Carbon fiber cloth bag cast-in-situ anti-arch curved surface combined irregular-shaped pile and construction method thereof

A reverse arched surface, carbon fiber technology, applied in sheet pile walls, infrastructure engineering, construction and other directions, can solve the problems of poor durability of special-shaped piles, insufficient ability to resist negative friction damage, and easy damage to the pile body. The effect of negative friction resistance on the pile side, reducing the effect of soil squeeze on the pile side, and accelerating the consolidation of the soil around the pile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Fabrication and welding of steel immersed tubes (including anti-arch curved steel immersed tubes), steel sleeves and stiffeners, carbon fiber bag stitching technology, device down-pressing technology, concrete ratio of pile body, special-shaped prefabricated pile tip and pile top cover plate and The external dopant etc. will not be repeated in this embodiment, and the embodiments of the present invention related to the structure will be explained emphatically.

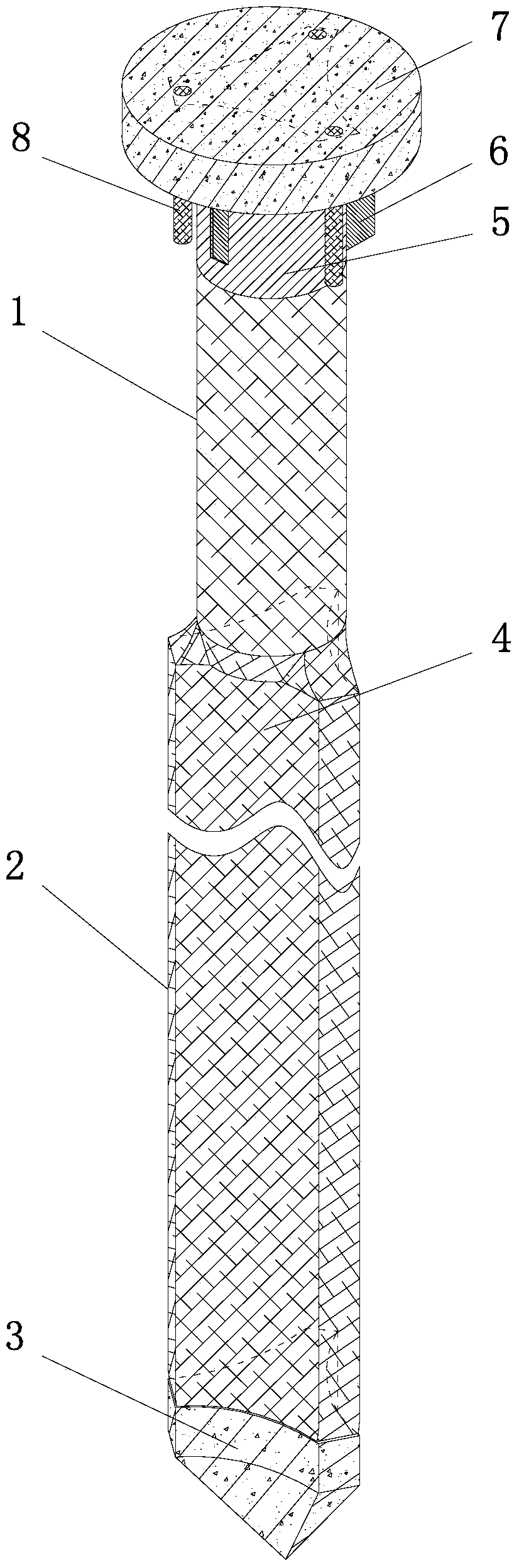

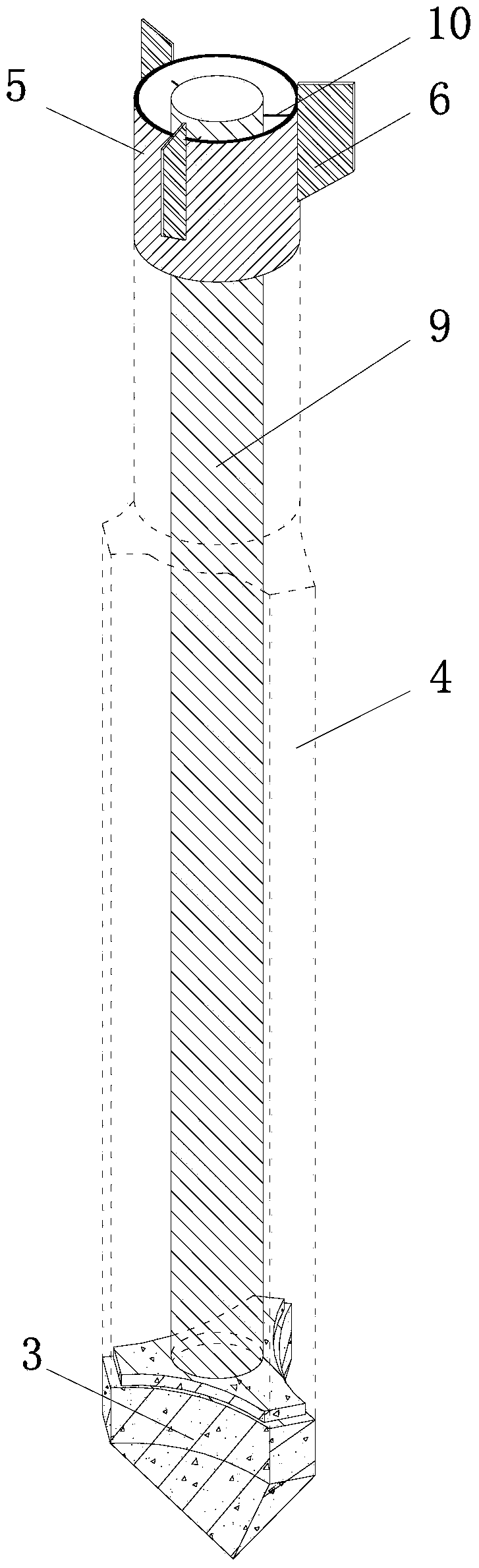

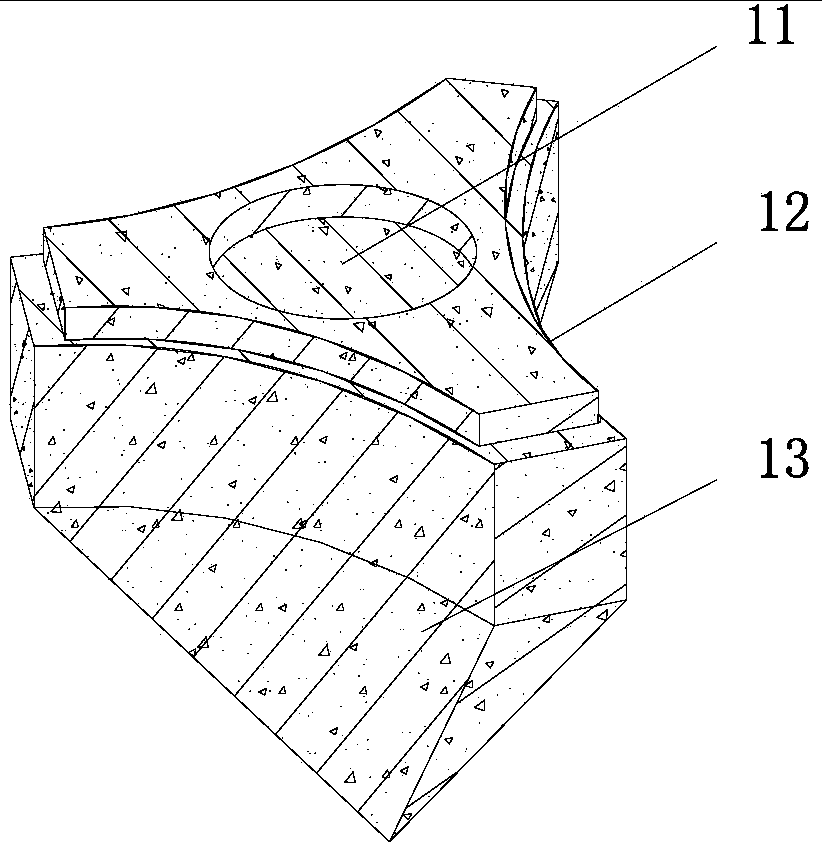

[0040] figure 1 It is a schematic diagram of a carbon fiber cloth bag cast-in-place anti-arch curved surface combination special-shaped pile of the present invention; figure 2 It is a schematic diagram of the construction device of the present invention; image 3 It is a schematic diagram of the special-shaped prefabricated pile tip of the present invention; Figure 4 It is a schematic diagram of the cross-section of the anti-arch curved pile body of the present invention; Figure 5 It is a cross-sectional s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com