Method and device for improving selectivity of low-carbon olefin preparation using oxygen-containing compound converting

A technology of low-carbon olefins and compounds, which is applied in the field of improving the selectivity of oxygen-containing compounds to produce low-carbon olefins and its devices. Poor selectivity and other problems, to achieve the effect of promoting ideal reaction, improving catalytic activity and selectivity, and improving reaction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

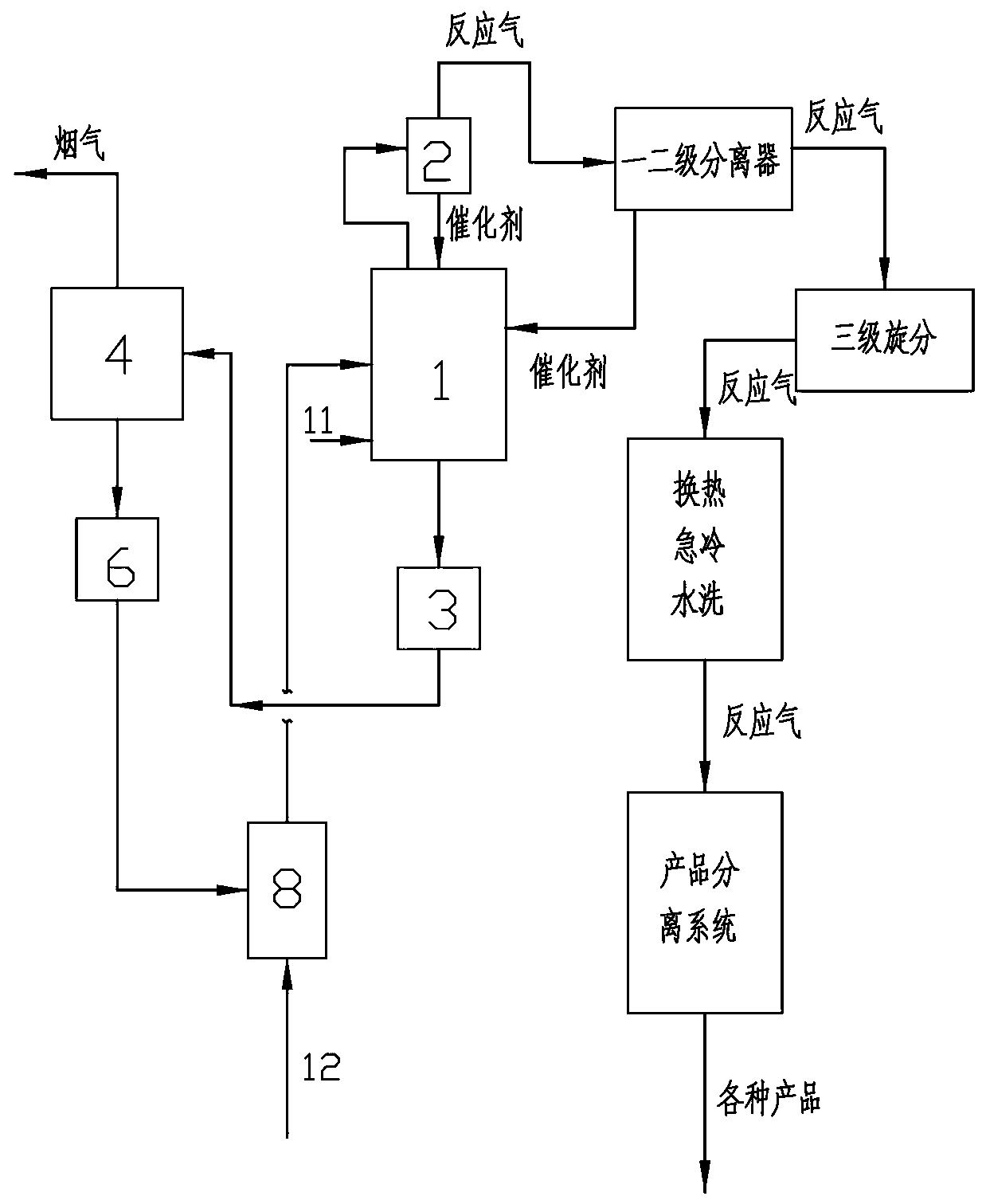

[0106] For Example 1, the oxygenate feedstock is methanol, using figure 2 In the process flow shown, the catalyst is SAPO-34, the methanol conversion reactor and the regenerator adopt conventional operating conditions, and the reaction gas is used as the activation medium. s, the pre-hydrocarbon pooling reaction temperature is ~460°C, and the contact time is 60-80 minutes.

[0107] Here, the hydrocarbon pool active species on the regenerated regenerated catalyst is basically recovered, and a reasonable level of carbon deposition is formed. Simulation results show that after adding the pre-hydrocarbon pooling facility of the present invention, compared with the existing MTO technology, the low-carbon olefins of the present invention (C 2 = +C 3 = ) selectivity increased by 5.7 percentage points.

[0108] The main parameters and effect comparison are shown in Table 1.

[0109] Table 1

[0110] parameter Existing MTO technology this invention Conversion...

example 2

[0112] For Example 2, the oxygenate feedstock is methanol, using figure 2 In the process flow shown, the catalyst is SAPO-34, the methanol conversion reactor and the regenerator adopt conventional operating conditions, and the reaction gas is used as the activation medium. s, the pre-hydrocarbon pooling reaction temperature is 460°C, and the contact time is 30-40 minutes.

[0113] Simulation results show that after adding the pre-hydrocarbon pooling facility of the present invention, compared with the existing MTO technology, the low-carbon olefins of the present invention (C 2 = +C 3 = ) selectivity increased by 3.1 percentage points.

[0114] The main parameters and effect comparison are shown in Table 2.

[0115] Table 2

[0116] parameter Existing MTO technology this invention Conversion reaction temperature ℃ 480 480 Regeneration temperature ℃ 680 680 Agent / alcohol specific gravity / weight 0.23 0.23 Regenerant fixed carbon % ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com