Heat exchange method in hydrocarbon oil conversion process and hydrocarbon oil conversion method

A technology of conversion process and thermal method, which is applied in the field of heat exchange and hydrocarbon oil conversion in the process of hydrocarbon oil conversion, can solve problems such as low heat exchange efficiency, and achieve the effects of small heat loss, lower temperature, and lower catalyst consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This example is used to illustrate the heat exchange method in the hydrocarbon oil conversion process provided by the present invention.

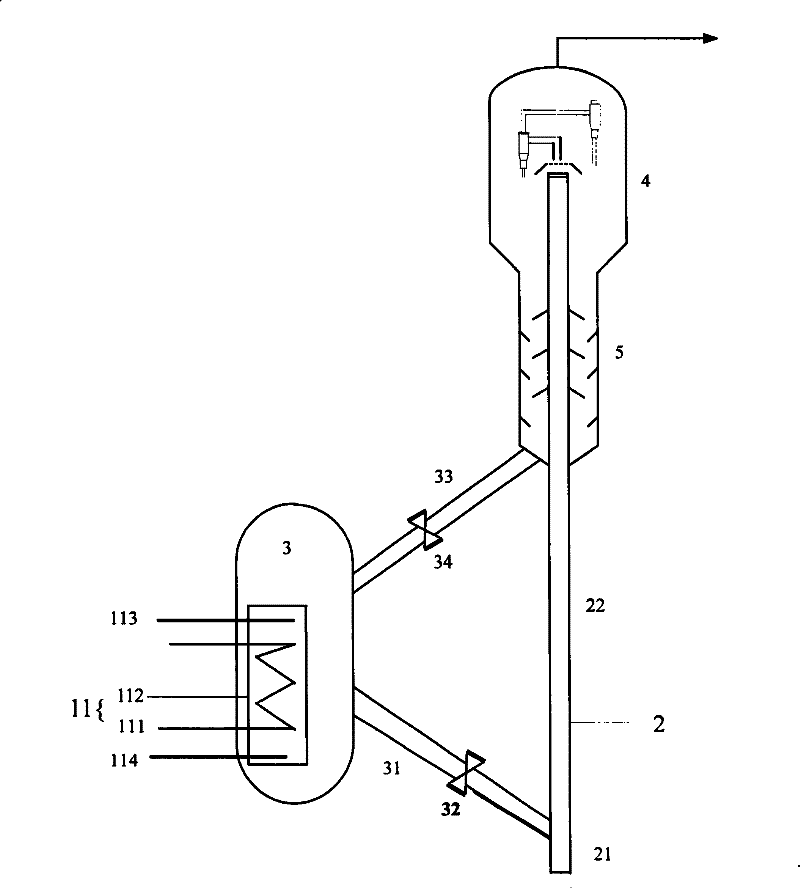

[0042] Such as figure 1 As shown, the shell-and-tube heat exchanger 11 is located in the regenerator 3, and 3 kg of hydrocarbon oil with a temperature of 160° C. enters the heat exchanger pipe 111 of the shell-and-tube heat exchanger 11, and the temperature in the regenerator 3 is 20 kg of regenerated catalyst at 685°C for heat exchange. The space between the heat exchanger shell 112 and the heat exchanger pipe 111 of the shell-and-tube heat exchanger 11 is filled with water vapor as a heat transfer medium, and the weight ratio of water vapor to hydrocarbon oil is 0.9:1. After 15 minutes of heat exchange, the temperature of the hydrocarbon oil after heat exchange was 280°C, and the temperature of the regenerated catalyst after heat exchange was 640°C.

Embodiment 2

[0047] This example is used to illustrate the hydrocarbon oil conversion method provided by the present invention.

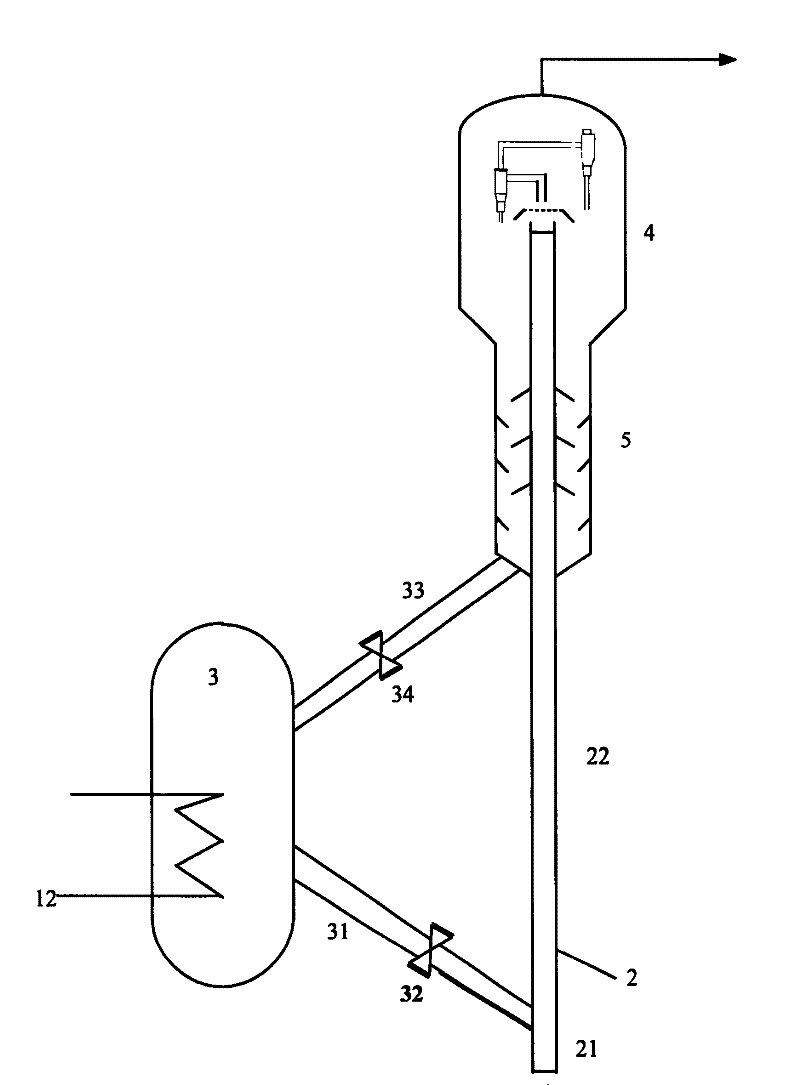

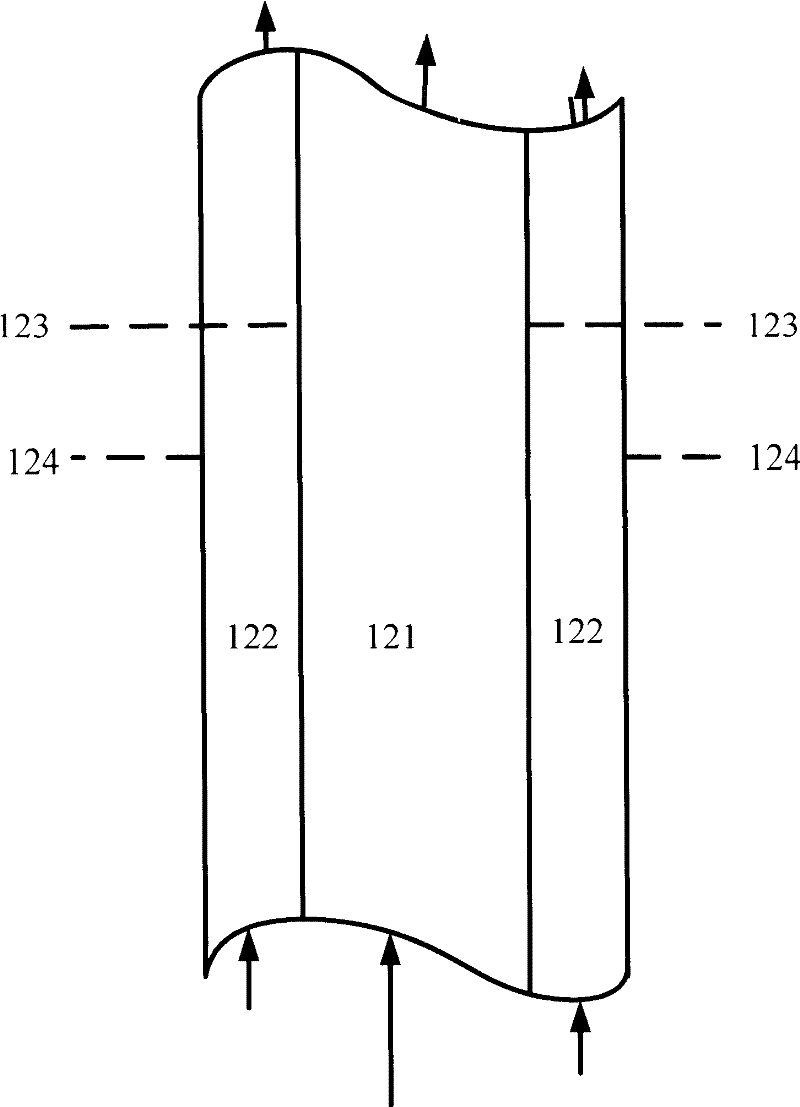

[0048] Such as figure 2 with image 3 As shown, the hydrocarbon oil with a temperature of 160°C enters the inner pipe 121 of the heat exchange pipe 12, and exchanges heat with the regenerated catalyst at a temperature of 685°C in the regenerator, and the outer pipe of the heat exchange pipe 12 is filled with water vapor as Heat transfer medium, the weight ratio of water vapor to hydrocarbon oil is 1.2:1. The temperature of the hydrocarbon oil after heat exchange is 255°C, and it enters the reactor 2. The temperature of the regenerated catalyst after heat exchange is 635° C., and enters the reactor 2 from the regenerated catalyst delivery pipeline 31 through the regenerated slide valve 32 .

[0049] The regenerated catalyst after heat exchange contacts with the hydrocarbon oil after heat exchange in the reaction section 22 of the reactor 2 to carry out cataly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com