Setting and Treatment Method of Drainage Swirl Grouting Pile Foundation Used in Underconsolidated Soil

A treatment method and technology of under-consolidated soil, which is applied in the field of special foundation treatment in geotechnical engineering, to achieve the effect of reducing post-construction settlement, facilitating promotion, and shortening drainage distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

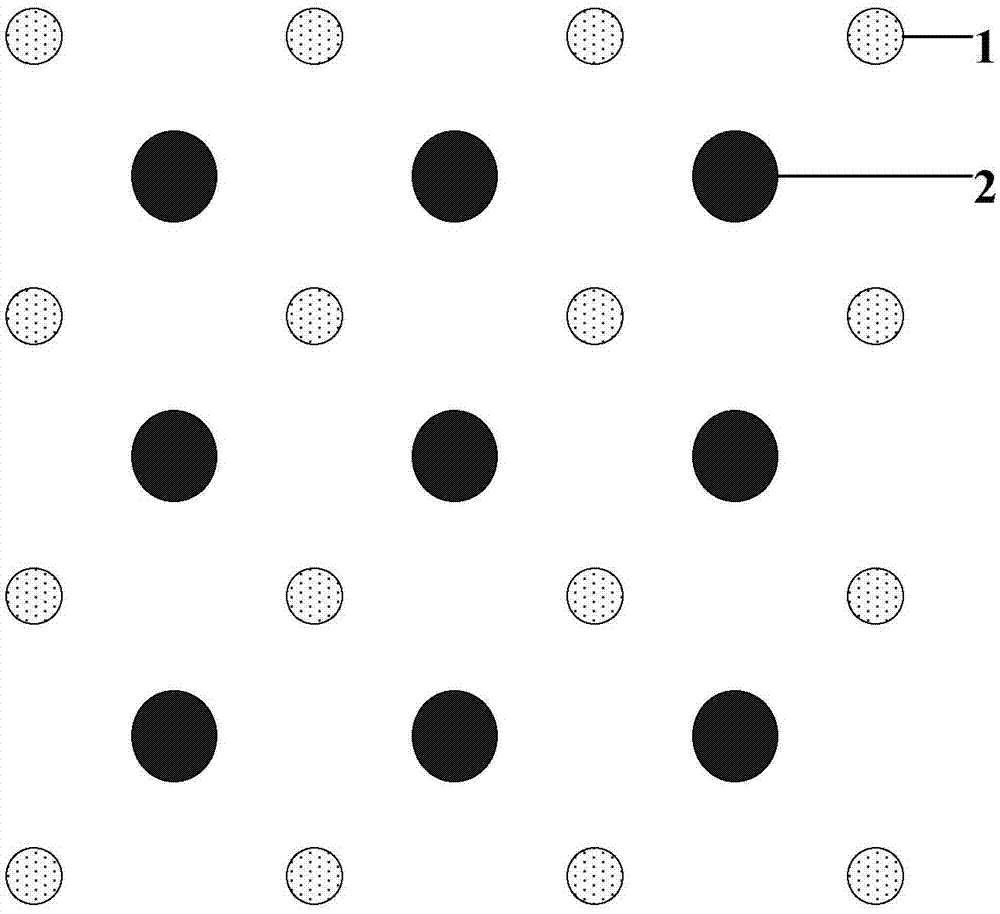

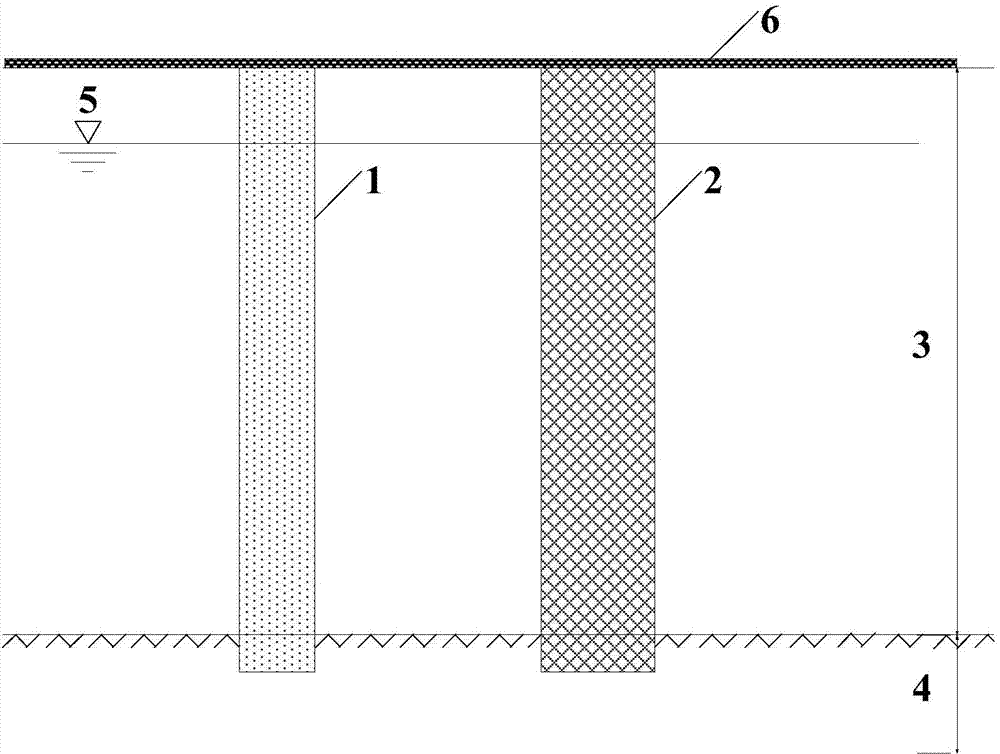

[0018] 1) Immersed tube compacted sand and gravel pile construction: the material of the pile body is gravel, pebbles, stone chips and other hard materials, the filling coefficient is 1.1-1.3, and the diameter of the gravel is between 20-50mm. According to different site requirements, the construction of immersed tube compacted sand and gravel piles can adopt pile methods such as vibrating tube sinking method, hammer sinking tube method or impact hole forming. To eliminate the liquefaction effect of silt and sandy soil, it is suitable to adopt the vibrating immersed tube method. The construction procedure of immersed tube compacted sand and gravel piles should be constructed from the periphery to the middle in the silt and sandy soil stratum, and from the middle to the periphery in the cohesive soil stratum. If local density is not good for construction, jumping or row-by-row construction can be carried out. The length of the immersed tube compacted sand-stone pile is between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com