Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Reduce hydrothermal deactivation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

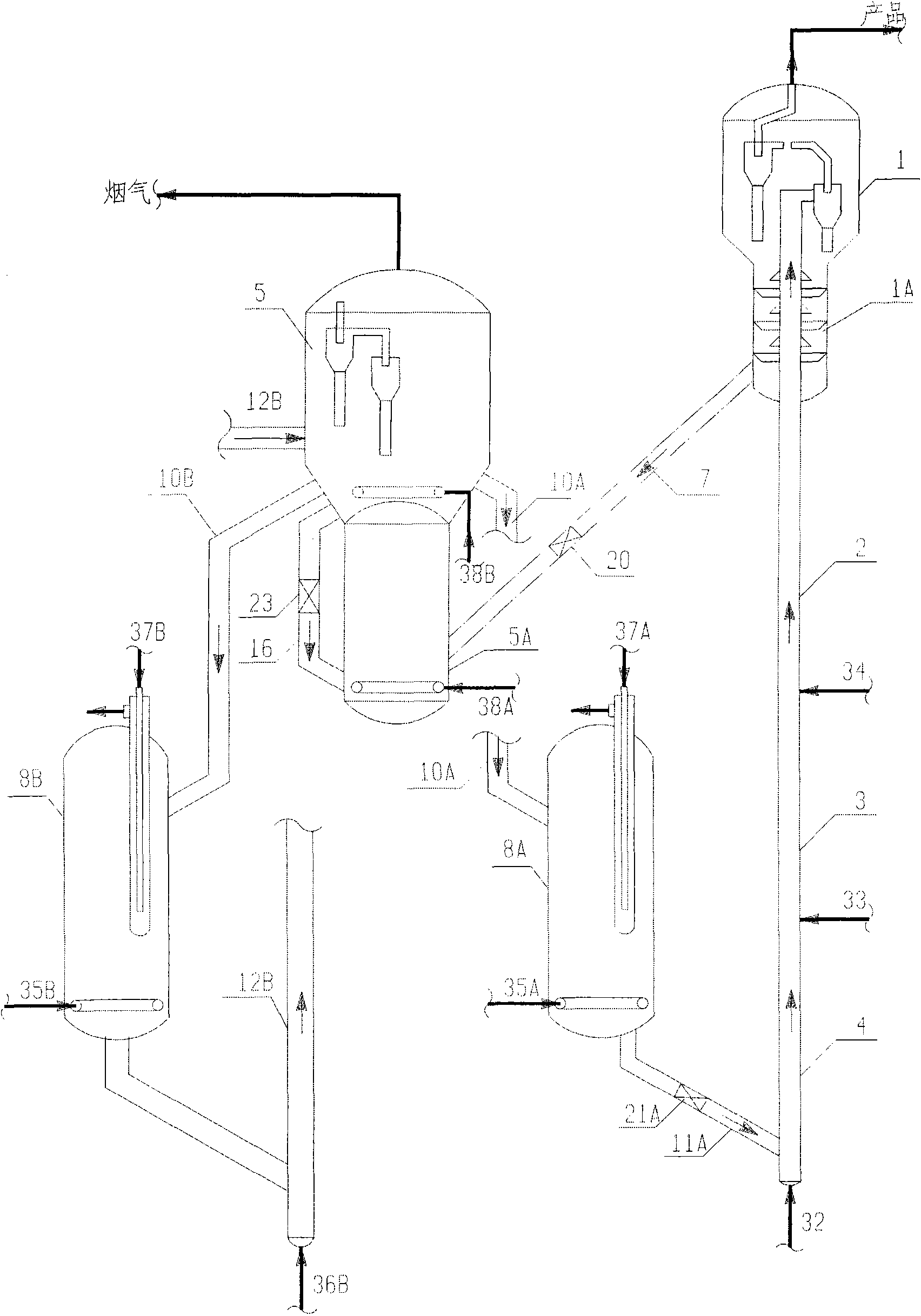

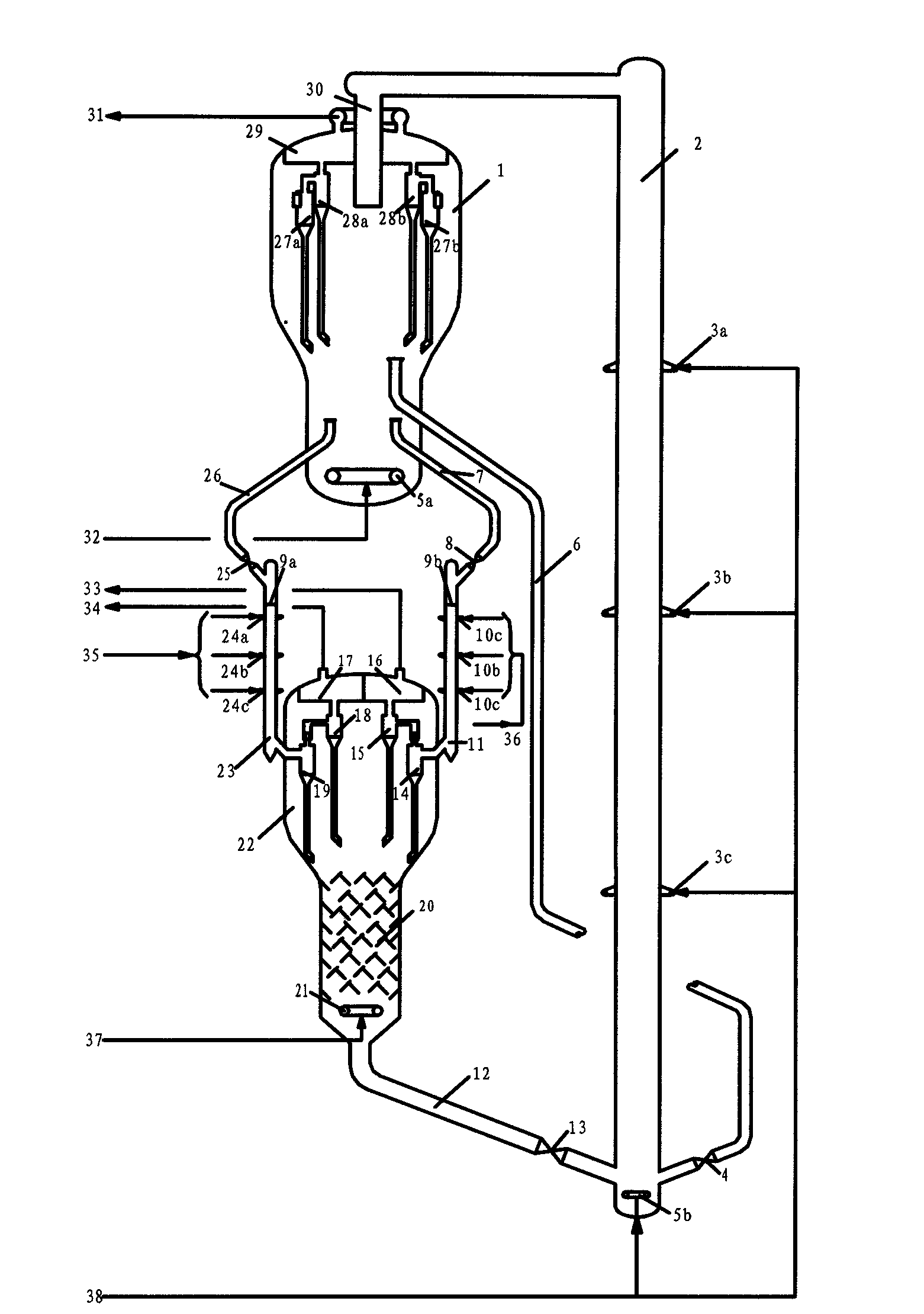

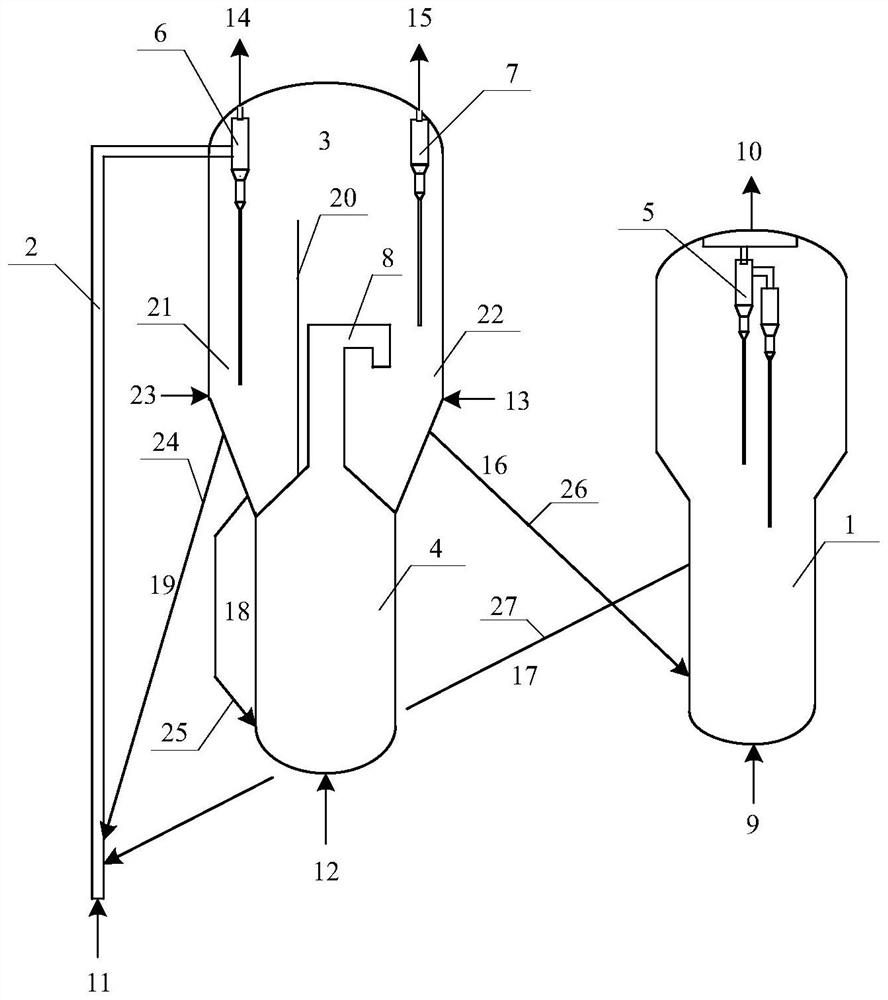

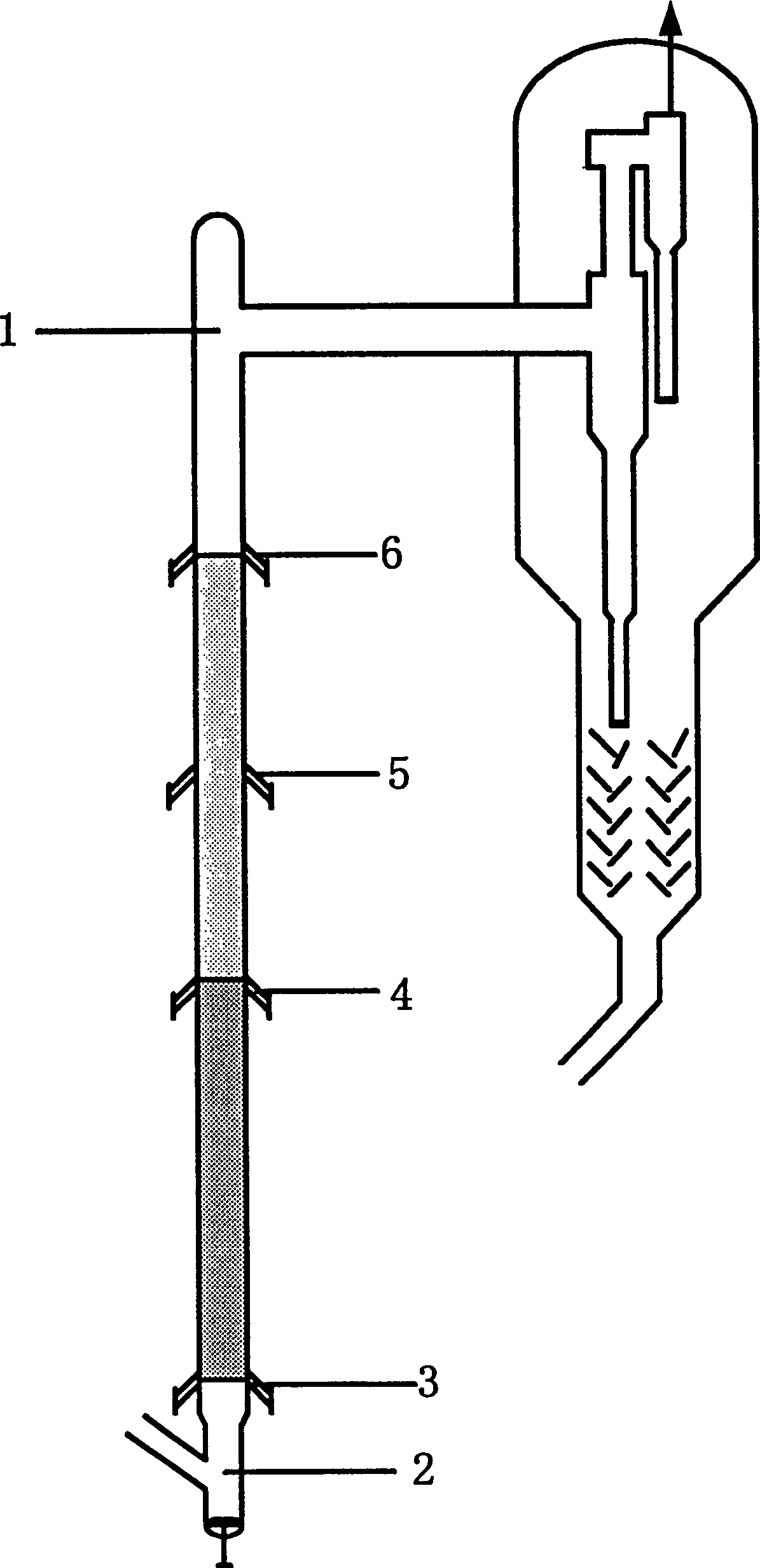

Method for catalytic conversion of heavy oil and device thereof

ActiveCN1664074ARaise the preheat temperaturePromote atomizationTreatment with plural serial stages onlyCatalytic transformationPtru catalyst

The invention provides a method of heavy raw material catalytic conversion and the device, comprising: the heavy hydrocarbon raw material passing through the first and second reaction area of the raiser reactor and contacting with catalyst for first reaction and second reaction, the reactants entering into the settler for the separation of catalyst and oil gas, steam stripping the separated catalyst through stripping section and introducing it to the reactivator for carbon burning reactivation, the reactivated catalyst returning to the raiser reactor after cooled or directly to the raiser reactor for reuse. After the heavy oil passing through the device said above, the volume content of olefin decreases by 10~40%, octane value increases 0.5~1 units, sulfur content in petrol decreases 10~30% by weight. After the poor petrol passing through the device said above, the volume content of olefin decreases by 10~60%, octane value increases 0.5~40 units, sulfur content in petrol decreases 10~50% by weight.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

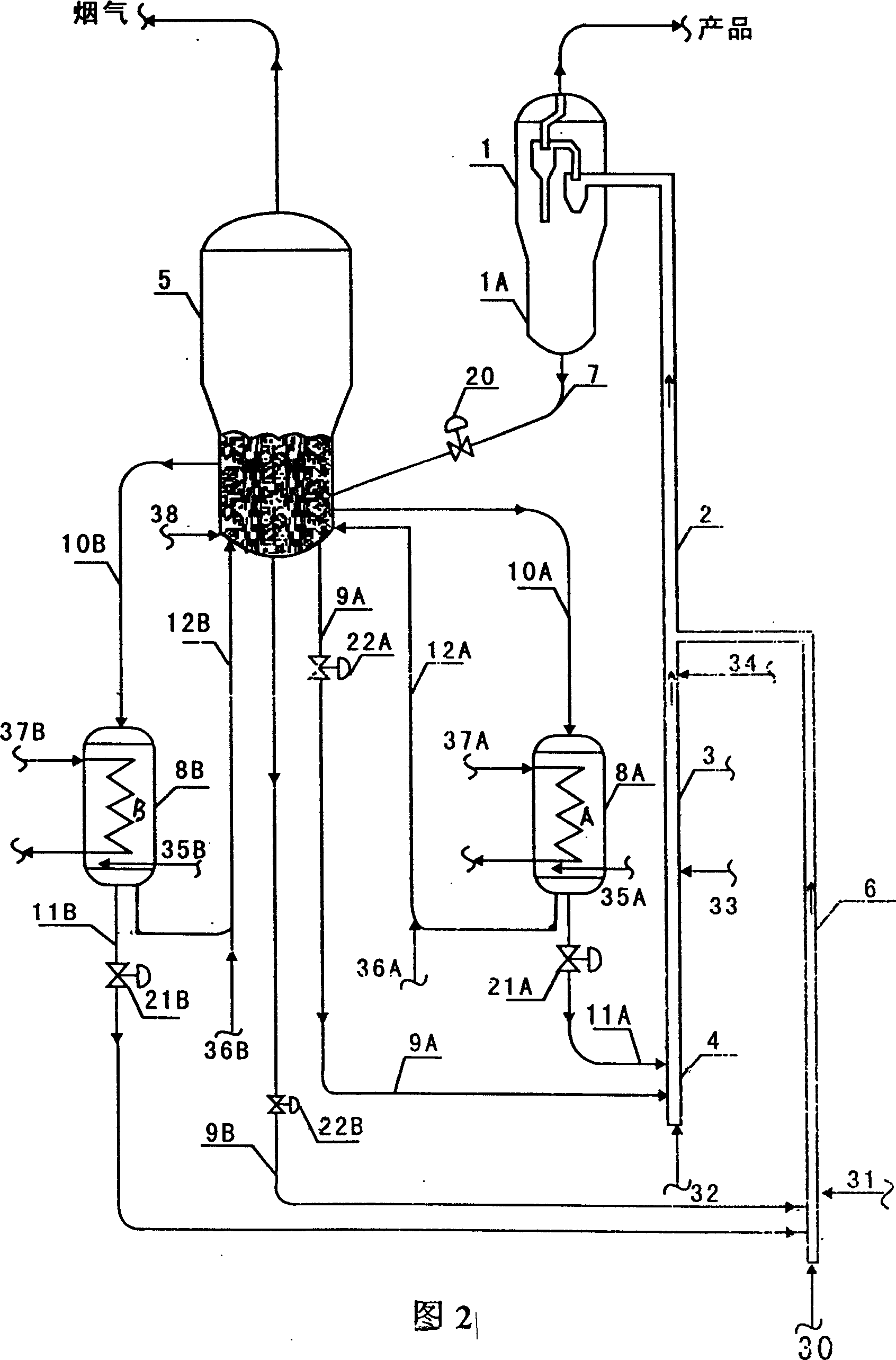

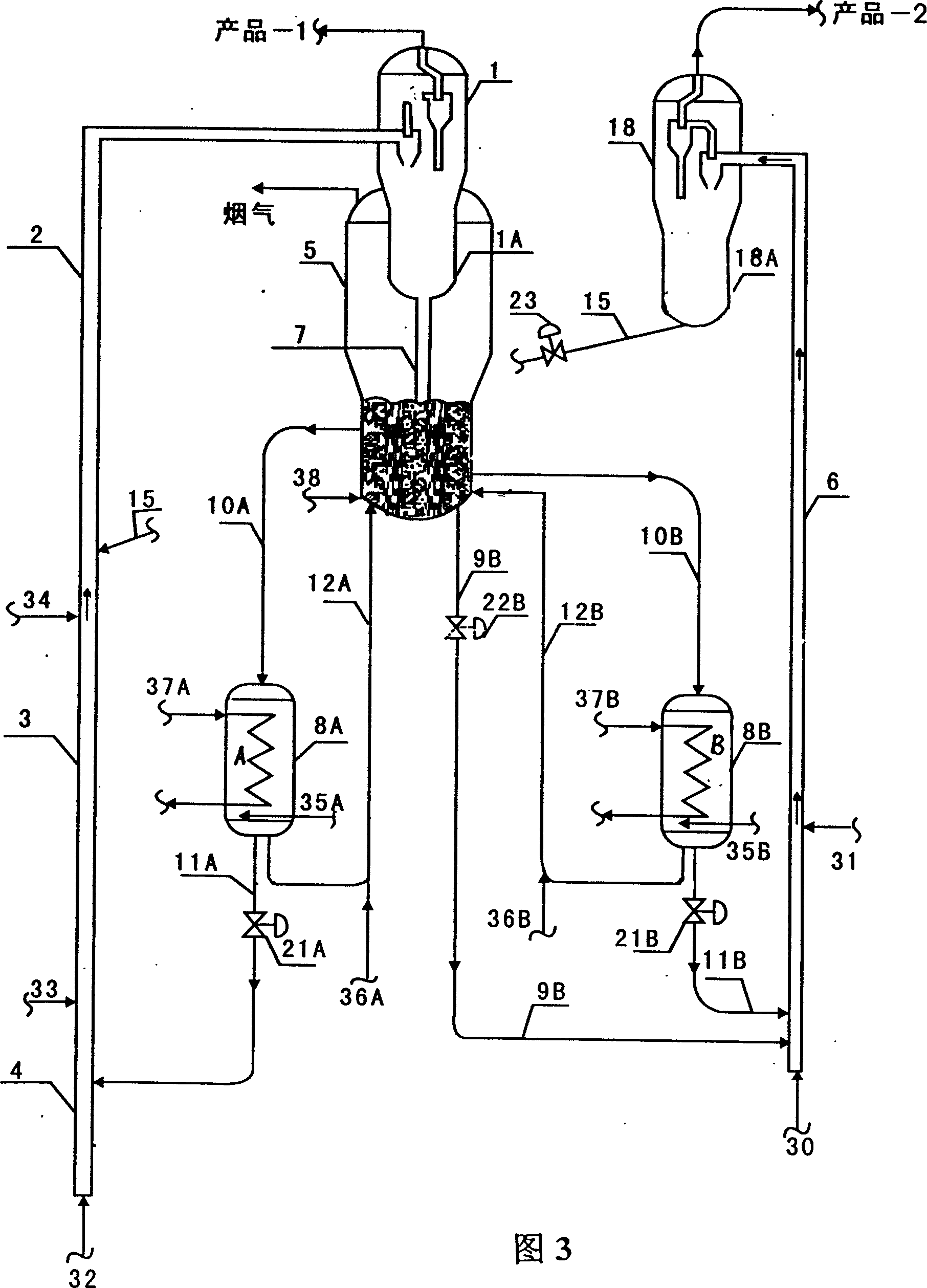

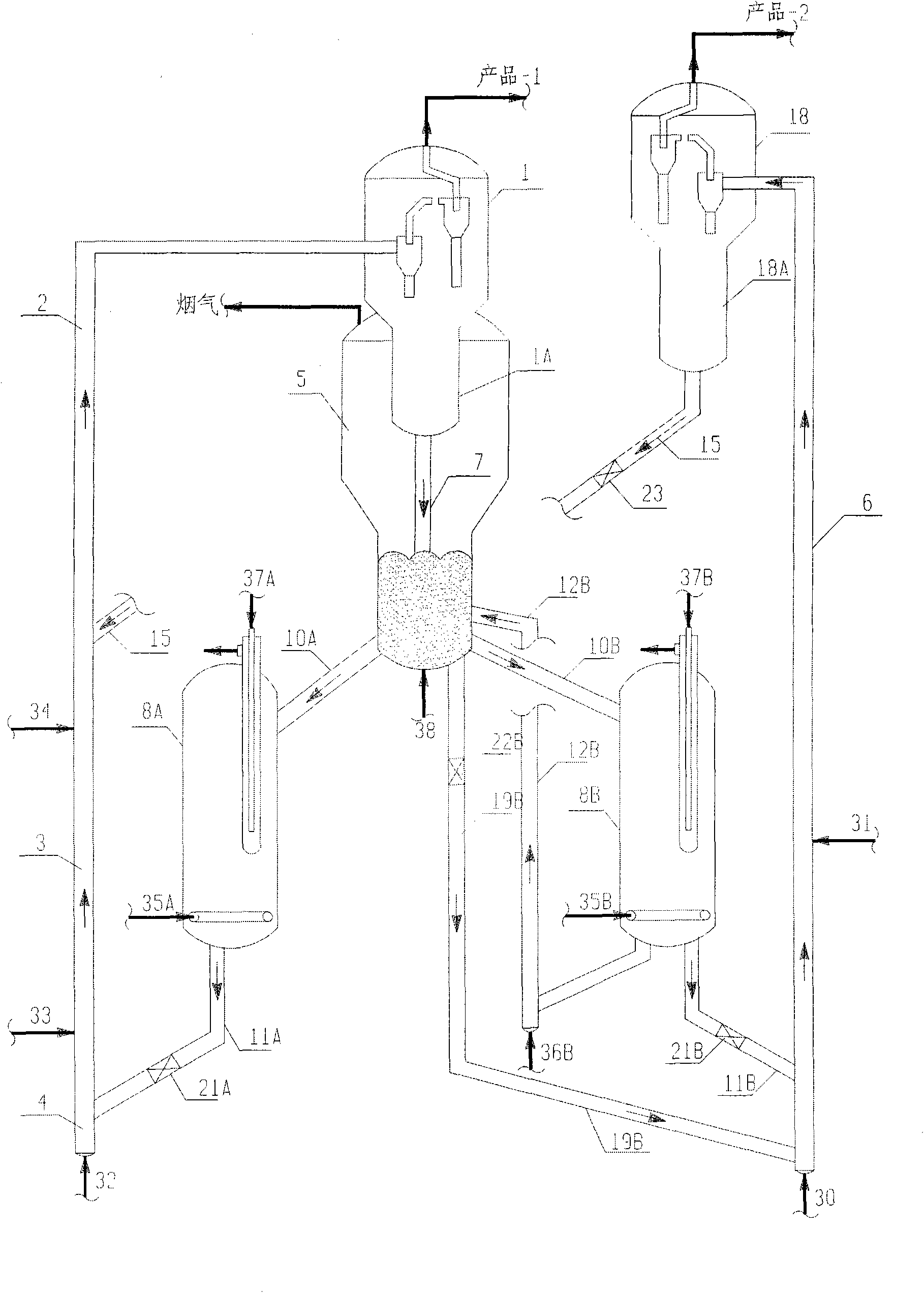

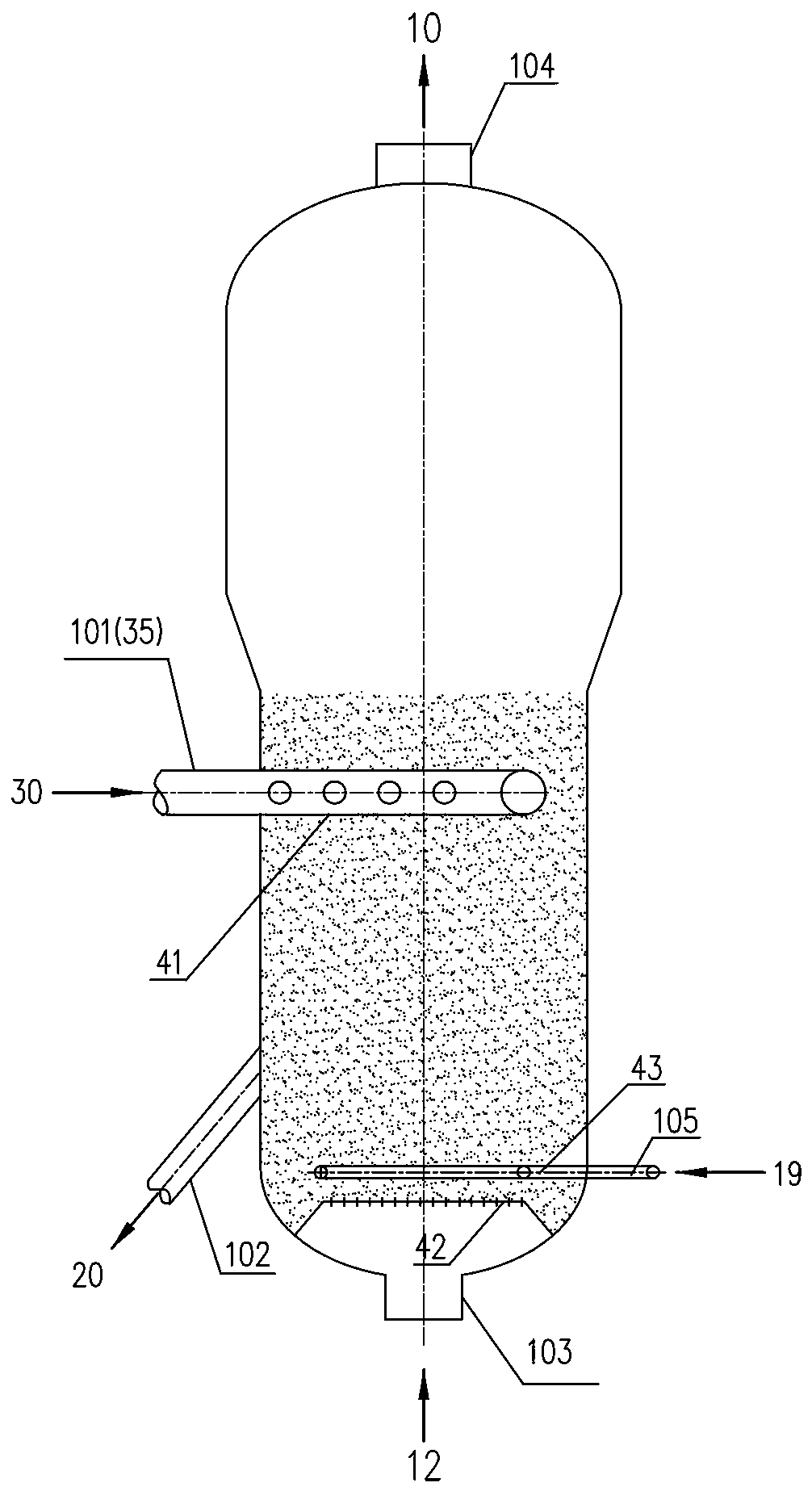

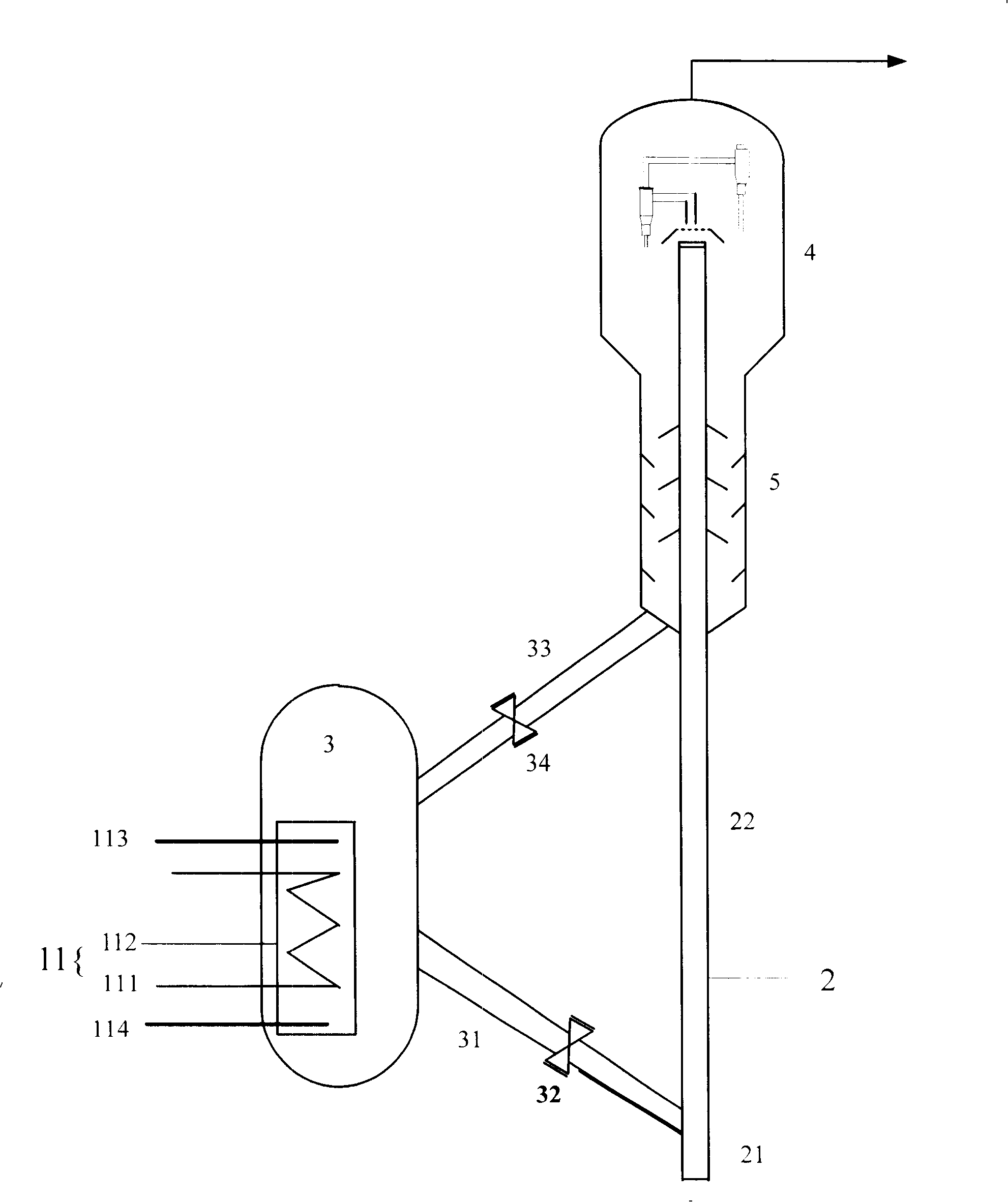

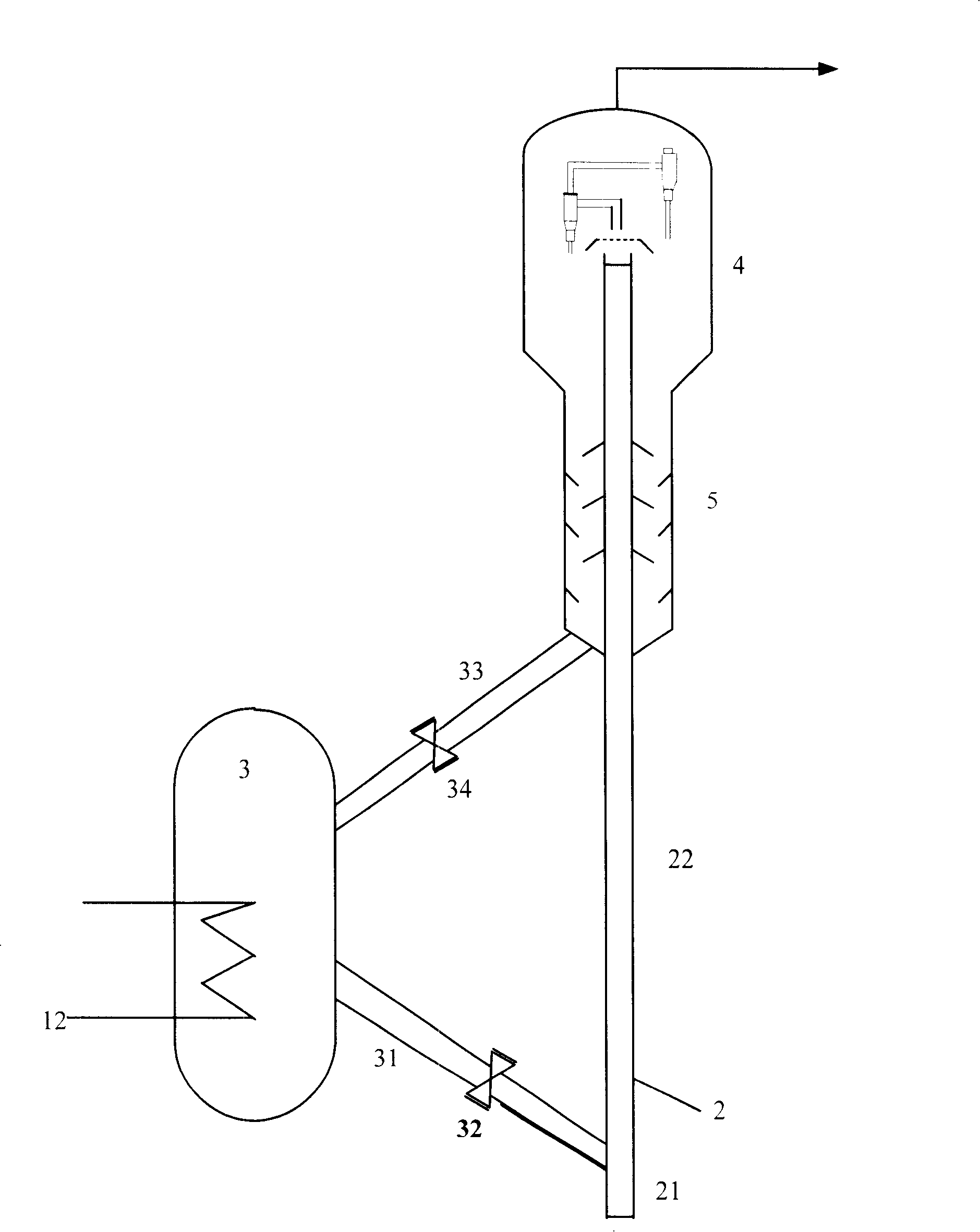

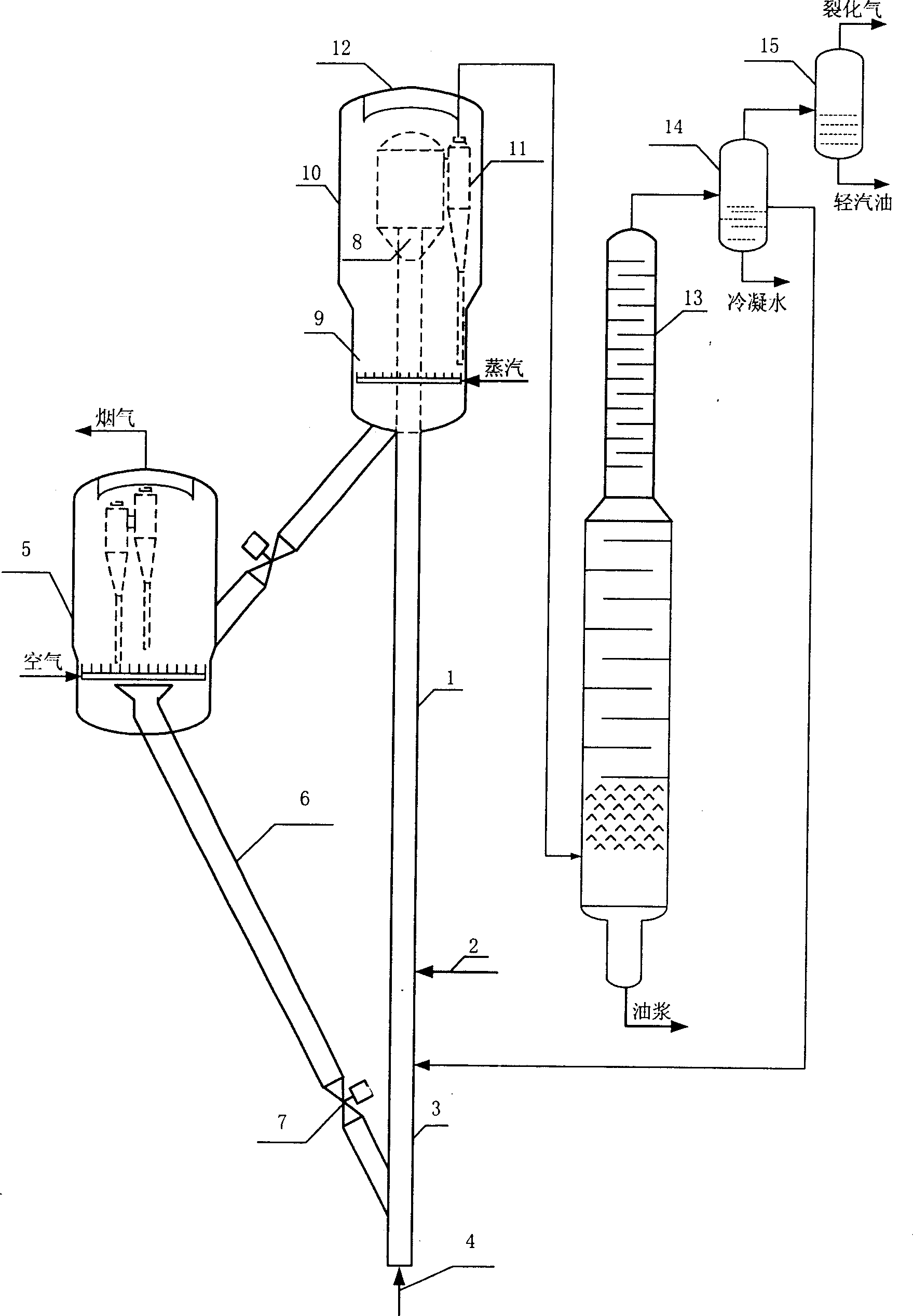

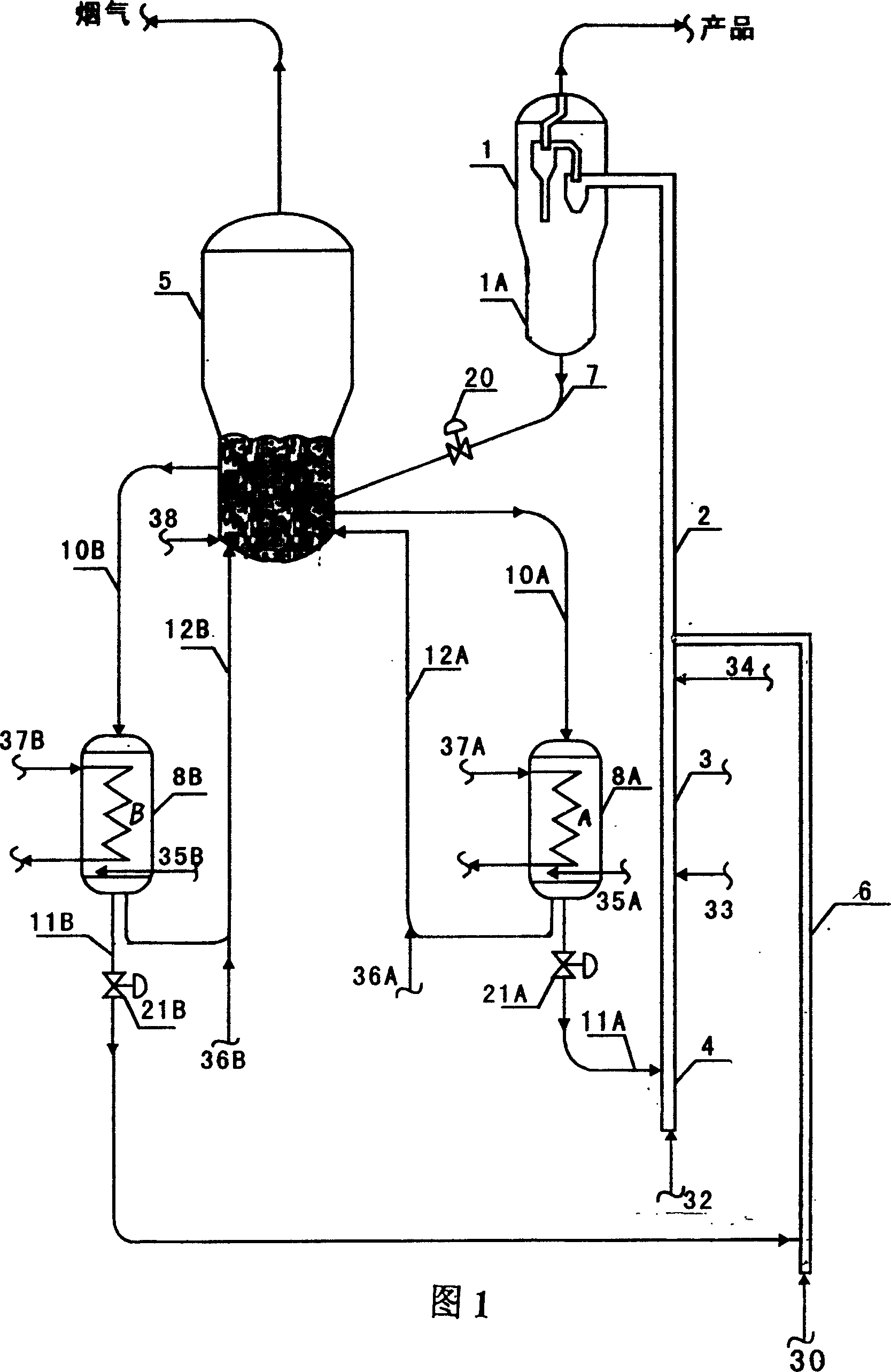

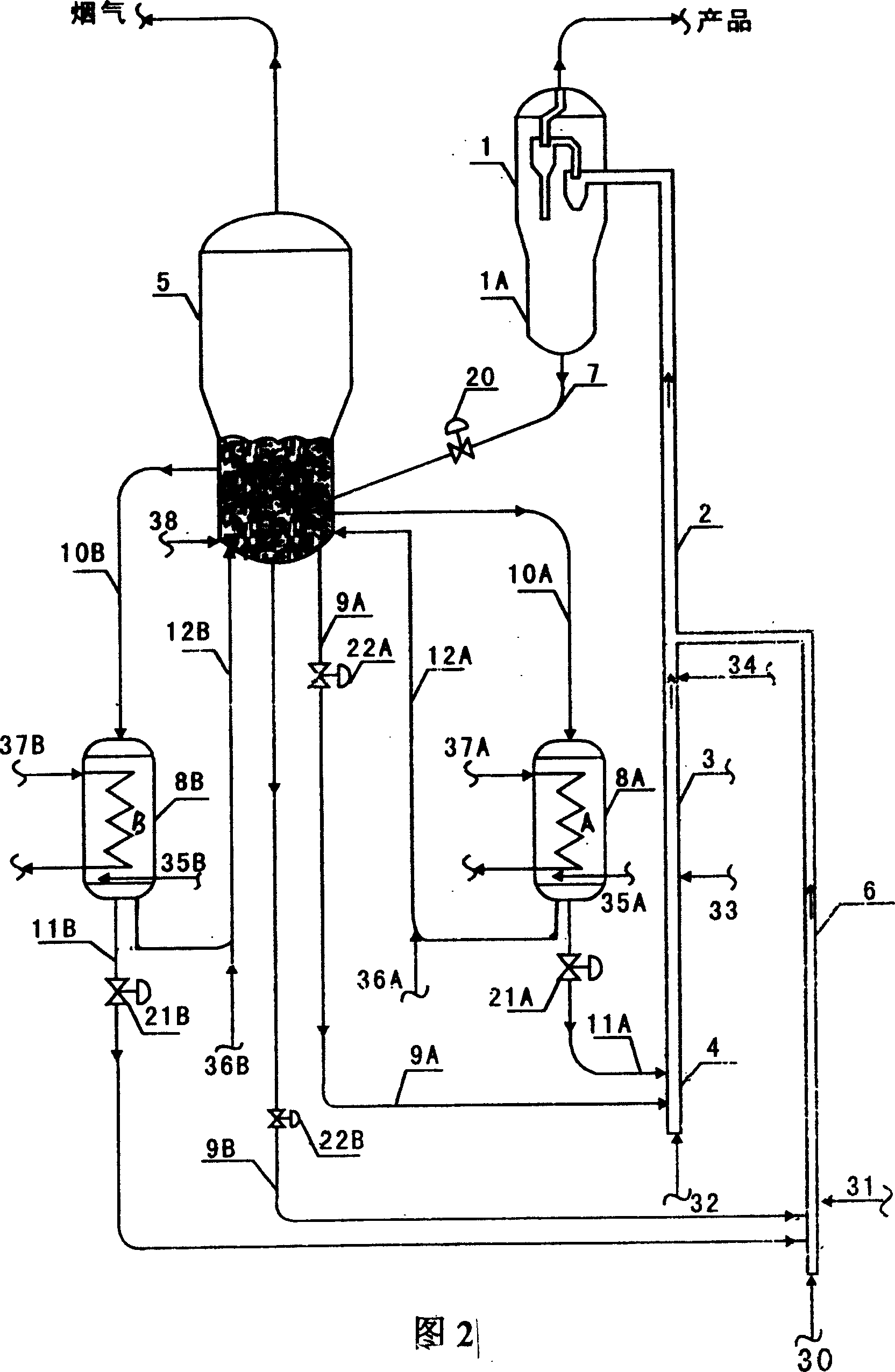

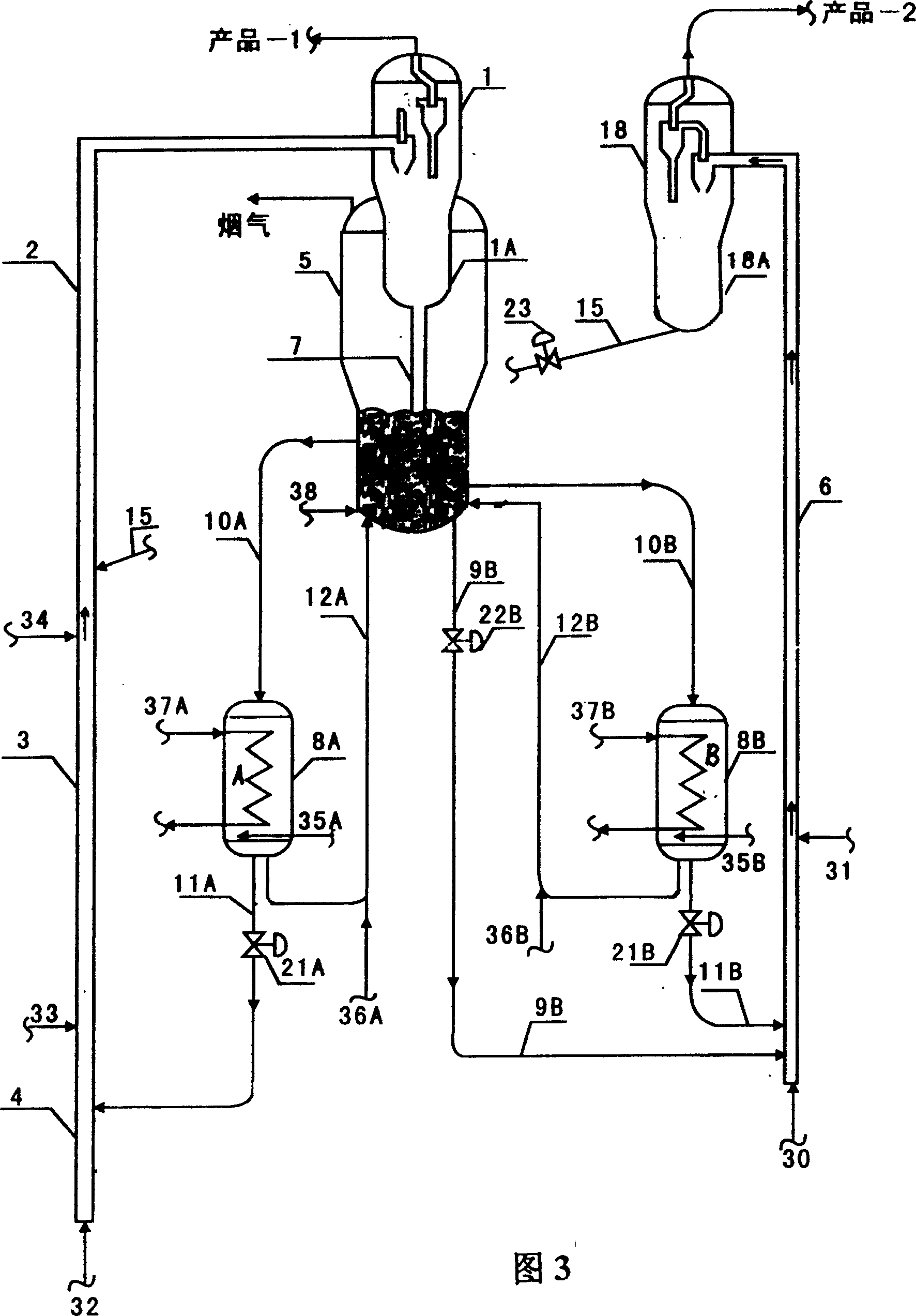

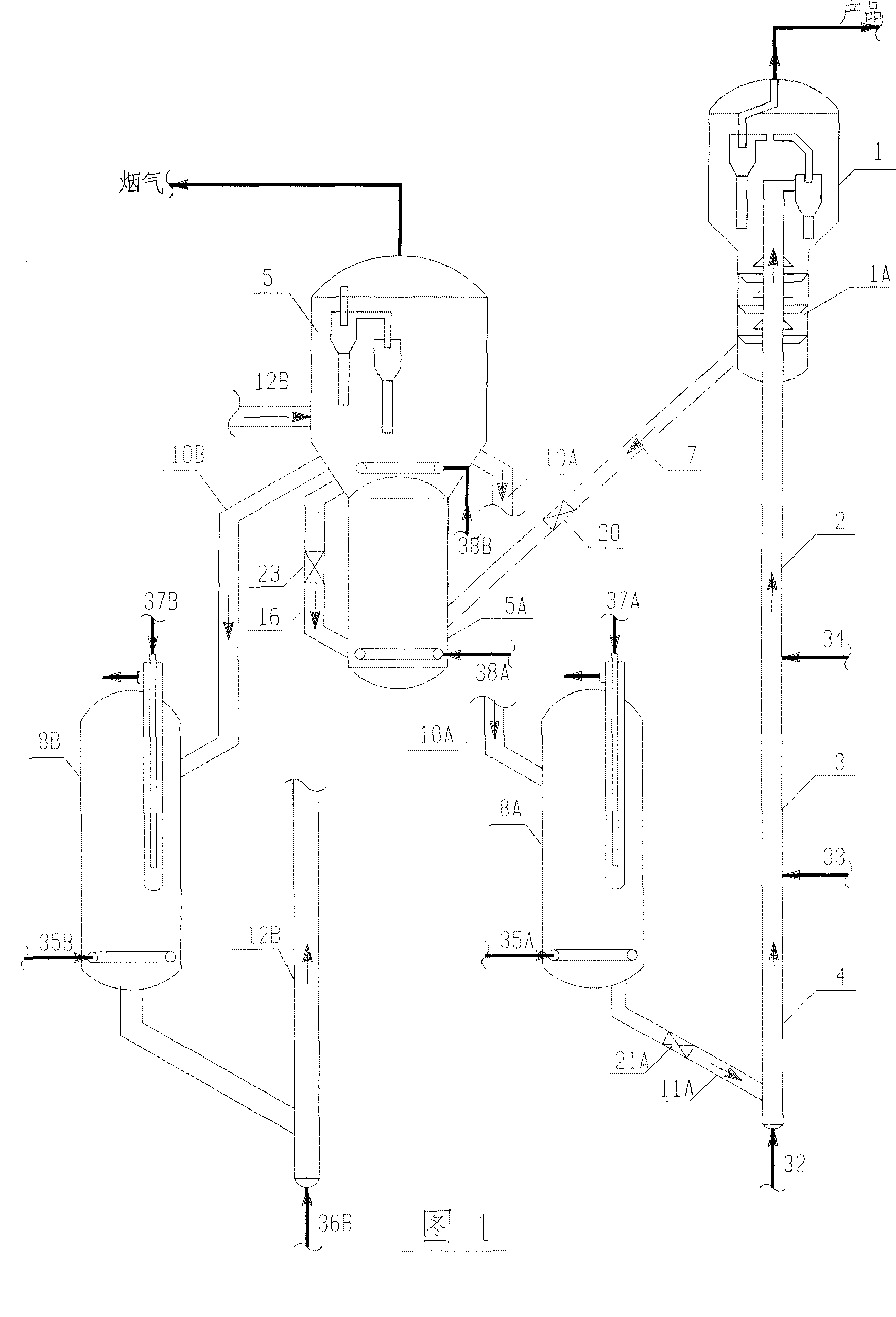

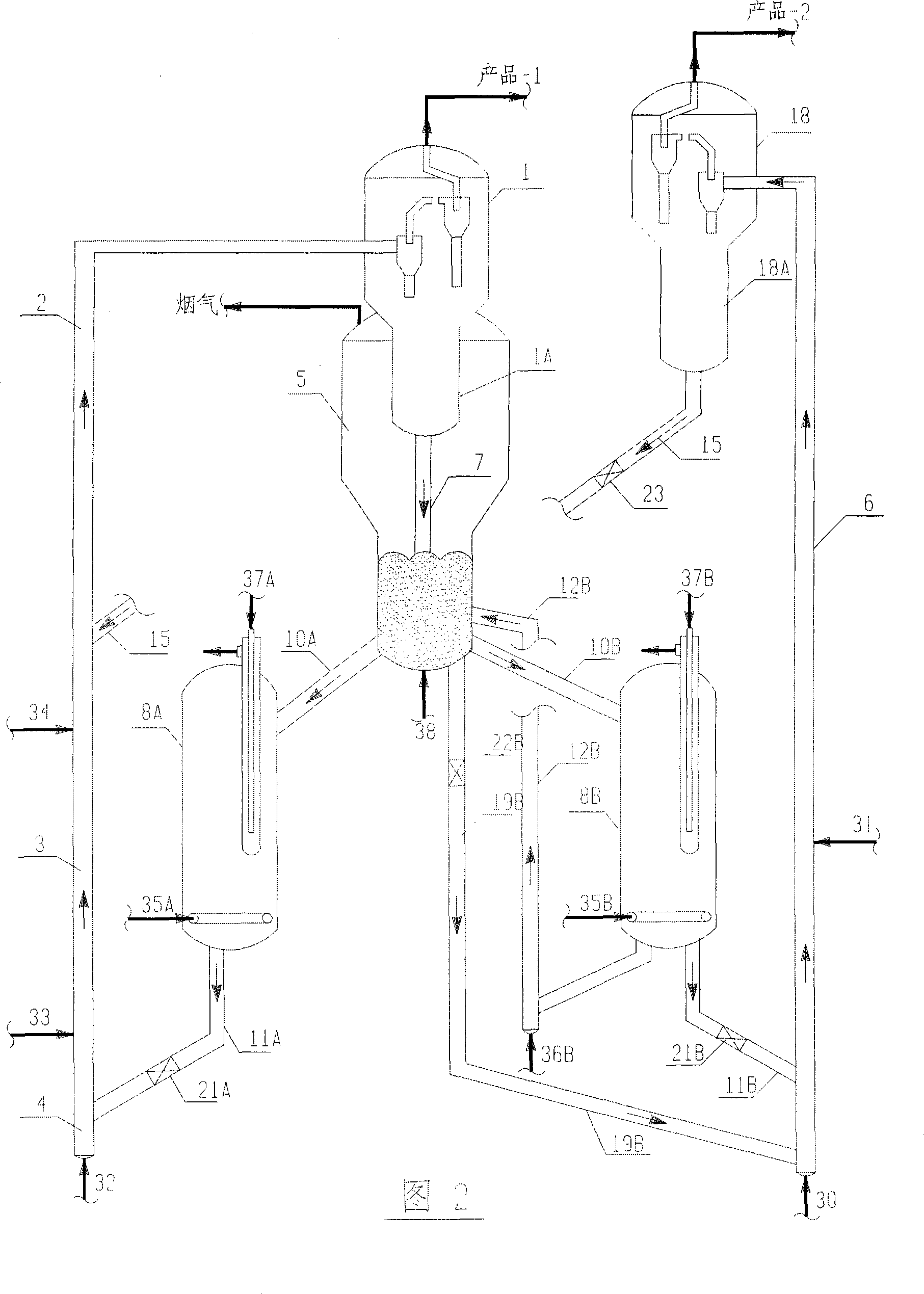

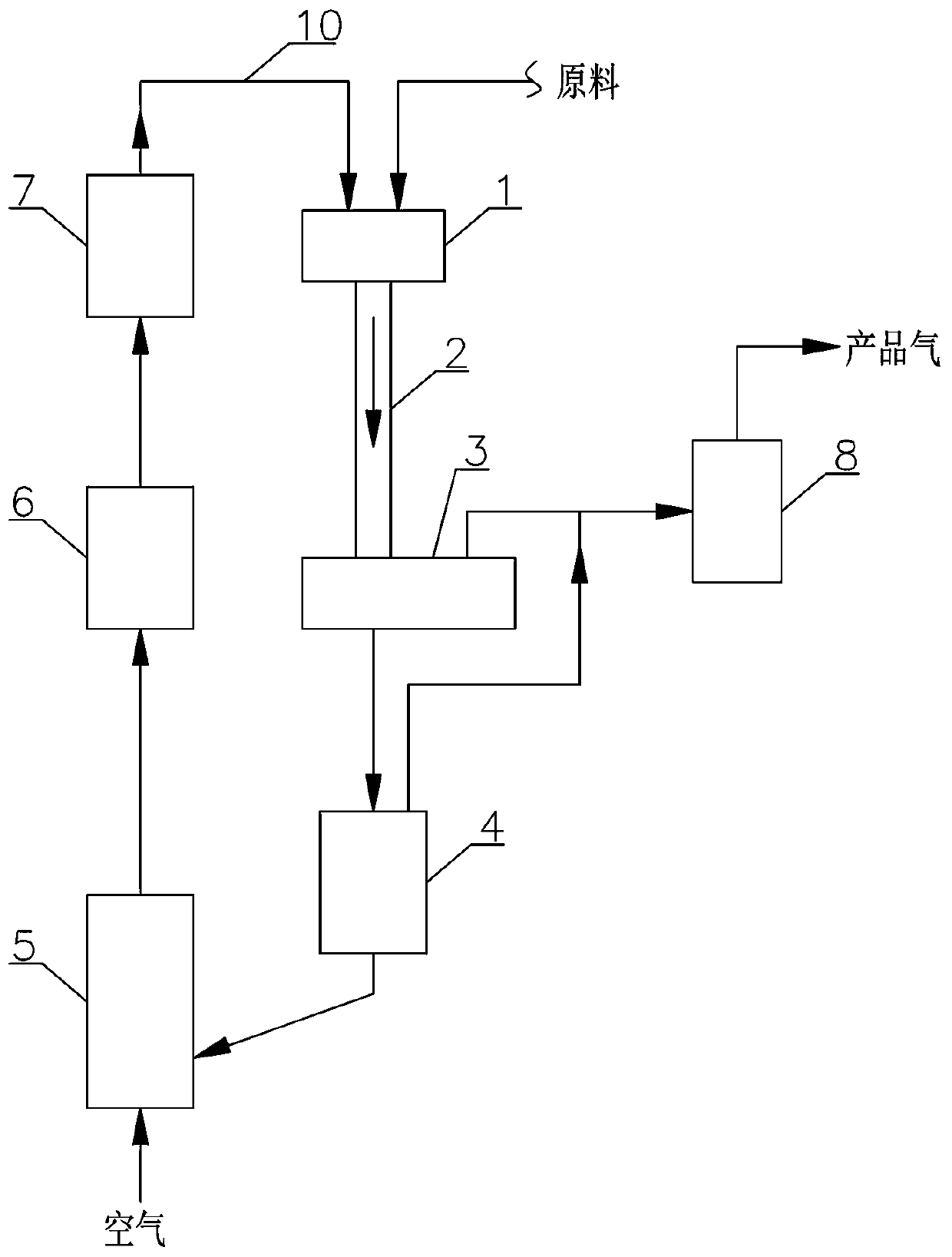

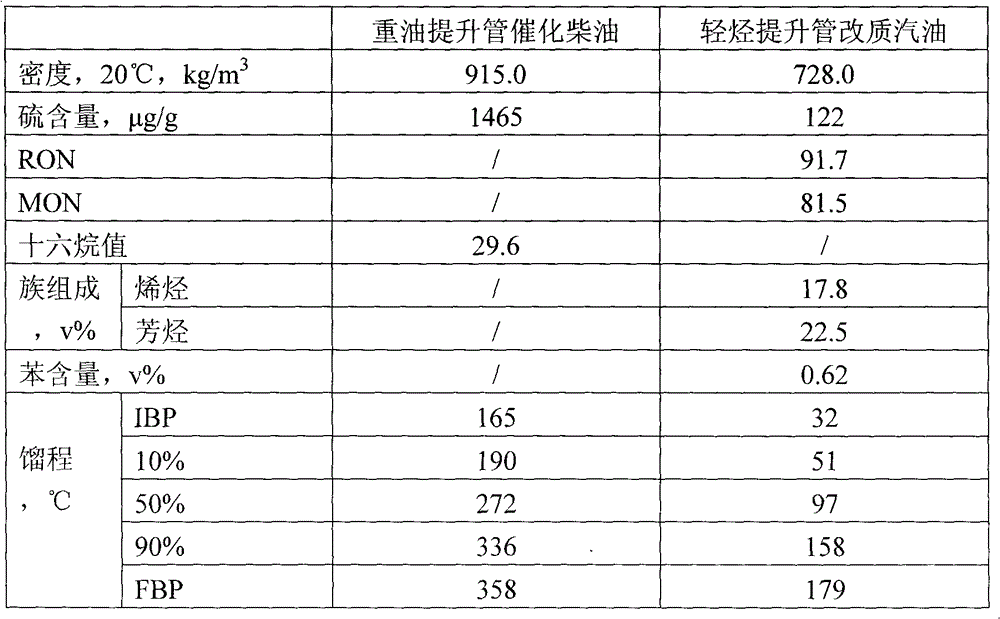

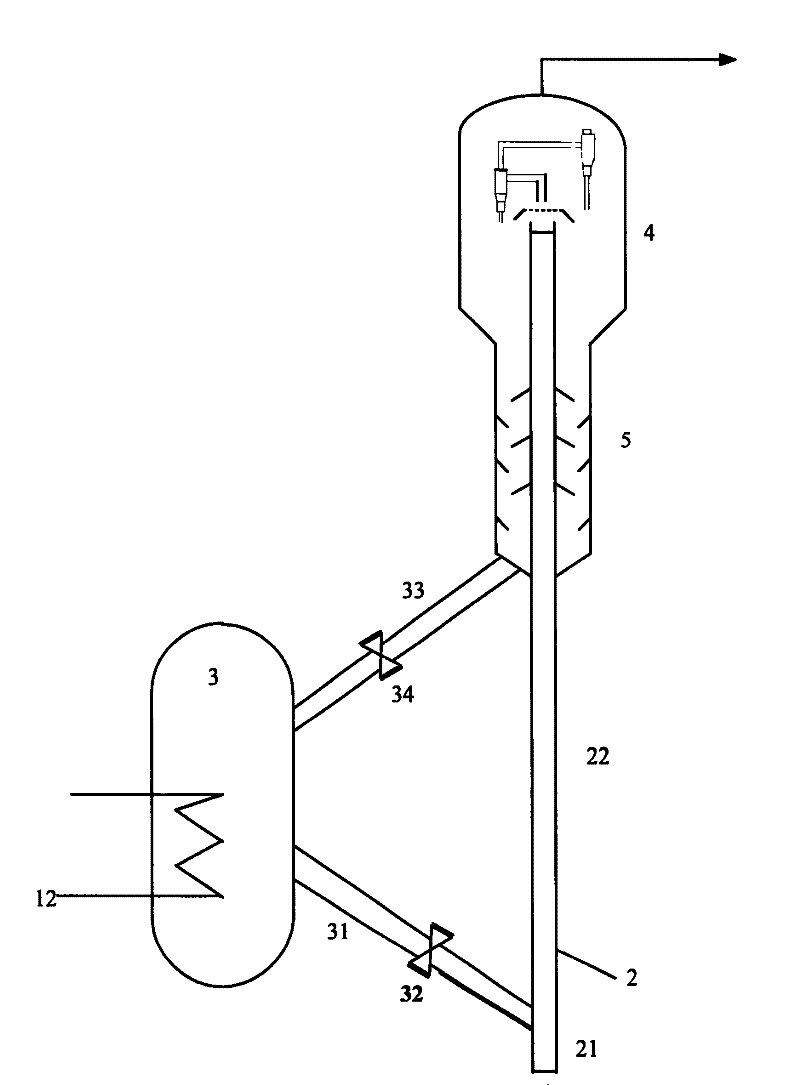

Method and device for circulating cold regenerated catalyst

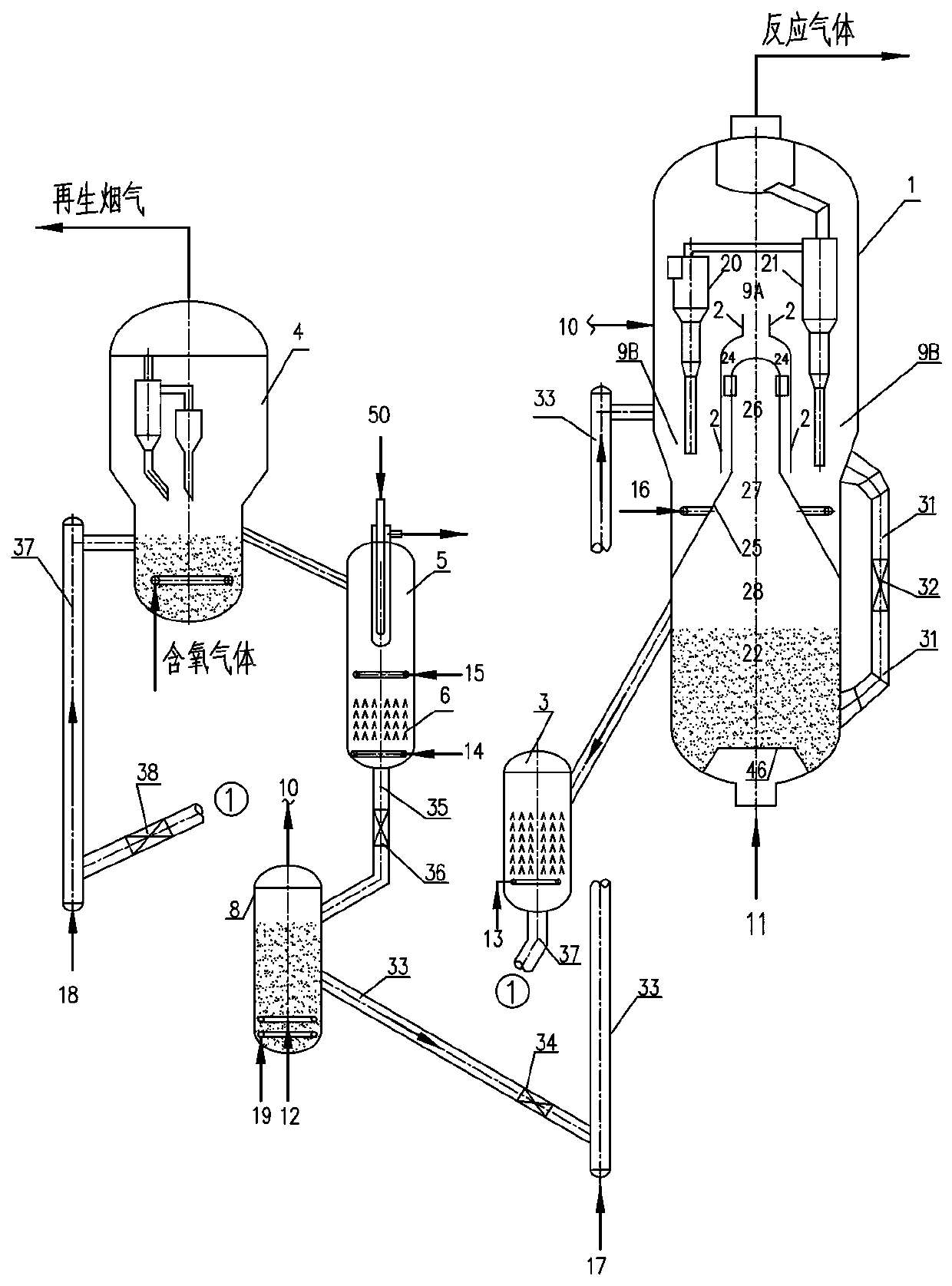

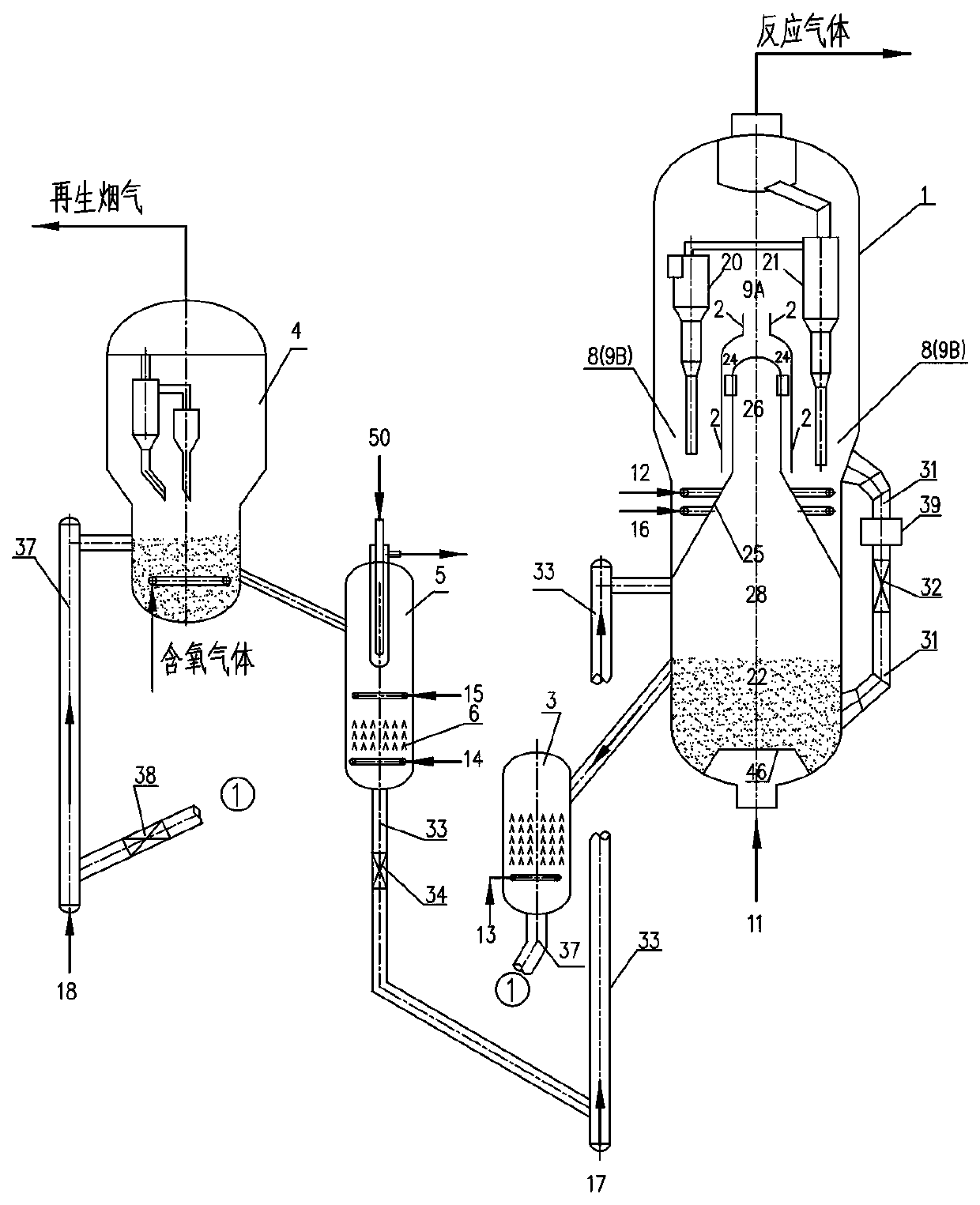

The invention provides a method for circulating a cold regenerated catalyst and application thereof. A regenerated catalyst from a regenerator is cooled by a catalyst cooler to between 200 and 720DEGC, and is not mixed with a hot regenerated catalyst to directly enter a riser reactor, or is mixed with another part of uncooled hot regenerated catalyst into a mixed regenerated catalyst of which thetemperature is not lower than that of the regenerator to enter the riser reactor; and a hydrocarbon raw material undergoes contact reaction with the catalyst in the riser reactor, the reaction material flow enters a settler for the separation of the catalyst and oil gas, the separated catalyst to be regenerated is subjected to steam stripping in a steam stripping section, and then enters the regenerator for coke burning regeneration, and the regenerated catalyst is cooled and returns to the riser reactor for recycling. The method for circulating the cold regenerated catalyst has wide application, can be used for various fluid catalytic cracking processes comprising resid fluid catalytic cracking, wax oil catalytic cracking, gasoline catalytic conversion upgrading and the like, and also can be sued for other gas-solid reaction processes comprising residual oil pretreatment, fluid coking and the like.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

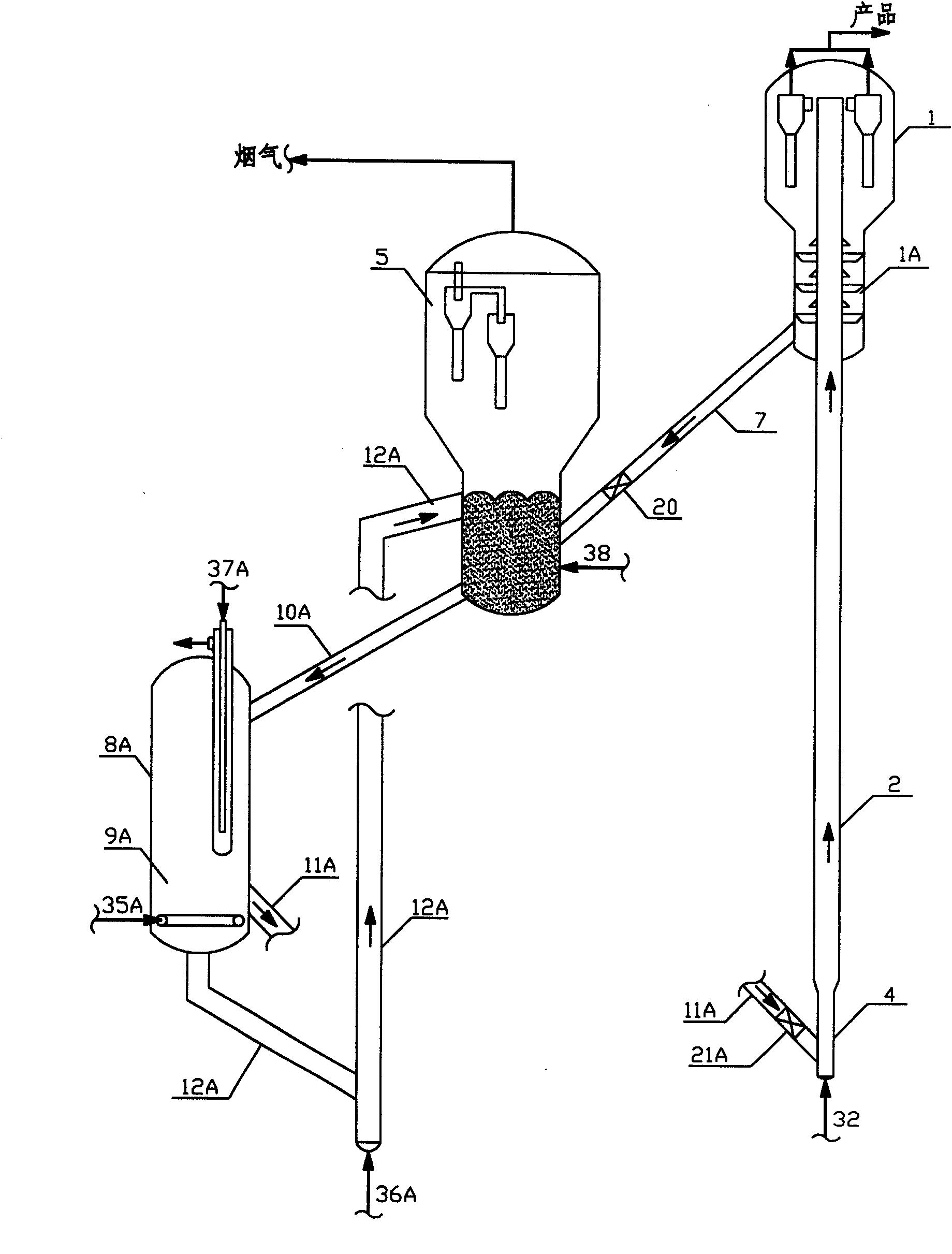

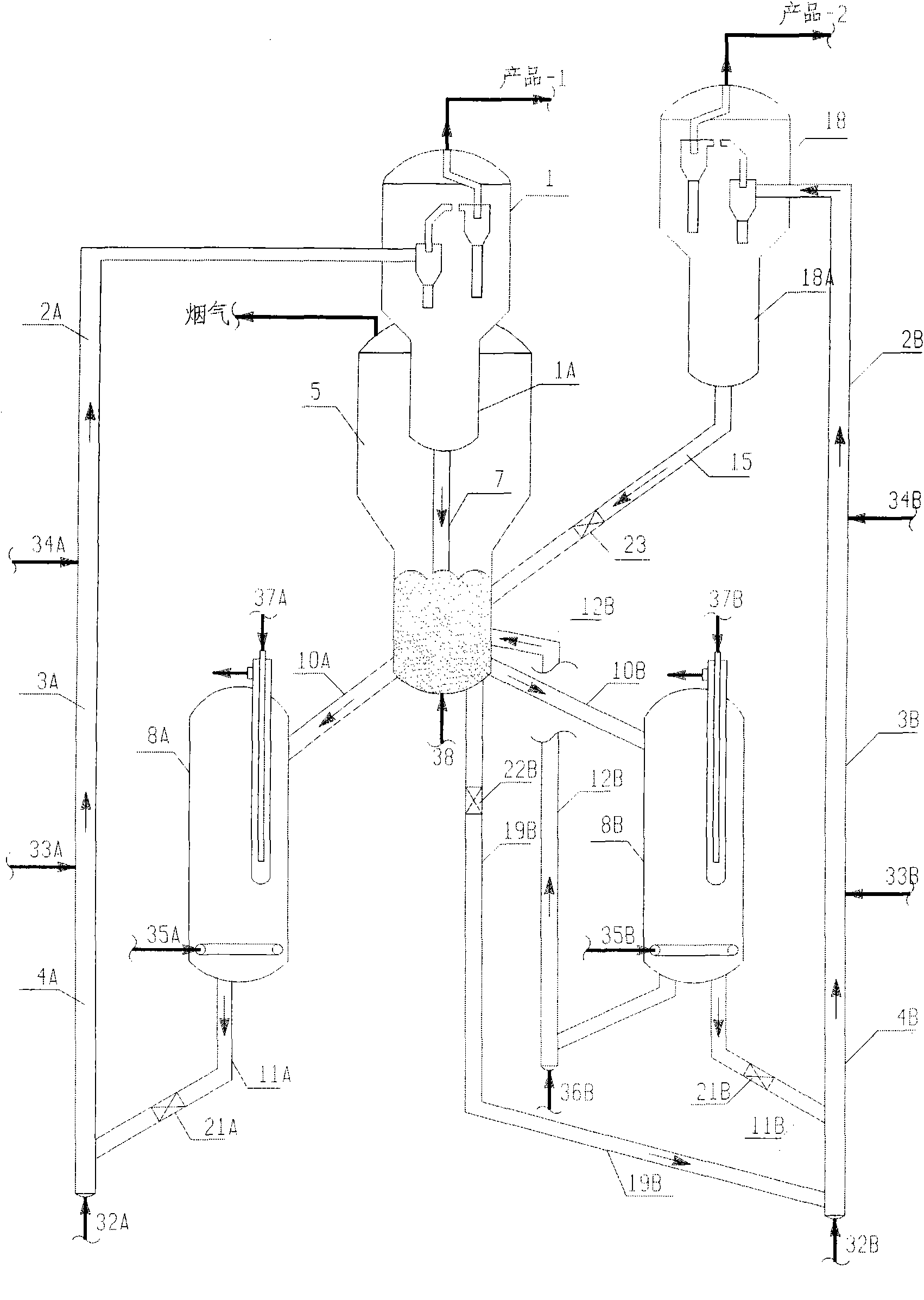

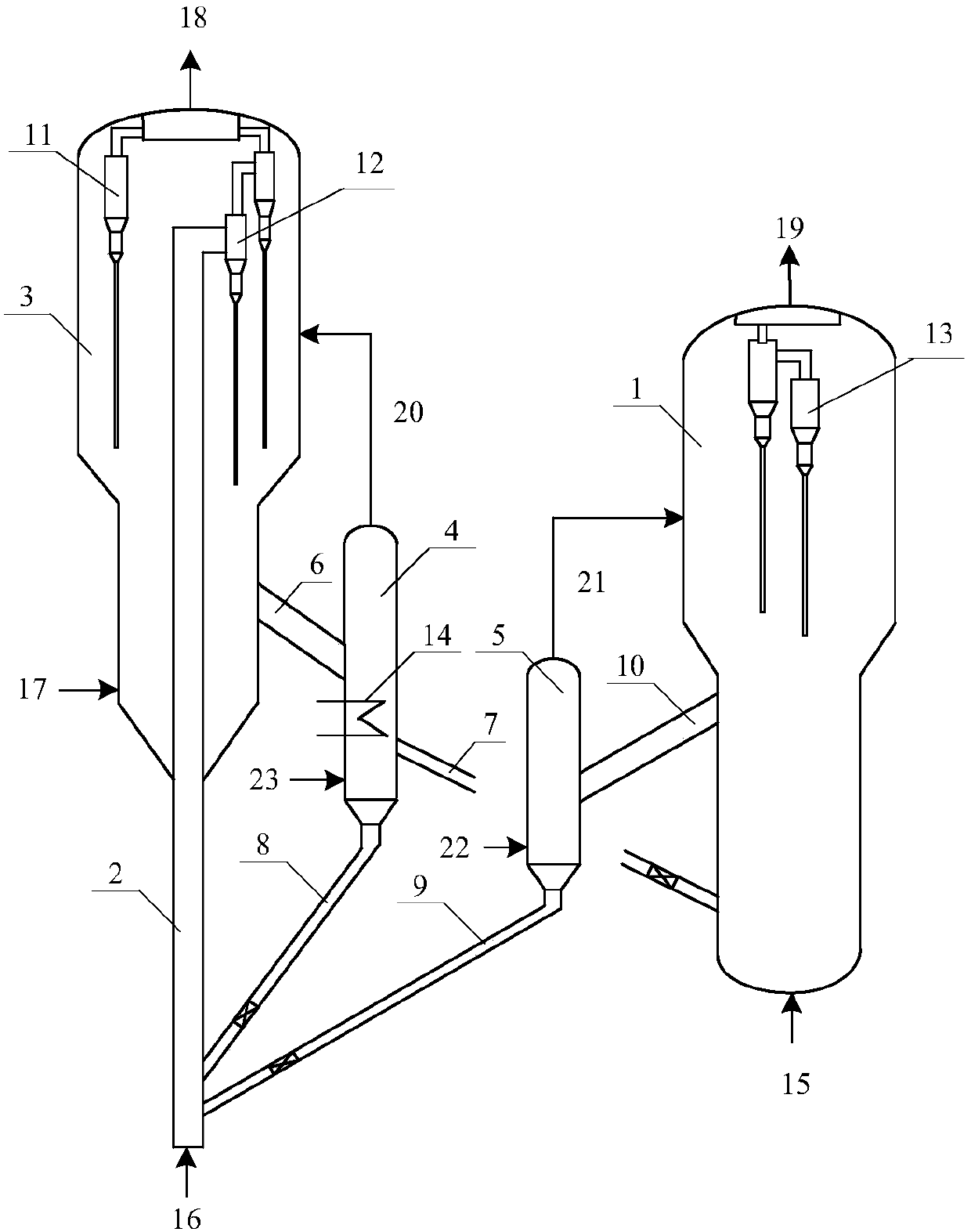

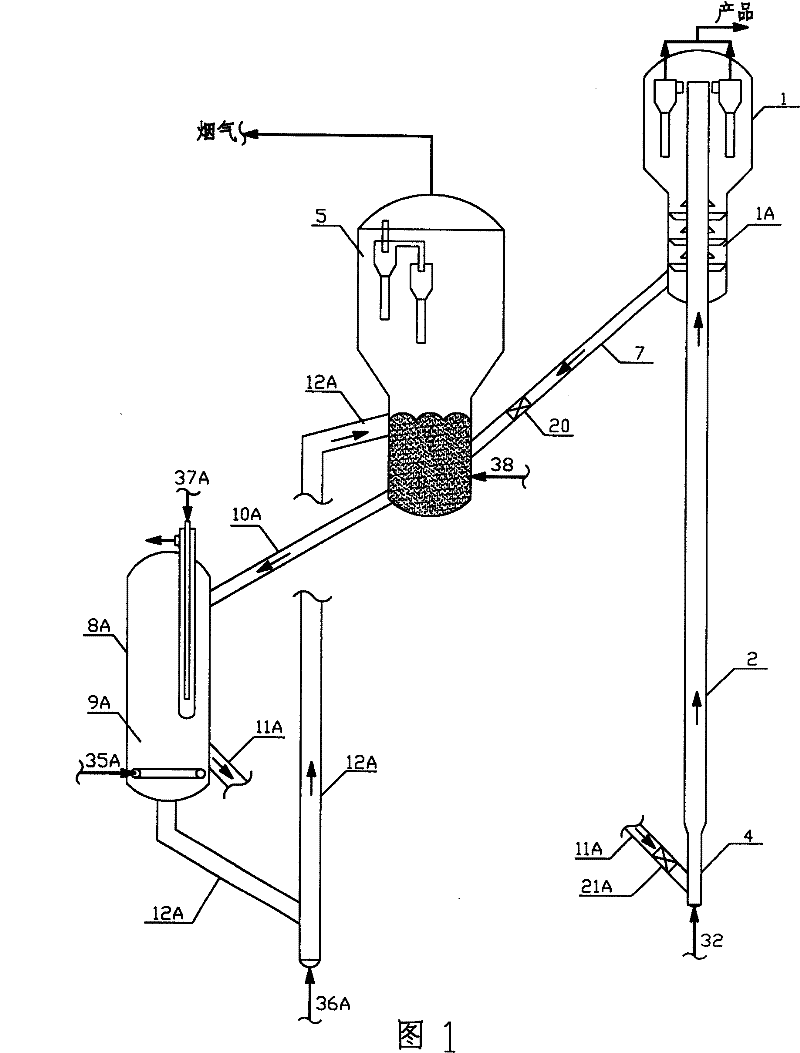

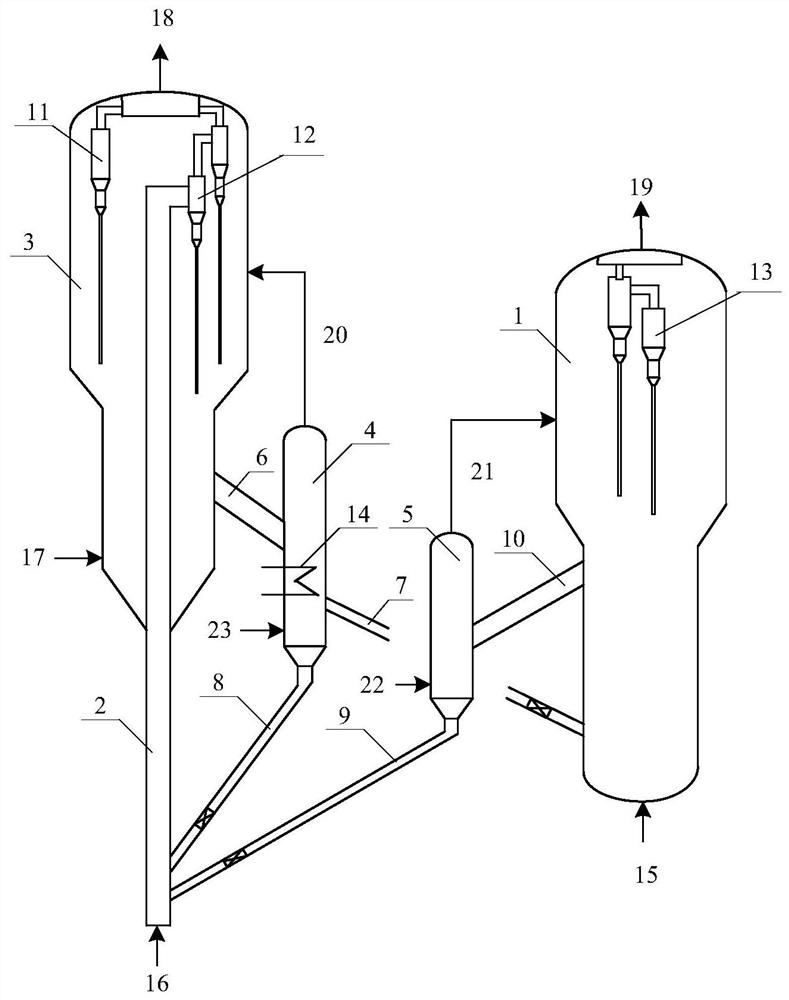

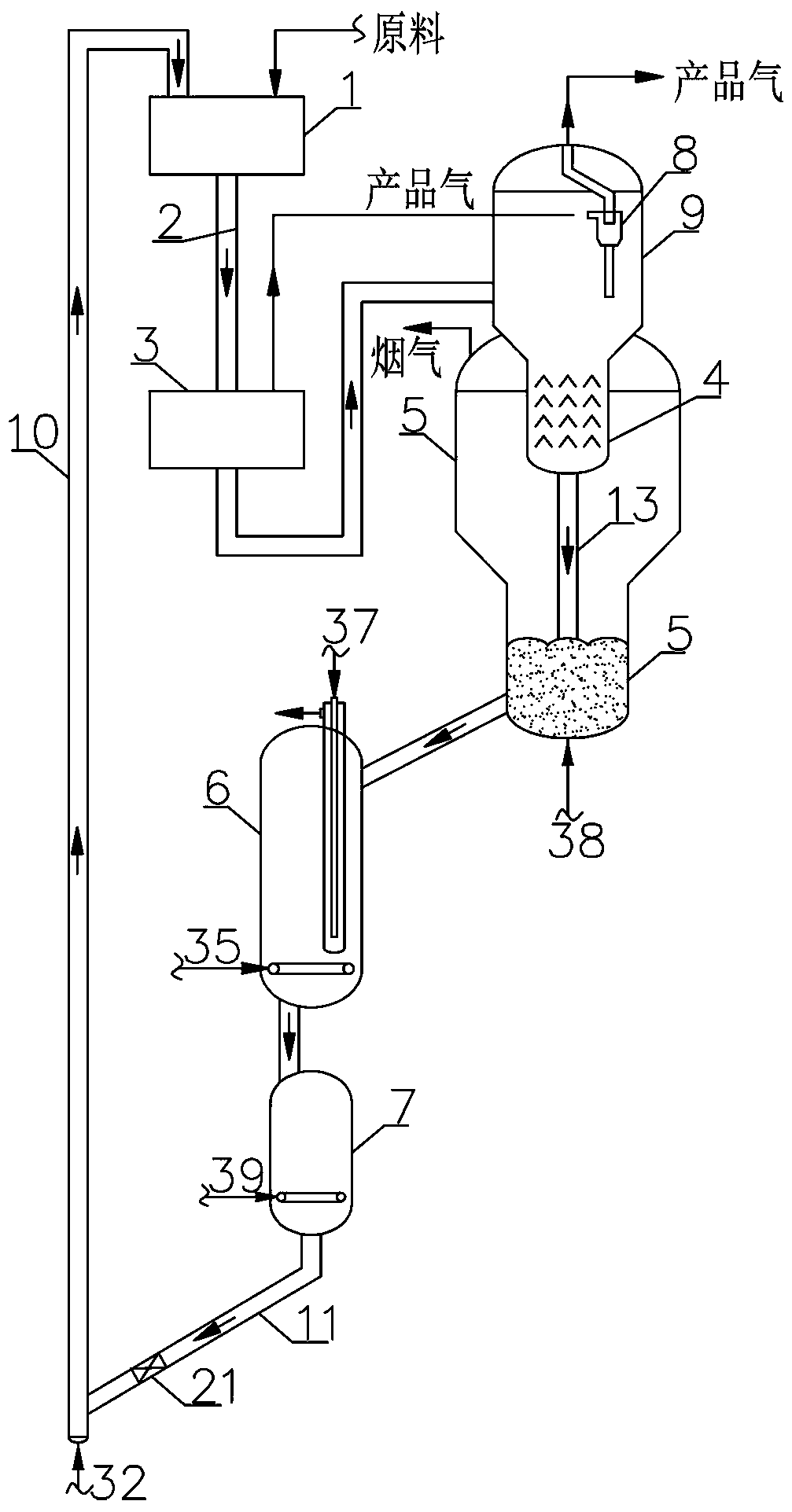

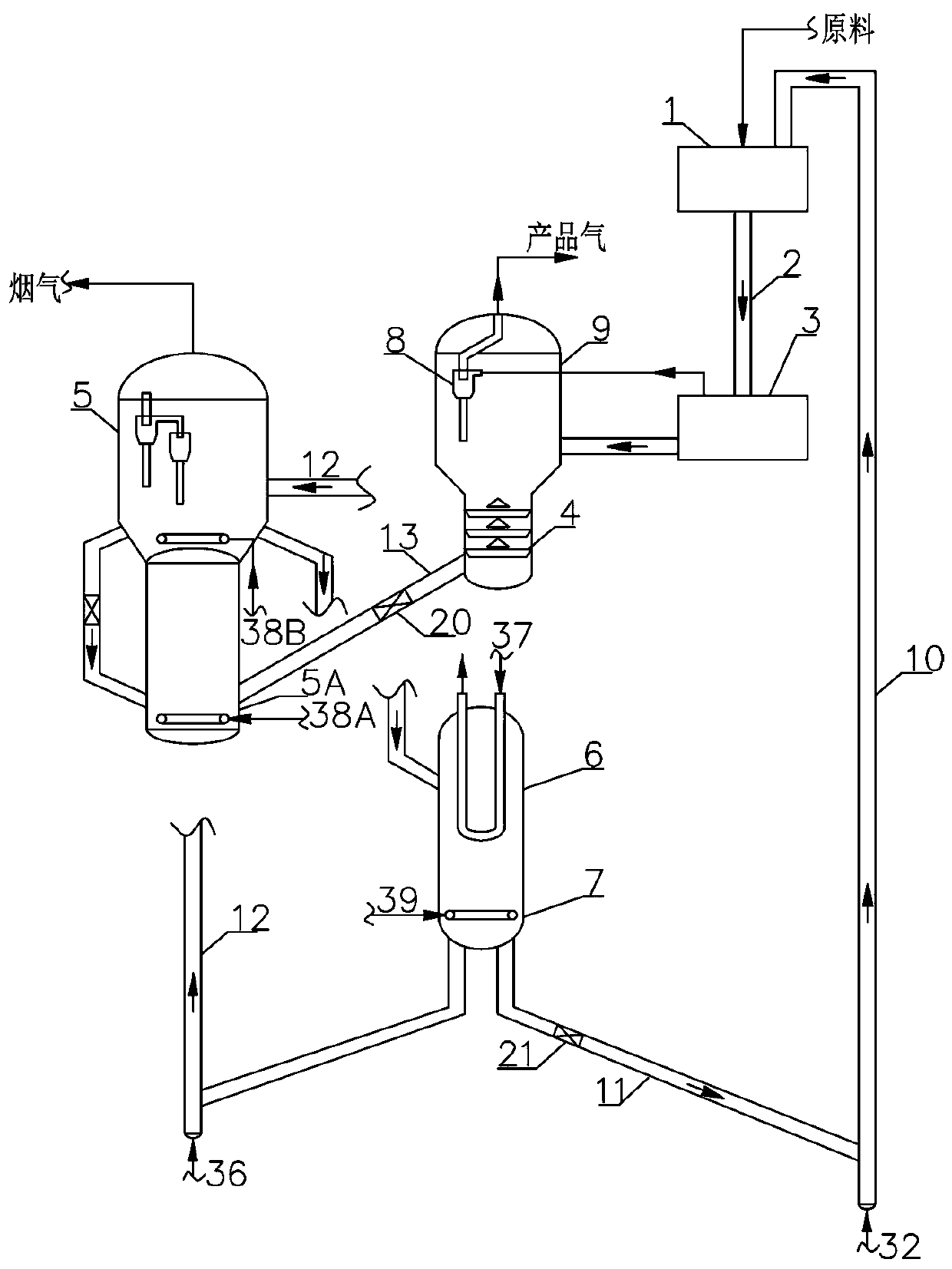

Method and device for fluidized catalytic conversion

ActiveCN101665712AReduce the temperatureRaise the preheat temperatureCatalytic crackingCatalytic transformationContact time

The invention provides a method for catalytic conversion of heavy oil, which comprises a fluidized catalytic conversion process that: heavy hydrocarbon raw materials contacts a catalyst in a riser reactor or fluidized bed reactor to react; the reaction temperature is 400 to 650 DEG C (preferably 480 to 560 DEG C); the reaction pressure is 0.11 to 0.4MPa; the contact time is 0.05 to 5 seconds (preferably 0.1 to 3 seconds); and the weight ratio of the catalyst to the raw materials ( catalyst to oil ratio) generally is 3 to 15, preferably 5 to 12. The reaction products flow in a settler for catalyst and oil gas separation; the separated catalyst to be regenerated is stripped by a stripping section and enters a regenerator for coke burning regeneration; and the regenerated catalyst is cooled or directly returns to the riser reactor to be recycled. The method can solve the problems encountered in the resid-blend ratio improvement and gasoline upgrade and update processes of the prior catalytic conversion.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

Catalytic converting method for improving petrol octane number

ActiveCN1611573ABoost octaneInhibit coking tendencyCatalytic naphtha reformingSeparation systemChemistry

One catalyzed conversion method to increase gasoline octane number is to emit the heavy petrol whose first distillate point is higher than 100deg.C into the first conversion zone at the bottom of the reactor riser and there contact the regenerated catalyst from the regenerator which causes reaction. The product flow upward along the reactor riser; separate the reaction gas from the catalyst, through stripping and regenerated, the catalyst can be recycled; the separated reaction oil gas is sent to the retral separation system to be further separated into various products. This invention can be carried out by common catalyzed conversion equipment, and can achieve the aim to increase octane number of catalyzed cracked gasoline, without any need to use particular catalyst or to modify the equipment in a big way.

Owner:CHINA PETROLEUM & CHEM CORP +1

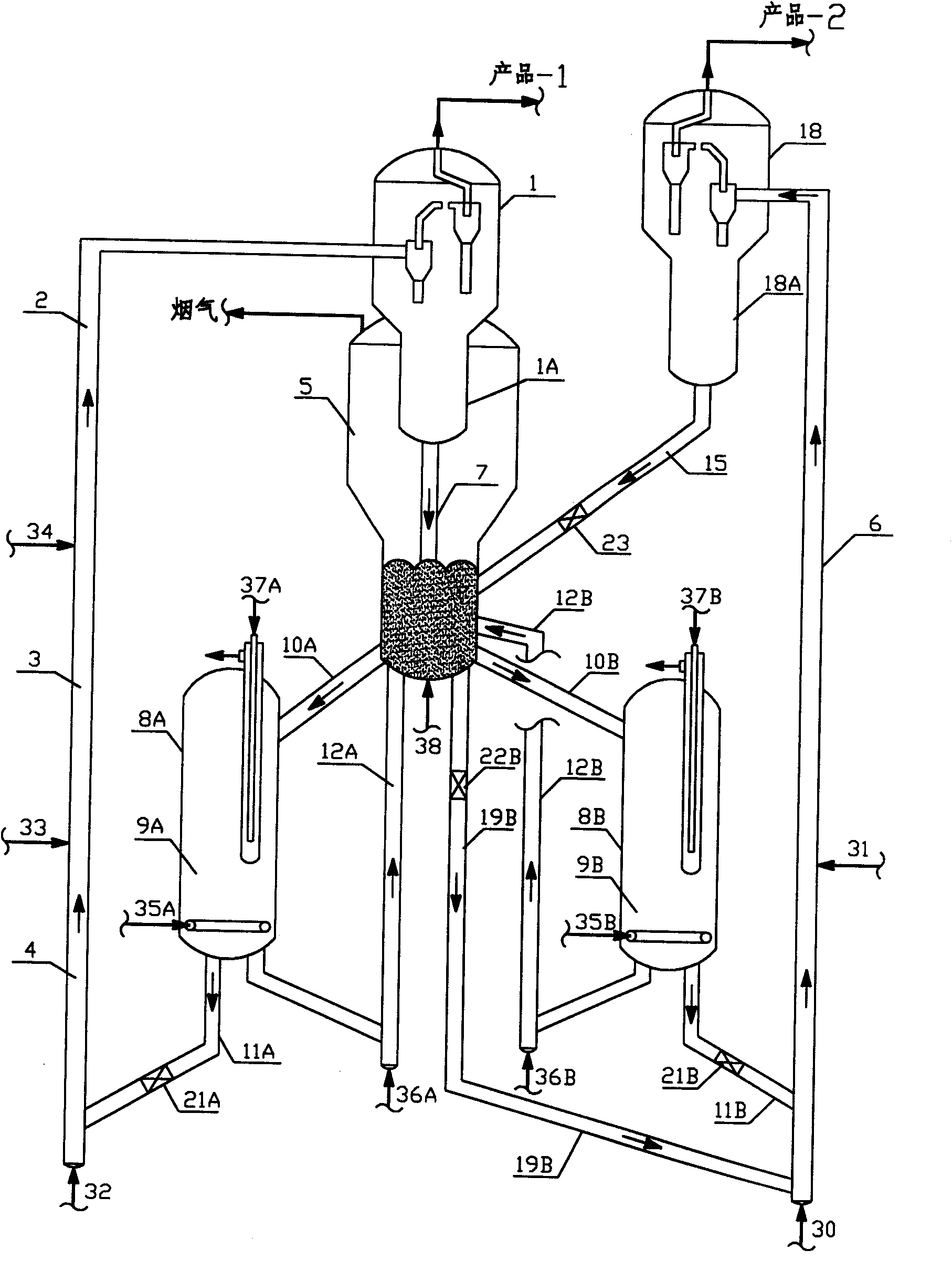

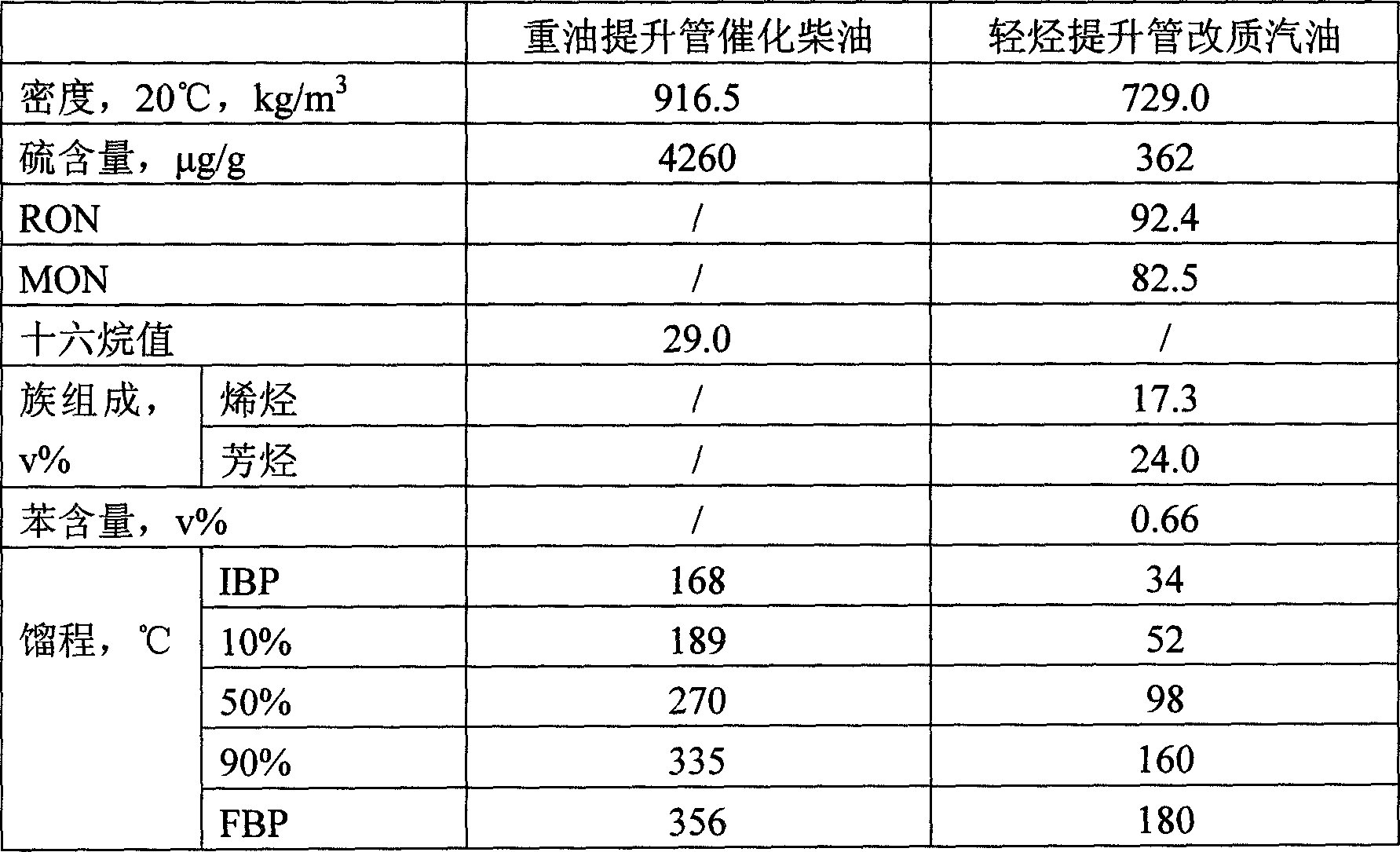

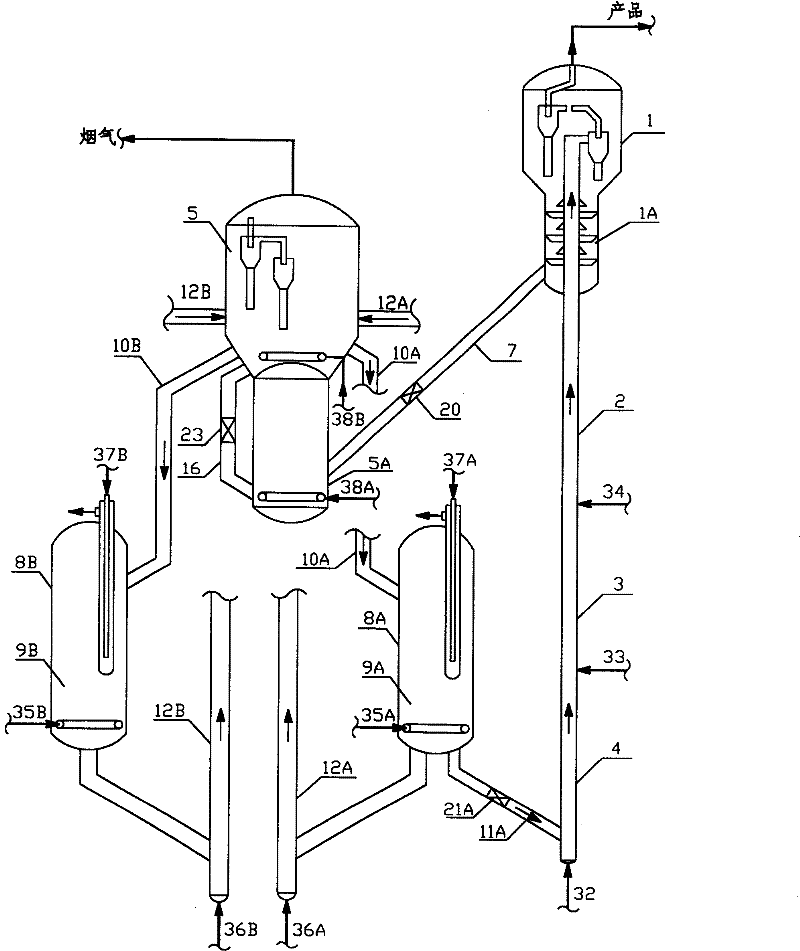

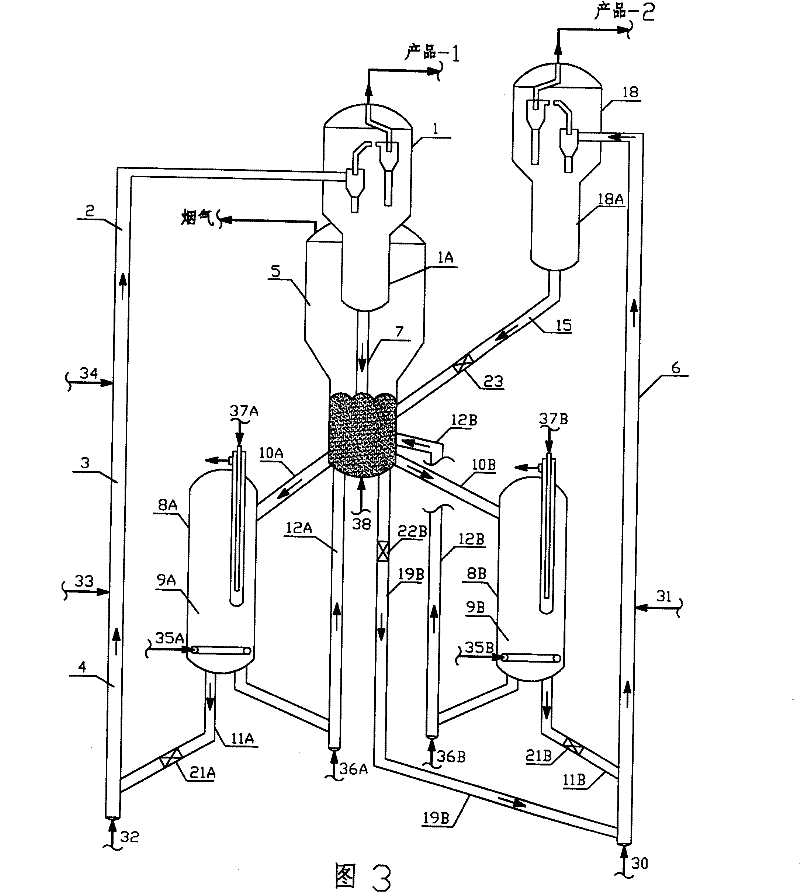

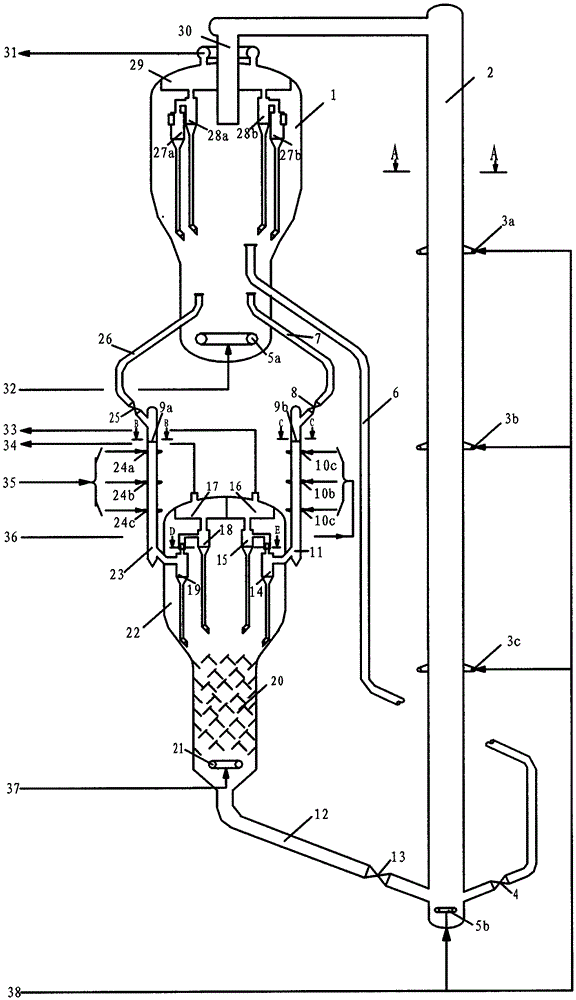

Catalytic cracking method

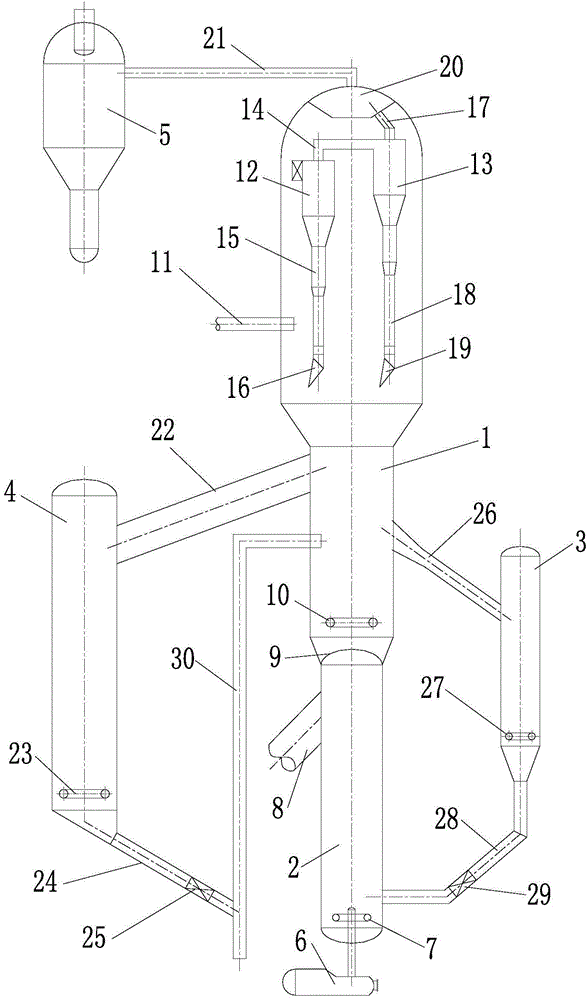

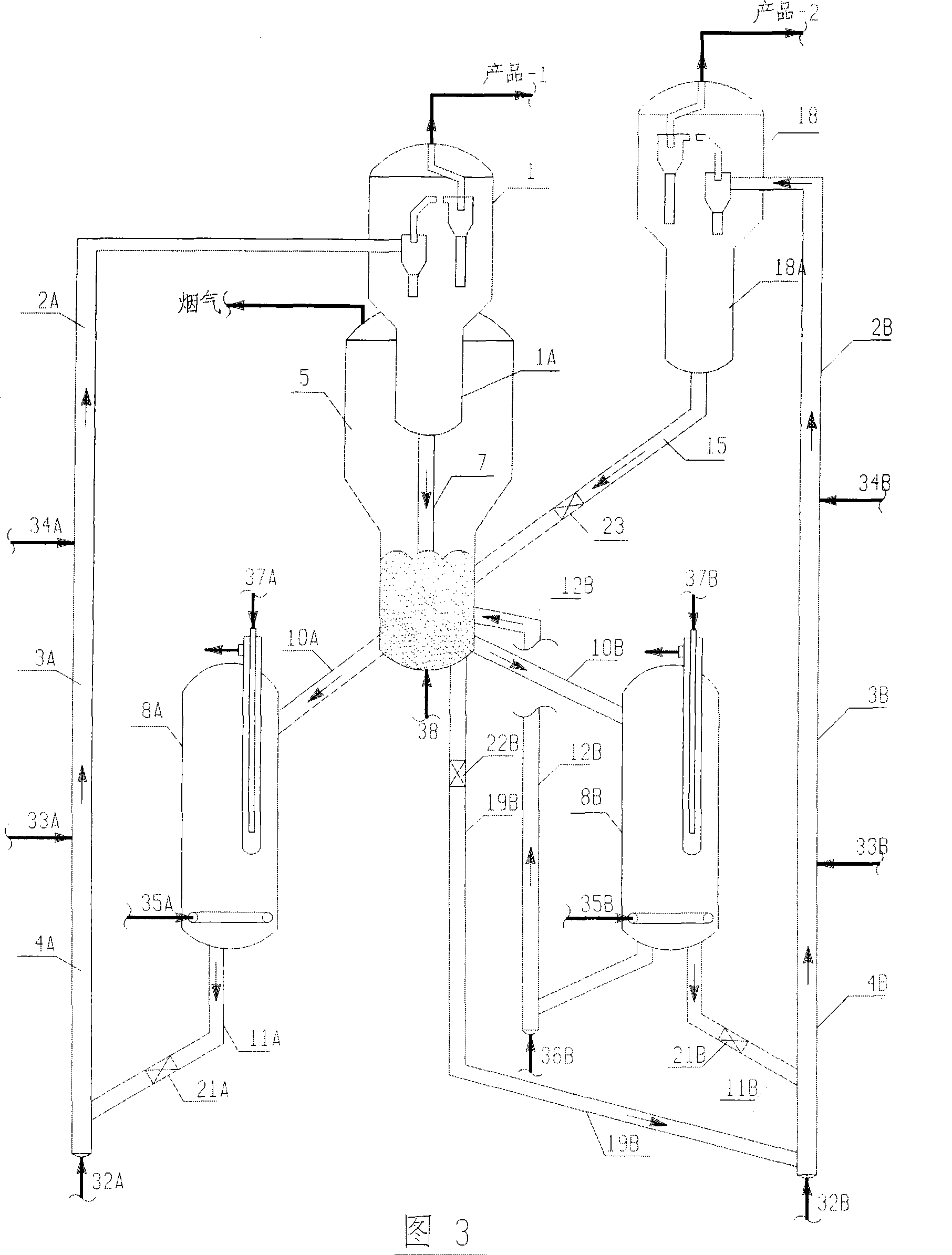

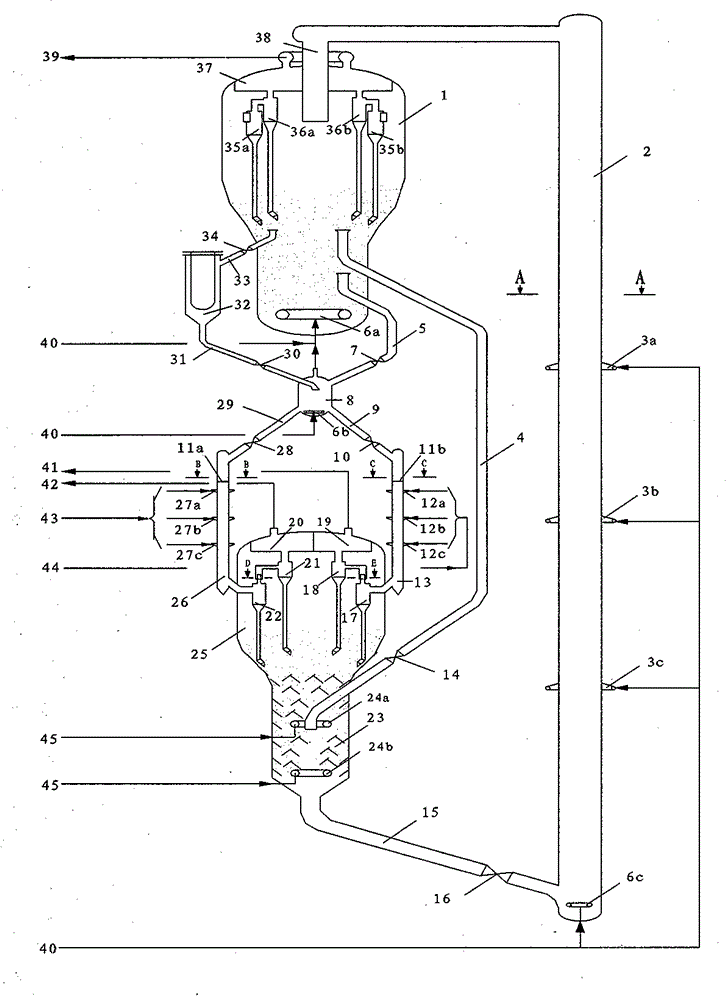

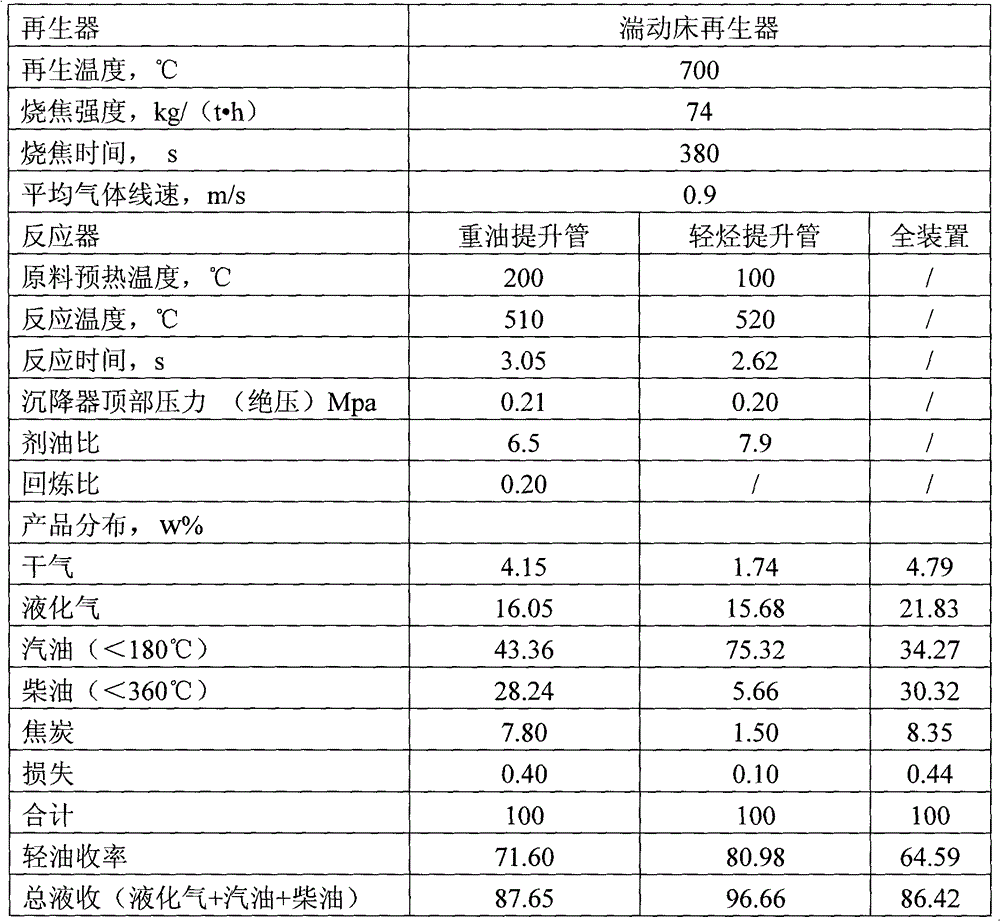

The invention discloses a catalytic cracking method. The method comprises the following steps: two descendent tube reactors capable of multipoint feeding are adopted to respectively perform heavy oil catalytic cracking and light hydrocarbon catalytic reforming; two reactant streams flow into a precipitator and are respectively subjected to gas-solid separation by different cyclone separators; a mixed regenerative agent is subjected to steam stripping, enters a multipoint-air-intake riser regenerator to be mixed with a regenerated catalyst stream to perform charring regeneration; the generated semi-regenerated catalyst enters a turbulent bed regenerator to be subjected to charring regeneration; the regenerated catalyst returns to the two reactors for cyclic use; and heavy oil reaction oil gas and light hydrocarbon reaction oil gas are respectively fractionated by the respective special fractionating towers. The method can improve the catalytic cracking product distribution, enhance the light oil yield and lower the yield of the cracked gas and coke; the method can be used for producing low-olefin-content catalytic gasoline and high-cetane-number catalytic diesel; and the method enhances the charring efficiency and decelerates the hydrothermal inactivation of the catalyst.

Owner:CHINA PETROCHEMICAL CORP +1

Method and device for improving selectivity of low-carbon olefin preparation using oxygen-containing compound converting

PendingCN111018646AImprove distributionHigh selectivityMolecular sieve catalystCatalyst regeneration/reactivationPtru catalystProcess engineering

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD +1

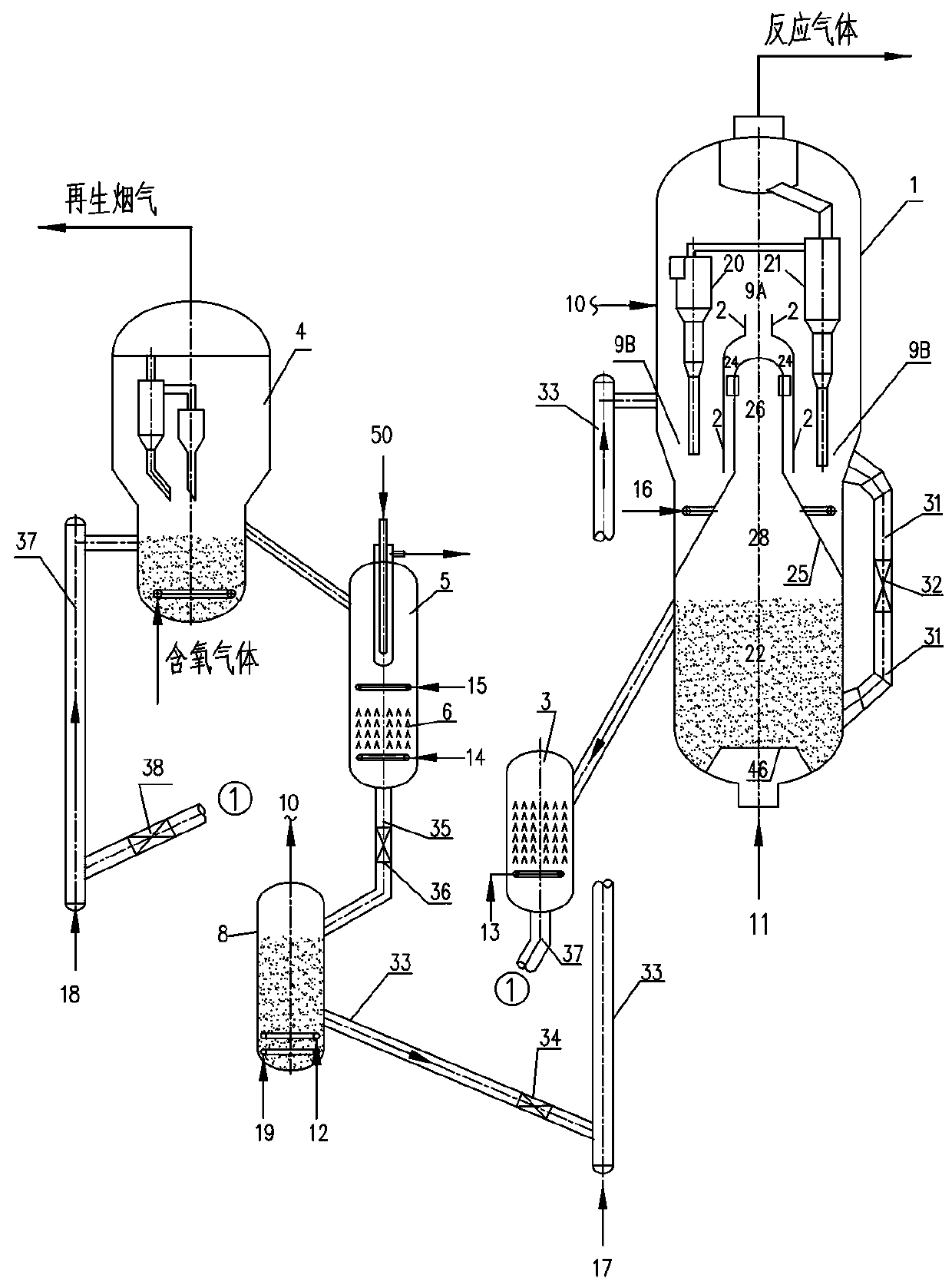

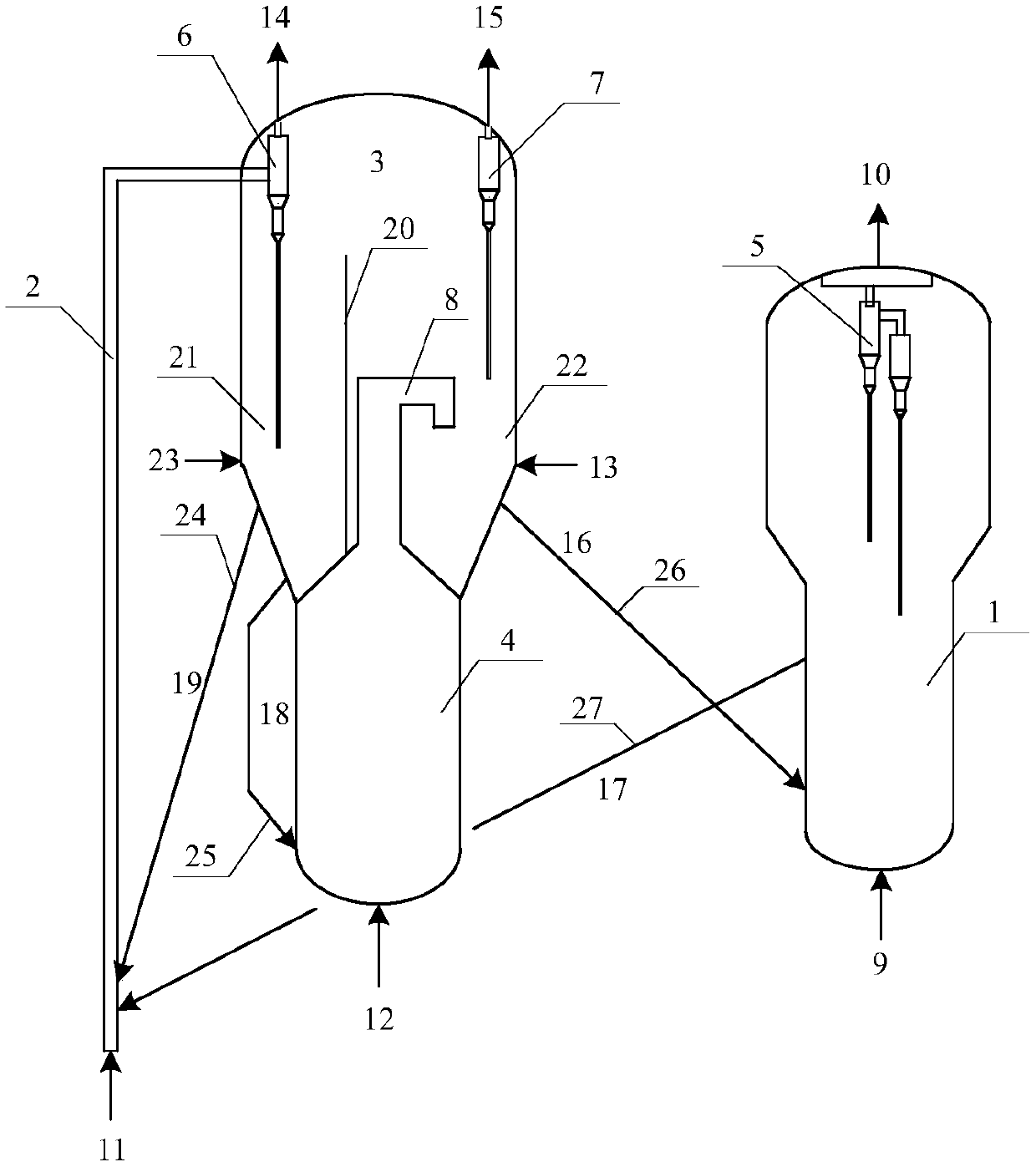

Reaction system and reaction method for preparing aromatic hydrocarbon through catalytic conversion of methanol

ActiveCN111056901AReduce hydrothermal deactivationIncrease aromatics yieldMolecular sieve catalystsMolecular sieve catalystCatalytic transformationPtru catalyst

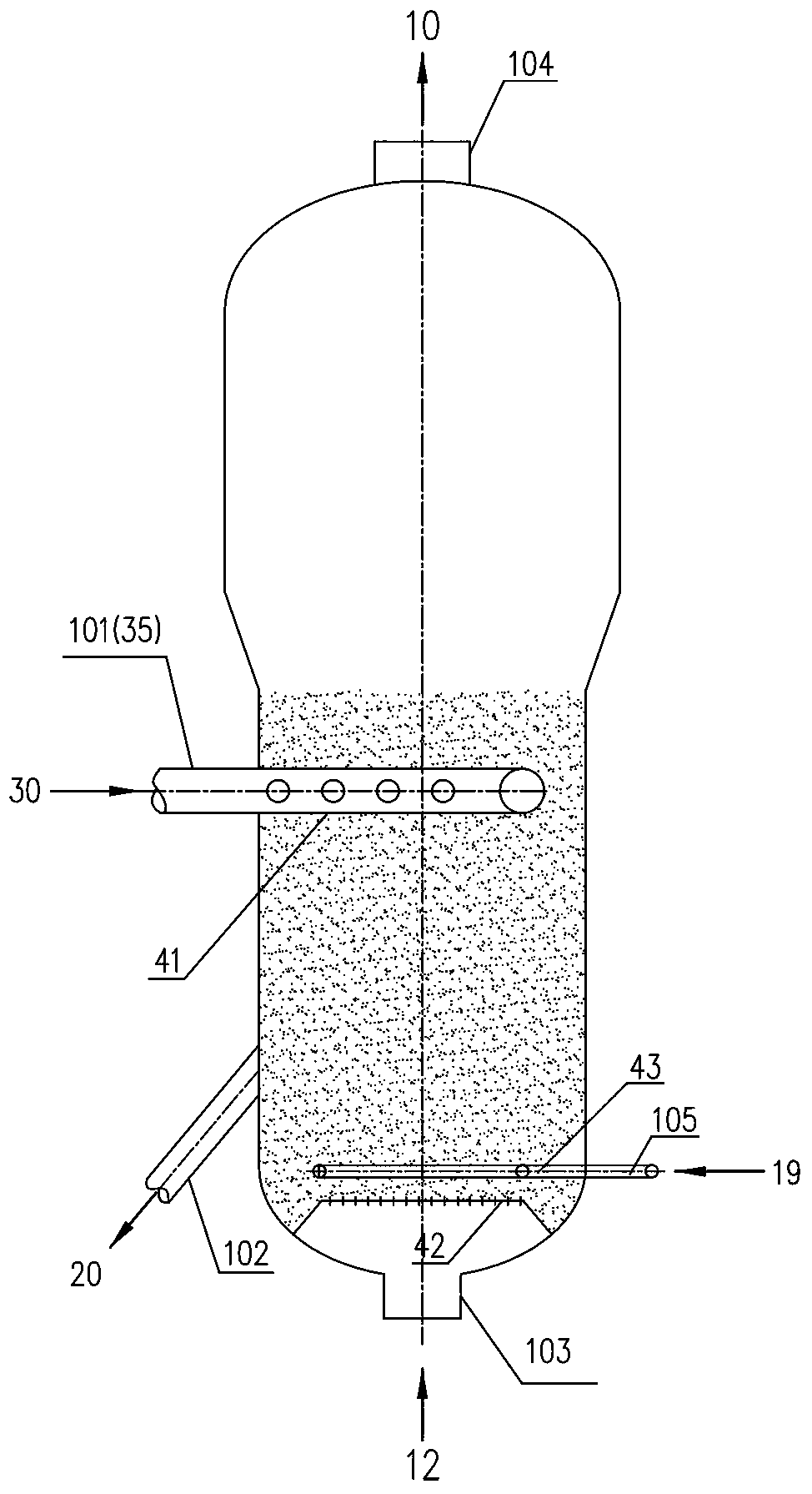

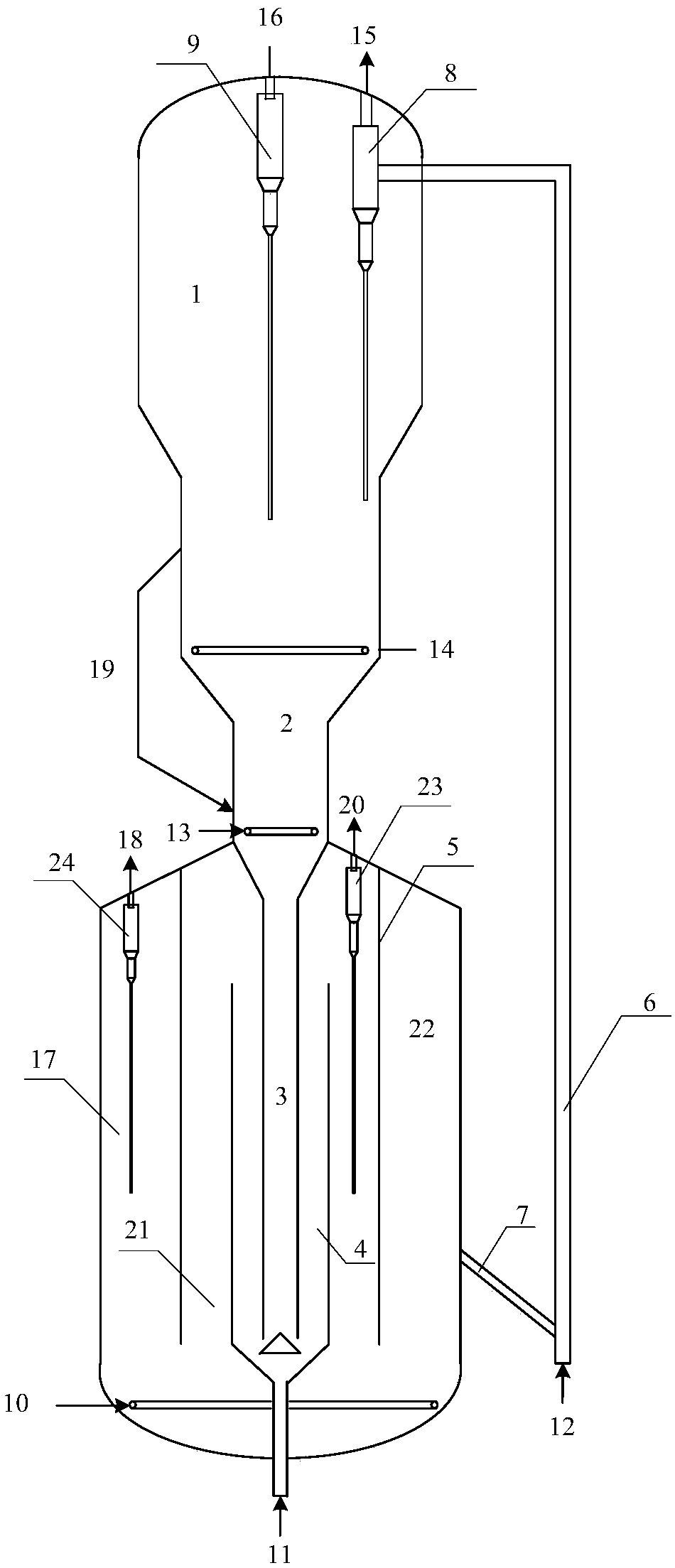

The invention relates to a reaction system for preparing aromatic hydrocarbon through catalytic conversion of methanol and a reaction method thereof, and mainly solves the problem of low aromatic hydrocarbon yield in the prior art. According to the invention, a methanol raw material enters a methanol reaction zone of a fluidized bed reactor and is subjected to a contact reaction with a modified ZSM-5 catalyst; the obtained spent catalyst enters a riser regenerator through a spent inclined pipe; the obtained semi-regenerated catalyst enters a riser regeneration cyclone separator connected withthe riser regenerator; the separated semi-regenerated catalyst enters a fluidized bed regenerator and is regenerated; the obtained regenerated catalyst enters a degassing zone through a regeneration inclined pipe, the degassed regenerated catalyst enters a light hydrocarbon reaction zone through a vertical pipe and is subjected to a contact reaction with a light hydrocarbon raw material, and the obtained semi-spent catalyst descends in a descending zone and enters a methanol reaction zone, so that the problems are well solved, and the reaction system and reaction method can be used for industrial production of aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device for improving selectivity of production of low-carbon olefin from methanol conversion

PendingCN111004077AHigh selectivityHigh activityHydrocarbon from oxygen organic compoundsEthylene productionPtru catalystProcess engineering

The invention belongs to the technical field of low-carbon olefin preparation, and discloses a method and device for improving selectivity of production of low-carbon olefin from methanol conversion.The method comprises the following steps: cooling a regenerated catalyst from a regenerator to a temperature lower than a methanol conversion reaction temperature through a regenerant cooler, introducing the cooled regenerated catalyst into a pre-hydrocarbon pooling facility, and carrying out a pre-hydrocarbon pooling reaction with an activation medium to form a 'hydrocarbon pool' active substances; and conveying the catalyst subjected to pre-hydrocarbon pooling activation treatment into a conversion reactor to be recycled. According to the invention, the pre-hydrocarbon pooling facility is arranged; the regenerated agent is subjected to pre-hydrocarbon pooling treatment, so that the regenerant forms hydrocarbon pool active substances and carbon deposit before entering the methanol conversion reactor, and the hydrocarbon pool active substance distribution and carbon deposit distribution of the catalyst in the methanol conversion reactor are improved, thereby shortening or eliminating the reaction induction period and enhancing the activity and selectivity of the regeneration agent methanol-to-low carbon olefin reaction.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD +1

Method for preparing aromatic hydrocarbons through conversion of methanol

ActiveCN109694296AKeep aliveReduce hydrothermal deactivationMolecular sieve catalystCatalystsCycloneFluidized bed

The invention relates to a method for preparing aromatic hydrocarbons through catalytic conversion of methanol. A purpose of the present invention is mainly to solve the problems of low aromatic hydrocarbon yield and serious hydrothermal deactivation of the catalyst in the prior art. According to the technical scheme, a methanol raw material enters a fluidized bed reactor, and is subjected to a contact reaction with a modified ZSM-5 catalyst to obtain an aromatic hydrocarbon-containing product and a spent catalyst; the steam stripped spent catalyst enters a riser regenerator, and contacts a regeneration medium I, and charring is performed at a temperature of 500-600 DEG C; the outlet of the riser regenerator is connected to at least a set of closed cyclone separators; the semi-regeneratedcatalyst separated by the closed cyclone separators enter a fluidized bed regenerator, and contacts a regeneration medium II, and charring is continuously performed at a temperature of 630-700 DEG C;the regenerated catalyst enters a degassing tank; and the degassed product returns to the fluidized bed regenerator. With the technical scheme, the problems in the prior art are well solved. The method of the present invention can be used in the industrial production of aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

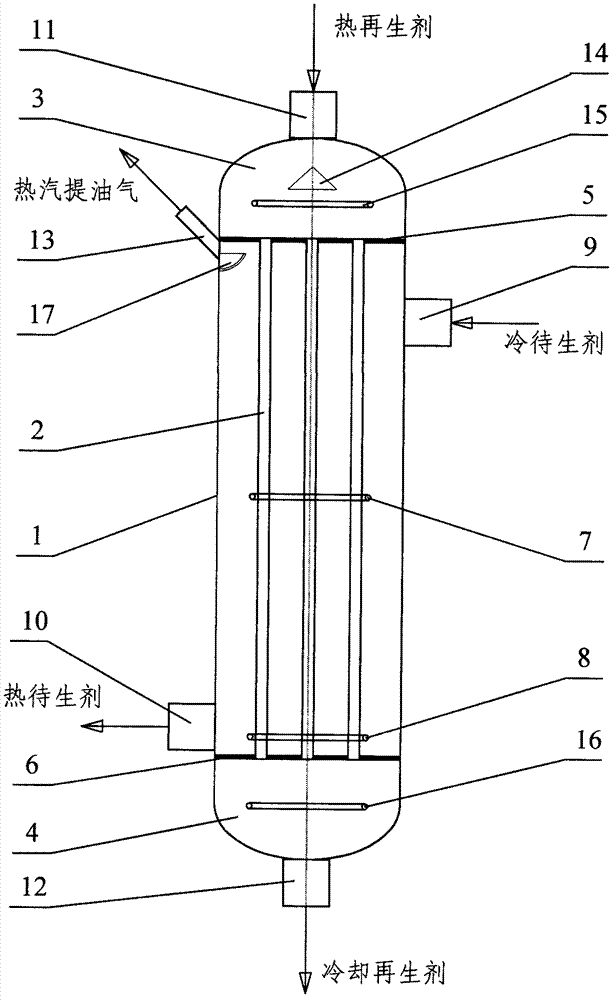

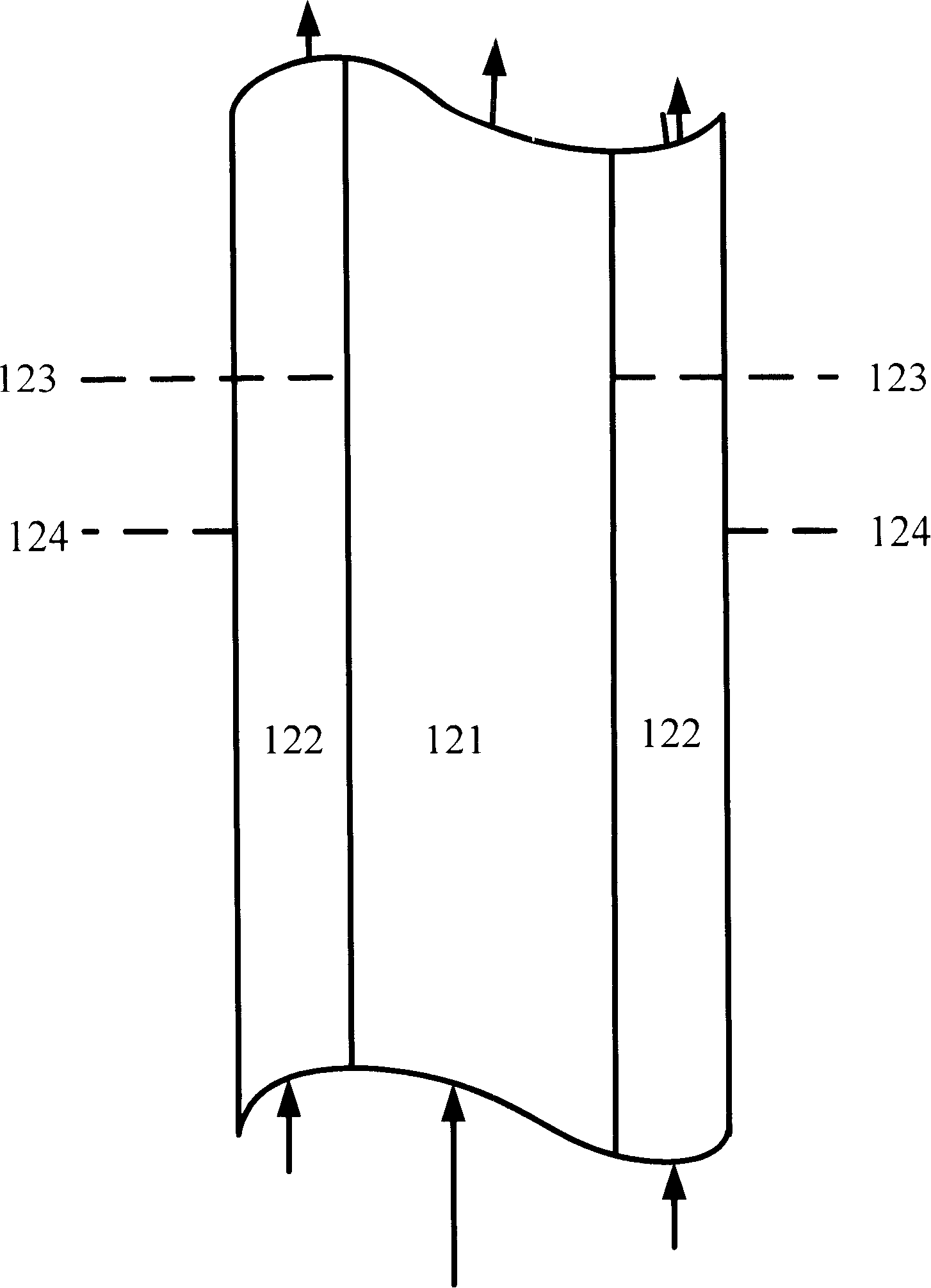

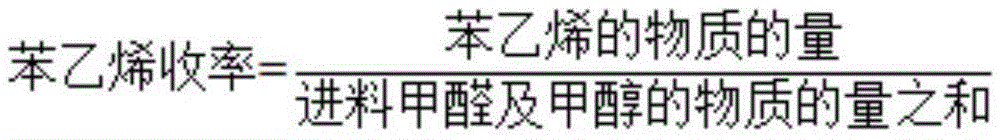

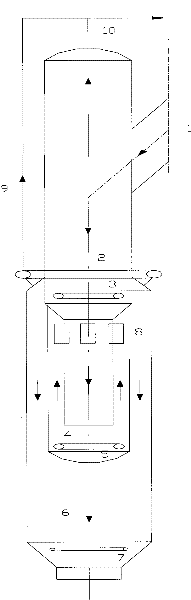

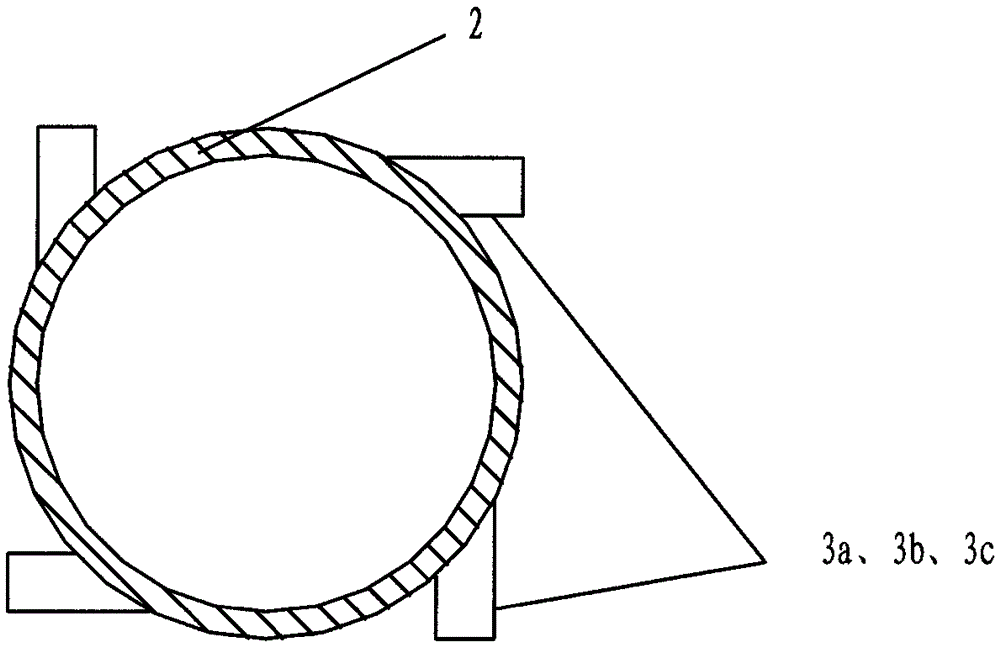

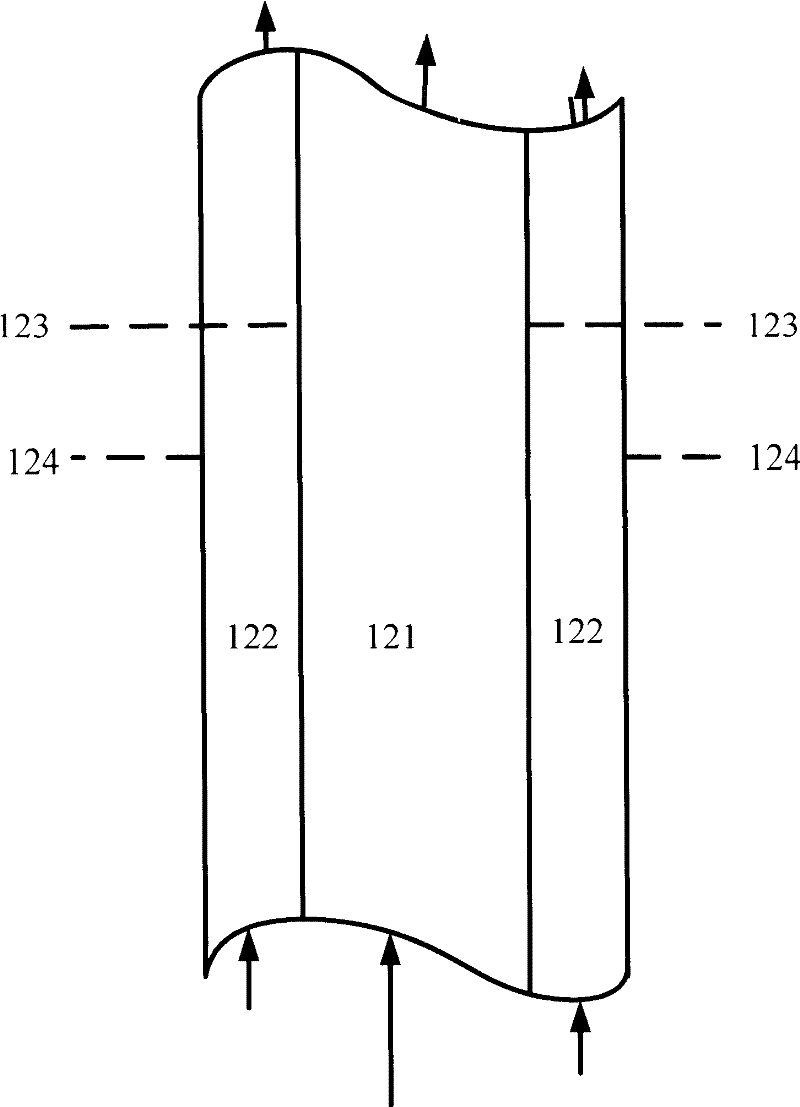

Tube-shell type solid-solid heat exchanger

InactiveCN103289726BGuaranteed thermal balanceGuaranteed to maintain heat balance under the condition of large agent-to-oil ratioCatalytic crackingSolid particleEngineering

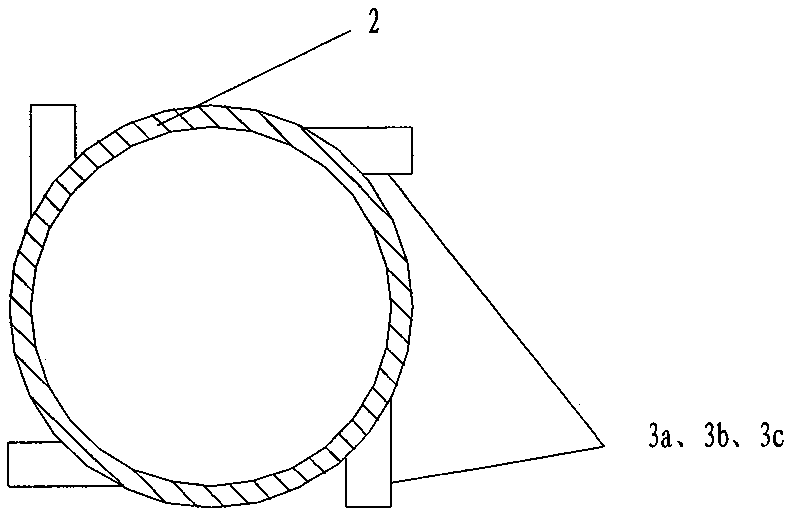

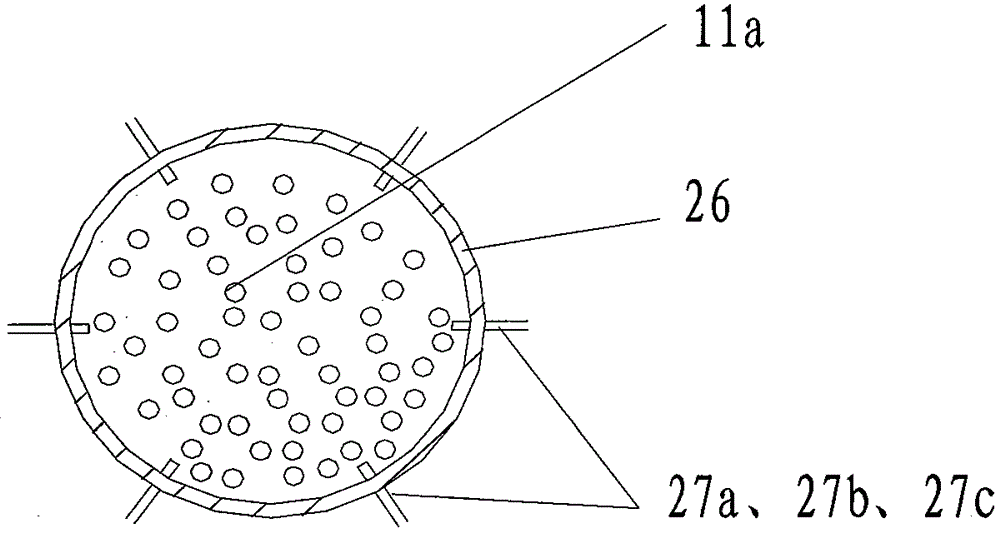

The invention relates to a tube-shell type solid-solid heat exchanger without blending between cold and hot solid particles for heat exchange, inner spaces of an upper sealing head (3) and a lower sealing head (4) and the inner space of a heat exchange tube (2) form a tube pass, a space defined by a shell (1), an upper tube plate (5), a lower tube plate (6) and a heat exchange tube (2) forms a shell pass, fluidizers are respectively arranged in the tube pass and the shell pass, the cold and hot solid particles are fluidified and flow in the shell pass and the tube pass respectively, and heat exchange is realized between the cold and hot solid particles by virtue of the heat exchange tube (2). By adopting the tube-shell type solid-solid heat exchanger, heat exchange can be carried out between a thermal regeneration agent and a cold spent agent of a catalytic cracking unit, thus stable operation with high agent-oil ratio is realized, thermal balance of the whole device is maintained, and liquid yield of the tube-shell type solid-solid heat exchanger is increased; and thermal steam stripping on the spent agent can be realized, and benefit of the catalytic cracking unit is increased. The tube-shell type solid-solid heat exchanger provided by the invention can be applied to all the catalytic cracking units and other devices requiring heat exchange between the cold and hot solid particles.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

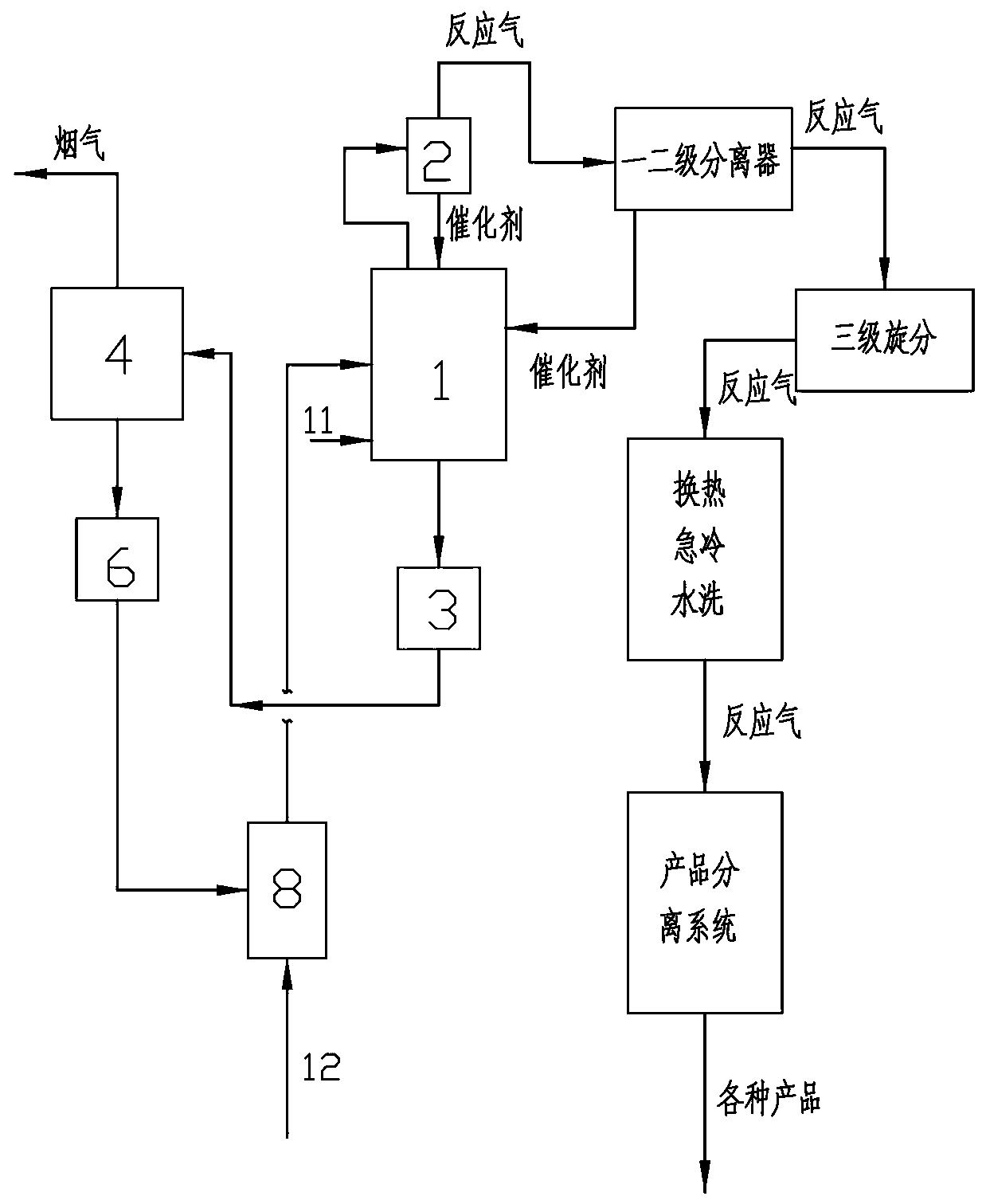

Regeneration method of catalyst for producing aromatic hydrocarbon from organic oxide through catalytic conversion

ActiveCN105983454AAdvantages of regeneration methodMeet regeneration requirementsCatalyst regeneration/reactivationFlue gasOrganic Oxide

The invention discloses a regeneration method of a catalyst for producing aromatic hydrocarbon from organic oxide through catalytic conversion. The method includes the steps of: 1) feeding a to-be-regenerated catalyst from a system of producing the aromatic hydrocarbon from the organic oxide through the catalytic conversion to a first regenerator to contact the catalyst with a first oxygen-containing gas to perform first regeneration at 500-650 DEG C to obtain a semi-regenerated catalyst and a first regeneration flue gas; and 2) feeding the semi-regenerated catalyst to a second regenerator to contact the catalyst with a second oxygen-containing gas to perform second regeneration at 600-750 DEG C to obtain the regenerated catalyst and a second regeneration flue gas, and then feeding the regenerated catalyst back into a system of producing the aromatic hydrocarbon from the organic oxide through catalytic conversion, wherein the two regenerators are arranged in an up-and-down manner and the first regenerator is arranged above the second regenerator. Compared with the prior art, the method is safer and is low in hydrothermal deactivation and loss rate of the catalyst.

Owner:SINOPEC ENG +1

Heat exchange method in hydrocarbon oil conversion process and hydrocarbon oil conversion method

ActiveCN101210189AReduce hydrothermal deactivationReduce consumptionCatalytic crackingLiquid productUnit mass

A heat exchanging method in hydrocarbon oil transforming process comprises the step of exchanging heat of hydrocarbon oil with that of a regeneration catalyst in a regenerator by a heat exchanger, wherein the heat exchanger is positioned in the regenerator. The invention also provides a hydrocarbon oil transforming method including the heat exchanging method. According to the heat exchanging method in the hydrocarbon oil transforming process in the invention, the heat exchanger is positioned in the regenerator to exchange the heat of the high-temperature regeneration catalyst with that of the raw material oil in the regenerator, so that the high-temperature regenerator catalyst has less heat loss and that the amount of the raw material oil that can be heated by reducing a certain temperature of the regeneration catalyst per unit is improved, thus improving the heat exchanging efficiency. Additionally, the heat exchanging method of the method can simultaneously perform the function of lowering temperature in the regenerator and preventing the catalyst from hydrothermal deactivation due to overhigh temperature, thus reducing the amount of fresh catalyst to be supplemented and reducing the catalyst consumption. The hydrocarbon oil transforming method of the invention can reduce the yields of dry gas and coke and improve the yield of liquid products.

Owner:CHINA PETROLEUM & CHEM CORP +1

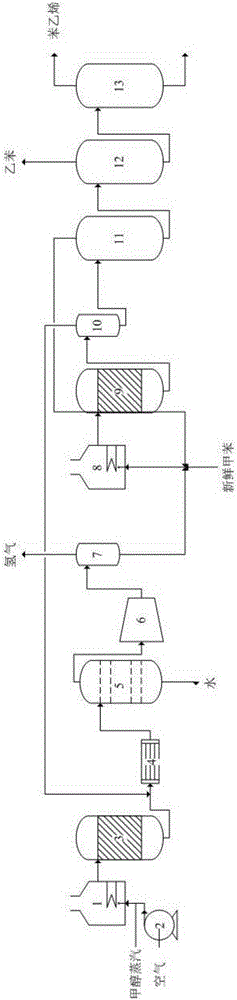

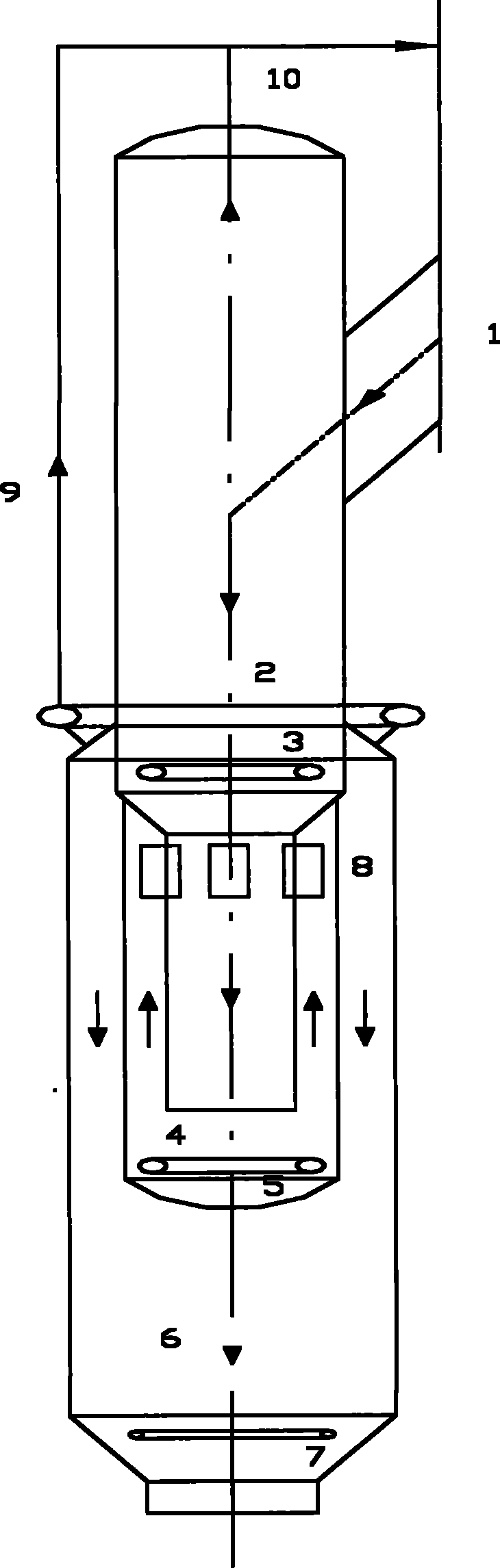

Technique for producing styrene by alkylating toluene and methanol side chains

InactiveCN105348032AReduce contentReduce the degree of side effectsOrganic compound preparationHydrocarbon by hydrocarbon and non-hydrocarbon condensationLiquid productSide chain

The invention discloses a technique for producing styrene by alkylating toluene and methanol side chains. The method comprises the steps of mixing and heating methanol vapor and air to obtain a mixture, enabling the mixture to enter a reactor producing formaldehyde by using methanol, and generating formaldehyde under the action of a catalyst; condensing a product, enabling the condensed product to enter a rectifying tower so as to remove water generated in the reaction, pressurizing a product at the tower top, enabling the pressurized product to enter a high-pressure separator, discharging noncondensable gas containing hydrogen from the top of the high-pressure separator, mixing and heating and a product at the bottom and toluene, enabling the mixture to enter a side chain alkylation reactor, enabling a gaseous product to return to therectifying tower after a product obtained in the reaction is subjected to separation by a gas-liquid separator, enabling a liquid product to enter a toluene tower, an ethylbenzene tower and a styrene tower sequentially, enabling toluene to return to the side chain alkylation reactor, and discharging ethylbenzene, styrene and C9<+>heavy aromatics. The technique is of a two-step method for toluene and methanol side chain alkylation, not only can the generation degree of a side reaction between styrene and hydrogen be effectively inhibited, but also the hydrothermal deactivation of the catalyst for side chain alkylation can be alleviated.

Owner:CHINA NAT OFFSHORE OIL CORP +2

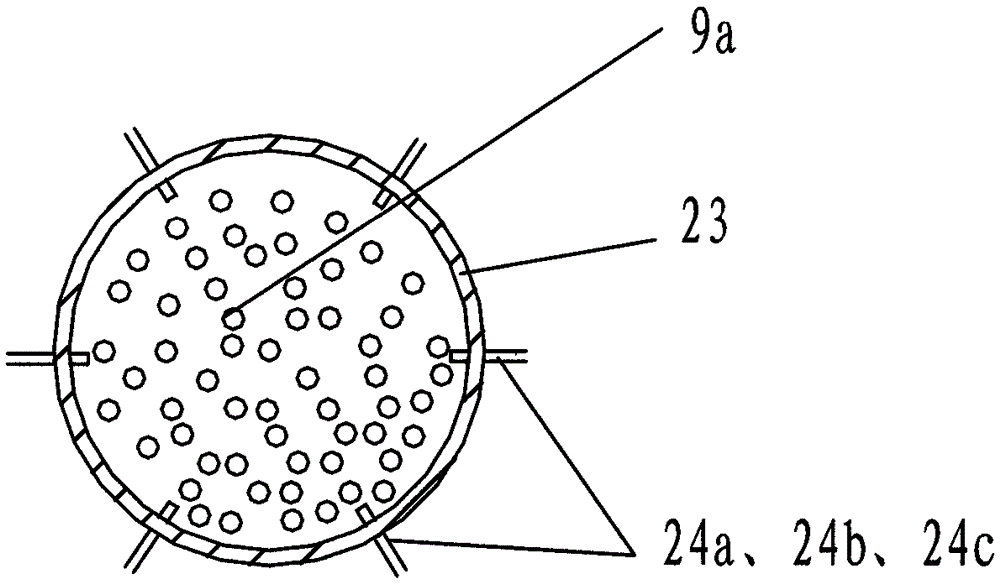

Equipment and method for degassing regenerated catalyst

ActiveCN102019211AImproved flue gas removal efficiencyDoes not affect degassingCatalyst regeneration/reactivationThree stagePetroleum engineering

The invention relates to equipment and a method for degassing a regenerated catalyst, which belongs to the technical field of efficient degassing of the regenerated catalyst which is regenerated by singeing. The technology is characterized in that: the regenerated catalyst from a regenerator is fed into a three-stage degassing bed; a fresh degassing medium is injected into each stage of degassing bed; each stage of degassed gas is separately discharged; and the degassing medium injected into each stage of degassing bed is gradually reduced so as to form different fluidization forms of each stage of catalyst bed layer, so that the regenerated catalyst can effectively contact the fresh degassing medium at each stage, the mass transfer driving force for degassing is improved, and the degassing effect is improved.

Owner:CHINA PETROCHEMICAL CORP +1

Method for preparing aromatic hydrocarbons through efficient conversion of methanol

ActiveCN109694294AImprove technical effectKeep aliveMolecular sieve catalystCatalystsCycloneFluidized bed

The invention relates to a method for preparing aromatic hydrocarbons through efficient conversion of methanol. A purpose of the present invention is mainly to solve the problems of low aromatic hydrocarbon yield and serious hydrothermal deactivation of the catalyst in the prior art. According to the technical scheme, a methanol raw material enters a fluidized bed reactor, and is subjected to a contact reaction with a modified ZSM-5 catalyst under the effective reaction conditions; a spent catalyst enters a riser regenerator, and is regenerated; the obtained semi-regenerated catalyst and fluegas I enter a riser regeneration cyclone separator connected to the riser regenerator; the separated semi-regenerated catalyst enters the zone A of a two-dense bed, and is degassed; the degassed semi-regenerated catalyst partially returns to the riser regenerator, and partially enters a fast bed regenerator and is regenerated; and the obtained regenerated catalyst enters the zone B of the two-dense bed and is degassed and the degassed regenerated catalyst enters the fluidized bed reactor. With the technical scheme, the problem in the prior art is well solved. The method of the present invention can be used in the industrial production of aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

Equipment and method for degassing regenerated catalyst

The invention relates to equipment and a method for degassing a regenerated catalyst, which belongs to the technical field of efficient degassing of the regenerated catalyst which is regenerated by singeing. The technology is characterized in that: the regenerated catalyst from a regenerator is fed into a three-stage degassing bed; a fresh degassing medium is injected into each stage of degassingbed; each stage of degassed gas is separately discharged; and the degassing medium injected into each stage of degassing bed is gradually reduced so as to form different fluidization forms of each stage of catalyst bed layer, so that the regenerated catalyst can effectively contact the fresh degassing medium at each stage, the mass transfer driving force for degassing is improved, and the degassing effect is improved.

Owner:CHINA PETROCHEMICAL CORP +1

Catalytic converting method for improving petrol octane number

InactiveCN1234813CBoost octaneInhibit coking tendencyCatalytic naphtha reformingSeparation systemChemistry

One catalyzed conversion method to increase gasoline octane number is to emit the heavy petrol whose first distillate point is higher than 100deg.C into the first conversion zone at the bottom of the reactor riser and there contact the regenerated catalyst from the regenerator which causes reaction. The product flow upward along the reactor riser; separate the reaction gas from the catalyst, through stripping and regenerated, the catalyst can be recycled; the separated reaction oil gas is sent to the retral separation system to be further separated into various products. This invention can be carried out by common catalyzed conversion equipment, and can achieve the aim to increase octane number of catalyzed cracked gasoline, without any need to use particular catalyst or to modify the equipment in a big way.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device for circulating cold regenerated catalyst

ActiveCN101665713BReduce the temperatureRaise the preheat temperatureCatalytic crackingEthylene productionWaxGasoline

The invention provides a method for circulating a cold regenerated catalyst and application thereof. A regenerated catalyst from a regenerator is cooled by a catalyst cooler to between 200 and 720DEG C, and is not mixed with a hot regenerated catalyst to directly enter a riser reactor, or is mixed with another part of uncooled hot regenerated catalyst into a mixed regenerated catalyst of which the temperature is not lower than that of the regenerator to enter the riser reactor; and a hydrocarbon raw material undergoes contact reaction with the catalyst in the riser reactor, the reaction material flow enters a settler for the separation of the catalyst and oil gas, the separated catalyst to be regenerated is subjected to steam stripping in a steam stripping section, and then enters the regenerator for coke burning regeneration, and the regenerated catalyst is cooled and returns to the riser reactor for recycling. The method for circulating the cold regenerated catalyst has wide application, can be used for various fluid catalytic cracking processes comprising resid fluid catalytic cracking, wax oil catalytic cracking, gasoline catalytic conversion upgrading and the like, and also can be sued for other gas-solid reaction processes comprising residual oil pretreatment, fluid coking and the like.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

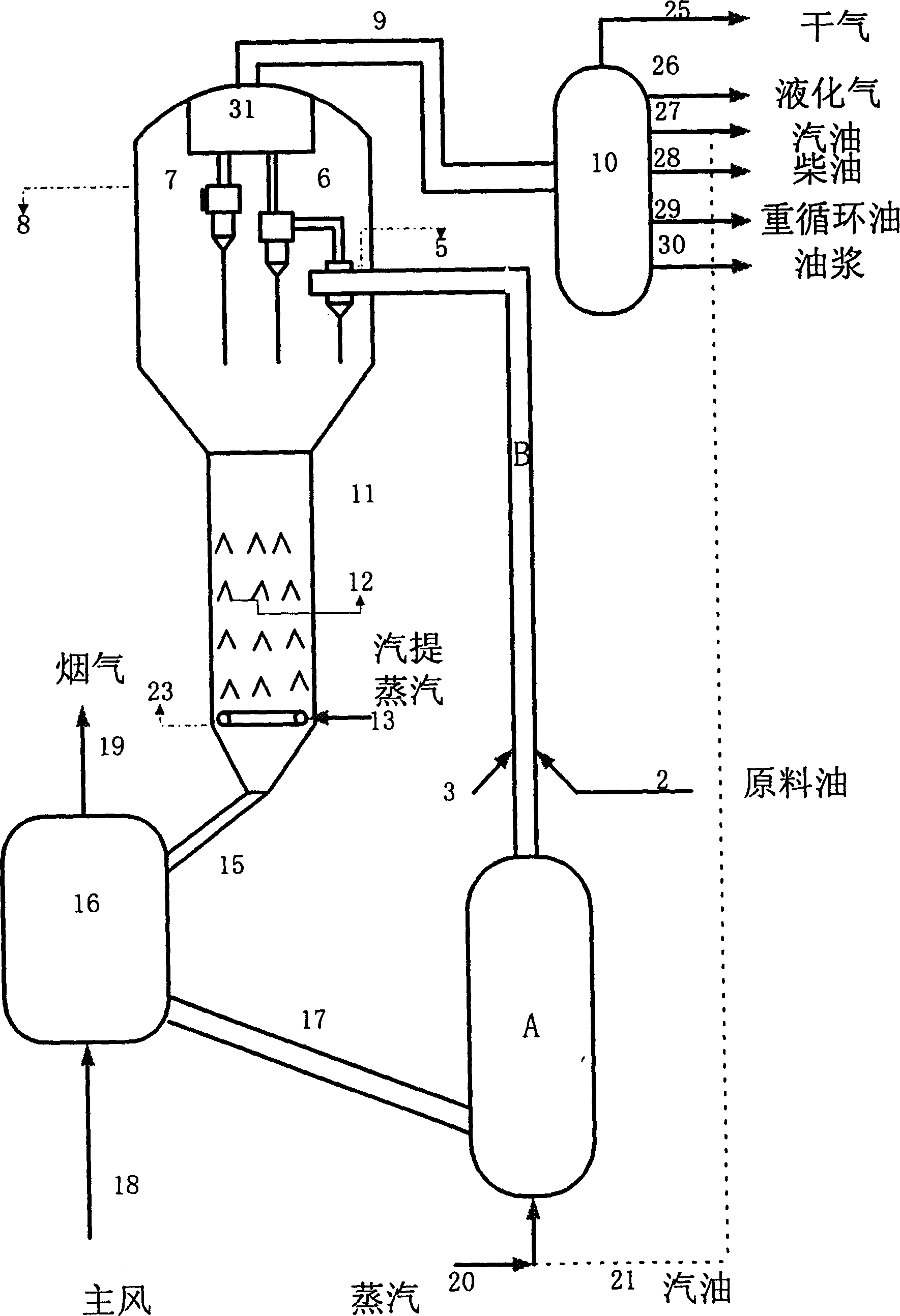

Reaction and regeneration process for improving oil refining efficiency in petroleum refining process

InactiveCN107760364AReduce hydrothermal deactivationHigh precisionHydrocarbon oils treatmentPetroleumDry gas

The invention discloses an anti-reprocessing process for improving oil refining efficiency in the process of oil refining. Mixed wax oil and atmospheric residual oil are respectively fed into a static mixer in a device from a raw material tank in a tank farm and mixed evenly, and then enter a raw material buffer tank. Then use the raw material pump to pump out, pass through the flow control valve, return to heat exchange, and then exchange heat with the oil slurry to 170-220 ° C, and enter the static mixer together with the refined oil to mix evenly. The steam enters the riser through six feed nozzles, contacts with the high-temperature regenerated catalyst from the secondary stage and immediately vaporizes, cracks into light products and generates oil slurry, dry gas and coke. The process strictly controls the reaction and regeneration process, so that the obtained product meets the quality, improves the refining precision, and improves the utilization rate of oil.

Owner:陈飞

Method for methanol conversion to aromatics

ActiveCN109694296BKeep aliveReduce hydrothermal deactivationMolecular sieve catalystCatalystsCatalytic transformationPtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for efficiently converting methanol to aromatics

ActiveCN109694294BKeep aliveReduce hydrothermal deactivationMolecular sieve catalystCatalystsPtru catalystFlue gas

The invention relates to a method for efficiently converting methanol to produce aromatics, which mainly solves the problems of low yield of aromatics and serious hydrothermal deactivation of catalysts in the prior art. In the present invention, the methanol raw material enters the fluidized bed reactor and the modified ZSM-5 catalyst is contacted and reacted under effective reaction conditions; the unborn catalyst enters the riser regenerator for regeneration, and the obtained semi-regenerated catalyst and flue gas I enter and rise the riser The riser regeneration cyclone separator connected to the regenerator, the separated semi-regenerated catalyst enters the double-dense bed A area for degassing; after degassing, the semi-regenerated catalyst part returns to the riser regenerator, and part of it enters the fast bed regenerator for regeneration, and the obtained regenerated The technical scheme that the catalyst enters the double-dense bed B area for degassing, and the regenerated catalyst enters the fluidized bed reactor after degassing solves this problem well, and can be used in the industrial production of aromatics.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for catalyzing and transfering petroleum hydrocarbon compounds by using reactor with dual reacting regions

Owner:CHINA PETROLEUM & CHEM CORP +1

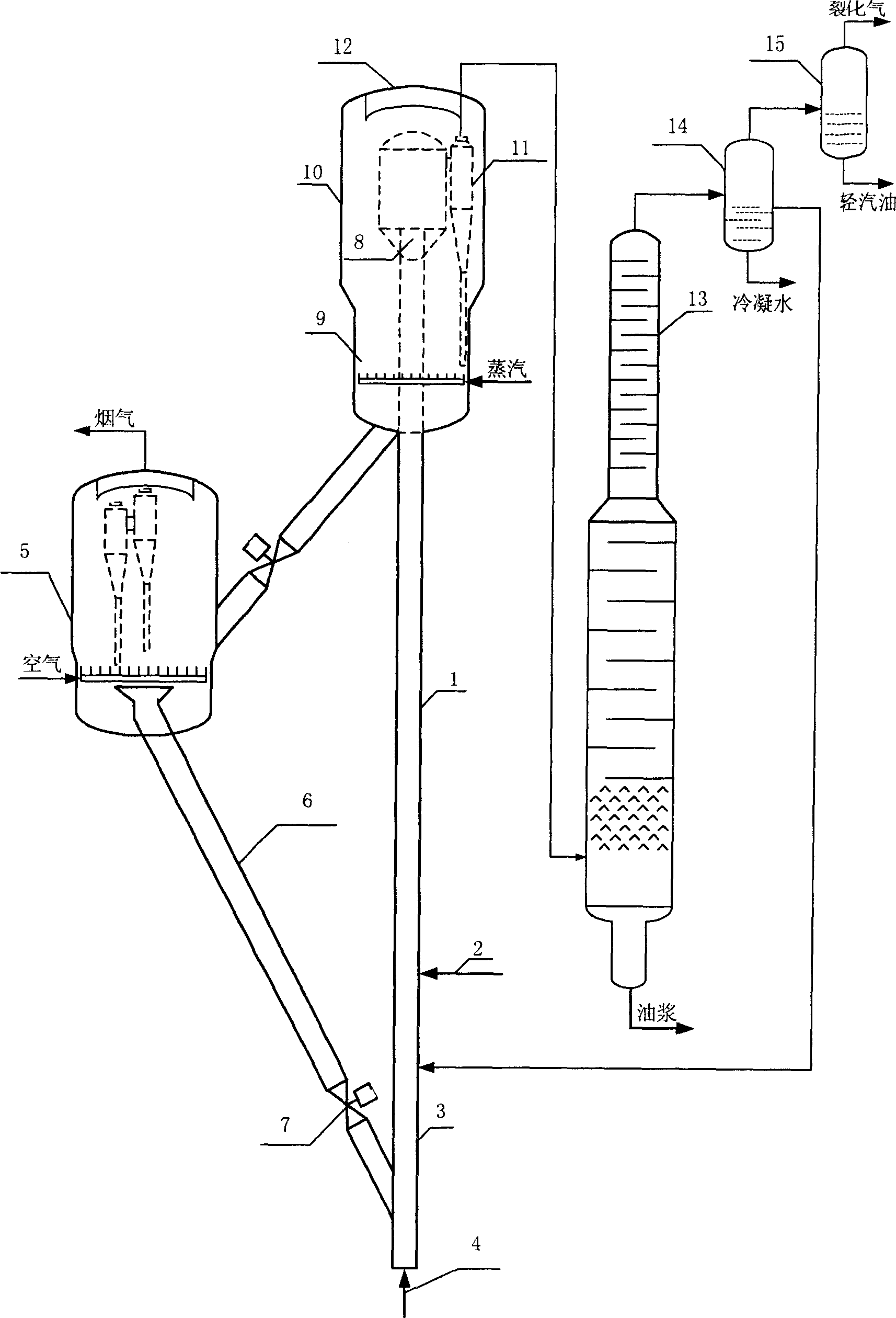

Catalytic conversion process of heavy petroleum hydrocarbon for increasing output of ethylene and propylene

A process for catalytic conversion of heavy petroleum hydrocarbon to increase output of ethylene and propylene includes such steps as reaction of crude hydrocarbon oil on catalyst containing pentacycle high-Si zeolite, segmentally filling steam, separating oil gas from carbon-deposited catalyst, separating oil from gas, and gas stripping and regenerating catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalytic cracking unit

Owner:CHINA PETROCHEMICAL CORP +1

Method for catalytic conversion of heavy oil and device thereof

ActiveCN1324116CRaise the preheat temperaturePromote atomizationCatalytic crackingTreatment with plural serial stages onlyCatalytic transformationGasoline

The invention provides a method of heavy raw material catalytic conversion and the device, comprising: the heavy hydrocarbon raw material passing through the first and second reaction area of the raiser reactor and contacting with catalyst for first reaction and second reaction, the reactants entering into the settler for the separation of catalyst and oil gas, steam stripping the separated catalyst through stripping section and introducing it to the reactivator for carbon burning reactivation, the reactivated catalyst returning to the raiser reactor after cooled or directly to the raiser reactor for reuse. After the heavy oil passing through the device said above, the volume content of olefin decreases by 10~40%, octane value increases 0.5~1 units, sulfur content in petrol decreases 10~30% by weight. After the poor petrol passing through the device said above, the volume content of olefin decreases by 10~60%, octane value increases 0.5~40 units, sulfur content in petrol decreases 10~50% by weight.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

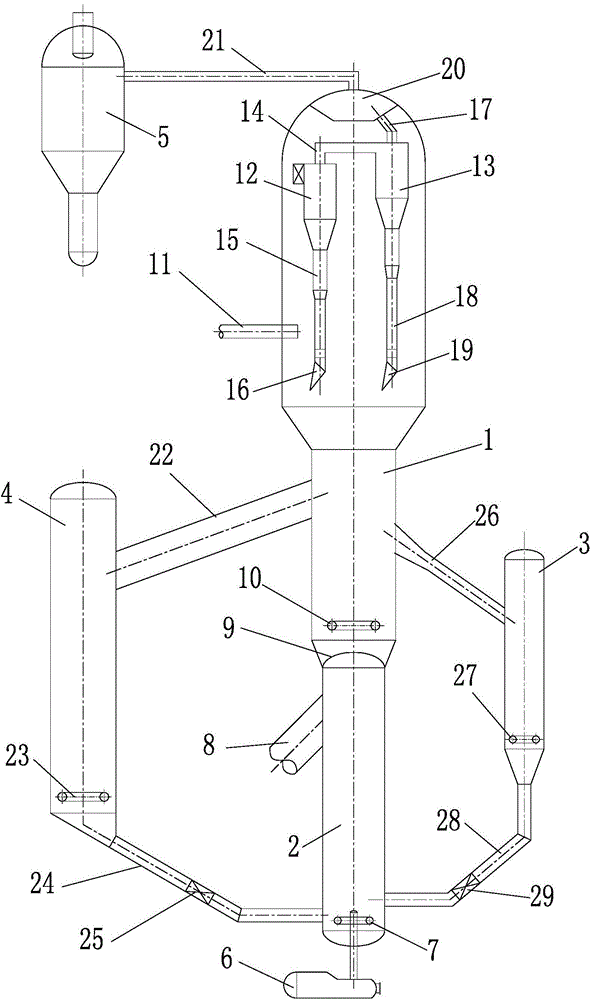

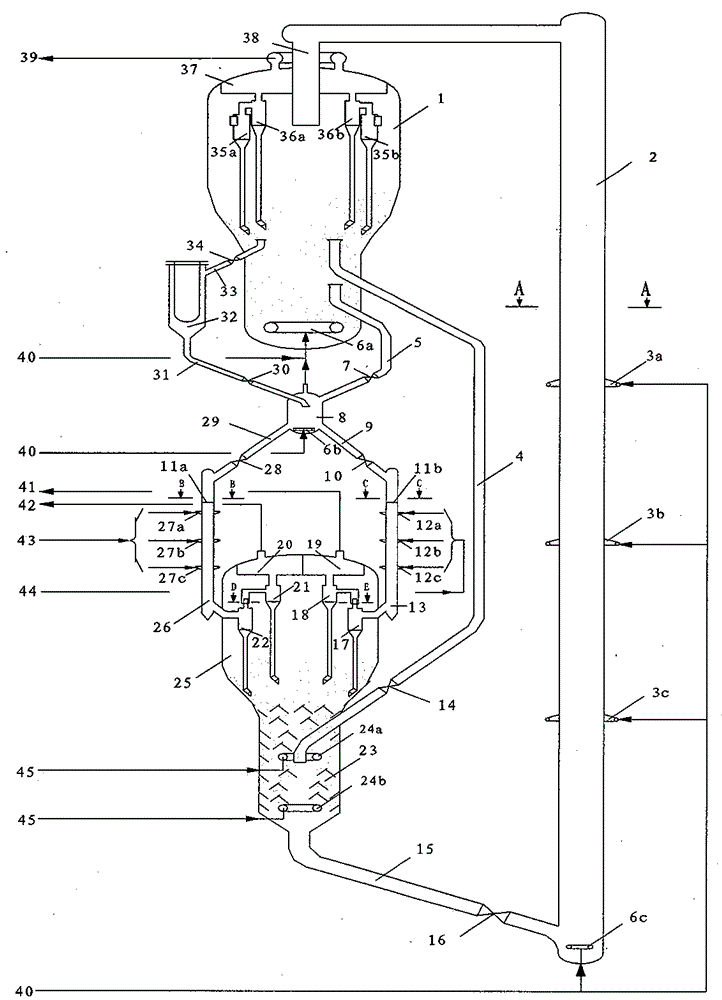

A descending catalytic cracking unit

ActiveCN103540346BReduce yieldHigh yieldTreatment with plural serial stages onlyPtru catalystGasoline

The invention disclosed a downlink catalytic cracking device.The device mainly includes equipment such as heavy oil downward tube reactors, light hydrocarbon downbone reactors, sinking device, improving pipe regeneration, turbulent bed recycler, catalyst mixing tank and external heat device.The turbulent bed regeneration device is connected to the hybrid tube of the high -temperature catalyst of the catalyst mixing tank and the external thermal device; the catalyst mixed tanks are connected to the subsidencer through the heavy oil down tube reactor and the light hydrocarbon down tube reactor;The device is connected to the improvement of the pipe regeneration;The present invention can improve the distribution of catalytic cracking products, increase light oil receipts, and reduce the production rate of qi and coke; it can also produce low olefin content catalyzed gasoline and high sixteenane value catalytic diesel;Lost.

Owner:CHINA PETROCHEMICAL CORP +1

Method and device for fluidized catalytic conversion

ActiveCN101665712BReduce the temperatureRaise the preheat temperatureCatalytic crackingCatalytic transformationPtru catalyst

The invention provides a method for catalytic conversion of heavy oil, which comprises a fluidized catalytic conversion process that: heavy hydrocarbon raw materials contacts a catalyst in a riser reactor or fluidized bed reactor to react; the reaction temperature is 400 to 650 DEG C (preferably 480 to 560 DEG C); the reaction pressure is 0.11 to 0.4MPa; the contact time is 0.05 to 5 seconds (preferably 0.1 to 3 seconds); and the weight ratio of the catalyst to the raw materials ( catalyst to oil ratio) generally is 3 to 15, preferably 5 to 12. The reaction products flow in a settler for catalyst and oil gas separation; the separated catalyst to be regenerated is stripped by a stripping section and enters a regenerator for coke burning regeneration; and the regenerated catalyst is cooled or directly returns to the riser reactor to be recycled. The method can solve the problems encountered in the resid-blend ratio improvement and gasoline upgrade and update processes of the prior catalytic conversion.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

Downer reactor light hydrocarbon catalytic converting method and device

PendingCN109609175AImprove temperature distributionReduce yieldCatalytic crackingContact timeReaction temperature

The invention provides a downer reactor light hydrocarbon catalytic converting method and device. The method specifically includes the following steps of firstly, making a preheated or non-preheated light hydrocarbon raw material and a low-temperature regenerant from a regenerant cooler enter the inlet end of a downer reactor and flow downwards along the reactor for catalytic cracking and other reactions, and making a mixture of reaction oil gas and a catalyst go downwards to the tail end of the reactor to be rapidly separated so that the catalyst and the oil gas can be rapidly separated, wherein the main operation conditions include the reaction temperature of 520-680 DEG C, the reaction pressure of 0.11-0.4 MPa, the contact time of 0.05-2 seconds and the agent-to-oil ratio of 6-50; secondly, making a separated to-be-generated agent enter a regenerator to be burned and regenerated after the to-be-generated agent is subjected to steam stripping through a to-be-generated agent stripper,wherein the regeneration temperature is controlled to be 630-730 DEG C; thirdly, making a regenerant from the regenerator enter the regenerant cooler to be cooled into 200-720 DEG C, and making the regenerant recycled in the downer reactor.

Owner:李群柱

Catalytic cracking method

ActiveCN103540345BReduce yieldHigh yieldCatalytic crackingTreatment with plural serial stages onlyFuel oilFractional distillation

The invention discloses a catalytic cracking method. A downer reactor is respectively subjected to heavy oil catalytic cracking and light hydrocarbon catalytic modification, and a reactant enters a settler so as to be subjected to gas-solid separation; after being mixed and stripped, the spent catalyst is scorched and regenerated together with a part of regenerated catalyst through a riser regenerator, and a semi-regenerated catalyst enters a turbulent bed so as to be further regenerated; a part of regenerated catalyst enters a catalyst mixing tank after being cooled by an external cooler and is mixed with the other part of regenerated catalyst, and then, the regenerated catalyst returns to two reactors in two paths so as to be recycled; the reacted oil gas is subjected to fractional distillation. By using the catalytic cracking method, the distribution of catalytic cracked products can be improved, the yield of light oil can be increased, and the yields of cracked gas and cokes can be reduced.

Owner:CHINA PETROCHEMICAL CORP +1

Heat exchange method in hydrocarbon oil conversion process and hydrocarbon oil conversion method

ActiveCN101210189BReduce hydrothermal deactivationReduce consumptionCatalytic crackingLiquid productHeat losses

A heat exchanging method in hydrocarbon oil transforming process comprises the step of exchanging heat of hydrocarbon oil with that of a regeneration catalyst in a regenerator by a heat exchanger, wherein the heat exchanger is positioned in the regenerator. The invention also provides a hydrocarbon oil transforming method including the heat exchanging method. According to the heat exchanging method in the hydrocarbon oil transforming process in the invention, the heat exchanger is positioned in the regenerator to exchange the heat of the high-temperature regeneration catalyst with that of theraw material oil in the regenerator, so that the high-temperature regenerator catalyst has less heat loss and that the amount of the raw material oil that can be heated by reducing a certain temperature of the regeneration catalyst per unit is improved, thus improving the heat exchanging efficiency. Additionally, the heat exchanging method of the method can simultaneously perform the function of lowering temperature in the regenerator and preventing the catalyst from hydrothermal deactivation due to overhigh temperature, thus reducing the amount of fresh catalyst to be supplemented and reducing the catalyst consumption. The hydrocarbon oil transforming method of the invention can reduce the yields of dry gas and coke and improve the yield of liquid products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com