Composite foundation pile with lower portion enlarged diameter section and construction method of composite foundation pile

A construction method and composite foundation technology, which is applied in the field of foundation engineering, can solve the problems of waste, pile diameter, pile length increase, etc., and achieve the effects of short pile length, reduced negative friction resistance, and increased bearing capacity of the lower pile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to specific embodiments.

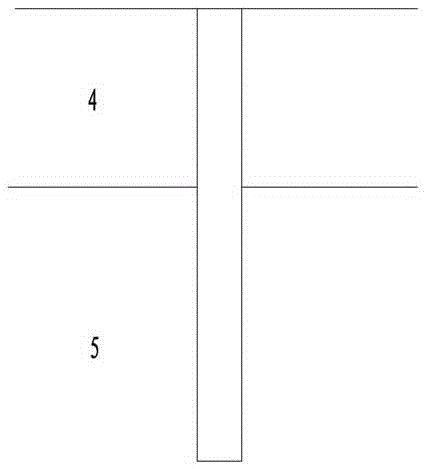

[0036] like figure 1 The shown composite foundation pile with an enlarged diameter section at the lower part includes a precast concrete pile body 1, and the precast concrete pile body is a PHC pipe pile. The upper part of the precast concrete pile body 1 is located in the weaker soil layer 4, the lower part is located in the better soil layer 5, and the lower part of the precast concrete pile body 1 is located outside the better soil layer 5 with a cast-in-place pile 3. The cast-in-place pile 3 includes a cylindrical pile body 32 and a conical cylinder 31 connected to the upper part of the pile body 32. The diameter of the lower bottom surface of the conical cylinder 31 is equal to the diameter of the pile body 32, and the pile body 32 and the conical cylinder 31 is an integral structure, and the included angle between the generatrix of the conical cylinder 31 and the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com