Regeneration method of catalyst for producing aromatic hydrocarbon from organic oxide through catalytic conversion

A technology of organic oxides and catalytic conversion, applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of regeneration systems that do not involve the reaction of organic oxides to aromatics, and have not proposed specific regeneration systems form, low catalyst recovery rate, etc., to achieve the effect of reducing operating costs, reducing floor space and equipment investment, and reducing hydrothermal deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

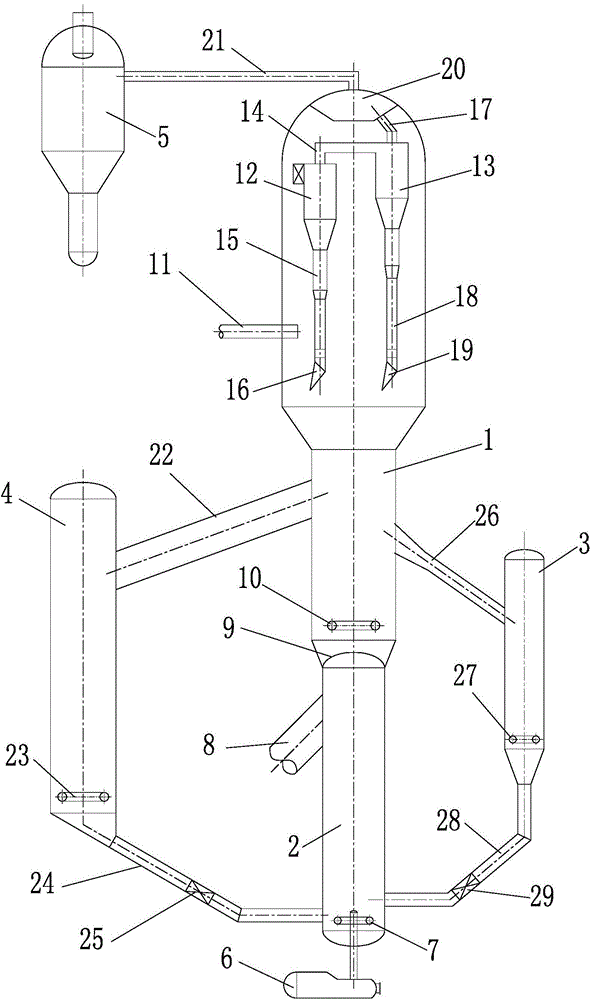

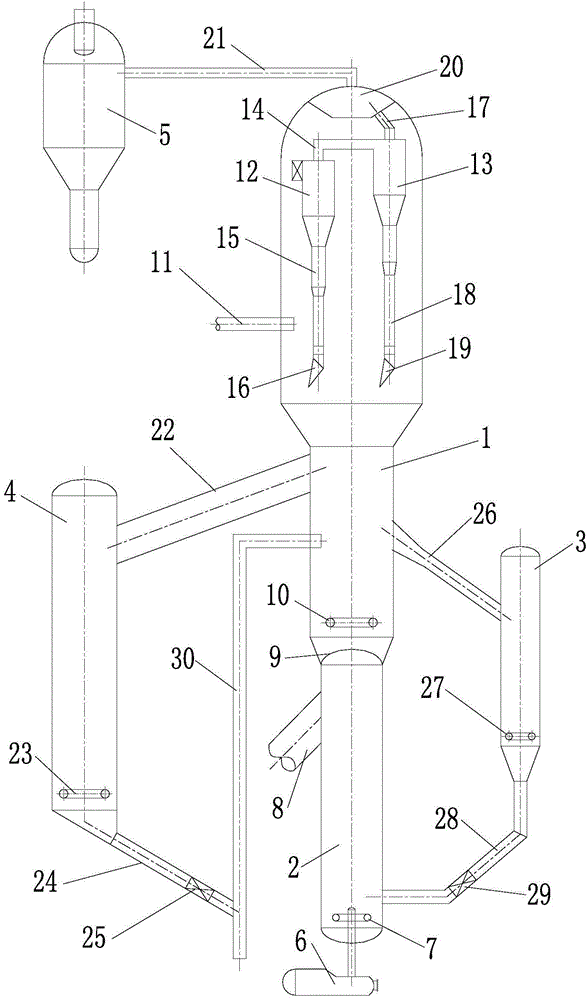

[0045] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0046] The invention provides a method for regenerating catalysts for catalytic conversion of organic oxides to aromatics, the method comprising: sending the spent catalyst from the reaction system for catalytic conversion of organic oxides to aromatics into a first regenerator and from the first regenerator The first oxygen-containing gas at the bottom is contacted and the first regeneration is performed at a regeneration temperature of 500-650° C. to obtain the semi-regenerated catalyst and the first regenerated flue gas; wherein the hydrogen element weight of the coke contained in the semi-regenerated catalyst is controlled to be 0-40% by weight of the hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com