Drainage cast-in-situ concrete thin-wall pipe pile construction method

A technology of thin-walled pipe piles and construction methods, which is applied in the direction of foundation structure engineering, construction, etc., can effectively solve the problem of mutual extrusion deformation and damage of pile bodies, affecting the pile quality and bearing performance of cast-in-place thin-walled pipe piles, Issues that affect the quality of the pile body and the effect of foundation treatment, etc., to ensure the construction quality, accelerate drainage consolidation, and ensure the quality of the pile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In this embodiment, the technical requirements for steel plate cutting and welding construction, steel cage binding construction technical requirements, prefabricated pile tip design and construction technical requirements, vibrating immersed tube construction technical requirements, pile body concrete mix ratio design and pouring technical requirements will not be repeated here. , emphatically explaining the embodiment of the present invention related to the structure.

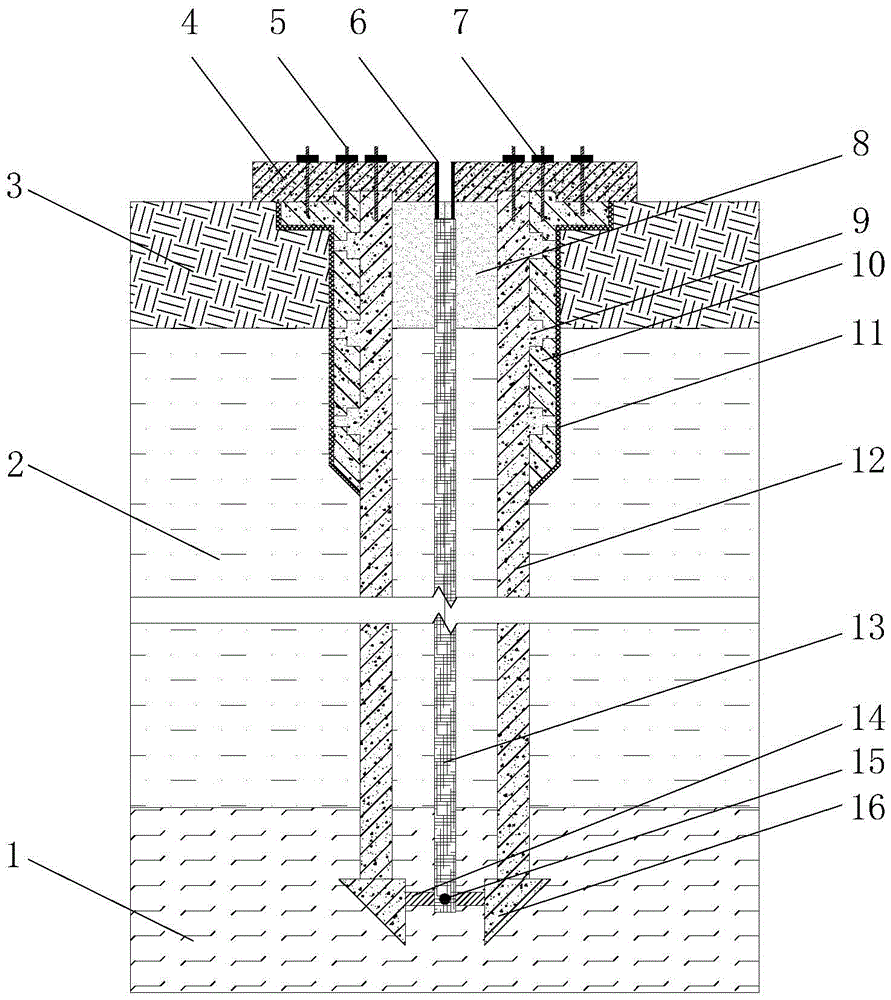

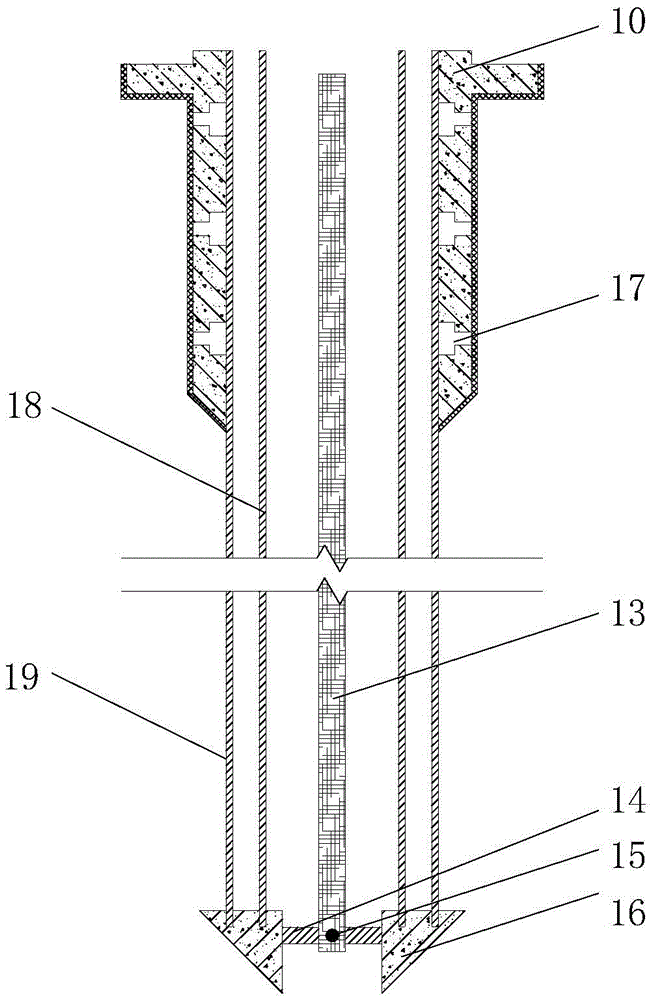

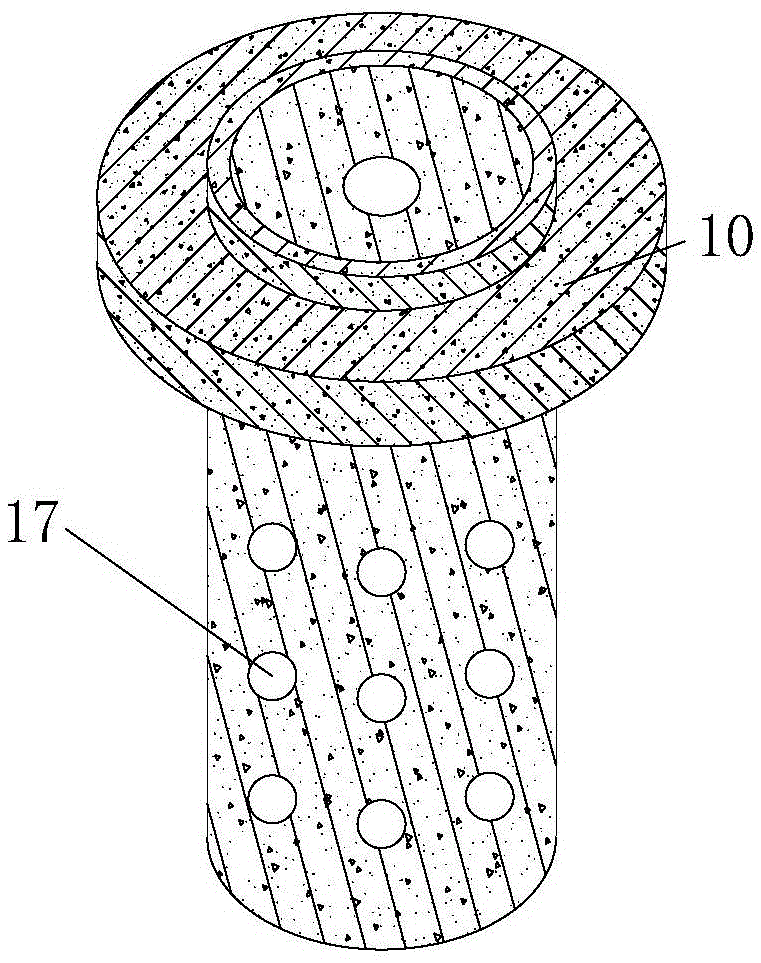

[0036] figure 1 It is a structural schematic diagram of a drainage type cast-in-place concrete thin-walled pipe pile of the present invention, figure 2 It is a schematic diagram of a drainage type cast-in-place concrete thin-walled pipe pile construction device of the present invention, image 3 is the schematic diagram of the prefabricated permeable concrete sleeve. Figure 4 It is a construction flow chart.

[0037] refer to Figure 1~3 The drainage type cast-in-place concrete thin-walled pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com