Method for reinforcing existing pile foundation in collapsed loess area by slip casting

A technology of collapsible loess and grouting reinforcement, which is applied in the repair of foundation structures, sheet pile walls, foundation structure engineering, etc., can solve the problems of different construction techniques and reinforcement costs, and achieve the goals of reducing settlement and improving bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

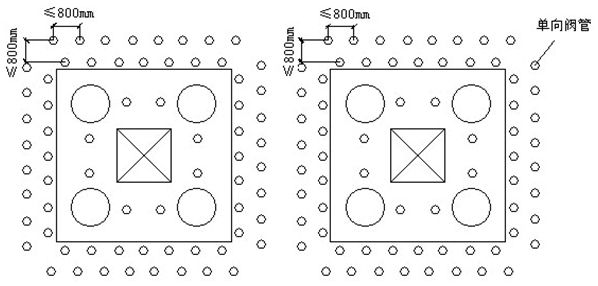

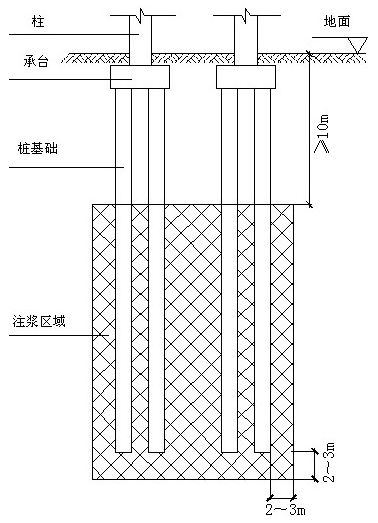

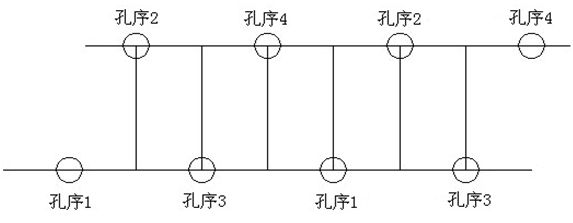

[0019] As a grouting process with strong adaptability, the one-way valve pipe grouting method is currently widely used in subway projects. It has the characteristics of sequential, segmental, fixed depth, quantitative, intermittent, and repeated grouting, and The one-way valve pipe grouting method is simple and fast in construction, and the construction difficulty is low. The construction equipment can be carried out in a narrow space, the construction period is short, and the impact on the surrounding environment is also small. The applicant cited it in the pile foundation reinforcement. These characteristics can be fully utilized, and it can reduce the negative friction of the pile body caused by the collapsibility of the soil around the pile foundation in the collapsible loess area, and has a better effect on the reinforcement of the pile foundation. A new pile foundation reinforcement method in the area to meet the needs of existing reinforcement works.

[0020] This examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com