Reinforcing structure and method of roadbed foundation of structure with basaltic layer sandwiched between soft soil layers

A basalt layer and reinforcement structure technology, applied in soil protection, infrastructure engineering, roads, etc., can solve problems such as strict construction control requirements, high project cost, and slow progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

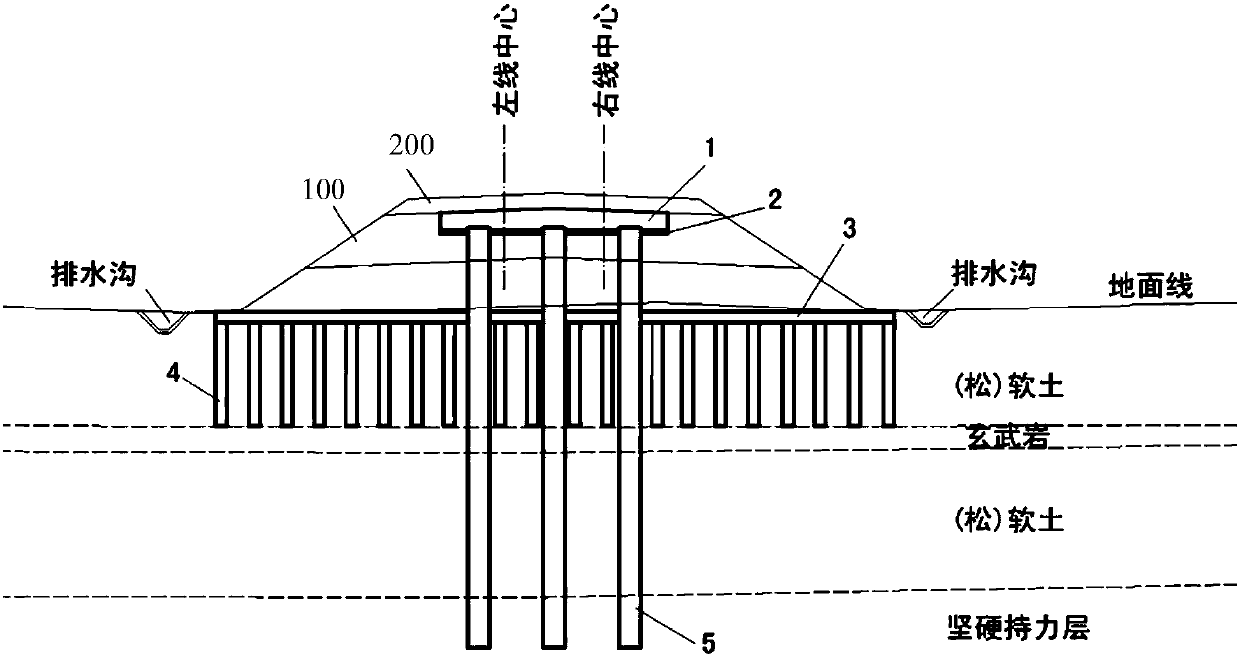

[0028] figure 1 A cross-sectional schematic view of the reinforcing structure in this embodiment is shown. The reinforcing structure in the present invention can be applied to the subgrade foundation of the soft soil layer sandwiching the basalt layer structure, and the soft soil layer sandwiching the basalt layer structure is from top to bottom , followed by a structure of soft soil layer-basalt layer-soft soil layer, and the soft soil includes soft soil. The reinforcement structure includes:

[0029] At least two rows of first reinforcement piles 5, the top of each first reinforcement pile 5 protrudes into the roadbed 100, and the lower ends of the first reinforcement piles 5 pass through the soft soft layer above the basalt layer of the roadbed foundation in turn. The soil layer, the basalt layer and the soft soil layer at the bottom of the basalt layer, the first reinforcement piles 5 are horizontally arranged, and the number is 2 or more, which can be symmetrically and e...

Embodiment 2

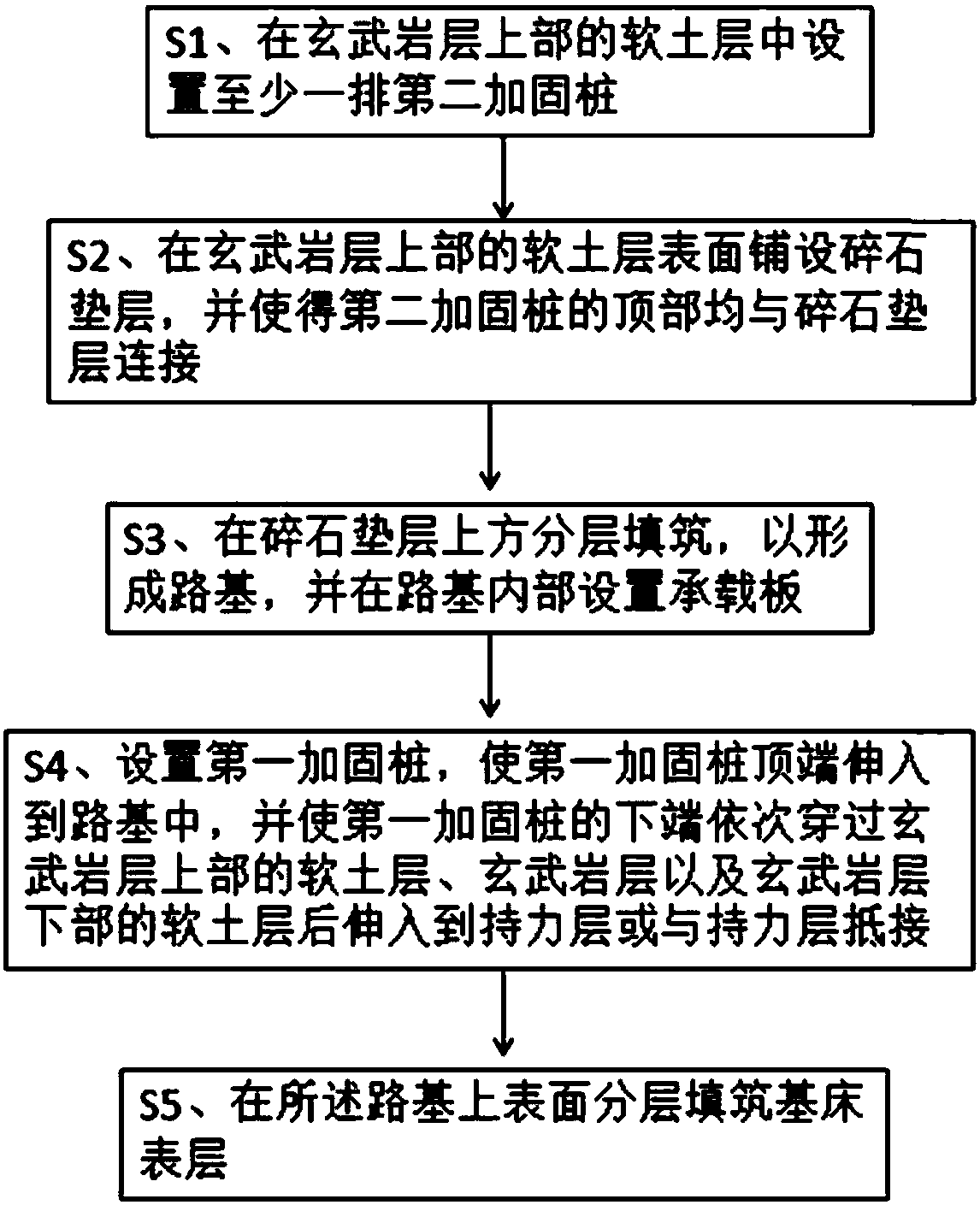

[0037] figure 2 Shown is a method for reinforcing a roadbed foundation with a soft soil layer sandwiching a basalt layer structure, which includes the following steps:

[0038] S1, setting at least one row of second reinforcement piles 4 in the soft soil layer above the basalt layer;

[0039] S2. Lay a gravel cushion 3 on the top of the soft soil layer above the basalt layer, and connect the top of each second reinforcement pile 4 to the gravel cushion 3;

[0040] S3, filling in layers above the gravel cushion 3 to form a roadbed 100, and setting a bearing plate 1 inside the roadbed 100;

[0041] S4, setting the first reinforcement pile 5, so that the top of the first reinforcement pile 5 extends into the roadbed 100, and makes the lower end of the first reinforcement pile 5 pass through the upper part of the basalt layer of the roadbed foundation in sequence The soft soil layer, basalt layer and the soft soil layer below the basalt layer extend into the bearing layer or ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com