Above-water coating construction method for reducing negative friction force of pile body

A technology of negative friction force and construction method, which is applied in the direction of geotextile, sheet pile wall, foundation structure engineering, etc., can solve the problems of collision damaged pile body investment, failure to popularize, poor fixation, etc., to achieve small investment, reduce The effect of small adverse effects and convenient material collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

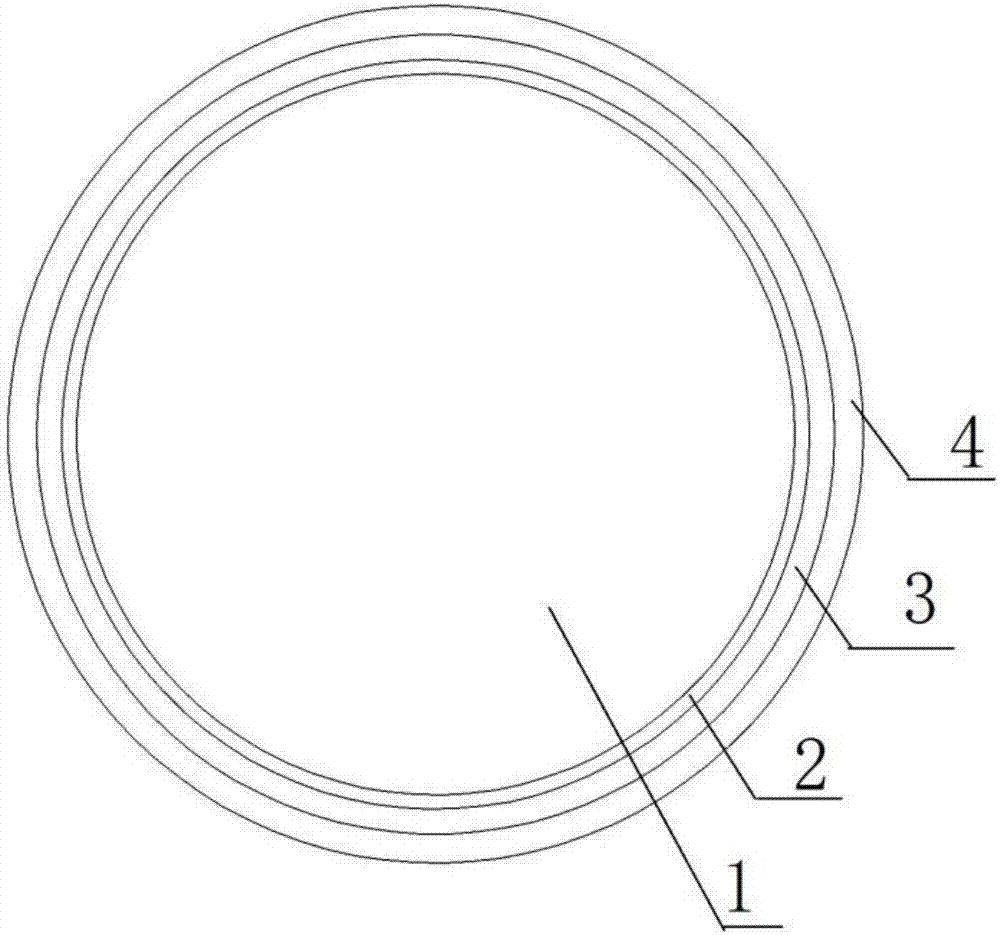

[0023] An above-water coating construction method for reducing the frictional force of the pile body, the part of the pile body above the water surface is the above-water pile body 1, and the part of the pile body under the water is the underwater pile body:

[0024] Before the asphalt is applied, clean the surface of the pile body first, and apply cold bottom oil on the surface of the dried pile body 1 above water to form the upper cold bottom oil layer 2. Because the cold bottom oil has low viscosity and good fluidity, it can be applied on the pile body On the concrete surface, it can quickly penetrate into the surface pores of the pile body, and after the solvent volatilizes, it will be firmly combined with the pile surface. The asphalt is heated to 150°C, and the upper asphalt layer 3 is formed on the surface of the pile body 1 after the cold base oil has penetrated or volatilized. The thickness of the upper asphalt layer 3 is 8mm. The thickness of the upper cold bottom oi...

Embodiment 2

[0032] In this embodiment, the asphalt is heated to 165° C. and poured on the surface of the pile body 1 on the water after the cold base oil has penetrated or volatilized, and the thickness of the upper asphalt layer 3 is 9 mm. The thickness of the upper cold bottom oil layer 2 is 0.5mm, and the thickness of the upper geotextile layer 4 is 3.5mm. The asphalt used in the upper asphalt layer 3 has a softening point of 55°C and a penetration of 60dmm at 25°C. The surface of the asphalt layer is wrapped with geotextiles and finally reinforced outside the geotextiles. Other contents of the technical solution of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0034] Heat the asphalt to 180°C and pour it on the surface of the pile body 1 above the water after the cold base oil has penetrated or volatilized. The thickness of the upper asphalt layer 3 is 10mm. The thickness of the upper cold bottom oil layer 2 is 0.8 mm, and the thickness of the upper geotextile layer 4 is 5 mm. The asphalt used in the upper asphalt layer 3 has a softening point of 60°C and a penetration of 70dmm at 25°C. The surface of the asphalt layer is wrapped with geotextiles and finally reinforced outside the geotextiles. Other contents of the technical solution of this embodiment are the same as those of Embodiment 1.

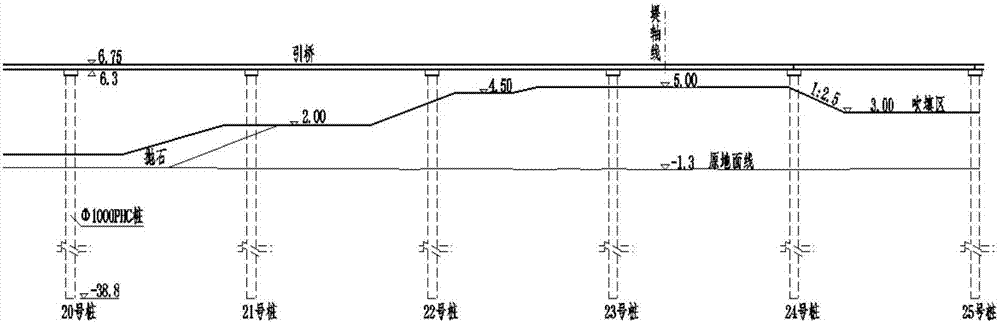

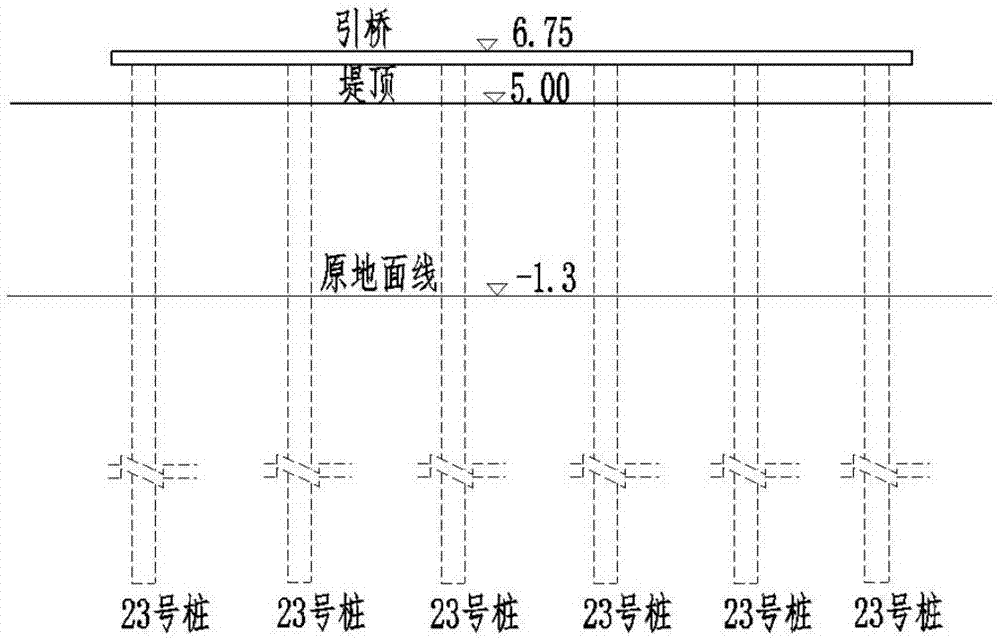

[0035] A new embankment needs to cross the existing approach bridge of an enterprise, such as figure 2 with image 3 As shown, in order to ensure the normal operation of the approach bridge during embankment construction, the constraints of vertical displacement and horizontal displacement must be met, otherwise, reinforcement measures must ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com