A method for efficiently converting methanol to aromatics

A technology for methanol and aromatics, applied in the field of high-efficiency conversion of methanol to aromatics, can solve the problems of low yield of aromatics, hydrothermal deactivation of catalysts, etc., achieve high yield of aromatics, good technical effect, and maintain the effect of catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

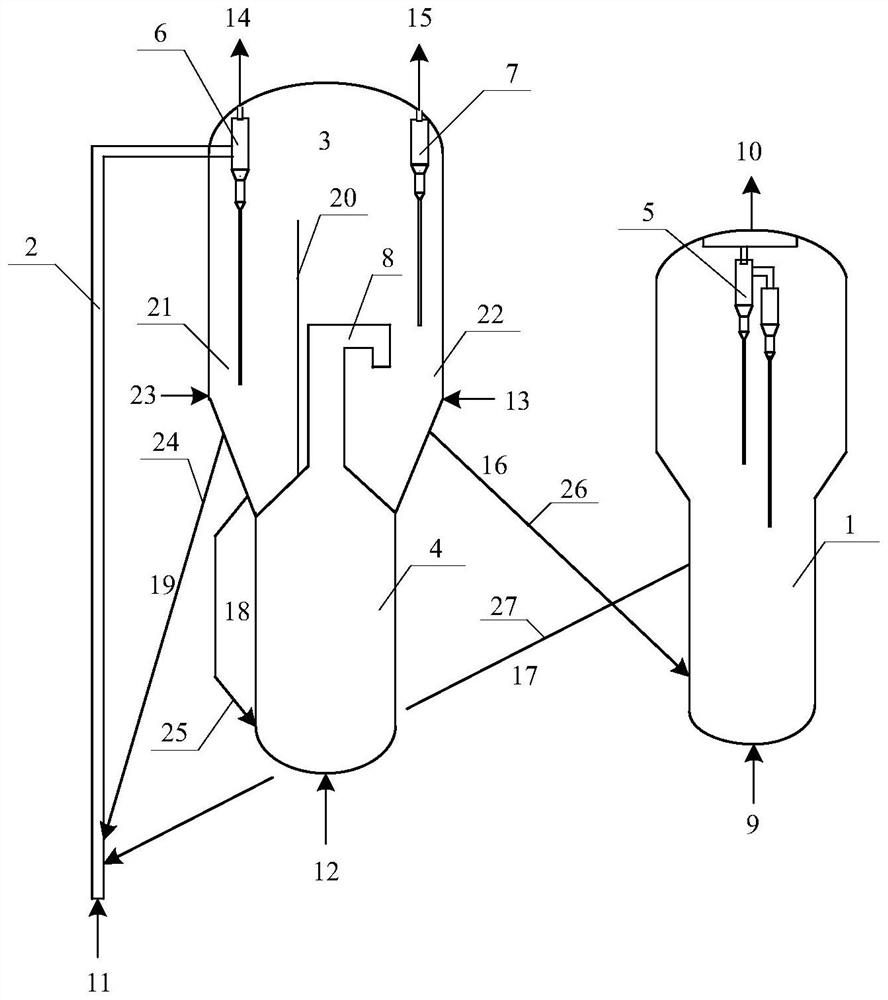

[0027] The methanol mass percentage content is 100% methanol raw material enters the fluidized bed reactor and the modified ZSM-5 catalyst at 440 ° C, the reaction gauge pressure is 0 MPa, and the methanol weight space velocity is 0.2 hours -1 Under the conditions of contact reaction, the reaction product containing aromatics and the raw catalyst are separated by the cyclone separator of the reactor, and the reaction product enters the subsequent separation system; The catalyst and flue gas I enter the riser regeneration cyclone separator connected to the riser regenerator, and the separated semi-regenerated catalyst enters the double-dense bed A area to contact with the degassing medium I, and the separated flue gas I enters the subsequent flue gas system ; After degassing, 20% of the semi-regenerated catalyst returns to the riser regenerator, and after degassing, 80% of the semi-regenerated catalyst enters the fast bed regenerator and regeneration medium II for contact regene...

Embodiment 2

[0037] According to the conditions and steps described in Example 1, methanol mass percentage content is 10% methanol raw material enters the fluidized bed reactor and catalyst at 550 ° C, the reaction gauge pressure is 1 MPa, and the methanol weight space velocity is 15 hours -1 50% of the semi-regenerated catalyst after degassing returns to the riser regenerator, and 50% of the semi-regenerated catalyst enters the fast-bed regenerator after degassing and contacts regeneration medium II.

[0038] The height of the partition is 90% of the total height of the double dense bed; the volume ratio of the area A of the double dense bed and the area B of the double dense bed is 1:1.

[0039] The temperature of the catalyst in the fast bed regenerator is 700°C, the density of the catalyst bed is 110 kg / m3, and the residence time of the catalyst is 5 minutes.

[0040] The catalyst temperature in the riser regenerator is 600°C, the catalyst density is 50 kg / m3, and the catalyst residenc...

Embodiment 3

[0046] According to the conditions and steps described in Example 1, methanol mass percentage composition is 98% methanol raw material enters fluidized bed reactor and catalyst at 490 ° C, reaction gauge pressure is 0.3 MPa, methanol weight space velocity is 4 hours -1 30% of the semi-regenerated catalyst is returned to the riser regenerator after degassing, and 70% of the semi-regenerated catalyst after degassing enters the fast bed regenerator and is contacted with regeneration medium II for regeneration.

[0047] The height of the partition is 70% of the total height of the double dense bed; the volume ratio of the area A of the double dense bed and the area B of the double dense bed is 0.8:1.

[0048] The temperature of the catalyst in the fast bed regenerator is 650°C, the density of the catalyst bed is 180 kg / m3, and the residence time of the catalyst is 25 minutes.

[0049] The catalyst temperature in the riser regenerator is 570°C, the catalyst density is 82 kg / m3, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com