Method for preparing aromatic hydrocarbons through efficient conversion of methanol

A technology for methanol and aromatics, applied in the field of high-efficiency conversion of methanol to aromatics, which can solve the problems of hydrothermal deactivation of catalysts and low yield of aromatics, and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

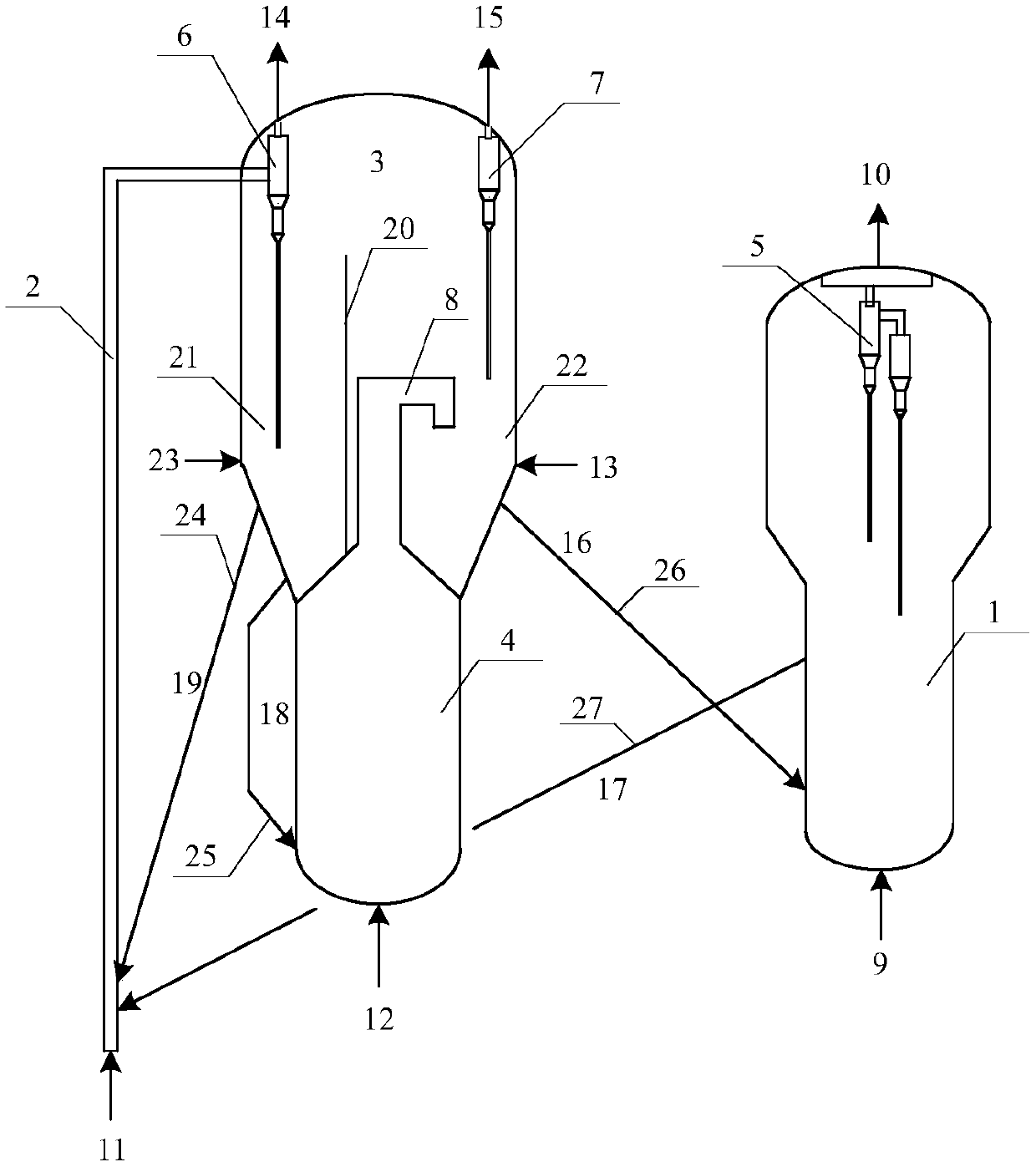

[0027] The methanol raw material with a methanol mass percentage of 100% enters the fluidized bed reactor and the modified ZSM-5 catalyst at 440°C, the reaction gauge pressure is 0 MPa, and the methanol weight space velocity is 0.2 hours -1 The reaction product containing aromatic hydrocarbons and the catalyst to be generated are separated by the cyclone separator of the reactor, and the reaction product enters the subsequent separation system; the catalyst to be generated enters the riser regenerator and is contacted and regenerated with the regeneration medium I, and the obtained semi-regenerated The catalyst and flue gas I enter the riser regeneration cyclone which is connected to the riser regenerator, the separated semi-regenerated catalyst enters the second dense bed zone A to contact with the degassing medium I, and the separated flue gas I enters the subsequent flue gas system ; 20% of the semi-regenerated catalyst after degassing is returned to the riser regenerator, a...

Embodiment 2

[0037] According to the conditions and steps described in Example 1, the methanol raw material with a methanol mass percentage content of 10% entered the fluidized bed reactor and the catalyst at 550°C, the reaction gauge pressure was 1 MPa, and the methanol weight space velocity was 15 hours. -1 50% of the semi-regenerated catalyst after degassing returns to the riser regenerator, and 50% of the semi-regenerated catalyst after degassing enters the fast bed regenerator and is contacted and regenerated by regeneration medium II.

[0038] The height of the partition is 90% of the total height of the second-dense bed; the volume ratio of the second-dense bed A area and the second-dense bed B area is 1:1.

[0039] The temperature of the catalyst in the fast-bed regenerator was 700° C., the density of the catalyst bed was 110 kg / m3, and the catalyst residence time was 5 minutes.

[0040] The catalyst temperature in the riser regenerator was 600°C, the catalyst density was 50 kg / m3,...

Embodiment 3

[0046] According to the conditions and steps described in Example 1, the methanol raw material with a methanol mass percentage content of 98% entered the fluidized bed reactor and the catalyst at 490 ° C, the reaction gauge pressure was 0.3 MPa, and the methanol weight space velocity was 4 hours. -1 30% of the semi-regenerated catalyst after degassing returns to the riser regenerator, and 70% of the semi-regenerated catalyst after degassing enters the fast bed regenerator and is contacted and regenerated by regeneration medium II.

[0047] The height of the partition is 70% of the total height of the second-dense bed; the volume ratio of the second-dense bed area A and the second-dense bed area B is 0.8:1.

[0048] The temperature of the catalyst in the fast-bed regenerator was 650° C., the density of the catalyst bed was 180 kg / m3, and the catalyst residence time was 25 minutes.

[0049] The catalyst temperature in the riser regenerator was 570°C, the catalyst density was 82 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com