Deep vertical shaft self-adaptive protection device based on constant-resistance large-deformation structure

A technology of constant resistance, large deformation and protection device, which is applied in shaft equipment, shaft lining, mining equipment, etc., can solve the problems of long construction period and high treatment cost, and achieve the effects of prolonging life, ensuring production safety and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

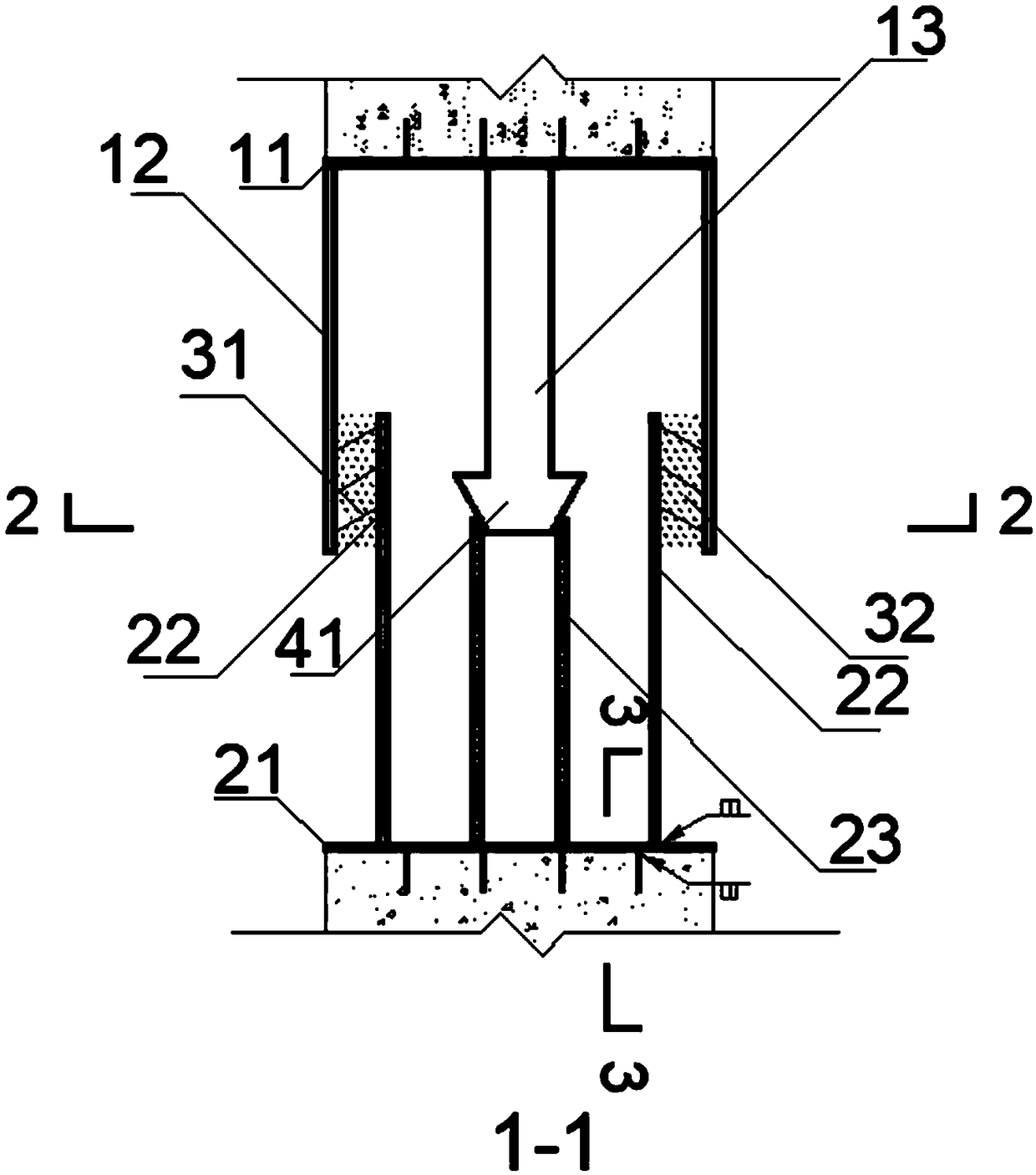

[0050] In this case, a deep shaft self-adaptive protection device based on constant resistance and large deformation structure, such as figure 1 As shown, the constant resistance large deformation device is fixed on the wellbore through the top plate and the base, the sealing device is welded on the top plate and the base, and the wire brush is fixed on the inner sealing cylinder. When the negative friction resistance of the wellbore reaches a certain value, the constant resistance body in the large deformation device overcomes the friction force and moves downward, thereby releasing a certain negative friction resistance to protect the shaft of the vertical shaft.

[0051] The device includes: a constant resistance large deformation device, a sealing structure and a connecting structure.

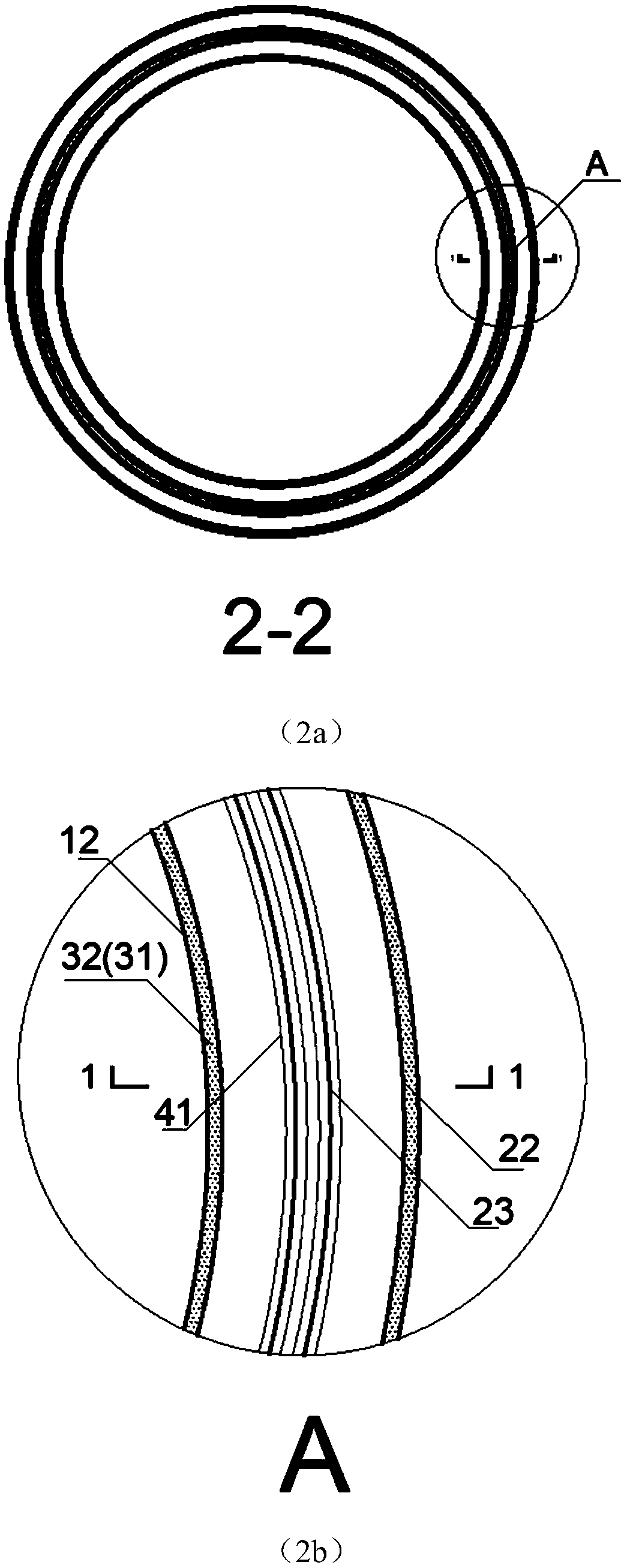

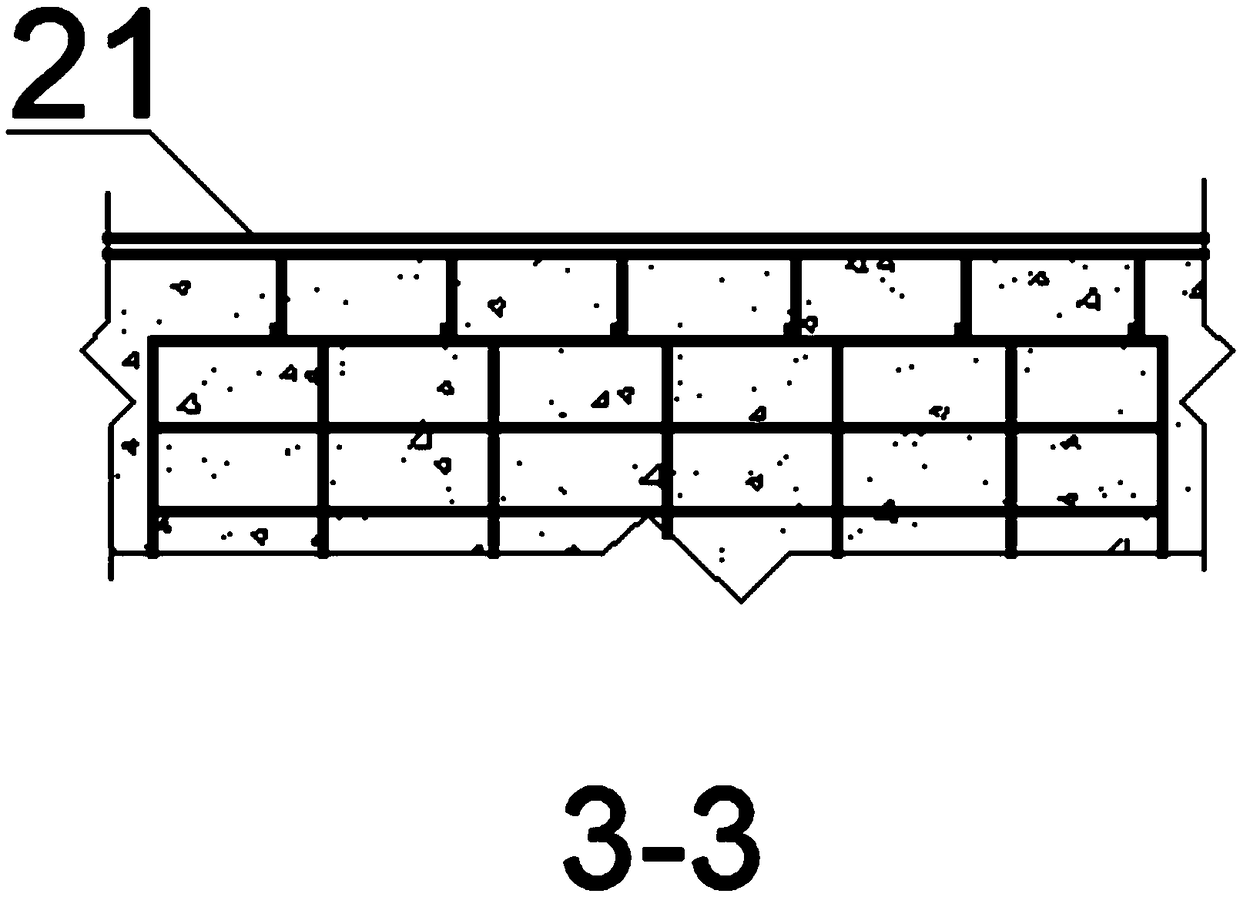

[0052] The sealing structure includes an inner sealing cylinder 21, an outer sealing cylinder 22, a wire brush 23 and grease 24. When the device is installed 100 meters from the ground, the thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com