Upper straight rod and lower expanded-base structure cast-in-place pile capable of reducing negative frictional resistance and construction method thereof

A technology of negative friction resistance and cast-in-situ piles, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of superstructure damage, increased load of end-bearing piles, affecting the appearance or function of buildings, etc. Achieve the effect of good negative friction resistance and reduce negative friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

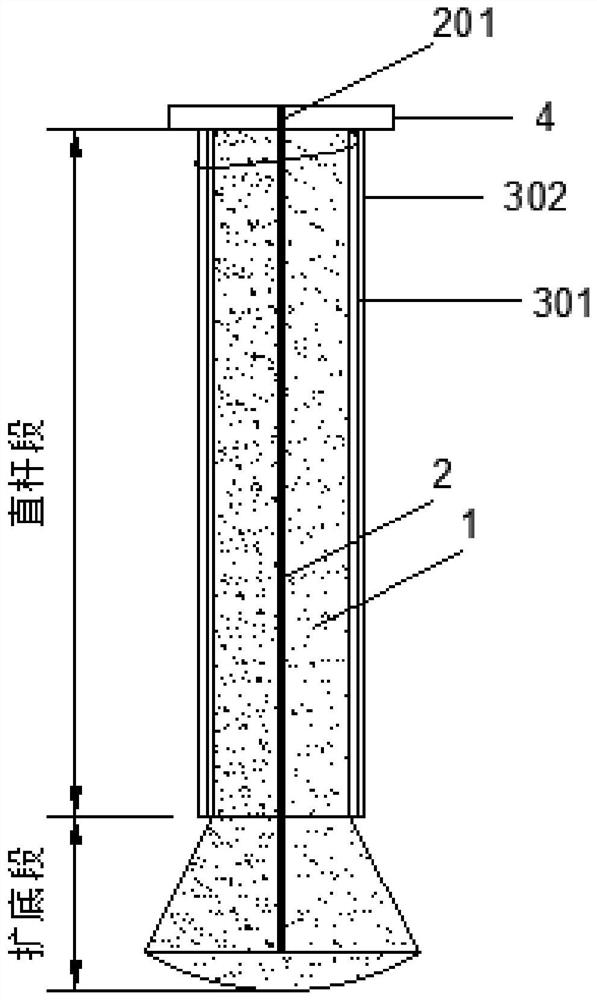

[0031] Such as figure 1 As shown, the present invention includes a concrete pouring pile 1, a prestressed steel bar 2 located in the concrete pouring pile 1, an external casing 3 of the pile body outside the concrete pouring pile 1, and a cap 4 arranged at the upper end of the concrete pouring pile 1.

[0032] Such as figure 1 As shown, the concrete pouring pile 1 is directly connected by the upper straight bar section and the lower bottom expanding section, and the prestressed steel bar 2 is coaxially arranged with the concrete pouring pile 1 to form an upper straight bar and a bottom expanding bottom structure pouring pile. The outer wall of the straight part of the concrete cast-in-place pile 1 is covered with the outer sleeve 3 of the pile body. The outer sleeve 3 of the pile body includes an inner sleeve 301 and an outer sleeve 302. The prestressed steel bar 2 is reserved beyond the concrete cast-in-place pile. The joint 201 of the top part of the pile 1 is connected wit...

Embodiment 2

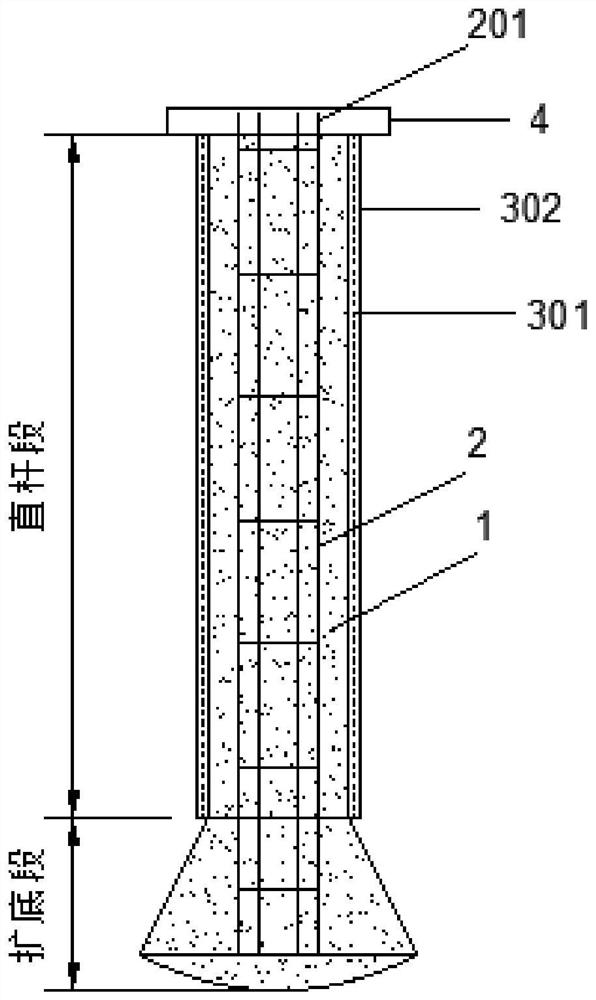

[0038] Such as figure 2 As shown, the present invention includes a concrete pouring pile 1 , a reinforcement cage 2 located in the concrete pouring pile 1 , an external sleeve 3 outside the concrete pouring pile 1 , and a cap 4 arranged at the upper end of the concrete pouring pile 1 .

[0039] The concrete cast-in-place pile 1 is directly connected by the upper straight bar section and the lower bottom-expanded section, and the steel cage 2 is coaxially arranged with the concrete cast-in-place pile 1 to form an upper straight bar and lower bottom-expanded structural cast-in-place pile. The outer wall of the straight part of the concrete cast-in-place pile 1 is covered with the outer sleeve 3 of the pile body. The outer sleeve 3 of the pile body includes an inner sleeve 301 and an outer sleeve 302. The reinforcement cage 2 is reserved beyond the concrete cast-in-place pile 1. The joint 201 of the pile top part is connected with the cap 4.

[0040] The lower end of the cast-i...

Embodiment 3

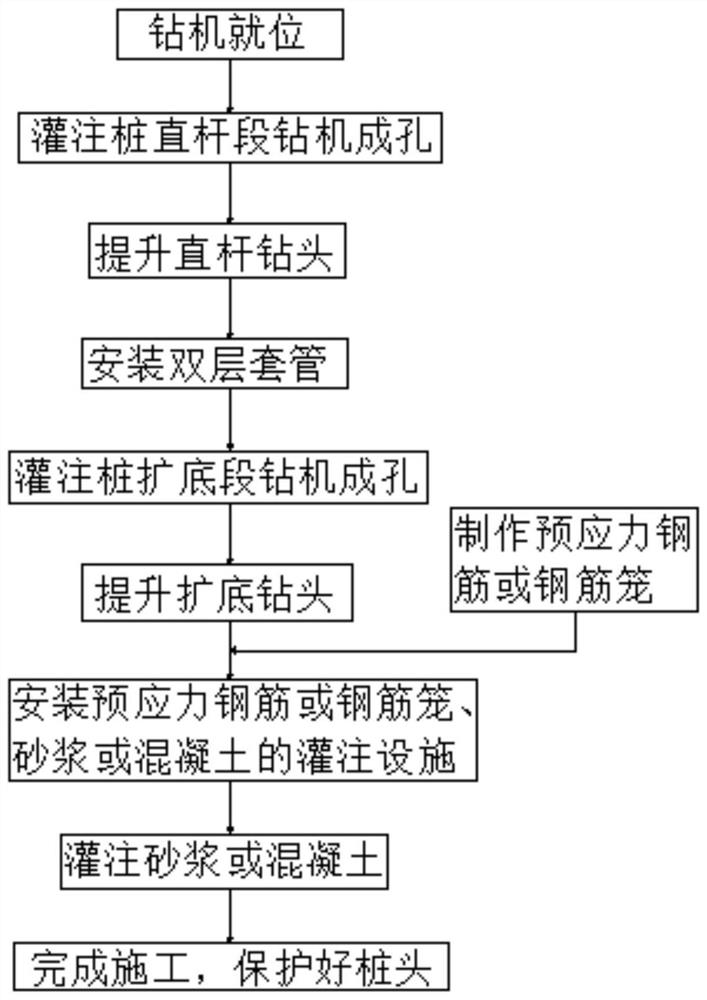

[0044] Such as image 3 Shown, the construction method of the bottom-expanding structure cast-in-place pile under the upper straight bar of the present invention that reduces negative frictional resistance comprises the following steps:

[0045] (1) The drilling rig is in place to make prestressed steel bars or prestressed steel cages;

[0046] The drill bits of the drilling rig are common straight rod drill bits and bottom expansion drill bits, and the drill bits of the drilling rig can be extended as required.

[0047] (2) The straight bar section of the cast-in-place pile with the upper straight bar and the lower bottom expansion structure is drilled into the hole;

[0048] The depth drilled into the ground by the drill bit of the straight section is the length of the straight section of the cast-in-situ pile. The straight drill bit can be extended at the upper end as required.

[0049] (3) Lift the drill bit of the straight bar section;

[0050]The straight-stem drill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com