A Construction Method of Underwater Coating for Reducing Friction Force of Pile Body

A technology of negative friction force and construction method, which is applied in the direction of geotextile, sheet pile wall, foundation structure engineering, etc., can solve the problems of collision damaged pile body investment, failure to popularize, and poor fixation, etc., to achieve small investment and reduction The effect of small adverse effects and convenient material collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

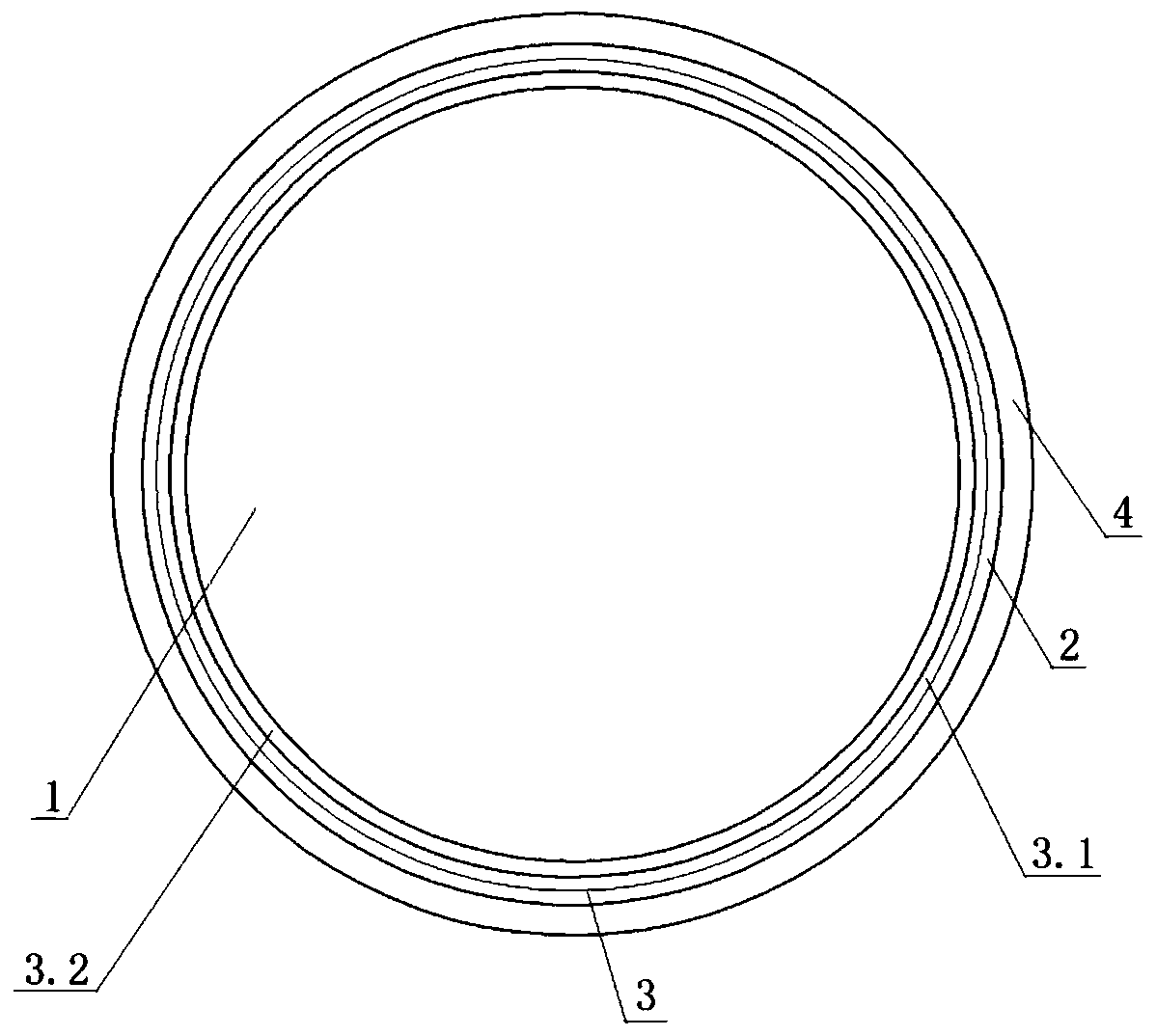

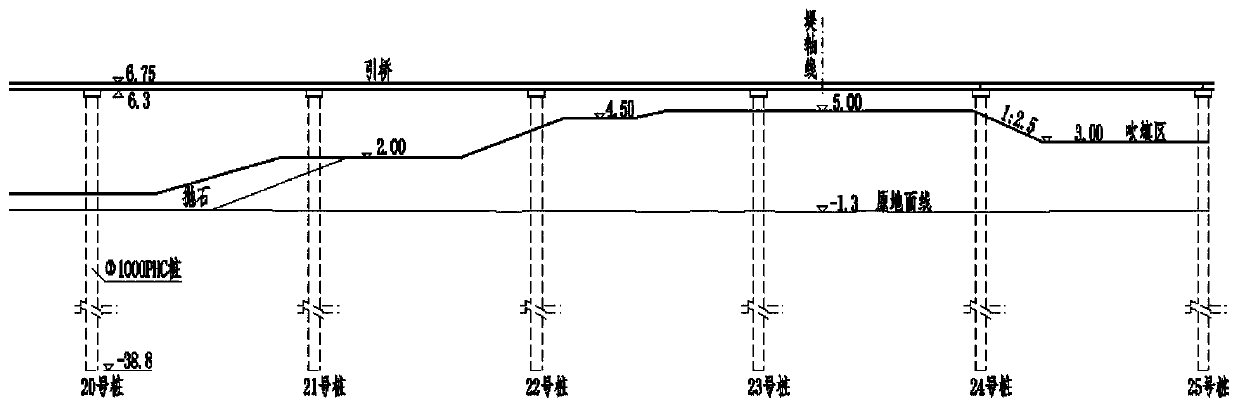

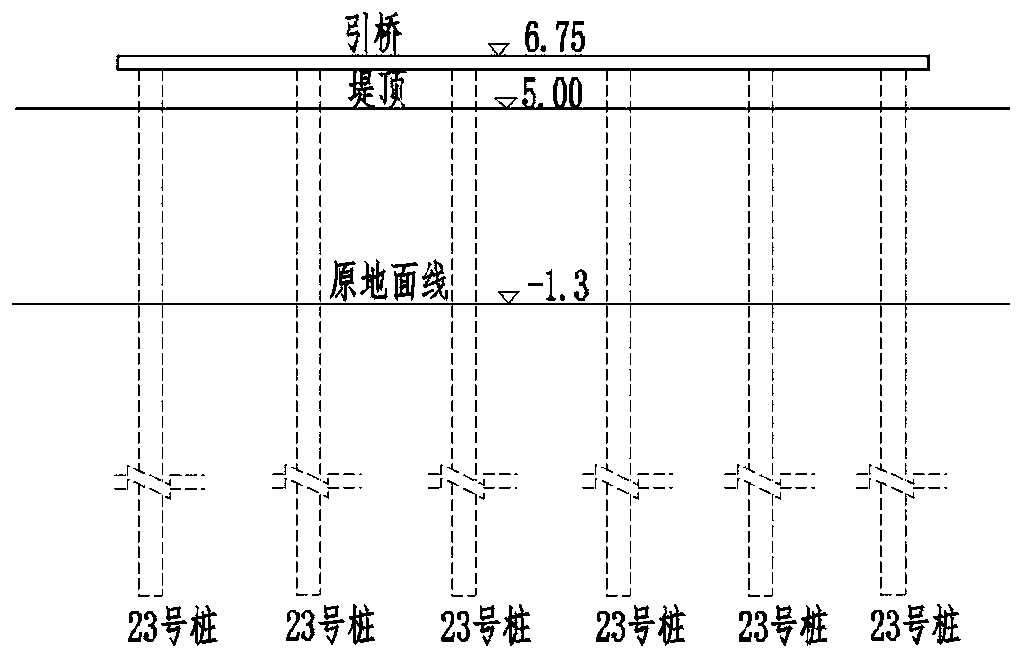

[0023] The part of the pile body that is located underwater is the underwater pile body 1. A construction method for underwater coating that reduces friction on the pile body in this embodiment includes:

[0024] A geotextile sheet matching the size of the underwater pile body 1 is cut from the geotextile 4, and the surface of the geotextile sheet is sequentially coated with cold primer and the lower asphalt layer 3 is laid. The processed asphalt-coated geotextile sheet is made of Transport the asphalt-coated cloth to the construction site manually, wrap the underwater pile body 1 tightly and reinforce it; during construction, several geotextile sheets are constructed sequentially from the lower end of the underwater pile body 1 to the upper section, Two adjacent geotextile sheets are lapped together. If necessary, two layers of geotextile sheets can be wrapped at the same section height.

[0025] After the geotextile sheet is smeared with cold primer, the first layer of asph...

Embodiment 2

[0032] Heat the asphalt to 165°C to lay the first asphalt layer 3.1. The softening point of the asphalt used in the first asphalt layer 3.1 is 55°C, and the penetration at 25°C is 60dmm.

[0033] In this embodiment, the asphalt is heated to 165° C., and poured on the surface of the pile body above the water after the cold base oil has penetrated or volatilized, and the thickness of the upper asphalt layer is 9 mm. The asphalt used in the upper bituminous layer has a softening point of 55°C and a penetration of 60dmm at 25°C. The geotextile 4 is wrapped on the surface of the asphalt layer and finally reinforced outside the geotextile 4 . Other contents of the technical solution of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0035] Heat the asphalt to 180°C to lay the first asphalt layer 3.1. The softening point of the asphalt used in the first asphalt layer 3.1 is 60°C, and the penetration at 25°C is 70dmm.

[0036] Heat the asphalt to 180°C and pour it on the surface of the pile body above the water after the cold base oil has penetrated or volatilized. The thickness of the upper asphalt layer is 10mm. The asphalt used in the upper bituminous layer has a softening point of 60°C and a penetration of 70dmm at 25°C. The geotextile 4 is wrapped on the surface of the asphalt layer and finally reinforced outside the geotextile 4 . Other contents of the technical solution of this embodiment are the same as those of Embodiment 1.

[0037] Through the construction method described in this embodiment, an underwater coating structure that reduces the frictional force of the pile body is formed on the surface of the underwater pile body 1. The coating structure includes:

[0038]The surface of the underwat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com