High fill area end bearing pile foundation construction method

A technology for foundation construction and high filling, which is applied to the end-bearing pile foundation in high filling area and the field of end-bearing pile foundation construction in high filling area, can solve the problem of increasing soil consolidation degree, large negative friction resistance, and hole formation. Difficulty and other problems, to achieve the effect of speeding up the construction progress, reducing negative frictional resistance, and high value retention rate of holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

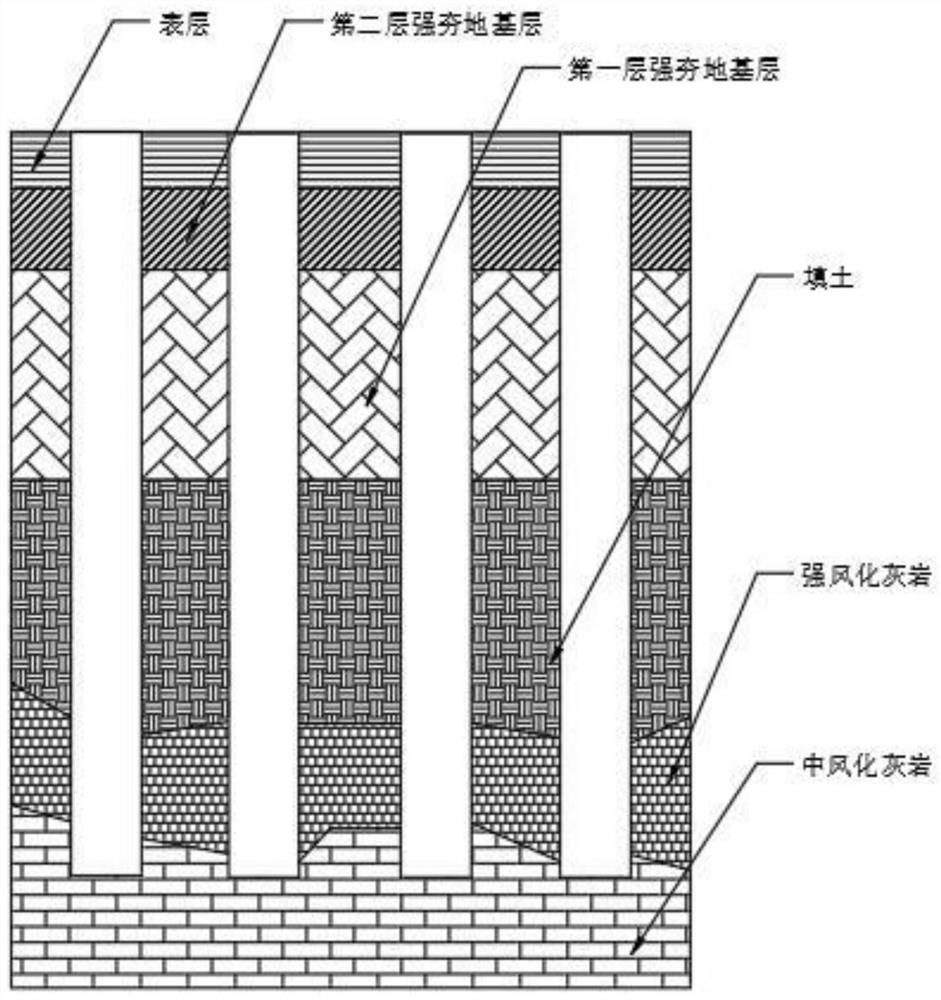

[0039] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

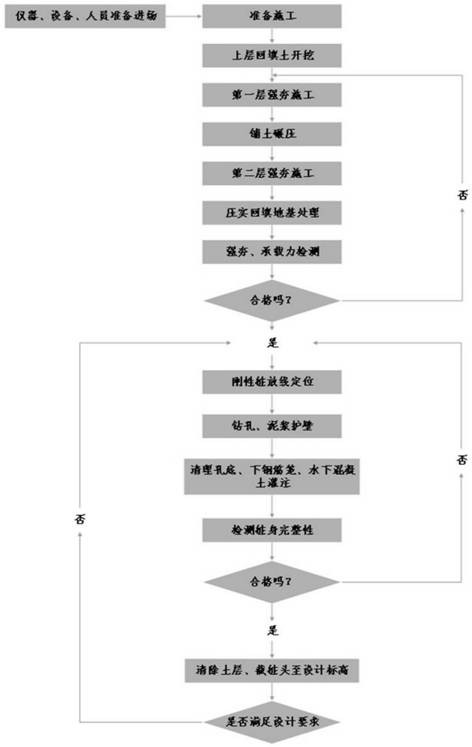

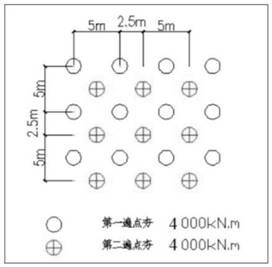

[0040] Such as figure 1 and figure 2 As shown, the construction method of the end-bearing pile foundation in the high fill area includes the following steps, the first step, construction preparation

[0041] (1) The technical person in charge of the project shall make the preparation, report to the technical department of the company for review and approval, and then report to the supervisory unit and the construction unit for final approval. The relevant person in charge, person in charge, on-site management personnel, on-site operators, etc. of the implementation of the construction plan shall make a detailed technical disclosure, and the construction can only be carried out after passing the assessment.

[0042] (2) Check the layout of water and electricity, transportation roads and construction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com