Based on supercritical co 2 Method for regenerating waste lubricating oil

A waste lubricating oil, supercritical technology, applied in the direction of lubricating composition, etc., can solve the problems of not specifically discussing the quality of regenerated oil, how to deal with waste lubricating oil, and not establishing high-pressure phase equilibrium data and solubility models, etc., to achieve metal The effect of content reduction, performance index improvement, and strong decontamination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

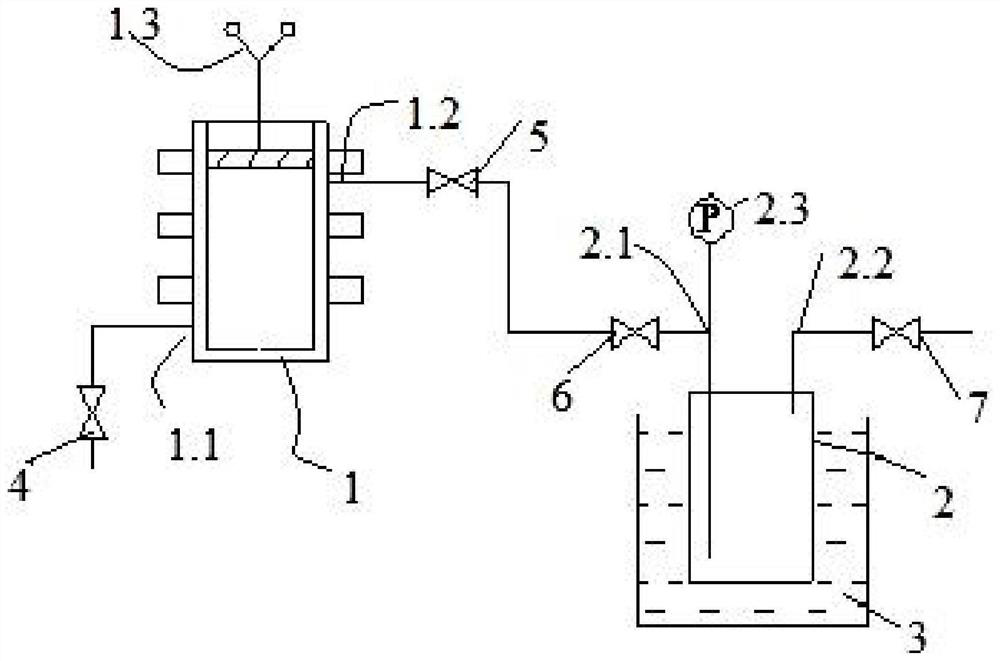

Method used

Image

Examples

Embodiment 1

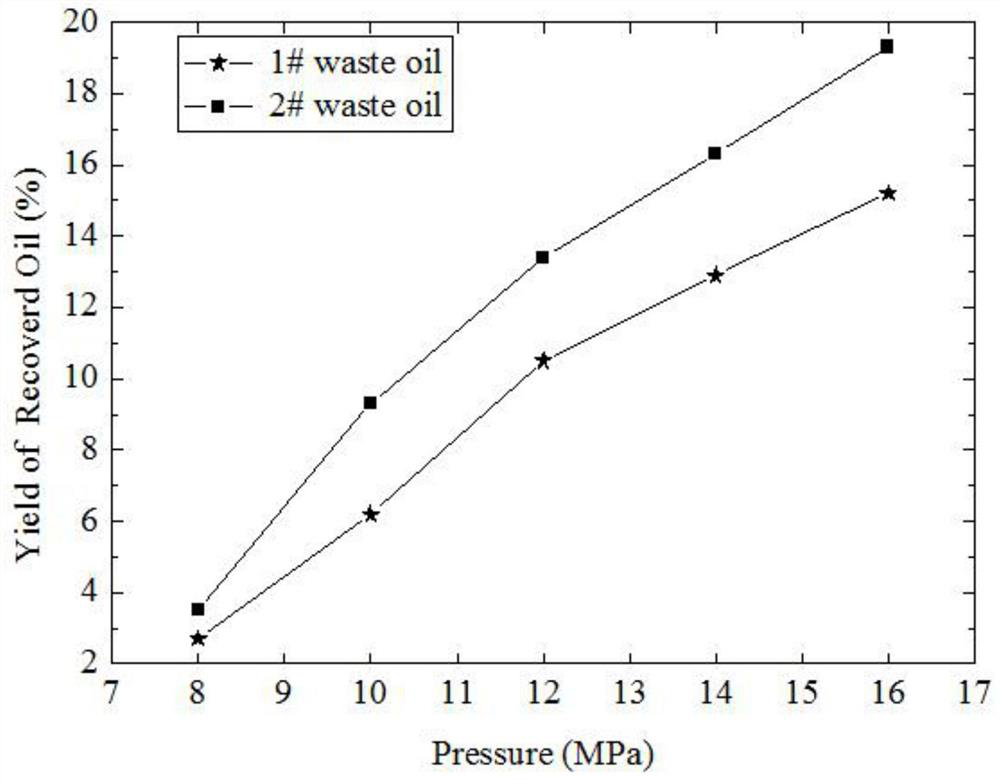

[0050] Explore the effect of pressure on the recovery oil yield;

[0051] The extraction temperature was set to 308.2K, the extraction time was 180min, and the influence of pressure on the yield of regenerated oil was investigated. The results figure 2 . Depend on figure 2 It can be seen that the yields of the two kinds of waste oil regeneration oil increase with the increase of pressure, supercritical CO 2 The extraction rate increased nearly 6 times within 8MPa pressure difference. This is because under the condition of constant temperature, the higher the extraction pressure, the higher the supercritical CO 2 The greater the density of the fluid, the stronger the solvation effect of the solvent, and the stronger the ability to dissolve substances. Therefore, the base oil components in supercritical CO 2 The solubility in the solution showed an increase. According to this, it can be seen that the size of the pressure is the most important factor affecting the supercri...

Embodiment 2

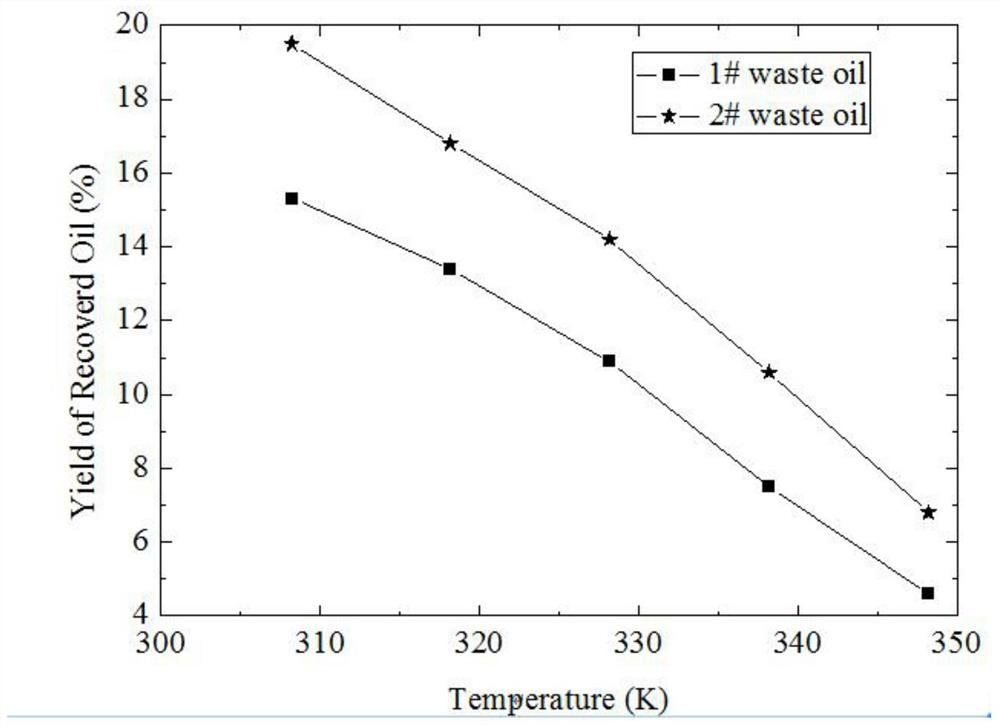

[0054] Explore the effect of temperature on the yield of recycled oil;

[0055] Set the extraction pressure to 16MPa, the extraction time to 180min, and investigate the influence of temperature on the yield of regenerated oil. The results are shown in image 3 . Depend on image 3 As shown, the recovery oil yield gradually decreased with the increase of temperature. temperature vs. supercritical CO 2 The extraction of base oil components has two effects: one is the temperature on the CO 2 Density effect, with increasing temperature, supercritical CO 2 Density decreases, leading to supercritical CO 2 The solvency of the waste oil decreases, so that the base oil components in the waste oil 2 The solubility in the medium decreases, and the extraction rate decreases; on the other hand, the influence of temperature on the vapor pressure of the solute, as the temperature increases, the vapor pressure of the solute increases, and the volatility increases, so that the solute in ...

Embodiment 3

[0058] Explore the effect of extraction time on the yield of recycled oil;

[0059] Set the extraction pressure to 16MPa, the extraction temperature to 308.2K, and investigate the influence of extraction time on the yield of regenerated oil. The results are shown in Figure 4 . Depend on Figure 4 As shown, with the prolongation of the extraction time, the recovery oil yield increased, and when the time was from 0 min to 180 min, supercritical CO 2 The extraction rate increased sharply, and the extraction basically reached equilibrium after 180 minutes. With the increase of time, the recovery oil yield increased slightly. In actual production, if the time is extended without limit to increase the yield of recycled oil, the cost will increase and the efficiency of equipment use will also decrease. Therefore, choosing a suitable and effective extraction time can make the yield of recycled oil high and the utilization efficiency of equipment high. .

[0060] Depend on Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com