Method for improving pile foundation performance of soil-compaction piles by lateral soil-compaction, drainage and consolidation

A technology for drainage consolidation and extruding soil piles is applied in the field of extruding soil piles, which can solve the problems of low permeability, slow consolidation and low lateral resistance index of high water content silt soft soil foundations, and achieve the effect of improving the performance of pile foundations. High, the possibility of voiding is reduced, and the effect of reducing the size of the base plane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific examples.

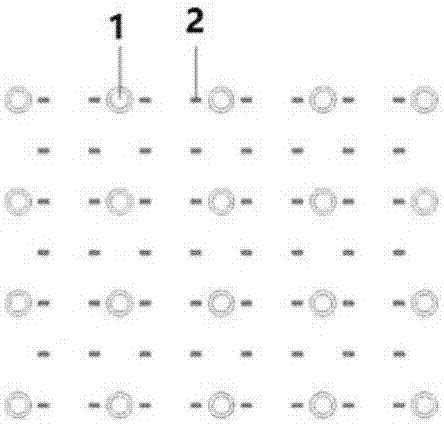

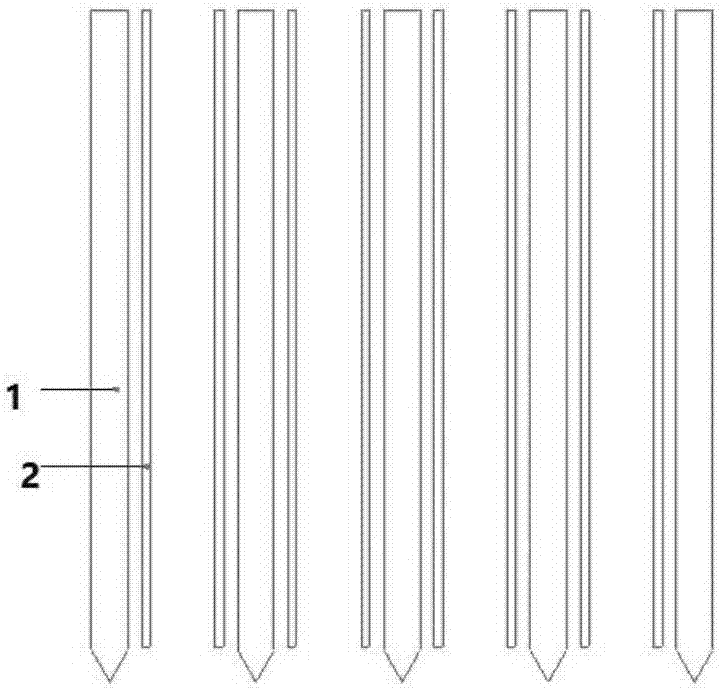

[0029] After the site is leveled, before constructing the soil-squeezing piles, a vertical drainage body 2, such as a drainage board, is inserted into the foundation between the soil-squeezing piles 1 to form a drainage channel; then, when the soil-squeezing piles are constructed. When constructing soil-squeezing piles, due to the soil-squeezing effect of the piles, the soil around the piles is squeezed laterally, and the vertical drainage body is used for drainage and consolidation to improve the physical and mechanical indicators of the soil around the piles, thereby improving the performance of the pile foundation.

[0030] Such as figure 1 and figure 2 As shown in , two vertical drainage bodies 2 are respectively arranged between every two soil-squeezing piles 1, and the distance between the vertical drainage bodies 2 and the soil-squeezing piles 1 is 1 meter, which can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com