A pretreatment method for ultra-thick waste soil foundation

A soil foundation and waste soil technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of foundation bearing capacity not meeting the design requirements, secondary environmental pollution, and limited reinforcement depth, etc., to reduce the foundation Effects of settlement, pollution reduction, and improvement of foundation soil strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: When the ultra-thick waste soil foundation is an ultra-thick waste land foundation with a porosity greater than 10% and does not contain domestic waste, or an ultra-thick waste land foundation of construction or industrial waste fill.

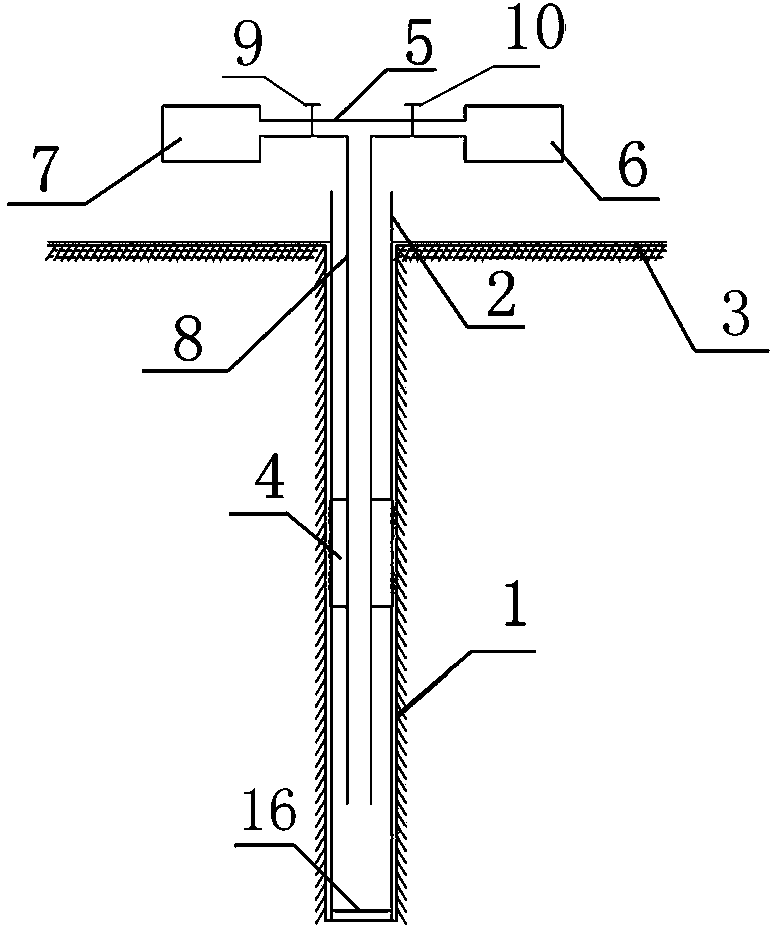

[0044] Such as figure 1 As shown, this ultra-thick waste soil foundation pretreatment method includes the following steps.

[0045] Step 1: Level and compact the surface of the ultra-thick waste soil site.

[0046] Step 2: Laying air-permeable composite geotextile 3 on the surface of the super-thick waste soil site to prevent the surface from ventilating.

[0047] Step 3: Drilling hole 1 is constructed on the ultra-thick waste soil site where air-proof composite geotextile 3 is laid, the hole diameter is greater than 89 mm, and the hole depth is designed to reach the bottom of the waste soil.

[0048] Step 4: Treat the ultra-thick waste soil foundation with vacuum negative pressure method.

[0049] The processing steps a...

Embodiment 2

[0057] Embodiment 2: When the water content in the ultra-thick waste soil foundation is higher than 25%, and the organic matter content is higher than 20%.

[0058] Such as figure 1 As shown, this ultra-thick waste soil foundation pretreatment method includes the following steps.

[0059] Step 1: Level and compact the surface of the ultra-thick waste soil site.

[0060] Step 2: Laying air-permeable composite geotextile 3 on the surface of the super-thick waste soil site to prevent the surface from ventilating.

[0061] Step 3: Drilling 1 is constructed on the super-thick waste soil site where the breathable composite geotextile 3 is laid, the hole diameter is greater than 400 mm, and the hole depth is designed to reach the bottom of the waste soil.

[0062] Step 4: Deeply degrade the domestic waste in the ultra-thick waste soil foundation.

[0063] Deep degradation further includes the following steps.

[0064] Step a: Put degradable materials into the borehole 1, and sele...

Embodiment 3

[0067] Embodiment 3: When the waste soil is located above the groundwater level, the water content is less than 5%, and the plastic and organic matter content is greater than 10%.

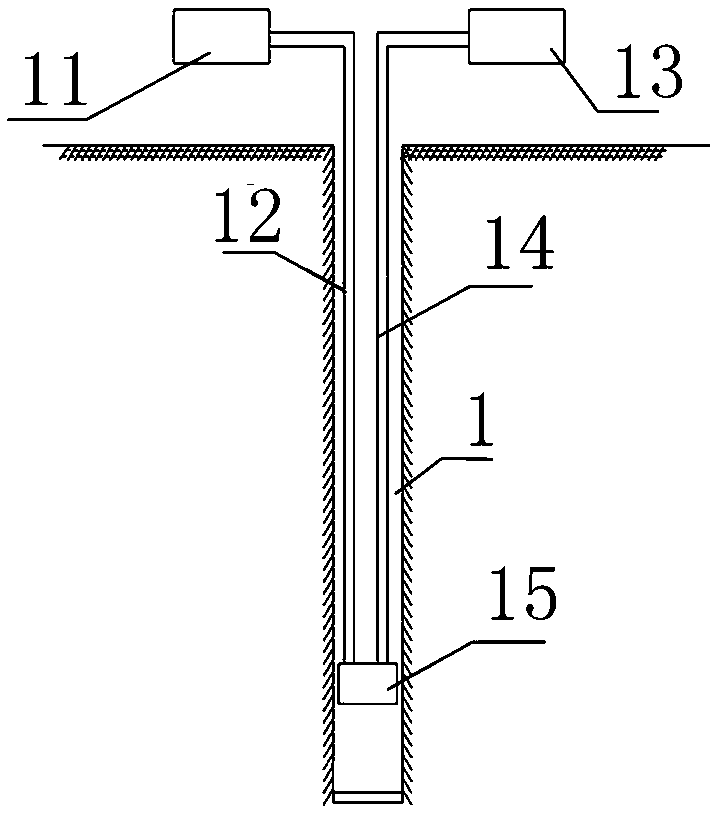

[0068] Such as figure 2 As shown, this ultra-thick waste soil foundation pretreatment method includes the following steps.

[0069] Step 1: Level and compact the surface of the ultra-thick waste soil site.

[0070] Step 2: Laying air-permeable composite geotextile 3 on the surface of the super-thick waste soil site to prevent the surface from ventilating.

[0071] Step 3: Drilling 1 is constructed on the super-thick waste soil site where the breathable composite geotextile 3 is laid, the hole diameter is greater than 400 mm, and the hole depth is designed to reach the bottom of the waste soil.

[0072] Step 4: Incinerate the domestic waste in the ultra-thick waste land foundation.

[0073] Step a: Install the incinerator.

[0074] Step b: Introduce oxygen and liquefied gas into the borehole 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com