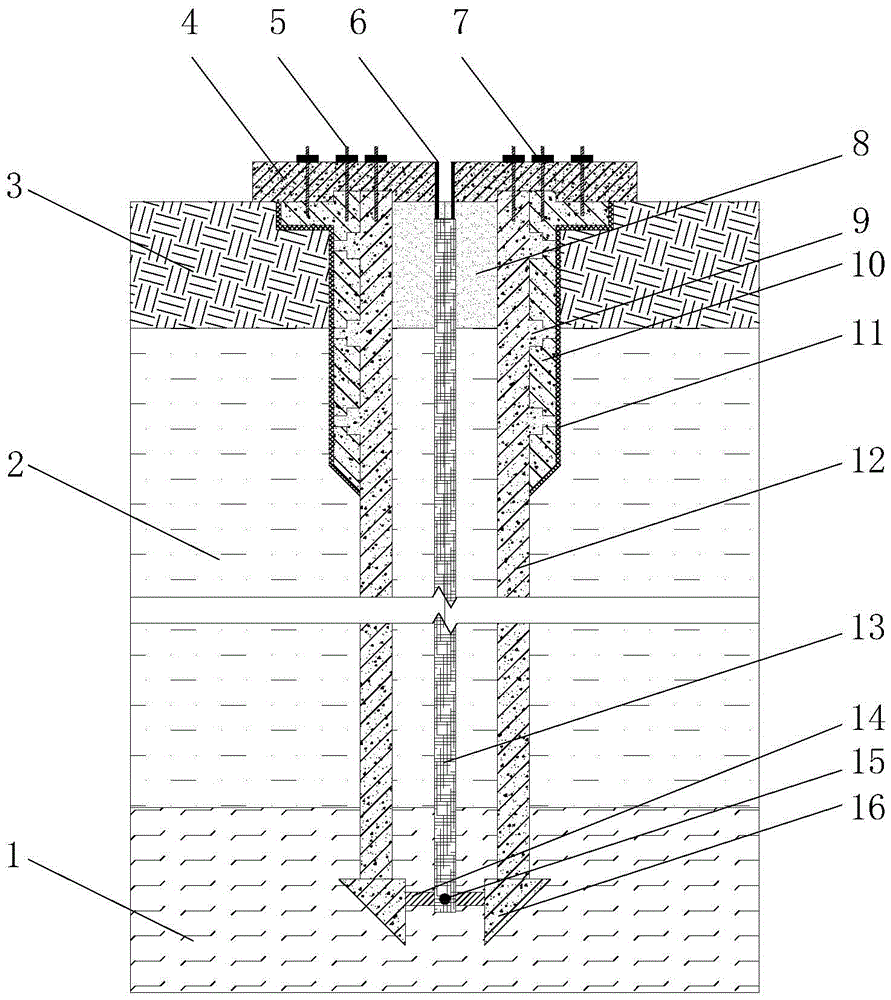

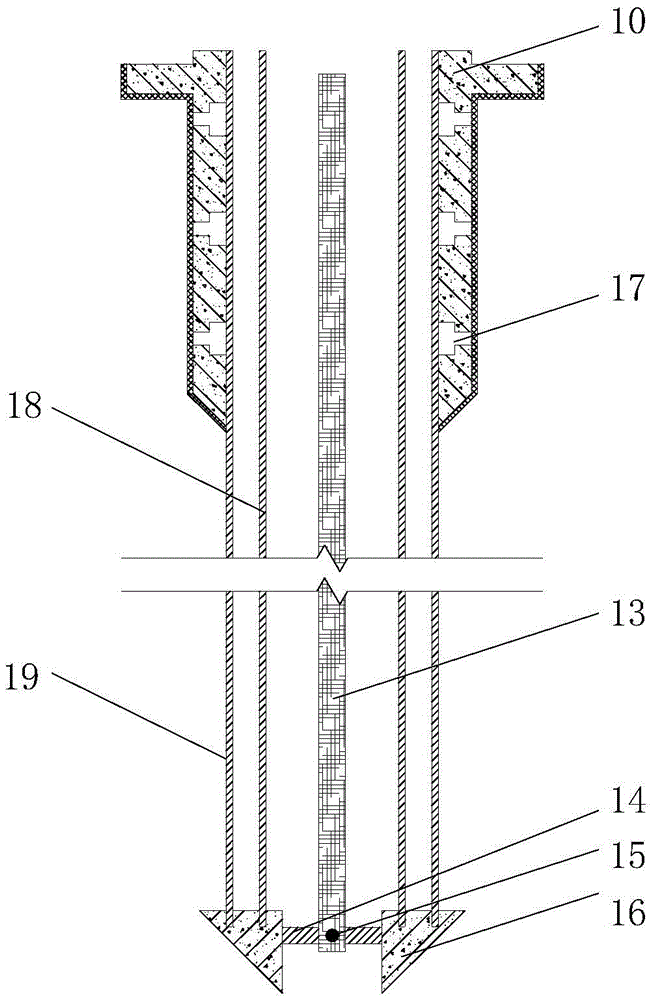

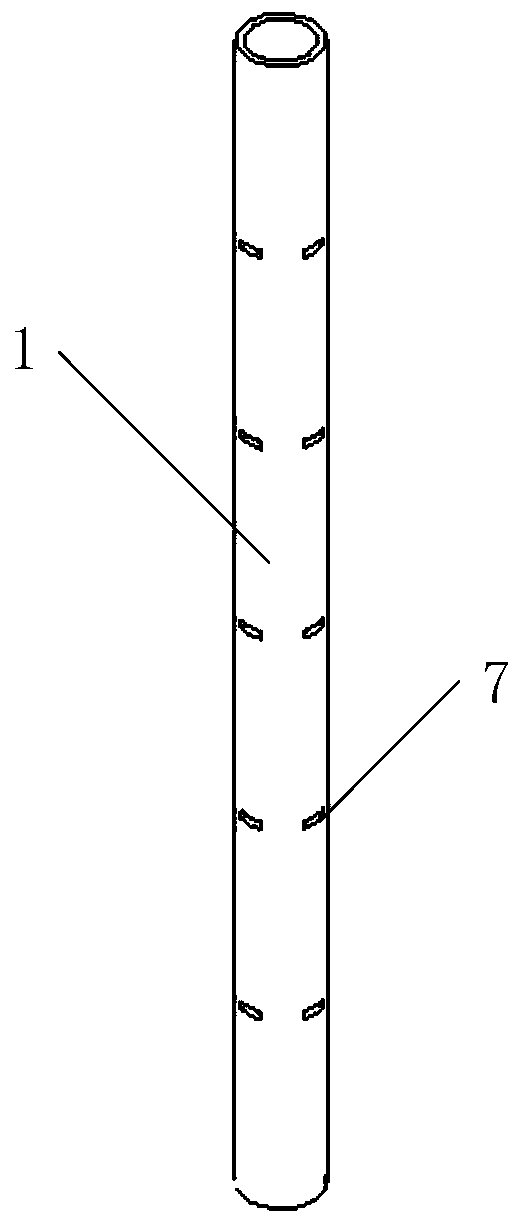

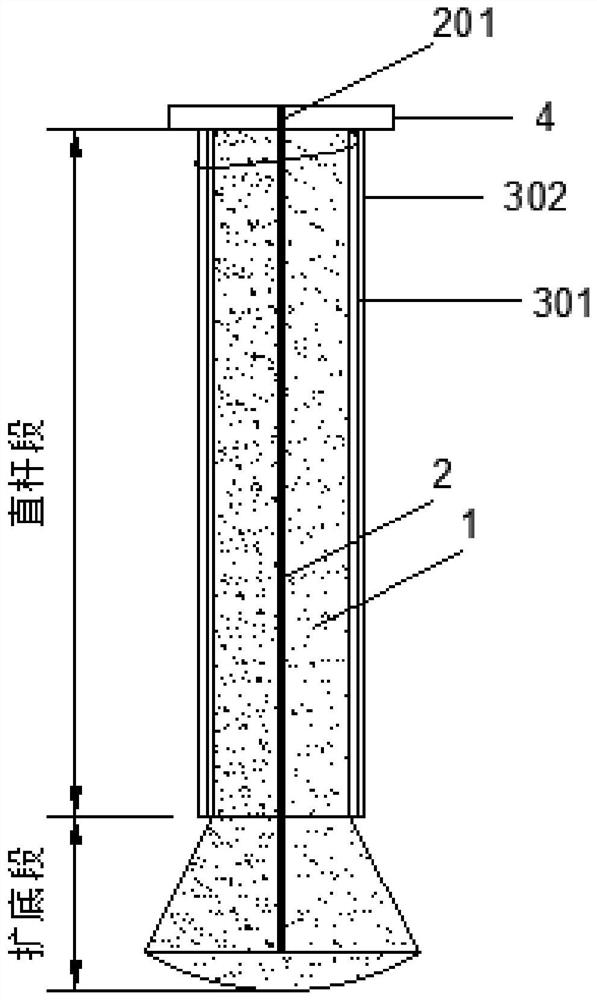

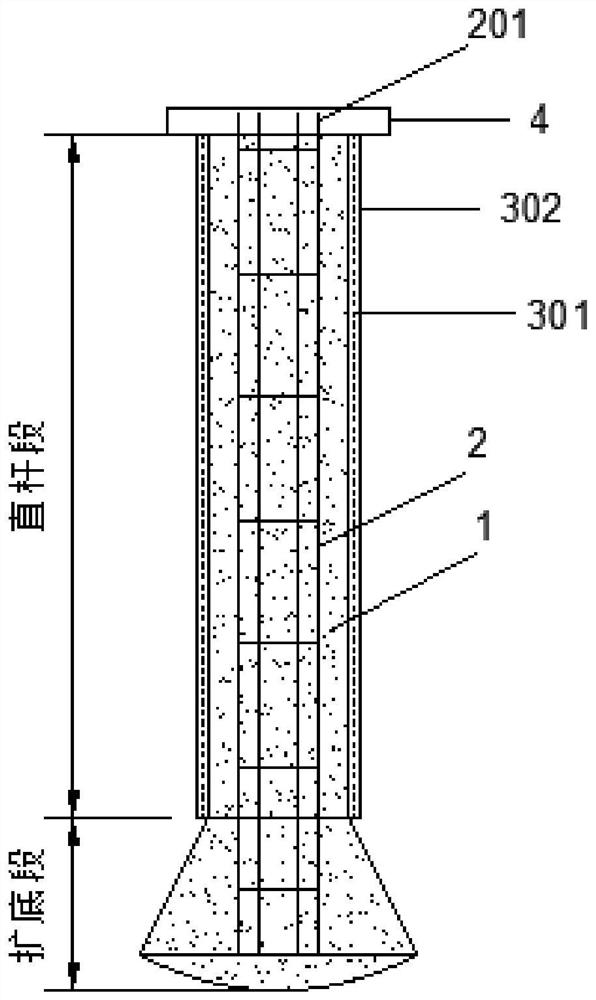

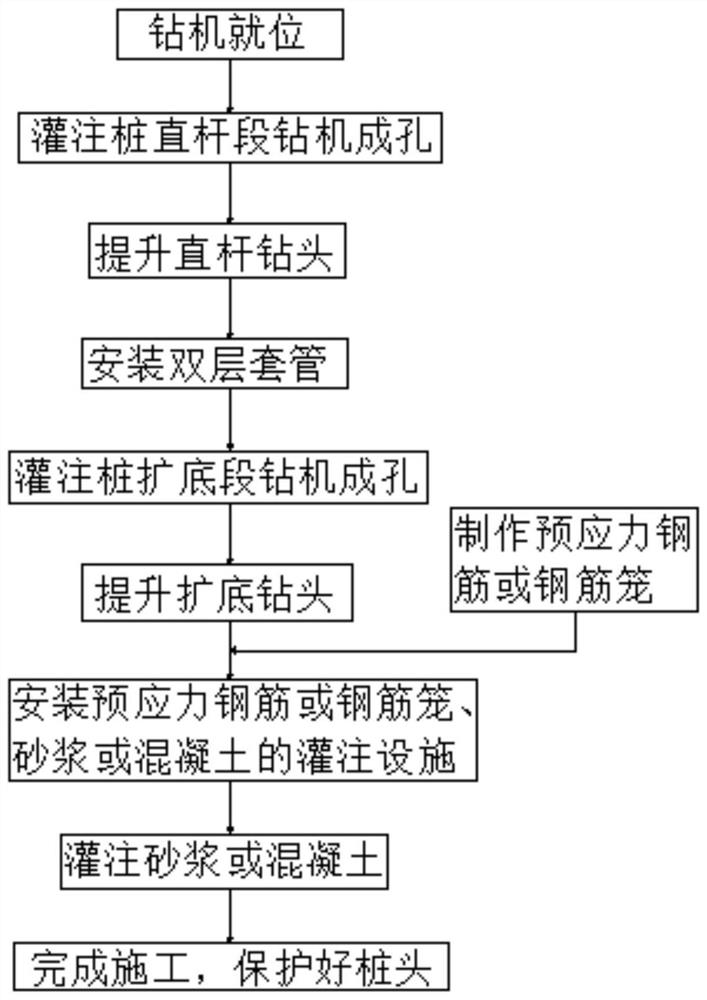

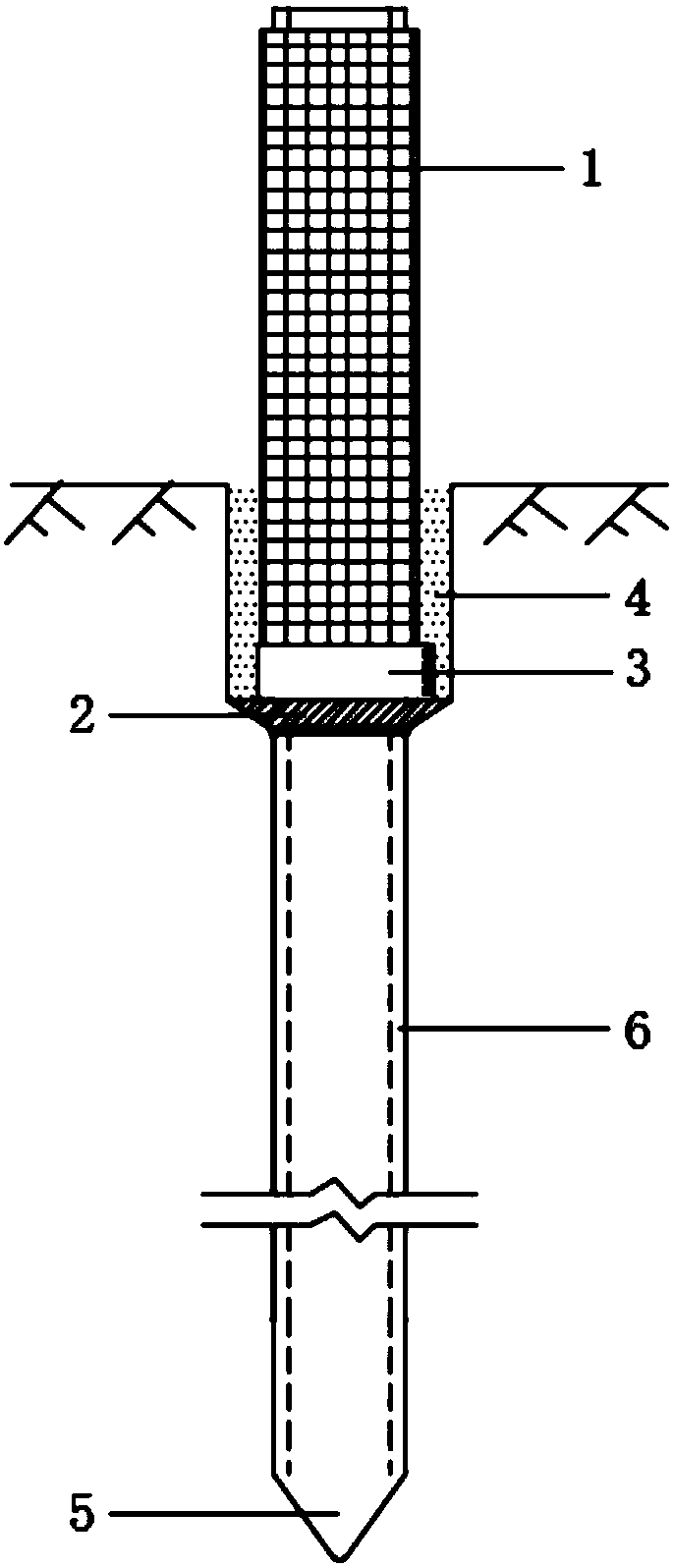

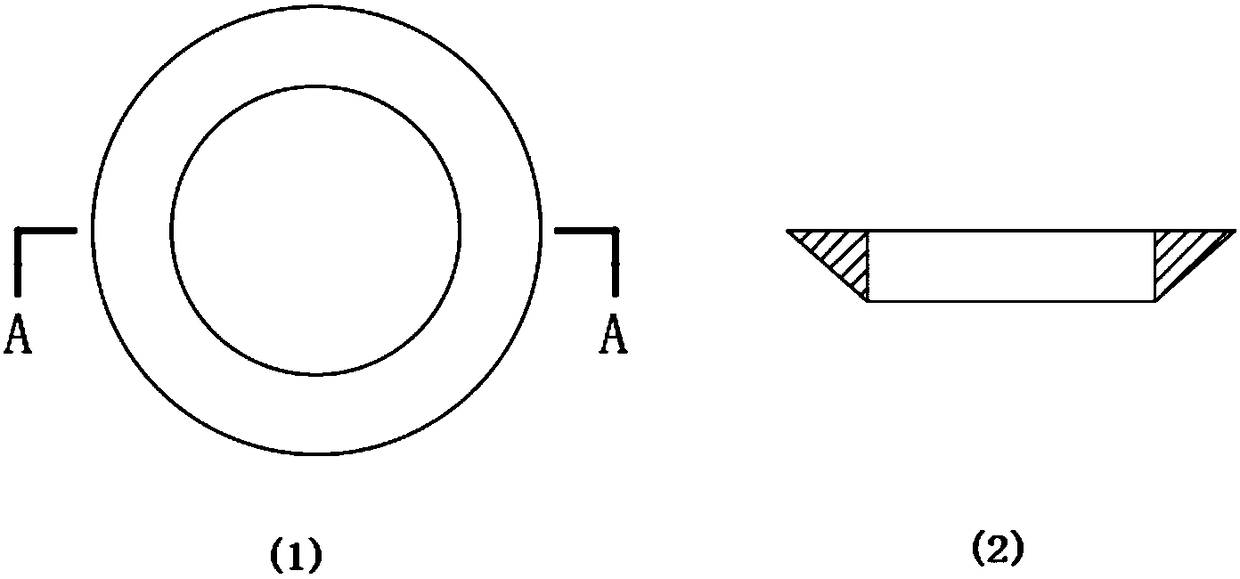

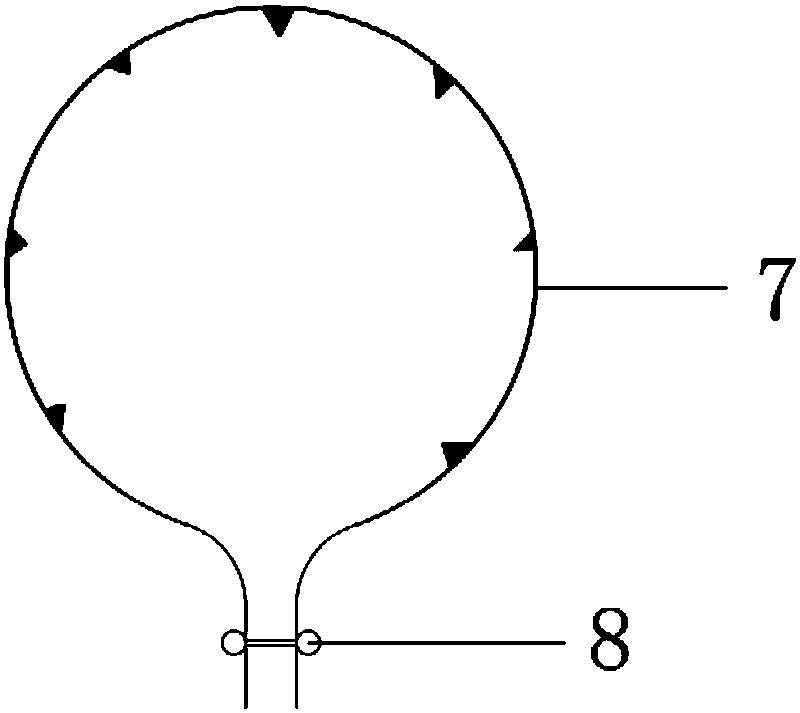

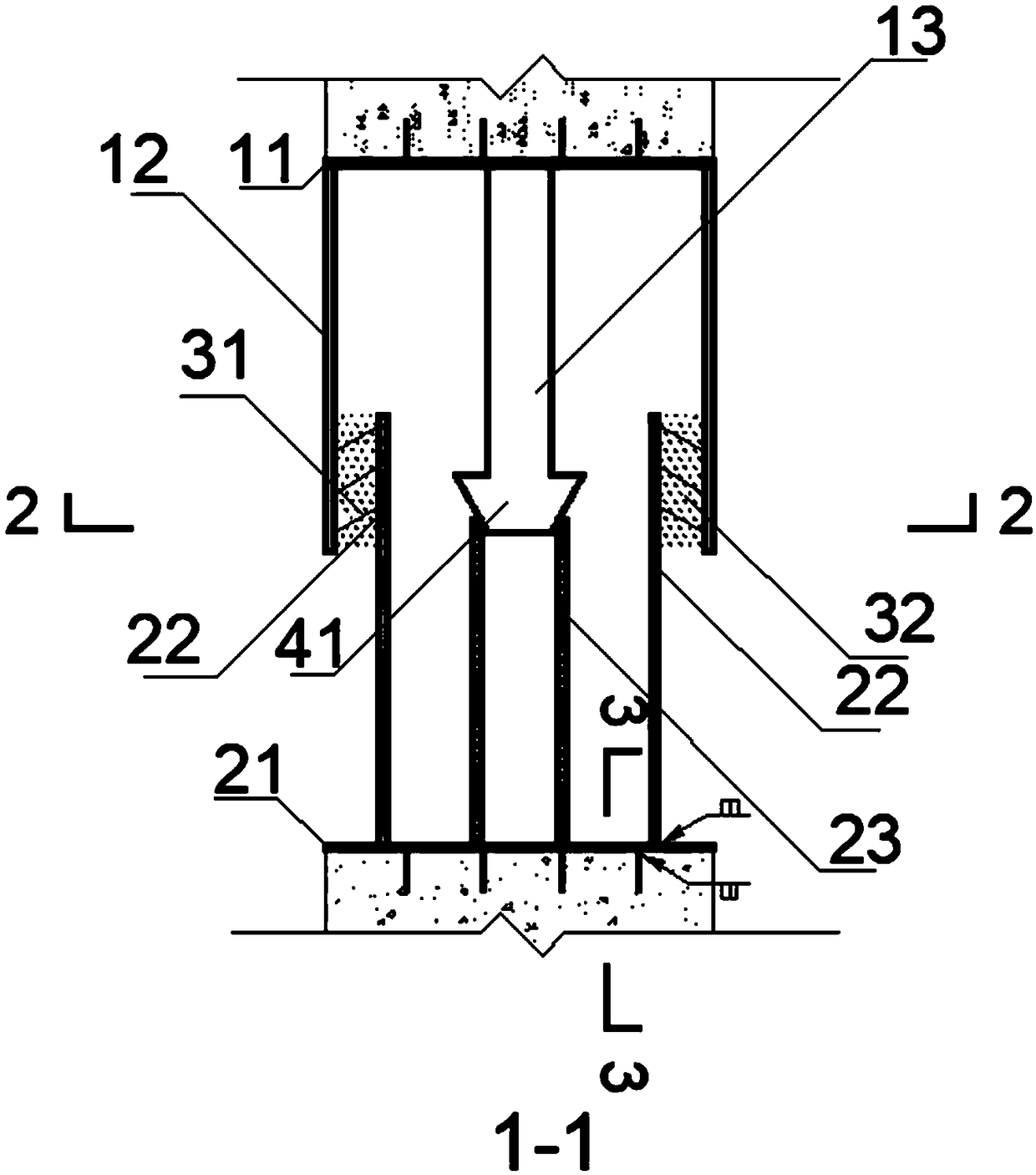

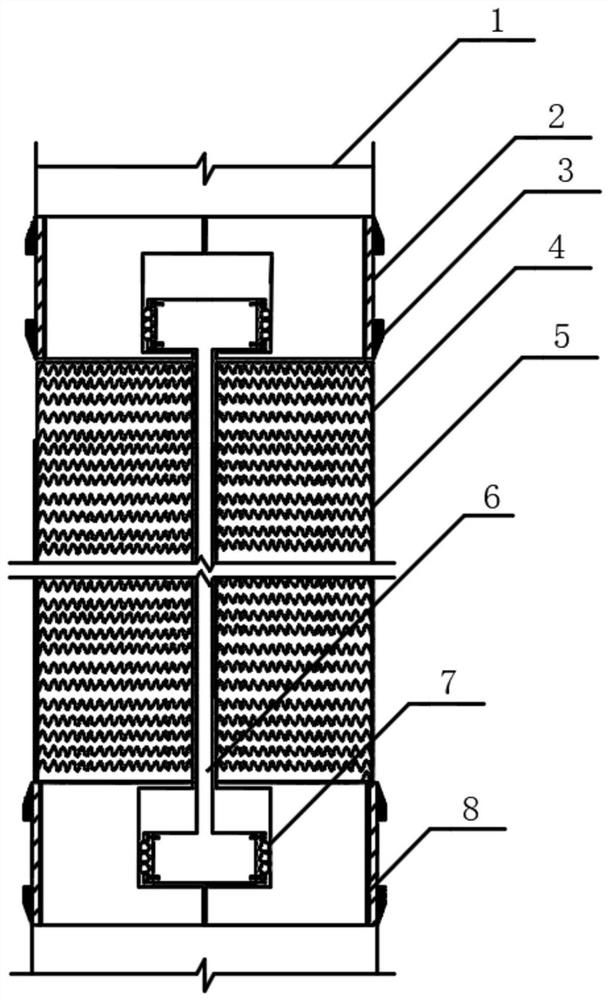

Upper straight rod and lower expanded-base structure cast-in-place pile capable of reducing negative frictional resistance and construction method thereof

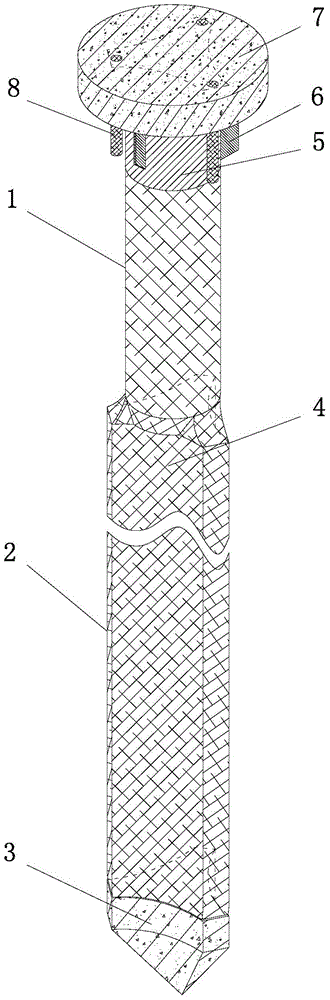

The invention discloses an upper straight rod and lower expanded-base structure cast-in-place pile capable of reducing negative frictional resistance and a construction method thereof. The upper straight rod and lower expanded-base structure cast-in-place pile comprises a cast-in-place concrete pile, prestressed reinforcements located in the cast-in-place concrete pile, a pile body outer sleeve located outside the cast-in-place concrete pile and a bearing platform arranged at the upper end of the cast-in-place concrete pile; the cast-in-place concrete pile is formed by directly connecting an upper straight rod section and a lower expanded-base section, and the prestressed reinforcements and the cast-in-place concrete pile are coaxially arranged to form the upper straight rod and lower expanded-base structure cast-in-place concrete pile; the outer wall of the straight rod part of the cast-in-place concrete pile is sleeved with the pile body outer sleeve; and the pile body outer casing pipe comprises an inner layer casing pipe and an outer layer casing pipe, and joints, exceeding the pile top of the cast-in-place concrete pile, of the prestressed reinforcements are reserved to be connected with the bearing platform. The method has a good effect of reducing the negative friction under the geological conditions of high-compressibility soil layers such as soft soil, collapsible loess and dredger fill.

Owner:LIAONING TECHNICAL UNIVERSITY

Device and method for reducing negative friction resistance of prefabricated pipe pile

InactiveCN108277801AReduce coefficient of frictionFast degradation rateBulkheads/pilesGeomembraneNegative resistance

The invention discloses a device and a method for reducing the negative friction resistance of a prefabricated pipe pile. The concrete outer surfaces of a neutral-point pipe pile section and pipe pilesections above the neutral-point pipe pile section are wrapped by composite geomembrane layers capable of sliding relative to each other, the composite geomembrane layers can be basically degraded when the settlement amount of a soil body is smaller than that of a pile foundation, a pile hole expanding structure is welded on a steel end plate at the lower end of the neutral-point pipe pile section, and a fixing structure is arranged at the position, close to the steel end plate of the pipe pile, of the lower ends of the composite geomembrane layers. According to the device, the composite geomembrane layers capable of sliding relative to each other are used for wrapping the neutral-point pipe pile section and the concrete outer surfaces of the pipe pile sections above the neutral-point pipe pile section, so that the neutral-point pipe pile section is reduced, the friction coefficient of a pile-soil interface is reduced, and the negative friction resistance of the pipe pile is reduced;and when the settlement amount of the soil body is smaller than that of the pile foundation, the composite geomembrane layers can be basically degraded, and the upward positive friction resistance isgenerated along the full length of the pile body. The method is simple and easy to implement and convenient to construct, and can effectively reduce the damage caused by the negative friction resistance of the prefabricated pipe pile.

Owner:WUHAN UNIV

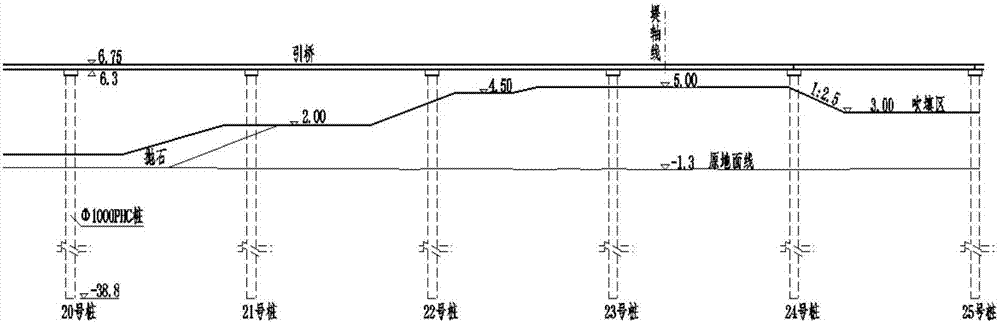

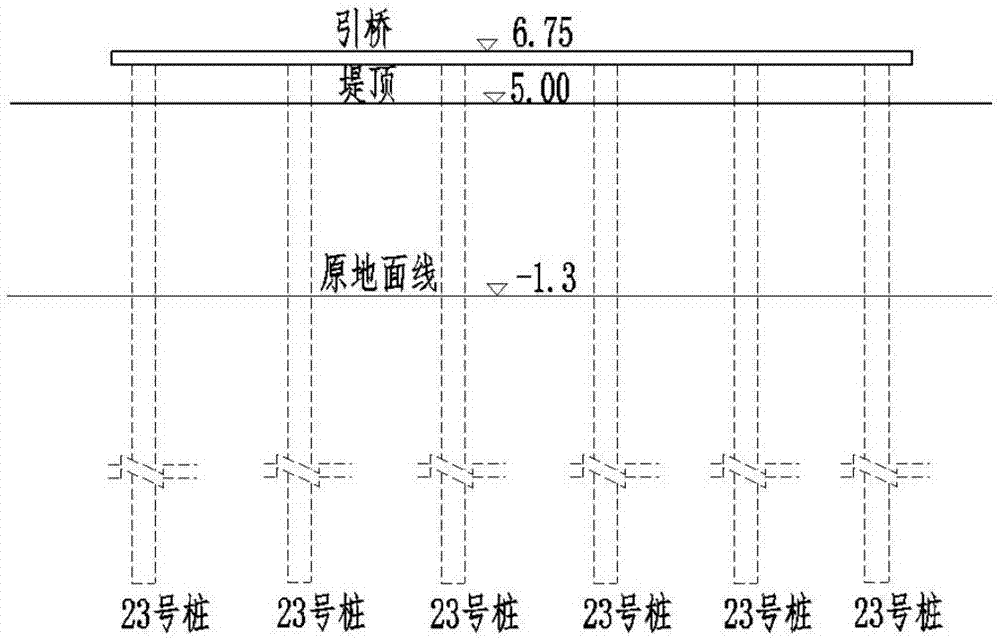

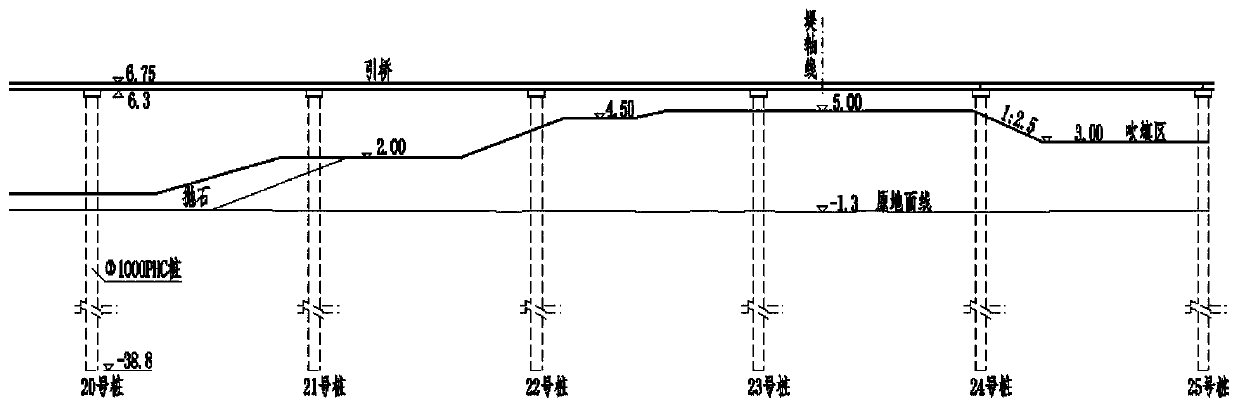

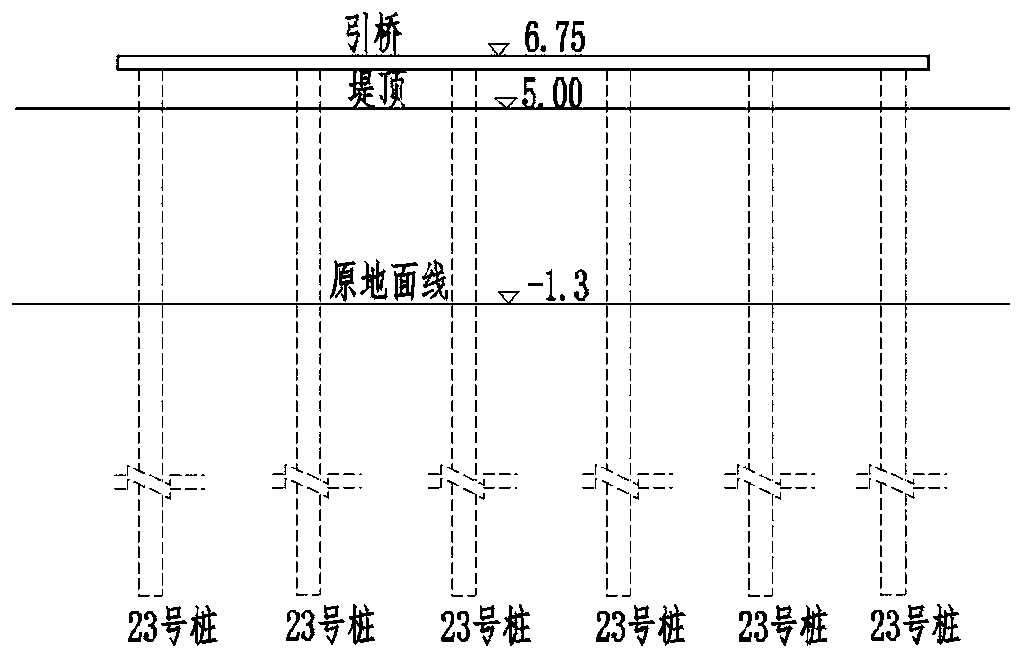

Above-water coating construction method for reducing negative friction force of pile body

InactiveCN107447753AReduce adverse effectsReduce the adverse effect of negative friction on the pile bodyGeotextilesBulkheads/pilesSite monitoringStructural engineering

The invention discloses an above-water coating construction method for reducing negative friction force of a pile body. An above-water pile body is a part of the pile body located above a water surface, and an under-water pile body is a part of the pile body located under the water. The construction method for above-water coating for reducing the negative friction force for the pile body comprises the steps that the surface of the above-water pile body after dried is coated with cold base oil, and after the cold base oil infiltrates the above-water pile body or volatilizes from the surface of the above-water pile body, heated asphalt is poured on the surface of the above-water pile body to form an upper section asphalt layer; and the surface of the asphalt layer is wrapped with geotextile, and finally reinforcing is conducted on outside of the geotextile. The above-water coating construction method for reducing the negative friction force of the pile body is simple in process, convenient to operate and low in investment, after on-site monitoring for an actual project, it is shown that operability for reducing the negative friction force of the pile body is high, and the effect is obvious.

Owner:长江河湖建设有限公司

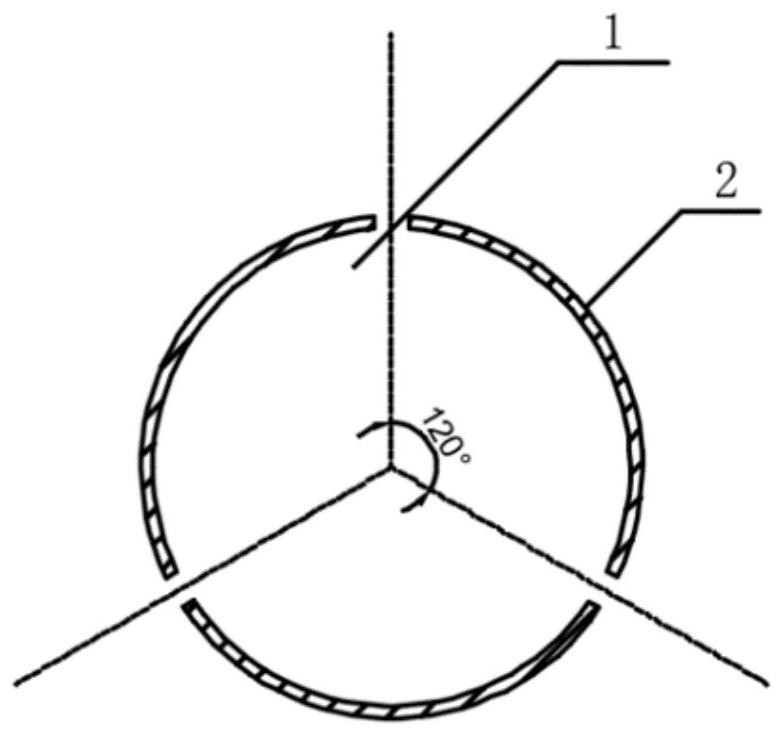

Splicing variable-diameter rigid pile casing compaction pile and construction method thereof

ActiveCN114673148AAvoid twisting and breakingImprove integrityBulkheads/pilesSoil preservationArchitectural engineeringStructural engineering

The compaction pile comprises a pile body and the pile casing arranged outside the pile body in a sleeving mode, the pile casing comprises a bottom cylinder, a middle cylinder and a top cylinder which are coaxially connected in sequence, and bottom cylinder fixing bolts are evenly distributed on the outer wall of the end, close to the middle cylinder, of the bottom cylinder in the annular direction; first middle cylinder fixing bolts are evenly distributed on the outer wall of the end, close to the bottom cylinder, of the middle cylinder in the annular direction, second middle cylinder fixing bolts are evenly distributed on the outer wall of the end, close to the top cylinder, of the middle cylinder in the annular direction, top cylinder fixing bolts are evenly distributed on the outer wall of the end, close to the middle cylinder, of the top cylinder in the annular direction, and the bottom cylinder fixing bolts and the first middle cylinder fixing bolts are connected through first connecting plates. And the middle cylinder second fixing bolt and the top cylinder fixing bolt are connected through a second connecting plate, the bottom cylinder, the middle cylinder and the top cylinder are all composed of a plurality of arc-shaped plates which are spliced with one another, and the purposes of preventing the compaction pile body from being twisted and broken, improving the integrity of the pile body, improving the compaction effect and effectively reducing negative friction can be achieved.

Owner:LANZHOU PETROCHEM COLLEGE OF VOCATIONAL TECH

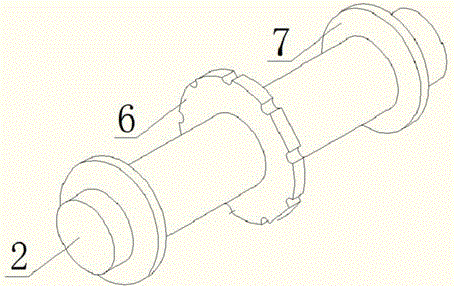

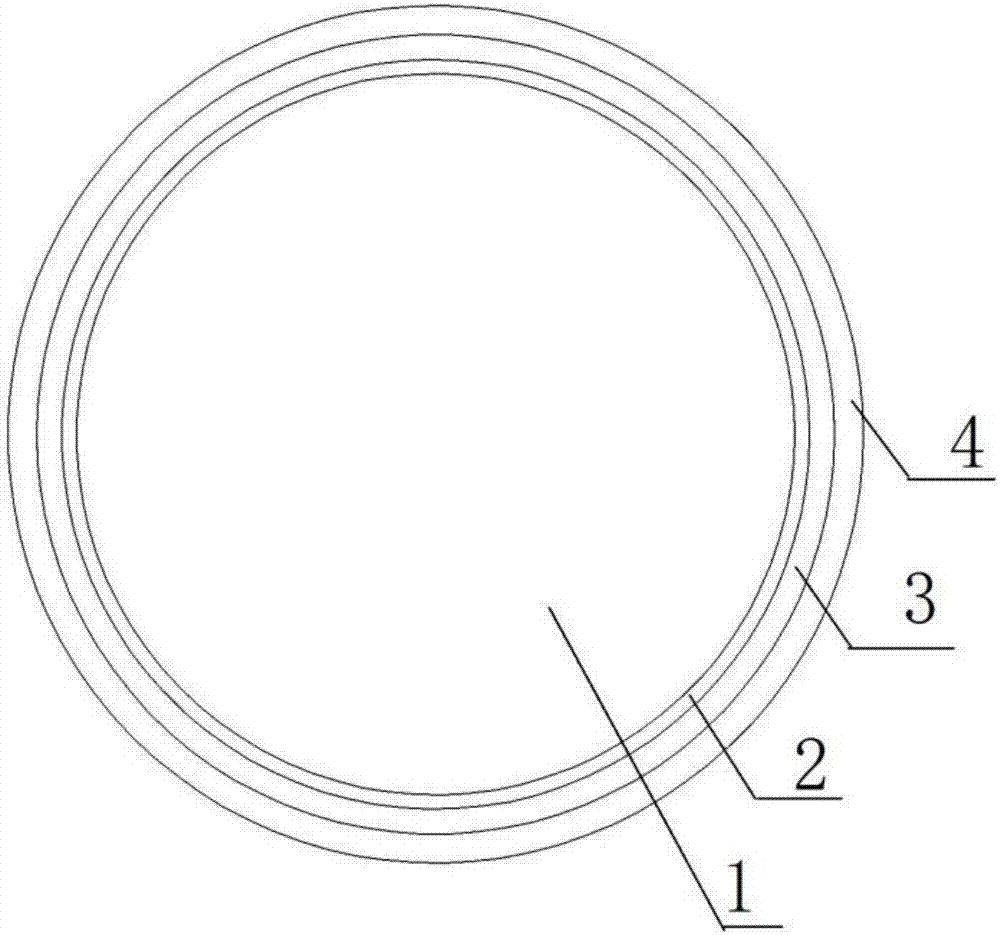

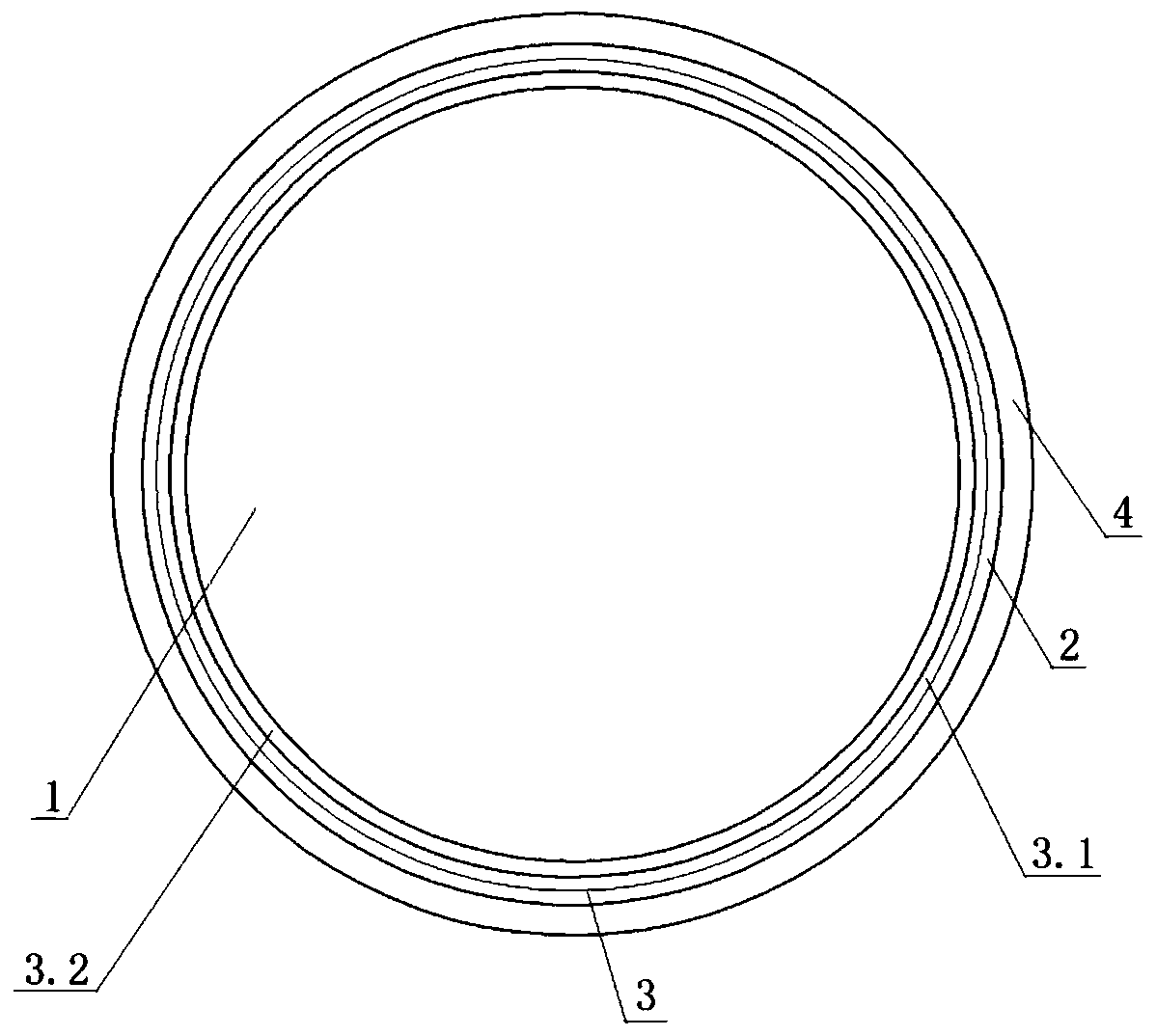

A combined phc pipe pile that reduces negative frictional resistance

InactiveCN105200988BReduce or even eliminate negative frictionIncrease side frictionBulkheads/pilesFriction effectEngineering

The invention discloses a combined PHC pipe pile capable of reducing a negative friction effect. The combined PHC pipe pile comprises an upper PHC pipe pile section and a lower PHC pipe pile section, wherein a telescopic part is arranged between the two PHC pipe pile sections; the telescopic part comprises a telescopic part top plate, a telescopic part bottom plate and a hydraulic jack positioned between the telescopic part top plate and the telescopic part bottom plate; a hook is welded at the lower bottom surface of the telescopic part top plate; small pulleys are welded at the top surface of the telescopic part bottom plate; the telescopic part is internally provided with a steel strand; one end of the steel strand is tied to the hook at the lower bottom surface of the telescopic top plate, and the other end of the steel strand downwards bypasses two small pulleys on the telescopic part bottom plate, then upwards passes through a small hole of the telescopic part top plate and then is connected with an intra-pile bracket on the top of the PHC pipe pile through the interior of the PHC pipe pile; the top of the PHC pipe pile is provided with a displacement transfer device. According to the combined PHC pipe pile, the hydraulic jack is utilized for actively settling the upper PHC pipe pile section, so that the negative friction resistance of a pile body can be effectively reduced or even eliminated.

Owner:HOHAI UNIV

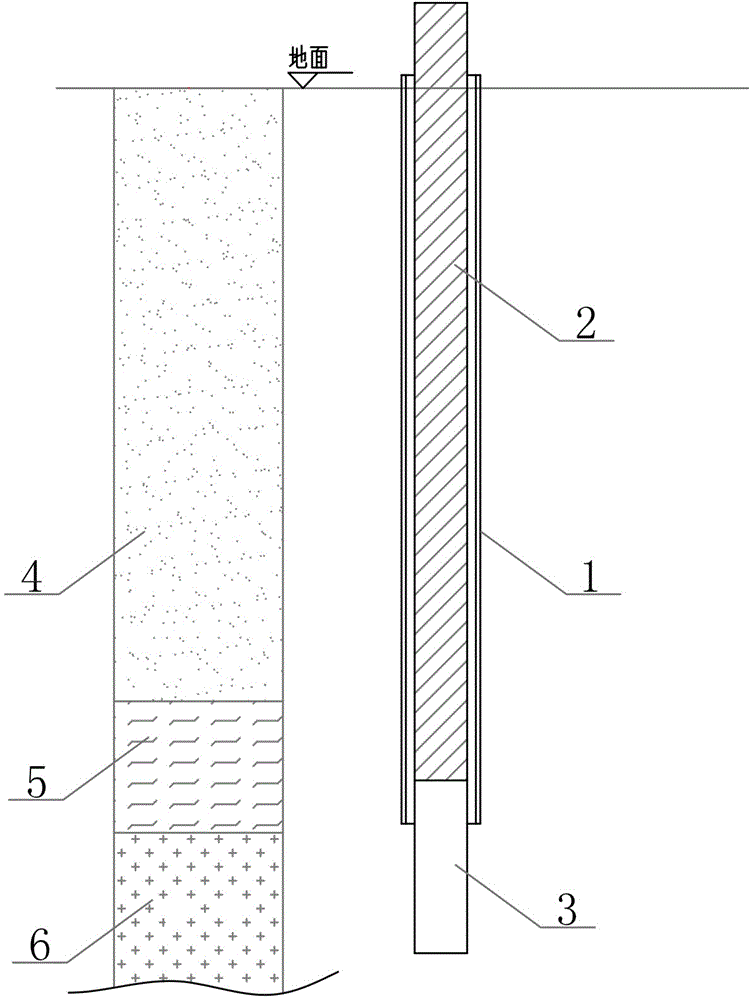

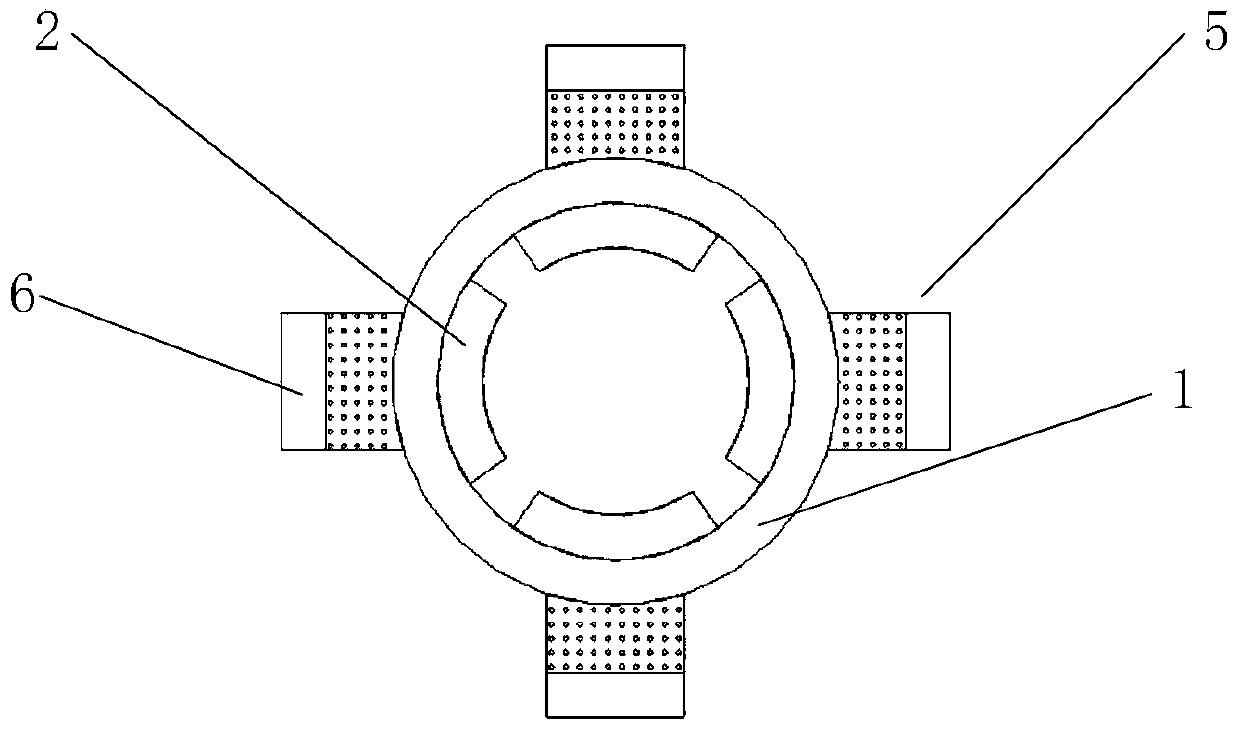

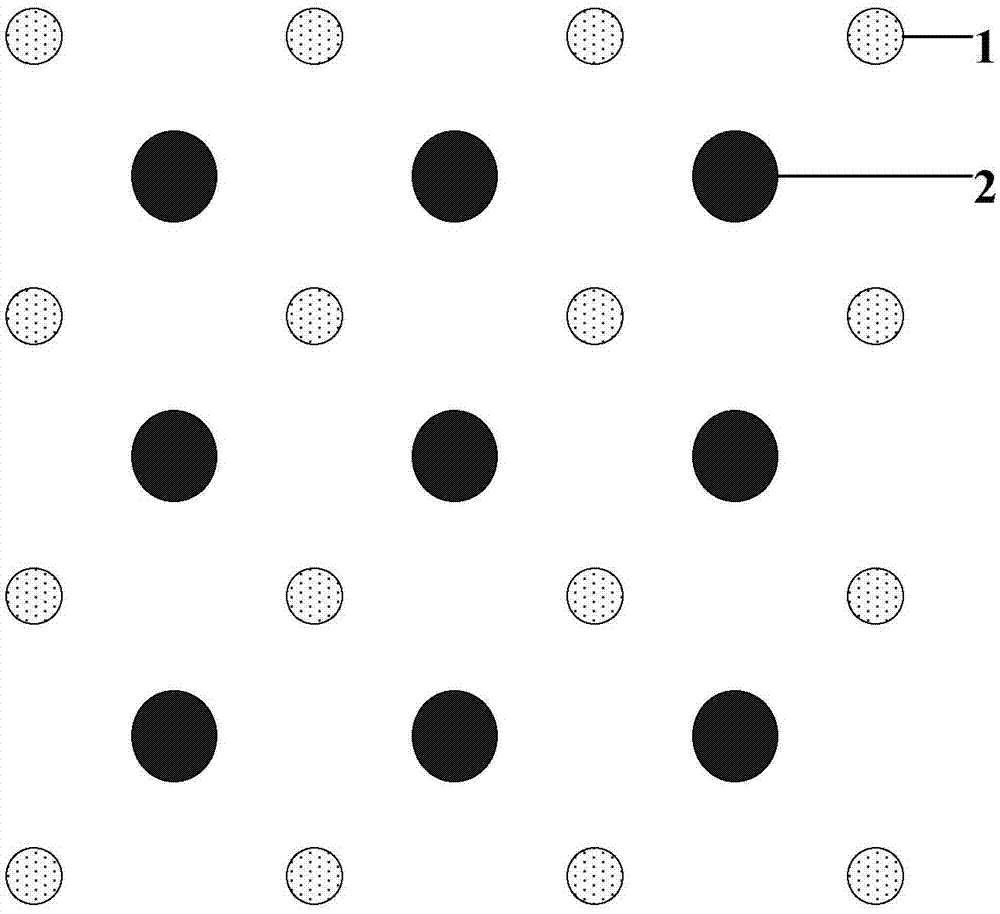

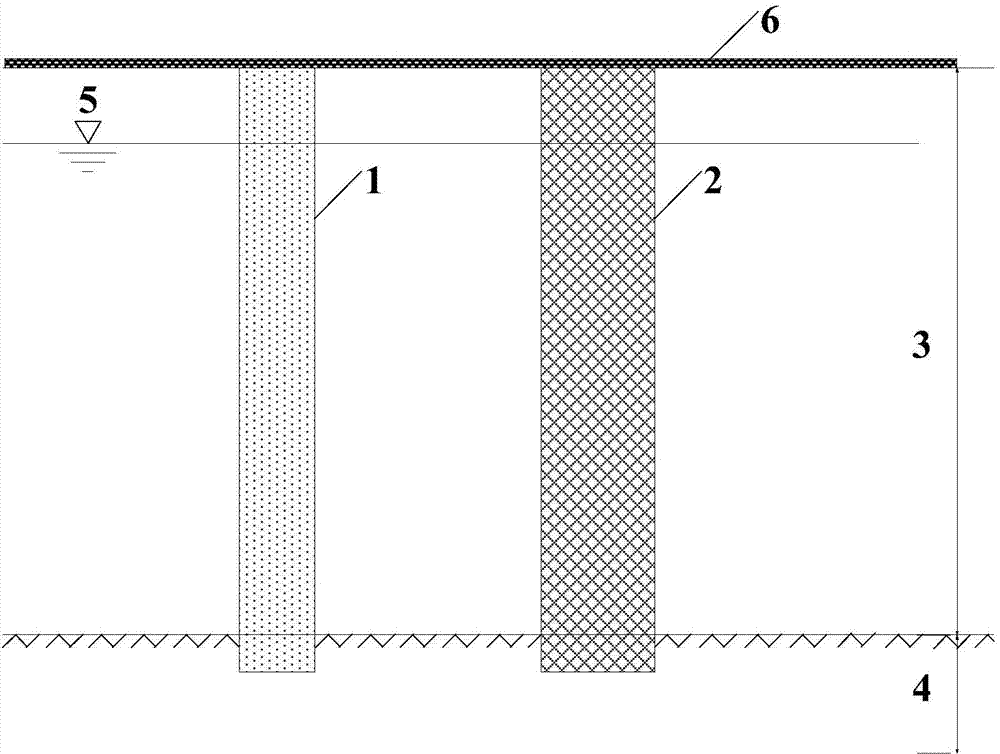

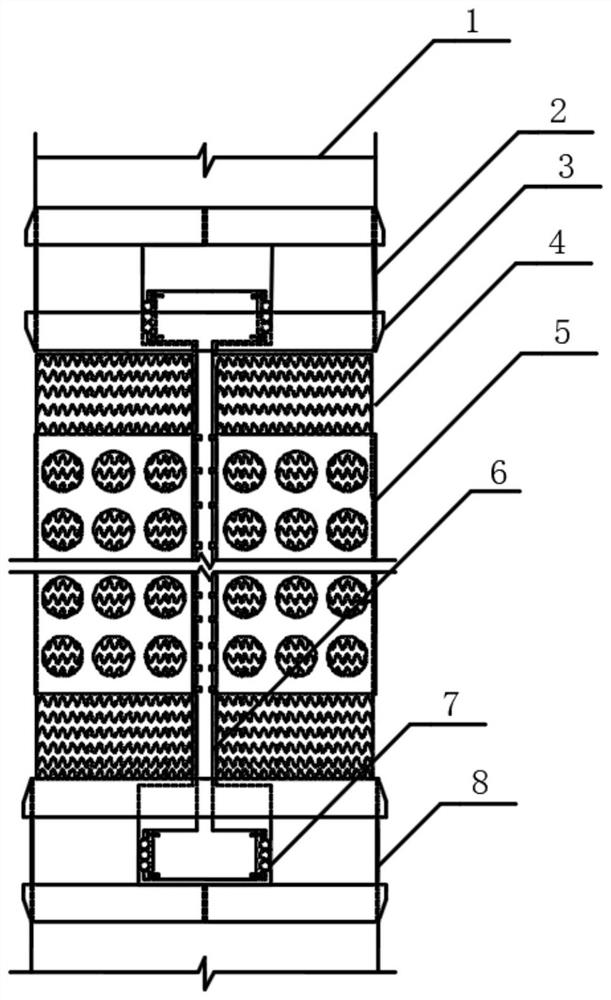

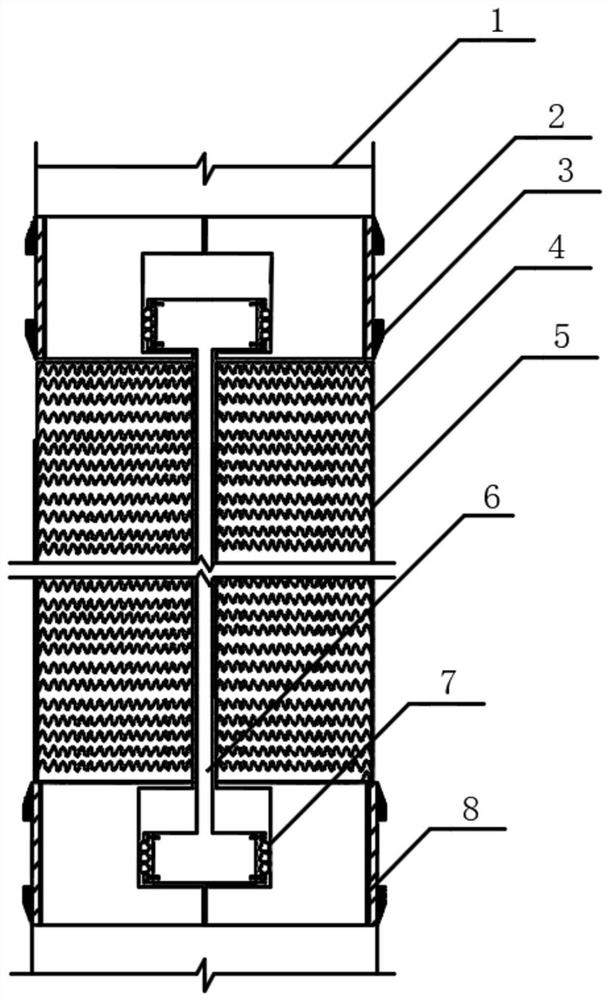

Setting and Treatment Method of Drainage Swirl Grouting Pile Foundation Used in Underconsolidated Soil

The invention discloses an arrangement and a processing method for a long firm and oil solidated water draining chemical churning pile foundation. The water draining chemical churning pile foundation comprises water draining immersed tube compaction gravel piles (1) and high pressure jet grouting piles (2). The water draining immersed tube compaction gravel piles (1) and the high pressure jet grouting piles (2) are arranged in separating row and intersection, a gravel water draining cushion ply (6) is paved on the surface of the base of the upper portion of the water draining immersed tube compaction gravel piles (1) and the high pressure jet grouting piles (2), the high pressure jet grouting piles (2) are arranged at a diagonal intersection point of four adjacent water draining immersed tube compaction gravel piles (1), and each of the high pressure jet grouting piles (2) forms a isosceles right triangle arrangement with two adjacent adjacent water draining immersed tube compaction gravel piles (1). The immersed tube compaction gravel piles and the high pressure jet grouting piles are utilized in combination, the water draining immersed tube compaction gravel piles are constructed first, and then the high pressure jet grouting piles are constructed. The water draining immersed tube compaction gravel piles (1) and the high pressure jet grouting piles (2) are arranged in separating row and intersection, and the gravel water draining cushion ply (6) is paved on the surface of the base of the upper portion of the water draining immersed tube compaction gravel piles (1) and the high pressure jet grouting piles (2), so that bearing capacity of the base is increased.

Owner:SOUTHEAST UNIV

A Construction Method of Underwater Coating for Reducing Friction Force of Pile Body

ActiveCN107447752BReduce adverse effectsReduce negative frictionGeotextilesBulkheads/pilesLap jointBase oil

Owner:长江河湖建设有限公司

A pretreatment method for ultra-thick waste soil foundation

A pretreatment method for a super-thick waste soil foundation comprises the following steps that 1, the surface of a super-thick waste soil field is leveled and compacted; 2, air permeability preventing composite geotechnical cloth is laid on the surface of the super-thick waste soil field; 3, the super-thick waste soil field where the air permeability preventing composite geotechnical cloth is laid is constructed for hole drilling; 4, a vacuum negative pressure method or a deep degradation method or an incineration method is determined as a treatment method of the super-thick waste soil foundation; and 5, the portions, around drilled holes, of the super-thick waste soil foundation are ram-reamed and compacted, and pile foundation engineering is constructed. According to the pretreatment method, a super-thick waste soil layer is pretreated into a regenerated soil layer, so that the foundation soil strength is improved, the foundation settlement amount is reduced, and negative friction resistance of foundation soil to latterly constructed piles is reduced; and the technical problems that a traditional foundation treatment method is narrow in application range and limited in reinforced depth, and the bearing force of a reinforced foundation cannot meet design requirements are solved.

Owner:黄明 +1

Method for reinforcing existing pile foundation in collapsed loess area by slip casting

InactiveCN102162255BReduce negative frictionImprove carrying capacityFoundation repairBulkheads/pilesCheck valveUltimate tensile strength

The invention discloses a method for reinforcing an existing pile foundation in a collapsed loess area by slip casting. The method is a method required for reinforcement of a checking valve pipe of the existing pipe foundation adjacent to an underground project during construction. In the method, checking valve pipe slip casting is adopted as a main reinforcing technical measure; and the method comprises the following steps of: distributing slip casting hole positions on a pile foundation bearing table and at the periphery of the pile foundation bearing table within a certain range; after a driller finishes drilling, installing a checking valve pipe; filling a prepared shell material into an annular space between the checking valve pipe and the wall of the drilled hole; when the shell material reaches certain strength, reinforcing the soil at the periphery of the pile foundation by slip casting; after slip casting, covering a slip casting protective cover; and performing slip casting at any time as required. By the reinforcing method, a pile body negative friction force of the soil body at the periphery of the pile foundation in the collapsed loess area due to collapsibility can be reduced, the bearing capacity of the pile foundation is enhanced, the settlement of the pile foundation due to the underground project construction is decreased, and an aim of reinforcing by slip casting is fulfilled.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A crawler steel pipe pile with reduced negative friction resistance and its construction method

ActiveCN106836260BIncrease positive frictionReduce negative frictionBulkheads/pilesEngineeringFoundation engineering

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

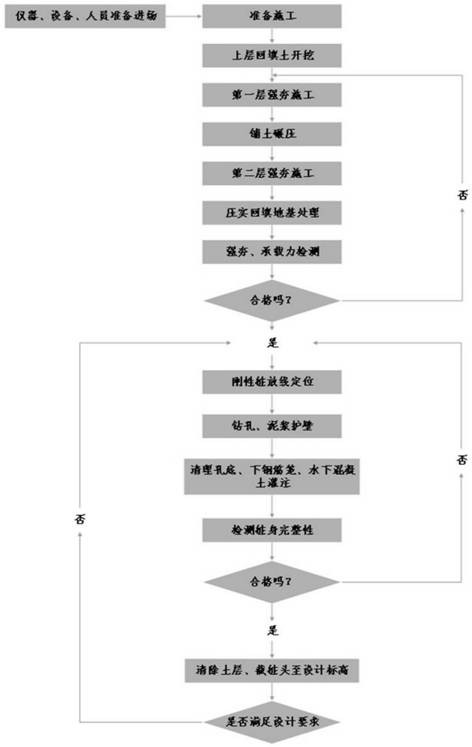

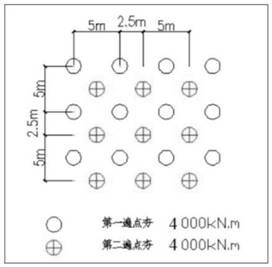

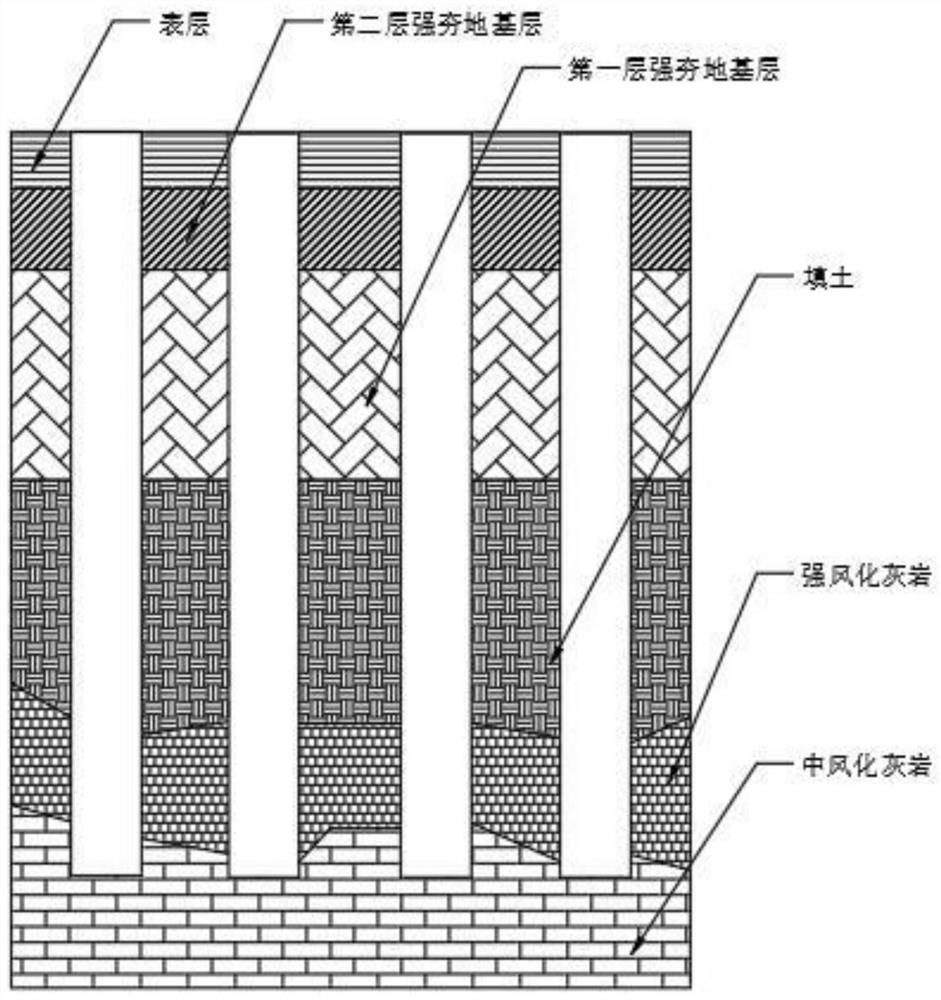

High fill area end bearing pile foundation construction method

PendingCN114232593AHigh hole-forming value retention rateReduce negative frictionBulkheads/pilesSoil preservationDynamic compactionArchitectural engineering

The invention relates to the technical field of civil engineering, in particular to a high fill area end bearing pile foundation construction method which comprises the steps of construction preparation, surface layer backfill soil excavation, first layer dynamic compaction foundation layer construction, soil paving and rolling compaction, second layer dynamic compaction foundation layer construction, compaction backfill foundation treatment, bearing capacity detection, rigid pile paying-off positioning and drilling. According to the construction method for the end bearing pile foundation of the high fill area, the negative friction resistance of backfill soil on the pile side is reduced, it is guaranteed that the pile and the soil are jointly stressed, and the construction efficiency of the end bearing pile foundation of the high fill area is improved. After the foundation which is not suitable for building a high-rise building originally is treated, the requirement for the bearing capacity of the designed foundation can be met, the land utilization rate is greatly increased, the land cost is saved, and compared with an existing replacement filling method for compacting the foundation, construction is fast, economical efficiency is good, and social and economic benefits are remarkable.

Owner:重庆建工第七建筑工程有限责任公司

Deep vertical shaft self-adaptive protection device based on constant-resistance large-deformation structure

PendingCN109372515AEffective protectionImprove playbackShaft liningHydro energy generationEngineeringLarge deformation

The invention relates to a deep vertical shaft self-adaptive protection device based on a constant-resistance large-deformation structure. The device is arranged between two of multiple sections of shaft walls which are arranged in a deep vertical shaft from top to bottom. The device comprises an upper module, a lower module, a sealing module and a constant resistance body. The upper module comprises a circular ring-shaped top plate, a hollow annular outer sealing barrel and a constant-resistance large-deformation rod body, the lower module comprises a circular ring-shaped base, a hollow annular inner sealing barrel and a constant-resistance large-deformation sleeve, the inner sealing barrel is inserted in the outer sealing barrel, the sealing module comprises a steel wire brush arranged in the inserted gap between the outer sealing barrel and the inner sealing barrel and grease with which the steel wire brush is filled, the constant resistance body is installed on the lower surface ofthe constant-resistance large-deformation rod body, the lower surface of the constant resistance body makes pressing contact with the constant-resistance large-deformation sleeve, the lower surface of the constant resistance body is pressed into the deformation sleeve when pressed by the upper portion, and therefore opening deformation of the deformation sleeve is achieved. Compared with the prior art, the deep vertical shaft self-adaptive protection device has the advantages that protection is effective, sealing performance is good, deep vertical shaft structure safety is ensured, installation is flexible, and monitoring and early warning are achieved.

Owner:TONGJI UNIV

A construction method of special-shaped piles with carbon fiber bag cast-in-place anti-arch curved surface combination

Owner:JIANGSU ZHONGRUI ROAD & BRIDGE CONSTR

Device for negative friction resistance reduction and positive friction resistance transmission of precast pile and using method

ActiveCN112211183AReduce negative frictionNo pollution in the processFoundation testingBulkheads/pilesArchitectural engineeringStructural engineering

The invention discloses a device for negative friction resistance reduction and positive friction resistance transmission of a precast pile and a using method. The device comprises a first fixing part, a degradable disordered wire laminated fiberboard and a second fixing part which are sequentially arranged on the outer side of the precast pile from top to bottom; the first fixing part and the second fixing part are each provided with a cavity, the two cavities are connected through a sliding connecting rod, sliding parts are arranged at the two ends of the sliding connecting rod, and the sliding parts are limited in the cavities to slide up and down; and a porous permeation plate is arranged on the outer side of the degradable disordered filament laminated fiberboard and used for wrappingand fixing the degradable disordered filament laminated fiberboard to the outer side of the precast pile. The device and the method have the advantages that an existing precast pile foundation construction technology is enriched, and the device capable of reducing negative friction resistance of the precast pile and a use technology are developed; and by means of the degradable disordered filament laminated fiberboard, slippage is promoted, the negative friction resistance is further reduced, and the non-pollution and degradable effects are achieved.

Owner:NANJING INST OF TECH +1

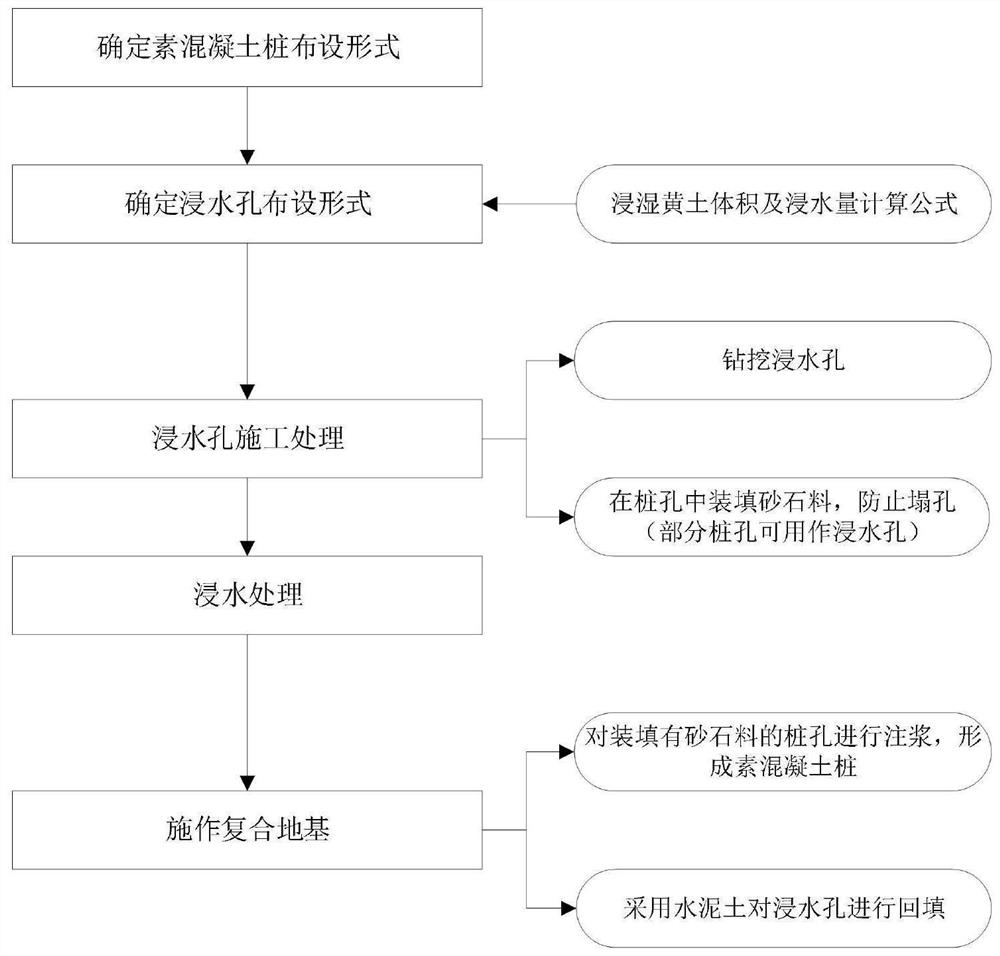

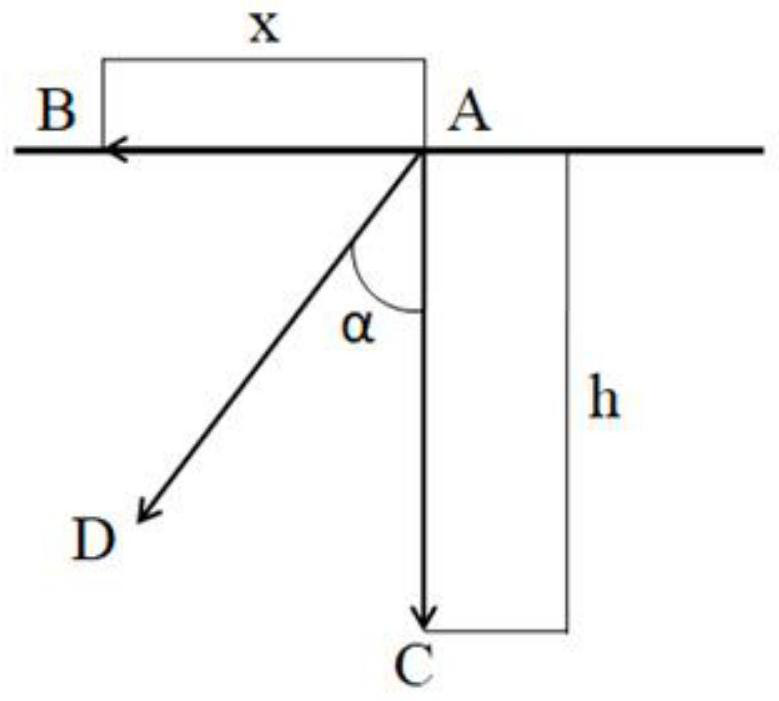

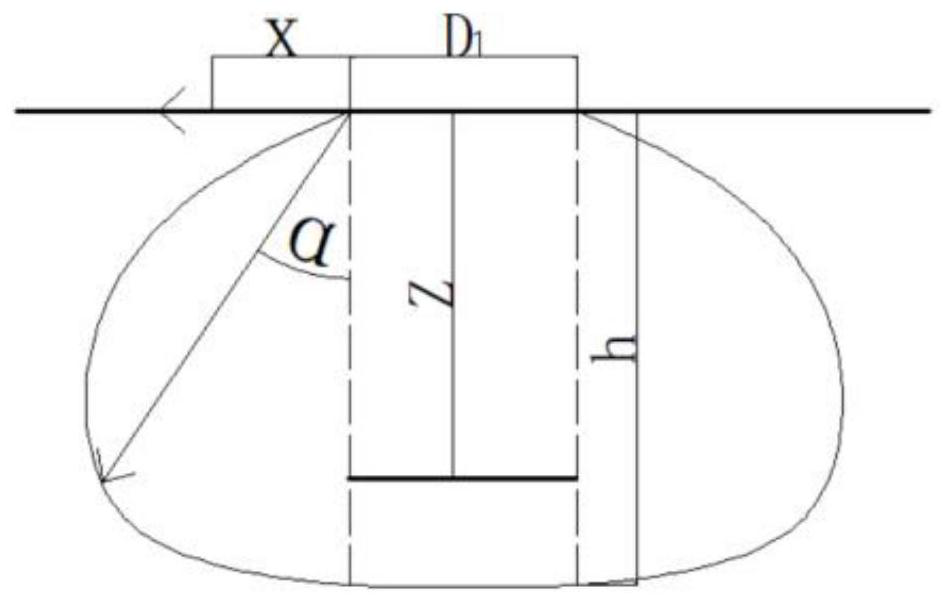

A method for treating collapsible loess foundation with controllable presoaking water

ActiveCN110656642BSolve the problem that the range of water immersion is difficult to controlLong waiting time for resolutionBulkheads/pilesSoil preservationSoil scienceWater volume

The invention discloses a controllable pre-soaking method for treating collapsible loess foundations. When treating collapsible loess foundations, the water-soaking range and the required water-soaking range are calculated according to the known required collapsible elimination range. Determine the layout of the soaking holes, and use the soaking holes to soak the collapsible loess foundation. After the soaking is completed, plain concrete piles are applied to form a composite foundation. The foundation treatment method in the present invention can not only effectively solve the problems of difficult control of the water soaking range and water soaking amount when the original presoaking water method is used to treat collapsible loess foundations, but also solve the problem that in large thickness collapsible loess layers with low water content, DDC At the same time, when the controllable pre-soaking water is used for foundation treatment, the pile foundation can be directly constructed after the immersion is completed, without waiting for the water to dissipate, and without re-drilling to construct the cast-in-place pile, which can effectively Save time and cost.

Owner:XIAN UNIV OF SCI & TECH

Device and method for negative friction resistance reduction and positive friction resistance transmission of prefabricated piles

ActiveCN112211183BReduce negative frictionNo pollution in the processFoundation testingBulkheads/pilesMassageStructural engineering

The invention discloses a prefabricated pile negative friction resistance reduction and positive friction resistance transmission device and use method, comprising: a fixing part 1 sequentially arranged on the outside of the prefabricated pile from top to bottom, a degradable random fiber laminated fiberboard and a fixing part 2. Both the fixed part 1 and the fixed part 2 are provided with a cavity, and the two cavities are connected by a sliding link, and the two ends of the sliding link are provided with a sliding part, and the sliding part is limited up and down in the cavity Sliding; the outside of the degradable random-filament laminated fiberboard is provided with a porous permeable plate, which is used to wrap and fix the degradable random-filament laminated fiberboard on the outside of the prefabricated pile. Advantages: It enriches the existing prefabricated pile foundation construction technology, and develops a device and application technology that can reduce the negative friction resistance of prefabricated piles; through the degradable random fiber laminated fiberboard, the slippage is promoted to further reduce the negative friction resistance, and there is no pollution biodegradable.

Owner:NANJING INST OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com