Technique for producing styrene by alkylating toluene and methanol side chains

A process method, styrene technology, applied in the direction of chemical instruments and methods, carbon-based compound preparation, organic compound preparation, etc., can solve the problems of difficult industrialization, low income, high cost, etc., to reduce content and slow down water heat loss The effect of improvement of activity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

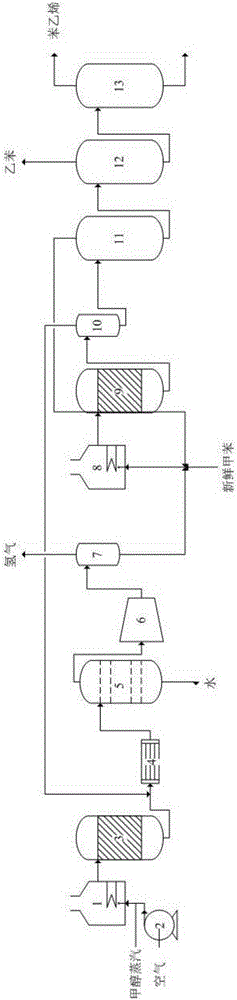

Method used

Image

Examples

Embodiment 1

[0032] Methanol-to-formaldehyde catalyst using Ag-SiO with 20% Ag loading 2 Catalyst, the reaction conditions are: temperature 635°C, pressure 0.05MPa, oxygen alcohol molar ratio=0.4.

[0033] Side chain alkylation using KX / K 2 O-KZSM-5 molecular sieve catalyst fixed bed reactor, the molecular sieve catalyst used is K 2 O loading at 1%, KX and K 2 O-KZSM-5 is a catalyst prepared by mechanical mixing and grinding with a mass ratio of 1:1. The reaction conditions are: temperature 420°C, pressure is normal pressure, and the total mass space velocity of raw materials is 1h -1 , n(toluene) / n(methanol)=5.

[0034] The operating pressure of the high-pressure separator is 7MPa, and the operating temperature of the gas-liquid separator is 135°C.

[0035] The yield of styrene obtained by this process is 8.3%.

Embodiment 2

[0037] Methanol-to-formaldehyde catalyst using Ag-SiO with 2% Ag loading 2 Catalyst, the reaction conditions are: temperature 655°C, pressure normal pressure, oxygen-alcohol molar ratio=0.5.

[0038] Side chain alkylation using KX / K 2 O-KZSM-5 molecular sieve catalyst fluidized bed reactor, the molecular sieve catalyst used is K 2 O loading at 3%, KX and K 2 O-KZSM-5 is a catalyst prepared by mechanical mixing and grinding with a mass ratio of 1:1. The reaction conditions are: temperature 435°C, pressure is normal pressure, and the total mass space velocity of raw materials is 1.5h -1 , n(toluene) / n(methanol)=6.

[0039] The operating pressure of the high-pressure separator is 6MPa, and the operating temperature of the gas-liquid separator is 120°C.

[0040] The yield of styrene obtained by this process is 7.6%.

Embodiment 3

[0042] Methanol-to-formaldehyde catalyst using Ag-SiO with 10% Ag loading 2 Catalyst, the reaction conditions are: temperature 615°C, pressure 0.05MPa, oxygen alcohol molar ratio=0.2.

[0043] Side chain alkylation using KX / K 2 O-KZSM-5 molecular sieve catalyst moving bed reactor, the molecular sieve catalyst used is K 2 O loading at 5%, KX and K 2 O-KZSM-5 is a catalyst prepared by mechanical mixing and grinding with a mass ratio of 1:1. The reaction conditions are: temperature 405°C, pressure is normal pressure, and the total mass space velocity of raw materials is 1h -1 , n(toluene) / n(methanol)=4.

[0044] The operating pressure of the high-pressure separator is 8MPa, and the operating temperature of the gas-liquid separator is 150°C.

[0045] The yield of styrene obtained by this process is 6.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com